1. Introduction

The development of new components for aircraft engines often relies on improvement and refinement of an existing “legacy design”. To be able to meet the targets set by Flightpath 2050 [

1], as well as contemporary developments in air travel [

2], manufacturers need to explore and develop conceptually new designs. Such novel concepts are required on an aircraft and engine system level, but equally on a component level [

3,

4].

Examples for such novel product concepts are the open rotor design [

5] or electrical and hybrid propulsion designs [

6]. Such concepts bring new arrangements of parts, and require new functions to be met by the engine components.

Such radically new concepts—as well as the components they are composed of—need to be developed, designed and evaluated first. In the case of developing physical products, such as aeroengine components, this requires their embodiment in a sufficient level of detail for engineering analysis. In most cases, this means that a geometry model in the form of computer aided design (CAD) of each concept needs to be created. To be able to assess all relevant product properties, analyses on solid geometry models may be required [

7]. As a result, this publication is focused on the management and generation of solid CAD models.

To be able to develop novel products outside the already known design space, developers need reliable methods and tools that support them in the generation of concepts and models as well as their analysis and evaluation [

8,

9,

10]. Currently available—and applied—methods such as parameterisation [

11] or knowledge-based engineering (KBE) [

12] cover only a dimensional variation of existing concepts or require an expensive setup of a master model. Therefore, these geometry based approaches only allow for the exploration of a subset of the available design space [

8,

13]. To enable conceptual design, which explores alternative functions and solutions, a design space exploration (DSE) method needs to take into account a representation of the product’s function [

14,

15].

The DSE method function and geometry exploration (FGE) has been developed to fulfil this premise: through a connection of the functional and geometrical domain, a wider and more efficient exploration is to be enabled [

16]. However, while the FGE approach itself has been presented and verified in [

16], its effect on improving DSE in practice has not been validated. This publication reports from a study to validate the approach through application in an industrial setting. Validation refers in this case to test whether it is useful, that means it has a positive impact on the product development process in an applied context [

17,

18].

The validation is performed through a qualitative study about the application of the FGE approach in a development project for a static turbine structure, a fan frame guide vane (GV). The study has been conducted in tight collaboration with an aerospace manufacturer. The study investigates into whether FGE does improve DSE in that it enables the capture, representation and embodiment of novel design concepts.

An over view over the underlying theories is given in

Section 2, and the FGE approach itself is shortly explained in

Section 2.1. How the study has been setup and how the approach has been evaluated is explained in

Section 3. The application of FGE in the industrial setting is presented in

Section 4. The practitioners’ evaluation and reflections on the application of the approach are presented in

Section 4.2.

Section 5 discusses these results in relation to the problematic described above as well as compared to similar approaches from literature. Lastly,

Section 6 summarises the contribution of this paper and proposes directions for further development of the approach.

2. Frame of Reference

In the conceptual phases of product development, multiple alternative concepts need to be evaluated. The sum of all possible concepts which fulfil the respective requirements is called the design space [

19]. The more, and more different, concepts can be investigated—corresponding to a larger area of the design space being covered—the higher the probability that a good, or even the best possible, concept has been selected [

8].

To achieve this, the design space needs to be defined and the concepts residing in it need to be devised and evaluated against each other [

9]. For the evaluation against each other, that is assessing whether, and how well, they fulfil requirements and functions, the concepts’ need to be simulated in terms of different behaviour. For most of such simulations, a geometrical product representation in the form of a CAD model is needed [

10].

CAD models are a representation of a product’s geometry and topology. Geometry refers to the shape of the product, whereas topology refers to the relations of the individual shapes towards each other [

20]. Most commercial CAD software operate as feature-based parametric CAD, where geometric and topological information is contained in features, which are set into relation in a procedurally operated feature-tree. If set-up and maintained correctly, the alteration and exchange of such features should allow for easy adjustment of the CAD model [

21]. Furthermore does parameterisation allow for a variation of geometry model’s dimensions [

22].

While parameterised, feature-based CAD models are theoretically easily altered, in practice the alteration of is difficult. A lack of consistent modelling practices, the complexity of relations in a master model and ambiguous feature definitions make CAD models difficult to edit and lead to failures in their regeneration [

20,

21,

23]. Furthermore is parameterisation considered “a big challenge”, and even in the best case “offers little flexibility”, since the parameterisation of the master model already defines all possible concepts and does not allow for the introduction of novel solutions [

24].

To avoid such failures, CAD models are build following design guidelines. While the composition of a CAD model’s structure represents the model’s design intent, this does rarely coincide with the product’s design rationale (DR). Hence are changes to the product, which are based on the introduction of new functions or new solutions for identified functions, difficult, since the CAD model does not contain any of this teleological information [

14,

15].

Function models on the other hand can represent a product’s DR, together with architectural or systemic product properties. As such, they provide a good basis for teleologically motivated DSE: through the representation of functions and solutions, developers can precisely target their design effort [

25]. Furthermore can function models be used for systemic analysis [

26], automated DSE and concept generation [

27,

28] or product platforms [

25,

29]. However, while in some cases enabling “physics-based reasoning” [

30], function models do not provide a basis for most engineering analysis, where product geometry models are needed. Connecting the two modelling domains of function and geometry has been a long standing challenge in engineering design research (EDR) [

14,

15,

31].

