Influence of WC-Based Pin Tool Profile on Microstructure and Mechanical Properties of AA1100 FSW Welds

Abstract

1. Introduction

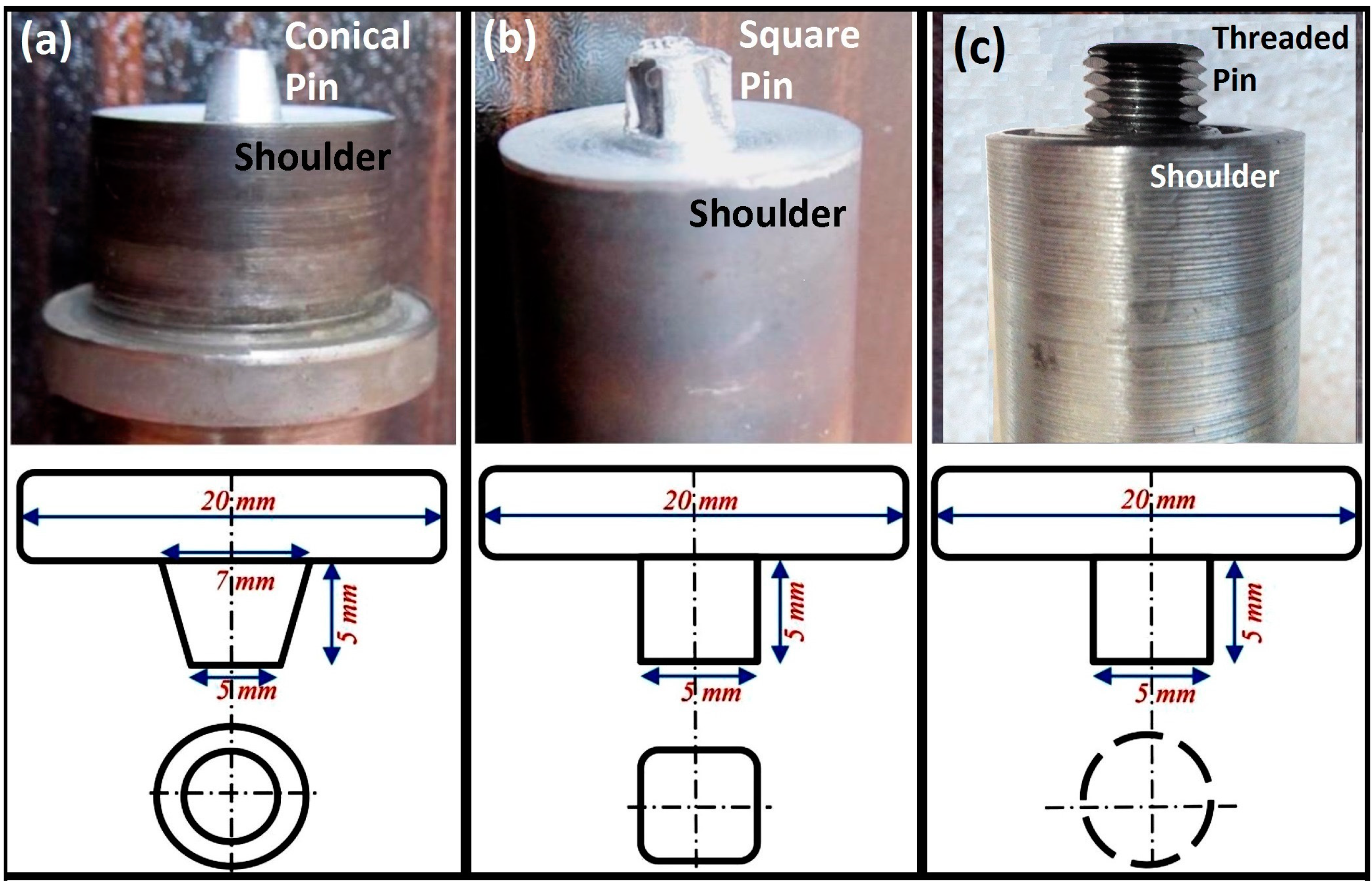

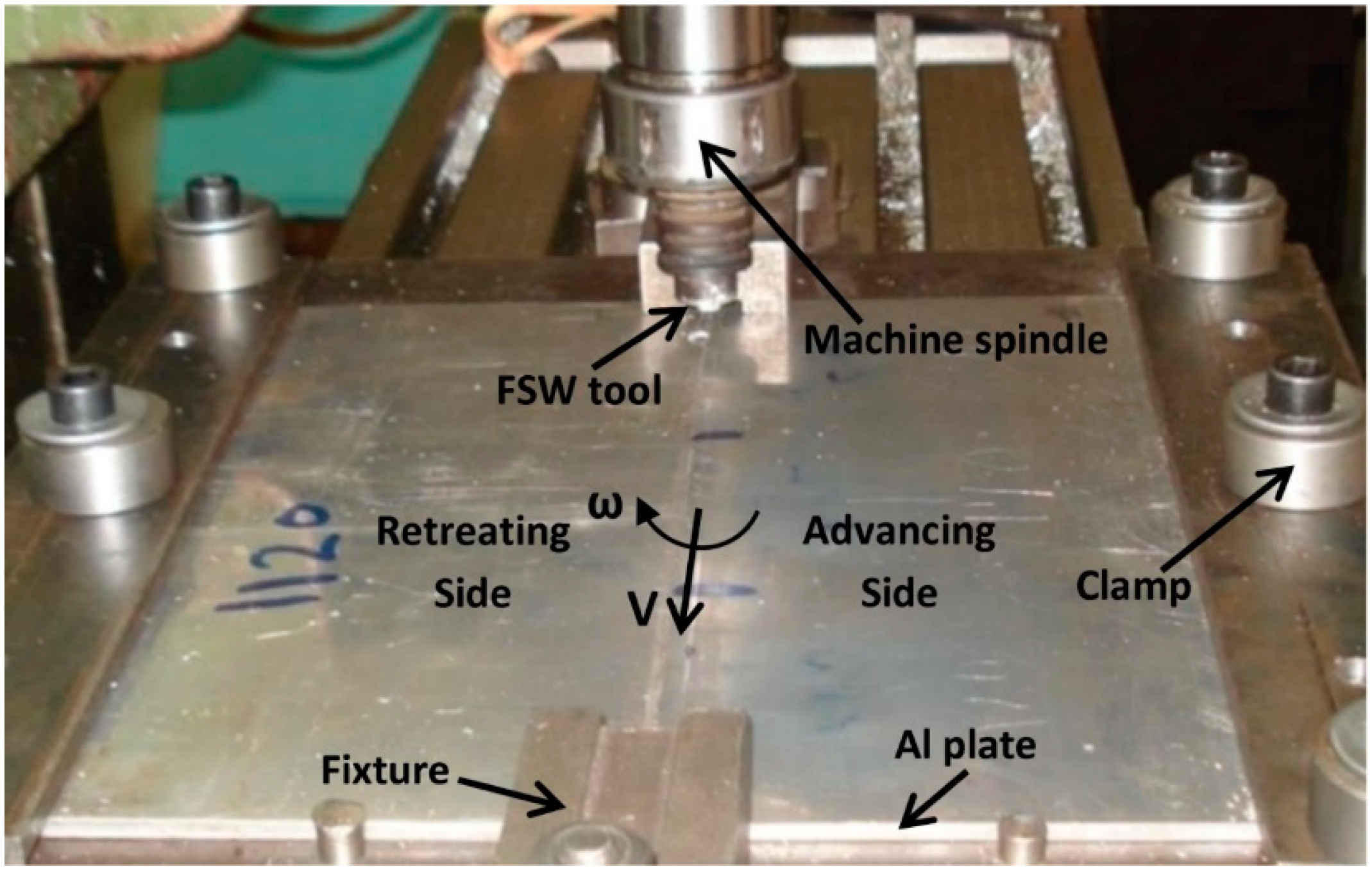

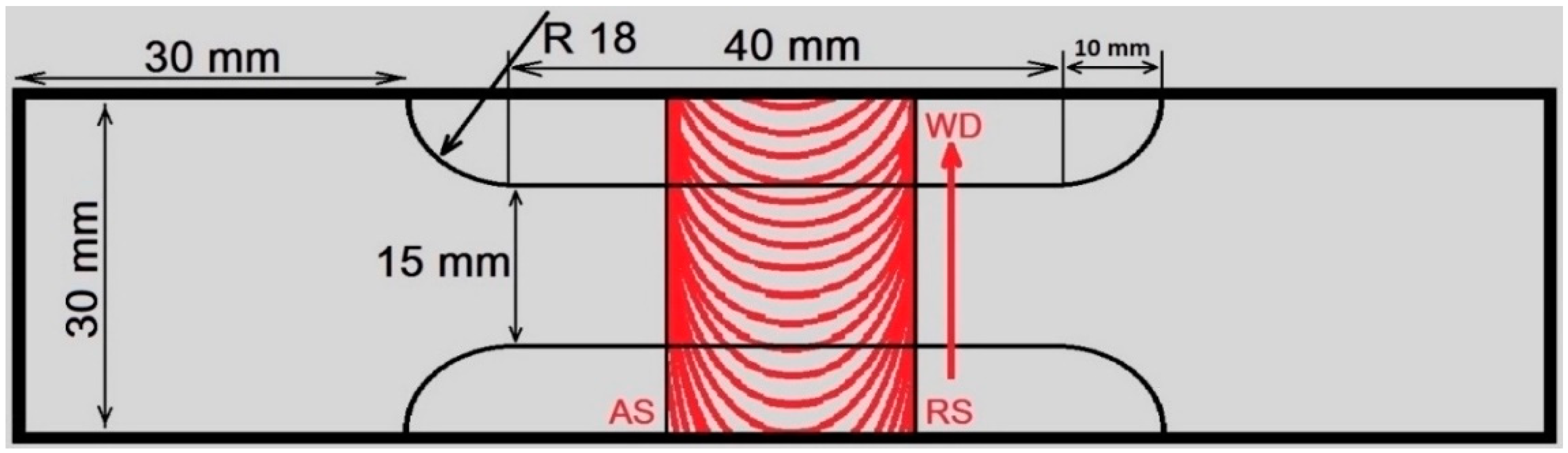

2. Materials and Methods

3. Results

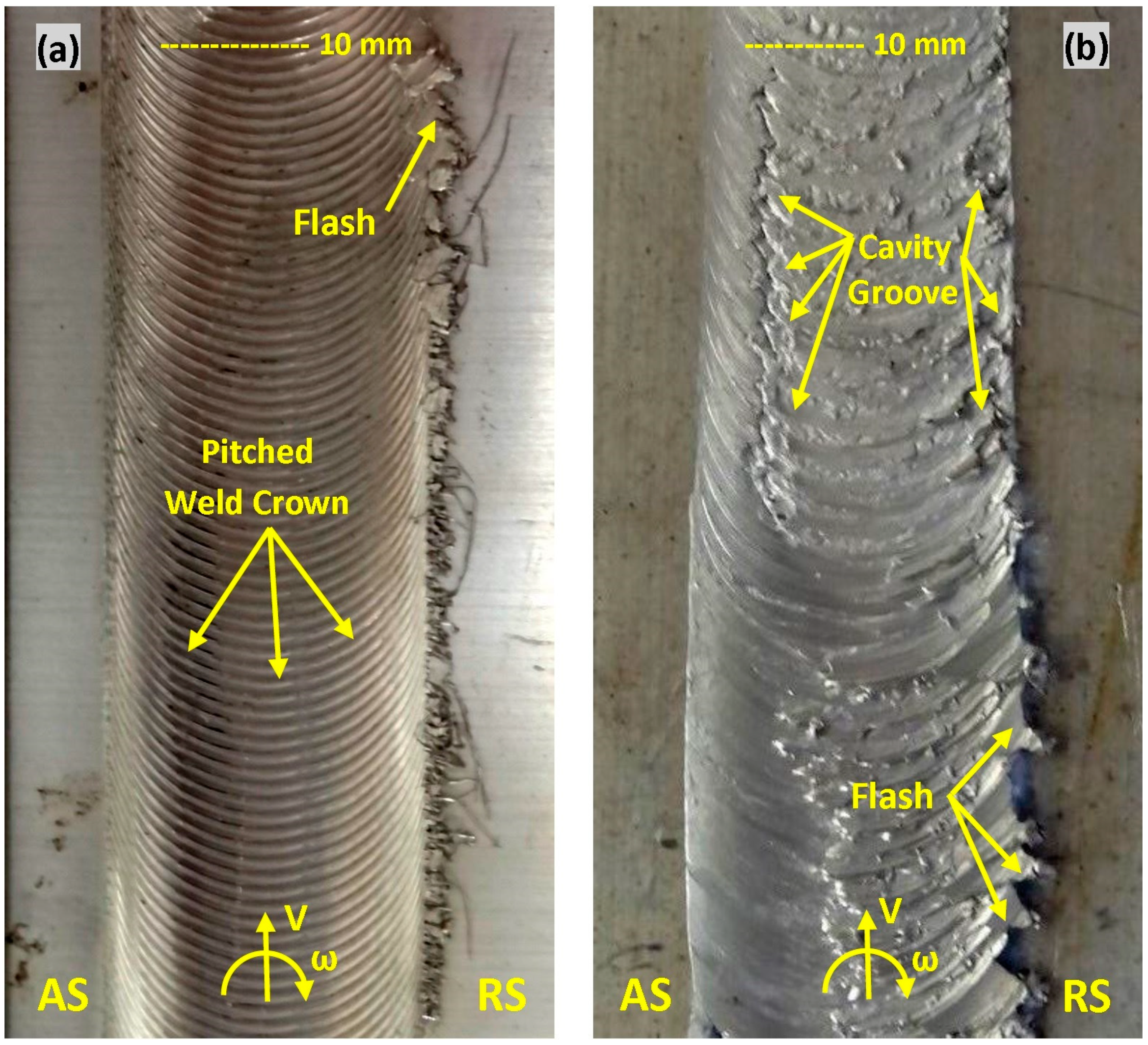

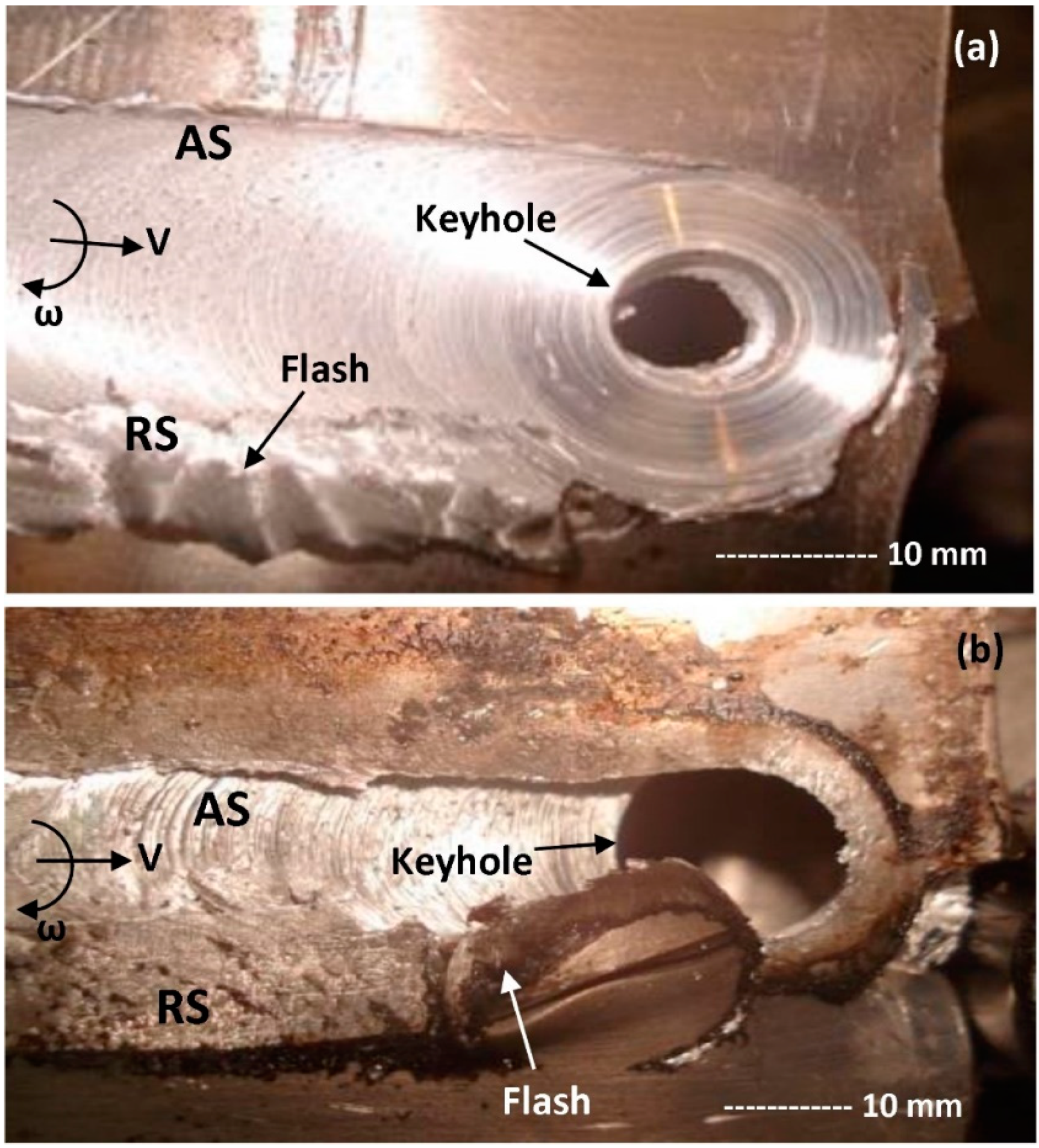

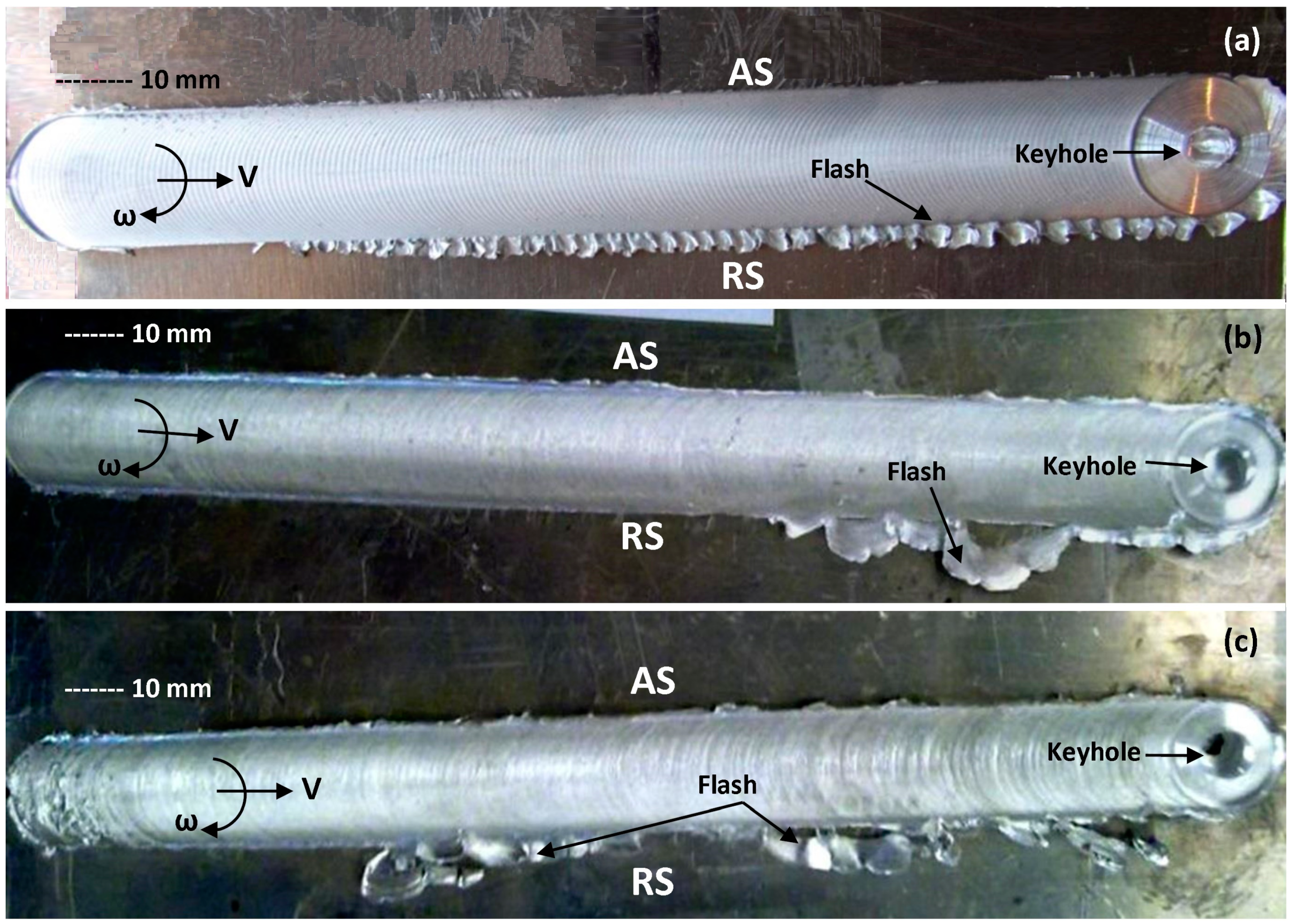

3.1. General Appearances of the FSW Weld

