1. Introduction

Tiltrotors, combining the vertical take-off and landing (VTOL) and hovering capabilities of helicopters with the high-speed cruise performance of fixed-wing aircraft, represent a versatile platform with broad applications. This unique blend of attributes has garnered significant attention from aerospace researchers [

1]. Increasing demand for high-altitude unmanned aerial vehicles (UAVs), particularly for reconnaissance, search, and rescue missions in both military and civilian sectors, has further cemented tiltrotors as a preferred solution [

2].

The aerodynamic design of proprotors is crucial for achieving optimal performance in both hover and cruise conditions, particularly at high altitudes where low air density significantly affects aerodynamic efficiency. Mainstream rotor aerodynamic models typically fall into three categories. The Blade Element Momentum Theory (BEMT) model [

3], renowned for its computational efficiency and reasonable accuracy in predicting conventional rotor performance, faces limitations when dealing with more complex geometries and in low-density environments. Vortex-based wake models, including the free wake model [

4] and the vortex particle model [

5], strike a balance between accuracy and computational efficiency. Lastly, the grid-based Computational Fluid Dynamics (CFD) [

6] approach provides the highest accuracy but at the cost of significant computational resources. Studies such as those on the XV-15 rotor [

7] have extensively validated CFD, which, when combined with Computational Structural Dynamics (CSD), can achieve high-fidelity predictions of rotor loads and deformations [

8].

Research into the V-22 tiltrotor’s rotor blades has driven significant advancements in proprotor design. Farrell’s multi-objective optimization work [

9] and Rosenstein’s comprehensive analysis of aerodynamic components [

10] have been particularly influential. Rosenstein’s work demonstrated notable improvements in rotor efficiency and reduced interference, surpassing the performance of the XV-15 rotor in both hover and cruise through wind tunnel testing and theoretical validation.

Proprotor design for high-altitude UAVs faces substantial challenges due to conflicting hover and cruise performance requirements, as well as the reduced air density at high altitudes [

11]. To perform optimally, proprotors must achieve a high figure of merit (

) in standard atmospheric conditions (

) [

12] while maintaining high propulsive efficiency during high-speed cruise in low-density environments, such as 4500 m above sea level (

) [

13]. Hover performance benefits from increased blade radius and tip speed, while cruise performance is enhanced by reducing rotational speed or blade radius to minimize drag. Moreover, blade twist plays a critical role; smaller twist angles improve hover by increasing lift at low forward speeds, while larger twist angles enhance cruise efficiency by reducing drag and optimizing lift distribution along the blade span. These conflicting design requirements are further complicated by the varying atmospheric densities across the operating envelope, making the optimization process heavily reliant on iterative design–test cycles [

14].

Recent advancements in active rotor technologies—such as adaptive rotor diameters [

15], active blade rotational speed/twist control [

16], and active blade tip control [

17]—show potential for resolving these conflicting requirements through dynamic optimization of proprotor blade profiles. However, practical implementation remains hindered by mechanical complexities and structural limitations.

Thus, multi-objective optimization techniques that address the conflicting aerodynamic requirements of proprotor blades across varying flight conditions are critical. In addition to selecting chord, twist, and airfoil distributions, other factors such as the blade tip anhedral [

18] and sweep [

19] play important roles in optimizing rotor performance in different flight modes [

20]. While aeroelastic effects and blade deformations are crucial factors in rotor design [

21], this study focuses primarily on axial flow optimization, leaving these effects for future research.

Further, recent research has emphasized the need to integrate both aerodynamic and structural models in proprotor optimization. Hoyos et al. [

22], for example, developed an aero-structural optimization method that combines BEMT and particle swarm optimization, yielding higher thrust and efficiency by carefully considering both aerodynamic and structural constraints. Although this paper focuses on aerodynamic optimization, future work will consider incorporating structural models to evaluate their impact on design.

Several previous studies have successfully applied optimization techniques to various rotorcraft configurations, such as tiltrotors and compound helicopters. Yeo and Johnson [

23] employed a multidisciplinary approach, combining Lifting-Line Methods with optimization to balance hover and cruise performance. Droandi et al. [

24] developed a two-layer optimization framework combining BEMT with CFD, while Hwang and Ning [

25] focused on optimizing cruise and high-lift propellers for NASA’s X-57 aircraft, showing significant performance improvements [

26,

27]. Despite the comprehensive nature of CFD-based optimization [

28], its high computational cost [

29] has led to the adoption of surrogate or low-fidelity models to achieve a balance between efficiency and accuracy [

30,

31].

Sridharan and Sinsay [

32] proposed a multi-fidelity optimization framework that employs surrogate models like Gaussian Processes and neural networks to enhance the efficiency and accuracy of rotor aerodynamic design. Similarly, Cornelius and Schmitz [

33] introduced a machine-learning-based approach to optimize rotor designs with reduced computational costs while maintaining high fidelity. Anusonti-Inthra [

34] applied an orthogonal CST method combined with surrogate modeling to improve airfoil parameterization, which has promising applications in rotorcraft optimization. While surrogate models allow for high-precision rotor design optimization, their development requires extensive high-fidelity sampling, which incurs significant computational costs. Moreover, optimization outcomes using surrogate models may not always align with results obtained from metamodels. Thus, incorporating models with greater computational efficiency remains practically valuable, provided that fidelity is maintained.

Nonetheless, many optimization frameworks still rely on baseline blade shapes, limiting convergence when applied to varied design objectives. To address this, Zhang et al. [

35] proposed a general framework combining BEMT models with high-fidelity CFD for validation, but reliance on low-fidelity models during the optimization phase can still lead to deviations from the true optimal solution.

