Decoding Carbon Footprints: How U.S. Climate Zones Shape Building Emissions

Abstract

1. Background

2. Literature Review

2.1. Embodied and Operational Carbon Emissions of Buildings

2.2. Embodied Carbon Evaluation by BIM

3. Methodology and Materials

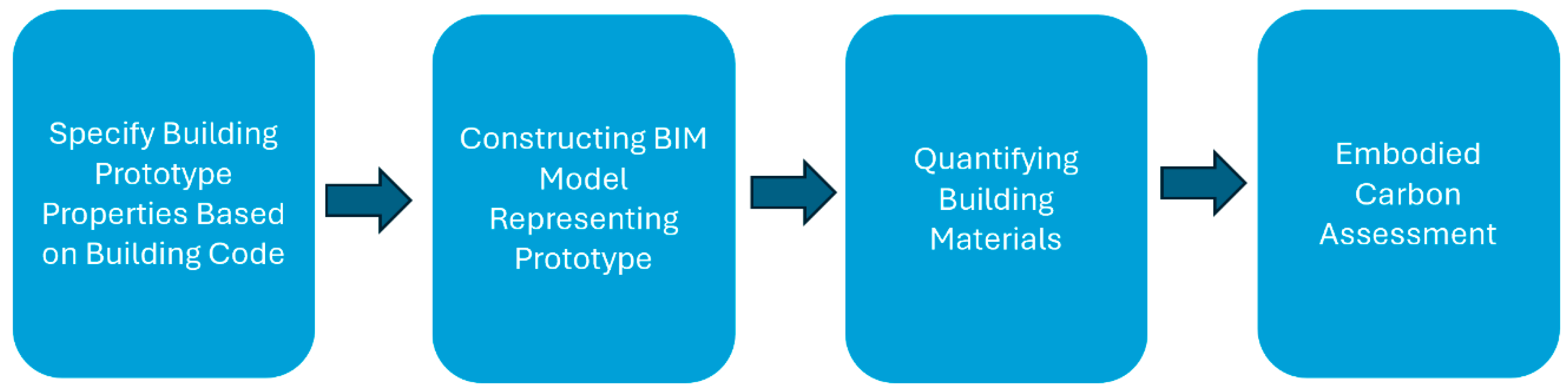

3.1. Research Flow

3.2. Specifications of Building Prototype Properties Based on Building Code

3.3. Constructing BIM Model Representing Prototype

3.4. Quantifying Building Materials

3.5. Embodied Carbon Assessment

4. Findings

4.1. Impact of Climate Zone Condition on Lifecycle Embodied Carbon

4.2. Building Components’ Contribution to Embodied Carbon

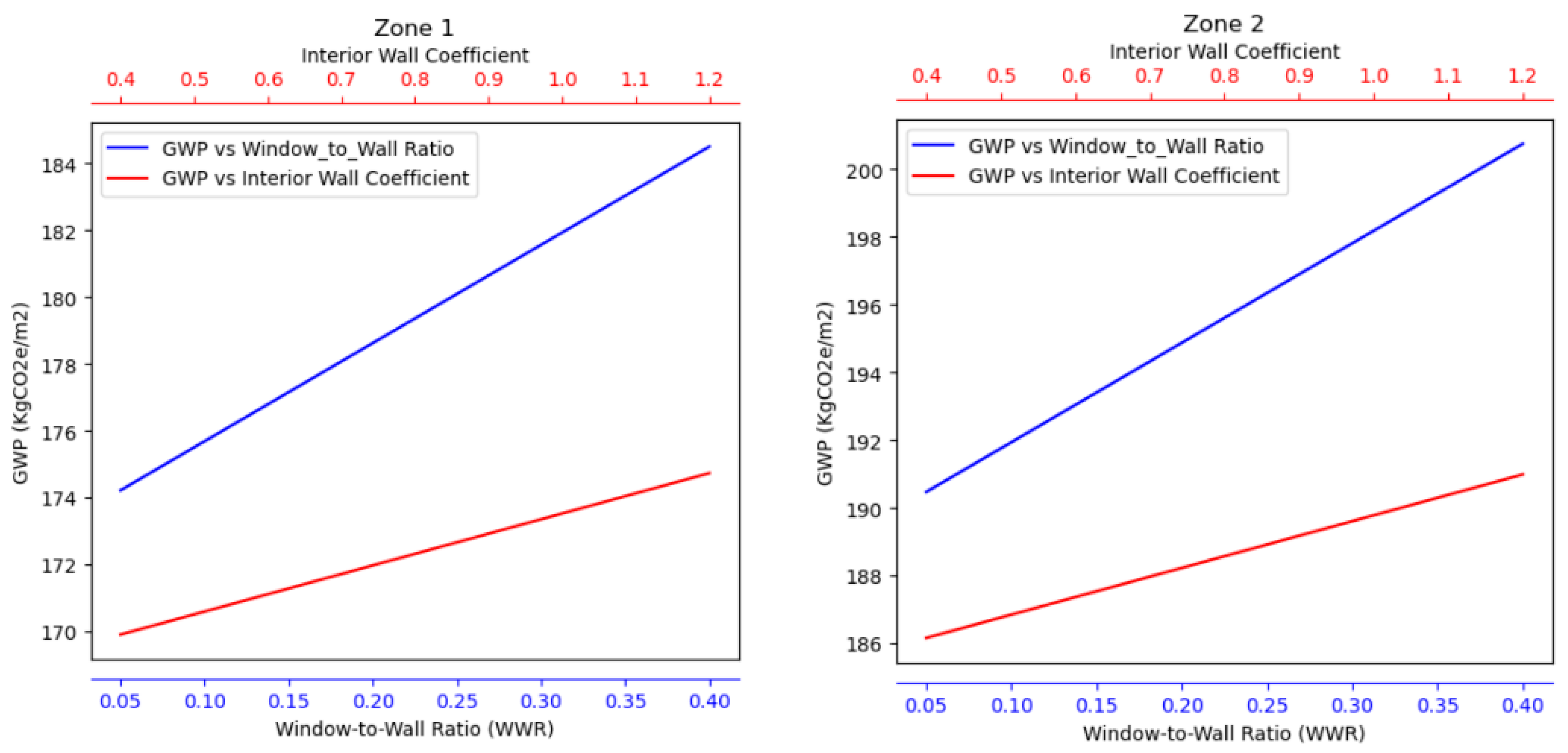

4.3. Sensitivity Analysis

4.4. Baseline Lifecycle Embodied Carbon Values for Different Climate Zones

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kwok, K.Y.G.; Kim, J.; Chong, W.K.O.; Ariaratnam, S.T. Structuring a Comprehensive Carbon-Emission Framework for the Whole Lifecycle of Building, Operation, and Construction. J. Archit. Eng. 2016, 22, 04016006. [Google Scholar] [CrossRef]

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A Review of Carbon Footprint Reduction in Construction Industry, from Design to Operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef] [PubMed]

- Hamida, A.; Alsudairi, A.; Alshaibani, K.; Alshamrani, O. Parametric study of the impact of building envelope systems on embodied and operational carbon of residential buildings. Int. J. Build. Pathol. Adapt. 2021, 40, 753–774. [Google Scholar] [CrossRef]

