1. Introduction

The scramjet engine is being extensively researched by many countries and research institutions for hypersonic air-breathing propulsion. Since the 1990s, many hypersonic flight demonstrators have been developed, i.e., X-43A, X-51 of the USA, HFL Kholod of Russia, and HyShot of Australia are related to the hypersonic flight test [

1]. For these hypersonic vehicles, various experimental studies are being actively conducted [

2,

3,

4,

5,

6,

7,

8,

9]. However, there are still numerous technical challenges. Among the numerous technical challenges associated with scramjet engines, the primary challenges include achieving reliable ignition methods, improving mixing efficiency, and stabilizing combustion in supersonic flow. As a key feature of hypersonic vehicles and scramjet engines, they intake air at supersonic speeds to achieve hypersonic flight. The residence time of the flow inside combustor for scramjet vehicles flying at Mach 5 or above is approximately 1 ms. On the other hand, the chemical reaction time varies from 10

−10 to 1 s depending on the flow temperature, pressure, and mixture composition [

10]. Moreover, in scramjet aircraft flying at relatively low speeds around Mach 5–8, the low stagnation temperature at the combustor inlet can induce unstable ignition. Therefore, the reliable ignition method and flame stabilization are very important issues. Also, as scramjet research advances, phenomena related to combustion instability and oscillations in the supersonic combustor have been observed.

Choi et al. analyzed vibrations occurring in a shear layer of fuel flow and dynamic characteristics of the combustor through computational analysis using the Hyshot test model [

11,

12]. Jeong et al. numerically investigated a laboratory-scale scramjet combustor using gaseous hydrogen as fuel. In this study, it was emphasized that not only the local oscillation but also the fully coupled flow/combustion dynamics directly influence low-frequency combustion instability [

13]. Nakaya et al. experimentally studied a Mach 2 model scramjet combustor using ethylene/methane as fuel. They conducted POD and DMD analyses on CH* chemiluminescence images, investigating the influence of equivalence ratio and stagnation temperature on combustion mode. Through this, they captured the frequencies and dominant peaks occurring in the combustor [

2]. Lee et al. experimentally investigated the flame dynamics in a cavity-stabilized scramjet model using a staged fuel injection scheme. In a scramjet combustor with an inlet Mach number of 2.2, a high-amplitude response at 50 Hz occurred at the thermal choking limit [

14]. Ma et al. investigated thermoacoustic instability through numerical analysis based on a scramjet model conducted at the Air Force Research Laboratory, reproducing observed flow oscillations. They confirmed that flow oscillations occurred due to acoustic–convective interactions between the fuel injector and the flame region [

15]. These studies show the various phenomena of instability in a scramjet engine. Also, many researchers are researching various methods to solve these problems. Liu et al. understood that achieving sufficient mixing and initiating chemical chain reactions to overcome activation energy are essential for efficient combustion in supersonic flows [

16]. In this respect, they categorized the recent technologies into four categories: (1) improved flow mixing through turbulence generation, such as vortex generators; (2) methods of physical flame holding, such as using a cavity; (3) methods of energetic enhancements, such as spark and plasma discharge; and (4) shock-induced combustion in scramjet engines. Some of these methods can be further classified into passive and active methods. As a passive method, it involves constructing structures such as cavities, struts, etc. Also, pulse jet, pulse detonation, electrical (plasma) discharge, and air-throttling schemes are widely known as active methods [

17,

18,

19]. Within passive methods, a cavity has recently been considered not only for flame holders but also as a potential acoustic driver device, generating acoustic waves [

20]. The cavity necessitates no active control and remains indirectly exposed to the flow, courtesy of its recessed structure. Furthermore, its rigidity under given conditions makes it suitable for enhancing combustion in supersonic flow. However, it is crucial to apply a suitable design, considering that the acoustic frequency varies depending on the geometry and conditions.

In the case of active methods, most of them require additional control. Flow blockage and pulse jet techniques can slightly increase residence time but require significant gas flow. In the case of electrical (plasma) discharge, this device can provide high temperature and radical, but they need a large electrical energy. To generate significant electrical energy, batteries or additional devices are necessary, making it a disadvantageous method for aircraft. Therefore, if additional fuel is available, it may be efficient to use fuel chemical energy. Therefore, considering the pulse detonation (PD) method using the same fuel as scramjet engines is an option.

Many studies have been conducted at the U.S. Air Force Research Laboratory to utilize pulse detonators for scramjet engines. Some of their research reported that pulse detonators significantly disrupted the supersonic flow. When the PD ignited inside the cavity, it was reported that the fuel flow into the cavity decreased due to the high-pressure PD exhaust [

21]. On the other hand, they investigated the enhanced mixing and conditioning when PD and transverse jet were applied in the cross flow at Mach 2 [

22,

23]. In this study, the high momentum flux of the PD pulses interacted with the jet exhaust, forming a large barrel shock structure. The distribution of the upstream injectant and the temperature rise due to the PD plume could provide significant conditioning of the flow. Therefore, they assessed the potential to control combustion efficiency more effectively. The research aiming to utilize PD within supersonic combustors continued, and references can be found for more information [

24,

25,

26].

In this study, the goal was to impose active excitation on the supersonic flow field through the low-frequency operation of a micro-pulse detonation engine (μPDE). The study involves periodically applying active excitation to the supersonic combustor by integrating both passive methods (cavity) and active methods (pulse detonation). For this, μPDE with a diameter of 4.22 mm, operating at a frequency of 10, 20 Hz, was developed. This device was attached to the Puan National University direct-connect scramjet combustor and the combustion experiment was conducted. Combustion and flow phenomena were investigated with high-speed camera images of the Schlieren method and wall pressure profiles.

2. Experimental Apparatus

2.1. Direct-Connect Scramjet Combustor Configuration

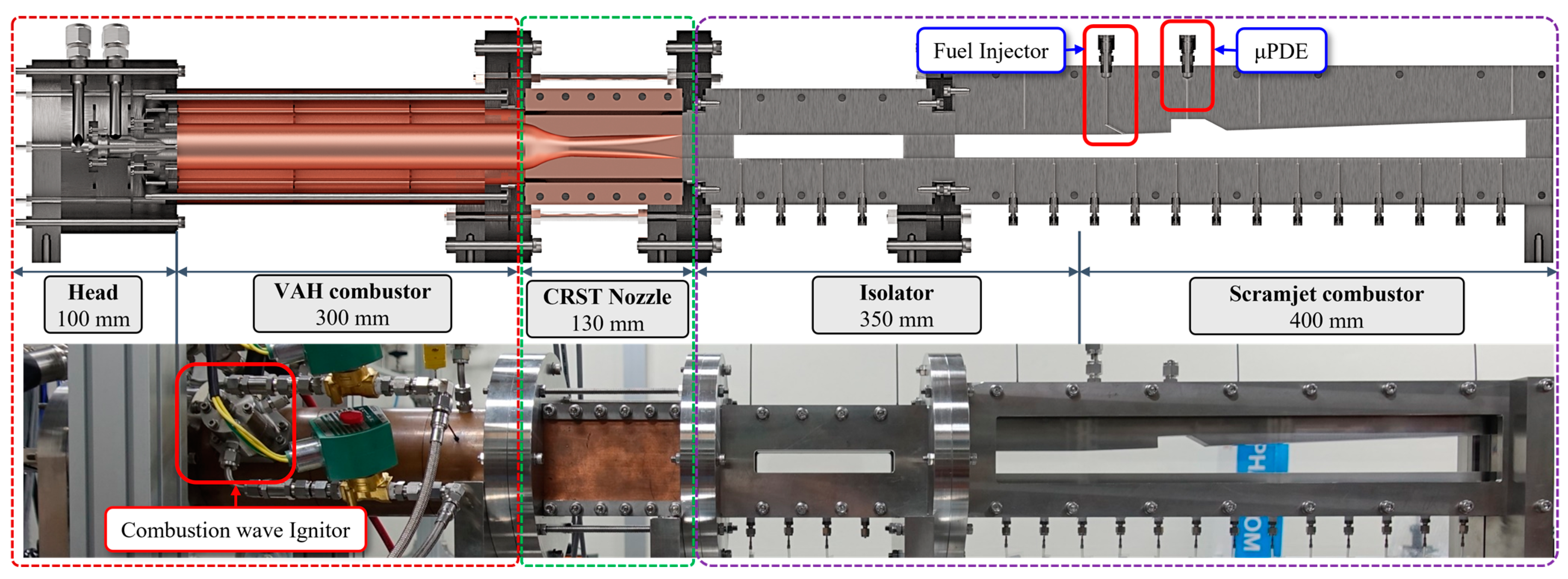

A direct-connect scramjet combustor of Pusan National University (PNU-DCSC) has been constructed for supersonic combustion experiments, and it is shown in

Figure 1. This device is composed of a total of four sections, i.e., vitiation air heater (VAH), circular to rectangular (CRST) nozzle [

27], isolator, and scramjet combustor.