In this paper, we extend previous research by developing an improved multi-objective optimization framework for proprotor blades, specifically targeting performance in hover and high-altitude cruise conditions. This improved framework offers a generalized method for determining key proprotor parameters, such as the number of blades, rotational speed, and solidity, which are critical for meeting mission-specific performance targets, particularly at high altitudes. Based on these parameters, ideal bounds for chord and twist distributions are established to ensure a balanced performance between hover and cruise efficiency. Airfoil distributions along the blade span are carefully selected to optimize aerodynamic performance across various flight conditions, including those encountered at high altitudes.

A high-fidelity simulation tool based on the reformulated Vortex Particle Method (rVPM) [

36,

37,

38] is employed to compute the figure of merit (

) for hover and the cruise efficiency (

). The rVPM model accurately handles complex flow phenomena, such as blade–vortex interactions, while remaining computationally efficient. These aerodynamic models are then coupled with a many-objective hybrid optimizer (MOHO), dynamically selecting optimization algorithms based on real-time performance during the search process. This approach allows for rapid convergence to Pareto-optimal blade configurations that simultaneously optimize both hover and cruise efficiency. The resulting optimized designs achieve a hover efficiency of

and a cruise efficiency of

, exceeding mission requirements and demonstrating the effectiveness of this optimization strategy.

2. Numerical Methodology

2.1. Rapid Estimation Model for Overall Parameters

This study initially constructs semi-empirical estimation models for hover efficiency and high-altitude cruise propulsive efficiency. These models are then integrated with the classical Nelder–Mead efficient optimization algorithm [

39] to expeditiously determine the overall parameters of the high-altitude tiltrotor, encompassing rotor diameter (

D), solidity (

), and rotor speed (

).

Based on Glauert’s momentum theory, the ideal induced inflow ratio of the hovering rotor

is given by the following:

where

T represents the rotor thrust,

represents the thrust coefficient,

denotes the air density,

signifies the rotor disk area, and

is the rotor radius.

For pure axial flow conditions, the estimation formula for the inflow ratio [

40] is expressed as follows:

where

denotes the axial component of the advance ratio (for pure axial flow,

),

is the axial freestream velocity,

is the rotor tip speed, and

.

The Newton–Raphson method, with appropriate relaxation factors to enhance convergence, is employed to solve the iterative process of induced velocity. In this study, a relaxation factor of 0.5 is determined to be optimal, with calculations converging in three to four iterations.

Rotor power is composed of induced power, profile power, interference power, and parasite drag power. This study focuses primarily on induced and profile power. Induced power is calculated from the ideal power:

. The empirical coefficient

accounts for effects such as non-uniform inflow, non-ideal spanwise loading, tip losses, vortex interactions, and blockage (

) [

40], where

values typically range between 1.1 and 1.3, depending on rotor design.

Profile power is determined from the average drag coefficient

of the blade:

where

, and

accounts for the increase in blade section velocity due to the rotor’s edgewise and axial speeds. The empirical parameters used in this study are derived from statistical data and prior research [

41]. Specifically, the average drag coefficient

is calculated using the following semi-empirical formula:

This formula reflects the dependency of the average drag coefficient on the thrust coefficient, solidity, rotor diameter, and freestream velocity, providing a reliable estimate for profile power calculation under various operating conditions.

Hover efficiency and high-altitude cruise propulsive efficiency are two critical performance metrics in proprotor design. Hover efficiency is computed using the figure of merit, with the induced power coefficient (

) and profile power coefficient (

) determined using empirical formulas [

40]. High-altitude cruise propulsive efficiency is calculated based on

,

,

, and axial flow velocity

. The expressions for the figure of merit (

) and cruise propulsive efficiency (

) are as follows:

The Nelder–Mead efficient optimization algorithm [

39] is employed to optimize the overall parameters through the following steps:

Initialization: Based on the rotor power estimation method from [

40], the initial ranges for rotor diameter (

D), solidity (

), and rotor speed (

) are determined.

Optimization process: Within the defined ranges, the optimization algorithm iteratively computes to simultaneously optimize hover and cruise efficiencies. Using the Pareto frontier method, the algorithm identifies optimal trade-offs between these two objectives. The most suitable solution is selected based on the Knee Point Selection method.

Parameter update: The final values for rotor diameter, solidity, and rotor speed are established.

Result transfer: The resulting overall parameters are passed to the ideal chord and twist distribution estimation model for further analysis.

2.2. Ideal Chord and Twist Distribution Bounds Estimation Model

In the aerodynamic shape optimization of high-altitude tiltrotor blades, providing the bounds for the ideal chord length and twist distribution is essential for achieving optimal aerodynamic performance. These bounds are derived based on the principle of minimum energy loss, with the ideal chord and twist distributions computed for both hover and cruise conditions. The parameter variation ranges are specified according to tolerance margins to ensure robust performance across varying conditions.

Initially, the proprotor’s operating conditions, including vortex wake displacement velocity (), thrust coefficient (), and power coefficient (), are established. The vortex wake displacement velocity is assumed to remain constant in the radial direction, forming a rigid vortex sheet as the freestream passes through the proprotor disk. It is important to distinguish vortex wake displacement velocity () from wake convective velocity. While the latter includes contributions from both freestream and induced velocities, specifically refers to the velocity imparted by the rotational and translational motion of the proprotor blades.

The determination of ideal chord and twist distributions is grounded in the minimum energy loss theory, as introduced by Betz [

42] and Glauert [

43]. By minimizing energy loss at the design point, the bound circulation of the rotor blade element is given by the following equation:

where

R is the blade radius,

is the non-dimensional radial station,

F is the correction factor,

w is the vortex-induced velocity,

is the inflow angle,

is the number of blades,

is the local lift coefficient,

c is the local chord length, and

U is the local flow velocity.

