Effects of Gamma Irradiation on Solid Propellant Conventional and UV-Cured Binders

Abstract

1. Introduction

2. Background

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Irradiation Tests

3.2.2. Characterization Techniques

4. Results and Discussion

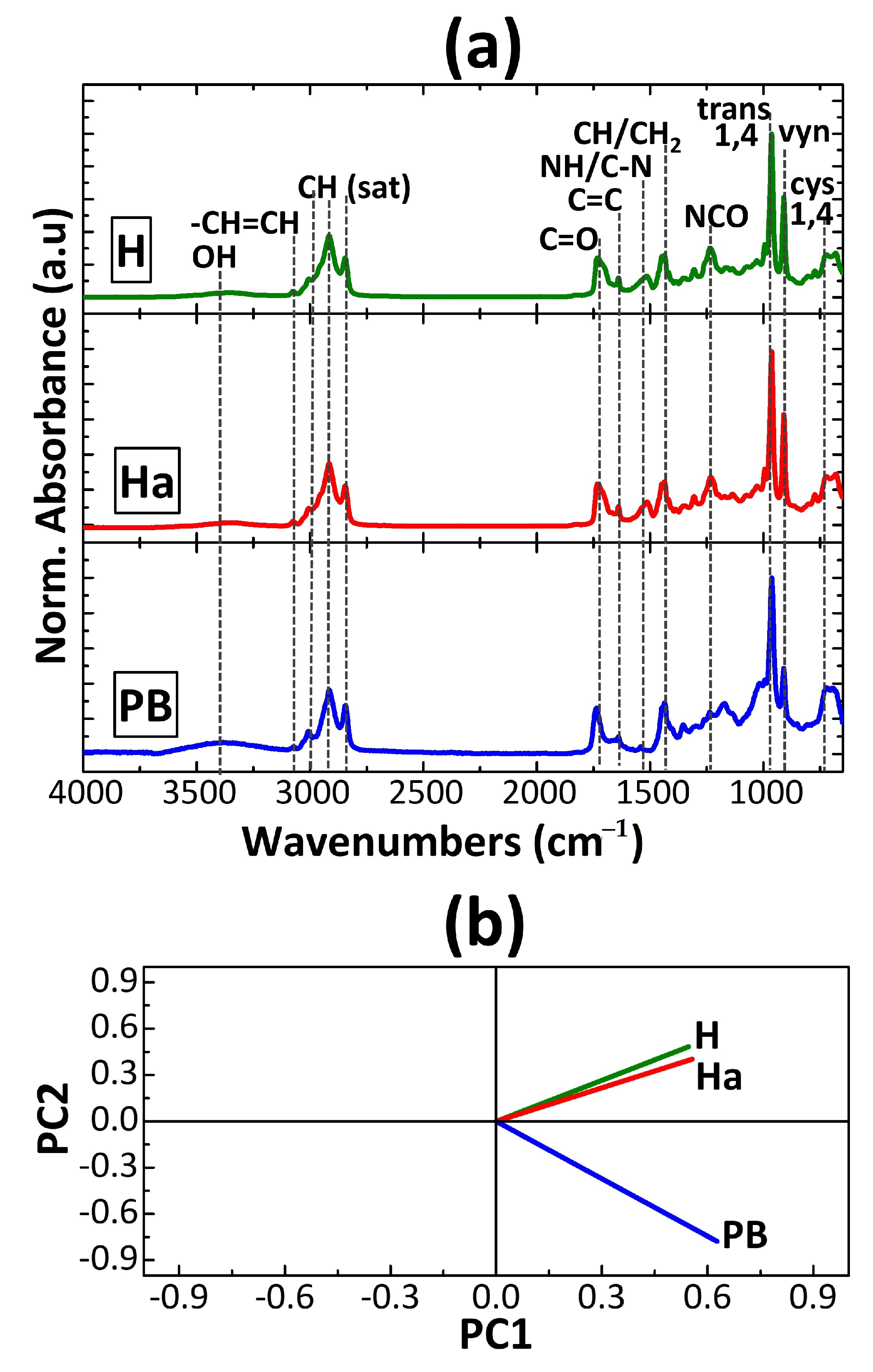

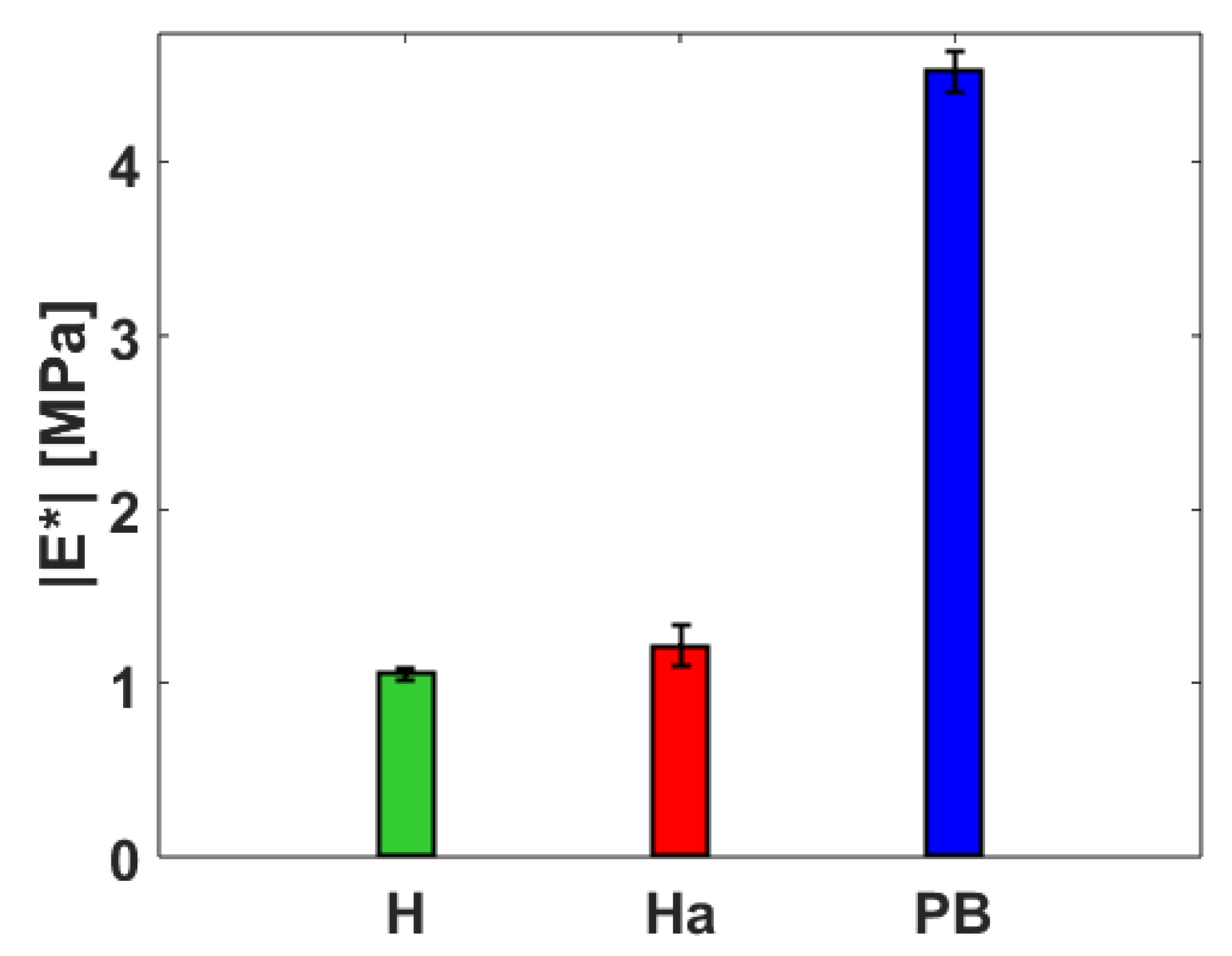

4.1. Unirradiated Samples

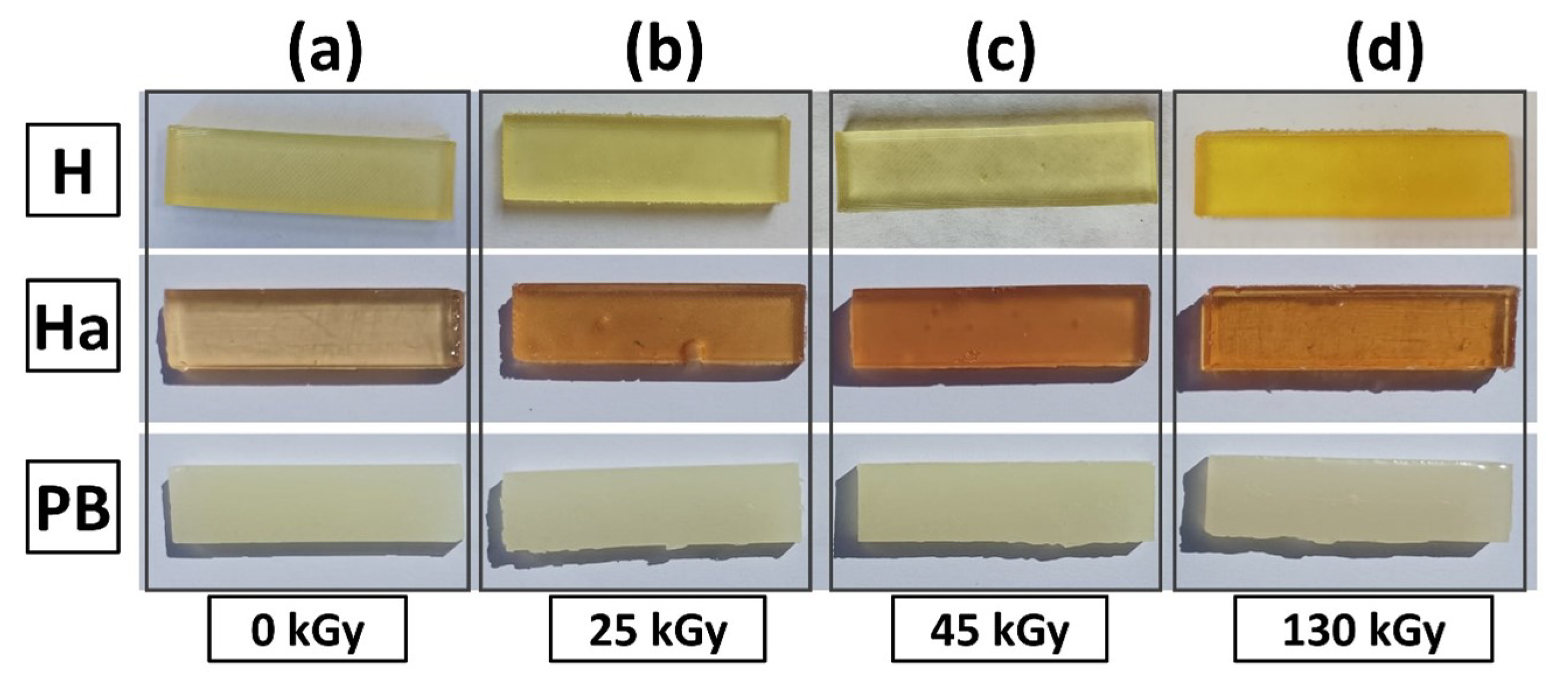