The VAH consisted of a combustion chamber with a diameter of 40 mm and utilized hydrogen, oxygen, and air to generate high-enthalpy vitiated air. Gaseous hydrogen and oxygen were supplied from the central coaxial injector of the VAH, and air was supplied at a position adjacent to the wall for film cooling. During combustion, vitiated air at a pressure of 1.68 MPa and a total temperature of 1600 K was generated and supplied to the entrance of the CRST nozzle. The operating flow rates of the VAH are 5.68 g/s for hydrogen, 69 g/s for oxygen, and 293 g/s for air. The chemical composition after combustion is presented in

Table 1.

The CRST nozzle is a type of nozzle that transitions from a circular inlet to a rectangular outlet with a height and width of 20 mm. It was designed to achieve a uniform flow at Mach 2 at the outlet. The exit static temperature of the nozzle was 1000 K. The VAH and CRST nozzles were designed and validated through analysis and experiments by previous researchers [

27,

28]. The isolator had a cross-section with the same height and width of 20 mm as the exit of the CRST nozzle, and its length was 350 mm. The scramjet combustor was 400 mm in length and had an expansion angle of 2°. The geometry of the isolator and scramjet combustor used in this study is presented in

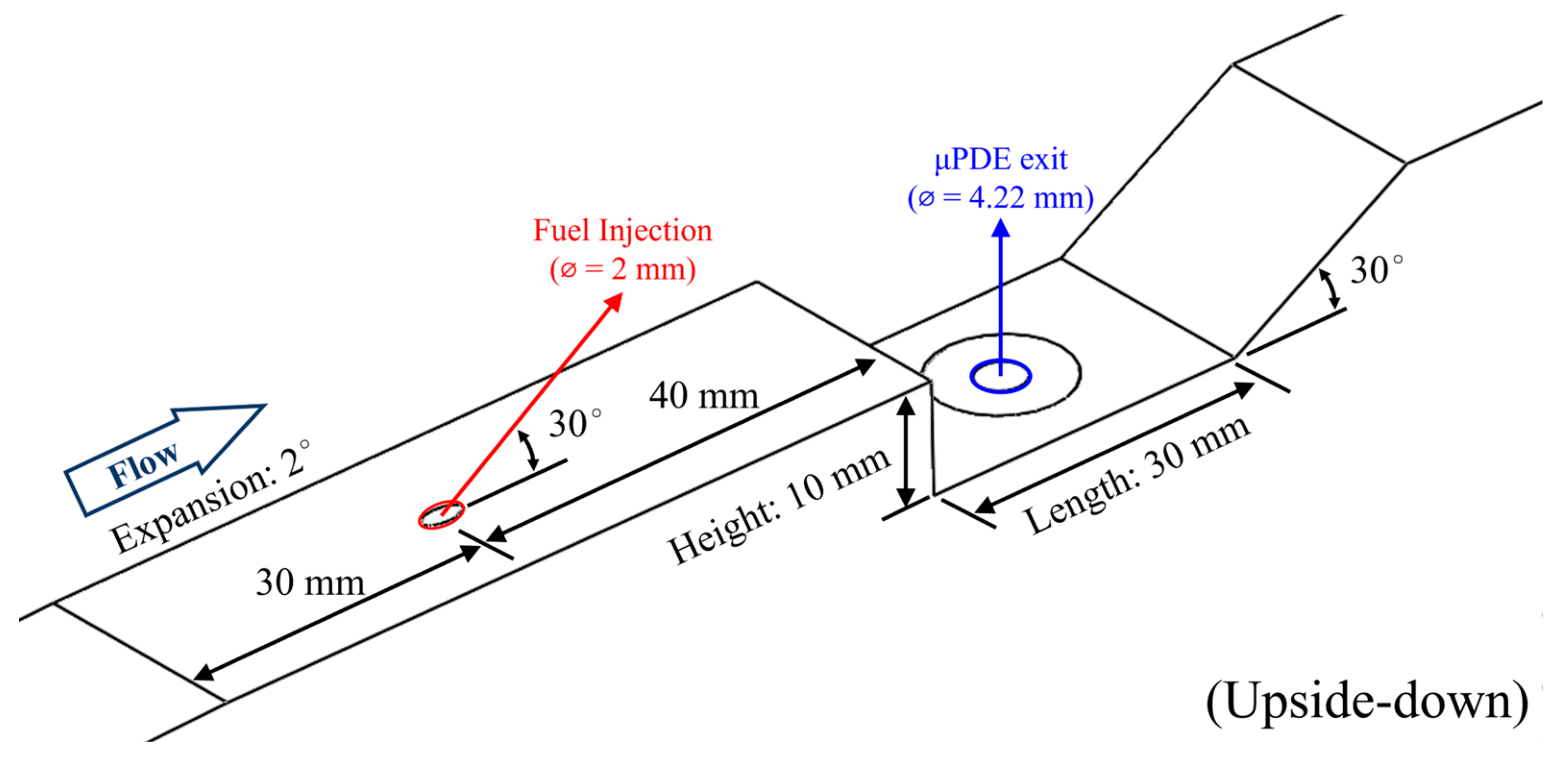

Figure 2.

The fuel injector of the scramjet combustor is located 30 mm from the entrance of the scramjet combustor. The injector supplies gaseous hydrogen fuel at an angle of 30° from the combustor upper wall, and the cross-sectional diameter of the injector is 2 mm. Generally, a transverse jet injection method which can interact with the freestream to form a strong bow shock is preferred. The induced strong bow shock creates a back pressure gradient and forms a high-pressure recirculation zone. However, transverse injectors cause a total pressure loss due to the strong bow shock. To alleviate this, the present study adopts an inclined injection method. The inclined injection method can increase the axial momentum of the fuel jet, contributing to improving thrust efficiency [

29,

30,

31,

32,

33,

34,

35]. The cavity is located 70 mm from the entrance of the scramjet combustor, and the specific geometry of the cavity is presented in

Figure 3. The depth of the cavity is 10 mm, and the bottom wall length is 30 mm. The trailing edge of the cavity has a ramp angle of 30°. Due to the ramp angle, the length to depth ratio (L/D) of the cavity is 3.86. This corresponds to the shape of an open cavity [

36]. The exit of the μPDE is located at the center of the cavity’s bottom wall and is installed perpendicular to the flow direction of the scramjet combustor. The detailed configuration of the μPDE will be described in

Section 2.2. On the bottom wall surfaces of the isolator and scramjet combustor, there are 16 pressure sensor ports positioned to measure pressure at various locations. The positions of each channel are indicated with numbers 1–16 in

Figure 2.