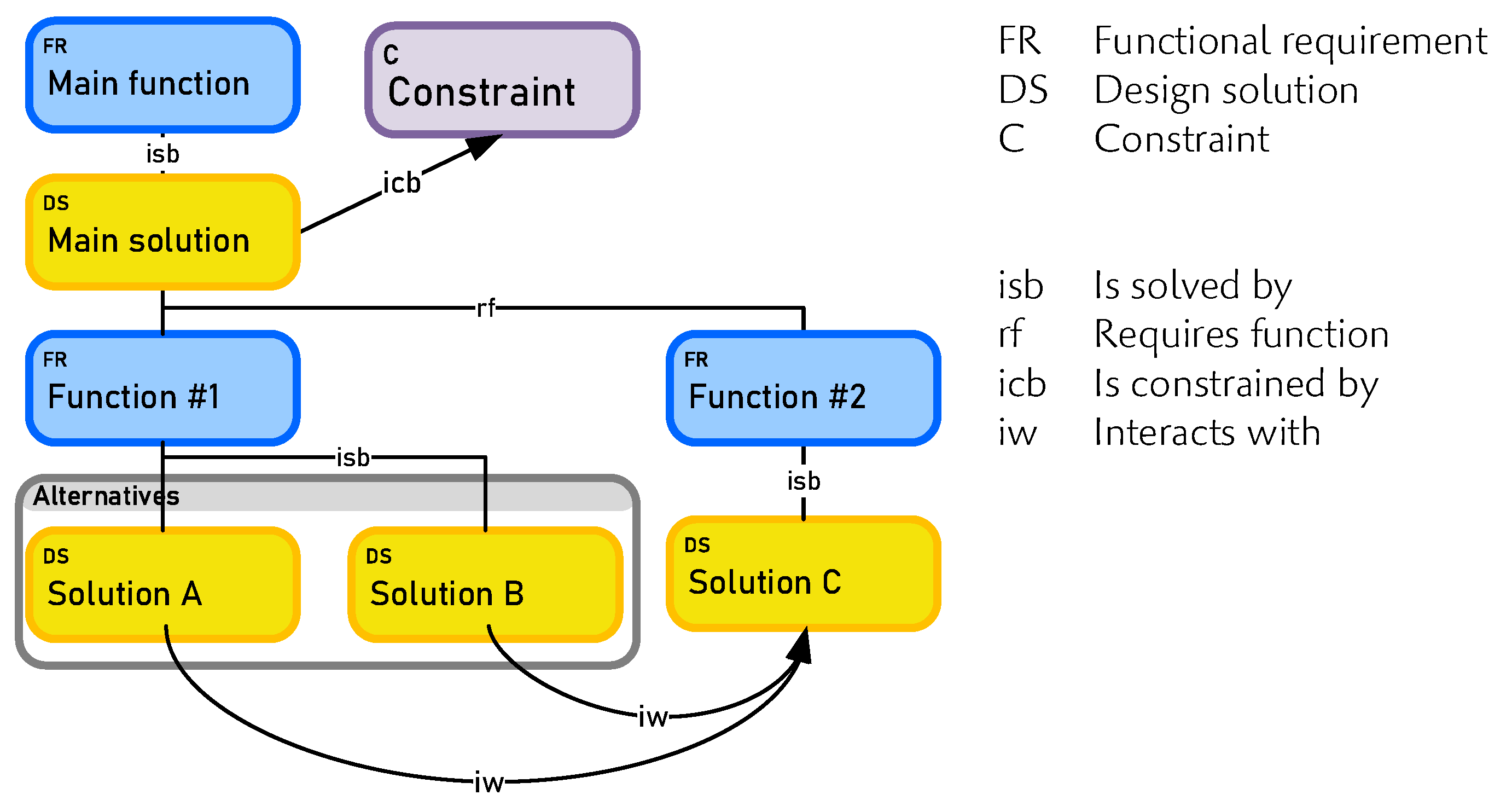

Enhanced function-means (EF-M) modelling is a function modelling approach which represents the design space through alternating functional requirement (FR) and design solution (DS) objects [

32]. A DS can be subject to individual constraints, which place limits on design parameters or behaviour. The basic modelling elements of EF-M are presented in

Figure 1. They create a hierarchical product architecture representation, which enables the introduction of novel solutions and sub-functions on arbitrary levels of granularity into an existing product structure [

33].

Since EF-M follows the axiom of independence of Suh’s axiomatic design [

34], each FR is—in one concept—solved by only one DS. If there are more DS per FR modelled, these represent alternatives. This is illustrated in

Figure 1 in the form of “Solution A” and “Solution B”.

Since new DS are captured for different functions on individual branches of the EF-M tree, they can be combined into a multitude of different concepts. In the presented example in

Figure 1, only two concepts can be instantiated, one with each alternative DS. In

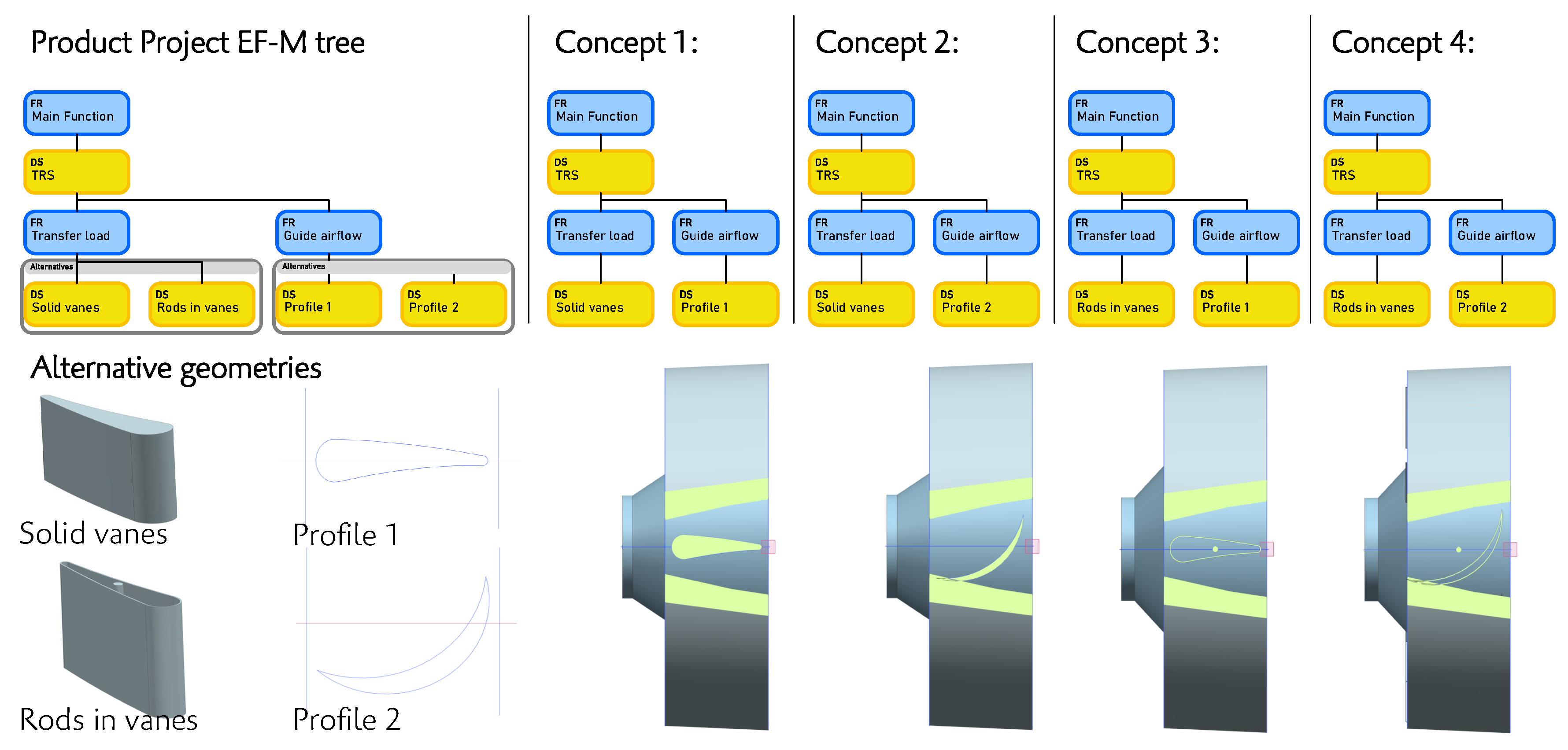

Figure 2 two times two alternatives become four concepts.