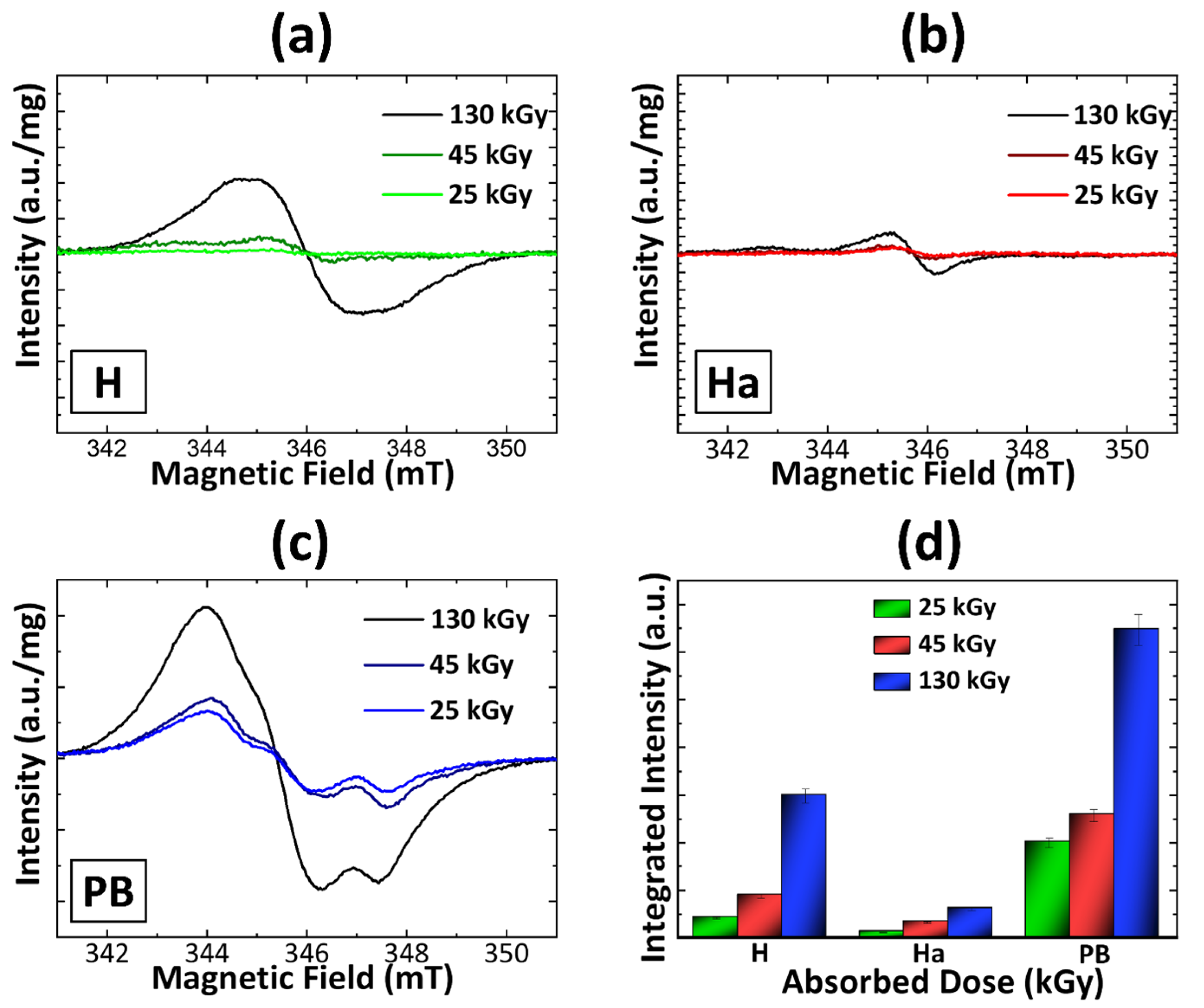

4.2. Irradiated Samples

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AP | ammonium perchlorate |

| ATR | attenuated total reflectance |

| BAPO | phenylbis(2,4,6- 191 trimethylbenzoyl)phosphine oxide |

| CI | carbonyl index |

| DLO | diffusion-limited oxidation |

| DMA | dynamic mechanical analysis |

| DOA | dioctyl adipate |

| ECSS | European Cooperation for Space Standardization |

| EPR | electron paramagnetic resonance |

| FTIR | Fourier transform infrared |

| HTPB | hydroxyl-terminated polybutadiene |

| MSFC | Marshall Space Flight Center |

| PB | polybutadiene |

| PCA | principal component analysis |

| SRM | solid rocket motor |

| Thiol | pentaerythritol tetrakis(3-mercaptopropionate) |

| TIN | dibutyltin diacetate |

| UV | ultraviolet |

| UVA | ultraviolet A light |

References

- Burkhardt, H.; Sippel, M.; Krülle, G.; Janovsky, R.; Kassebom, M.; Lübberstedt, H.; Romberg, O.; Fritsche, B. Evaluation of propulsion systems for satellite end-of-life de-orbiting. In Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Indianapolis, IN, USA, 7–10 July 2002. AIAA Paper N. 4208-2002. [Google Scholar]

