Abstract

While the free and open-source Broadly Reconfigurable and Expandable Automation Device (BREAD) has demonstrated functionality as an inexpensive replacement for many commercial controllers, some aspects of its design require updating to make it more aligned with commercial supervisory control and data acquisition (SCADA) systems. Some of these updates to BREAD for version 2 included improvements to the mechanical design for stability with an alignment cover, rail mounting with Deutsche Institut für Normung (DIN) rail clips, ESP32 Loaf Controller with local wireless connectivity, and open-source web browser-based software control. These updates were validated by comparing BREAD v2 to an existing commercial controller used for airline-based pH control for industrial seaweed production. BREAD v2 was integrated into an electrical enclosure complete with pH probes, CO2 lines, solenoid valves, and a power supply. After comparing the two approaches, BREAD v2 was found to be more precise by roughly a factor of five, and less expensive by a factor of three than proprietary systems, while also offering additional functionality like data logging and wireless monitoring. Although able to match or beat specific functions of SCADA systems, future work is needed to transform BREAD into a full SCADA system.

1. Introduction

Despite the success of open-source software [1,2], open-source hardware is still significantly behind in its adoption in research and industrial projects [3]. Open-source hardware [4] has an advantage over proprietary hardware in its repairability, customizability, and cost savings [5]. This is because open-source devices, in most cases, have extensive documentation that outlines the internal circuitry, provides a full bill of materials (BOM), and provides the source code [6]. Ideally, the user could fully replicate the device using this documentation depending on their proficiency in electronics. Additionally, the community of “makers” that often forms around these devices becomes voluntary customer support via online forums and social media groups [7]. These characteristics of open- source devices make them desirable for research and educational settings [8].

Open-source devices are also commonly associated with home “DIY” (do it yourself) projects. The applications of open hardware, however, are widespread and provide high-end research tools like laboratory liquid handling [9], microfluidic sensing and control [10,11], and electrical impedance tomography [12], to more industrial solutions like smart energy converter testing [13] and building air quality and energy monitoring [14]. Unfortunately, combining open-source devices for novel research processes can be difficult due to differences in communication protocols (i.e., I2C, UART, SPI, MQTT, etc.), lack of hardware connection ports (i.e., USB, QWIIC, etc.), and differences in software language/abstraction (i.e., C, Python, etc.). This reliance on the user’s proficiency in electronics has been a major bottleneck in the adoption of open hardware in spaces that commonly rely on proprietary hardware [5]. The Broadly Reconfigurable and Expandable Automation Device (BREAD) framework was created to enable the interoperability of open-source devices by integrating new and existing open-source designs together into a consistent hardware and software standard [15]. BREAD has demonstrated its capabilities as a data acquisition (DAQ) system for temperature monitoring [16] as well as a supervisory control and data acquisition (SCADA) system for automating biological growth experiments within a bioreactor [17] or controlling the heating zones within a pyrolysis reactor to break down plastic waste into fuel, oil, and wax [18]. SCADA systems consist of physical hardware responsible for controlling and monitoring actuators and sensors, and software to display these data and allow users to interact with the system. Proprietary SCADA devices like National Instrument’s (NI) CompactRIO (cRIO) [19] and Opto 22’s groov EPIC systems [20] are commonly used in research and industry to automate experiments and industrial pilot projects. For example, the cRIO system has been used for power grid simulation [21], power factor correction and monitoring [22], and railway acoustic roughness measurement [23]. There are other open-source SCADA systems, including those for power system monitoring [24], monitoring industrial processes [25], and several forms of open-source software for SCADA systems [26,27], which do well in comparison to proprietary software [28,29].

Unfortunately, the proprietary hardware/software packages are prohibitively expensive for research projects in low-resource environments, which limits access to high-quality SCADA [8]. Open-source SCADA exist (e.g., based on SCADA-LTS [30], OpenSCADA [27], Node-Red [31], and Thinger.IO [32]) and the hardware for the open-source versions is focused on specific applications (e.g., open-source solar-powered reverse osmosis [33], solar photovoltaic power monitoring [34,35] and biomass plant monitoring [36]) rather than being broadly useful for any SCADA application. A novel process may require multiple reconfigurations of the control system before an optimal process is determined, which leads to additional costs when non-customizable and proprietary hardware is used [18]. BREAD has proven to be a significantly less expensive alternative to some of the functions of proprietary SCADA systems without sacrificing functionality as shown in Table 1. This, in part, is due to the well-established economic savings for open hardware [37], as it is built upon the Arduino platform [38]. Despite BREAD’s advantages, in its current configuration, it can be difficult to set up and lacks the robustness and hardware organization typical of commercial products like NI’s cRIO and Opto 22’s groov EPIC systems. The motivation for this study is to move BREAD towards a full SCADA system. Some of the aspects of BREAD, summarized in Table 2, were improved to make the system more robust and desirable for eventual SCADA applications. This article will summarize and validate the improvements made to BREAD by comparing it with a commercial pH controller used to balance the pH of small-scale seaweed growth tanks as a case study.

Table 1.

Cost comparison between NI CompactRIO and BREAD for a bioreactor control system (approximate costs assume each circuit board is ~$5 from JLCPCB [39]).

Table 2.

Changes to BREAD v1 and v2.

2. Materials and Methods

While the new BREAD v2 architecture remains the same, some changes to the Slice cases, Loaf Backplane and new Loaf Controller enable the system to be expandable. All changes to the BREAD system in this article are available on the Open Science Framework [46] and the live version is available on GitHub: https://github.com/FHafting/BREAD (accessed on 21 March 2025) [47].