2.1. The FGE Approach

The function and geometry exploration (FGE) approach combines the representation of product architecture and DR, and the flexibility to introduce novel solutions into an existing legacy design with a feature based CAD approach. The approach builds on the function modelling method EF-M and combines it with a design automation (DA) approach based on user defined features (UDFs). One main assumption behind the approach is that every geometrical element in a product has a specific function [

35]. This function can be identified, and the related geometry can be isolated. As a result, these two information sets can be coupled. The other main assumption for the approach is that if the function of a geometry element is identified, alternative solutions for that function can be identified and integrated into the product architecture [

25,

36].

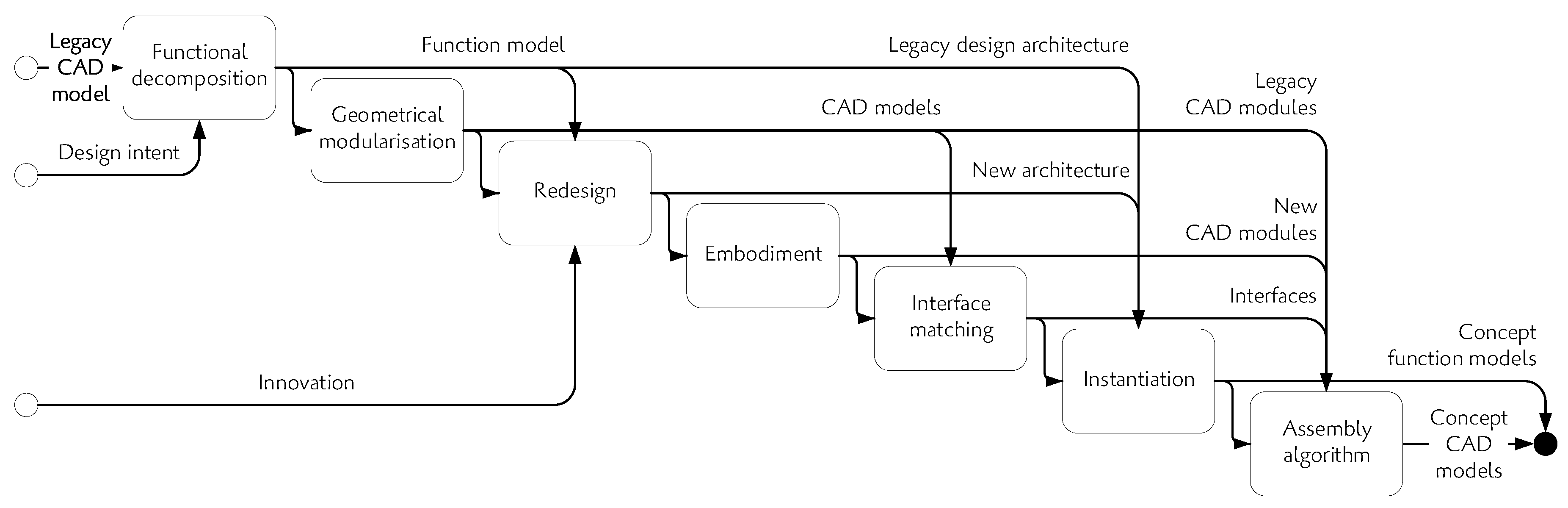

The FGE method is based on three main phases: decomposition of the legacy CAD model, an innovation stage in the functional domain and an embodiment phase to generate CAD models of the concepts.

Figure 3 presents the steps inside these three main stages: the decomposition takes part in both the function- as well as geometry-model, whereas the geometrical modularisation is based on the structure of the EF-M model and the resulting UDF are directly linked to their respective DS. The innovation stage includes redesign, where novel functions and solutions are captured in the function model, embodiment of said solutions into UDF and the matching of their interfaces towards the existing product structure. Lastly, the different concepts are instantiated first from the function model and then embodied through the included assembly algorithm.

To represent the relations between function modelling objects and design features, the FGE approach relies on the object model for function and geometry (OMFG). This object model has been presented and verified in [

16].

The FGE approach assumes the existence of a legacy design in the form of a CAD model. In the first step the model is decomposed into an EF-M model, in a bottom-up approach where the functions of individual geometric elements are identified. Once the geometrical elements are captured as DS, they are linked to their function in the form of FR. Potential constraints are also captured in the EF-M model in relation to the respective DS. The decomposition of a legacy design into an EF-M model and the constraining of the design space in both the functional and geometrical domain is described in detail in [

37]. Once they are associated to a DS, the geometrical features are captured in a UDF with clearly defined interfaces and design parameters. Both of these are captured in the OMFG and provide the basis for the DA of FGE.

Since UDF are available in most commercial CAD systems, these geometry modules can be generated and edited by CAD engineers with minimal additional training. Through the flexibility of UDF and the possibility to parameterise them, this enables a fine granular control of the geometry via the EF-M model [

38]. The interfaces between the UDF—and therefor DS—are captured in the OMFG and represented in the EF-M model as interacts with (iw) connections.

Alternative concepts are instantiated from the alternative solutions captured in the EF-M model. The instantiation algorithm produces concepts as a combinatorial of all alternative DS, as is illustrated in

Figure 2. The assembly algorithm based on architectural and geometrical data captured in the OMFG automatically generates the CAD models of all technically feasible concepts captured in the EF-M model.