- Naumann, K.; Weigand, A.; Ringeisen, A. Solid rocket motors for the de-orbiting of satellites. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- Okninski, A. Solid rocket propulsion technology for de-orbiting spacecraft. Chin. J. Aeronaut. 2022, 35, 128–154. [Google Scholar] [CrossRef]

- Krejci, D.; Lozano, P. Space propulsion technology for small spacecraft. Proc. IEEE 2018, 106, 362–378. [Google Scholar] [CrossRef]

- Guery, J.F.; Chang, I.S.; Shimada, T.; Glick, M.; Boury, D.; Robert, E.; Napior, J.; Wardle, R.; Pérut, C.; Calabro, M.; et al. Solid propulsion for space applications: An updated roadmap. Acta Astronaut. 2010, 66, 201–219. [Google Scholar] [CrossRef]

- Sathiyanathan, K.; Lee, R.; Chesser, H.; Dubois, C.; Stowe, R.; Farinaccio, R.; Ringuette, S. Solid propellant microthruster design for nanosatellite applications. J. Propuls. Power 2011, 27, 1288–1294. [Google Scholar] [CrossRef]

- Chandru, R.A.; Balasubramanian, N.; Oommen, C.; Raghunandan, B.N. Additive Manufacturing of Solid Rocket Propellant Grains. J. Propuls. Power 2018, 34, 1090–1093. [Google Scholar] [CrossRef]

- McClain, M.; Gunduz, I.; Son, S. Additive manufacturing of ammonium perchlorate composite propellant with high solids loadings. Proc. Combust. Inst. 2019, 37, 3135–3142. [Google Scholar] [CrossRef]

- McClain, M.S.; Afriat, A.; Rhoads, J.F.; Gunduz, I.E.; Son, S.F. Development and Characterization of a Photopolymeric Binder for Aditively Manufactured Composite Solid Propellant Using Vibration Assisted Printing. Propellants Explos. Pyrotech. 2020, 45, 853–863. [Google Scholar] [CrossRef]

- Pastrone, D.; Sangermano, M.; Garino, S.; Maggi, F. Composite Propellant Manufacturing Process Based on Deposition and Light-Activated Polymerization for Solid Rocket Motors. Patent IT201900005788A1. WO2020212785A1, 20 October 2020. [Google Scholar]

- Garino, S.; Antonaci, P.; Pastrone, D.; Sangermano, M.; Maggi, F. Photo-polymerization for additive manufacturing of composite solid propellants. Acta Astronaut. 2021, 182, 58–65. [Google Scholar] [CrossRef]

- Galavotti, A.; Noè, C.; Polizzi, G.; Antonaci, P.; Maggi, F.; Masseni, F.; Pastrone, D. Solid Rocket Propellant Photo-Polymerization with an In-House LED-UV Prototype. Polymers 2023, 15, 1633. [Google Scholar] [CrossRef]

- Xiangyang, X.; Yupeng, C.; Han, L.; Wenfang, Z.; Lixia, F.; Renming, P. A Kind of Solid Propellant 3D Printing and Forming Method Based on Ultraviolet Light Solidification. Patent CN107283826A, 24 October 2017. [Google Scholar]

- Dey, A.; Kumar, A.; Sikder, A.K.; Gupta, M. Chemically Collapsible Mandrel for Solid Rocket Motor Processing. J. Aerosp. Technol. Manag. 2015, 7, 277–284. [Google Scholar] [CrossRef]

- Korah Bina, C.; Kannan, K.G.; Ninan, K.N. DSC study on the effect of isocyanates and catalysts on the HTPB cure reaction. J. Therm. Anal. Calorim. 2004, 78, 753–760. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Hoyle, C.E.; Bowman, C.N. Thiol–Ene Click Chemistry. Angew. Chem. Int. Ed. 2010, 49, 1540–1573. [Google Scholar] [CrossRef]

