Moving the Open-Source Broadly Reconfigurable and Expandable Automation Device (BREAD) Towards a Supervisory Control and Data Acquisition (SCADA) System

Abstract

1. Introduction

2. Materials and Methods

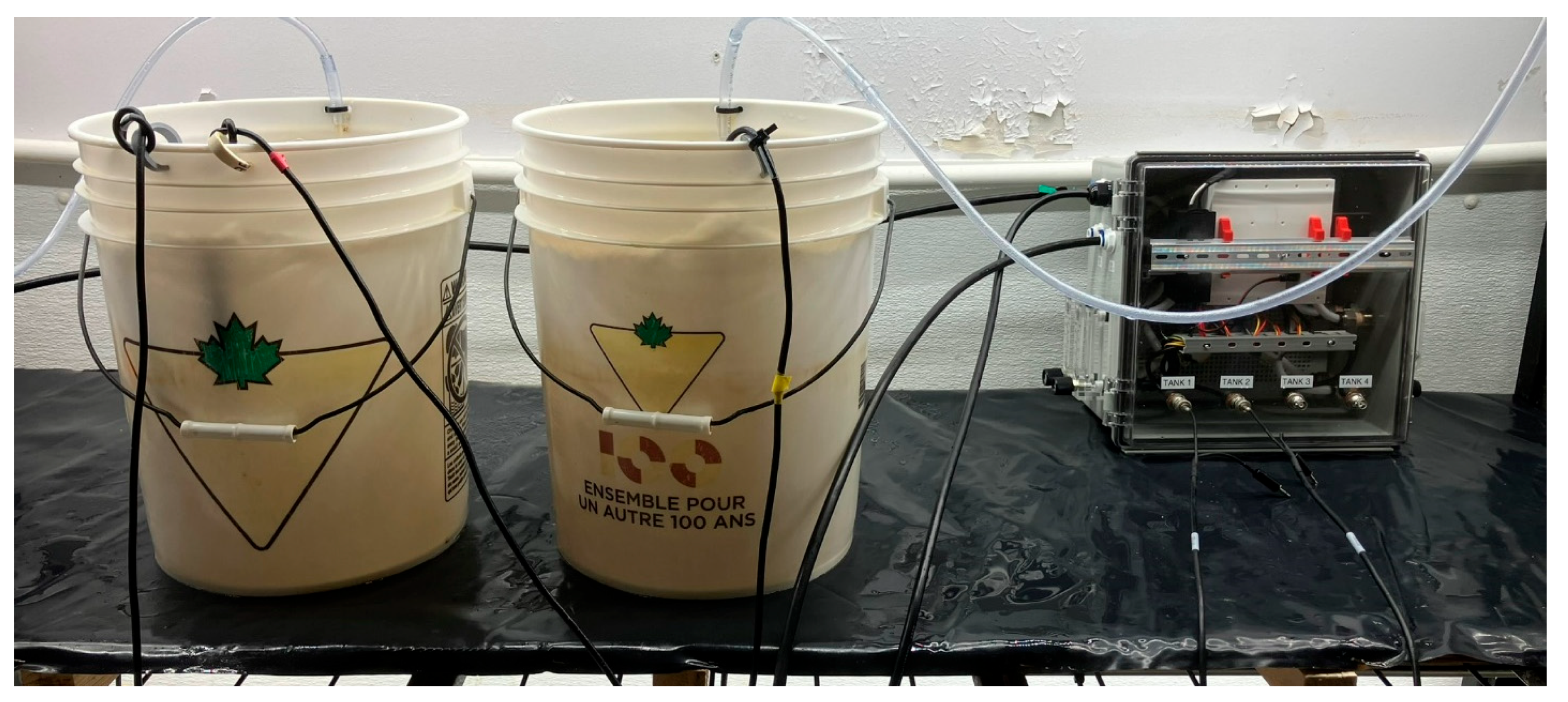

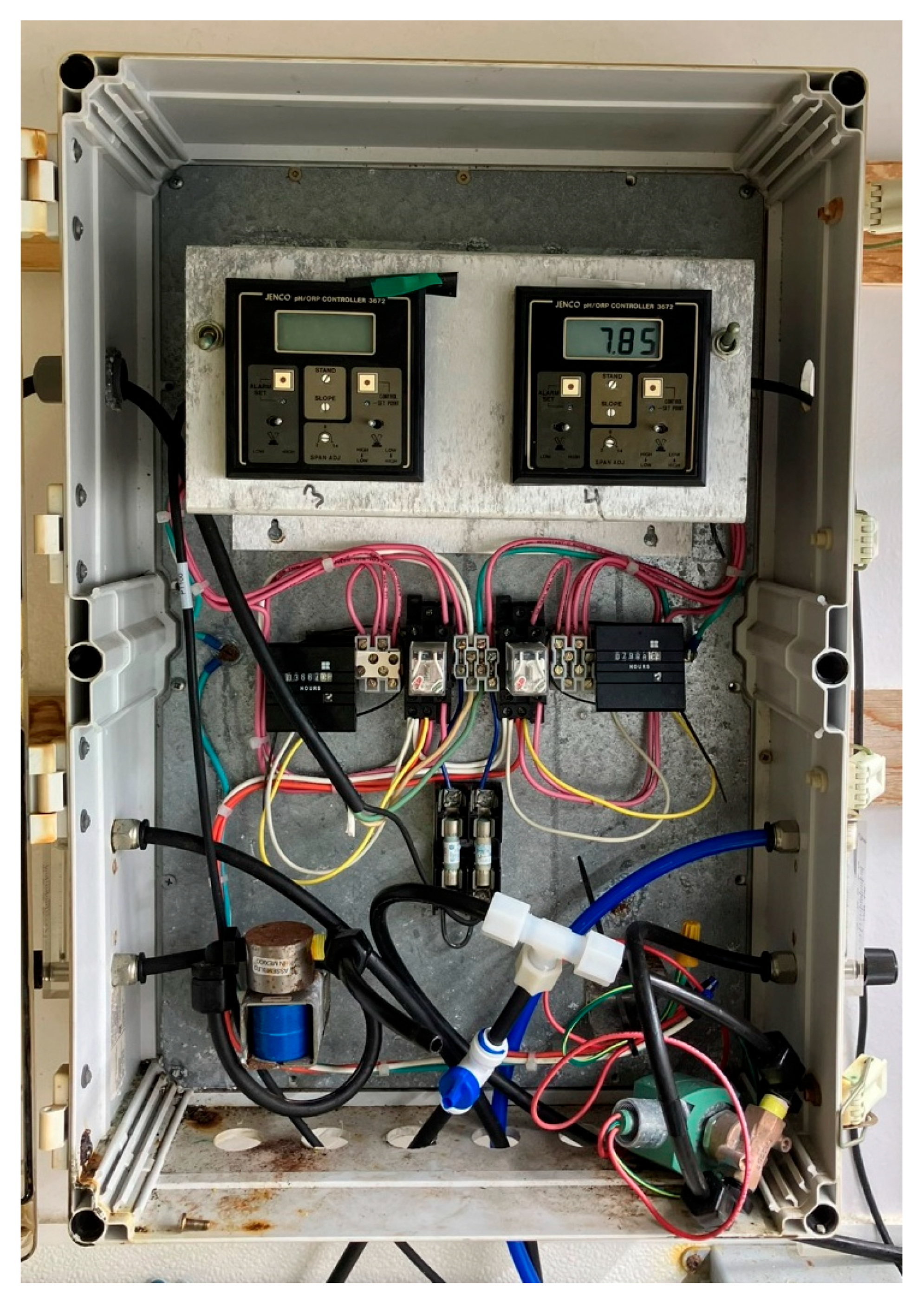

2.1. Comparison Setup

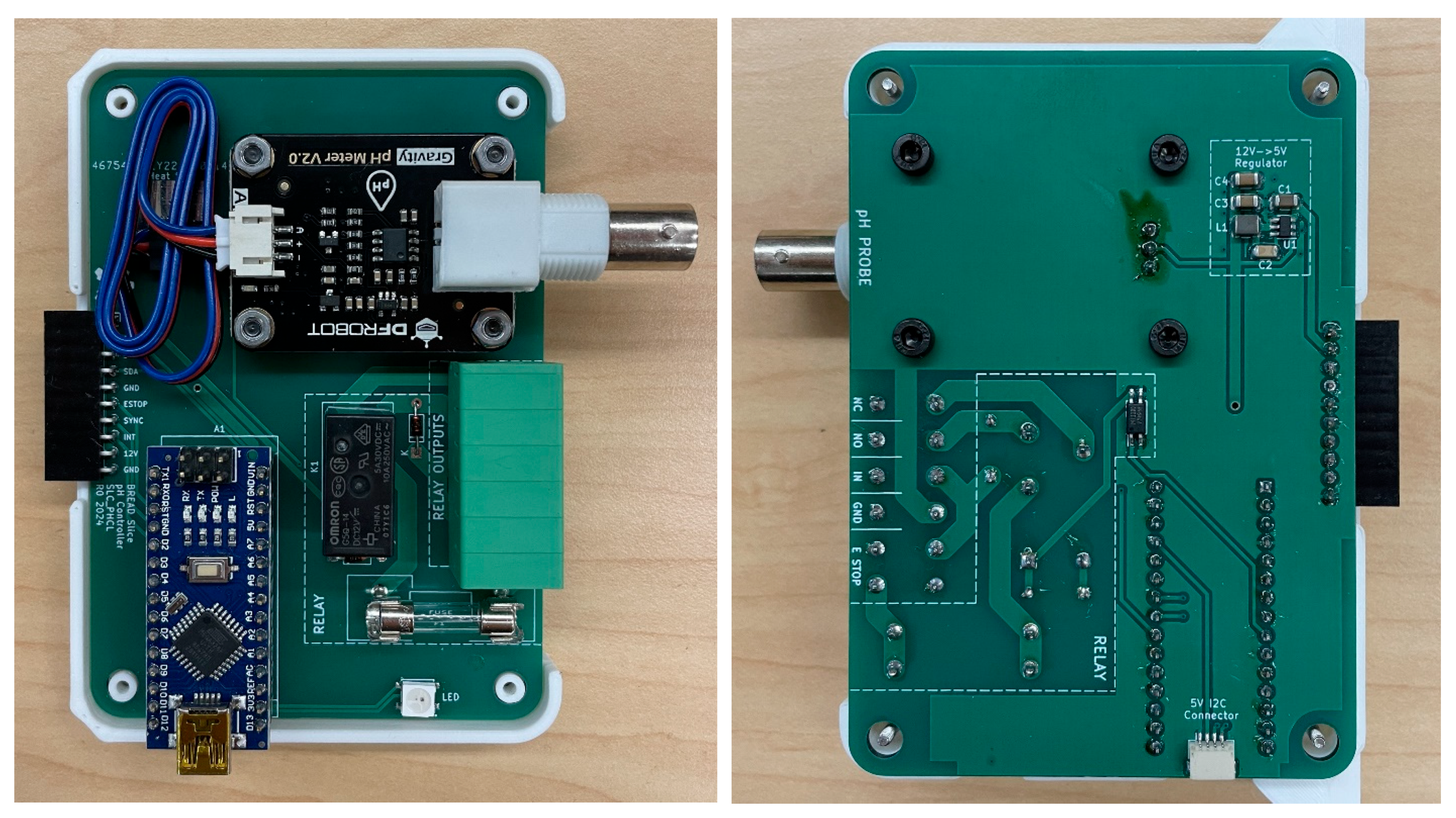

2.2. BREAD Hardware

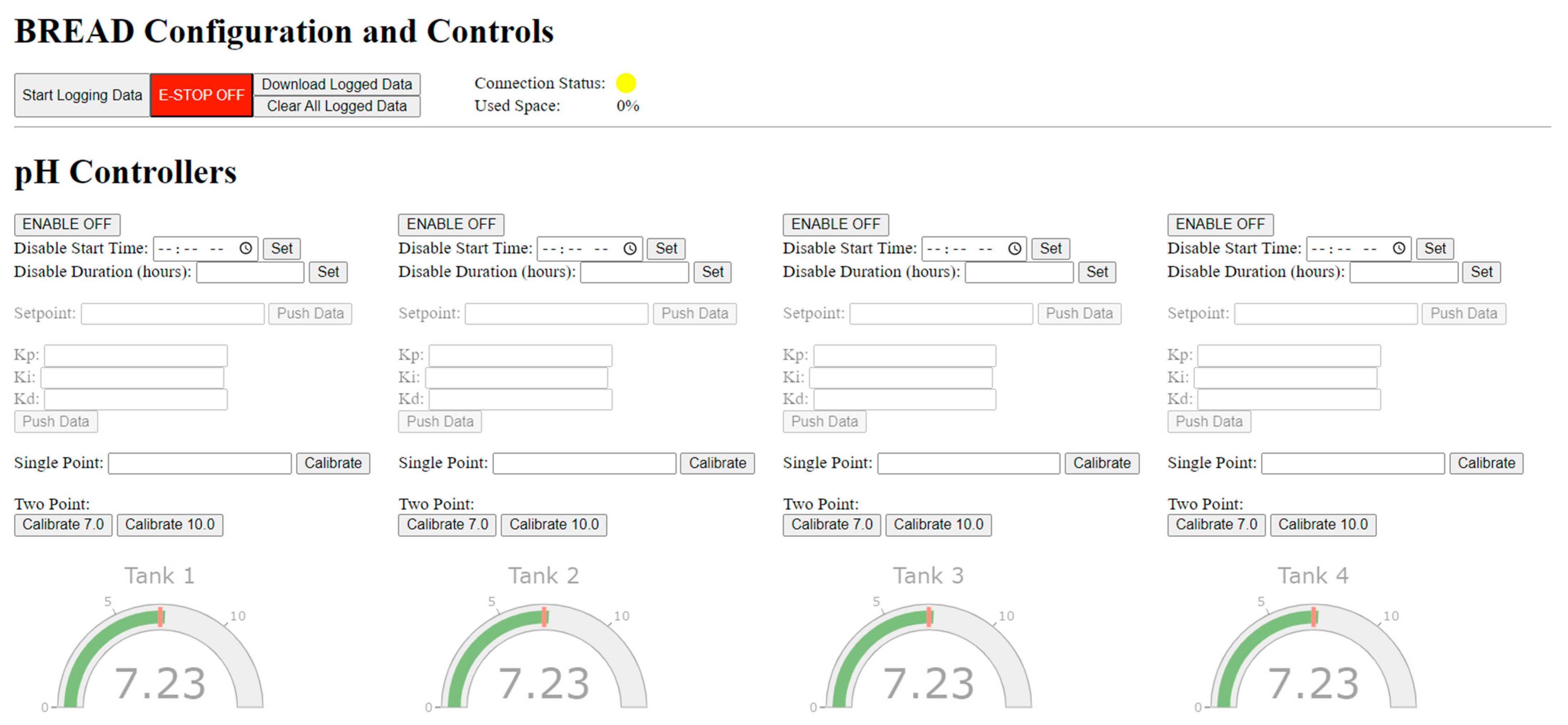

2.3. BREAD Software

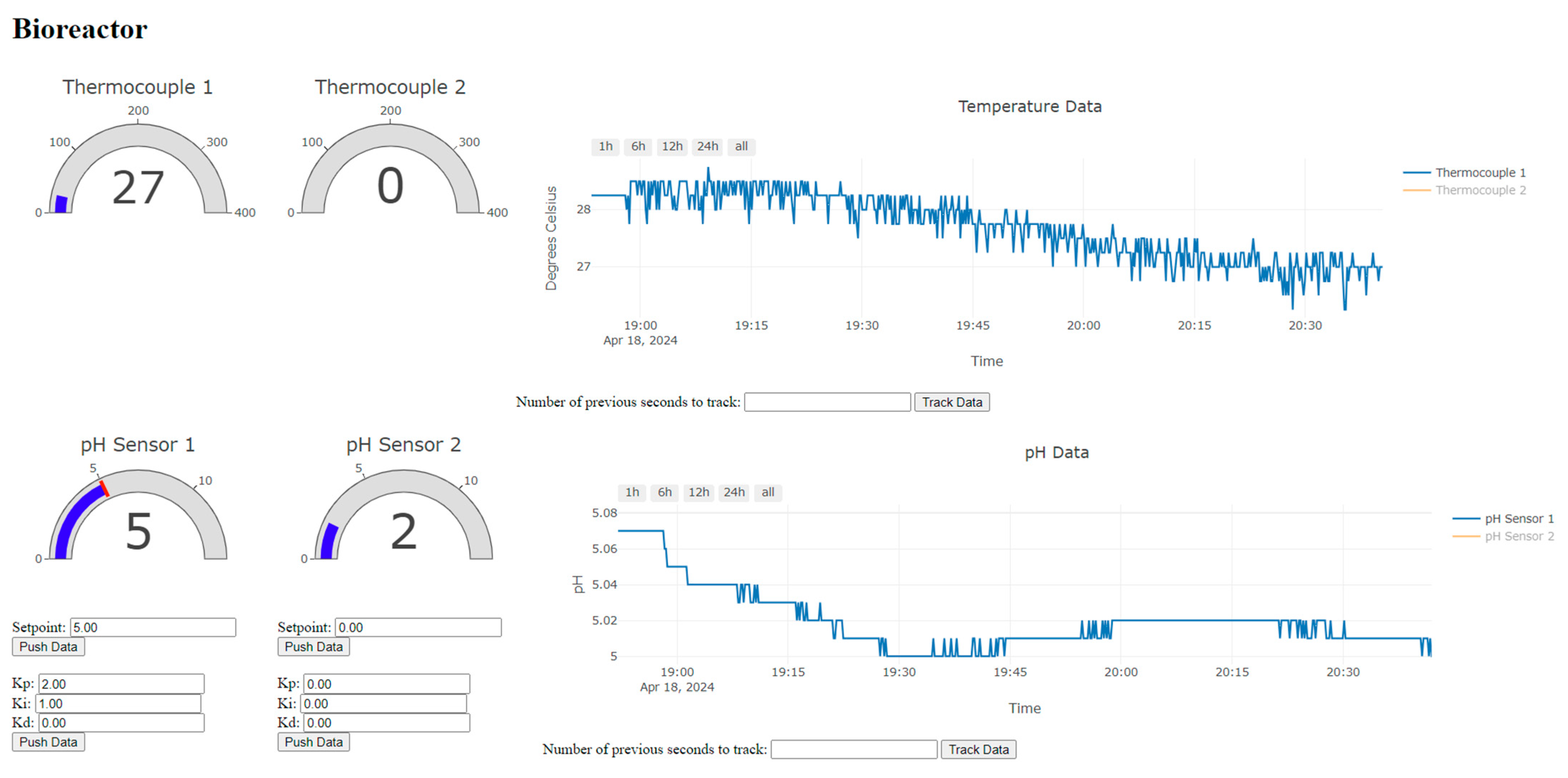

- Real-time data tracking with scrollable and resizable graphs (e.g., temperature, pH, etc.).