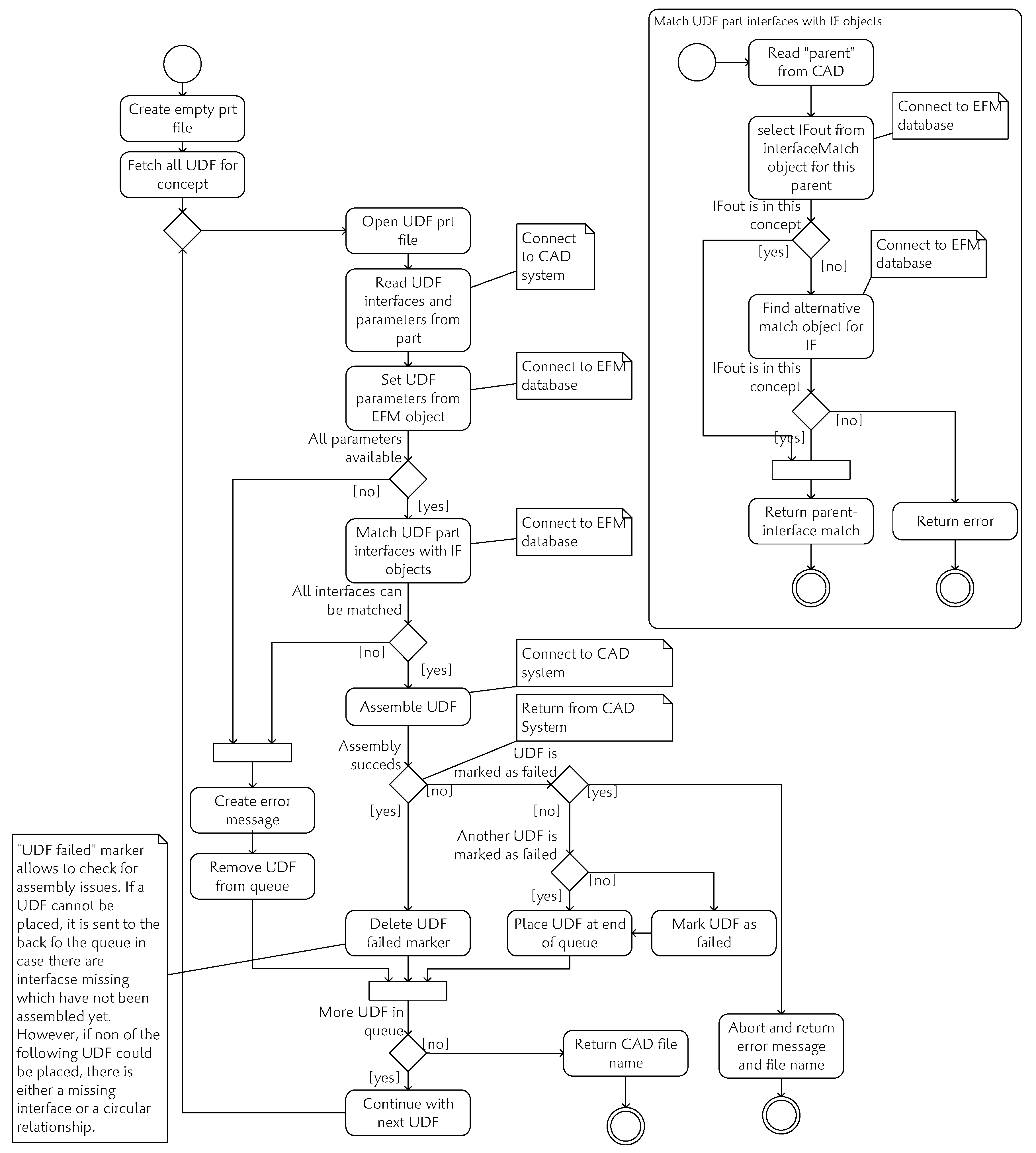

This assembly algorithm, presented in as a UML diagram in

Appendix A,

Figure A1, iterates through all DS of a concept and tries to place the UDF into a part file. While the current implementation of the OMFG into a DA tool generates part files, the generation of assemblies is theoretically feasible using the same technologies and approaches. The individual UDF are attempted to be placed in an arbitrary order, and placed at the back of the queue if the requirements for placement (availability of interfaces and parameters) are not given. Only if all UDF have been placed, or all remaining UDF have failed to be placed, is the model returned. While this approach is computationally expensive, since it may require multiple placement attempts for even larger UDF, it provides a high flexibility and theoretical robustness against interface mismatches.

Following this approach, presented and verified in [

16], the geometry not for each new concept has to be remodelled, but only for each new DS, which reduces the cost of introducing new product concepts based on a legacy design. This modularisation, including a precise interface capture and management through the FGE object model, allows for automated generation of the CAD models of all feasible concepts.

3. Materials and Methods

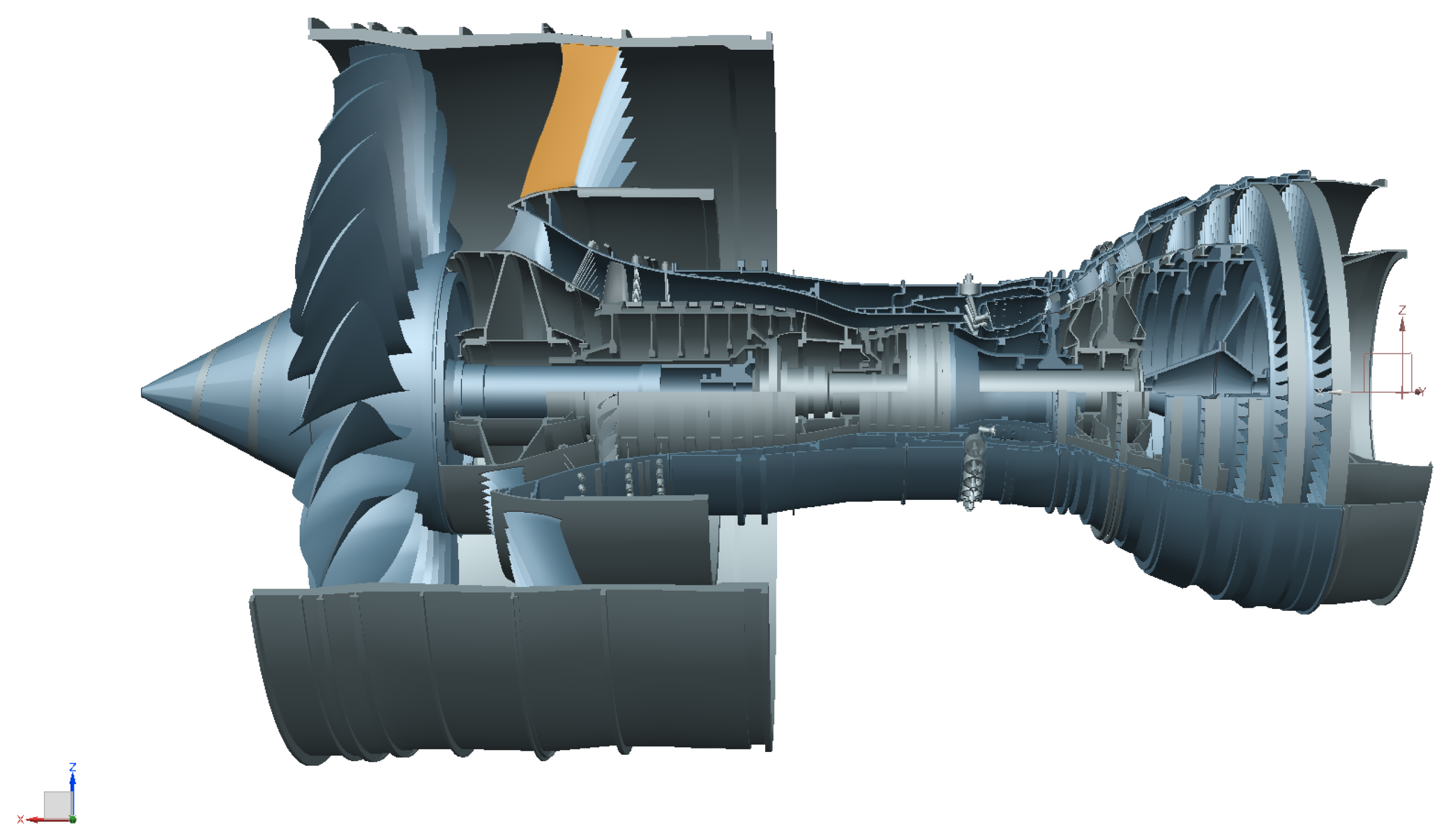

This study is conducted in tight collaboration with a Swedish aerospace manufacturer, and is centred around the design of a new part for turbofan engines, a guide vane (GV). The part is located in the bypass of the turbofan engine, positioned just behind the fan, as shown in

Figure 4. The set of all GV has the main function to deswirl the airflow from the main rotor, thereby reducing aerodynamic losses. Furthermore, the vane has a structural function in that it connects the shroud of the bypass to the engine core, thereby creating a load path for the turbine mass to the pylon. Furthermore, the part has to withstand axial loads from the engine thrust.