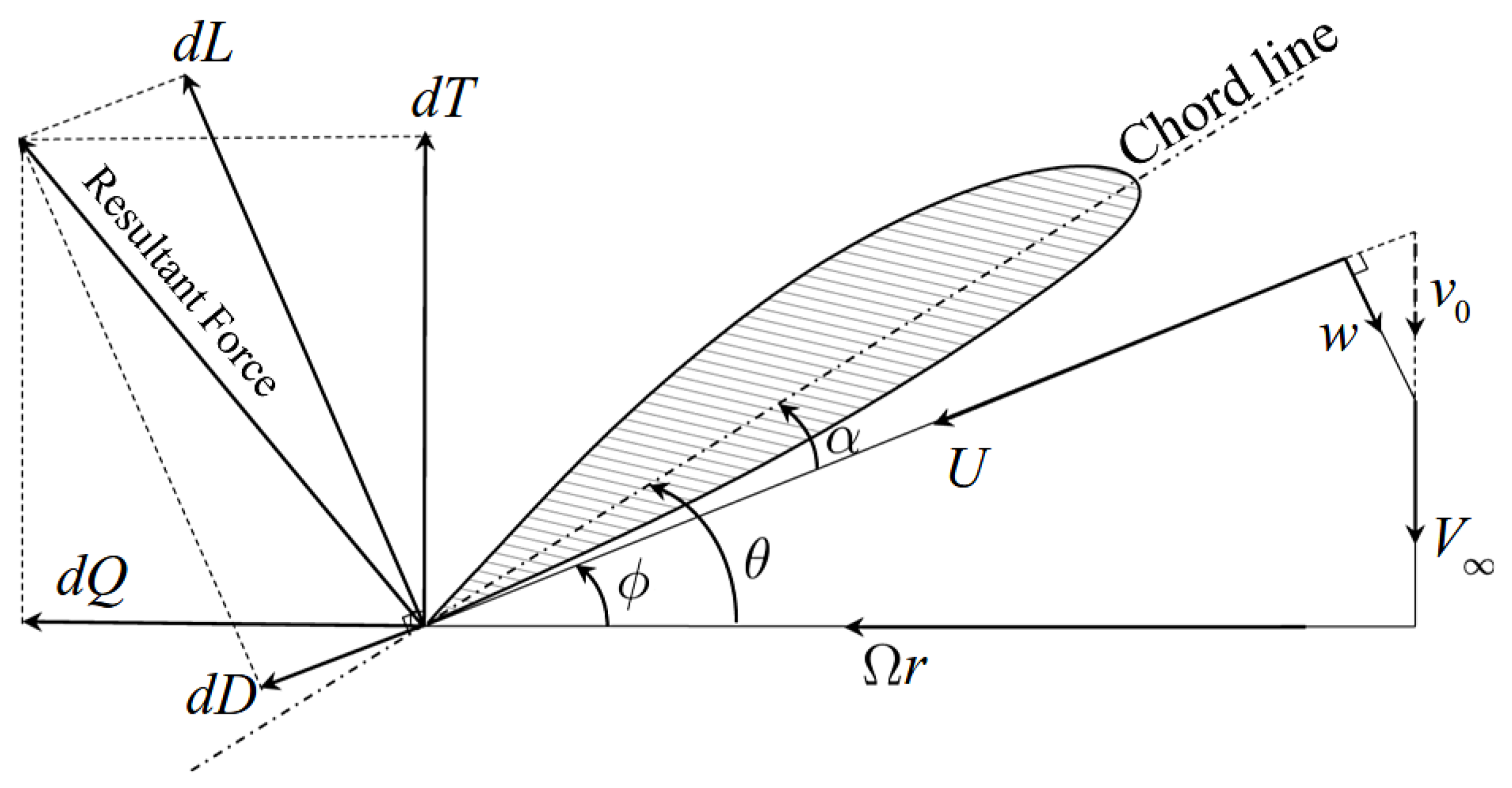

The local blade loading [

44] is given by the following:

where

is the advance ratio,

is the non-dimensional rotation velocity, and

is the non-dimensional induced velocity, as shown in

Figure 1. According to the principle of minimum energy loss [

43,

44],

, so

w is perpendicular to

U.

is the non-dimensional velocity, and

F is the Prandtl tip loss factor, defined as follows:

By combining the above equations, the ideal chord distribution and twist distribution can be derived as and , respectively. Here, denotes the local lift coefficient under ideal conditions, and represents the angle of attack corresponding to the maximum lift-to-drag ratio.

The calculation of ideal chord and twist distributions is performed separately for hover and cruise conditions, with trim thrust and power coefficients used as constraints. An iterative calculation adjusts the vortex wake displacement velocity until the proprotor’s thrust coefficient () and power coefficient () match target values. The initial non-dimensional velocity is set to , and is incrementally increased by until convergence is achieved.

The resulting ideal chord and twist distributions, calculated using the aforementioned methods, are then used to define the design bounds. To facilitate the initial design stage and ensure efficient optimization, positive and negative margins of 20% are applied to these ideal values. These adjusted bounds provide a suitable range for initializing the optimization process, allowing for rapid determination of design variables through low-fidelity models.