- Macha, M.; Senajova, D.; Giles, T.; Calviani, M.; Girard, S.; Ferrari, M. Effects of Radiation Dose on Lubricants: A Review of Experimental Studies. ACS Appl. Mater. Interfaces 2025, 17, 14773–14800. [Google Scholar] [CrossRef]

- Ferrante, C.; Lucchesi, L.; Cemmi, A.; Di Sarcina, I.; Scifo, J.; Verna, A.; Taschin, A.; Senni, L.; Beghini, M.; Monelli, B.D.; et al. Gamma Irradiation Effect on Polymeric Chains of Epoxy Adhesive. Polymers 2024, 16, 1202. [Google Scholar] [CrossRef]

- Drobny, J.G. Ionizing Radiation and Polymers: Principles, Technology, and Applications; William Andrew: Norwich, NY, USA, 2013. [Google Scholar]

- Bouquet, F.L.; Price, W.E.; Newell, D.M. Designer’s guide to radiation effects on materials for use on Jupiter fly-bys and orbiters. IEEE Trans. Nucl. Sci. 2007, 26, 4660–4669. [Google Scholar] [CrossRef]

- Pisacane, V. The Space Environment and Its Effects on Space Systems; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2008. [Google Scholar]

- Grossmann, E.; Gouzman, I. Space environment effects on polymers in low earth orbit. Nucl. Instrum. Methods Phys. Res. B 2003, 208, 48–57. [Google Scholar] [CrossRef]

- Gutiérrez, O.; Prieto, M.; Perales-Eceiza, A.; Ravanbakhsh, A.; Basile, M.; Guzmán, D. Toward the Use of Electronic Commercial Off-the-Shelf Devices in Space: Assessment of the True Radiation Environment in Low Earth Orbit (LEO). Electronics 2023, 12, 4058. [Google Scholar] [CrossRef]

- ECSS-Q-ST-70-06C; Particle and UV Radiation Testing for Space Materials. Standard, European Cooperation for Space Standardization, European Space Agency: Noordwijk, NL, USA, 2008.

- AGARD. Structural Assessment of Solid Propellant Grains; Technical Report AGARD-AR-350; AGARD Advisory Report: Neuilly sur Seine, France, 1997. [Google Scholar]

- Yıldırım, H.; Özüpek, Ş. Structural assessment of a solid propellant rocket motor: Effects of aging and damage. Aerosp. Sci. Technol. 2011, 15, 635–641. [Google Scholar] [CrossRef]

- Naikwadi, A.T.; Sharma, B.K.; Bhatt, K.D.; Mahanwar, P.A. Gamma radiation processed polymeric materials for high performance applications: A review. Front. Chem. 2022, 10, 837111. [Google Scholar] [CrossRef] [PubMed]

- Perera, R.; Albano, C.; Gonzalez, J.; Silva, P.; Ichazo, M. The effect of gamma radiation on the properties of polypropylene blends with styrene–butadiene–styrene copolymers. Polym. Degrad. Stab. 2004, 85, 741–750. [Google Scholar] [CrossRef]

- Shulman, H.; Ginell, W. Nuclear and space radiation effects on materials. NASA SP-8053. 1 June 1970. [Google Scholar]

- Hyla, M.; Filipecki, J.; Świątek, J.; Mervinskii, R. Gamma irradiation effects on UV-cured polymers based on acrylate oligomers studied by positron annihilation lifetime spectroscopy. J. Non-Cryst. Solids 2005, 351, 1473–1476. [Google Scholar] [CrossRef]

- Emerson, J.F.; Abbaszadeh, Y.; Lo, J.N.; Tsinas, Z.; Pettersson, J.; Ward, P.; Al-Sheikhly, M.I. Sterilizing photocurable materials by irradiation: Preserving UV-curing properties of photopolymers following E-beam, gamma, or X-ray exposure. J. Mater. Sci. Mater. Med. 2017, 28, 185. [Google Scholar] [CrossRef]

- Gardner, R.E. Effects of Ionizing Radiation on Solid Rocket Motor Components. ARS J. 1962, 32, 1050–1053. [Google Scholar] [CrossRef]