For the GV being a relatively large component, it is necessary to find low weight designs. As a result, low-weigth designs are given high priorities by the design team. This can be achieved by the introduction of new manufacturing and material options. The common manufacturing and material choice is a metallic core structure [

39]. Alternative options are composites or combined solutions.

A GV commonly consists of a vane structure, a predominantly aerodynamically defined structure, and two end attachments which fasten the vane to the engine core on the inside, and the outer fan case on the outside, as can be seen in

Figure 4 and

Figure 5. Both parts provide interfaces the GV assembly has to comply to.

The development team is composed of both design and analysis engineers with experience in aerospace engineering ranging from five to thirty years. These engineers partake in the development in defined percentage of their work-time, between 10% and 70%.

It is important to mention that the company is using and developing KBE techniques with a high degree of DA for design space exploration. This means that the engineers possess a benchmark system for comparison with the FGE. The benchmark system can be compared in make-up and extend to the parameterisation-based multi-disciplinary analysis (MDA) framework presented in [

40].

Study Setup

The research has been performed as a participatory action research study, where the researchers accompany the development process investigating into new opportunities for a fan frame GV [

41]. The researchers participated in regular team meetings together with the design team, and had the ability to observe the engineers during their work. Notes from these meetings and observations are part of the data supporting the presented results.

Beyond the observation throughout the product development project, a set of studies has been conducted to investigate the perception of the presented method. For the specific purpose of validating the FGE method and tool, two consecutive workshops were organised together with the design team.

In a first workshop together with the GV development team (eight participants), a functional decomposition of the part was performed and captured. Hence, this workshop is referred to as the “decomposition workshop”. The actual workshop was predated with a one hour long test-workshop in one of the regular team meetings to evaluate the motivation of the practitioners and the requirements for the actual workshop. The results of this “test-workshop” are included in the results of the decomposition workshop. The decomposition was performed using large-scale print-outs of drawings a GV which were annotated in a group exercise. The annotated drawings were collected, digitised and used for the creation of function-geometry model in FGE for the legacy design.

A second workshop (eight participants) covered the innovation stage of the FGE approach. The workshop was held with the same development team, using the same product. The workshop was held online due to the social distancing regulations in response to the COVID-19 pandemic.

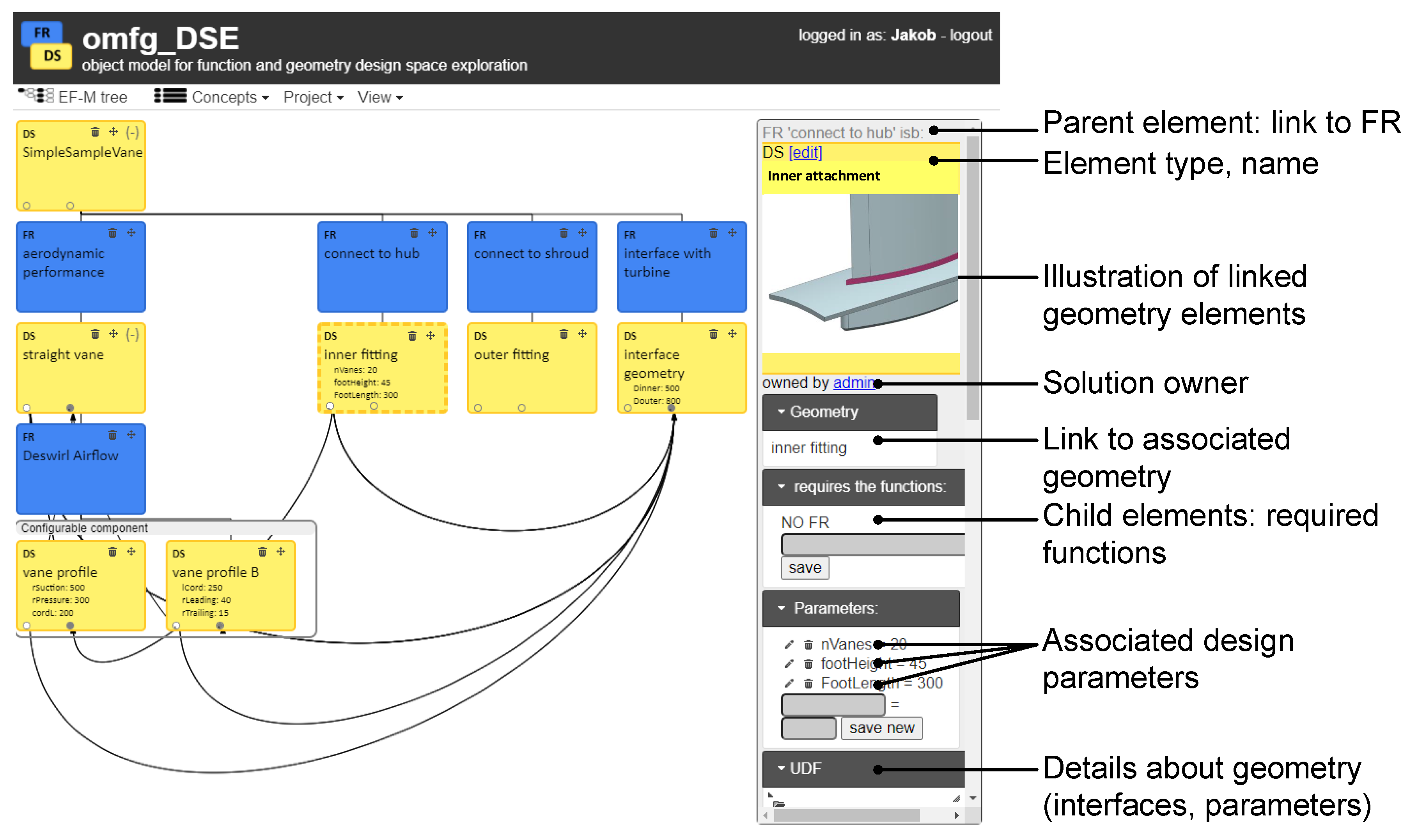

For the second workshop, a proof-of-concept tool of the FGE approach was created. The tool works server-based with a web interface (illustrated in

Figure 6), allowing users with different skill levels and operating systems to connect to the same database. The tool incorporates a fully functional implementation of an EF-M modeller with additional functionality to capture geometric information for each DS. As such, it is able to capture alternative design solutions and instantiate them into different concepts. Furthermore, the tool includes a geometrical modelling algorithm to automatically generate CAD models of each concept, based on previous geometrical modularisation in Siemens NX. The structure and mechanics of the tool are illustrated in [

16].