2.3. Rotor Wake rVPM Model

In the classical Vortex Particle Method (VPM) [

45], the rotor wake is discretized into a vortex particle model with finite core sizes [

46]. This method solves the vorticity form of the Navier–Stokes equations in a Lagrangian framework, with the governing equation expressed as follows:

where

represents the flow velocity,

is the kinematic viscosity of air,

is the vorticity field,

denotes the material derivative, and

is the Laplacian operator. The discretized vorticity field is given by the following:

where

represents the spatial position, the subscript

p denotes the

p-th vortex particle,

is the total number of vortex particles in the flow field,

is the circulation strength of the

p-th vortex particle,

is the smoothing kernel function, and

is the core radius of the

p-th particle. The smoothing kernel function is defined as follows:

where

is the Gaussian smoothing function.

The governing equations describing the evolution of vortex particle strength and spatial position are given by the following:

where the local velocity of the vortex particle

is composed of the freestream velocity

and the induced velocity

of the vorticity field. The induced velocity is obtained through the Biot–Savart law.

Although the classical Vortex Particle Method (VPM) achieves a balance between efficiency and accuracy in tiltrotor simulations [

1,

47], it frequently encounters numerical instability during the transition to turbulence, particularly in low-air-density environments [

48]. These instabilities arise due to violations in the Lagrangian deformation and the incompressibility of the vorticity field [

49].

To address these issues, this study adopts the reformulated Vortex Particle Method (rVPM) developed by Alvarez et al. [

36,

50]. The rVPM significantly enhances the conservation of local mass and angular momentum by dynamically adjusting particle sizes, improving numerical stability in simulations involving complex wake structures [

36]. This reformulation refines the traditional vortex stretching and tilting mechanisms, ensuring enhanced conservation of mass and momentum, especially under high rotational speeds and complex blade–vortex interactions [

51]. As a result, the prediction accuracy of aerodynamic loads and rotor performance metrics is significantly improved [

52].

The key governing equations are adjusted to incorporate the evolution of vortex particle size, optimizing the method’s efficacy in simulating complex aerodynamic phenomena. These modifications are expressed as follows:

In these equations,

is the filter width at the position of the

p-th particle,

governs the evolution of the vortex particle size, and

represents the filtered vorticity strength. The coefficients

and

, as defined in Equation (

15), ensure the conservation of angular momentum and mass within the vortex core.

Additionally, the Particle Strength Exchange (PSE) method [

53] is employed to handle viscous diffusion, allowing for accurate resolution of the diffusion term in the governing equations. The PSE method ensures that the diffusion of vorticity is accurately captured without introducing significant numerical diffusion, a common issue in traditional vortex methods.

To further enhance computational efficiency, the Fast Multipole Method (FMM) [

54] is incorporated to accelerate the N-body problem associated with calculating the induced velocity of each vortex particle. The FMM reduces the computational complexity from

to approximately

, enabling the simulation of large-scale vortex systems with significantly improved performance.

Moreover, to improve the stability and accuracy of the rVPM, Large Eddy Simulation (LES) principles are incorporated into the framework. LES models the effects of smaller, unresolved scales by introducing a subgrid-scale stress tensor,

[

36]. This tensor captures the interactions between the resolved large-scale dynamics and the unresolved subgrid-scale dynamics, which are crucial for accurately modeling turbulence. The LES-filtered Navier–Stokes equations, expressed in vorticity form, are given by the following:

where

represents the subfilter-scale (SFS) vorticity advection, and

represents SFS vortex stretching.

By integrating LES principles into the rVPM, this study introduces a numerically stable and grid-free LES scheme which not only preserves vortex structures but also eliminates the need for complex grid generation, avoiding the numerical dissipation typically associated with grid-based CFD methods. The scheme is further enhanced by not being constrained by the Courant–Friedrichs–Lewy (CFL) condition, allowing for larger time steps and faster simulations. For a comprehensive mathematical derivation of this method, please refer to [

36].

In summary, the rVPM, with its enhanced particle size evolution mechanism and incorporation of LES principles, significantly improves the stability and computational efficiency of Vortex Particle Methods, making it highly applicable for rotor performance evaluation in various aerodynamic environments. This method offers a robust and efficient tool for accurately predicting the aerodynamic characteristics of proprotors in both hover and high-altitude cruise.

2.4. Rotor Blade Lifting Surface Model

The aerodynamic model of proprotor blades requires accurate computation of rotor thrust and induced velocity. Traditionally, the Lifting-Line Method (LLM) and Lifting Surface Method (LSM) have been widely used, often in conjunction with the Vortex Particle Method [

55]. The Lifting Surface Method provides higher computational accuracy, especially for analyzing three-dimensional blade shapes with a taper and anhedral. Thus, the Lifting Surface Method is employed in this study to model the rotor blades’ aerodynamics.

In this approach, the blade is discretized into infinitesimal segments along the span, represented by a mean camber surface with zero thickness. For blades with sweep and taper, the grid lines at the leading and trailing edges are adjusted accordingly. Each blade segment is divided into columns along the span and rows along the chord, forming a grid system. Spanwise bound vortices are positioned at the quarter-chord line, while chordwise bound vortices are arranged along the spanwise grid. The trailing edge vortex is located at the quarter-chord line of the adjacent grid, and the vortex grid at the trailing edge generates vortex particles that shed into the rotor wake.

The vortex sources generated at the trailing edge are calculated using the following formula:

where

is the strength of the newly generated vortex,

represents the bound circulation of the blade, and

is the local velocity of the bound vortex, including contributions from blade rotation, freestream, induced velocity, and interference. The first term accounts for the trailing vortex generated by spanwise variation in bound circulation, while the second term represents the shedding vortex due to azimuthal variations. To ensure stability, the Kutta condition is applied at the trailing edge at each time step, maintaining vorticity balance.