- Joseph, V.R.; Mustaffa, N.K. Carbon emissions management in construction operations: A systematic review. Eng. Constr. Archit. Manag. 2023, 30, 1271–1299. [Google Scholar] [CrossRef]

- Kumar, D.; Kamran, M.; Zhang, C.; Wang, L.; Zhai, H.; Demirkesen, S. Evaluating the Impact of Contracting and Procurement Methods on Energy and Carbon Emissions Reduction in the Public Construction Sector. Am. Soc. Civ. Eng. 2023, 886–894. [Google Scholar]

- Wu, P.; Song, Y.; Zhu, J.; Chang, R. Analyzing the influence factors of the carbon emissions from China’s building and construction industry from 2000 to 2015. J. Clean. Prod. 2019, 221, 552–566. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Q. Impact of climate change heating and cooling energy use in buildings in the United States. Energy Build. 2014, 82, 428–436. [Google Scholar] [CrossRef]

- Charles, A.; Maref, W.; Ouellet-Plamondon, C.M. Case study of the upgrade of an existing office building for low energy consumption and low carbon emissions. Energy Build. 2019, 183, 151–160. [Google Scholar] [CrossRef]

- Kalua, A. Urban Residential Building Energy Consumption by End-Use in Malawi. Buildings 2020, 10, 31. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H. A comprehensive life cycle water analysis framework for residential buildings. Build. Res. Inf. 2014, 42, 685–695. [Google Scholar] [CrossRef]

- Hu, M. Embodied Carbon Emissions of the Residential Building Stock in the United States and the Effectiveness of Mitigation Strategies. Climate 2022, 10, 135. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar]