After each workshop, the practitioners were asked for their experiences through questionnaires and open feedback discussions. The results of the first workshop were recorded through adhesive notes and remarks on the drawings, as well as protocol notes. The results of the online workshop were captured through audio and video recording and through a change protocol in the database of the FGE tool.

For this publication, a generic design of a GV was created, which differs from the design used in the workshops. However, the generic design has a sufficient degree of realism to enable dialogue, but with company specific features left out.

4. Results

This section presents the results of the application of FGE in the industrial context as well as the practitioners feedback and observations.

4.1. Design Space Exploration Using FGE

The DSE approach is separated into three phases decomposition, innovation and embodiment, following [

36]. The presented workshop focuses on the interactions with practitioners in the phases decomposition and innovation.

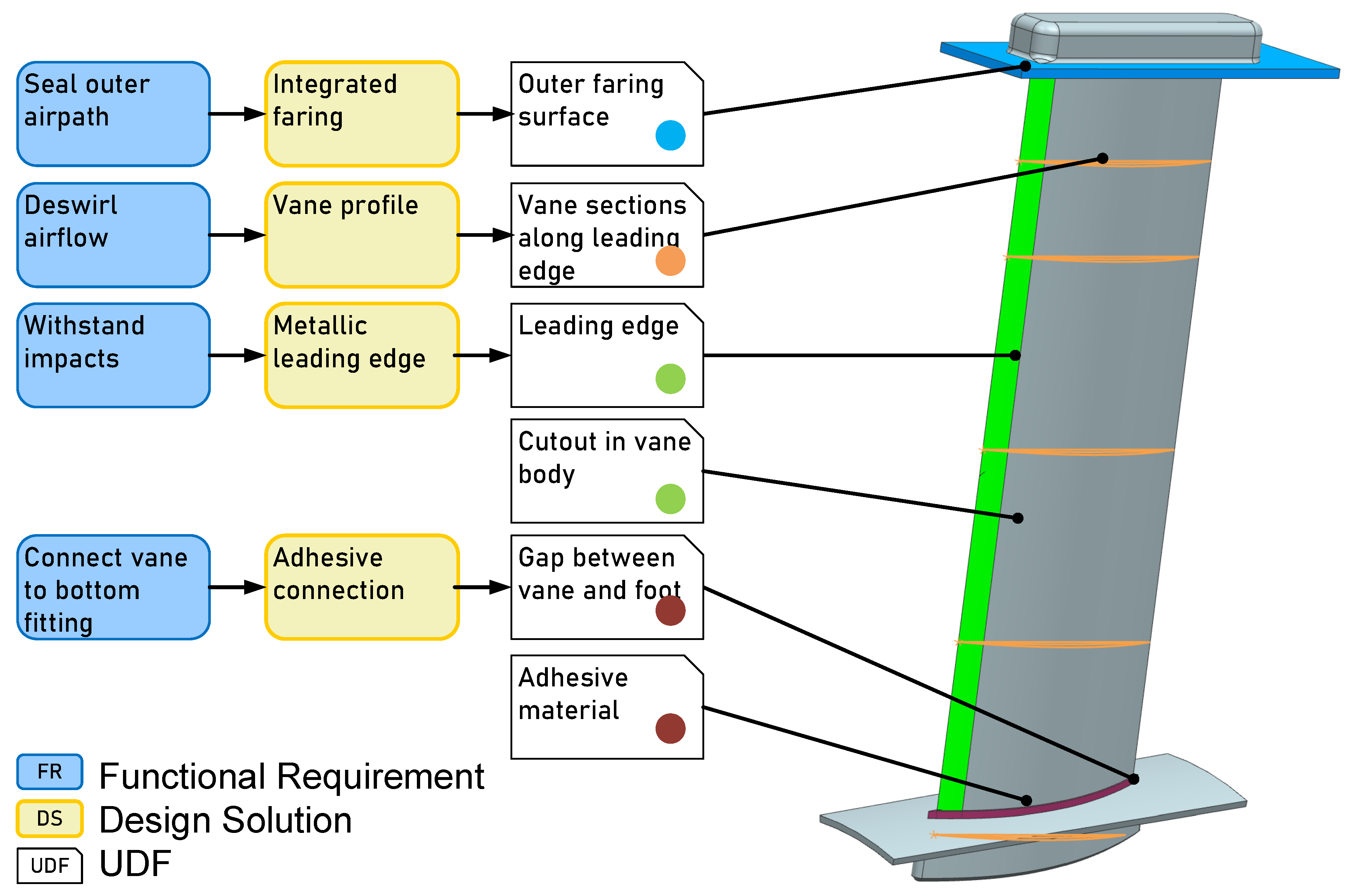

In the first workshop (decomposition), the legacy design of the GV was captured in an EF-M model based on the available geometry. The model contains three main functions, and 18 different design solutions on the concrete (lowest) level. Since the model was created through decomposition, all DSs are directly linked to one or several geometry elements. A modularised CAD model was created based on the original geometry, modularised according to the decomposition.

Figure 5 exemplary shows this modularisation and connection for four individual DSs and the related UDFs. For example, the leading edge of the decomposed GV is covered by a metallic edge. This metallic edge, as a geometrical element, has been associated with the function “Withstand impacts” through the solution “Metallic edge”. The respective geometry, of both the edge insert and the cutout in the vane to place it in, are captured as two UDFs which are then associated with the DSs.

This decomposition served as input for the following workshop, focused on innovation.

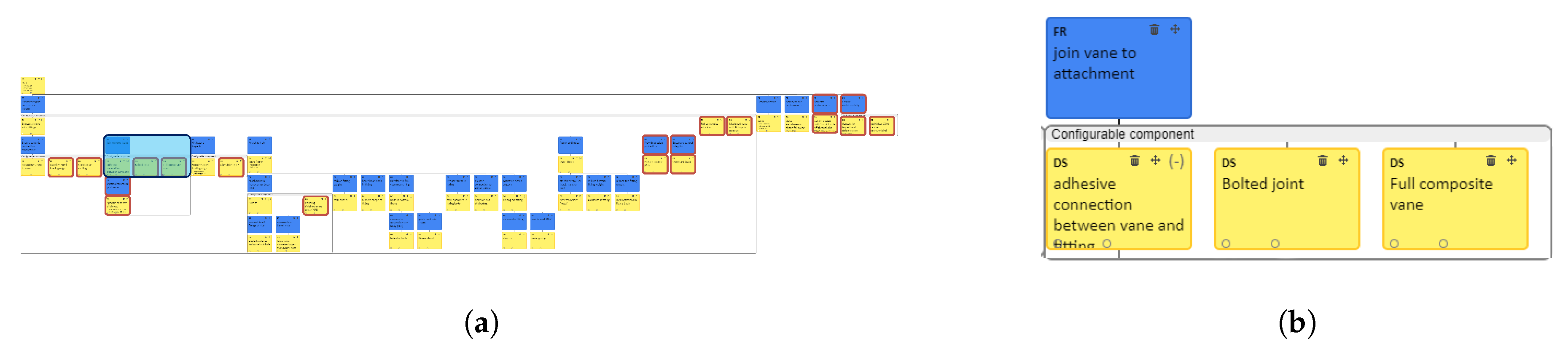

In the second workshop (innovation) the prototype tool was used to capture novel design solutions. As a result, the product model was extended by five new sub-functions with their respective solutions and 10 new alternative DSs. As an example for new FR, sub-functions related to acoustic performance were added to the model. The nature of the DSs ranged from material alternatives over different interface approaches to variations in shape and dimensions of the existing solutions. The entire EF-M tree, with all new FR and DS highlighted with red borders, is shown in

Figure 7a. Based on the new alternative DSs, 52 different concepts could be instantiated.