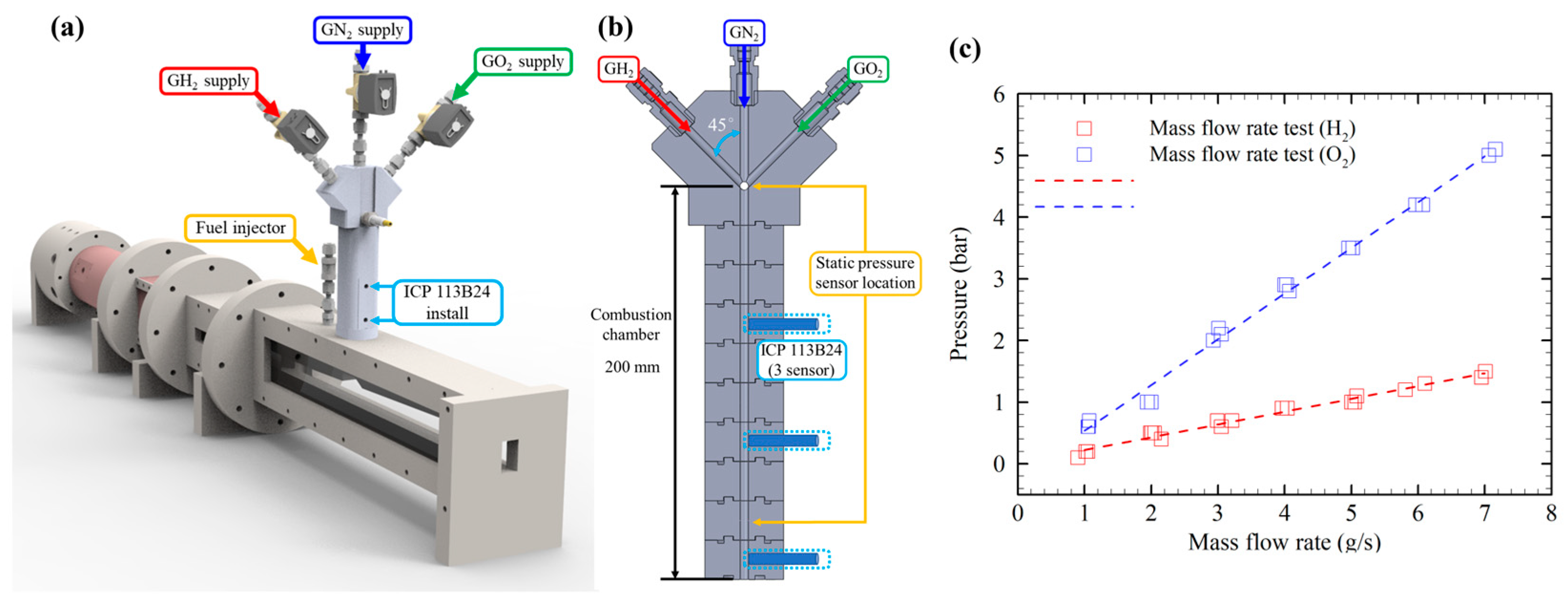

2.2. Micro-Pulse Detonation Engine (μPDE) Configuration

A preliminary test on μPDE was conducted in a separate device to demonstrate its operability. The configuration of μPDE and the shape integrated with the scramjet combustor and μPDE are the same as in

Figure 4. Referring to the previous research results [

37], the combustion chamber diameter of μPDE was adopted as 4.22 mm, which is equivalent to a commercial 1/4-inch pipe inner diameter. To conduct experiments on various shapes of μPDE, μPDE can be assembled using a module measuring 40 × 40 × 20 mm in size. In this study, the combustion chamber length of the μPDE was configured as 200 mm. Gaseous hydrogen and oxygen were utilized as fuel and oxidizer, respectively, while gaseous nitrogen was utilized as purge gas. Hydrogen, oxygen, and nitrogen were all supplied at room temperature. Due to various advantages of hydrogen fuel, there is a high possibility of using hydrogen fuel in scramjet engines [

38], and hydrogen has been adopted as the fuel for μPDE to enable it to use the same fuel as the aircraft. However, since hydrogen and oxygen reactions produce H

2O steam, a small amount of purge gas is used to ensure μPDE operation. Additionally, for enhancement of mixing in the μPDE, hydrogen and oxygen are supplied at a 45° angle from the combustion chamber. In contrast, nitrogen gas is supplied parallel to the combustion chamber for an efficient purge process.

The μPDE utilizes low mass flow rates, making it difficult to use mass flow meters due to the short duration of experiments within a second. Therefore, mass flow rates are measured based on supplied pressure through cold flow experiments, and these results are presented in

Figure 4c. These results were obtained by measuring the weight difference of a 3.4 L cylinder before and after the cold flow experiments.

To ensure stable μPDE operation, preliminary combustion tests were conducted at various equivalence ratios using a separate ground-based facility. With hydrogen supplied at 6 bar and oxygen at 7 bar, stable ignition was achieved, and the detonation velocity was successfully measured. At this supply condition, the equivalence ratio was 2.0, and the details are presented in

Table 2. Extensive research has also been conducted on the operating sequence of the μPDE, and the most stable sequence is presented in

Table 3. Due to the difficulty in presenting results for all conditions,

Table 4 includes the maximum, minimum, and average detonation velocities observed during frequency combustion tests.

To understand the physical phenomena at the exit of the μPDE, Schlieren imaging was conducted concurrently. Both 10 Hz and 20 Hz operating frequencies were tested, and Schlieren snapshots were presented in

Figure 5.

In these images, fresh mixture and hot product gas can be clearly distinguished due to the difference in density gradients caused by chemical composition. The supply of the mixture into the μPDE initiates (1), followed by the propagation of detonation from the exit into the atmosphere after ignition (2). Detonation appears coupled at the exit, but it can be observed that detonation separates within a very short time (2–3). Subsequently, hot product gas continues to be expelled (4). Once the purge process is completed, the expulsion of hot product gas also finishes (5), and the remaining residual gas is discharged (6). Based on these experimental results, the purge process of the μPDE is crucial. If the purge process is omitted, the high-temperature products and H2O steam may interfere with the next cycle, making it difficult to perform the pulse detonation process. In this study, the purge process was conducted using minimal nitrogen gas. After all ground tests were concluded, the μPDE was integrated into the scramjet combustor.

2.3. Setup of Gas Supply, Measurement, and Control System

A schematic diagram of the gas supply system used in this study has been illustrated in

Figure 6. Gas is supplied from an external gas facility to the internal test facility. The external gas facility consists of 25 cylinders of 40 L capacity for air; 6 cylinders of 47 L capacity for hydrogen; 5 cylinders of 40 L capacity for oxygen; and 4 cylinders of 40 L capacity for nitrogen. One nitrogen cylinder is supplied to the ProportionAir Inc.’s electronic regulator (McCordsville, IN, USA, GX series), which controls the Swagelok Inc.’s dome regulator (Solon, OH, USA, RDHN series). The dome regulator controls the pressure downstream and supplies it to the scramjet experimental device. Mass flow rate is measured using a mass flow meter from Enbac Inc.’s FM153 series (Daejeon, Republic of Korea).

For measurement and control purposes, National Instruments’ compactRIO chassis (Austin, TX, USA) is being utilized. The necessary modules for control and measurement were selected and used with the cRIO-9045, as listed in

Table 5. For synchronization of the experiment start times for high-speed cameras and oscilloscopes, the NI 9401 module, which is capable of TTL signal output, is also being used. Additional experimental equipment used besides NI equipment has been summarized in

Table 6.

To measure the detonation velocity of the μPDE, a combination of Yokogawa’s oscilloscope (Tokyo, Japan) and PCB’s 113B24 ICP dynamic pressure sensor (Depew, NY, USA) was used. Detonation phenomena were captured through high-speed sample rates, and the detonation velocity was measured based on time differences according to position. To visualize the flow in the scramjet combustor, the Schlieren equipment was introduced. It was configured with a Z-type Schlieren system (KOMI Inc., Suwon, Republic of Korea), and a high-speed camera, the Phantom v2512 (Wayne, NJ, USA), was utilized. The Schlieren image was recorded using a high-speed camera with a sample rate of 110,000 fps and an acquisition resolution of 1024 × 208. All experiments were recorded with the same settings.

3. Results and Discussion

During experiments conducted in the scramjet combustor, four cases have been summarized in

Table 7. Single ignition experiments were also conducted for comparison with the active excitation results, and the results will be presented together. Due to the low static temperature of the flow entering the isolator, it is difficult for hydrogen fuel to auto-ignite. Therefore, the scramjet combustor was ignited using a single operation of μPDE (single shot sequence).