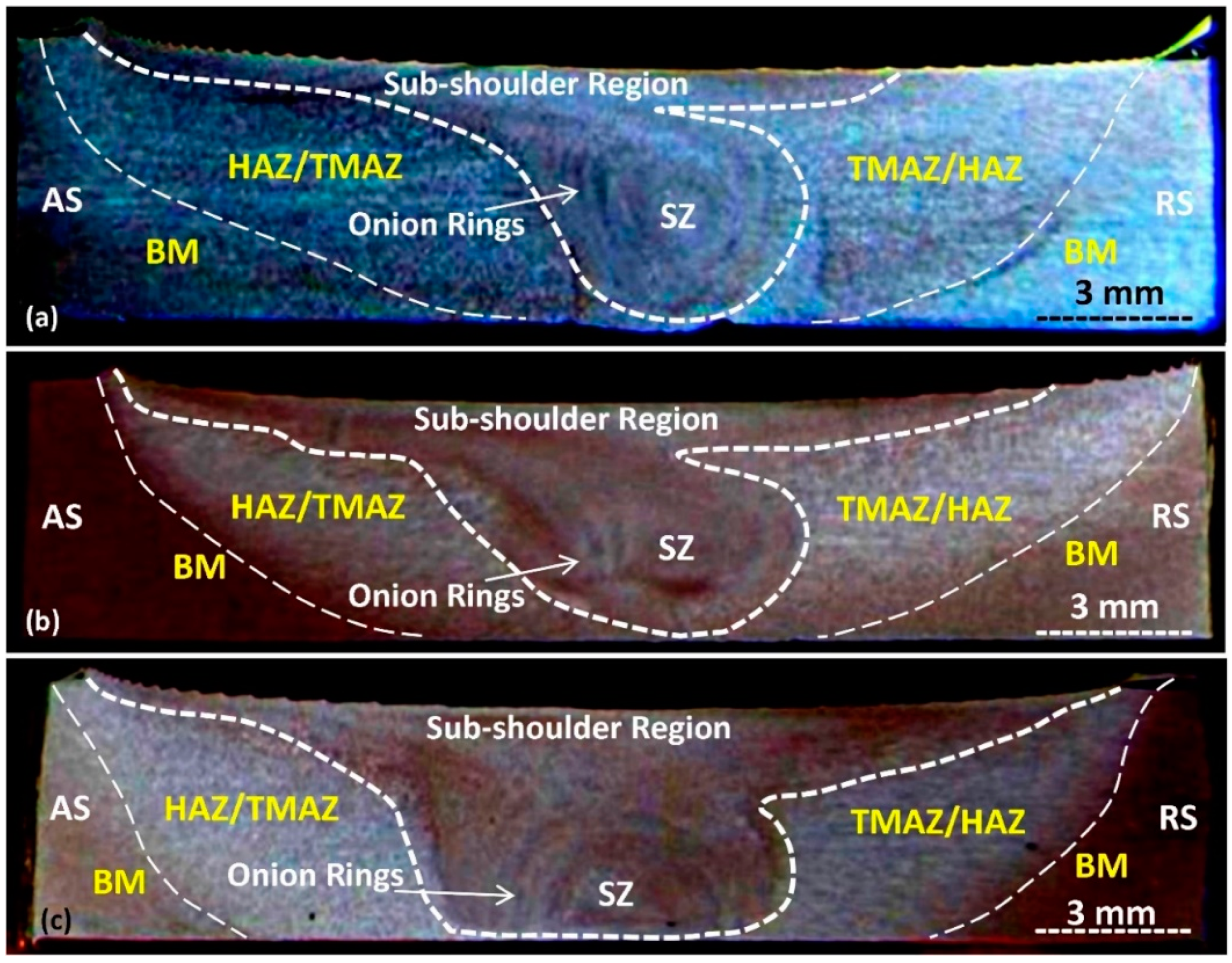

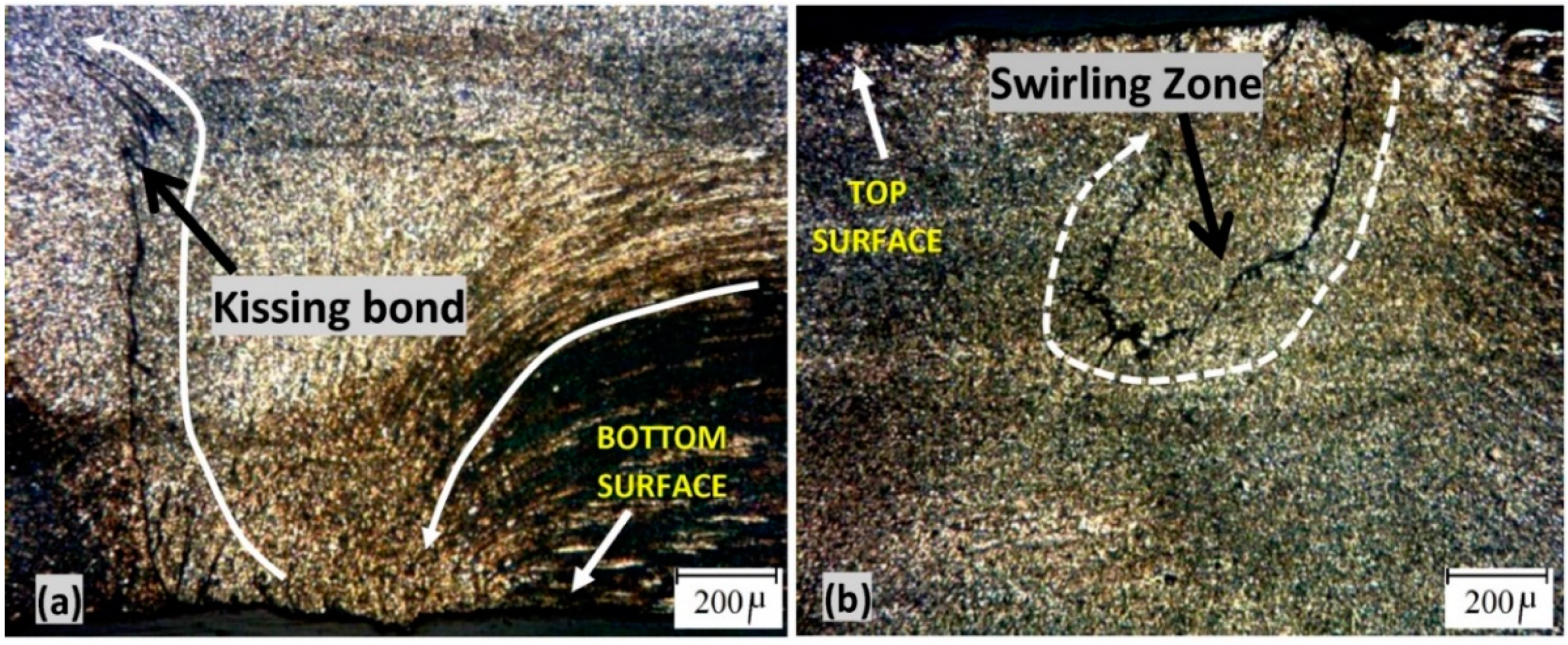

3.2. Macrostructure of the Weld Region

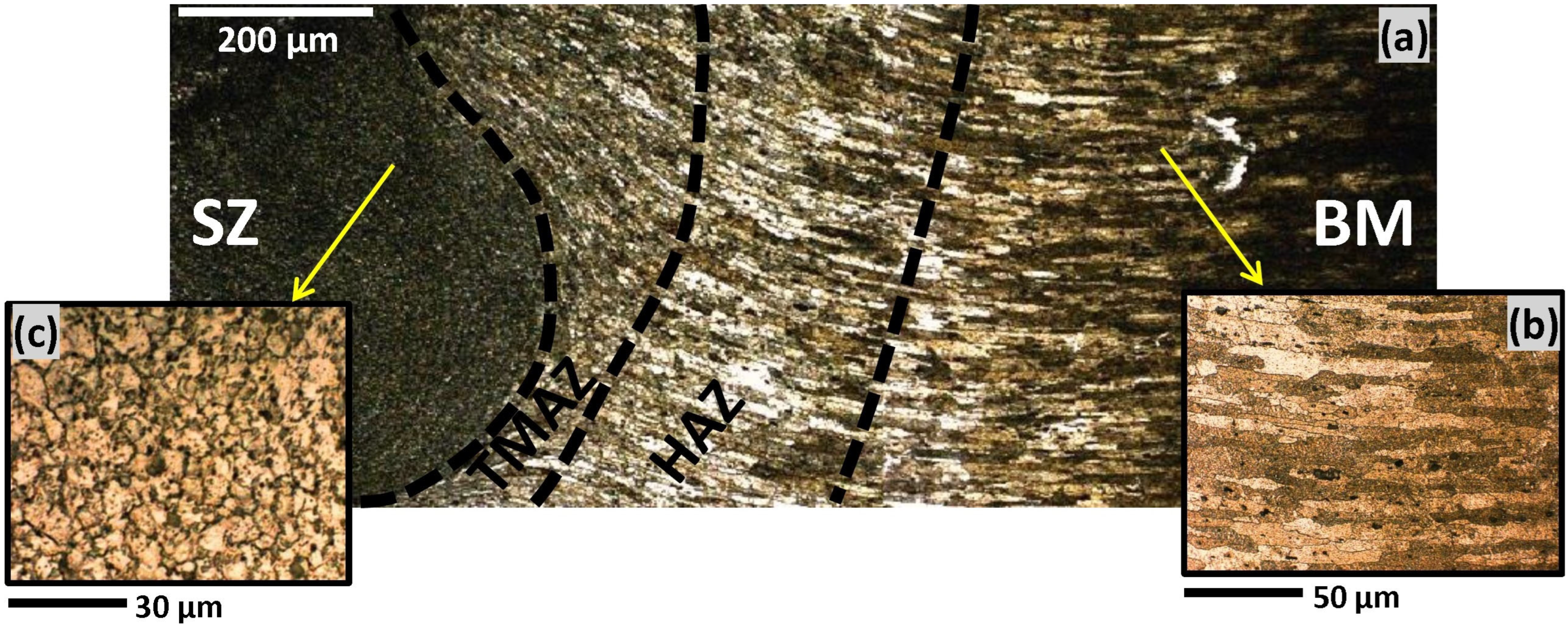

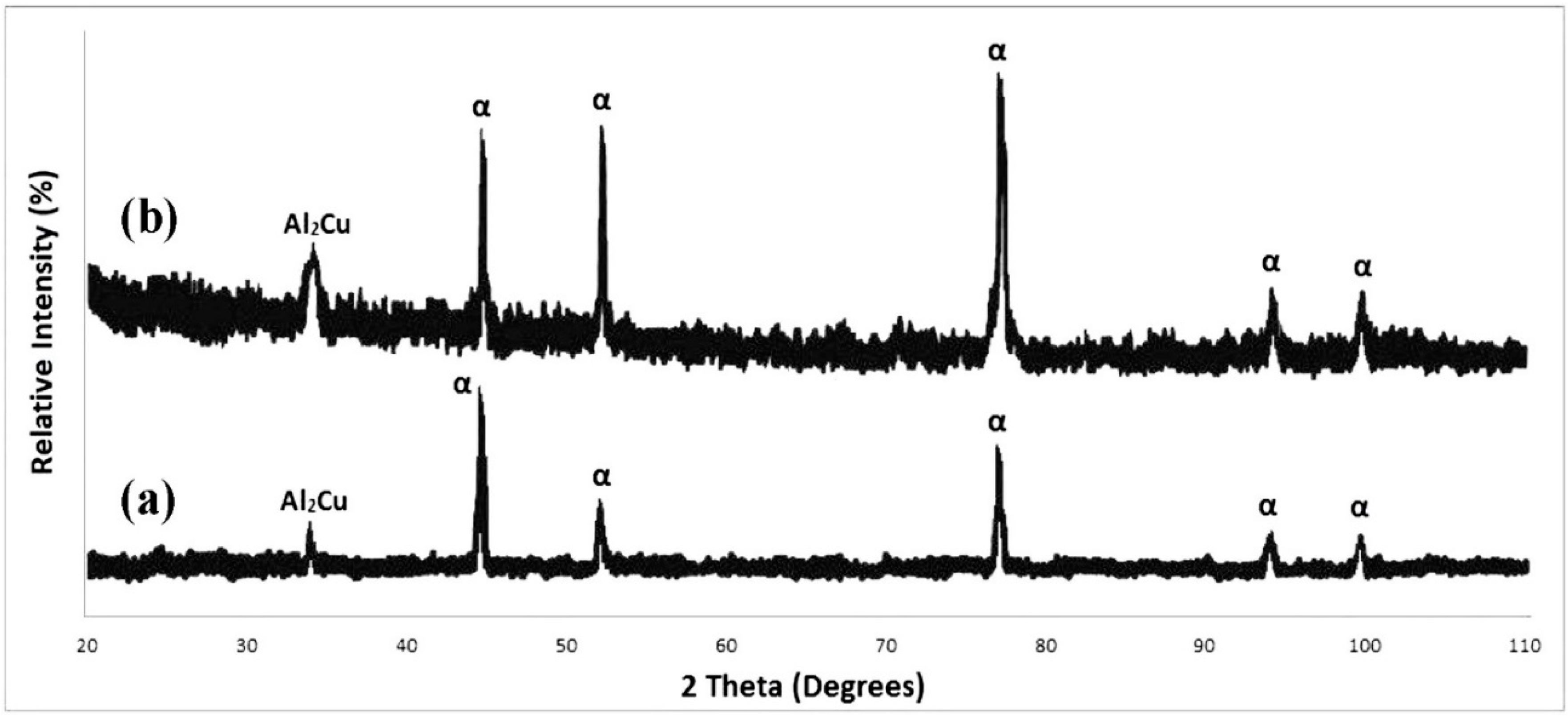

3.3. Microscopic Measurements of the Weld

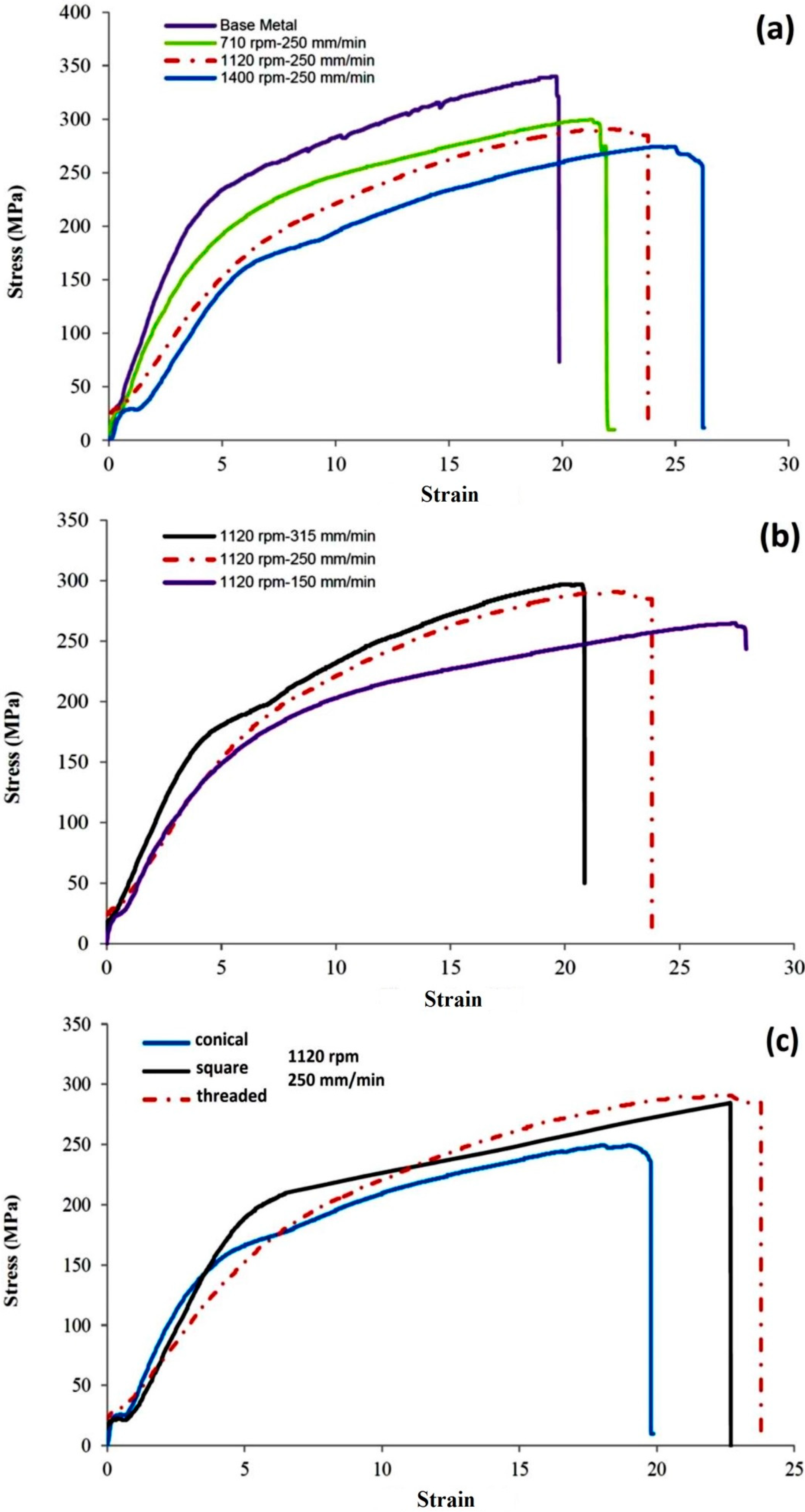

3.4. Mechnical Strength of the Weld

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomas, W.; Nicholas, E.; Needham, J.; Murch, M.; Temple-Smith, P.; Dawes, C. Friction Stir Butt