The majority of the novel solutions shows a conceptual difference from the legacy design. As an example, the FR “Join vane to attachment” is in the legacy design solved by the DS “Adhesive connection”, meaning that the vane is glued to the attachment using resin. This DS, and the respective UDF, are illustrated in

Figure 5. The two alternative DSs, as results from the workshop, were “Bolted joint” and “Fully integrated solution”. The respective DS are shown in

Figure 7b, whereas the geometry related to these DSs is shown in the context of the GV in

Figure 8.

The embodiment phase of the FGE approach has not been performed in its entirety, since the DA section of the proof-of-concept tool has not sufficiently matured to handle the complex geometries of the solutions devised in the innovation workshop. For a verification of the proof-of-concept tool on another turbine structure, see [

16].

Figure 8 shows an exemplary embodiment of three concepts with alternative DSs for the FR “Join vane to attachment” shown in

Figure 7b. While otherwise using the same configuration, each of the geometries is adapted to accommodate the respective geometric changes in the concept. The instantiation and assembly algorithms embedded in the FGE model allow for automated generation of the CAD models of all feasible concepts.

The following section reports on the practitioners’ feedback and reflections after the application of the method on their industrial use case.

4.2. Reflections Form Industrial Practitioners Regarding the Application of the Method

The practitioners have stated that the workshops—as activities in addition to their regular design activities—contribute to the development project. Furthermore, all workshop participants would like to repeat the workshop concept, both in the same, but even more so in other projects. The following sections will go through the main mechanisms that have been highlighted by the industrial practitioners, in particular the ability of the approach to:

Represent and capture design rationale and the design space

Capture, integrate and model novel solutions

Provide support for the embodiment of novel concepts that would otherwise remain unexplored

4.2.1. Capture and Representation of Design Rationale and Design Space

“I learned a lot of things about the GV just by reading the graph.”

—aerodynamics analysis engineer

This quote illustrates a common problem during the design of aerospace products. As components are designed and conceptualised over long times, and by heterogenuous teams, it is difficult to retain the design rationale (DR) of a product (that is, why a product has been designed in this form) [

42]. This DR is especially hard to read in highly integrated and complex products such as aerospace engine components, where a single geometrical artefact may fulfil multiple functions in different domains [

43]. For practitioners, the FGE approach supports the ability to visualise the rationale in both the geometrical domain, visualising “what is”, and the functional domain, “why it is”.

In terms of the use of FGE, it appears to be a major benefit of FGE for the practitioners that they improved their knowledge about the product and participated in a forum that permitted exchange about the product’s functions and solutions. The questionnaire accompanying the workshop revealed that no team member had full confidence about the GV, but most rated their understanding of the GV higher after the workshop than before. The workshop also fostered the awareness of meta-product-knowledge, since many engineers were not even aware who knew the rationale behind a specific element. Only through discussions and participation of engineers of multiple disciplines could the entire DR be captured in the EF-M model.

An example for how FGE enables access to DR is the interface of the tool used in the study, which collects all information of a solution in a single place.

Figure 6 shows on the right hand side how the geometry, parameterisation and other information about a solution is collected in a single window pane. The top of the pane shows which function is solved, and the highlighting of the solution shows its position in the product architecture.

Furthermore, the approach can illustrate the geometrical interfaces between solutions through iw connectors in the EF-M model. This are seen as black arcs in the interface of

Figure 6, left hand side. This approach of information representation was referred to as “comprehensive” by the workshop participants.

Beyond the information about individual solutions, the FGE interface provides an overview over the possible alternatives through EF-M. This was perceived to be an efficient way to represent the design space, providing “good possibilities to look at different solutions”. However, it was also noted by one participant in the workshop that the function models can quickly grow to be too complex. The function model created in this study (see

Figure 7a) was considered “almost too large”.

4.2.2. Ability to Capture, Integrate and Model Novel Solutions

“Parametric solutions exist but limited to parameters that we easily can change, dimensions, angles or thicknesses for example. When it comes to exploring different design solutions in early phases we foresee larger challenges.”

—development team leader

This quotes stands exemplary for the practitioners’ reflections over the in-house KBE system for DSE adopted by the company, which is built around state of the art KBE approaches. However, the practitioners are well aware about the limitations of highly automated CAD approaches in representing conceptually different design solutions. While the exploration of dimensional variety is possible and appreciated by the practitioners, the need to realise topologically and geometrically different options has been stated explicitely. This matches with observations from literature, where it is stated that “a parametric model offers little flexibility” [

44].

According to the practitioners, FGE has the potential to deliver this through the modularisation of the geometry, and the connection to the DR of the product.

It was perceived by the participants of the workshop that the use of the FGE approach supports the introduction of new solutions (4 on a scale of 1 “no support for new solutions” to 5 “totally supports”). It was furthermore stated that part of the identified DS would probably not have been found—or considered—in a regular modelling approach, with a majority () stating “maybe some, but not all”. The other participants stated either “none of them” or “most of them” would have been identified without FGE.

Beyond only exploring new solutions for existing functions, FGE also enables the capture of newly identified functions or sub-functions. The workshop results showed that through five new functions being identified during the innovation workshop. Practitioners feedback further supported this, although the ability to integrate new solutions is perceived to be more important than that of new functions.

To summarise this, the practitioners perceive FGE as a viable method to capture novel solutions and functions. Having a formal, and even computer supported, modelling approach at hand when generating conceptual alternatives directly in creative design meetings was found very applicable.

4.2.3. Support for the Embodiment of Novel Concepts

“There are still gaps within early concept phase—this is one possibility to generate, and evaluate, lots of concepts, get trend curves and so on.”

—design engineer

As has been stated in the section above, there is a substantial need for a DSE modelling approach to capture geometrically and topologically different DS. The practitioners agree that FGE is an approach which can support such exploration.

However, the sole representation of alternative concepts in function models would be insufficient. To enable the necessary analyses, geometry models in the form of CAD are required.

The practitioners stated that the CAD models needed for effective DSE need to be of sufficient quality to be meshed automatically. This requires certain quality criteria such as surface continuity. Furthermore would the CAD models require automated “tagging” of relevant geometry elements for analyses, for example where forces attack or constraints apply.