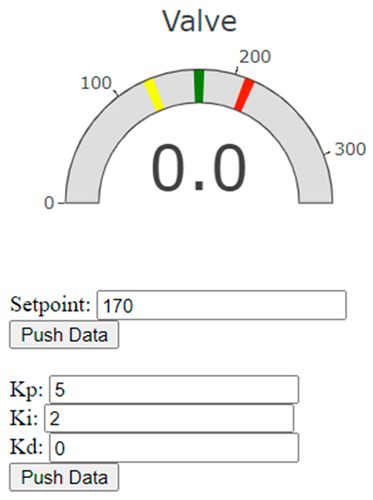

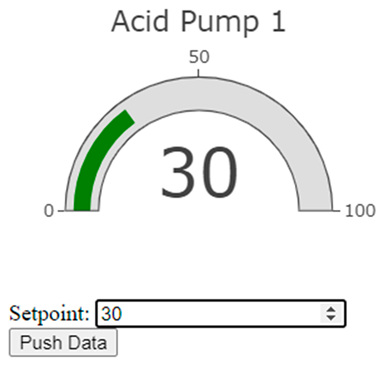

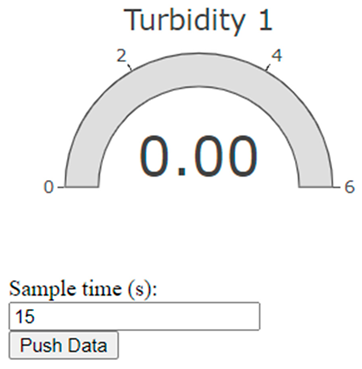

- Color-changing gauges to quickly show real-time data and indicate values well below or above a desired setpoint (e.g., overheating).

- Inputs for variables (e.g., temperature and pH setpoints and motor speed) along with the proportional (Kp), the integral (Ki), and the derivative (Kd) components for the PID controllers.

- Data logged to an SD card in comma-separated value (CSV) files.

- The ability to download and clear data directly from the webpage.

- Connection indicator to show if the user is connected to the ESP32.

- Emergency stop button that immediately sets all actuators to a safe state.

- Individual disable buttons for cleaning and startup (different from an E-STOP button which temporarily disables all Slices through hardware).

- Saved settings in event of a power outage (system will continue working as normal when the power comes back on).

- SD card indicator to show how much space is filled with data.