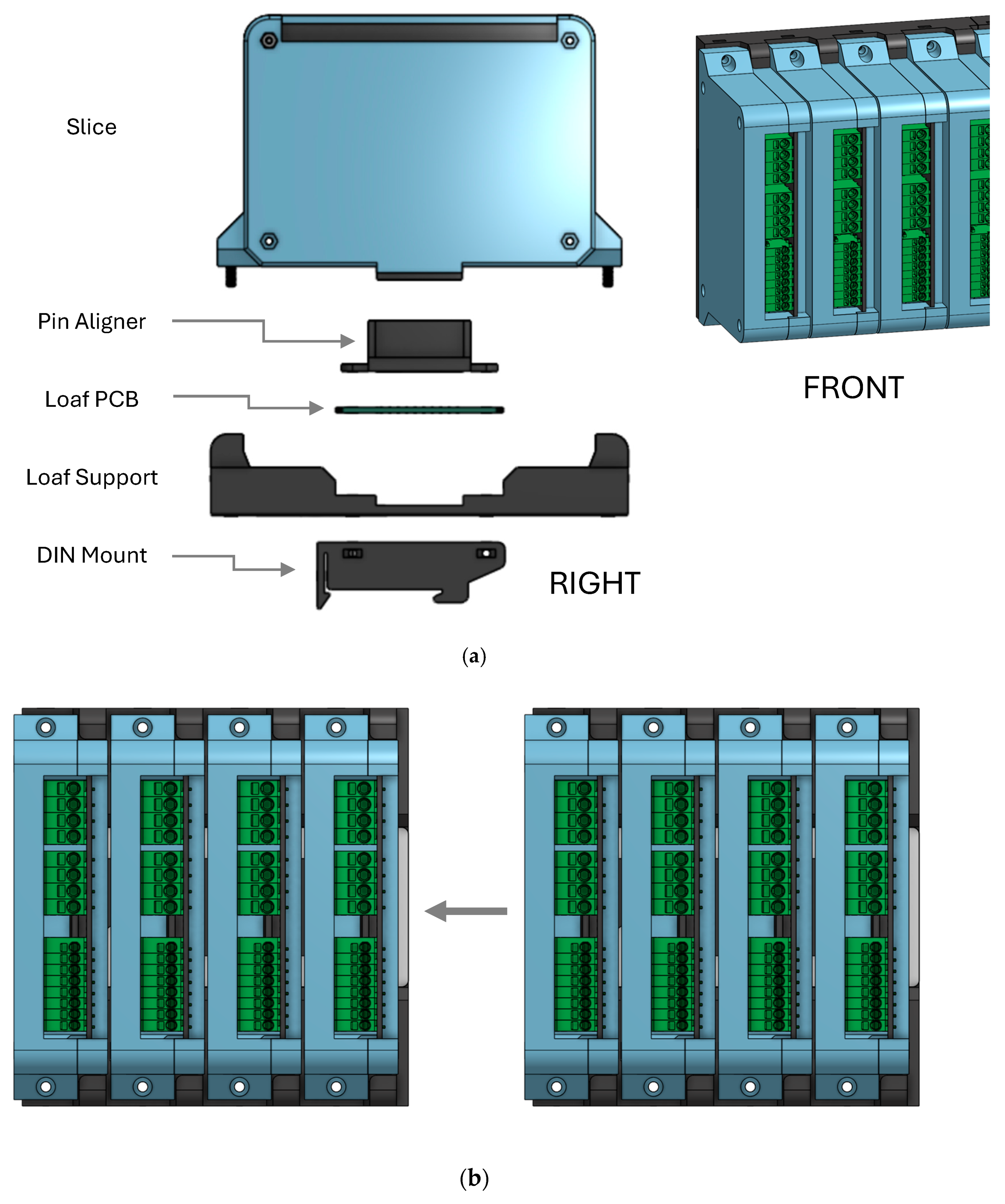

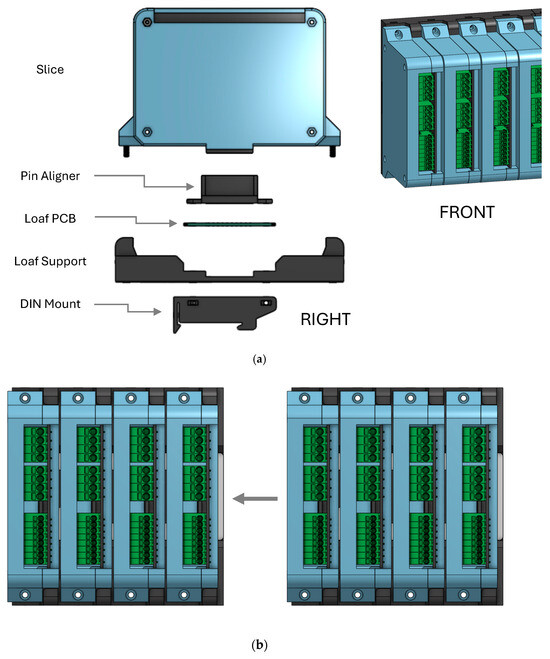

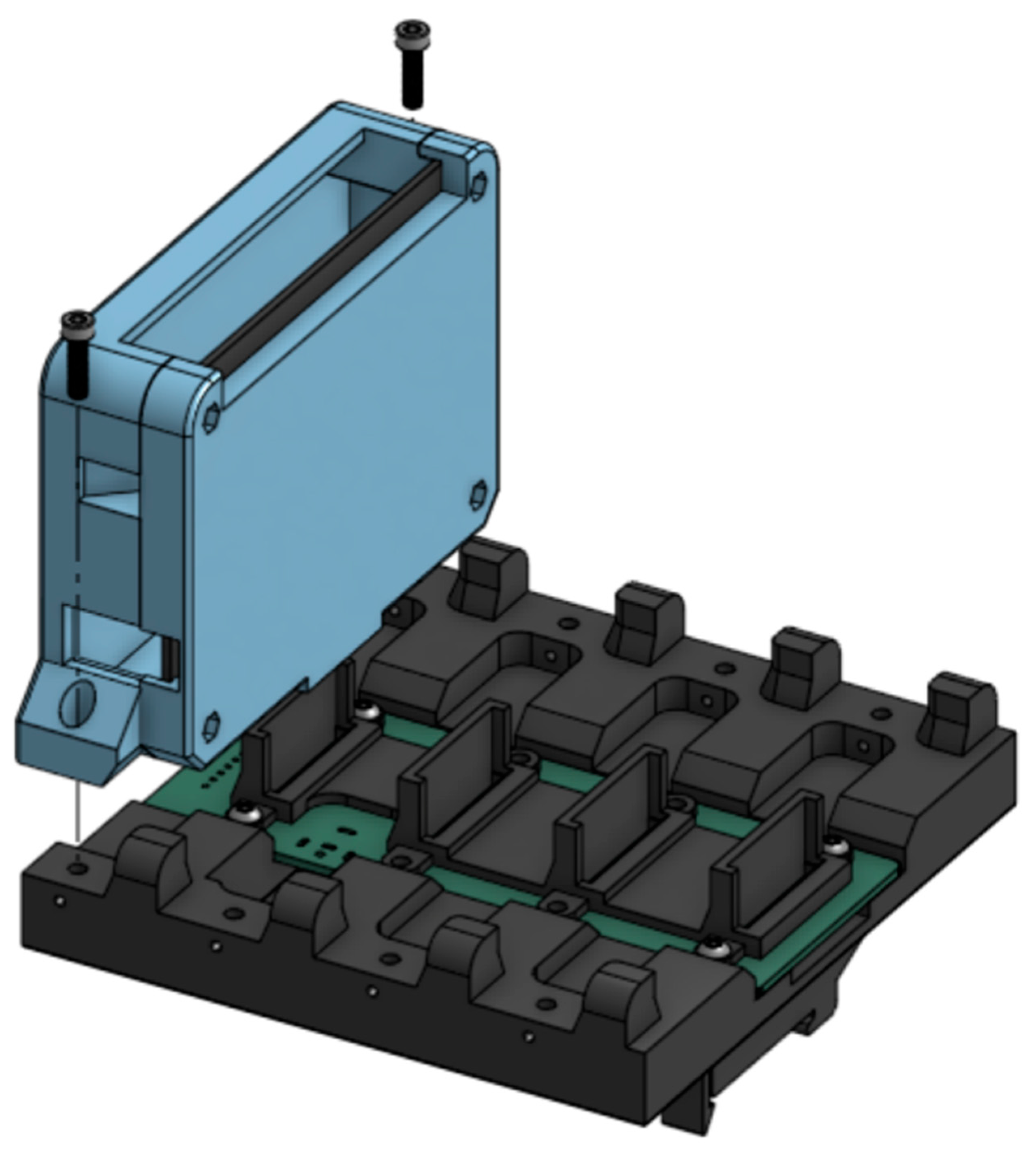

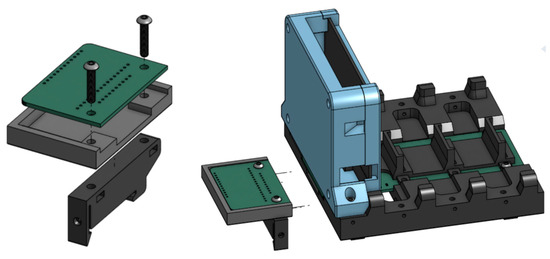

Figure 1a shows how the Slices plug into the Loaf and all mount to a Deutsches Institut für Normung (DIN) rail for installation in an electrical enclosure. The new Loaf configuration has 4 Slices per circuit board and multiple Loafs can be connected to create larger systems (Figure 1b). The new Loaf Controller connects to the left-most Loaf in the system (Figure 2) and is responsible for running the software Butter v1 [48]. Assembly instructions are shown in Appendix A.

Figure 1.

(a). Slice connection configuration. (b). Loaf connection configuration.

Figure 2.

Loaf Controller connection configuration.

New software, called “Butter”, was created to facilitate real-time control of each Slice through a convenient web interface hosted by an ESP32 microcontroller (Loaf Controller). It is responsible for logging data from Slices to an SD card, sending commands to Slices when new parameters are assigned by users, and displaying the current state of each Slice. The ESP32 hosts its own local Wi-Fi network that users first connect to. Then they can type in the IP address “192.168.4.1” into a Chrome web browser where, after 20–30 s, the web interface will display allowing the user full control of the BREAD system. Butter was created for a specific BREAD system that combines the pyrolysis reactor [18], bioreactor [17], and a chemical deconstruction reactor. As shown later in this study, however, the software can be modified to suit a variety of BREAD configurations.

A high-level bill of materials (BOM) is shown in Table 3. This is consistent with every BREAD v2 system; however, the specific Slice PCB will need to be chosen by the user from the Open Science Framework (OSF) repository.

Table 3.

BREAD v2 general bill of materials.

2.1. Comparison Setup

Controlling the pH of large tanks in a continuous manner is common in swimming pool facilities. Products exist which balance the pH of the pool by injecting carbon dioxide (CO2) such as Clearwater’s pH Pure [49]. Similar control is used to balance the pH of seaweed growth tanks. During photosynthesis, CO2 is consumed by seaweed, driving a seawater pH increase, which can result in a productivity decrease if left unchecked. A controller is used to facilitate CO2 injection, when needed, to maintain a desired setpoint. Commercial controllers work by monitoring the pH and actuating a solenoid valve to inject CO2 until the pH reaches a value below the setpoint. This feedback loop allows the controller to balance the pH. The world’s largest seaweed production tanks are shown in Figure 3 (Acadian Seaplants, Nova Scotia).

Figure 3.

Acadian Seaplants Industrial Seaweed Growth Plant, Nova Scotia, Canada.

Some open-source controllers could balance a single tank’s pH with CO2, like the pHysio-stat [50] or this solenoid-based pH controller [51]; however, they cannot be connected together and monitored from a central device which is common in SCADA systems. Within the realm of proprietary controllers, simple tasks like pH control and heating become expensive when data logging capabilities are also desired. BREAD is less expensive than many proprietary controllers, provides more functionality in terms of control customizability, and has data logging capabilities [15].

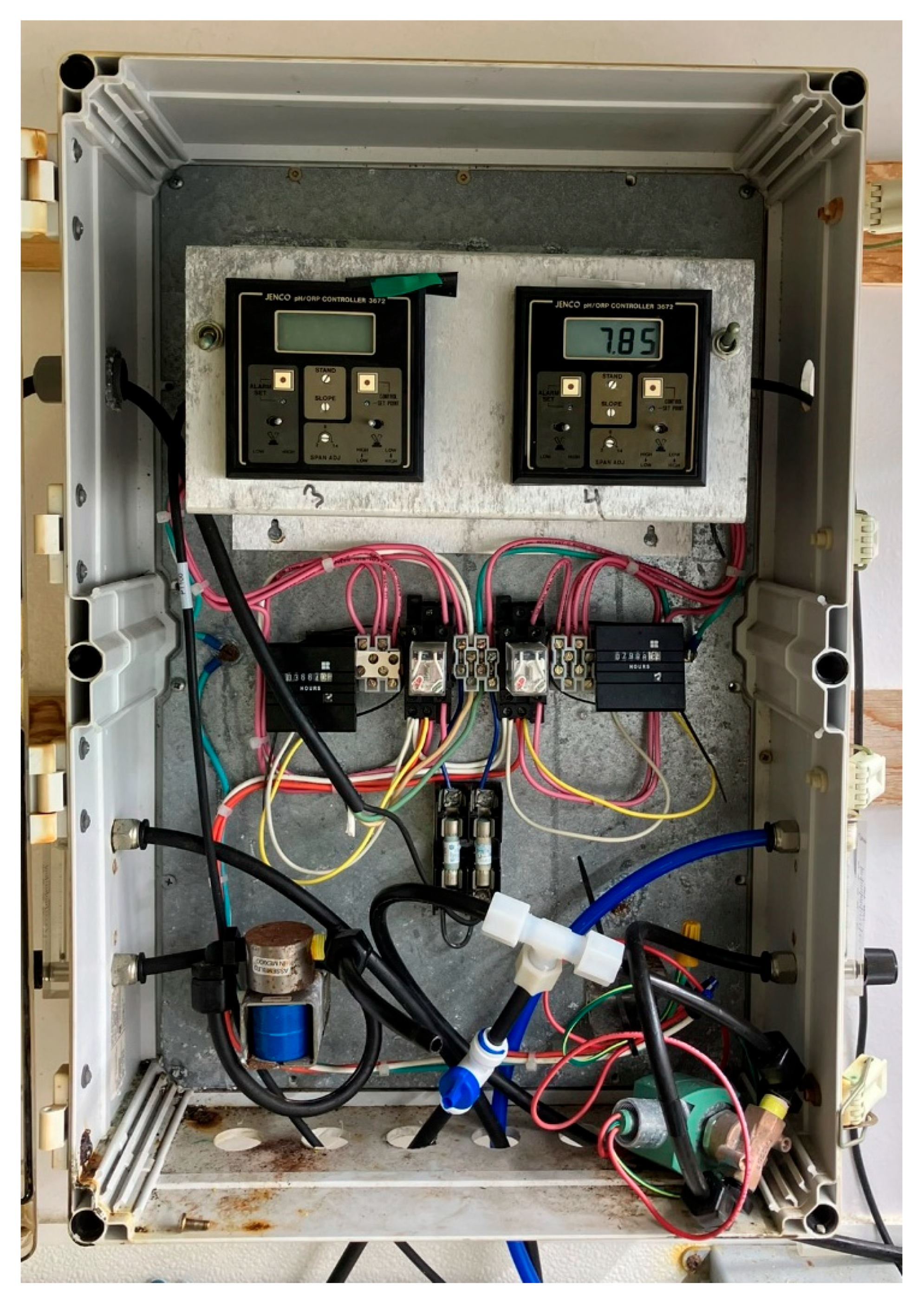

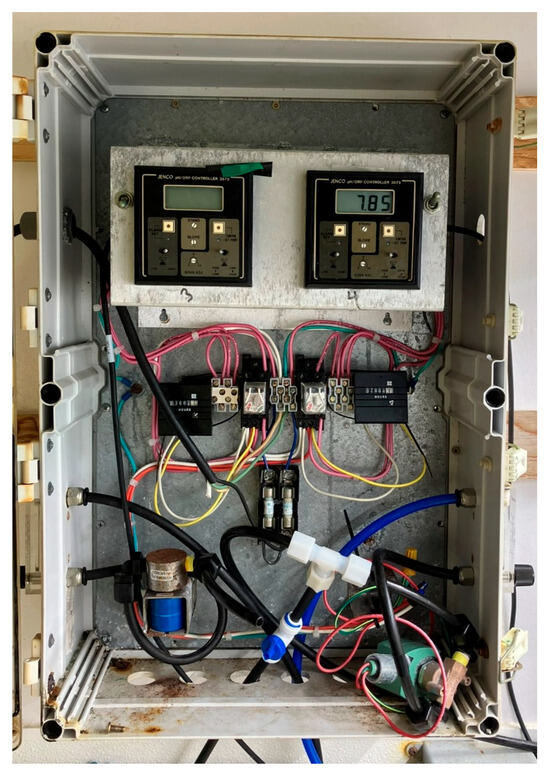

To validate BREAD v2, it was compared to a JENCO pH/ORP Controller 3672 [52], referred to as the “commercial controller”, which is already installed at Acadian Seaplants (Figure 3) and used for balancing pH. Because this controller is proprietary and has no data logging capabilities, when it fails, the researchers are unable to diagnose the issue or determine when the failure occurred. Additionally, the commercial controller is large and difficult to move during lab reconfigurations. The BREAD controller, detailed below, is already more compact, modular, and provides data logging. Thus, after comparing the two controllers, BREAD will be considered an improvement if it can achieve a similar control precision while being less expensive.