- Chen, W.; Yang, S.; Zhang, X.; Jordan, N.D.; Huang, J. Embodied energy and carbon emissions of building materials in China. Build. Environ. 2022, 207, 108434. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar]

- Pomponi, F.; Piroozfar, P.A.E.; Southall, R.; Ashton, P.; Farr, E.R.P. Energy performance of Double-Skin Façades in temperate climates: A systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2016, 54, 1525–1536. [Google Scholar]

- Simonen, K.; Rodriguez, B.X.; De Wolf, C. Benchmarking the Embodied Carbon of Buildings. Technol.|Archit. + Des. 2017, 1, 208–218. [Google Scholar]

- Fenner, A.E.; Kibert, C.J.; Li, J.; Razkenari, M.A.; Hakim, H.; Lu, X.; Kouhirostami, M.; Sam, M. Embodied, operation, and commuting emissions: A case study comparing the carbon hotspots of an educational building. J. Clean. Prod. 2020, 268, 122081. [Google Scholar]

- Hu, M.; Ghorbany, S. Building Stock Models for Embodied Carbon Emissions—A Review of a Nascent Field. Sustainability 2024, 16, 2089. [Google Scholar] [CrossRef]

- Gauch, H.L.; Dunant, C.F.; Hawkins, W.; Cabrera Serrenho, A. What really matters in multi-storey building design? A simultaneous sensitivity study of embodied carbon, construction cost, and operational energy. Appl. Energy 2023, 333, 120585. [Google Scholar]

- Fereidoni, S.; Nabisi, M.; Fereidooni, L.; Javidmehr, M.; Zirak, N.; Kasaeian, A. An assessment of the impact of building envelope design on the tradeoff between embodied and operating energy. Energy Build. 2023, 298, 113542. [Google Scholar] [CrossRef]

- Crawford, R.H.; Bartak, E.L.; Stephan, A.; Jensen, C.A. Evaluating the life cycle energy benefits of energy efficiency regulations for buildings. Renew. Sustain. Energy Rev. 2016, 63, 435–451. [Google Scholar] [CrossRef]

- Gregory, K.; Moghtaderi, B.; Sugo, H.; Page, A. Effect of thermal mass on the thermal performance of various Australian residential constructions systems. Energy Build. 2008, 40, 459–465. [Google Scholar] [CrossRef]

- Mahlan, S.; Francis, A.; Thumuganti, V.; Thomas, A.; Sadick, A.-M.; Tokede, O. An integrated life cycle assessment and energy simulation framework for residential building walling systems. Build. Environ. 2024, 257, 111542. [Google Scholar] [CrossRef]

- Rodrigues, C.; Freire, F. Environmental impact trade-offs in building envelope retrofit strategies. Int. J. Life Cycle Assess. 2017, 22, 557–570. [Google Scholar] [CrossRef]

- Wong, K.; Fan, Q. Building information modelling (BIM) for sustainable building design. Facilities 2013, 31, 138–157. [Google Scholar]

- Migilinskas, D.; Popov, V.; Juocevicius, V.; Ustinovichius, L. The Benefits, Obstacles and Problems of Practical Bim Implementation. Procedia Eng. 2013, 57, 767–774. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M. Identifying and prioritizing the benefits of integrating BIM and sustainability practices in construction projects: A Delphi survey of international experts. Sustain. Cities Soc. 2018, 40, 16–27. [Google Scholar] [CrossRef]

- Tamanaeifar, M.H.; Shahosseini, V.; Nouri, A.; Salimi, M.H. Determining the optimal path of Water Distribution System using AHP based on integrated GIS and BIM model. Sharif J. Civ. Eng. 2021, 37, 23–32. [Google Scholar]

- Llatas, C.; Soust-Verdaguer, B.; Passer, A. Implementing Life Cycle Sustainability Assessment during design stages in Building Information Modelling: From systematic literature review to a methodological approach. Build. Environ. 2020, 182, 107164. [Google Scholar] [CrossRef]

- Potrč Obrecht, T.; Röck, M.; Hoxha, E.; Passer, A. BIM and LCA Integration: A Systematic Literature Review. Sustainability 2020, 12, 5534. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Lu, Y.; Le, V.H.; Song, X. Beyond Boundaries: A Global Use of Life Cycle Inventories for Construction Materials. J. Clean. Prod. 2017, 156, 876–887. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A.; Gómez de Cózar, J.C. BIM-Based LCA Method to Analyze Envelope Alternatives of Single-Family Houses: Case Study in Uruguay. J. Archit. Eng. 2018, 24, 05018002. [Google Scholar] [CrossRef]

- KT Innovations Tally. Available online: https://choosetally.com/ (accessed on 30 June 2024).