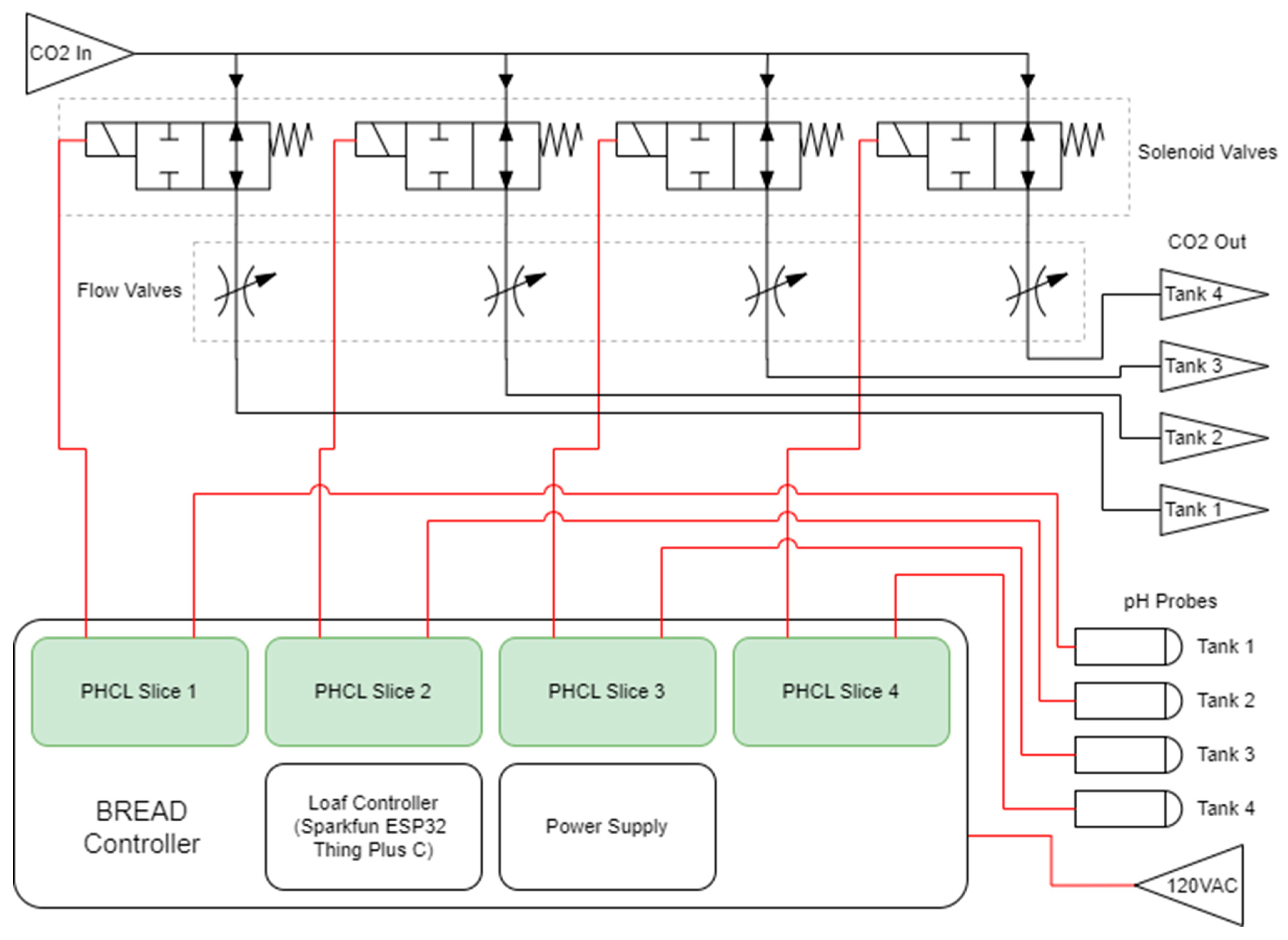

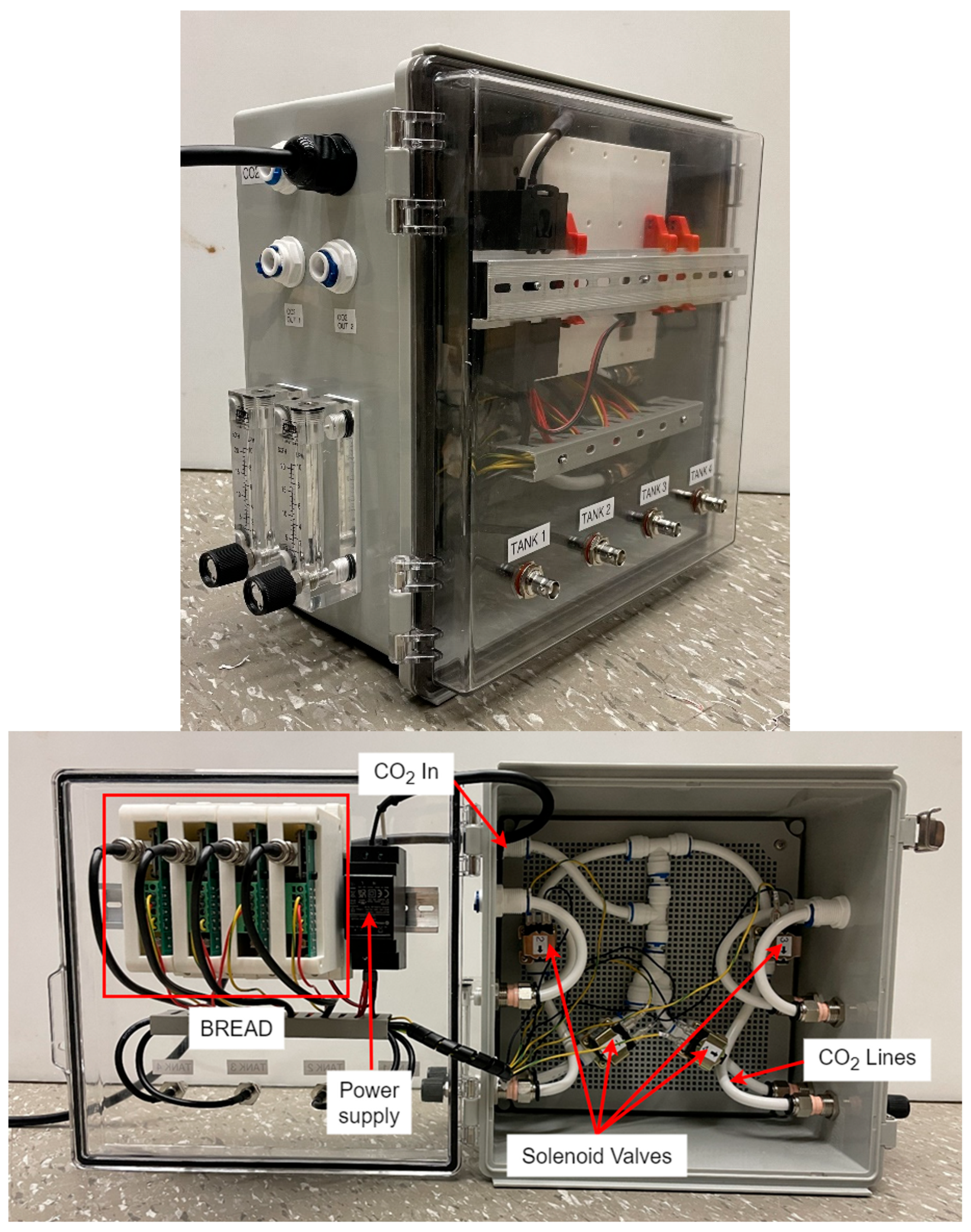

2.4. Experimental Setup

3. Results

4. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

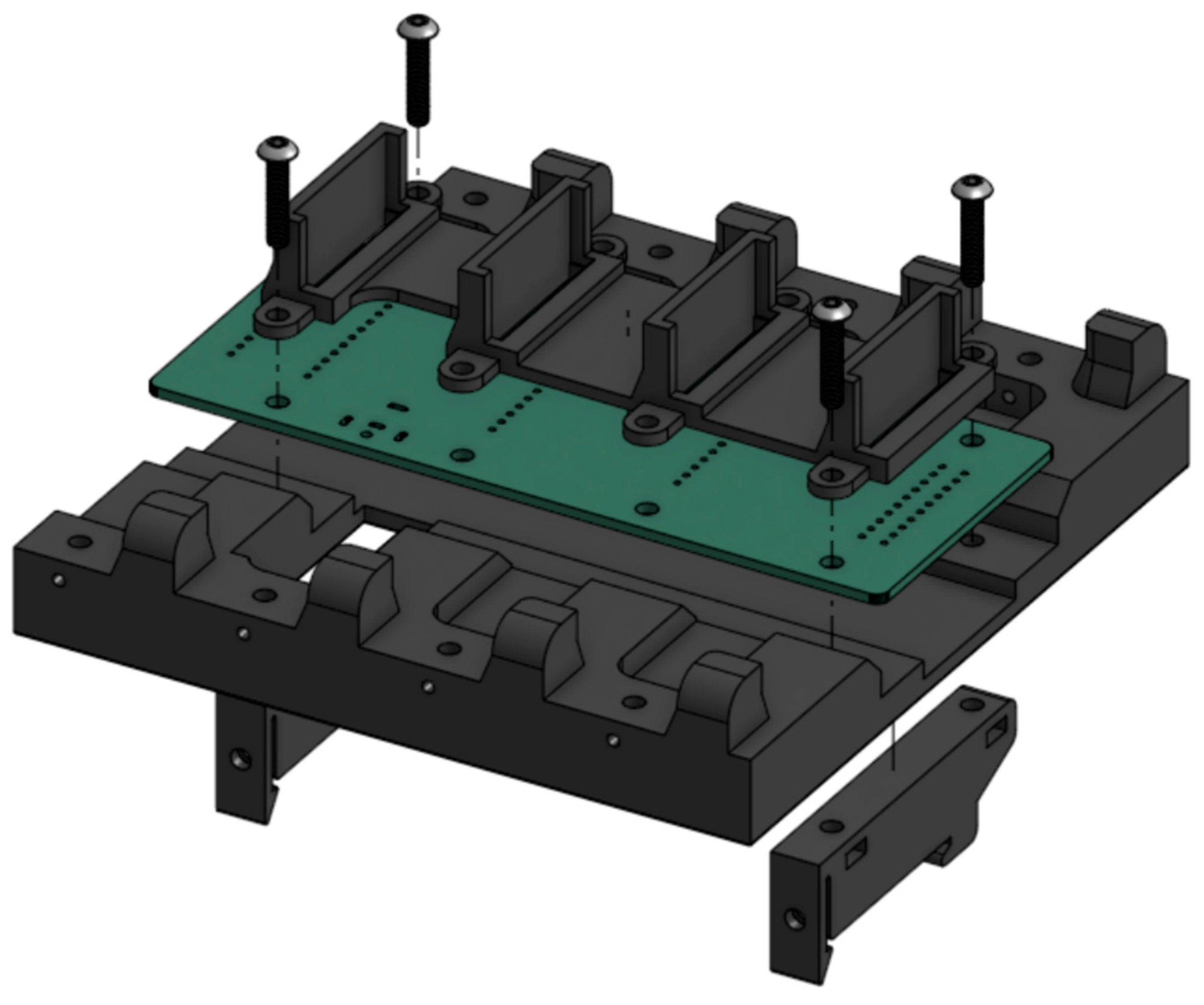

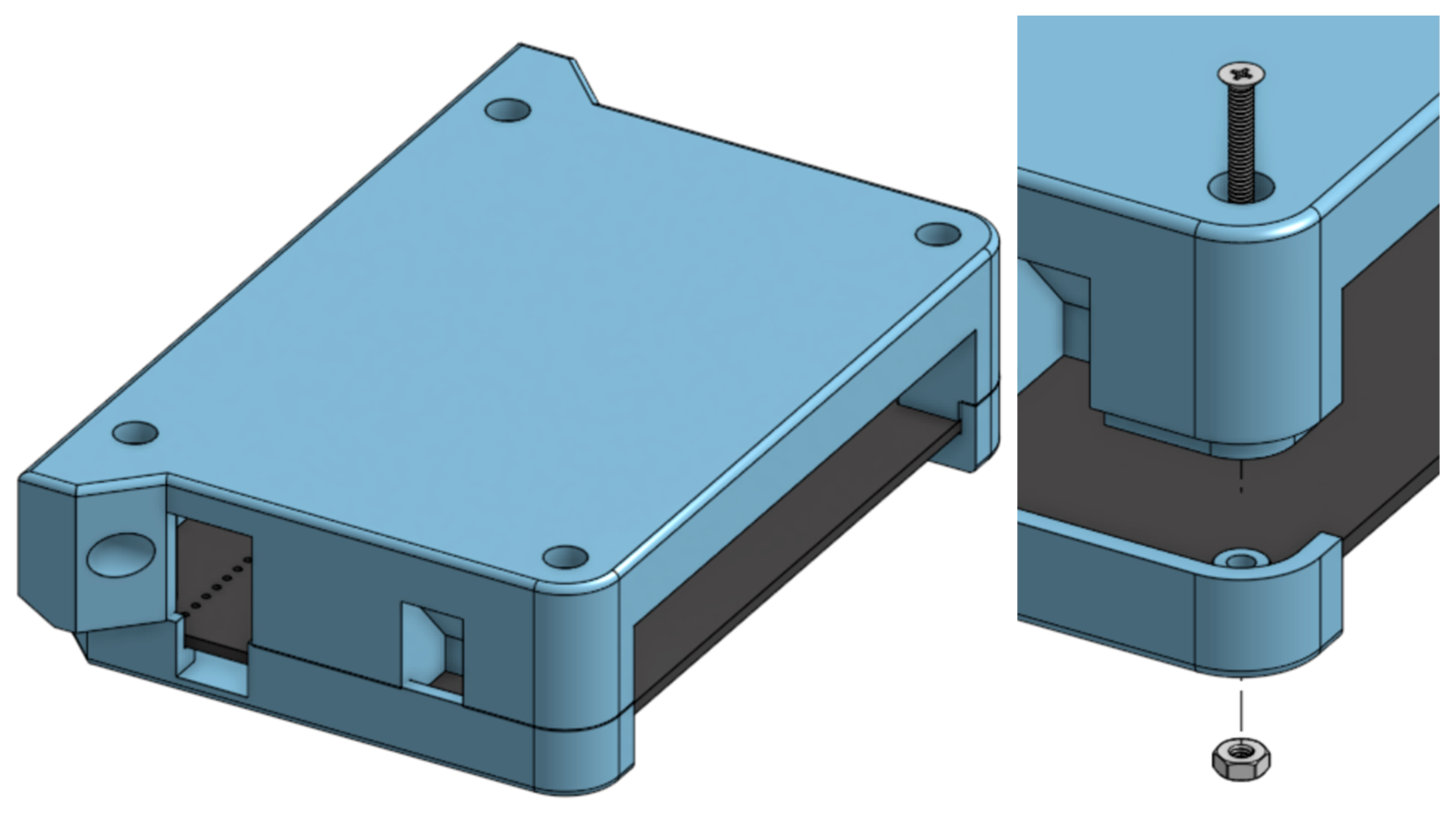

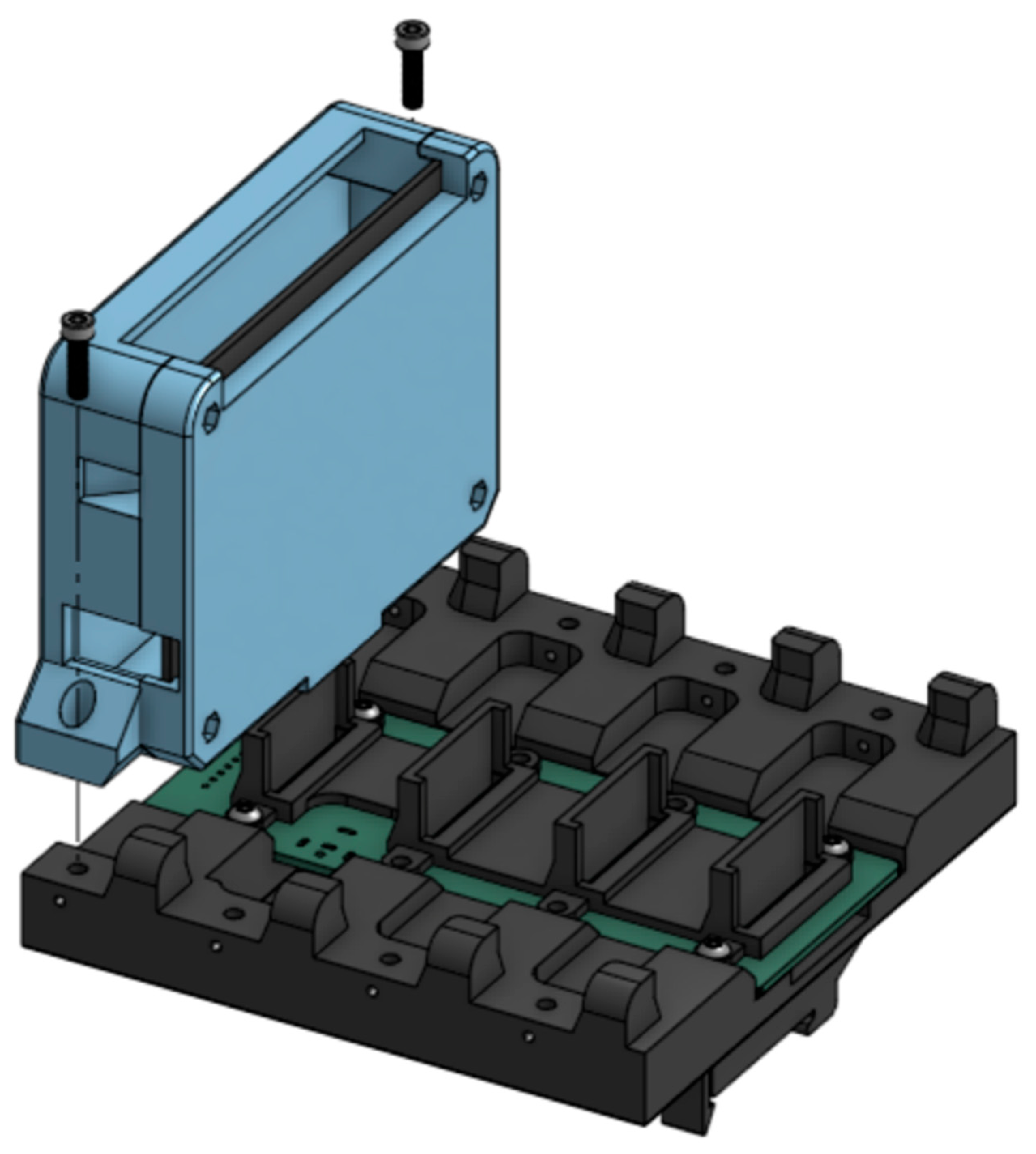

Appendix A. BREAD Assembly Instructions

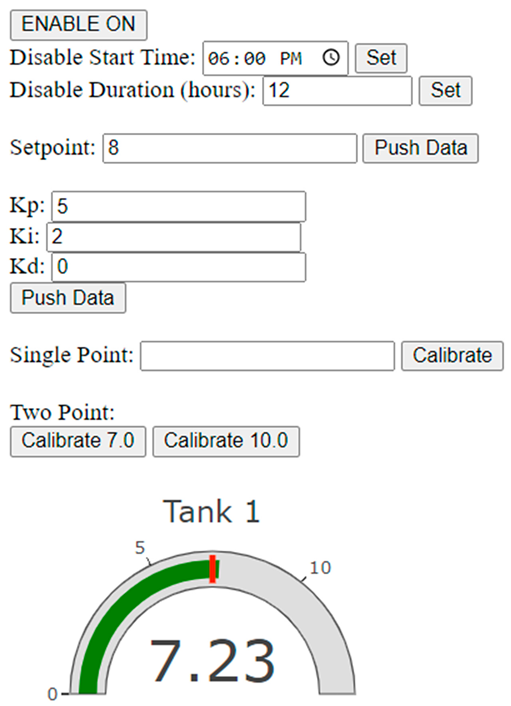

- Place M3 nuts within the Loaf support and DIN mount parts as shown in Figure A1.

- Connect Slice to Loaf according to Figure A4.

- Connect Loaf Controller to Loaf according to Figure A5.

Appendix B. Operation Instructions

- Download the contents from the GitHub repository: https://github.com/FHafting/BREAD-Local-Software (accessed on 21 March 2025).

- Upload the contents under “Website Code on SD Card” to the SD card on the ESP32.

- Upload the code under “Arduino Code” to the ESP32.

- Turn on the system and connect to the “BREAD” Wi-Fi network. The password is 12345678.

- Navigate to a Chrome browser and type “192.168.4.1” into the address bar. Wait 20–30 s for the web interface to display.