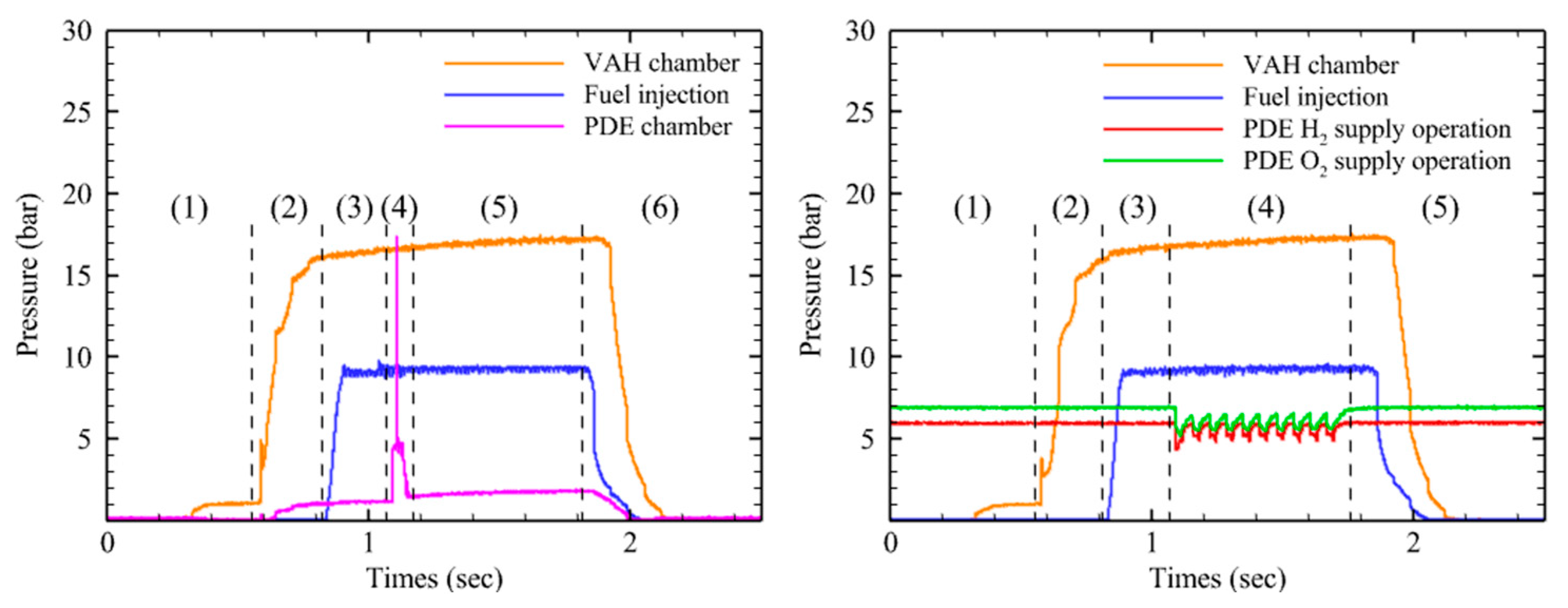

The sequence of single-shot ignition and active excitation is depicted in

Figure 7. The ignition process through a single shot is as follows: Gaseous hydrogen and oxygen are supplied into the VAH (1). Pressure increases due to VAH ignition, and air is supplied within the VAH (2). Hydrogen fuel injection begins into the scramjet combustor (3). Single operation of μPDE and ignition of the scramjet combustor (4). The experiment is conducted for one second (5). The valve closes and the experiment ends (6). The process of the active excitation experiment is as follows: Gaseous hydrogen and oxygen are supplied into the VAH (1). Pressure increases due to VAH ignition, and air is supplied within the VAH (2). Hydrogen fuel injection begins into the scramjet combustor (3). Through the operation of the μPDE at 10–20 Hz, the scramjet combustor is ignited, and the combustor active excitation experiment is conducted (4). The valve closes and the experiment ends (5).

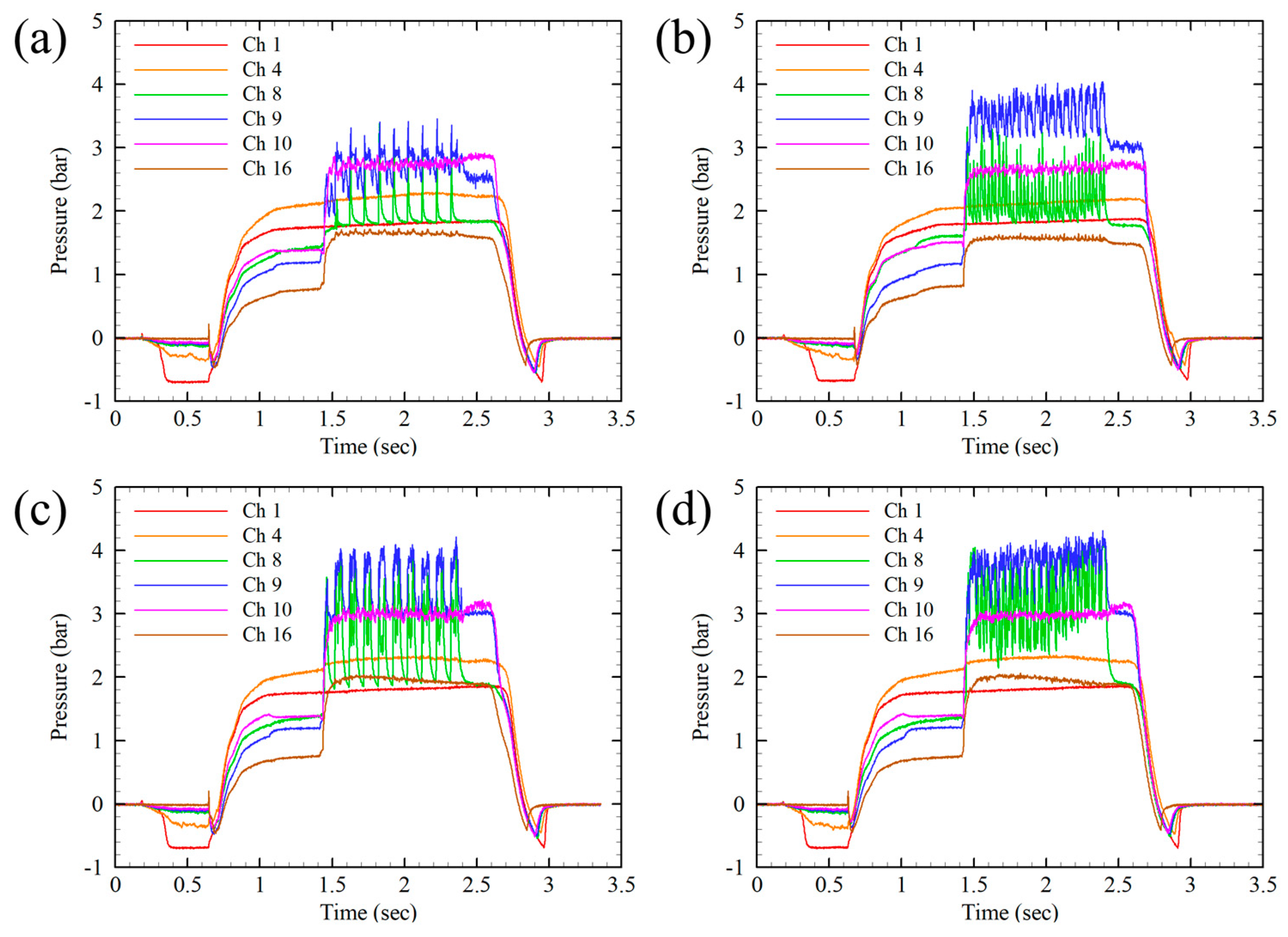

The results of the bottom wall pressure variations according to the experiment time for each case are summarized in

Figure 8. It is important to note that the μPDE exit is located at the center of the cavity on the upper wall, while the ports of the pressure scanner are positioned on the bottom wall. With a sampling speed of 500 Hz, the pressure scanner may not directly measure the detonation but is sufficient for capturing pressure changes.

Figure 8 shows that the pressure excitation effect was effectively transmitted to the bottom wall at the operation frequency of the μPDE. Notably, channel 8 is located just below the cavity leading edge, and channel 9 is situated below the cavity trailing edge. In both channels, it can be observed that the pressure repeatedly rises and falls with the operation of the μPDE. The analysis of Schlieren snapshots to examine the effects of active excitation through μPDE will be detailed in

Section 3.2 and

Section 3.3. The discussion on the pressure change according to the position of the pressure scanner’s ports will be presented in

Section 3.4.

3.1. Scramjet Combustor Ignition Process

In the active excitation sequence, the μPDE was operated directly without combustor ignition. In this way, the scramjet combustor was ignited by the first detonation wave of the μPDE operation. Therefore, it is necessary to verify whether the combustor was ignited stably during the initial detonation of μPDE.