2.2. BREAD Hardware

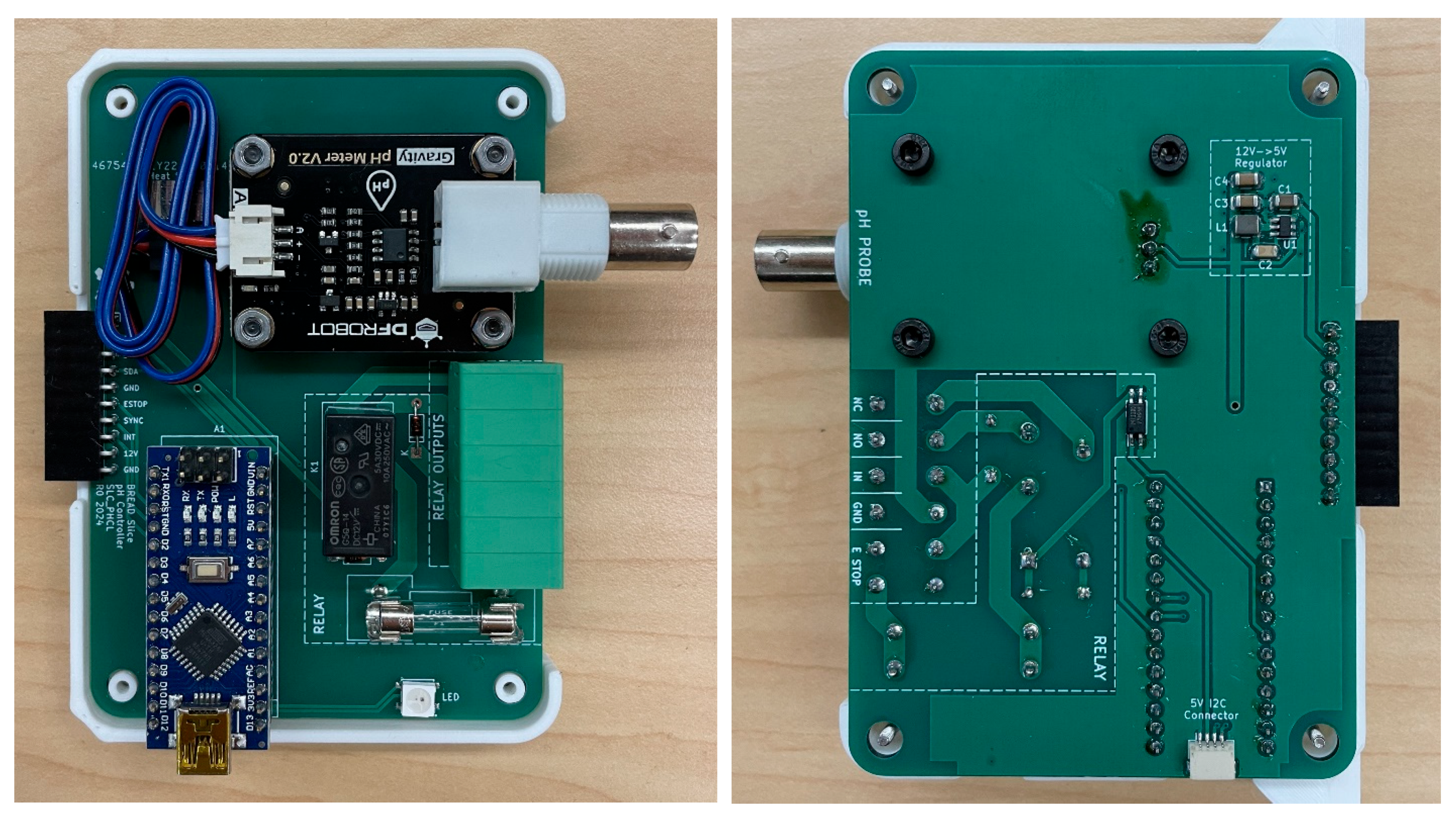

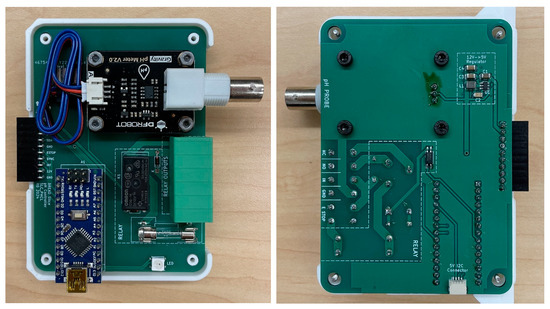

Within the BREAD framework, no Slice exists which monitors pH and can control a solenoid valve. A new Slice called “PHCL” was created for this purpose. To first validate the feasibility of using BREAD as a commercial pH controller alternative, an open-source amplifier board from DF Robot was integrated into each Slice. The Gravity pH Meter V2.0 is a simple amplifier circuit which scales the ±0.414 V potential measured at the pH probe (equivalent to pH 14–0, respectively,) to 5–0 V which can be measured with an Arduino Nano analog-to-digital converter (ADC). This board can only be purchased within a $57 kit, so the cost of this Slice can be further reduced by integrating the amplifier circuit components into the next Slice iteration. Solenoid actuation was achieved by reusing the relay circuit found in the RLHT Slice used for pyrolysis heating control [18]. The finished Slice is shown in Figure 4.

Figure 4.

PHCL Slice ((Left): Top, (Right): Bottom).

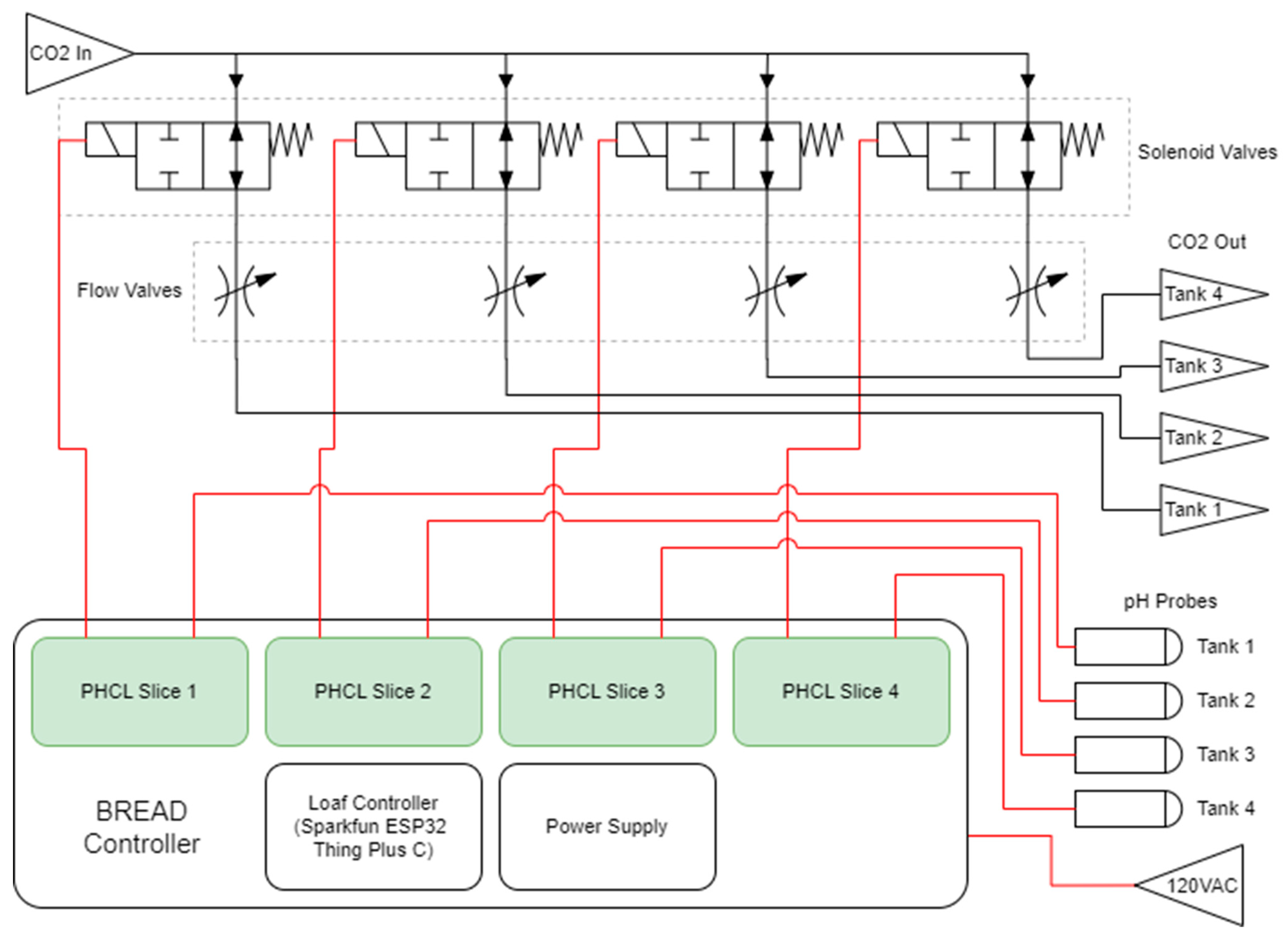

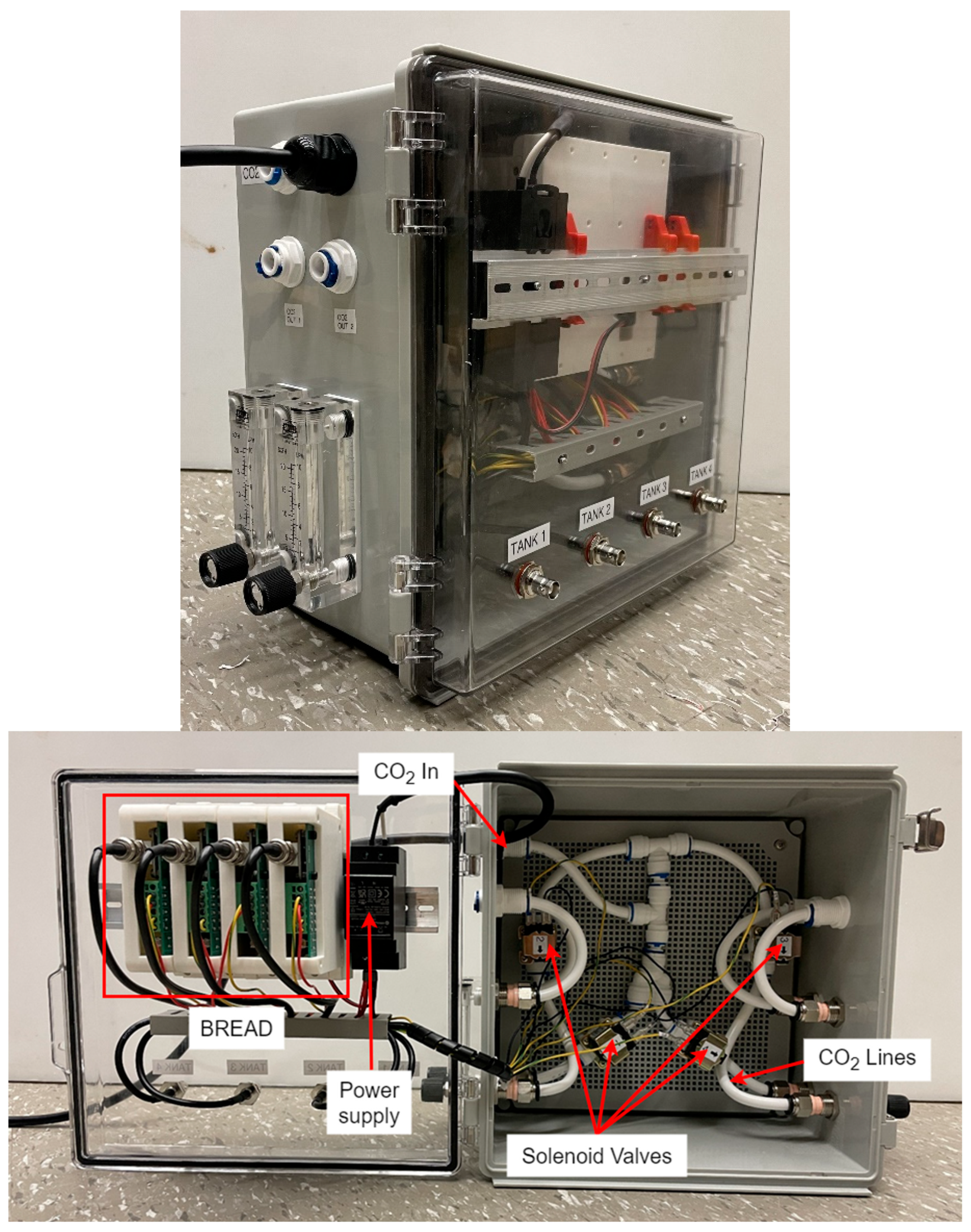

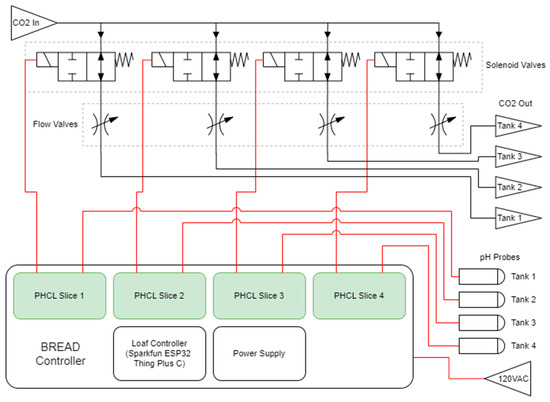

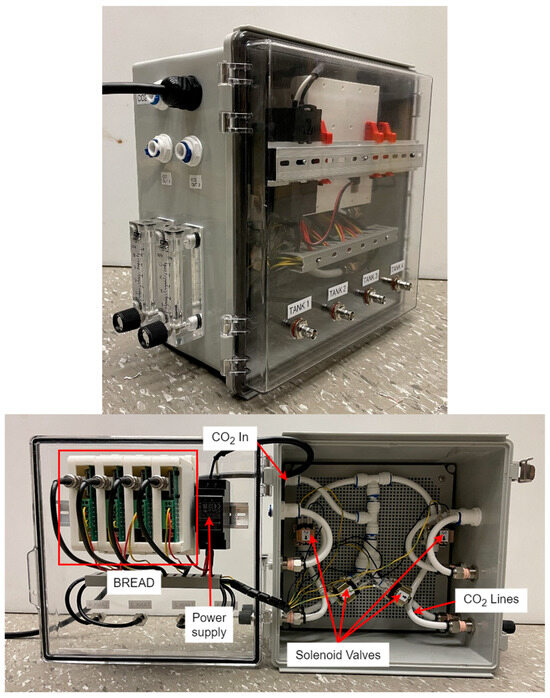

To compare BREAD with a commercial pH controller, complete with a system to deliver CO2, an electrical enclosure was made to contain the BREAD system with CO2 lines, solenoid valves, and a power supply (Figure 5 and Figure 6). Since each BREAD Loaf can hold 4 Slices, the enclosure was sized for 4 tanks. Sizing for 4 tanks was also more cost effective than a single tank since most of the cost of the system was the enclosure and CO2 line hardware.

Figure 5.

BREAD controller schematic (black: pneumatic connections, red: electrical connections).

Figure 6.

BREAD enclosure: closed (top) and open (bottom).