Welding. International Patent Application No. PCT/GB92 Patent Application 9125978.8, 6 December 1991. [Google Scholar]

- Murr, L.; Flores, R.; Flores, O.; McClure, J.; Liu, G.; Brown, D. Friction-stir welding: Microstructural characterization. Mater. Res. Innov. 1998, 1, 211–223. [Google Scholar] [CrossRef]

- Thomas, W.; Nicholas, E. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- Threadgill, P.; Leonard, A.; Shercliff, H.; Withers, P. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Tamadon, A. Characterization of Flow-Based Bobbin Friction Stir Welding Process. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2019. [Google Scholar]

- Tamadon, A.; Pons, D.; Sued, M.; Clucas, D.; Wong, E. Analogue Modelling of Bobbin Tool Friction Stir Welding. In Proceedings of the International Conference on Innovative Design and Manufacturing (ICIDM2016), Auckland, New Zealand, 24–26 January 2016. [Google Scholar]

- Barcellona, A.; Buffa, G.; Fratini, L.; Palmeri, D. On microstructural phenomena occurring in friction stir welding of aluminium alloys. J. Mater. Process. Technol. 2006, 177, 340–343. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Clucas, D. Afm characterization of stir-induced micro-flow features within the aa6082-t6 bfsw welds. Technologies 2019, 7, 80. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.; Sued, K.; Clucas, D. Thermomechanical grain refinement in aa6082-t6 thin plates under bobbin friction stir welding. Metals 2018, 8, 375. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.; Sued, K.; Clucas, D. Formation mechanisms for entry and exit defects in bobbin friction stir welding. Metals 2018, 8, 33. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.; Sued, K.; Clucas, D. Development of metallographic etchants for the microstructure evolution of a6082-t6 bfsw welds. Metals 2017, 7, 423. [Google Scholar] [CrossRef]