After a demonstration of the assembly algorithm of FGE and the geometry modularisation, the practitioners agreed that such an approach can deliver the required models. Therefore, the ability to generate topologically different variant concepts was seen as a benefit of the presented method:

“Generation of CAD models based on different configurations is a key functionality.”

—development team leader

4.2.4. Implementation Challenges

Despite the interest in the approach, the practitioners pointed out certain implementation challenges.

As a feedback to the modelling process, using EF-M to capture and represent alternative solutions, a practitioner mentioned that the re-use of existing solution’s geometry for another function is hardly possible to model using EF-M. Although there exist horizontal relations in EF-M modelling, they increase the modelling complexity and reduce readability. Therefore, such complex relationship modelling has not been implemented yet in the prototype tool, and does not contribute to alleviate the challenges of complexity in function modelling stated by [

31,

33].

The ratio of complexity between the functional domain and geometrical domain was point for critique. It was stated that a large function model (such as the one in the workshop became through the innovation) reduces the overview over the model. It was suggested to use less FR/DR elements and more, but potentially more complex, geometric modules. However, the experience with function modelling and/or web-based applications may play a role in how difficult the tool use was perceived.

While FGE supports the exploration of technically, functionally and topologically different solutions, the in-house KBE solution is optimised for parametric variation. Being used to the already existing MDA method at the company, the practitioners rather viewed an implementation of FGE as a complement, preferably integrated with the existing system.

5. Discussion

The FGE approach aims to support DSE in the conceptual product development phases through a three-phase approach, namely decomposition, innovation and embodiment. The approach relies on the OMFG, which provides a connection between the previously divided modelling domains of function and geometry. As a result, novel solutions can be integrated into an existing legacy design, and be embodied based on information stored in the function model. This information, the DR of the product, is the driving force behind the implemented DA approach. The coupling of the function and geometric modelling domain, and the resulting opportunities for DSE, distinguish the approach from other DA approaches and CAD model parameterisation. The approach has been evaluated in a case study with a product development team of an aerospace manufacturer.

The practitioners gave an overall positive feedback about the approach, stating that FGE—or a similar approach—can provide what is needed to improve current product development practice. The need was stated to be about capturing and presenting alternative solutions in a systematic way, as well as an automated generation of CAD models ready for analysis. The use of a non-geometrical modelling approach representing teleological product knowledge, “how it all connects”, has been received positively by the practitioners. This is in line with authors such as [

8,

14,

15] who call for models for DSE to carry information beyond the geometrical domain.

While the results of this study can be interpreted as generally positive for the presented FGE method in terms of user acceptance and improved DSE, it is only a single case study, and hence difficult to generalise from [

45]. While the engineering design research community is aware of the challenge to properly validate a new method or methodology [

46,

47], this study can only be an initial step into validating FGE. Similar studies with other development teams, and in other engineering domains, are required before a conclusive image of the contribution of FGE to DSE can be presented.

Practitioner feedback has shown challenges of understanding the instantation, EF-M and CAD integration of the approach. In general, from the observations throughout the workshops, did the time to understand and learn the new approach take up a large part of the workshops’ time. Hence, the studies results and conclusions are influenced by the novelty of the tool and method for the practitioners. This can be a factor in the enthusiasm and positive feedback for the method, in a variant of the “Hawthorne-effect” [

48]. However, it could also be argued that the method can only show its full contribution once the practitioners have grown familiar with it. Which of these two factors predominates cannot be said at this moment.

Many participants highlighted the contribution of the method for knowledge capture and exchange inside the group. Although this is not among the primary objectives of the FGE method, the capture, representation and retrieval of design rationale is beneficial to the product development process [

49]. However, it can be argued that not the use of this specific method, but the general interaction of engineers of different disciplines focused on a shared product could provide this [

50].

The registered numbers for captured novel design solutions, concepts and functions have been identified by the participants in the study as subjectively higher than without the method. However, to be able to judge a significant impact of the use of method on the quantity—or quality—of the generated design concepts, further and especially more longitudinal studies are required [

45]. The presented FGE approach for DSE relies heavily on a DA implementation for the assembly of individual concepts’ CAD models. This approach has been presented in detail in [

16]. The practitioners in the study have already voiced concerns about the robustness of the DA approach and the quality of the resulting CAD models for meshing and FEM. Similar to other DA approaches and parameterisation, FGE is sensitive to modelling errors, ambiguously defined datums or over-constrained models [

20,

21,

23]. The definite sensitivity to modelling errors has to be evaluated in further studies.

However, the actual contribution of the FGE approach lies not in the DA implementation, which in similar fashion can be found in existing feature-based design approaches [

51]. More than providing a feature-based geometry approach does FGE provide a function-based approach to geometry modelling. A change in product function—or change of a solution—directly impacts the CAD model. The underlying OMFG provides a direct link between the two domains, and therefor enables a DSE approach which is guided by “the most important concept in determining a product’s basic characteristics”: function [

14].

6. Conclusions

FGE is a novel DSE approach which has been presented in [

16]. While this previous presentation has presented the technical workings of the approach and verified the DA algorithm, the approach as a method in EDR has to be validated through application in an industrial context.

This paper presented the application of a DSE approach combining function modelling and automated geometry model generation for the conceptual product development phases of turbofan engines. The modelling approach tackles the challenges of representing alternative concepts in the design space, design rationale capture and storage as well as support for the generation of CAD models. Through the application of the FGE approach in an engineering case, the method has been validated to target a real problem in the conceptual development of aerospace engine components and to provide a feasible solution for it.

Through the use of a prototype tool implementing the FGE method, engineers in a aerospace supplier were able to share product knowledge and explore novel design solutions. This has lead to both, a perceived increased knowledge about the developed product inside the development team, as well as the opportunity to explore previously unconsidered design solutions. According to the statements of the product developers participating in this study, this leads to more and more novel functions and solutions being explored.

The FGE approach uses function modelling as a tool to represent the design space and perform its population. While this has shown to be feasible, domain specific challenges similar to as reported for example in [

31] have shown. This points towards further development for EF-M modelling in order to increase applicability and reduce abstraction. Furthermore did practitioners point out the problems of modelling a “make use of” relationship for a DS, as described in

Section 4.2. Similar challenges have already been identified in [

33] and pointed towards further development of the EF-M approach.

The presented prototype tool has shown to efficiently provide an interface for collaborative DSE. To a degree it has reduced the abstraction of function modelling by providing a connection to tangible geometry. However, further studies with increased practitioner training are seen as a goal for future work. While the embodiment process has been illustrated in [

16], further studies have to show the scalability of it. In particular, the quality of the generated CAD models—with a focus on meshing—has to be in the focus of development, since in the presented study it has been highlighted that it is crucial for analysis of the concepts.

In summary, while there have been identified areas for improvement, the FGE approach was perceived to be “one possibility to generate, and evaluate, lots of concepts”—which is what it aims for.