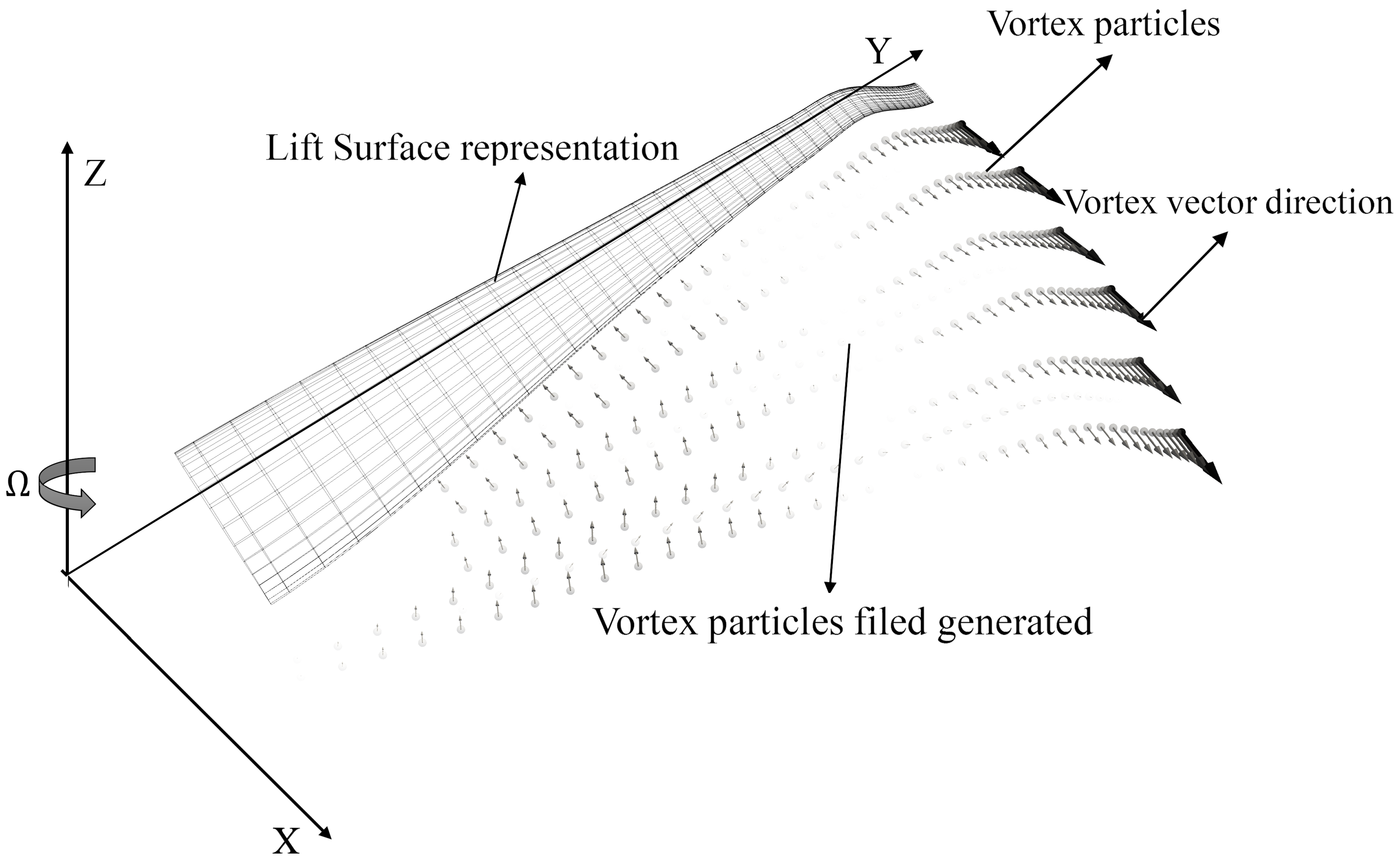

The total circulation source

, generated from changes in bound circulation, is distributed across an interpolation surface representing the blade’s convective trajectory. The vortex particle field is initialized based on this circulation source, allowing for accurate coupling between the vortex particle field and the lifting surface. This coupling forms the rVPM/LSM aerodynamic analysis model, as illustrated in

Figure 2.

After determining the bound circulation, aerodynamic forces on the blade sections are calculated using the Kutta–Joukowski theorem. To account for viscous effects, corrections are applied using pre-generated airfoil C81 data tables, allowing for a more accurate estimation of profile drag. For implementation details, including code, please refer to the open-source rotor aerodynamic analysis package DUST, provided by Montagnani et al. on GitLab [

56].

2.5. Model Validation

To assess the accuracy of the developed rVPM/LSM model in calculating the aerodynamic characteristics of proprotors, several rotor and propeller models were simulated and compared against experimental data and CFD results. In all validation cases, a consistent set of simulation settings was applied. The minimum time step was set to radians, and the wake was truncated when it extended beyond a cube with a side length of centered at the rotor hub. The initial vortex particle size was set to 1.2 times the local lifting surface grid size, ensuring overlap between particles. The blade lifting surface was divided into 50 radial sections and 5 chordwise sections, with additional refinement near the blade tip.

Each simulation ran for at least 12 revolutions, and convergence was confirmed if either the average wake position changed by less than 2.5% or the average thrust varied by less than 1% over two consecutive revolutions. Once convergence was achieved, the time-averaged results from the final revolution were used.

Initially, a parametric model was constructed based on the proprotor designed by Droandi et al. [

24], and the results were compared with hover test and CFD results. The results are shown in

Figure 3.

As is evident from the figure, the computational results of the rVPM/LSM model demonstrate good agreement with both the experimental data and CFD results. This indicates that the rVPM/LSM model employed in this study exhibits high accuracy and reliability in predicting the hover performance of proprotors, achieving a level of confidence comparable to CFD.