2.3. BREAD Software

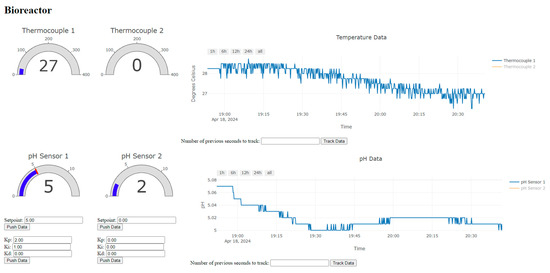

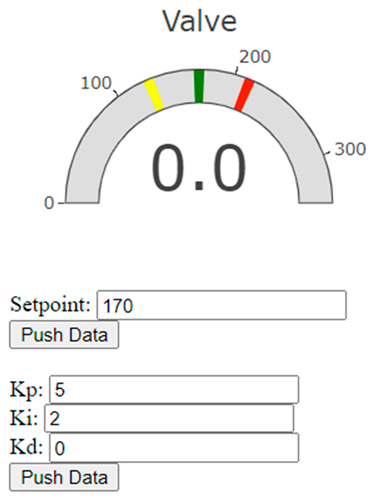

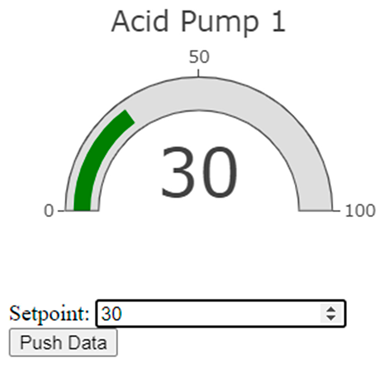

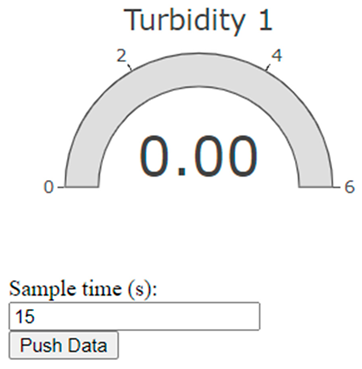

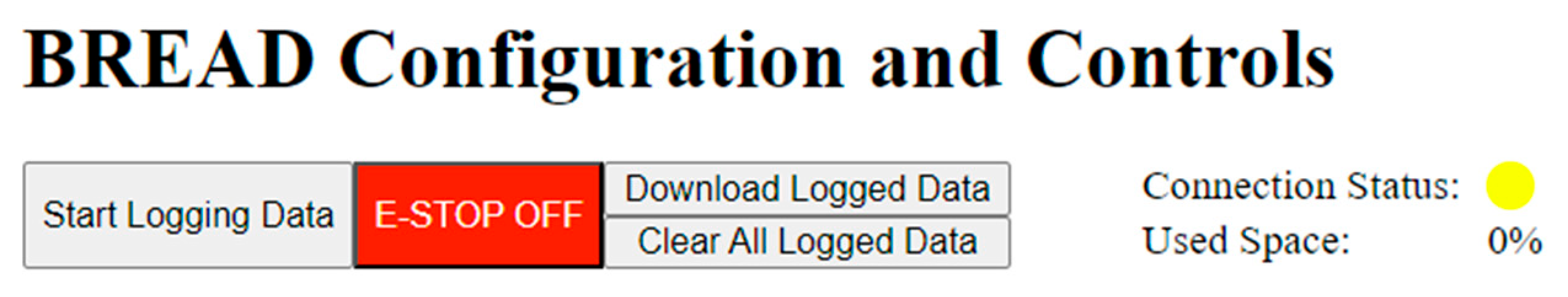

The software, aptly named Butter, allows users to control BREAD wirelessly from any device without a Wi-Fi network in place. The user first connects to the local network running on an ESP32 microcontroller and then enters an IP address in their web browser to view the user interface (UI) as a webpage. By entering setpoints and controller tuning parameters, they can monitor and operate the sensors and actuators attached to their BREAD system. This new software improves upon the MOST OpenReactor software v1 [53] which was used previously to control BREAD. Features include the following:

- Real-time data tracking with scrollable and resizable graphs (e.g., temperature, pH, etc.).

- Color-changing gauges to quickly show real-time data and indicate values well below or above a desired setpoint (e.g., overheating).

- Inputs for variables (e.g., temperature and pH setpoints and motor speed) along with the proportional (Kp), the integral (Ki), and the derivative (Kd) components for the PID controllers.

- Data logged to an SD card in comma-separated value (CSV) files.

- The ability to download and clear data directly from the webpage.

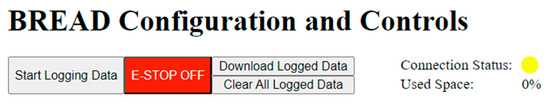

- Connection indicator to show if the user is connected to the ESP32.

- Emergency stop button that immediately sets all actuators to a safe state.

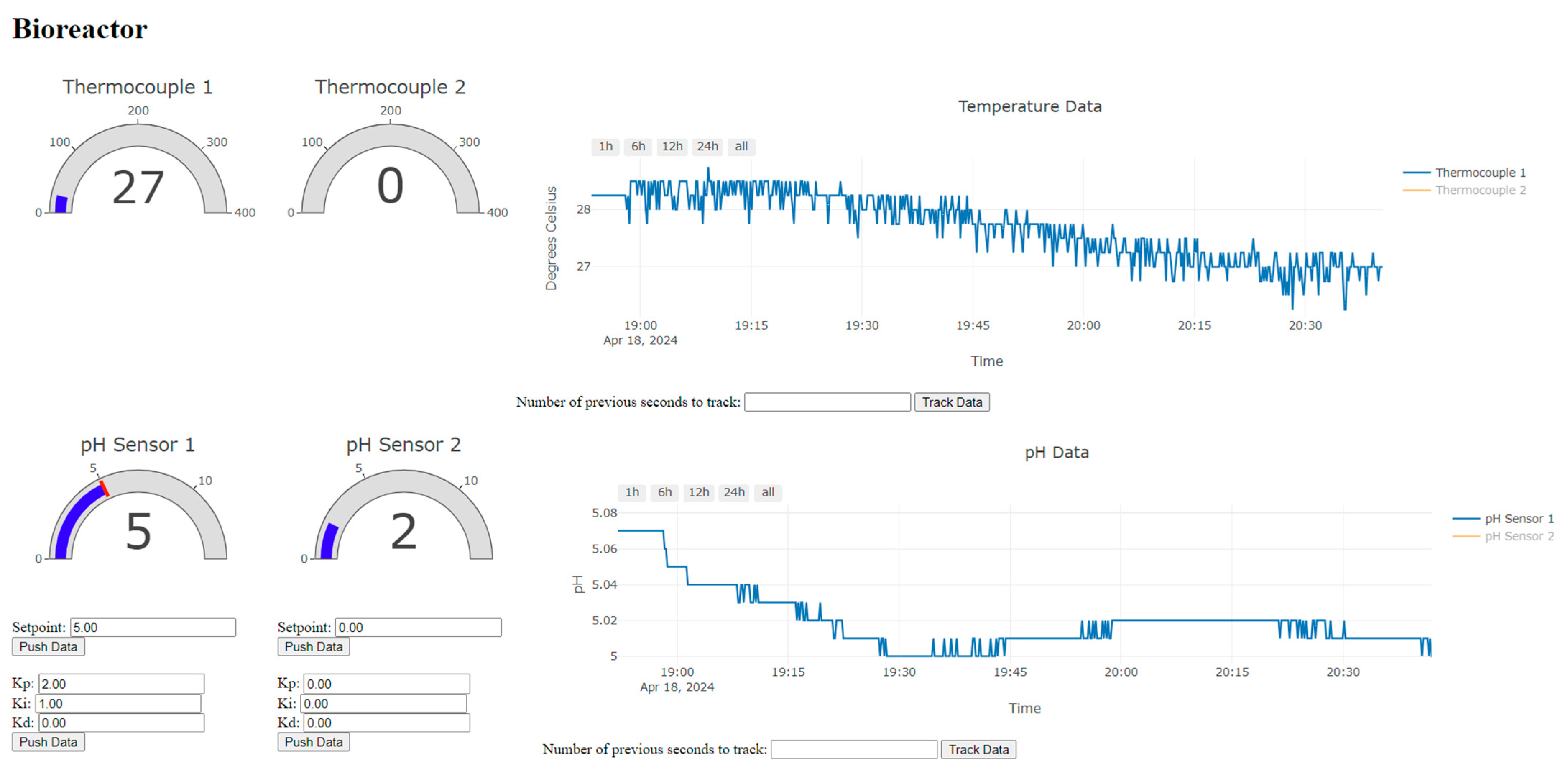

Note that the software was created for a specific setup consisting of a pyrolysis reactor [18], bioreactor, and chemical deconstruction reactor. However, alternative setups can be created by copying software elements like the gauges and graphs and modifying their labels. Part of the bioreactor section of Butter is shown in Figure 7.

Figure 7.

Thermocouple and pH sensor elements of Butter software for bioreactor.

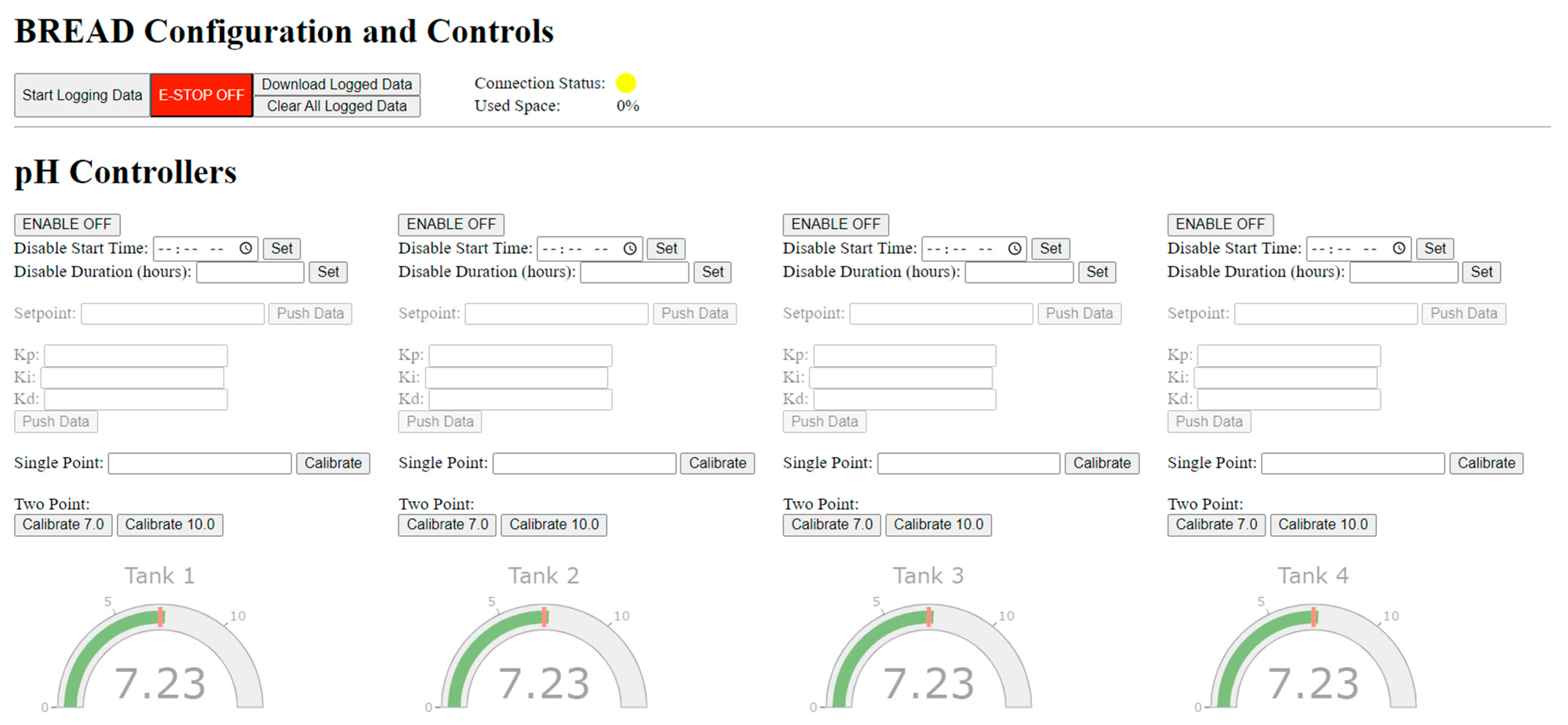

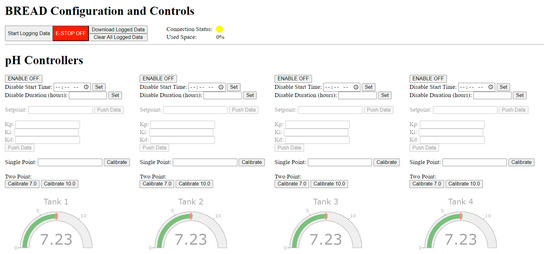

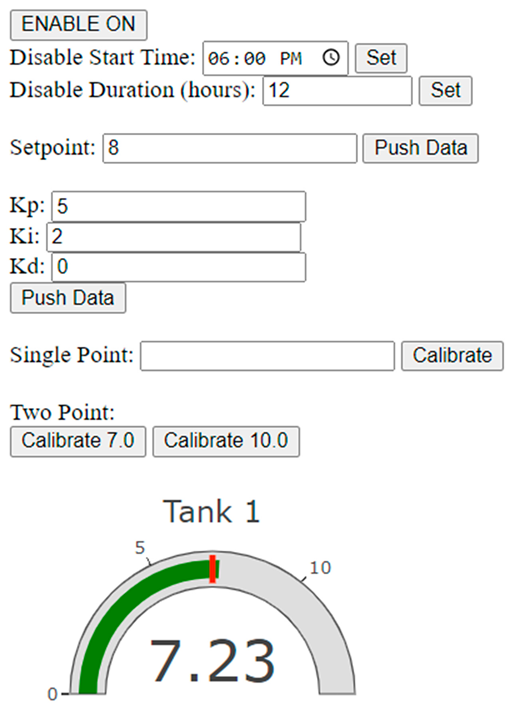

Additionally, the software for BREAD, Butter [48], was modified for pH control which allowed users to use single or two-point calibration, show the current pH of each tank, and set a window of time when pH control is enabled (for experimentation). Additional features, added for convenience and potential future experimentation, are listed below:

- Individual disable buttons for cleaning and startup (different from an E-STOP button which temporarily disables all Slices through hardware).