- Sued, M.; Tamadon, A.; Pons, D. Material flow visualization in bobbin friction stir welding by analogue model. Proc. Mech. Eng. Res. Day 2017, 2017, 368–369. [Google Scholar]

- Colligan, K. Material flow behavior during friction welding of aluminum. Weld. J. 1999, 75, 229s–237s. [Google Scholar]

- Tamadon, A.; Pons, D.; Sued, M.; Clucas, D.; Wong, E. Preparation of plasticine material for analogue modelling. In Proceedings of the International Conference on Innovative Design and Manufacturing (ICIDM2016), Auckland, New Zealand, 24–26 January 2016. [Google Scholar]

- Elrefaey, A.; Gouda, M.; Takahashi, M.; Ikeuchi, K. Characterization of aluminum/steel lap joint by friction stir welding. J. Mater. Eng. Perform. 2005, 14, 10–17. [Google Scholar] [CrossRef]

- Watanabe, T.; Takayama, H.; Yanagisawa, A. Joining of aluminum alloy to steel by friction stir welding. J. Mater. Process. Technol. 2006, 178, 342–349. [Google Scholar] [CrossRef]

- Kimapong, K.; Watanabe, T. Friction stir welding of aluminum alloy to steel. Weld. J. 2004, 83, 277. [Google Scholar]

- Tamadon, A.; Pons, D.J.; Clucas, D. Microstructural study on thermomechanical behaviour of 6082-t6 aluminium bfsw weld plates. In Materials@UC 2018; University of Canterbury: Christchurch, New Zealand, 2018. [Google Scholar]

- Murr, L.; Liu, G.; McClure, J. Dynamic recrystallization in friction-stir welding of aluminium alloy 1100. J. Mater. Sci. Lett. 1997, 16, 1801–1803. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Clucas, D. Thermomechanical performance of bobbin tool design as an innovative variant for friction stir welding. In Manufacturing and Design Conference (MaD 2019); NZ’s Manufacturing, Design and Entrepreneurship (MaDE) Network: Auckland, New Zealand, 2019. [Google Scholar]

- Tamadon, A.; Pons, D.J.; Clucas, D.; Sued, K. Internal material flow layers in aa6082-t6 butt-joints during bobbin friction stir welding. Metals 2019, 9, 1059. [Google Scholar] [CrossRef]

- Hattingh, D.; Blignault, C.; Van Niekerk, T.; James, M. Characterization of the influences of fsw tool geometry on welding forces and weld tensile strength using an instrumented tool. J. Mater. Process. Technol. 2008, 203, 46–57. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.; Clucas, D. Analogue modelling of flow patterns in bobbin friction stir welding by the dark-field/bright-field illumination method. Adv. Mater. Sci. 2020, 20, 56–70. [Google Scholar] [CrossRef]

- Siddiquee, A.N.; Pandey, S. Experimental investigation on deformation and wear of wc tool during friction stir welding (fsw) of stainless steel. Int. J. Adv. Manuf. Technol. 2014, 73, 479–486. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M.; de Saracibar, C.A. A fast and accurate two-stage strategy to evaluate the effect of the pin tool profile on metal flow, torque and forces in friction stir welding. Int. J. Mech. Sci. 2017, 122, 215–227. [Google Scholar] [CrossRef]

- Ramulu, P.J.; Narayanan, R.G.; Kailas, S.V.; Reddy, J. Internal defect and process parameter analysis during friction stir welding of al 6061 sheets. Int. J. Adv. Manuf. Technol. 2013, 65, 1515–1528. [Google Scholar] [CrossRef]

- Kumar, S.S.; Ravisankar, B.; Raviram, R.D. Evaluation of mechanical properties of friction stir welded commercially pure aluminium. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; p. 04003. [Google Scholar]

- Uthayakumar, M.; Balasubramanian, V.; Rani, A.M.A.; Hadzima, B. Effects of Welding on the Fatigue Behaviour of Commercial Aluminum aa-1100 Joints. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012065. [Google Scholar]

- Tamadon, A.; Pons, D.J.; Clucas, D.; Sued, K. Texture evolution in aa6082-t6 bfsw welds: Optical microscopy and ebsd characterisation. Materials 2019, 12, 3215. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Clucas, D. Flow-based anatomy of bobbin friction-stirred weld; aa6082-t6 aluminium plate and analogue plasticine model. Appl. Mech. 2020, 1, 3–19. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Clucas, D. Structural anatomy of tunnel void defect in bobbin friction stir welding, elucidated by the analogue modelling. Appl. Syst. Innov. 2020, 3, 2. [Google Scholar] [CrossRef]

- Egea, A.S.; Rodriguez, A.; Celentano, D.; Calleja, A.; De Lacalle, L.L. Joining metrics enhancement when combining fsw and ball-burnishing in a 2050 aluminium alloy. Surf. Coat. Technol. 2019, 367, 327–335. [Google Scholar] [CrossRef]

- Kolbeck, C.; Pitonak, R.; Weissenbacher, R. Friction Stir Welding Tool. U.S. Patent Application No. 12/742,760, 14 October 2010. [Google Scholar]

- Ye, F.; Fujii, H.; Tsumura, T.; Nakata, K. Friction stir welding of inconel alloy 600. J. Mater. Sci. 2006, 41, 5376–5379. [Google Scholar] [CrossRef]

- Seighalani, K.R.; Givi, M.B.; Nasiri, A.; Bahemmat, P. Investigations on the effects of the tool material, geometry, and tilt angle on friction stir welding of pure titanium. J. Mater. Eng. Perform. 2010, 19, 955–962. [Google Scholar] [CrossRef]

- Tolle, C.R.; Clark, D.E.; Barnes, T.A. Friction Stir Welding Tool. U.S. Patent No. 7,357,292, 15 April 2008. [Google Scholar]

- Park, H.K.; Oh, I.H.; Yoon, H.J.; Son, H.T.; Lee, K.J.; Bang, H.S.; Bang, H.S. Preparation Method of Tungsten Carbide Sintered Body for Friction Stir Welding Tool. U.S. Patent No. 9,580,361, 28 February 2017. [Google Scholar]

- Bahaaddini, M.; Baharvandi, H.R.; Ehsani, N.; Khajehzadeh, M.; Tamadon, A. Pressureless sintering of lps-sic (sic-al2o3-y2o3) composite in presence of the b4c additive. Ceram. Int. 2019, 45, 13536–13545. [Google Scholar] [CrossRef]

- Machniewicz, T.; Nosal, P.; Korbel, A.; Hebda, M. Effect of fsw traverse speed on mechanical properties of copper plate joints. Materials 2020, 13, 1937. [Google Scholar] [CrossRef]