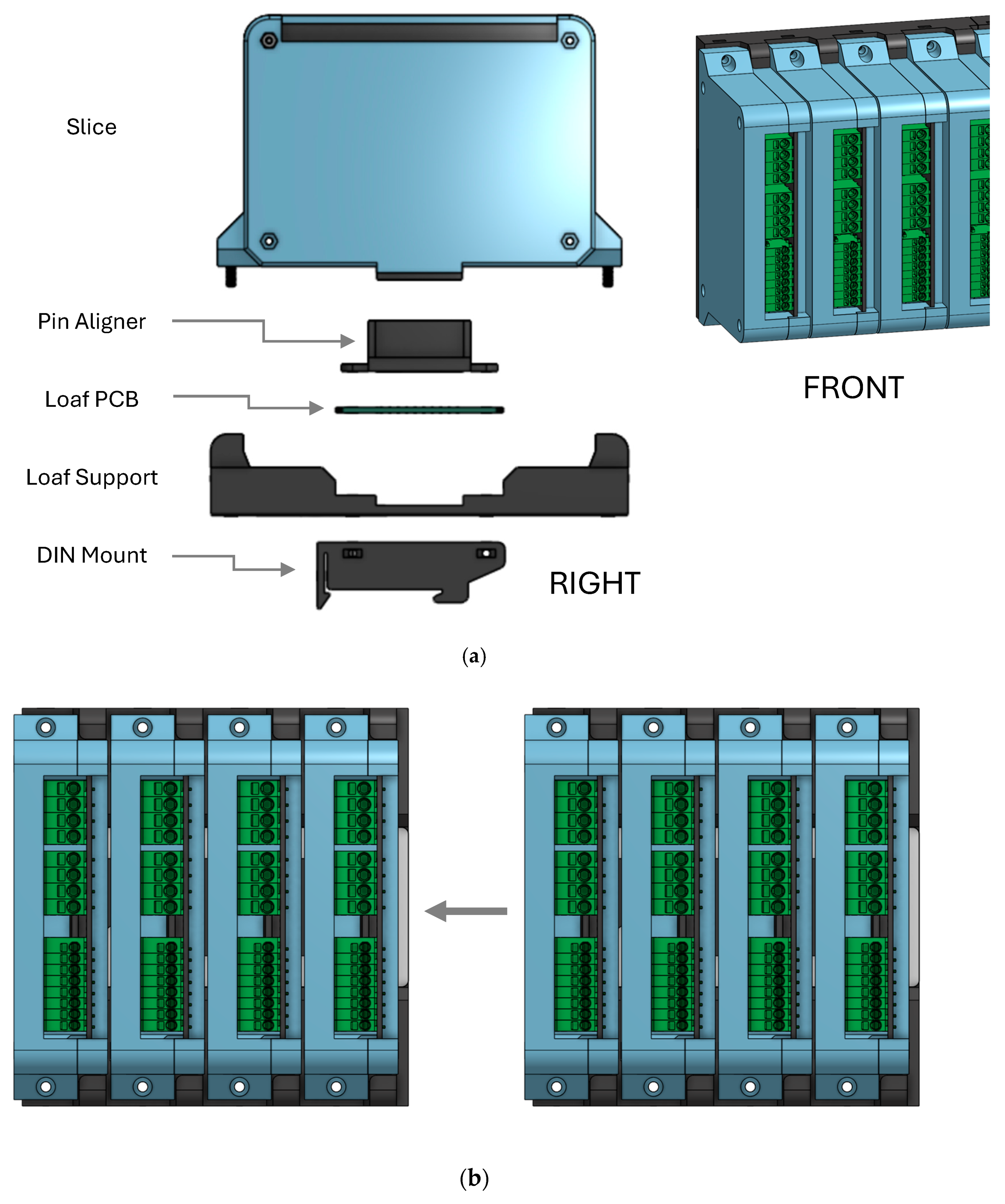

| Element | Image | Purpose |

|---|---|---|

| PID Controller |  | Assign the desired setpoint and PID tuning parameters for heating, cooling, or pH control. |

| Motor/Pump Controller |  | Assign the desired motor speed from −100% to 100% (full speed reverse and full speed forward, respectively). |

| Turbidity Controller |  | Assign the sampling interval of the turbidity pump. |

| New pH Controller |  | Based on the PID control block. Assign desired pH setpoint and PID tuning parameters. Assign disable period for experimentation. Set single point calibration or use two-point calibration for higher accuracy. |

Appendix C. BREAD Controller Cost Breakdown

| Part | # | Cost | Total | URL (Accessed on 21 March 2025) |

|---|---|---|---|---|

| Sparkfun Thing Plus C | 1 | $24.95 | $24.95 | https://www.sparkfun.com/products/20168 |

| 32GB SD Card | 1 | $34.98 | $34.98 | https://www.amazon.ca/Gigastone-32GB-U1-C10-Nintendo/dp/B07N73LB4T/ |

| Conn_01x10_Female | 1 | $1.09 | $1.09 | https://www.digikey.ca/en/products/detail/sullins-connector-solutions/PPTC101LGBN-RC/775904 |

| 22 μF | 3 | $0.51 | $1.53 | https://www.digikey.ca/en/products/detail/samsung-electro-mechanics/CL31A226KAHNNNE/3888705 |

| 100 nF | 1 | $0.16 | $0.16 | https://www.digikey.ca/en/products/detail/samsung-electro-mechanics/CL31B104KBCNNNC/3886675 |

| 4.7 μH | 1 | $2.32 | $2.32 | https://www.digikey.ca/en/products/detail/tdk-corporation/BCL322520RT-4R7M-D/15849704 |

| AP63205 | 1 | $1.31 | $1.31 | https://www.digikey.ca/en/products/detail/diodes-incorporated/AP63205WU-7/9858424 |

| Resistor 2.2k | 2 | $0.10 | $0.20 | https://www.digikey.ca/en/products/detail/yageo/RC0603JR-132K2L/14286397 |

| Total | $66.54 |

| Part | # | Cost | Total | URL (Accessed on 21 March 2025) |

|---|---|---|---|---|

| Conn_01x10_Male | 4 | $0.25 | $1.00 | https://www.digikey.ca/en/products/detail/amphenol-cs-fci/10129378-910002BLF/7915958 |

| 1x10 RA Male Header 2.54 mm Pitch | 1 | $0.23 | $0.23 | https://www.digikey.ca/en/products/detail/amphenol-cs-fci/10129379-910002BLF/7916010 |

| PinSocket_1x10_P2.54mm_Horizontal | 1 | $0.77 | $0.77 | https://www.digikey.ca/en/products/detail/sullins-connector-solutions/PPTC101LGBN-RC/775904 |

| BarrelJack_CUI_PJ-063AH_Horizontal | 1 | $1.61 | $1.61 | https://www.digikey.ca/en/products/detail/cui-devices/pj-063ah/2161208 |

| Total | $3.61 |

| Part | # | Cost | Total | URL (Accessed on 21 March 2025) |

|---|---|---|---|---|

| M2x25mm screws (×50) | 2 | $9.31 | $18.62 | https://www.mcmaster.com/92010A111/ |

| M2 nuts (×100) | 1 | $4.00 | $4.00 | https://www.mcmaster.com/90592A075/ |

| M3x12mm screws (×100) | 1 | $6.00 | $6.00 | https://www.mcmaster.com/91292A114/ |

| M3 nuts (×100) | 1 | $2.62 | $2.62 | https://www.mcmaster.com/90592A085/ |

| m3x15 bolts | 1 | $6.28 | $6.28 | https://www.mcmaster.com/92095A119/ |

| Total | $37.52 |

References

- Robles, G.; Amor, J.J.; Gonzalez-Barahona, J.M.; Herraiz, I. Evolution and Growth in Large Libre Software Projects. In Proceedings of the Eighth International Workshop on Principles of Software Evolution (IWPSE’05), Lisbon, Portugal, 5–6 September 2005; pp. 165–174. [Google Scholar]

- Weber, S. The Success of Open Source. In The Success of Open Source; Harvard University Press: Cambridge, MA, USA, 2005; ISBN 978-0-674-04499-9. [Google Scholar]

- Pearce, J.M. Sponsored Libre Research Agreements to Create Free and Open Source Software and Hardware. Inventions 2018, 3, 44. [Google Scholar] [CrossRef]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Addison-Wesley Professional: Boston, MA, USA, 2014; ISBN 978-0-13-337390-5. [Google Scholar]

- Oellermann, M.; Jolles, J.W.; Ortiz, D.; Seabra, R.; Wenzel, T.; Wilson, H.; Tanner, R.L. Open Hardware in Science: The Benefits of Open Electronics. Integr. Comp. Biol. 2022, 62, 1061–1075. [Google Scholar] [CrossRef] [PubMed]

- OSHWA Definition (English) 2024. Available online: https://www.oshwa.org/definition/ (accessed on 21 March 2025).