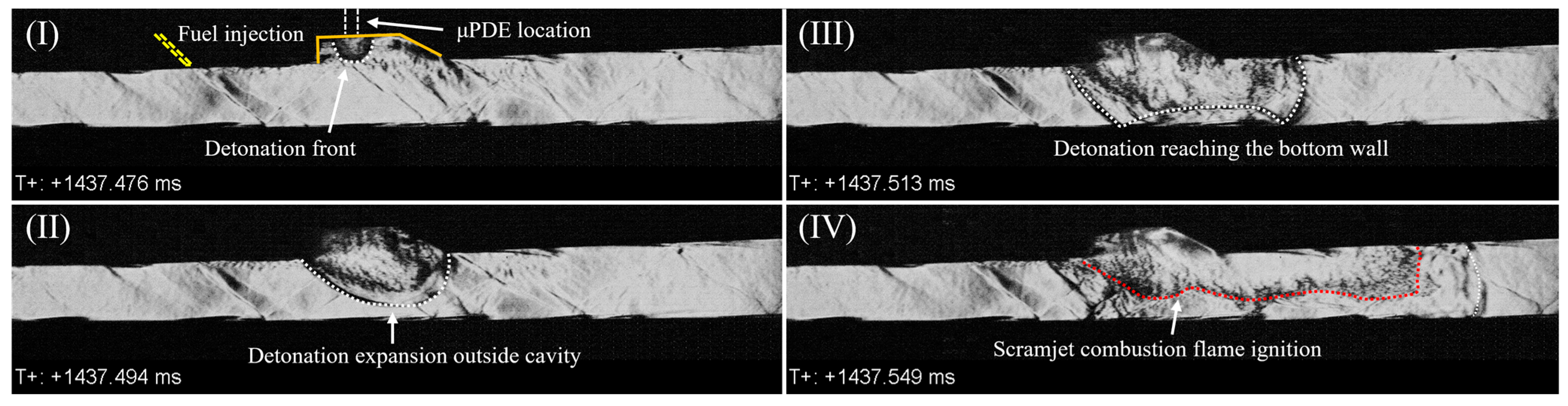

Figure 9 sequentially displays a Schlieren snapshot of the initial detonation wave igniting the scramjet combustor during μPDE operation at 10 Hz. The Roman numeral labels shown in the figure indicate the sequence.

The detonation wave propagates from the center of the cavity to the scramjet combustor (I), and the detonation wave successfully propagates to the bottom wall surfaces (II and III). Subsequently, the detonation wave propagated to the upstream and downstream of the combustor (III), and the combustor was ignited stably (IV). In previous studies, successful ignition was also ensured using μPDE. The ignition process of the scramjet combustor through a single shot is the same as the ignition process in

Figure 9.

3.2. Acitve Excitation Result at Equivalence Ratio 0.111

In order to compare the cases with and without μPDE active excitation, a snapshot of the Schlieren without active excitation was added as

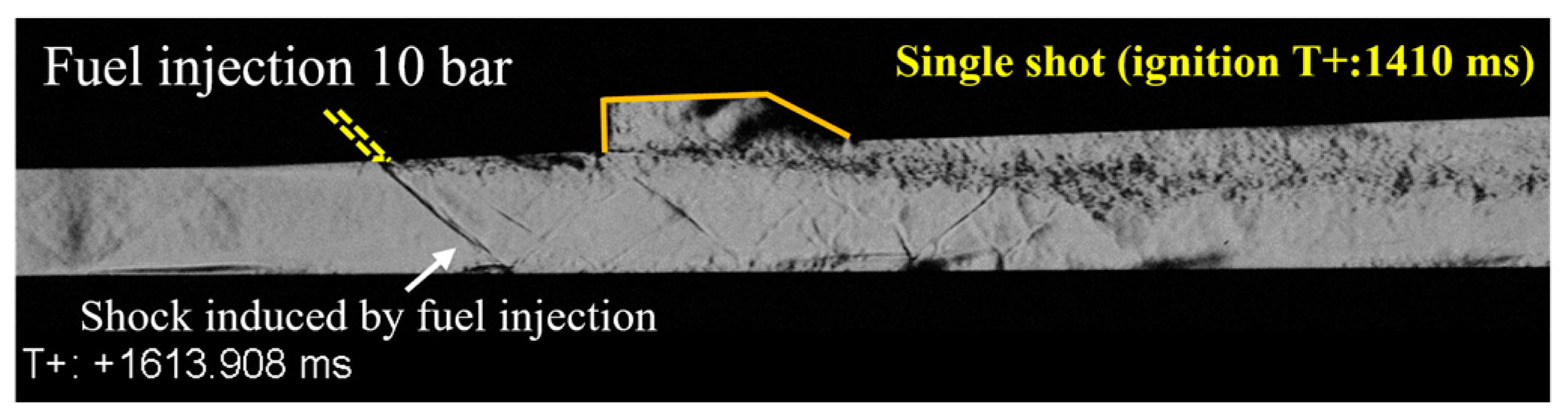

Figure 10. Fuel was injected at a constant pressure of 10 bar, and the equivalence ratio was calculated to be 0.108. The labeled ‘single shot’ represents the sequence where the PNU-DCSC was activated, followed by a single ignition of the μPDE after 1410 ms, which ignited the scramjet combustor. The test duration for the scramjet combustor ranged from 1.4 to 2.4 s, totaling 1 s. In the absence of active excitation, shock waves generated by the fuel injection and weak oblique shocks originating from the cavity leading edge were observed. The flame was stabilized in the cavity shear layer flame.