- Crippa, J.; Boeing, L.C.; Caparelli, A.P.A.; da Costa, M.d.R.d.M.M.; Scheer, S.; Araujo, A.M.F.; Bem, D. A BIM–LCA integration technique to embodied carbon estimation applied on wall systems in Brazil. Built Environ. Proj. Asset Manag. 2018, 8, 491–503. [Google Scholar] [CrossRef]

- Shafiq, N.; Nurrudin, M.F.; Gardezi, S.S.S.; Kamaruzzaman, A.B. Carbon footprint assessment of a typical low rise office building in Malaysia using building information modelling (BIM). Int. J. Sustain. Build. Technol. Urban Dev. 2015, 6, 157–172. [Google Scholar]

- Xu, J.; Teng, Y.; Pan, W.; Zhang, Y. BIM-integrated LCA to automate embodied carbon assessment of prefabricated buildings. J. Clean. Prod. 2022, 374, 133894. [Google Scholar] [CrossRef]

- Mowafy, N.; El Zayat, M.; Marzouk, M. Parametric BIM-based life cycle assessment framework for optimal sustainable design. J. Build. Eng. 2023, 75, 106898. [Google Scholar] [CrossRef]

- Iddon, C.R.; Firth, S.K. Embodied and operational energy for new-build housing: A case study of construction methods in the UK. Energy Build. 2013, 67, 479–488. [Google Scholar] [CrossRef]

- Shin, Y.; Cho, K. BIM Application to Select Appropriate Design Alternative with Consideration of LCA and LCCA. Math. Probl. Eng. 2015, 2015, 281640. [Google Scholar] [CrossRef]

- Bueno, C.; Fabricio, M.M. Comparative analysis between a complete LCA study and results from a BIM-LCA plug-in. Autom. Constr. 2018, 90, 188–200. [Google Scholar]

- Ullah, K.; Lill, I.; Witt, E. An Overview of BIM Adoption in the Construction Industry: Benefits and Barriers. In 10th Nordic Conference on Construction Economics and Organization; Emerald Publishing Limited: Bradford, UK, 2019; pp. 297–303. Available online: https://www.emerald.com/insight/content/doi/10.1108/s2516-285320190000002052/full/html (accessed on 1 December 2024).

- Miettinen, R.; Paavola, S. Beyond the BIM utopia: Approaches to the development and implementation of building information modeling. Autom. Constr. 2014, 43, 84–91. [Google Scholar] [CrossRef]

- Safari, K.; AzariJafari, H. Challenges and opportunities for integrating BIM and LCA: Methodological choices and framework development. Sustain. Cities Soc. 2021, 67, 102728. [Google Scholar] [CrossRef]

- Lu, K.; Jiang, X.; Tam, V.W.Y.; Li, M.; Wang, H.; Xia, B.; Chen, Q. Development of a Carbon Emissions Analysis Framework Using Building Information Modeling and Life Cycle Assessment for the Construction of Hospital Projects. Sustainability 2019, 11, 6274. [Google Scholar] [CrossRef]

- Yang, X.; Hu, M.; Wu, J.; Zhao, B. Building-information-modeling enabled life cycle assessment, a case study on carbon footprint accounting for a residential building in China. J. Clean. Prod. 2018, 183, 729–743. [Google Scholar] [CrossRef]

- International Energy Conservation Code (IECC). Available online: https://codes.iccsafe.org/content/IECC2021P1 (accessed on 1 November 2024).

- International Residential Code (IRC). Available online: https://codes.iccsafe.org/content/IRC2021P2 (accessed on 1 November 2024).

- DOE Building America Climate-Specific Guidance. Available online: https://www.energy.gov/eere/buildings/building-america-climate-specific-guidance (accessed on 1 November 2024).

- Kiviniemi, A.; Karlshøj, J.; Tarandi, V.; Bell, H.; Karud, O.J. Review of the Development and Implementation of IFC Compatible BIM. 2008. Available online: https://orbit.dtu.dk/files/131997343/Untitled.pdf (accessed on 22 July 2024).