- Seo-Zindy, R.; Heeks, R. Researching the Emergence of 3D Printing, Makerspaces, Hackerspaces and FabLabs in the Global South: A Scoping Review and Research Agenda on Digital Innovation and Fabrication Networks. Electron. J. Inf. Syst. Dev. Ctries. 2017, 80, 1–24. [Google Scholar] [CrossRef]

- Chagas, A.M. Haves and Have Nots Must Find a Better Way: The Case for Open Scientific Hardware. PLoS Biol. 2018, 16, e3000014. [Google Scholar] [CrossRef]

- Wierenga, R.P.; Golas, S.M.; Ho, W.; Coley, C.W.; Esvelt, K.M. PyLabRobot: An Open-Source, Hardware-Agnostic Interface for Liquid-Handling Robots and Accessories. Device 2023, 1, 100111. [Google Scholar] [CrossRef]

- Kehl, F.; Cretu, V.F.; Willis, P.A. Open-Source Lab Hardware: A Versatile Microfluidic Control and Sensor Platform. HardwareX 2021, 10, e00229. [Google Scholar] [CrossRef]

- Alistar, M.; Gaudenz, U. OpenDrop: An Integrated Do-It-Yourself Platform for Personal Use of Biochips. Bioengineering 2017, 4, 45. [Google Scholar] [CrossRef]

- Brazey, B.; Haddab, Y.; Zemiti, N.; Mailly, F.; Nouet, P. An Open-Source and Easily Replicable Hardware for Electrical Impedance Tomography. HardwareX 2022, 11, e00278. [Google Scholar] [CrossRef]

- Merenda, M.; Iero, D.; Pangallo, G.; Falduto, P.; Adinolfi, G.; Merola, A.; Graditi, G.; Della Corte, F.G. Open-Source Hardware Platforms for Smart Converters with Cloud Connectivity. Electronics 2019, 8, 367. [Google Scholar] [CrossRef]

- Ali, A.S.; Coté, C.; Heidarinejad, M.; Stephens, B. Elemental: An Open-Source Wireless Hardware and Software Platform for Building Energy and Indoor Environmental Monitoring and Control. Sensors 2019, 19, 4017. [Google Scholar] [CrossRef]

- Oberloier, S.; Whisman, N.G.; Hafting, F.; Pearce, J.M. Open Source Framework for a Broadly Expandable and Reconfigurable Data Acquisition and Automation Device (BREAD). HardwareX 2023, 15, e00467. [Google Scholar] [CrossRef] [PubMed]

- McDonald, M.T.; Hayibo, K.S.; Hafting, F.; Pearce, J.M. Economics of Open-Source Solar Photovoltaic Powered Cryptocurrency Mining. Ledger 2023, 8. [Google Scholar] [CrossRef]

- Hafting, F.K.; Yeung, S.; Al-Aribe, H.; Michels, E.; Pearce, J.M. Parametric Low-Cost Open Source Bioreactor Designed for Distributed Manufacturing. 2025; To be published. [Google Scholar]

- Hafting, F.K.; Kulas, D.; Michels, E.; Chipkar, S.; Wisniewski, S.; Shonnard, D.; Pearce, J.M. Modular Open-Source Design of Pyrolysis Reactor Monitoring and Control Electronics. Electronics 2023, 12, 4893. [Google Scholar] [CrossRef]

- CompactRIO Systems (cRIO). Available online: https://www.ni.com/en/shop/compactrio.html (accessed on 24 July 2024).

- Opto22—Groov EPIC System. Available online: https://www.opto22.com/products/groov-epic-system (accessed on 1 May 2024).

- Zhou, Y.; Wang, Z.; Miao, Z.; Fan, L. A Synchrophasor-Based SCADA Testbed. In Proceedings of the 2021 North American Power Symposium (NAPS), College Station, TX, USA, 14–16 November 2021; pp. 1–5. [Google Scholar]

- Băloi, A.; Molnar-Matei, F.; Băloi, F.; Băloi, A.; Molnar-Matei, F.; Băloi, F. Virtual Instrument for Single-Phase Control of Three-Phase Reactive Power Capacitive Compensators. In LabVIEW—Virtual Instrumentation in Education and Industry; IntechOpen: London, UK, 2023; ISBN 978-1-83969-064-8. [Google Scholar]

- Mauz, F.; Wigger, R.; Wahl, T.; Kuffa, M.; Wegener, K. Acoustic Roughness Measurement of Railway Tracks: Implementation of an Optical Measurement Approach & Possible Improvements to the Standard. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 236, 095440972210864. [Google Scholar] [CrossRef]

- Almas, M.S.; Vanfretti, L.; Løvlund, S.; Gjerde, J.O. Open Source SCADA Implementation and PMU Integration for Power System Monitoring and Control Applications. In Proceedings of the 2014 IEEE PES General Meeting | Conference & Exposition, National Harbor, MD, USA, 27–31 July 2014; pp. 1–5. [Google Scholar]

- Merchán, D.F.; Peralta, J.A.; Vazquez-Rodas, A.; Minchala, L.I.; Astudillo-Salinas, D. Open Source SCADA System for Advanced Monitoring of Industrial Processes. In Proceedings of the 2017 International Conference on Information Systems and Computer Science (INCISCOS), Quito, Ecuador, 23–25 November 2017; pp. 160–165. [Google Scholar]

- Minchala, L.I.; Ochoa, S.; Velecela, E.; Astudillo, D.F.; Gonzalez, J. An Open Source SCADA System to Implement Advanced Computer Integrated Manufacturing. IEEE Lat. Am. Trans. 2016, 14, 4657–4662. [Google Scholar] [CrossRef]

- Prokhorov, A.S.; Chudinov, M.A.; Bondarev, S.E. Control Systems Software Implementation Using Open Source SCADA-System OpenSCADA. In Proceedings of the 2018 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), Moscow, Russia, 29 January–1 February 2018; pp. 220–222. [Google Scholar]

- Barana, O.; Barbato, P.; Breda, M.; Capobianco, R.; Luchetta, A.; Molon, F.; Moressa, M.; Simionato, P.; Taliercio, C.; Zampiva, E. Comparison between Commercial and Open-Source SCADA Packages—A Case Study. Fusion Eng. Des. 2010, 85, 491–495. [Google Scholar] [CrossRef]

- Bidyanath, K.; Abonmei, A.; Tongbram, S. A Survey on Open-Source SCADA for Industrial Automation Using Raspberry Pi. In Proceedings of the Trends in Wireless Communication and Information Security; Chakraborty, M., Jha, R.K., Balas, V.E., Sur, S.N., Kandar, D., Eds.; Springer: Singapore, 2021; pp. 19–26. [Google Scholar]

- SCADA-LTS/Scada-LTS 2025. Available online: https://github.com/SCADA-LTS/Scada-LTS (accessed on 21 March 2025).

- Omidi, S.A.; Baig, M.J.A.; Iqbal, M.T. Design and Implementation of Node-Red Based Open-Source SCADA Architecture for a Hybrid Power System. Energies 2023, 16, 2092. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Low-Cost, Open Source IoT-Based SCADA System Design Using Thinger.IO and ESP32 Thing. Electronics 2019, 8, 822. [Google Scholar] [CrossRef]

- Uddin, S.U.; Baig, M.J.A.; Iqbal, M.T. Design and Implementation of an Open-Source SCADA System for a Community Solar-Powered Reverse Osmosis System. Sensors 2022, 22, 9631. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Development of an IoT Based Open Source SCADA System for PV System Monitoring. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; pp. 1–4. [Google Scholar]

- Ahsan, L.; Baig, M.J.A.; Iqbal, M.T. Low-Cost, Open-Source, Emoncms-Based SCADA System for a Large Grid-Connected PV System. Sensors 2022, 22, 6733. [Google Scholar] [CrossRef]

- Yuratsmeechan, P.; Manop, C. Open-Source IoT-Integrated SCADA System for Biomass Power Plant Monitoring. In Proceedings of the 2024 21st International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Khon Kaen, Thailand, 27–30 May 2024; pp. 1–7. [Google Scholar]

- Pearce, J.M. Economic Savings for Scientific Free and Open Source Technology: A Review. HardwareX 2020, 8, e00139. [Google Scholar] [CrossRef]

- Arduino—Home. Available online: https://www.arduino.cc/ (accessed on 23 July 2024).

- PCB Prototype & PCB Fabrication Manufacturer—JLCPCB. Available online: https://jlcpcb.com/?from=VGPCBA&gad_source=1&gclid=CjwKCAjw74e1BhBnEiwAbqOAjPinT95y3kicmEcGoxhGIT5N5ecGG8C3Ay0yHyRZPq2gG9kaOIsczhoC5jIQAvD_BwE (accessed on 25 July 2024).