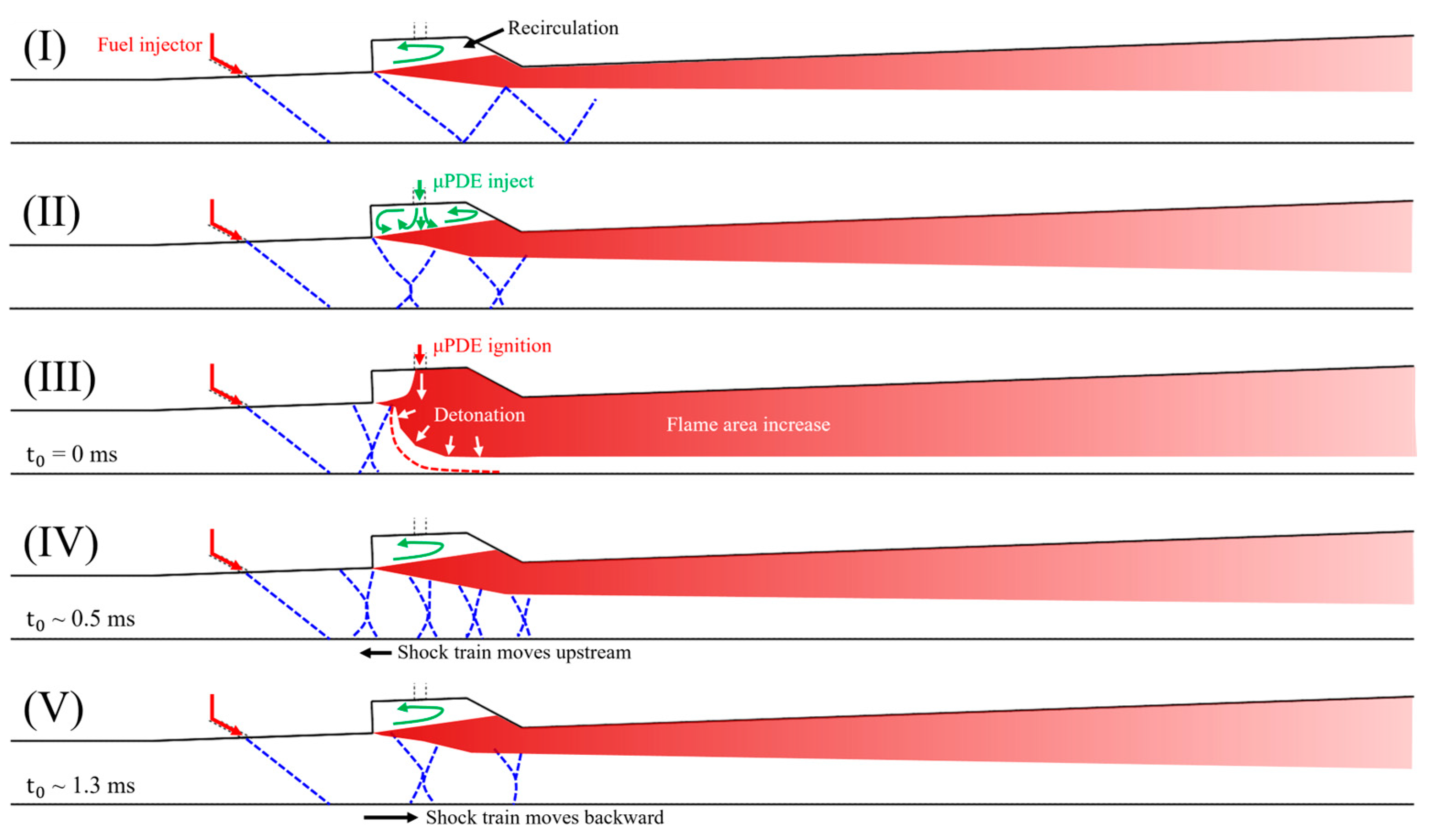

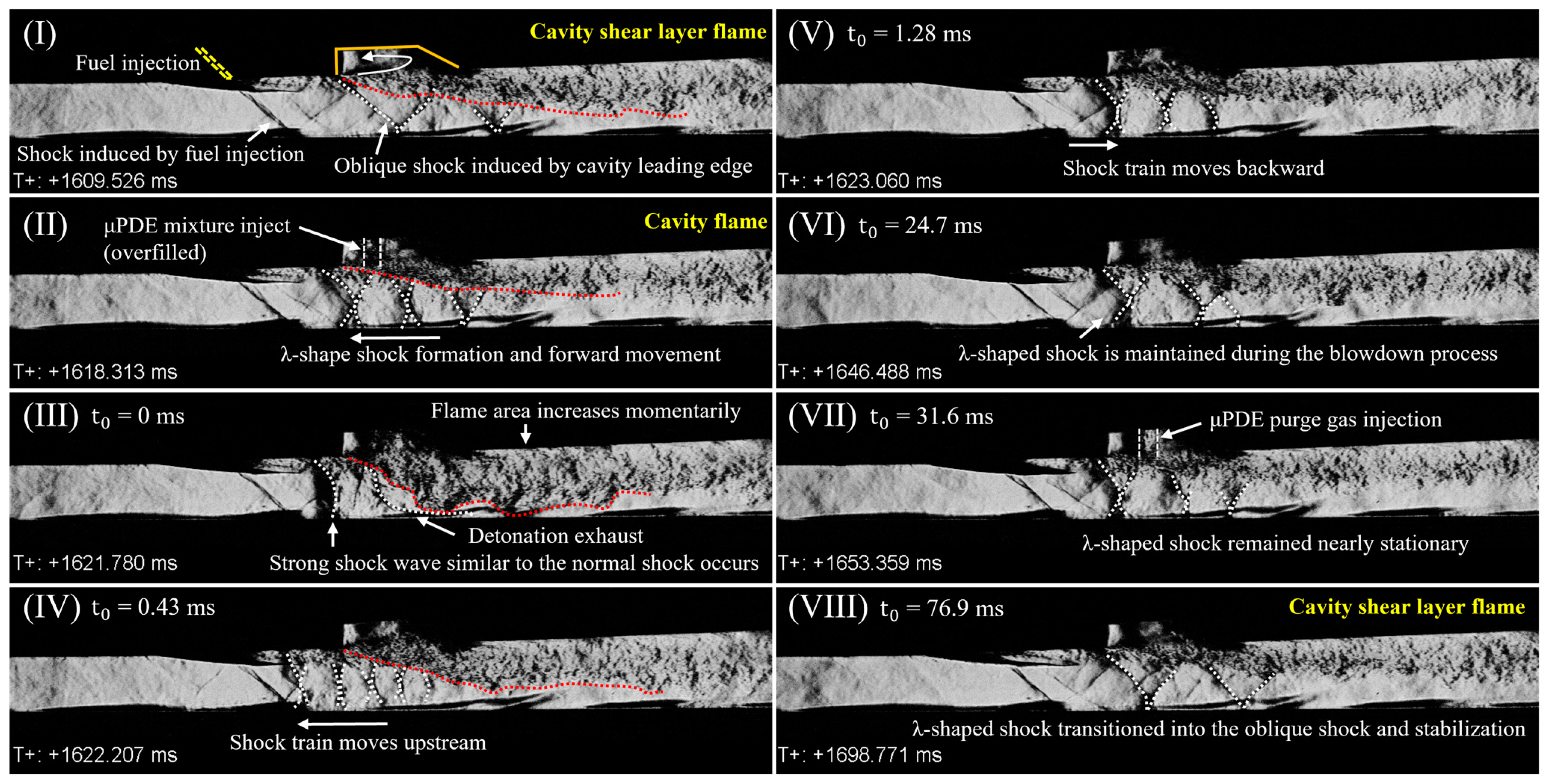

The Schlieren snapshots of case 1 and case 2 were depicted in

Figure 11 and

Figure 12, respectively. During active excitation, the flow changes before and after μPDE operation for one cycle were sequentially presented. In the Schlieren snapshots, the red dotted line indicates the flame area, and the white dotted line indicates the shockwave structure. Since the flow changes during active excitation at 10 Hz and 20 Hz are similar, figures are attached together. The schematics of the results are also included in

Figure 13. The time points (I)~(V) in the schematics are identical to the time points (I)~(V) in the Schlieren snapshots. The position of the oblique shock or shock train can be identified through

Figure 13. Before the operation of the μPDE, the flame was stabilized in the cavity shear layer flame. During this phase, the shock wave generated by fuel injection and weak oblique shock generated from the cavity leading edge were observed (I). Gaseous hydrogen and oxygen were supplied to the μPDE. The μPDE was overfilled with the mixture, resulting in the injection of the mixture into the scramjet combustor. During separate ground μPDE combustion tests, stable detonation propagation was observed in the overfilled state. Therefore, the μPDE operated in an overfilled state in all cases. Additionally, previous research results indicate that strongly coupled detonation in the overfilled state can induce significant OH emissions into the cavity step region of the scramjet combustor [

26]. The mixture flowing out from the μPDE led to additional combustion, developing into a cavity flame. During this process, the local equivalence ratio near the cavity increased to 0.222 ± 0.009. The additional heat addition caused the oblique shock wave to transform into a λ-shaped shock, moving forward and forming a shock train (II). Upon ignition of the μPDE, the detonation was formed in the μPDE chamber tube through the deflagration to detonation transition (DDT) process and propagated into the interior of the scramjet combustor. This process was designated as t

0 to denote the time difference with the following process. The detonation expanded, and the flame area spread to the bottom wall in a very short time (III). Immediately after the detonation expansion, the lead of the shock train moved slightly upstream of the cavity leading edge. The formation of the shock train indicates the occurrence of thermal choking over a very short period (IV). After t

0 = 1.1~1.7 ms, the shock train moved backward (V). During the blowdown process of the μPDE, the λ-shaped shock transitioned into oblique shock waves. The flame transitioned into a cavity shear layer flame (VI). During the purge process, nitrogen gas was injected from the exit of the μPDE. Only 0.057 g of nitrogen was injected over 10 ms, not affecting the chemical composition. The oblique shock waves formed from the cavity leading edge remained nearly stationary (VII).

Figure 11 (VII) shows a slight change in the shock structure during the purge process, but it was a transient phenomenon. After the purge process ended, the supersonic flow field stabilized back to the condition before the operation of the μPDE (VIII).

When comparing the single shot case in

Figure 10 with the active excitation cases in

Figure 11(I) and

Figure 12(I), it is observable that the supersonic flow field is slightly different even before the ignition of the μPDE. In

Figure 10, the density gradient of the oblique shock wave induced from the cavity leading edge appears faint. However, in cases with active excitation, the density gradient of the oblique shock wave is stronger. This indicates that even before the operation of the μPDE, the flow field near the cavity is influenced, leading to an increase in the strength of the oblique shock waves. This phenomenon indicates that the pressure near the cavity has increased compared to when active excitation was not performed, indicating additional combustion is occurring. Additionally, when comparing cases 1 and 2, the position and movement of the shock waves are mostly similar, but the intensity of the shock waves is stronger with 20 Hz active excitation. This phenomenon appears to be a result of the increased number of excitations leading to a slight increase in the amount of heat released.