- Saved settings in event of a power outage (system will continue working as normal when the power comes back on).

- SD card indicator to show how much space is filled with data.

Figure 8 shows the user interface. Operation instructions are shown in Appendix B.

Figure 8.

Modified software for pH control.

2.4. Experimental Setup

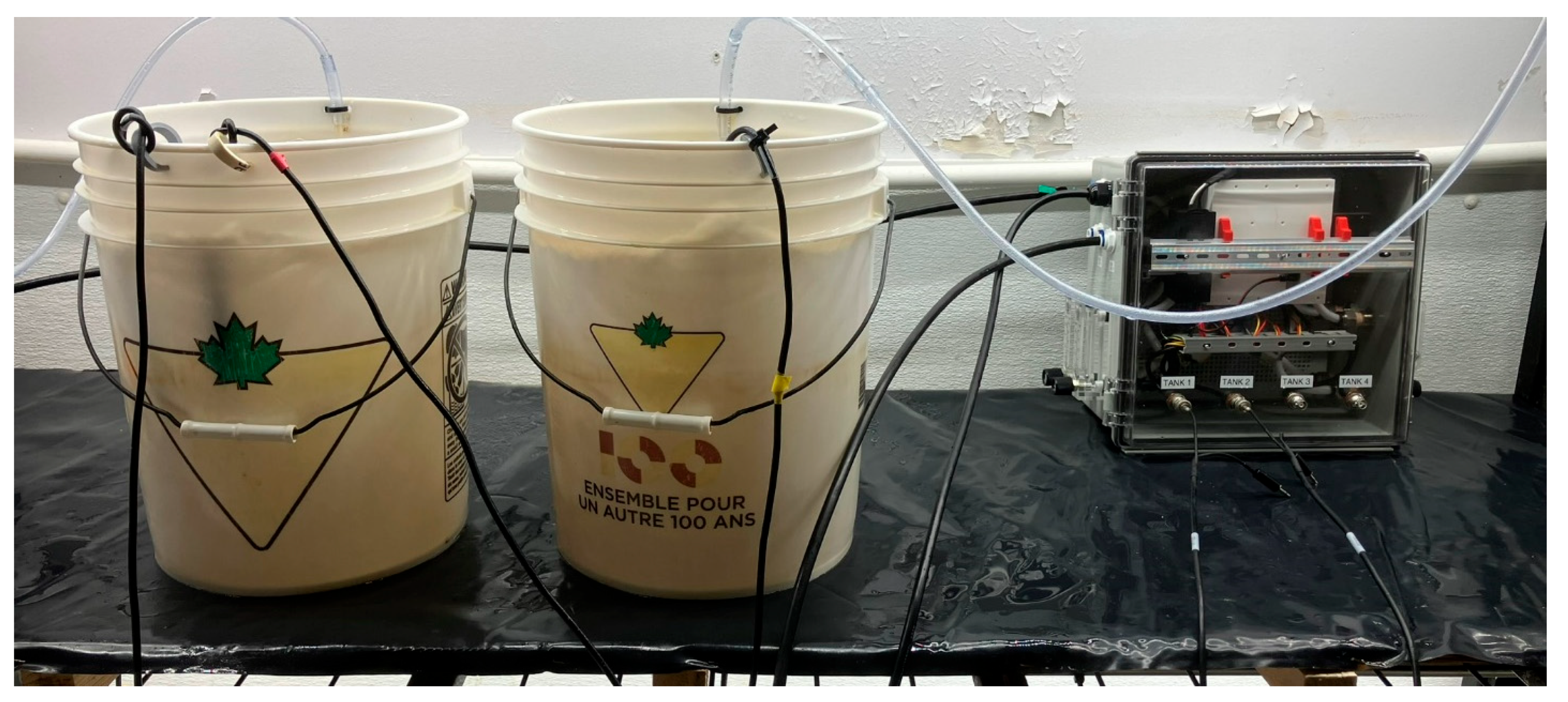

To compare the BREAD system with a commercial pH controller, two 5-gallon growth tanks were prepared, each with an airline and pH probe. The JENCO pH/ORP Controller 3672 performs bang-bang control [54], injecting CO2 into the tank’s airline when the pH rises above the setpoint. However, the control scheme cannot be modified and, since the controller has no data logging feature, the probe from Tank 1 of the BREAD controller was placed inside the tank to gather data. The BREAD controller was responsible for controlling the pH of tank 2 using a PID algorithm which adjusted the pulse duty cycle of a solenoid valve to inject CO2 into the airline. The specifications of each controller and setup are summarized in Table 4. PID tuning parameters were chosen through trial and error by observing the response over time. Figure 9 shows the experimental setup with the BREAD controller and Figure 10 shows the commercial controller. Both tanks were left for 12 h so each could reach a steady state.

Table 4.

Controller setup parameters. Note: Kp, Ki, and Kd represent the proportional, integral, and derivative gains, respectively, which are used to adjust the controller’s response to a deviation from the set point.

Figure 9.

Experimental setup ((Left): Tank 1, (Middle): Tank 2, (Right): BREAD controller).

Figure 10.

JENCO pH/ORP Controller 3672 “commercial controller”.

Before starting the experiment, the BREAD controller was calibrated using a two-point calibration of pH 7.0 and 10.0. Since both the BREAD and commercial controllers do not have temperature compensation of the pH readings, each requires calibration when moving to a new environment.

3. Results

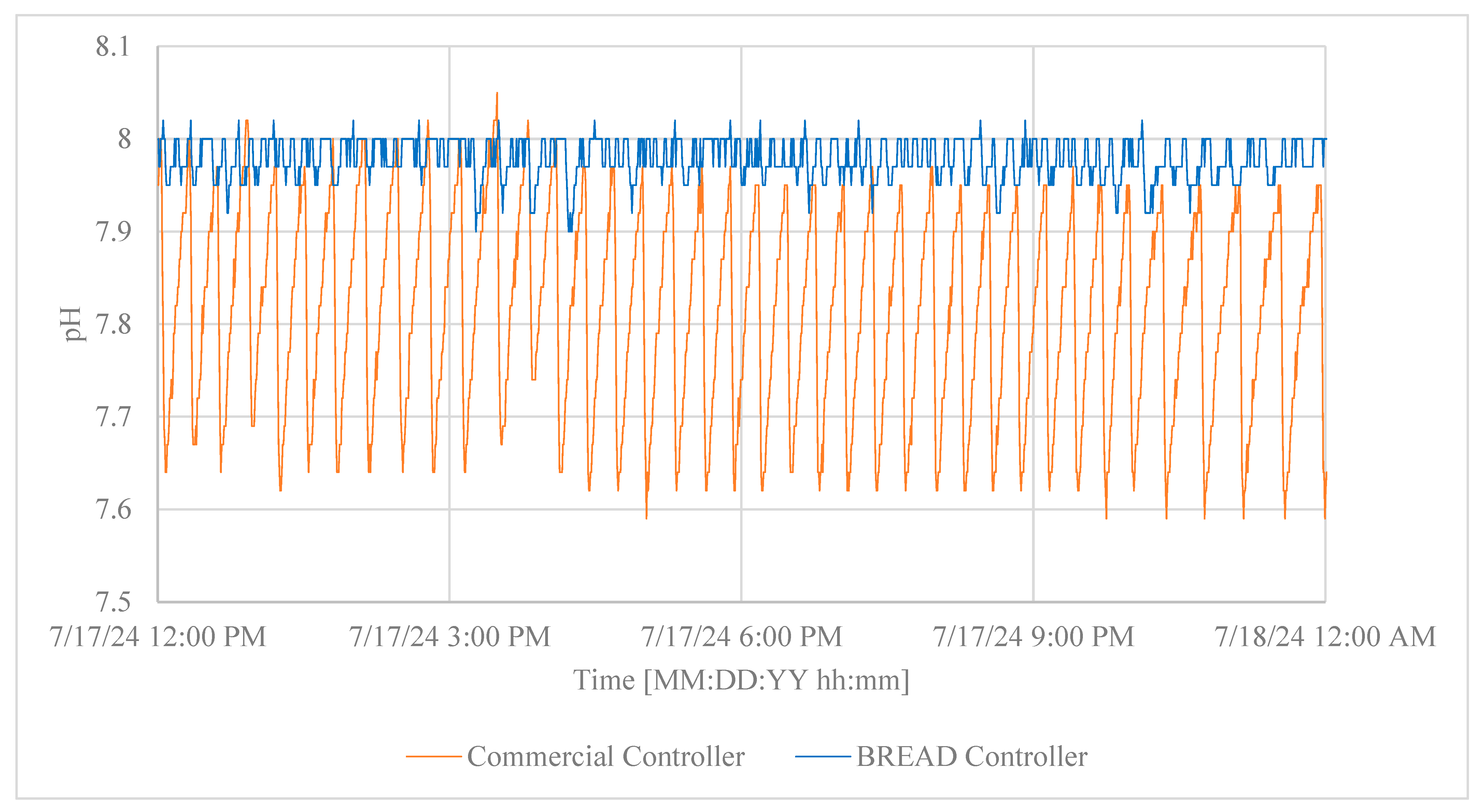

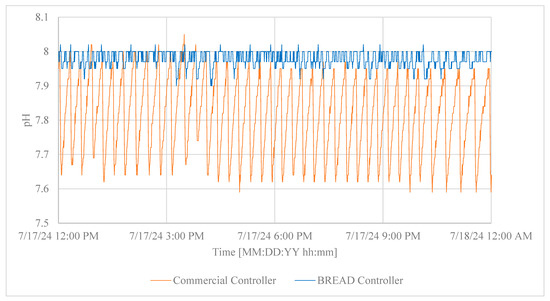

As mentioned previously, the BREAD controller is already more compact, modular, and provides data logging, so the following results investigate the performance and cost comparison. The pH from Tank 1, with the commercial controller, and Tank 2, with the BREAD controller, are plotted over time and shown in Figure 11. As can be seen in Figure 11, the BREAD controller exceeded the precision of the commercial controller and reduced the amount of undershoot around the setpoint. Table 5 summarizes the performance characteristics of both controllers. Bang-bang control requires a deadband around the setpoint so the solenoid is not continuously toggling. This preserves the longevity of the valve; however, this deadband also causes significant undershoot from the setpoint. Since the BREAD controller uses PID control to change the duty cycle of a set interval (5 s), there are only ever two toggles within that time frame. Thus, both the longevity and performance of the control system can be more easily predicted. Additionally, the BREAD controller tuning parameters were not optimized, so the precision of the controller could be further improved using tuning methods like the Ziegler–Nichols method (or other fine- tuning methods that are less aggressive) [55].

Figure 11.

Controller results comparing a commercial controller to the open-source BREAD controller.

Table 5.

Performance of both controllers.

The hardware to deliver CO2 to the tanks is the same, so the cost of both controllers can be compared directly. Table 6 summarizes the costs of the BREAD controller when compared to the commercial controller. For a more in-depth breakdown of the costs and components, see Appendix C. Not only is the BREAD controller more precise, but it is also close to three times less expensive than the commercial controller.

Table 6.

Cost breakdown of both controllers.

4. Conclusions and Future Work

The results are clear that the BREAD v2 controller is a significant improvement over the commercial controller, both in cost and functionality. It improved upon existing open-source pH controllers [50,51] by providing a dedicated user interface, customizable controller behavior (by means of PID tuning), and wireless operation. BREAD also continues to be a formidable alternative to some functions of commercial SCADA systems, with both a reduction in costs and improvement in specific functionality. More work is needed, however, before BREAD can provide all the functions of a full SCADA system. With that understanding, the new form factor of BREAD v2 enables it to be installed in an electrical enclosure, which widens its application possibilities. This study demonstrated how BREAD can be integrated into a full pH control system that can be easily set up and used.

While these controllers were compared under steady-state conditions, the startup conditions should also be addressed. The PID control worked well once it reached a steady state but was significantly slower than bang-bang control when trying to initially balance the pH to the setpoint. Fortunately, the BREAD v2 controller can be easily reprogrammed to use bang-bang control initially until the pH reaches the setpoint and switches to PID control to maintain a balance. This would be especially useful for larger commercial tanks. Additionally, the CO2 flow rate could not be adjusted during normal operation because the solenoid was being pulsed continuously. There needs to be a way to manually turn on the solenoid valve so the CO2 flow rate can be adjusted, or the adjustable flow valves could be removed entirely if reducing CO2 consumption is not a concern.