- Hu, M. Optimal renovation strategies for education buildings—A novel BIM–BPM–BEM framework. Sustainability 2018, 10, 3287. [Google Scholar] [CrossRef]

- Monteiro, A.; Poças Martins, J. A survey on modeling guidelines for quantity takeoff-oriented BIM-based design. Autom. Constr. 2013, 35, 238–253. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Méndez Echenagucia, T.; Moroseos, T.; Meek, C. On the tradeoffs between embodied and operational carbon in building envelope design: The impact of local climates and energy grids. Energy Build. 2023, 278, 112589. [Google Scholar] [CrossRef]

- Embodied Carbon in Construction Calculator. Available online: https://www.buildingtransparency.org/ (accessed on 1 November 2024).

- International EPD Library. Available online: https://www.environdec.com/library (accessed on 1 November 2024).

- Mastrucci, A.; Pérez-López, P.; Benetto, E.; Leopold, U.; Blanc, I. Global sensitivity analysis as a support for the generation of simplified building stock energy models. Energy Build. 2017, 149, 368–383. [Google Scholar] [CrossRef]

- Meneghelli, A. Whole-building embodied carbon of a North American LEED-certified library: Sensitivity analysis of the environmental impact of buildings materials. Build. Environ. 2018, 134, 230–241. [Google Scholar] [CrossRef]

- Röck, M.; Pristerá, G.; Ramon, D.; Van De Moortel, E.; Mouton, L.; Kockat, J.; Toth, Z.; Allacker, K. Science for Policy: Insights from Supporting an EU Roadmap for the Reduction of Whole Life Carbon of Buildings. IOP Conf. Ser. Earth Environ. Sci. 2024, 1363, 012008. [Google Scholar] [CrossRef]

- Mirabella, N.; Röck, M.; Ruschi Mendes Saade, M.; Spirinckx, C.; Bosmans, M.; Allacker, K.; Passer, A. Strategies to Improve the Energy Performance of Buildings: A Review of Their Life Cycle Impact. Buildings 2018, 8, 105. [Google Scholar] [CrossRef]

- Mandatory New Requirements for Sustainable Construction. 2023. Available online: https://global.eg.dk/news/2023/april/mandatory-new-requirements-for-sustainable-construction/ (accessed on 23 May 2024).

| Climate Zone | Roof | Exterior Wall | Foundation | Interior Walls | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Structure | Cavity Insulation | Rigid Insulation | Advanced Framing | Cavity Insulation | Rigid Insulation | Slab | Foundation Wall | Footing | Rigid Insulation | ||

| Zone 1 | Flat Roof | R-25 | R-5 | 2 × 6 @24 | 6″ | None | 4″ | 12″ | None | None | 4 7/8″ Partition |

| Zone 2 | Flat Roof | R-40 | R-10 | 2 × 6 @24 | 6″ | None | 4″ | 12″ | None | None | 4 7/8″ Partition |

| Zone 3 | Sloped Roof | R-49 | R-10 | 2 × 6 @24 | 6″ | R-5 | 4″ | 12″ | None | R-10 | 4 7/8″ Partition |

| Zone 4 | Sloped Roof | R-50 | R-10 | 2 × 6 @24 | 6″ | R-5 | 4″ | 12″ | 14″ | R-10 | 4 7/8″ Partition |

| Zone 5 | Sloped Roof | R-50 | R-10 | 2 × 6 @24 | 6″ | R-7.5 | 4″ | 14″ | 14″ | R-10 | 4 7/8″ Partition |

| Zone 6 | Sloped Roof | R-50 | R-10 | 2 × 6 @24 | 6″ | R-11.25 | 4″ | 16″ | 14″ | R-10 | 4 7/8″ Partition |

| Zone 7 | Sloped Roof | R-50 | R-10 | 2 × 6 @24 | 6″ | R-15 | 4″ | 16″ | 14″ | R-10 | 4 7/8″ Partition |

| Zone 8 | Sloped Roof | R-50 | R-10 | 2 × 6 @24 | 6″ | R-20 | 4″ | 16″ | 14″ | R-10 | 4 7/8″ Partition |