Subsequently, a computational model of the Beaver propeller was established, drawing upon experimental data from Dr. Veldhuis’s dissertation [

57]. The results were then compared with experimental data [

58] and computational results based on the rVPM and actuator line model by Alvarez [

51]. These comparisons are presented in

Figure 4.

Figure 4a illustrates the evolution of the Beaver propeller wake flow field after five revolutions under conditions of an advance ratio

and freestream velocity

.

Figure 4b depicts the variation of the thrust coefficient (

) with the advance ratio (

J), while

Figure 4c shows the variation of cruise efficiency (

) with the advance ratio (

J). The figures reveal that the present model’s predictions of thrust coefficient and cruise efficiency align well with experimental data across the entire range of advance ratios. Discrepancies between the present model and Alvarez’s model may be attributed to the fact that the actuator line model relies on the C81 airfoil data table, whereas the present model employs the Lifting Surface Method.

Additionally, the BEMT method based on Xfoil airfoil data [

22] is included in the figure. As shown, the BEMT method aligns well with experimental data in terms of thrust coefficient prediction, with minor deviations at lower advance ratios, likely due to low Reynolds number effects. For cruise efficiency, the BEMT method also exhibits satisfactory agreement, with a slight overestimation at moderate advance ratios. This comparison demonstrates that the BEMT method can achieve rapid iteration while maintaining sufficient accuracy in predicting proprotor performance. Our method, while significantly less efficient in rapid iteration compared to the BEMT method, performs better than CFD methods. Additionally, it offers advantages in analyzing blades with nonlinear planforms and tip anhedral designs, showcasing its potential for further development. Therefore, our method essentially represents a compromise between BEMT and CFD methods, balancing computational efficiency with the ability to cover a broader range of design variables. Overall, the present model’s calculations of cruise efficiency for proprotors exhibit consistency with both experimental data and validated computational results, affirming its effectiveness.

Finally, a model of the classic XV-15 three-blade tiltrotor was constructed and simulated. Geometric parameters of the blades (including planform shape, chord distribution, and twist distribution) were sourced from the literature [

59], and comparisons were made with wind tunnel test data for the XV-15 in hover and forward flight at a tip Mach number of 0.66 [

60], as well as CFD results [

30]. The results are presented in

Figure 5 and

Figure 6.

Figure 5 illustrates the wake field of the XV-15 rotor in (a) hover with a tip Mach number of

and (c) a typical cruise condition at

.

Figure 5b shows the different collective pitch of the proprotor in different operational conditions.

Figure 6a shows the variation of the figure of merit (

) with the rotor blade loading coefficient (

), while

Figure 6b depicts the variation of cruise efficiency (

) with the rotor blade loading coefficient (

).

The figures reveal that the present model demonstrates good agreement with experimental data for both hover and forward flight conditions of the XV-15 tiltrotor. Discrepancies between the model’s results and the CFD results may be attributed to the differences in the airfoil modeling between the two methods.

Table 1 summarizes the root mean squared error (RMSE), mean absolute error (MAE), and mean absolute percentage error (MAPE) between the rVPM/LSM model and the experimental data for the three computational cases discussed in this section. Generally, an RMSE within 0.01 and an MAPE within 5% are considered to indicate high fidelity; an RMSE between 0.01 and 0.05 and an MAPE between 5 and 10% signify medium fidelity; and exceeding these ranges indicates low fidelity. The results in

Table 1 demonstrate that the RMSE between the rVPM/LSM model and the experimental data ranges from 0.0004 to 0.0428, and the MAPE ranges from 2.59% to 9.57%.

Therefore, it can be concluded that the rVPM/LSM model developed in this study achieves medium-to-high fidelity in estimating tiltrotor performance, rendering it suitable for multi-objective optimization tasks in the preliminary design phase of proprotors.

On the workstation configuration detailed in

Table 2, the developed rVPM/LSM coupled model achieves single-point computation times ranging from 2.5 to 4.5 min, while single control input trim computation times range from 6 to 15 min. Notably, the trim time can be further reduced by utilizing gradient data precomputed based on the BEMT method.

In contrast, conventional grid-based CFD methods employing the Reynolds-Averaged Navier–Stokes (RANS) equation [

30] exhibit single-point computation times of 20 to 60 min, and the lattice Boltzmann methods (LBM) [

61] require at least 40 min, with neither accounting for control input trimming. Thus, the developed model strikes a favorable balance between accuracy and computational iteration cycle time, rendering it well suited for multi-objective design optimization tasks for proprotor blade aerodynamic shapes.

While CFD and LBM offer distinct advantages in capturing detailed flow features or vortex–surface interactions, the present method excels in balancing efficiency and accuracy for the preliminary design stage, where rapid iteration is paramount.

3. Design Optimization Framework

Figure 7 illustrates the comprehensive design optimization framework employed in this study. The framework encompasses three distinct stages.

Rapid Estimation of Overall Parameters: Based on the mission requirements, a rapid estimation model is utilized to determine the overall parameters of the proprotor, encompassing rotor diameter, solidity, and rotational speed. These determined parameters are then passed to the subsequent stage.

Estimation of Ideal Chord and Twist Distributions: The overall parameters obtained from the first stage are input into the ideal chord and twist distribution estimation model. Through this model, the optimal values for chord and twist distributions under hover and cruise conditions are determined based on the rigid vortex wake model and the principle of minimum energy loss. A positive and negative margin of 20% is then applied to establish the upper and lower bounds. The smallest value among these is taken as the lower boundary, and the largest value is taken as the upper boundary for the design variables. Subsequently, the range for the blade tip anhedral angle and its starting position is also specified. Finally, the radial distribution of the airfoil is determined according to the aerodynamic characteristics of typical flight conditions.