The reliability of BREAD should also be tested by running longer tests over weeks or months. In addition, the ESP32 has poor anti-interference ability, and an alternative version of BREAD would need to be used. Industrial controllers need to function in a variety of environments and the corrosive nature of the saltwater used to grow the seaweed could lead to poor connectivity of the external pH probe connectors. Testing the system for longer may also reveal runtime errors like timer overflows and idle loop states.

The BREAD controller was compared to a bang-bang control scheme; however, it should also be compared to a commercial controller using a similar PID control scheme. While this would be a closer performance comparison, the commercial controller was already in use and in need of improvement, which is why it was used in comparison instead. BREAD can also be compared to a commercial programmable logic controller (PLC) as this may have a similar cost and performance. BREAD is a clear improvement over the commercial controller; however, a highly functional system with a lower cost than NI’s cRIO system could also be a logical replacement.

Since BREAD is easily customizable, these changes can be added in the future, and the software can be continuously modified to ensure it best meets the needs of the user. Also, due to the open-source nature of BREAD, users with some coding knowledge can choose to add their own changes to suit their needs. The power of BREAD as a controller lies in its documentation [46]. Since users have free access to the continuously updated repository of Slice designs, they can diagnose hardware issues and purchase replacement parts without needing to buy a new system. Open-source hardware has made it easier than ever to replace proprietary products with powerful, easily customizable, and reparable alternatives that are both cheaper and provide more functionality.

Author Contributions

Conceptualization, F.K.H., J.T.H., and J.M.P.; methodology, F.K.H., J.T.H., and J.M.P.; software, A.W.H.C. and F.K.H.; validation, F.K.H.; data curation, J.T.H.; writing—original draft preparation, F.K.H. and J.M.P.; writing—review and editing, F.K.H. and J.M.P.; visualization, F.K.H.; supervision, J.M.P.; funding acquisition, J.M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Thompson Endowment.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data is available upon request.

Acknowledgments

The authors would like to acknowledge helpful discussions with S. Oberloier.

Conflicts of Interest

This is a completely open source project. The authors declare no conflicts of interest. Author Jeff T. Hafting was employed by the company Acadian Seaplants Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

Appendix A. BREAD Assembly Instructions

In-depth instructions on populating Slices with components from their BOM can be found in [15].

- Print all parts in needed quantities in 3D. The parts can be 3D printed on a self-replicating rapid prototype (RepRap)-class fused filament fabrication-based 3D printer [56,57,58].

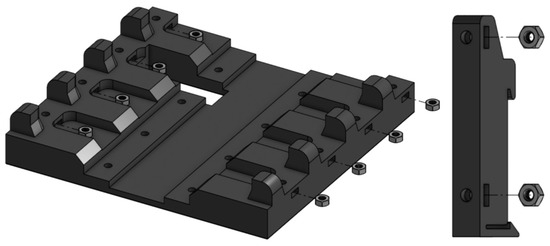

- Place M3 nuts within the Loaf support and DIN mount parts as shown in Figure A1.

- Connect Slice to Loaf according to Figure A4.

- Connect Loaf Controller to Loaf according to Figure A5.

Figure A1.

M3 Nut placement in Loaf support (left) and DIN mount (right) parts.

Figure A1.

M3 Nut placement in Loaf support (left) and DIN mount (right) parts.

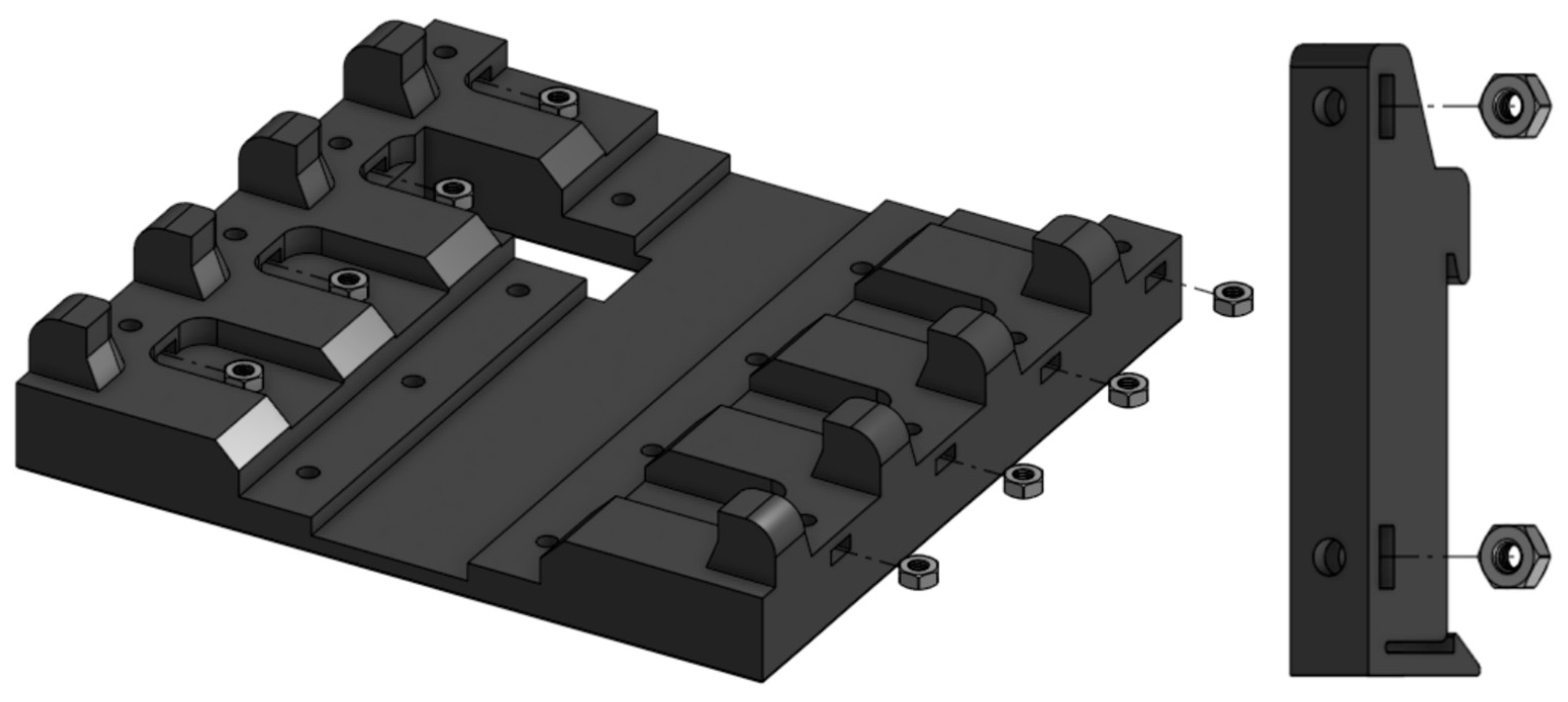

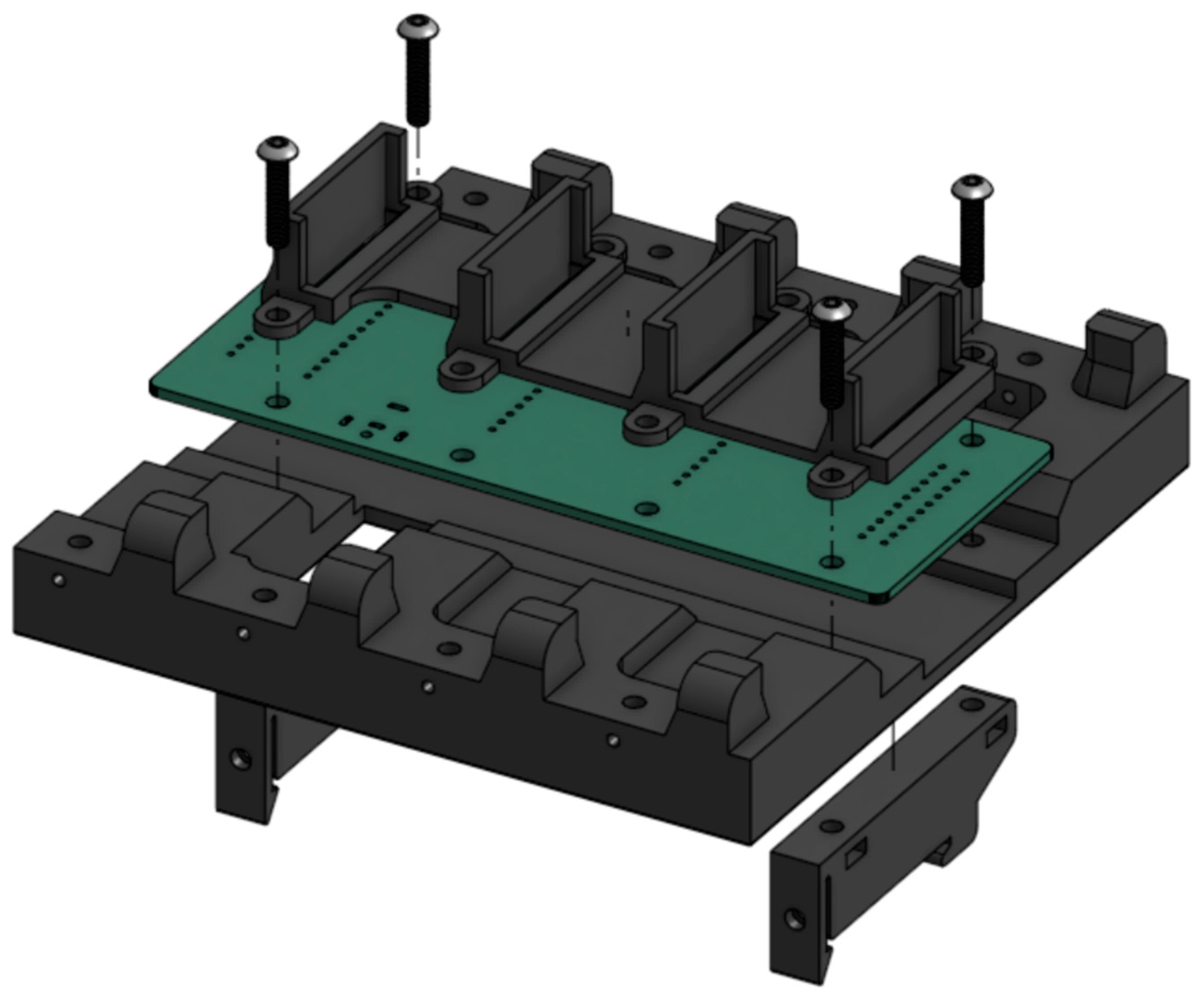

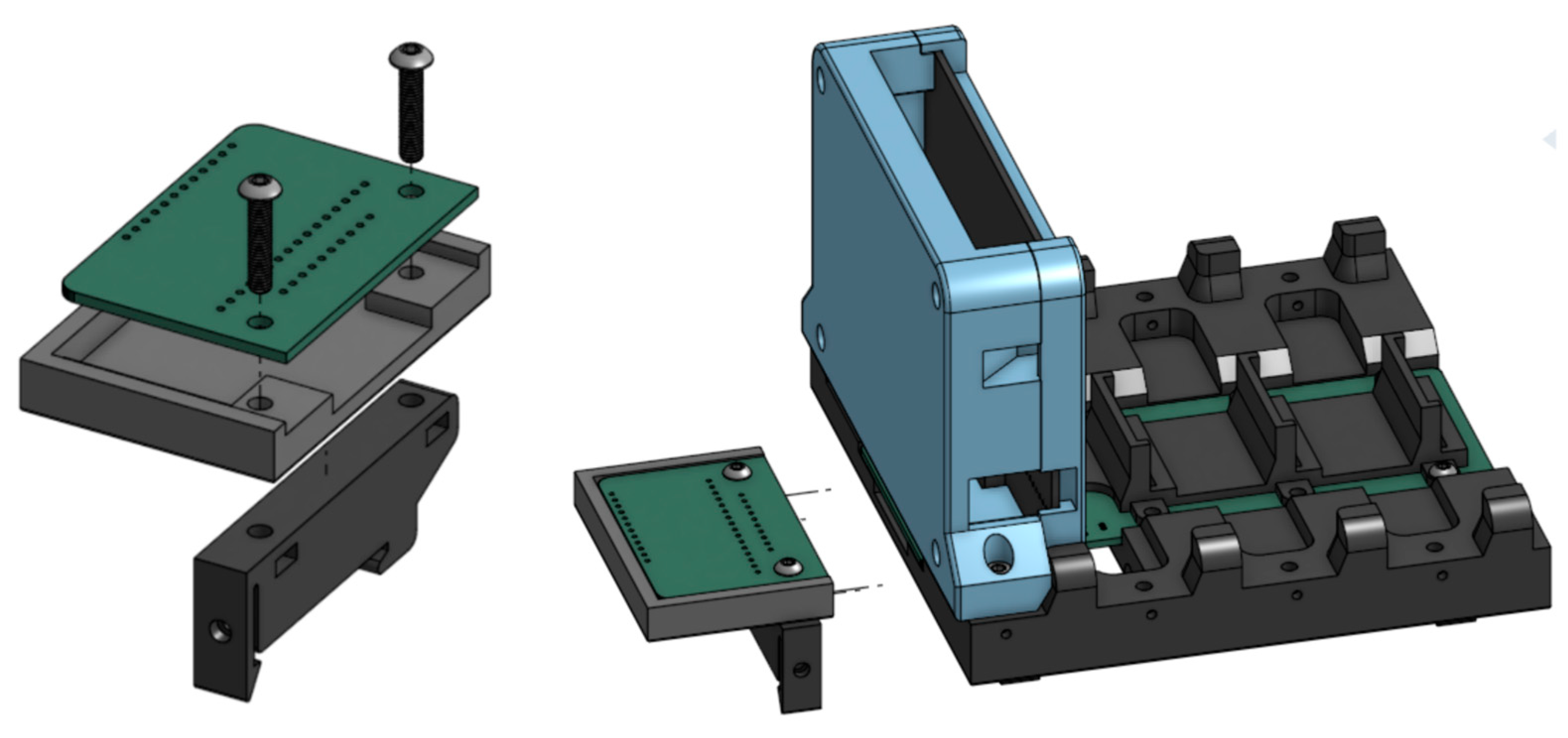

Figure A2.