3.3. Acitve Excitation Result at Equivalence Ratio 0.163

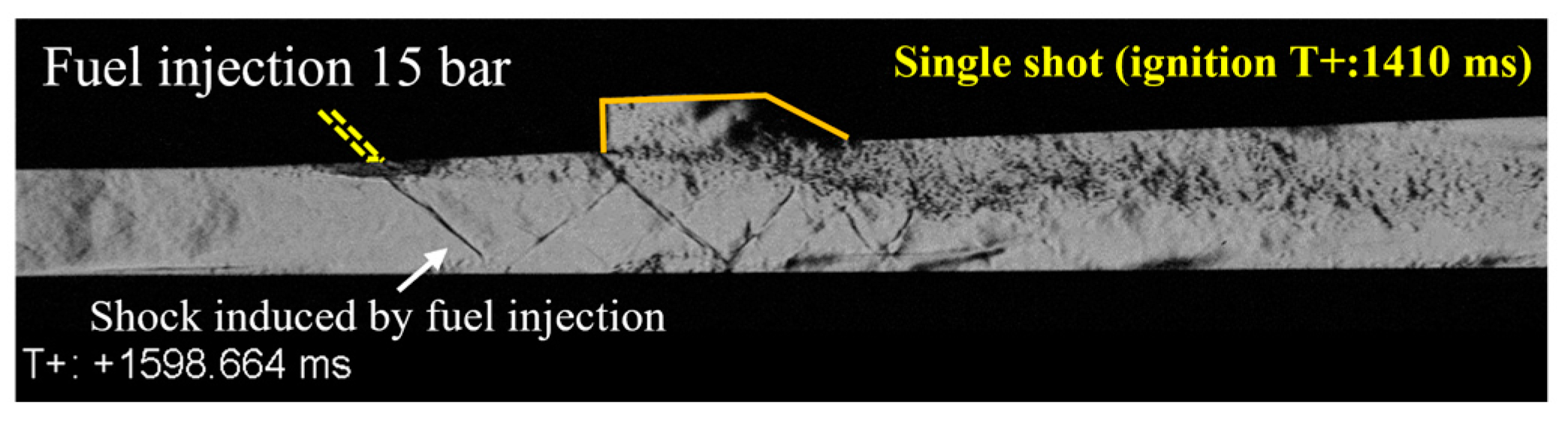

In the case without active excitation at a fuel injection pressure of 15 bar, depicted in

Figure 14, the equivalence ratio was calculated to be 0.168. Unlike

Figure 10, the oblique shock wave induced from the cavity leading edge was clearly observed. The flame was stabilized as a cavity shear layer flame.

The Schlieren snapshot results for cases 3 and 4 are depicted in

Figure 15 and

Figure 16, respectively. The schematics of the results are also included in

Figure 17. The processes (I) through (VIII) are identical to those in case 1 and case 2. Additionally, in the Schlieren snapshots, the red dotted line shows the flame area, and the white dotted line shows the shockwave structure. The time points (I)–(V) in the schematics match those in the Schlieren snapshots. Before the operation of the μPDE, in case 3, the flame was stabilized in the cavity shear layer flame. In case 4, both the cavity flame and the cavity shear layer flame appear together. The distinction between case 3 and case 4 is that, in case 3, oblique shock waves were observed, whereas in case 4, a weak λ-shaped shock was formed (I). Gaseous hydrogen and oxygen were supplied to the μPDE. Similarly, due to the overfilled state, the mixture was also injected into the interior of the scramjet combustor. With the addition of the mixture, the flame area spread, and the flame developed into a cavity flame. During this process, the local equivalence ratio near the cavity increased up to 0.276 ± 0.006. An oblique shock wave was not observed, and a shock train composed of λ-shaped shocks was formed and moved forward (II). After the ignition of the μPDE, a detonation propagated into the interior of the scramjet combustor, instantly reaching the bottom wall. This moment was designated as t

0. Due to the detonation expansion, a strong shock resembling a normal shock was momentarily formed in front of the cavity (III). Immediately after the detonation expansion, the lead of the shock train moved much further upstream compared to cases 1 and 2, but it did not reach the fuel injector (IV). After t

0 = 1.23~1.28 ms, the shock train moved backward (V). During the blowdown process of the μPDE, the λ-shape and position of the shock were maintained (VI). The structure and position of the shock were also maintained during the purge process (VII). After the purge process, in case 3, the shock transitioned into the form of oblique shock waves. In case 3, the flame transitioned into a cavity shear layer flame. In case 4, only a slight adjustment in the position of the shock occurred, maintaining its λ-shaped form (VIII).

Compared to cases 1 and 2, the shock intensity in cases 3 and 4 increased. Additionally, after the operation of the μPDE, the time for the shock to transition back to oblique shock waves lengthened in case 3, while oblique shock waves were not observed in case 4. The structure of the shock train also became more defined, suggesting the occurrence of thermal choking. Compared to

Figure 14, where no active excitation was performed, the structure of the shock waves developed more complexly, presumably due to an increased equivalence ratio and the added heat, which further increased the pressure in the combustor.