- Palopoli, S.; Katz, J.; Mcgrath, D. Europa Clipper Lander Solid Propulsion Retro Motor. In Proceedings of the AIAA Propulsion and Energy Forum (No. MSFC-E-DAA-TN70778), Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Dedgaonkar, V.; Navle, P.; Shrotri, P. Effect of gamma radiation on hydroxyl terminated polybutadiene-base elastomers loaded with ammonium perchlorate. J. Radioanal. Nucl. Chem. 1994, 187, 1–8. [Google Scholar] [CrossRef]

- Holler, M.; Mussbach, G.; Weigand, A.; Putzar, R.; Ringeisen, A.; Naumann, K.W.; Bel, F.V. Coping with space environment: Testing solid propellants for in-orbit use. Int. J. Energetic Mater. Chem. Propuls. 2023, 22, 45–66. [Google Scholar] [CrossRef]

- Quagliano, J.; Bocchio, J.; Ross, P. Mechanical and Swelling Properties of Hydroxyl-Terminated Polybutadiene-Based Polyurethane Elastomers. JOM 2019, 71, 2097–2102. [Google Scholar] [CrossRef]

- Cannaval Sbegue, L.; Villar, L. Comparative Assessment of Stabilised Polybutadiene Binder under Accelerated Ageing. J. Aerosp. Technol. Manag. 2016, 8, 122–129. [Google Scholar] [CrossRef]

- Treloar, L.G. The Physics of Rubber Elasticity; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Baccaro, S.; Cemmi, A.; Di Sarcina, I.; Ferrara, G. Gamma Irradiation Calliope Facility at ENEA-Casaccia Research Centre (Rome, Italy); ENEA Technical Report RT/2019/4/ENEA; Italian National Agency for New Technologies, Energy and Sustainable Economic Development (ENEA): Rome, Italy, 2019. [Google Scholar]

- Cemmi, A.; Di Sarcina, I.; D’Orsi, B. Gamma radiation-induced effects on paper irradiated at absorbed doses common for cultural heritage preservation. Radiat. Phys. Chem. 2023, 202, 110452. [Google Scholar] [CrossRef]

- Carcione, R.; Di Sarcina, I.; Ferrara, G.; Scifo, J.; Verna, A.; Cemmi, A.; D’Orsi, B. Optimization of Paper Characterization Procedures for Cultural Heritage; Technical Report, RT/2024/2/ENEA; Italian National Agency for New Technologies, Energy and Sustainable Economic Development (ENEA): Rome, Italy, 2024. [Google Scholar]

- Chelouche, S.; Trache, D.; Abdelaziz, A.; Tarchoun, A.F.; Bekhouche, S.; Pang, W. Enhancing accuracy in Equivalent In-Service-Time assessment for homogeneous solid propellants: A novel temperature-independent predictive model utilizing PCA of FTIR Data. FirePhysChem 2025, 5, 74–90. [Google Scholar] [CrossRef]

- Margaritis, A.; Pipintakos, G.; Jacobs, G.; Hernando, D.; Bruynen, M.; Bruurs, J.; Van den Bergh, W. Evaluating the role of recycling rate and rejuvenator on the chemo-rheological properties of reclaimed polymer-modified binders. Road Mater. Pavement Des. 2021, 22, S83–S98. [Google Scholar] [CrossRef]

- Celina, M.C.; Linde, E.; Martinez, E. Carbonyl identification and quantification uncertainties for oxidative polymer degradation. Polym. Degrad. Stab. 2021, 188, 109550. [Google Scholar] [CrossRef]

- Farhadian, A.; Tehrani, M.K.; Keshavarz, M.; Darbani, S. Raman spectroscopy combined with principle component analysis to investigate the aging of high energy materials. Laser Phys. 2017, 27, 075701. [Google Scholar] [CrossRef]

- França de Sá, S.; Ferreira, J.L.; Matos, A.S.; Macedo, R.; Ramos, A.M. A new insight into polyurethane foam deterioration–the use of Raman microscopy for the evaluation of long-term storage conditions. J. Raman Spectrosc. 2016, 47, 1494–1504. [Google Scholar] [CrossRef]

- Rossi, S.; Fedel, M.; Petrolli, S.; Deflorian, F. Accelerated weathering and chemical resistance of polyurethane powder coatings. J. Coat. Technol. Res. 2016, 13, 427–437. [Google Scholar] [CrossRef]