Loaf assembly.

Figure A2.

Loaf assembly.

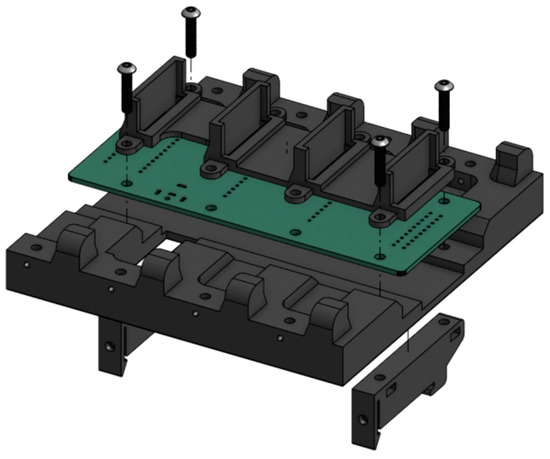

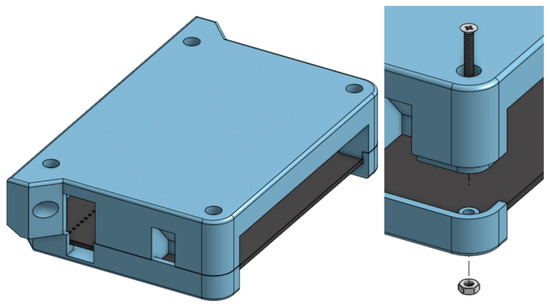

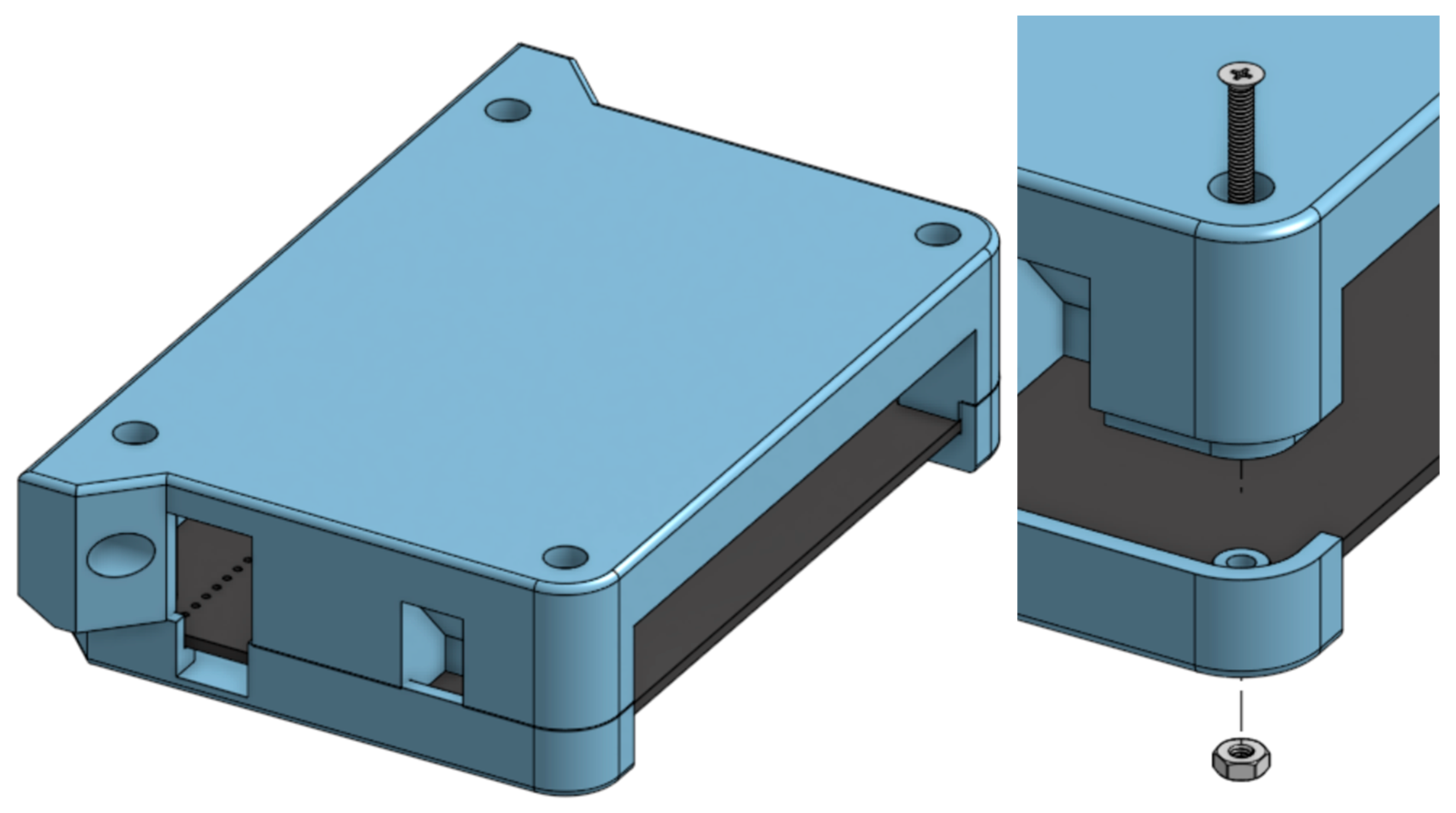

Figure A3.

Slice assembly ((Left): Full Slice, (Right): Screw location).

Figure A3.

Slice assembly ((Left): Full Slice, (Right): Screw location).

Figure A4.

Slice connection to Loaf.

Figure A4.

Slice connection to Loaf.

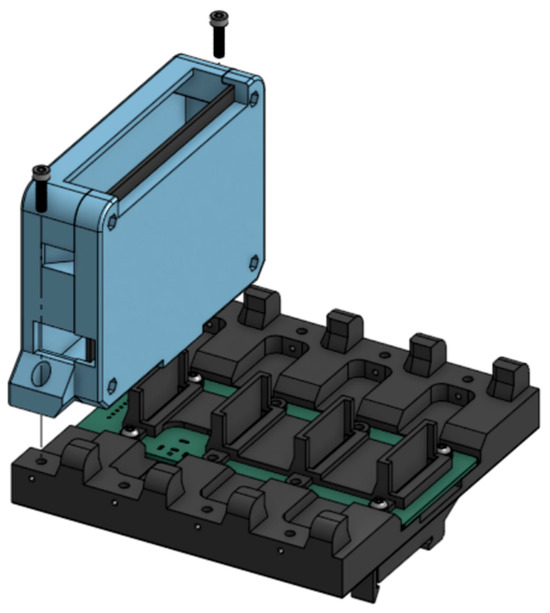

Figure A5.

Loaf Controller ((Left): Assembly, (Right): Connection to Loaf).

Figure A5.

Loaf Controller ((Left): Assembly, (Right): Connection to Loaf).

Appendix B. Operation Instructions

Setting up the firmware on each Slice is described in Appendix B of [18]. Setting up the Loaf Controller with Butter is outlined below:

- Download the contents from the GitHub repository: https://github.com/FHafting/BREAD-Local-Software (accessed on 21 March 2025).

- Upload the contents under “Website Code on SD Card” to the SD card on the ESP32.

- Upload the code under “Arduino Code” to the ESP32.

- Turn on the system and connect to the “BREAD” Wi-Fi network. The password is 12345678.

- Navigate to a Chrome browser and type “192.168.4.1” into the address bar. Wait 20–30 s for the web interface to display.

After opening the web interface, there are a variety of inputs, gauges, and graphs which are used to control Slices and display data. Their purposes are summarized in Table A1.

Table A1.

Gauge descriptions in Butter software.

Table A1.

Gauge descriptions in Butter software.

| Element | Image | Purpose |

|---|---|---|

| PID Controller |  | Assign the desired setpoint and PID tuning parameters for heating, cooling, or pH control. |

| Motor/Pump Controller |  | Assign the desired motor speed from −100% to 100% (full speed reverse and full speed forward, respectively). |

| Turbidity Controller |  | Assign the sampling interval of the turbidity pump. |

| New pH Controller |  | Based on the PID control block. Assign desired pH setpoint and PID tuning parameters. Assign disable period for experimentation. Set single point calibration or use two-point calibration for higher accuracy. |

The top header of the webpage is used to start logging data, set the emergency stop, download and clear data, show the current space used in the SD card, and show the connection status to the Loaf Controller (yellow: no communication, green: good communication). Figure A6 shows the webpage header.

Figure A6.

Butter Webpage Header.

Figure A6.

Butter Webpage Header.

Appendix C. BREAD Controller Cost Breakdown

Table A2.

Enclosure/Tubing cost.

Table A2.

Enclosure/Tubing cost.

Table A3.

PHCL Slice cost.

Table A3.

PHCL Slice cost.

Table A4.

Loaf Controller cost.

Table A4.

Loaf Controller cost.

| Part | # | Cost | Total | URL (Accessed on 21 March 2025) |

|---|---|---|---|---|

| Sparkfun Thing Plus C | 1 | $24.95 | $24.95 | https://www.sparkfun.com/products/20168 |

| 32GB SD Card | 1 | $34.98 | $34.98 | https://www.amazon.ca/Gigastone-32GB-U1-C10-Nintendo/dp/B07N73LB4T/ |

| Conn_01x10_Female | 1 | $1.09 | $1.09 | https://www.digikey.ca/en/products/detail/sullins-connector-solutions/PPTC101LGBN-RC/775904 |

| 22 μF | 3 | $0.51 | $1.53 | https://www.digikey.ca/en/products/detail/samsung-electro-mechanics/CL31A226KAHNNNE/3888705 |

| 100 nF | 1 | $0.16 | $0.16 | https://www.digikey.ca/en/products/detail/samsung-electro-mechanics/CL31B104KBCNNNC/3886675 |

| 4.7 μH | 1 | $2.32 | $2.32 | https://www.digikey.ca/en/products/detail/tdk-corporation/BCL322520RT-4R7M-D/15849704 |

| AP63205 | 1 | $1.31 | $1.31 | https://www.digikey.ca/en/products/detail/diodes-incorporated/AP63205WU-7/9858424 |

| Resistor 2.2k | 2 | $0.10 | $0.20 | https://www.digikey.ca/en/products/detail/yageo/RC0603JR-132K2L/14286397 |

| Total | $66.54 |

Table A5.

Loaf Backplane cost.

Table A5.

Loaf Backplane cost.

| Part | # | Cost | Total | URL (Accessed on 21 March 2025) |

|---|---|---|---|---|

| Conn_01x10_Male | 4 | $0.25 | $1.00 | https://www.digikey.ca/en/products/detail/amphenol-cs-fci/10129378-910002BLF/7915958 |

| 1x10 RA Male Header 2.54 mm Pitch | 1 | $0.23 | $0.23 | https://www.digikey.ca/en/products/detail/amphenol-cs-fci/10129379-910002BLF/7916010 |

| PinSocket_1x10_P2.54mm_Horizontal | 1 | $0.77 | $0.77 | https://www.digikey.ca/en/products/detail/sullins-connector-solutions/PPTC101LGBN-RC/775904 |

| BarrelJack_CUI_PJ-063AH_Horizontal | 1 | $1.61 | $1.61 | https://www.digikey.ca/en/products/detail/cui-devices/pj-063ah/2161208 |

| Total | $3.61 |

Table A6.

Slice case hardware cost.

Table A6.