| Material | Embodied Carbon (KgCO2e) | Declaration Unit |

|---|---|---|

| Ready-Mix Concrete | 332 | m3 |

| Mineral Wool | 68.7 | m3 |

| Timber | 133.75 | m3 |

| Gypsum | 3.11 | m2 |

| Plywood | 219.32 | m3 |

| Water Control Layer | 0.615 | m2 |

| Drainage Mat | 1.15 | m2 |

| Extruded Polystyrene | 185 | m3 |

| Roofing Membrane | 4.71 | m2 |

| Carpet | 10.9 | m2 |

| Carpet Padding | 1.33 | m2 |

| Asphalt Shingle | 1.6 | m2 |

| Underlayment | 1.76 | m2 |

| Wood/Aluminum Door | 65.6 | m2 |

| Wood/Aluminum Window | 174 | m2 |

| Zone | Condition | GWP (KgCO2e) | Change in Embodied Carbon (KgCO2e) |

|---|---|---|---|

| 1 |

| 25,768.81 | - |

| 2 |

| 28,287.68 | 2518.87 |

| 3 |

| 31,212.81 | 2925.12 |

| 4 |

| 37,957.94 | 6745.13 |

| 5 |

| 38,855.14 | 897.20 |

| 6 |

| 39,278.91 | 423.77 |

| 7 |

| 39,597.47 | 318.55 |

| 8 |

| 40,129.60 | 532.13 |

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 | Zone 8 | |

|---|---|---|---|---|---|---|---|---|

| Foundation | 6854.07 | 7616.35 | 8206.84 | 9912.00 | 10,522.45 | 10,580.37 | 10,623.90 | 10,696.64 |

| Ext Wall | 7127.49 | 7127.49 | 6210.41 | 11,240.68 | 11,504.78 | 11,857.71 | 12,123.02 | 12,566.24 |

| Int Wall | 1407.69 | 1407.69 | 1407.69 | 1407.69 | 1407.69 | 1407.69 | 1407.69 | 1407.69 |

| Roof | 5675.45 | 7432.05 | 10,683.76 | 10,693.47 | 10,716.11 | 10,729.05 | 10,738.75 | 10,754.93 |

| Door | 652.10 | 652.10 | 652.10 | 652.10 | 652.10 | 652.10 | 652.10 | 652.10 |

| Window | 442.74 | 442.74 | 442.74 | 442.74 | 442.74 | 442.74 | 442.74 | 442.74 |

| Finish | 3609.27 | 3609.27 | 3609.27 | 3609.27 | 3609.27 | 3609.27 | 3609.27 | 3609.27 |

| Sum | 25,768.81 | 28,287.68 | 31,212.81 | 37,957.94 | 38,855.14 | 39,278.91 | 39,597.47 | 40,129.60 |

| Climate Zones | Median | Q1 | Q3 | Whisker Low | Whisker High |

|---|---|---|---|---|---|

| Zone 1 | 169.52 | 165.39 | 173.42 | 157.19 | 181.05 |

| Zone 2 | 185.77 | 181.64 | 189.67 | 173.44 | 197.31 |

| Zone 3 | 207.21 | 202.54 | 211.77 | 192.41 | 222.13 |

| Zone 4 | 244.22 | 241.91 | 246.56 | 235.38 | 253.35 |

| Zone 5 | 249.69 | 247.41 | 251.98 | 241.14 | 258.52 |

| Zone 6 | 251.92 | 249.74 | 254.17 | 243.84 | 260.40 |

| Zone 7 | 253.66 | 251.50 | 255.88 | 245.86 | 261.82 |

| Zone 8 | 256.49 | 254.40 | 258.71 | 249.25 | 264.18 |

| Country | City | Embodied Carbon Limit (kgCO2e/m2) |

|---|---|---|

| Switzerland | Zurich | 425 (residential) |

| Denmark | Nation-wide | 600 |

| France | Nation-wide | 415 (residential) |

| UK | London | 970 (office) |

| 800 (residential) | ||

| 675 (school) | ||

| 690 (retail) | ||

| Canada | Vancouver | 400 |

| Toronto | 250–350 (mid–high-rise and non-residential) | |

| <250 (low-rise residential) | ||

| <350 (city-owned facility) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nouri, A.; Hu, M. Decoding Carbon Footprints: How U.S. Climate Zones Shape Building Emissions. Climate 2024, 12, 212. https://doi.org/10.3390/cli12120212

Nouri A, Hu M. Decoding Carbon Footprints: How U.S. Climate Zones Shape Building Emissions. Climate. 2024; 12(12):212. https://doi.org/10.3390/cli12120212

Chicago/Turabian StyleNouri, Ali, and Ming Hu. 2024. "Decoding Carbon Footprints: How U.S. Climate Zones Shape Building Emissions" Climate 12, no. 12: 212. https://doi.org/10.3390/cli12120212

APA StyleNouri, A., & Hu, M. (2024). Decoding Carbon Footprints: How U.S. Climate Zones Shape Building Emissions. Climate, 12(12), 212. https://doi.org/10.3390/cli12120212