- Torzewski, J.; Grzelak, K.; Wachowski, M.; Kosturek, R. Microstructure and low cycle fatigue properties of aa5083 h111 friction stir welded joint. Materials 2020, 13, 2381. [Google Scholar] [CrossRef]

- Msomi, V.; Mbana, N. Mechanical properties of friction stir welded aa1050-h14 and aa5083-h111 joint: Sampling aspect. Metals 2020, 10, 214. [Google Scholar] [CrossRef]

- Li, Y.; Sun, D.; Gong, W. Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welded 6082-t6 aluminum alloy. Metals 2019, 9, 894. [Google Scholar] [CrossRef]

- Wang, F.; Li, W.; Shen, J.; Hu, S.; Dos Santos, J. Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welding of al–li alloy. Mater. Des. 2015, 86, 933–940. [Google Scholar] [CrossRef]

- Wang, L.; Sabisch, J.; Lilleodden, E. Kink formation and concomitant twin nucleation in mg–y. Scr. Mater. 2016, 111, 68–71. [Google Scholar] [CrossRef]

- Korhonen, R.K.; Saarakkala, S. Biomechanics and modeling of skeletal soft tissues. In Theoretical Biomechanics; InTech: Rijeka, Croatia, 2011; pp. 113–132. [Google Scholar]

- Roeder, B.A.; Kokini, K.; Sturgis, J.E.; Robinson, J.P.; Voytik-Harbin, S.L. Tensile mechanical properties of three-dimensional type i collagen extracellular matrices with varied microstructure. J. Biomech. Eng. 2002, 124, 214–222. [Google Scholar] [CrossRef]

- Zitnay, J.L.; Weiss, J.A. Load transfer, damage, and failure in ligaments and tendons. J. Orthop. Res. 2018, 36, 3093–3104. [Google Scholar] [CrossRef]

- Mitsuhashi, K.; Ghosh, S.; Koibuchi, H. Mathematical modeling and simulations for large-strain j-shaped diagrams of soft biological materials. Polymers 2018, 10, 715. [Google Scholar] [CrossRef]

- Lee, B.; Zhou, X.; Riching, K.; Eliceiri, K.W.; Keely, P.J.; Guelcher, S.A.; Weaver, A.M.; Jiang, Y. A three-dimensional computational model of collagen network mechanics. PLoS ONE 2014, 9, e111896. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Shihab, S.K. Investigations on tunneling and kissing bond defects in fsw joints for dissimilar aluminum alloys. J. Alloy. Compd. 2015, 648, 360–367. [Google Scholar] [CrossRef]

- Kang, M.; Yoon, J.; Kim, C. Hook formation and joint strength in friction stir spot welding of al alloy and al–si-coated hot-press forming steel. Int. J. Adv. Manuf. Technol. 2020, 106, 1671–1681. [Google Scholar] [CrossRef]

- Krishnan, M.M.; Maniraj, J.; Deepak, R.; Anganan, K. Prediction of optimum welding parameters for fsw of aluminium alloys aa6063 and a319 using rsm and ann. Mater. Today 2018, 5, 716–723. [Google Scholar] [CrossRef]

- Liu, X.; Wu, C.; Padhy, G.K. Characterization of plastic deformation and material flow in ultrasonic vibration enhanced friction stir welding. Scr. Mater. 2015, 102, 95–98. [Google Scholar] [CrossRef]

- Mahto, R.P.; Anishetty, S.; Sarkar, A.; Mypati, O.; Pal, S.K.; Majumdar, J.D. Interfacial microstructural and corrosion characterizations of friction stir welded aa6061-t6 and aisi304 materials. Met. Mater. Int. 2019, 25, 752–767. [Google Scholar] [CrossRef]

- Nasir, S.N.N.M.; Sued, M.K.; Abidin, M.Z.Z. The effects of rotational tool speed on mechanical properties of bobbin friction stir welded aa1100. In Advances in Material Sciences and Engineering; Springer: Berlin, Germany, 2020; pp. 337–342. [Google Scholar]

- Shen, Z.; Li, W.; Ding, Y.; Hou, W.; Liu, X.; Guo, W.; Chen, H.; Liu, X.; Yang, J.; Gerlich, A. Material flow during refill friction stir spot welded dissimilar al alloys using a grooved tool. J. Manuf. Process. 2020, 49, 260–270. [Google Scholar] [CrossRef]

- Teimournezhad, J.; Masoumi, A. Experimental investigation of onion ring structure formation in friction stir butt welds of copper plates produced by non-threaded tool pin. Sci. Technol. Weld. Join. 2010, 15, 166–170. [Google Scholar] [CrossRef]

- Wen, Q.; Li, W.; Gao, Y.; Yang, J.; Wang, F. Numerical simulation and experimental investigation of band patterns in bobbin tool friction stir welding of aluminum alloy. Int. J. Adv. Manuf. Technol. 2019, 100, 2679–2687. [Google Scholar] [CrossRef]

- Wiedenhoft, A.G.; Amorim, H.J.D.; Rosendo, T.D.S.; Tier, M.A.D.; Reguly, A. Effect of heat input on the mechanical behaviour of al-cu fsw lap joints. Mater. Res. 2018, 21. [Google Scholar] [CrossRef]

| Element | Composition (wt %) |

|---|---|

| Al | 99.3 |

| Zn | 0.006 |

| Mn | 0.016 |

| Si | 0.138 |

| Cu | 0.009 |

| Cr | 0.03 |

| Fe | 0.182 |

| Mg | 0.007 |

| Welding Parameters | |||

|---|---|---|---|

| ω (rpm) | 710 | 1120 | 1400 |

| V (mm/min) | 150 | 250 | 315 |

| Tilt Angle | 3 degrees | ||

| Plunge Depth (shoulder) | 0.5 mm | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamadon, A.; Baghestani, A.; Bajgholi, M.E. Influence of WC-Based Pin Tool Profile on Microstructure and Mechanical Properties of AA1100 FSW Welds. Technologies 2020, 8, 34. https://doi.org/10.3390/technologies8020034

Tamadon A, Baghestani A, Bajgholi ME. Influence of WC-Based Pin Tool Profile on Microstructure and Mechanical Properties of AA1100 FSW Welds. Technologies. 2020; 8(2):34. https://doi.org/10.3390/technologies8020034

Chicago/Turabian StyleTamadon, Abbas, Arvand Baghestani, and Mohammad Ebrahim Bajgholi. 2020. "Influence of WC-Based Pin Tool Profile on Microstructure and Mechanical Properties of AA1100 FSW Welds" Technologies 8, no. 2: 34. https://doi.org/10.3390/technologies8020034

APA StyleTamadon, A., Baghestani, A., & Bajgholi, M. E. (2020). Influence of WC-Based Pin Tool Profile on Microstructure and Mechanical Properties of AA1100 FSW Welds. Technologies, 8(2), 34. https://doi.org/10.3390/technologies8020034