Slice case hardware cost.

| Part | # | Cost | Total | URL (Accessed on 21 March 2025) |

|---|---|---|---|---|

| M2x25mm screws (×50) | 2 | $9.31 | $18.62 | https://www.mcmaster.com/92010A111/ |

| M2 nuts (×100) | 1 | $4.00 | $4.00 | https://www.mcmaster.com/90592A075/ |

| M3x12mm screws (×100) | 1 | $6.00 | $6.00 | https://www.mcmaster.com/91292A114/ |

| M3 nuts (×100) | 1 | $2.62 | $2.62 | https://www.mcmaster.com/90592A085/ |

| m3x15 bolts | 1 | $6.28 | $6.28 | https://www.mcmaster.com/92095A119/ |

| Total | $37.52 |

References

- Robles, G.; Amor, J.J.; Gonzalez-Barahona, J.M.; Herraiz, I. Evolution and Growth in Large Libre Software Projects. In Proceedings of the Eighth International Workshop on Principles of Software Evolution (IWPSE’05), Lisbon, Portugal, 5–6 September 2005; pp. 165–174. [Google Scholar]

- Weber, S. The Success of Open Source. In The Success of Open Source; Harvard University Press: Cambridge, MA, USA, 2005; ISBN 978-0-674-04499-9. [Google Scholar]

- Pearce, J.M. Sponsored Libre Research Agreements to Create Free and Open Source Software and Hardware. Inventions 2018, 3, 44. [Google Scholar] [CrossRef]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Addison-Wesley Professional: Boston, MA, USA, 2014; ISBN 978-0-13-337390-5. [Google Scholar]

- Oellermann, M.; Jolles, J.W.; Ortiz, D.; Seabra, R.; Wenzel, T.; Wilson, H.; Tanner, R.L. Open Hardware in Science: The Benefits of Open Electronics. Integr. Comp. Biol. 2022, 62, 1061–1075. [Google Scholar] [CrossRef] [PubMed]

- OSHWA Definition (English) 2024. Available online: https://www.oshwa.org/definition/ (accessed on 21 March 2025).

- Seo-Zindy, R.; Heeks, R. Researching the Emergence of 3D Printing, Makerspaces, Hackerspaces and FabLabs in the Global South: A Scoping Review and Research Agenda on Digital Innovation and Fabrication Networks. Electron. J. Inf. Syst. Dev. Ctries. 2017, 80, 1–24. [Google Scholar] [CrossRef]

- Chagas, A.M. Haves and Have Nots Must Find a Better Way: The Case for Open Scientific Hardware. PLoS Biol. 2018, 16, e3000014. [Google Scholar] [CrossRef]

- Wierenga, R.P.; Golas, S.M.; Ho, W.; Coley, C.W.; Esvelt, K.M. PyLabRobot: An Open-Source, Hardware-Agnostic Interface for Liquid-Handling Robots and Accessories. Device 2023, 1, 100111. [Google Scholar] [CrossRef]

- Kehl, F.; Cretu, V.F.; Willis, P.A. Open-Source Lab Hardware: A Versatile Microfluidic Control and Sensor Platform. HardwareX 2021, 10, e00229. [Google Scholar] [CrossRef]

- Alistar, M.; Gaudenz, U. OpenDrop: An Integrated Do-It-Yourself Platform for Personal Use of Biochips. Bioengineering 2017, 4, 45. [Google Scholar] [CrossRef]

- Brazey, B.; Haddab, Y.; Zemiti, N.; Mailly, F.; Nouet, P. An Open-Source and Easily Replicable Hardware for Electrical Impedance Tomography. HardwareX 2022, 11, e00278. [Google Scholar] [CrossRef]

- Merenda, M.; Iero, D.; Pangallo, G.; Falduto, P.; Adinolfi, G.; Merola, A.; Graditi, G.; Della Corte, F.G. Open-Source Hardware Platforms for Smart Converters with Cloud Connectivity. Electronics 2019, 8, 367. [Google Scholar] [CrossRef]

- Ali, A.S.; Coté, C.; Heidarinejad, M.; Stephens, B. Elemental: An Open-Source Wireless Hardware and Software Platform for Building Energy and Indoor Environmental Monitoring and Control. Sensors 2019, 19, 4017. [Google Scholar] [CrossRef]

- Oberloier, S.; Whisman, N.G.; Hafting, F.; Pearce, J.M. Open Source Framework for a Broadly Expandable and Reconfigurable Data Acquisition and Automation Device (BREAD). HardwareX 2023, 15, e00467. [Google Scholar] [CrossRef] [PubMed]

- McDonald, M.T.; Hayibo, K.S.; Hafting, F.; Pearce, J.M. Economics of Open-Source Solar Photovoltaic Powered Cryptocurrency Mining. Ledger 2023, 8. [Google Scholar] [CrossRef]

- Hafting, F.K.; Yeung, S.; Al-Aribe, H.; Michels, E.; Pearce, J.M. Parametric Low-Cost Open Source Bioreactor Designed for Distributed Manufacturing. 2025; To be published. [Google Scholar]

- Hafting, F.K.; Kulas, D.; Michels, E.; Chipkar, S.; Wisniewski, S.; Shonnard, D.; Pearce, J.M. Modular Open-Source Design of Pyrolysis Reactor Monitoring and Control Electronics. Electronics 2023, 12, 4893. [Google Scholar] [CrossRef]

- CompactRIO Systems (cRIO). Available online: https://www.ni.com/en/shop/compactrio.html (accessed on 24 July 2024).

- Opto22—Groov EPIC System. Available online: https://www.opto22.com/products/groov-epic-system (accessed on 1 May 2024).

- Zhou, Y.; Wang, Z.; Miao, Z.; Fan, L. A Synchrophasor-Based SCADA Testbed. In Proceedings of the 2021 North American Power Symposium (NAPS), College Station, TX, USA, 14–16 November 2021; pp. 1–5. [Google Scholar]

- Băloi, A.; Molnar-Matei, F.; Băloi, F.; Băloi, A.; Molnar-Matei, F.; Băloi, F. Virtual Instrument for Single-Phase Control of Three-Phase Reactive Power Capacitive Compensators. In LabVIEW—Virtual Instrumentation in Education and Industry; IntechOpen: London, UK, 2023; ISBN 978-1-83969-064-8. [Google Scholar]

- Mauz, F.; Wigger, R.; Wahl, T.; Kuffa, M.; Wegener, K. Acoustic Roughness Measurement of Railway Tracks: Implementation of an Optical Measurement Approach & Possible Improvements to the Standard. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2022, 236, 095440972210864. [Google Scholar] [CrossRef]

- Almas, M.S.; Vanfretti, L.; Løvlund, S.; Gjerde, J.O. Open Source SCADA Implementation and PMU Integration for Power System Monitoring and Control Applications. In Proceedings of the 2014 IEEE PES General Meeting | Conference & Exposition, National Harbor, MD, USA, 27–31 July 2014; pp. 1–5. [Google Scholar]

- Merchán, D.F.; Peralta, J.A.; Vazquez-Rodas, A.; Minchala, L.I.; Astudillo-Salinas, D. Open Source SCADA System for Advanced Monitoring of Industrial Processes. In Proceedings of the 2017 International Conference on Information Systems and Computer Science (INCISCOS), Quito, Ecuador, 23–25 November 2017; pp. 160–165. [Google Scholar]

- Minchala, L.I.; Ochoa, S.; Velecela, E.; Astudillo, D.F.; Gonzalez, J. An Open Source SCADA System to Implement Advanced Computer Integrated Manufacturing. IEEE Lat. Am. Trans. 2016, 14, 4657–4662. [Google Scholar] [CrossRef]

- Prokhorov, A.S.; Chudinov, M.A.; Bondarev, S.E. Control Systems Software Implementation Using Open Source SCADA-System OpenSCADA. In Proceedings of the 2018 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), Moscow, Russia, 29 January–1 February 2018; pp. 220–222. [Google Scholar]

- Barana, O.; Barbato, P.; Breda, M.; Capobianco, R.; Luchetta, A.; Molon, F.; Moressa, M.; Simionato, P.; Taliercio, C.; Zampiva, E. Comparison between Commercial and Open-Source SCADA Packages—A Case Study. Fusion Eng. Des. 2010, 85, 491–495. [Google Scholar] [CrossRef]

- Bidyanath, K.; Abonmei, A.; Tongbram, S. A Survey on Open-Source SCADA for Industrial Automation Using Raspberry Pi. In Proceedings of the Trends in Wireless Communication and Information Security; Chakraborty, M., Jha, R.K., Balas, V.E., Sur, S.N., Kandar, D., Eds.; Springer: Singapore, 2021; pp. 19–26. [Google Scholar]

- SCADA-LTS/Scada-LTS 2025. Available online: https://github.com/SCADA-LTS/Scada-LTS (accessed on 21 March 2025).

- Omidi, S.A.; Baig, M.J.A.; Iqbal, M.T. Design and Implementation of Node-Red Based Open-Source SCADA Architecture for a Hybrid Power System. Energies 2023, 16, 2092. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Low-Cost, Open Source IoT-Based SCADA System Design Using Thinger.IO and ESP32 Thing. Electronics 2019, 8, 822. [Google Scholar] [CrossRef]

- Uddin, S.U.; Baig, M.J.A.; Iqbal, M.T. Design and Implementation of an Open-Source SCADA System for a Community Solar-Powered Reverse Osmosis System. Sensors 2022, 22, 9631. [Google Scholar] [CrossRef]

- Aghenta, L.O.; Iqbal, M.T. Development of an IoT Based Open Source SCADA System for PV System Monitoring. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; pp. 1–4. [Google Scholar]

- Ahsan, L.; Baig, M.J.A.; Iqbal, M.T. Low-Cost, Open-Source, Emoncms-Based SCADA System for a Large Grid-Connected PV System. Sensors 2022, 22, 6733. [Google Scholar] [CrossRef]

- Yuratsmeechan, P.; Manop, C. Open-Source IoT-Integrated SCADA System for Biomass Power Plant Monitoring. In Proceedings of the 2024 21st International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Khon Kaen, Thailand, 27–30 May 2024; pp. 1–7. [Google Scholar]

- Pearce, J.M. Economic Savings for Scientific Free and Open Source Technology: A Review. HardwareX 2020, 8, e00139. [Google Scholar] [CrossRef]

- Arduino—Home. Available online: https://www.arduino.cc/ (accessed on 23 July 2024).

- PCB Prototype & PCB Fabrication Manufacturer—JLCPCB. Available online: https://jlcpcb.com/?from=VGPCBA&gad_source=1&gclid=CjwKCAjw74e1BhBnEiwAbqOAjPinT95y3kicmEcGoxhGIT5N5ecGG8C3Ay0yHyRZPq2gG9kaOIsczhoC5jIQAvD_BwE (accessed on 25 July 2024).

- NI cRIO-9030. Available online: https://www.ni.com/en-ca/shop/model/crio-9030.html (accessed on 24 July 2024).

- NI 9210. Available online: https://www.ni.com/en-ca/shop/model/ni-9210.html (accessed on 24 July 2024).

- NI 9482. Available online: https://www.ni.com/en-ca/shop/model/ni-9482.html (accessed on 24 July 2024).

- NI 9470. Available online: https://www.ni.com/en-ca/shop/model/ni-9470.html (accessed on 24 July 2024).

- NI 9203. Available online: https://www.ni.com/en-ca/shop/model/ni-9203.html (accessed on 24 July 2024).

- NI 9219. Available online: https://www.ni.com/en-ca/shop/model/ni-9219.html (accessed on 24 July 2024).

- Oberloier, S.; Whisman, N.; Hafting, F.; Pearce, J.M. BREAD. HardwareX 2022. [Google Scholar] [CrossRef]

- Hafting, F. FHafting/BREAD. Available online: https://github.com/FHafting/BREAD (accessed on 12 February 2025).

- Hafting, F. Butter. Available online: https://github.com/FHafting/BREAD-Local-Software (accessed on 26 January 2025).

- Clearwater Pool Systems. pH PURETM CO2 Injection for pH Control—Swimming Pools; Clearwater Pool Systems: Largo, FL, USA.

- Garbacz, G.; Kołodziej, B.; Koziolek, M.; Weitschies, W.; Klein, S. An Automated System for Monitoring and Regulating the pH of Bicarbonate Buffers. AAPS PharmSciTech 2013, 14, 517–522. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Das, P.; Thaher, M.; Abdulquadir, M.; Faisal, M.; Hawari, A.H.; Al-Jabri, H. Application Note—A Novel, Low-Cost pH-Controlled Solenoid-Based CO2 Dosing Device for Microalgal and Cyanobacterial Cultivation Systems. Smart Agric. Technol. 2024, 7, 100373. [Google Scholar] [CrossRef]

- Jenco 3672 1/4 DIN pH/ORP Controllers, Adjustable Output from Cole-Parmer China. Available online: https://www.coleparmer.com.cn/i/jenco-3672-1-4-din-ph-orp-controllers-adjustable-output/0580200 (accessed on 26 January 2025).

- MTU MOST/MOST_OpenReactor GitLab. Available online: https://gitlab.com/mtu-most/most_openreactor (accessed on 10 March 2025).

- Wonham, W.M.; Johnson, C.D. Optimal Bang-Bang Control With Quadratic Performance Index. J. Basic Eng. 1964, 86, 107–115. [Google Scholar] [CrossRef]

- Åström, K.J.; Murray, R. Feedback Systems: An Introduction for Scientists and Engineers, Second Edition; Princeton University Press: Princeton, NJ, USA, 2021; ISBN 978-0-691-19398-4. [Google Scholar]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).