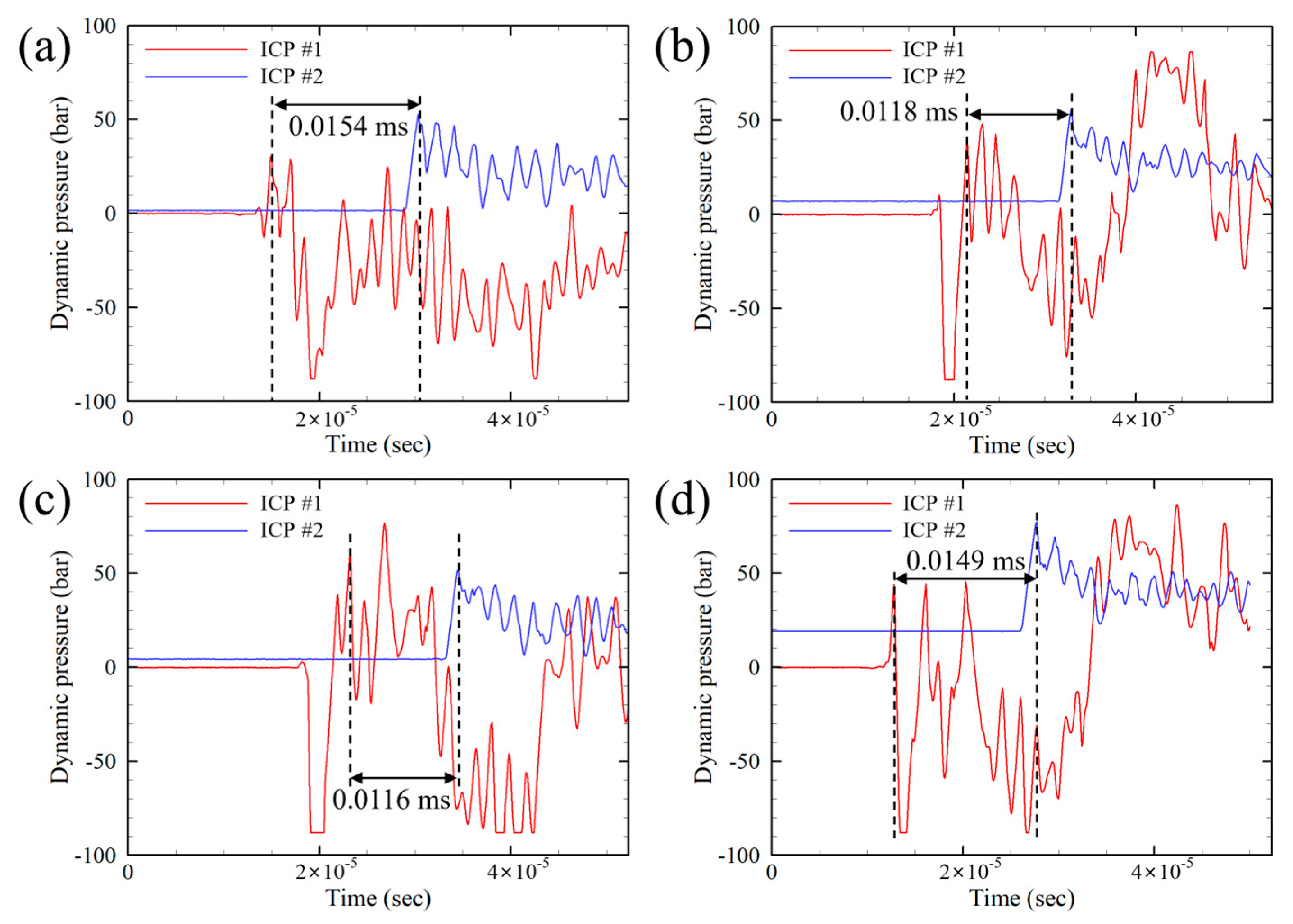

In the Schlieren snapshots of the scramjet combustor, it is challenging to observe detonation propagation due to the interaction between the supersonic crossflow and the flame. Therefore, the detonation velocity inside the μPDE was also measured. The detonation velocity measurements for the μPDE attached to the scramjet combustor were conducted using two piezoelectric pressure sensors. ICP #1 is located 80 mm from the spark plug and ICP #2 is 120 mm away. A high-speed oscilloscope was utilized to measure the detonation velocity using the difference in reaction times and the distance between the two sensors. The detonation velocity measurements for each case are as follows: 2597.4 m/s (case 1); 3389.8 m/s (case 2); 3448.3 m/s (case 3); and 2684.6 m/s (case 4). The CJ detonation velocity calculated through the NASA CEA code is 3461.9 m/s. The detonation velocity is not constant, but detonation velocity results close to the CJ detonation velocity were measured. The data in

Figure 18 support the successful propagation of detonation into the scramjet combustor.

3.4. Analysis of Bottom Wall Pressure for Each Case

The pressure history according to the port location of the pressure scanner situated on the bottom wall of the isolator and scramjet engine is depicted in

Figure 19. For comparison, the case of scramjet combustor ignition through a single operation of the μPDE is represented as a “single shot” legend. The pressures marked with blue lines indicate the pressure at points 1.6 s and 1.9 s before the μPDE operation, when the flow was stabilized. The green lines represent the pressure during the blowdown process immediately after the μPDE ignition.

In all cases, the pressure in the scramjet combustor was measured to be higher than in the single-shot case. Notably, even before the operation of the μPDE (before the mixture was injected), the combustor pressure was recorded to be high. The reason for the increased strength of the induced oblique shock wave from the cavity leading edge during active excitation can be attributed to the increase in pressure near the cavity. This phenomenon is a result of the increased pressure near the cavity, which in turn intensified the strength of the oblique shock wave. Moreover, in case 4, an oblique shock wave was not observed, and only λ-shaped shocks were maintained. On the other hand, the hydrogen fuel used for the operation of the μPDE was only consumed in amounts of 0.38 g/s for the 10 Hz operation and 0.51 g/s for the 20 Hz operation. The increase in combustor pressure observed relative to the additional hydrogen consumed by the μPDE was significantly higher. This indicates that the excitation effect by periodic detonation can induce additional combustion, leading to an improvement in combustion efficiency. Moreover, the instantaneous capture of the shock train indicates the occurrence of thermal choking, which appears to be an additional phenomenon resulting from the occurrence of additional combustion and the supply of heat. In conclusion, the high-temperature, high-pressure plume exhausted from the μPDE appears to have successfully enhanced the secondary combustion of hydrogen fuel.

Additionally, in this study, the scramjet combustor has a width of 20 mm, while the μPDE has a diameter of 4.22 mm. Therefore, it is necessary to consider a larger scramjet combustor in the future. Although further research is needed, in a scramjet combustor, if the engine size is increased, the heat addition effect of the μPDE is expected to decrease, while its effect on increasing the efficiency of the scramjet combustor is predicted to remain unchanged. This assumption can be estimated through the references. The supersonic wind tunnel facility used by the U.S. Air Force Research Laboratory can operate at a maximum mass flow rate of 15.4 kg/s, a peak stagnation pressure of 2860 kPa, and a temperature of 922 K [

22,

23]. In this reference study, the radical-rich plume from the pulse detonator likely increased the crossflow temperature, enhancing reactivity and significantly conditioning the flow field. Although this reference study only analyzed a single detonation pulse, when combined with the current results from our research group, it suggests the potential for improving the overall efficiency of larger scramjet engines by ensuring better combustion efficiency.

Previously, it was predicted that high-frequency excitation above 100 Hz would be necessary to achieve notable excitation effects. However, the effects of high-frequency active excitation using the μPDE also need to be reviewed. For thermal management and control, low-frequency operation of the μPDE may be more advantageous. In this study, instantaneous thermal choking occurred after the μPDE ignition. Additionally, the flow recovery time slowed after the μPDE operation as the equivalence ratio of the supersonic combustor increased. As a result, if the μPDE operates at high frequencies, the excessive heat addition could cause unintended transitions in combustion modes or instability. On the other hand, low-frequency operation of the μPDE can provide time for combustion stabilization, increasing combustion efficiency without significantly disrupting the supersonic flow. In this study, the low-frequency operation of the μPDE did not cause significantly destructive effects on the flow. Therefore, low-frequency operation can help improve overall combustion efficiency and maintain a stable combustion process. Utilizing these effects could substantially reduce the length and weight of future scramjet combustors.

Furthermore, based on the results of this experiment, μPDE shows potential for controlling combustion modes. The research team of Yu et al. [

39,

40] controlled the scramjet combustion modes by adjusting the number and position of fuel injectors. They intentionally distributed the heat release locations through multiple injector arrangements to control thermal choking. From the perspective of adding heat to the scramjet combustor, μPDE can supply additional heat into the combustor, which suggests that it can be used to control the combustion mode.

4. Conclusions

In this experimental study, the μPDE was developed to deliver active excitation to the scramjet combustor and was successfully integrated into the scramjet combustor. The μPDE generated and transmitted periodic detonation waves at frequencies of 10–20 Hz to the scramjet combustor. The μPDE operated under overfilled conditions in all cases. The effects of periodic active excitation were analyzed through bottom wall pressure measurement and Schlieren recording.

In all cases, the patterns of change in the supersonic flow field were similar. Prior to ignition, gaseous hydrogen and oxygen were supplied to the μPDE, and the overfilled mixture was injected into the scramjet combustor. However, the amounts of hydrogen fuel required for the operation of the μPDE at 10 Hz and 20 Hz were very minimal, at 0.38 g/s and 0.51 g/s, respectively. This resulted in an expansion of the flame area and the transformation of an oblique shock wave into λ-shaped shocks. In only one case, case 4, was the λ-shaped shock maintained even before the μPDE was ignited. When the μPDE was ignited and detonation was propagated to the scramjet combustor, the shock train moved further upstream instantaneously right afterward. In cases 3 and 4, a strong shock wave similar to the normal shock was formed instantaneously. In cases 1 and 2, 17 ms after the detonation expanded, the shock train disappeared, and the supersonic flow field stabilized. In cases 3 and 4, it took a considerable amount of time for the flow to stabilize. In case 4, even when the flow stabilized, λ-shaped shock waves were maintained below the cavity without the presence of an oblique shock wave. The nitrogen gas from the purge process had no significant effect on the supersonic crossflow.

The comparison of the bottom wall pressure history between the single shot case and the active excitation cases showed a significant increase in the pressure on the bottom wall of the scramjet combustor during active excitation. Even before the operation of the μPDE, the pressure near the cavity on the bottom wall remained high, indicating that additional combustion occurred near the cavity, enhancing combustion efficiency. The high-temperature, high-pressure, radical-rich plume exhausted from the μPDE led to an enhancement of secondary combustion of hydrogen fuel and increased the supersonic flow temperature, thereby enhancing reactivity.

Based on prior research from the U.S. AFRL, it is expected that even with a larger scramjet combustor, the combustion efficiency improvement through μPDE operation will be maintained. While high-frequency μPDE operation needs further review, low-frequency operation may be advantageous for thermal management and control. It provides time for combustion stabilization, improving efficiency without disrupting the flow. Low-frequency operation did not cause significant destructive effects, suggesting it can maintain stability and improve efficiency. Additionally, μPDE shows potential for controlling combustion modes by supplying additional heat.

Ultimately, it was confirmed that low-frequency excitation at f10–20 Hz, not high-frequency excitation above 100 Hz, can also provide sufficient excitation effects on the scramjet combustor. This has high applicability in scramjet vehicles based on hydrogen fuel, as it can enhance combustion efficiency with just a fraction of the fuel. Furthermore, leveraging these effects holds the potential to reduce the length and weight of scramjet combustors.