- NI cRIO-9030. Available online: https://www.ni.com/en-ca/shop/model/crio-9030.html (accessed on 24 July 2024).

- NI 9210. Available online: https://www.ni.com/en-ca/shop/model/ni-9210.html (accessed on 24 July 2024).

- NI 9482. Available online: https://www.ni.com/en-ca/shop/model/ni-9482.html (accessed on 24 July 2024).

- NI 9470. Available online: https://www.ni.com/en-ca/shop/model/ni-9470.html (accessed on 24 July 2024).

- NI 9203. Available online: https://www.ni.com/en-ca/shop/model/ni-9203.html (accessed on 24 July 2024).

- NI 9219. Available online: https://www.ni.com/en-ca/shop/model/ni-9219.html (accessed on 24 July 2024).

- Oberloier, S.; Whisman, N.; Hafting, F.; Pearce, J.M. BREAD. HardwareX 2022. [Google Scholar] [CrossRef]

- Hafting, F. FHafting/BREAD. Available online: https://github.com/FHafting/BREAD (accessed on 12 February 2025).

- Hafting, F. Butter. Available online: https://github.com/FHafting/BREAD-Local-Software (accessed on 26 January 2025).

- Clearwater Pool Systems. pH PURETM CO2 Injection for pH Control—Swimming Pools; Clearwater Pool Systems: Largo, FL, USA.

- Garbacz, G.; Kołodziej, B.; Koziolek, M.; Weitschies, W.; Klein, S. An Automated System for Monitoring and Regulating the pH of Bicarbonate Buffers. AAPS PharmSciTech 2013, 14, 517–522. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Das, P.; Thaher, M.; Abdulquadir, M.; Faisal, M.; Hawari, A.H.; Al-Jabri, H. Application Note—A Novel, Low-Cost pH-Controlled Solenoid-Based CO2 Dosing Device for Microalgal and Cyanobacterial Cultivation Systems. Smart Agric. Technol. 2024, 7, 100373. [Google Scholar] [CrossRef]

- Jenco 3672 1/4 DIN pH/ORP Controllers, Adjustable Output from Cole-Parmer China. Available online: https://www.coleparmer.com.cn/i/jenco-3672-1-4-din-ph-orp-controllers-adjustable-output/0580200 (accessed on 26 January 2025).

- MTU MOST/MOST_OpenReactor GitLab. Available online: https://gitlab.com/mtu-most/most_openreactor (accessed on 10 March 2025).

- Wonham, W.M.; Johnson, C.D. Optimal Bang-Bang Control With Quadratic Performance Index. J. Basic Eng. 1964, 86, 107–115. [Google Scholar] [CrossRef]

- Åström, K.J.; Murray, R. Feedback Systems: An Introduction for Scientists and Engineers, Second Edition; Princeton University Press: Princeton, NJ, USA, 2021; ISBN 978-0-691-19398-4. [Google Scholar]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

| Function | NI CompactRIO | Cost (CAD) | BREAD | Cost (CAD) |

|---|---|---|---|---|

| Chassis for plugging in modules | NI cRIO-9030 | $7695 [40] | Loaf Backplane | ~$10 |

| Loaf Controller | ~$70 | |||

| Temperature measurement | NI 9210 | $855 [41] | RLHT Slice | ~$75 |

| Heating/relay control | NI 9482 | $440 [42] | ||

| DC motor control | NI 9470 | $1580 [43] | DCMT Slice (×2) | ~$97 |

| pH sensing | NI 9203 | $1415 [44] | PHDO Slice | ~$715 |

| Dissolve oxygen sensing | NI 9219 | $2815 [45] | ||

| Total | $14,800 | Total | $1064 |

| BREAD Limitation | BREAD v2 Improvement |

|---|---|

| No Loaf mounting method. BREAD system could be easily knocked over. | Loaf mounted to DIN rail clips. Loaf form factor changed so multiple can be connected. Slice limit based on integrity of I2C signal (~30 Slices over 1 m). |

| Loafs could not be physically connected. Limit of 8 Slices per system. | |

| No Slice mounting method. Slices could become unplugged easily. | Slices mounted with two M3 screws to Loaf. |

| Difficult to align 10-pin Slice connector with Loaf to plug in Slices. | Each 10-pin connector has a 3D printed alignment cover. |

| Individual Loafs need a full Raspberry Pi (RPi) desktop for normal operation (RPi, monitor, keyboard, mouse). Impractical and expensive for multiple systems. | Loaf Controller changed to an ESP32. All communication with Loafs happens wirelessly over a locally hosted Wi-Fi network on the ESP32. |

| User interface requires users to have some comfort with Linux terminal coding to start up the system. | New software, hosted by the ESP32, runs in a Chrome web browser on the user’s laptop or computer of choice. |

| BREAD Element | Part | # | URL (All Accessed 21 March 2025) |

|---|---|---|---|

| Slice | Slice PCB | 1 | Order through JLCPCB. Gerbers found on OSF: https://osf.io/u2h4g/ |

| Slice Top Case | 1 | 3D Print: https://osf.io/wyfbr | |

| Slice Bottom Case | 1 | 3D Print: https://osf.io/ce6zv | |

| M2x25mm screws | 4 | https://www.mcmaster.com/92010A111/ | |

| M2 nuts | 4 | https://www.mcmaster.com/90592A075/ | |

| M3x12mm screws | 2 | https://www.mcmaster.com/91292A114/ | |

| Loaf Backplane | Loaf PCB | 1 | Order through JLCPCB. Gerbers found on OSF: https://osf.io/u2h4g/ |

| Loaf Support | 1 | 3D Print: https://osf.io/u453q | |

| Pin Aligner | 1 | 3D Print: https://osf.io/utq5c | |

| DIN Mount | 2 | 3D Print: https://osf.io/cna48 | |

| M3 nuts | 4 | https://www.mcmaster.com/90592A085/ | |

| M3x15mm screws | 4 | https://www.mcmaster.com/92095A119/ | |

| Loaf Controller | Loaf Controller PCB | 1 | Order through JLCPCB. Gerbers found on OSF: https://osf.io/u2h4g/ |

| Loaf Controller Case | 1 | 3D Print: https://osf.io/2xwr3 | |

| DIN Mount | 1 | 3D Print: https://osf.io/cna48 | |

| M3 nuts | 2 | https://www.mcmaster.com/90592A085/ | |

| M3x15mm screws | 2 | https://www.mcmaster.com/92095A119/ |

| Parameter | Tank 1 | Tank 2 |

|---|---|---|

| Controller | JENCO pH/ORP Controller 3672 | BREAD Controller |

| Control scheme | Bang-bang | PID |

| Tunings | N/A | Kp = 2 Ki = 1 Kd = 0 |

| Controller type | Average | Deviation |

|---|---|---|

| Commercial Controller | 7.81 | 0.095 |

| BREAD Controller | 7.98 | 0.019 |

| System | Part | Individual Cost (CAD) | Total Cost (CAD) |

|---|---|---|---|

| BREAD Controller | Slice | $86.78 (×4) | $454.80 |

| Loaf | $3.61 | ||

| Loaf Controller | $66.54 | ||

| Commercial Controller | Commercial Controller | $330 (×4) | $1320 |

| Full System | BREAD Controller | $454.80 | $861.66 (65% savings) |

| Enclosure/Tubing | $406.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hafting, F.K.; Chin, A.W.H.; Hafting, J.T.; Pearce, J.M. Moving the Open-Source Broadly Reconfigurable and Expandable Automation Device (BREAD) Towards a Supervisory Control and Data Acquisition (SCADA) System. Technologies 2025, 13, 125. https://doi.org/10.3390/technologies13040125

Hafting FK, Chin AWH, Hafting JT, Pearce JM. Moving the Open-Source Broadly Reconfigurable and Expandable Automation Device (BREAD) Towards a Supervisory Control and Data Acquisition (SCADA) System. Technologies. 2025; 13(4):125. https://doi.org/10.3390/technologies13040125

Chicago/Turabian StyleHafting, Finn K., Alexander W. H. Chin, Jeff T. Hafting, and Joshua M. Pearce. 2025. "Moving the Open-Source Broadly Reconfigurable and Expandable Automation Device (BREAD) Towards a Supervisory Control and Data Acquisition (SCADA) System" Technologies 13, no. 4: 125. https://doi.org/10.3390/technologies13040125

APA StyleHafting, F. K., Chin, A. W. H., Hafting, J. T., & Pearce, J. M. (2025). Moving the Open-Source Broadly Reconfigurable and Expandable Automation Device (BREAD) Towards a Supervisory Control and Data Acquisition (SCADA) System. Technologies, 13(4), 125. https://doi.org/10.3390/technologies13040125