Optimization Search Process: During the optimization search process, a many-objective hybrid optimizer (MOHO) is employed. The MOHO combines various optimization algorithms such as the NSGA-III, MOEA-DD, SPEA-R, NSDE-R1B, and NSDE-D3, dynamically selecting the most suitable optimization strategy based on the performance of each algorithm at the current stage. The initial population is randomly generated within the defined design bounds for chord and twist distributions, and the objective function values are calculated using the reformulated Vortex Particle Method (rVPM) and Lifting Surface Model (LSM). The MOHO enhances search efficiency and effectiveness through its dynamic switching mechanism. Each iteration includes at least 66 individuals, with a total of 50 search generations, ultimately yielding optimized blade designs.

This optimization framework ensures a systematic and rigorous design process, enhancing design efficiency while maintaining computational accuracy.

3.1. Design Requirements and Determination of Overall Parameters

The objective of this research is to optimize the aerodynamic design of proprotor blades to meet the dual requirements of efficient low-altitude hover and high-altitude cruise flight. The specific design requirements are outlined in

Table 3. Based on these mission requirements, the number of rotor blades is fixed at 3, the rotor diameter is constrained between 2.5 m and 3.3 m, and the rotor hover speed ranges from 1200 to 1350 RPM, with a solidity requirement between 0.07 and 0.12.

In terms of hover performance, the rotor is mandated to provide a hover thrust of 2000 N with a hover efficiency of no less than 0.70, evaluated at a standard atmospheric density of 1.225 kg/m3. To accommodate high thrust demands and ensure design robustness, the maximum thrust of the rotor in this state must not be less than 2600 N.

For forward flight performance, the propulsive efficiency should not fall below 0.75 at an altitude of 4500 m, a cruise speed of 80 m/s, and a design forward flight thrust of 350 N. The atmospheric density for this operating condition is derived from the International Standard Atmosphere table and is calculated as 0.78 kg/m3. Additionally, the forward flight speed should be approximately 70% of the hover speed. To address the high thrust requirements and maintain design robustness, the maximum thrust of the rotor in this state must not be less than 525 N.

After establishing the design objectives, these parameters are input into the rapid estimation model for the overall parameters to generate a set of feasible solutions, which are then weighted and ranked. Considering that the primary operating state of the proprotor is high-altitude cruise, the hover efficiency weight is set to 40%, and the high-altitude cruise propulsive efficiency weight is set to 60%. Based on the ranking results, the key design parameters of the proprotor with the optimal figure of merit are presented in

Table 4.

3.2. Determination of Blade Shape Design Variables and Bounds

The chord and twist distributions of the proprotor blades are parameterized using B-spline curves. A B-spline curve is a linear combination of a set of B-spline basis functions where the

order corresponds to a spline curve of degree

. A B-spline curve can be expressed as follows:

where

are the control points,

N is the number of internal knots of the B-spline curve,

are the basis functions,

represents the sample point position, and

represents the domain of the sample points. The geometric shape can be determined by

control points. In this study, the chord length and twist distribution curves of the high-altitude proprotor blades are represented by B-spline curves with five and four control points, respectively.

Previous studies have indicated that quadratic or cubic S-splines are generally sufficient for representing chord and twist distributions. However, in this work, five and four control points were chosen empirically to provide sufficient flexibility in capturing the geometric variations in blade chord length and twist. The spline curve equations are as follows:

where

represents the chord length,

represents the twist angle,

are the control point parameters for the chord length distribution B-spline curve, and

are the control point parameters for the twist distribution B-spline curve. The number of control points was determined empirically, with five and four found to be sufficient to represent the variations in blade chord length and twist, respectively. While limiting the number of control points can constrain the shape to more conventional geometries, using a higher number of control points provides the potential for generating more unique or exotic shapes, which may offer advantages in exploring unconventional designs. The B-spline curve for chord length distribution is represented by

as control point parameters, and the twist distribution spline is represented similarly. Through linear combinations of different basis functions and control point parameters, any curve shape within the range of

can be generated.

In addition to chord and twist, recognizing that blade tip anhedral can enhance both hover efficiency and potentially cruise efficiency [

20]. The starting radial position and angle of the anhedral are also incorporated as design variables in this study. Therefore, the rotor blade is characterized by a total of 11 design variables, forming a vector

defined as follows:

where

denotes the non-dimensional radial position of the blade tip anhedral start point, and

denotes the blade tip anhedral angle (negative values indicate wash-in). The design variable bounds are established based on the estimated model for optimal chord and twist distribution, while the radial position and angle of the anhedral are determined based on practical engineering and manufacturing constraints. The range of each variable is summarized in

Table 5.

Figure 8 illustrates the blade planform shape fitted with B-splines (a), the variation of the blade installation angle and the effect of blade tip anhedral (b), the chord length distribution curve fitted with B-splines (c), and the twist distribution curve fitted with B-splines (d). Overall, the B-spline fitting scheme adopted in this study effectively represents blade shapes with nonlinear chord length, twist distribution, and blade tip anhedral design.

The selection and arrangement of blade airfoils are primarily determined based on the Reynolds number (Re), Mach number (Ma), and ideal angle of attack distribution at different radial stations under representative operating conditions.

Figure 9 illustrates the distribution of Reynolds and Mach numbers at various radial stations of the blade in typical hover and cruise conditions. Both Ma and Re increase with the radius, exhibiting more pronounced variations in hover. In both flight conditions, the maximum Ma remains below 0.5, indicating negligible compressibility effects. The Re in cruise conditions varies between

and

across the entire radius. While in hover, it ranges from

to

.