- Villar, L.D.; Cicaglioni, T.; Diniz, M.F.; Takahashi, M.F.K.; Rezende, L.C. Thermal aging of HTPB/IPDI-based polyurethane as a function of NCO/OH ratio. Mater. Res. 2011, 14, 372–375. [Google Scholar] [CrossRef]

- Rus, A.Z.M.; Kemp, T.J.; Clark, A.J. Degradation studies of polyurethanes based on vegetable oils. Part 1. Photodegradation. Prog. React. Kinet. Mech. 2008, 33, 363–391. [Google Scholar] [CrossRef]

- Rus, A.Z.M.; Abdullah, N.M. Deterioration rate of renewable polyurethanes composites prior to ultra violet irradiation exposure. Compos. Part B Eng. 2019, 172, 750–759. [Google Scholar] [CrossRef]

- De Carvalho, C.L.; Silveira, A.F.; Rosa, D.d.S. A study of the controlled degradation of polypropylene containing pro-oxidant agents. SpringerPlus 2013, 2, 623. [Google Scholar] [CrossRef]

- Żuchowska, D.; Zagórski, Z.P.; Przybytniak, G.K.; Rafalski, A. Influence of butadiene/styrene copolymers on the modification of polypropylene in electron beam irradiation. Int. J. Polym. Mater. 2003, 52, 335–344. [Google Scholar] [CrossRef]

- Cardona, F.; Hill, D.J.T.; Pomery, P.J.; Whittaker, A.K. A comparative study of the effects of UV-and γ-radiation on copolymers of acrylonitrile/butadiene. Polym. Int. 1999, 48, 985–992. [Google Scholar] [CrossRef]

- Gillen, K.T.; Bernstein, R.; Celina, M. Challenges of accelerated aging techniques for elastomer lifetime predictions. Rubber Chem. Technol. 2015, 88, 1–27. [Google Scholar] [CrossRef]

- Gillen, K.T.; Celina, M. Predicting polymer degradation and mechanical property changes for combined radiation-thermal aging environments. Rubber Chem. Technol. 2018, 91, 27–63. [Google Scholar] [CrossRef]

| H and Ha | PB | |

|---|---|---|

| HTPB | 79.21 | - |

| IPDI | 7.68 | - |

| DOA | 13.11 | - |

| PB | - | 84.75 |

| BAPO | - | 3.39 |

| Thiol | - | 11.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carlotti, S.; Carcione, R.; D’Orsi, B.; Lusetti, T.; Finazzi, A.; Scifo, J.; Di Sarcina, I.; Ferrari, M.; Cemmi, A.; Maggi, F. Effects of Gamma Irradiation on Solid Propellant Conventional and UV-Cured Binders. Aerospace 2025, 12, 471. https://doi.org/10.3390/aerospace12060471

Carlotti S, Carcione R, D’Orsi B, Lusetti T, Finazzi A, Scifo J, Di Sarcina I, Ferrari M, Cemmi A, Maggi F. Effects of Gamma Irradiation on Solid Propellant Conventional and UV-Cured Binders. Aerospace. 2025; 12(6):471. https://doi.org/10.3390/aerospace12060471

Chicago/Turabian StyleCarlotti, Stefania, Rocco Carcione, Beatrice D’Orsi, Tommaso Lusetti, Alessandro Finazzi, Jessica Scifo, Ilaria Di Sarcina, Matteo Ferrari, Alessia Cemmi, and Filippo Maggi. 2025. "Effects of Gamma Irradiation on Solid Propellant Conventional and UV-Cured Binders" Aerospace 12, no. 6: 471. https://doi.org/10.3390/aerospace12060471

APA StyleCarlotti, S., Carcione, R., D’Orsi, B., Lusetti, T., Finazzi, A., Scifo, J., Di Sarcina, I., Ferrari, M., Cemmi, A., & Maggi, F. (2025). Effects of Gamma Irradiation on Solid Propellant Conventional and UV-Cured Binders. Aerospace, 12(6), 471. https://doi.org/10.3390/aerospace12060471