Figure 10 compares the lift-to-drag ratio of selected airfoils under Re and Ma conditions corresponding to the root and 0.7

R stations in typical hover and cruise conditions. The OA212 airfoil demonstrates a superior lift-to-drag ratio at low Re and low Ma with angles of attack exceeding

, making it suitable for the inner blade section. The NACA4412 airfoil performs well in both conditions near a

angle of attack, rendering it suitable for the outer section. The Boeing106 and VR07 airfoils exhibit excellent lift-to-drag ratio performance at moderate-to-small angles of attack, making them suitable for the middle section. The final radial distribution of airfoils is determined by calculating the lift and drag characteristics of each radial station airfoil based on the optimal chord and twist distributions, ensuring smooth and continuous airfoil transitions.

Table 6 presents the pre-arranged radial distribution of airfoils. This pre-arrangement significantly reduces the number of design variables, thereby enhancing computational efficiency during the optimization search process. Notably, the optimization framework in this study is fully capable of incorporating airfoil selection and distribution as design variables into the optimization search process. The inclusion of more selectable airfoils and parameterized airfoil profiles will be explored in future research.

3.3. Optimization Objectives and Constraints

In this study, the primary optimization objectives for the proprotor system were to maximize both the figure of merit () in hover and the propulsive efficiency () in high-altitude cruise. These objectives are paramount for enhancing the overall aerodynamic efficiency and performance of the tiltrotor across its operational envelope.

The figure of merit, a key performance indicator in rotorcraft aerodynamics, is often defined as the ratio of ideal power to actual power required for hovering. It quantifies the efficiency of the tiltrotor during hover, and optimizing this metric directly translates to improved hover performance and reduced power consumption during hover, which is essential for vertical take-off and landing (VTOL) aircraft. Similarly, the propulsive efficiency during high-altitude cruise is critical for improving the cruise efficiency of unmanned tiltrotors. This parameter directly impacts the aircraft’s fuel consumption and, consequently, its range. Optimizing the rotor blade geometry to enhance propulsive efficiency under cruise conditions ensures superior performance throughout the aircraft’s flight envelope.

Therefore, the optimization objective of this study was formulated as the maximization of both the figure of merit and the propulsive efficiency in high-altitude cruise, subject to fundamental design constraints.

To ensure the practicality and feasibility of the design results, a series of constraints was imposed, encompassing maximum rotor thrust, power limits, objective bounds, rotor solidity limits, and blade planform shape constraints. The specific constraints are detailed in

Table 7. Notably, the rotor solidity bounds were determined based on a sensitivity analysis of the rapid estimation model for the overall parameters and the upper and lower limits of the ideal chord length. The planform shape constraints primarily serve to prevent the spline curve parameters from generating unrealistic or singular shapes.

3.4. Optimization Strategy

The aerodynamic shape design of proprotor blades presents a multi-objective optimization problem characterized by numerous design variables, lengthy iteration cycles, and a non-convex solution space. Consequently, the optimization strategy must balance efficiency and global search capability, often conflicting objectives. Classic global algorithms, such as genetic algorithms, necessitate repeated calls to the rVPM/LSM method to evaluate objective functions for a large population of individuals, resulting in low optimization efficiency. Conversely, conventional nonlinear programming algorithms are prone to converging to local optima, potentially missing the global optimum.

To address these challenges, this study employs a many-objective hybrid optimizer (MOHO) [

62] as the optimization strategy for proprotor blade aerodynamic shape design. The MOHO is a versatile algorithm designed to tackle multi-objective optimization problems, particularly well suited for scenarios with complex design variables and computationally intensive evaluations. By integrating multiple optimization algorithms and dynamically switching among them based on their real-time performance, the MOHO overcomes the limitations of single algorithms in complex optimization landscapes.

Evolutionary algorithms (EAs) were selected for their ability to handle high-dimensional, multi-objective, and nonlinear optimization problems with complex design variables. EAs have been shown to be effective in exploring large and complex search spaces without relying on gradient information, which is often unavailable or unreliable in aerodynamic shape optimization tasks. Additionally, EAs can efficiently manage nonlinear constraints and discontinuities, which are common in multi-objective aerodynamic design.

The MOHO framework incorporates five distinct base optimization algorithms, each with unique strengths in handling specific types of optimization problems:

The core advantage of the MOHO lies in its dynamic switching mechanism. By monitoring the performance of each algorithm in each generation and switching based on the probability of success (POS) values, the MOHO adaptively selects the most suitable optimization strategy. The POS value reflects the effectiveness of each algorithm in the current optimization stage and is calculated as follows:

where

is the number of successful attempts, and

is the total number of attempts. By dynamically selecting the algorithm with the highest POS value, the MOHO can leverage the most appropriate algorithm at different stages of the optimization process, thereby enhancing overall optimization efficiency and effectiveness.

The MOHO demonstrates significant advantages in maintaining solution diversity and accelerating convergence. Its reference point partitioning technique ensures uniform exploration of the solution space, mitigating the risk of converging to local optima. Simultaneously, by integrating the strengths of different algorithms, the MOHO can more rapidly approach the global optimum, significantly accelerating convergence.

Employing the MOHO as the optimization strategy for proprotor blade aerodynamic shape design effectively improves optimization efficiency while ensuring global search capability, maintaining solution diversity, and facilitating convergence. This versatile optimization strategy is not only applicable to the current research problem but also holds broad potential for future rotorcraft aerodynamic design optimization, providing a robust theoretical and practical foundation.