1. Introduction

The 4th industrial revolution has been characterized by the rise of data, connectivity, and human machine integration; in manufacturing, this translates into the progressive digitization of processes, where more process-generated data are recorded than ever before. New monitoring and control systems are integrated into production, utilizing technologies that have been in development in the past decades. This rapid growth in digitization is accelerated by three main pillars. The first pillar is the new solid-state sensors that can now support demanding industrial environments with a more efficient form factor, making integration easier, without needing any interventions into equipment’s regular operation, at an industrially viable cost. The second pillar is the fifth generation of cellular networks (5G). Cellular networks allow for standalone connections between industrial locations, without interfering with already-existing network infrastructure. These high-speed connections can enable real-time communication between machines and locations, allowing decentralized applications. By utilizing the commercial 5G network, we bypass the need for the development of a private 5G network avoiding all the extra cost associated with 5G servers, like antennas, etc.. The development of public networks in Greece provides sufficient coverage [

1] and, furthermore, the price per gigabyte of using the public network has drastically decreased every year, including by 26% from 2023 to 2024 [

2]. The third pillar is the integration of machine learning models in manufacturing. Machine learning models enable the real-time prediction of complex phenomena that cannot be solved analytically and are now approached empirically. Industry 5.0 extends this paradigm by reintroducing the human into the loop, emphasizing human–AI collaboration, where operators provide context-aware judgments that machines cannot replicate. This collaborative intelligence enhances resilience, adaptability, and decision quality, particularly in complex and variable production environments [

3]. Furthermore, the human-centric approach aligns with sustainability objectives, as human oversight supports zero-defect manufacturing by reducing errors, material waste, and resource inefficiencies.

Monitoring systems are a critical component of modern manufacturing, as they provide the means to capture, process, and interpret data that reflects the actual state of machines and processes. Their effectiveness relies heavily on the quality of sensing and data acquisition, since accurate measurements of physical phenomena such as temperature, vibration, or force are essential for the timely detection of deviations and potential failures. The selection of appropriate sensors is particularly decisive, as poor sensing cannot be compensated for by advanced signal processing alone. By transforming raw signals into meaningful information, monitoring systems enable predictive maintenance, process optimization, and real-time operator support, thereby improving equipment effectiveness, ensuring product quality, and promoting zero-defect manufacturing [

4]. Up until now, most of the monitoring systems that are in use in manufacturing run on local deployment, placed on the shop floor area or running on dedicated servers. These approaches require vast resources in overhead equipment, personnel, and energy cost, as well as space on the machine floor. The drawbacks most of the time stall the mass integration of new monitoring systems, even if there are clear advantages for the manufacturing process. Recently, the rise of Software as a Service (SaaS) and Cyber-Physical Systems (CPS) have started penetrating into the manufacturing sector.

According to the Software as a Service (SaaS) approach, all the software components needed for infrastructure to run are managed by an external provider. This approach eliminates the need for heavy investments in security, data storage, and high-power artificial intelligence servers that up until now needed to run on-site. By eliminating these initial costs for the infrastructure, as well as the extra personnel that are needed to operate the overall equipment, manage data, and be responsible for the overall maintenance, the SaaS approach has become an increasingly attractive option for industrial applications. Initial implementations are cheaper compared to local deployments and the cost of mass adoption scales more linearly based on the needs of the client and are not constrained by traditional infrastructure limitations. Furthermore, updating already developed software, as well as debugging, can be performed off-site, requiring minimum to no effort from the facility personnel, and the party which handles the software does not have to intervene physically on the shop floor, causing delays to the production line. By decoupling the data management to a separate, off-site cloud-based database, access to the stored information is much easier across different facilities, enabling more accurate processing of collected information, better control of operations, and richer datasets for machine learning model training and validation.

Cyber-Physical Systems (CPS) are engineered to integrate both hardware and software components, aiming to connect the information collected by different kinds of sensing elements with high-power computational entities like machine learning models. CPS build upon the traditional monitoring system, making them more efficient, scalable, and resilient. In manufacturing CPS connects the different sensors placed into a production line or on a specific machine with computational modules with advanced computing capabilities for data analytics, and the integration of machine learning models and neural networks. These models allow CPS to close the loop and advance from a simple monitoring system to a partially or fully automated control system. Critical to closing the control loop are the real-time requirements on both decision making and data transmission between the areas involved.

The scope of this work is progressing beyond the established feasibility study on the utilization of the 5G network for the development of a cloud-based monitoring system [

5]; the work already presented was focused on researching whether the proposed architecture of utilizing the available 5G network in Greece was sufficient to support the real-time requirements of a monitoring system for demanding manufacturing processes. The results showcased that a monitoring system that utilizes the public 5G infrastructure to employ cloud computing is feasible and so this publication extends further towards the design, deployment, testing, and validation of a 5G- and cloud-based process-monitoring solution for the manufacturing sector’s requirements in two use cases, one in an industrial relevant environment and one in a real industrial facility.

This work presents the development of a distributed cyber-physical monitoring system, designed to be easily configured to monitor and address manufacturing process challenges driven by complex physical phenomena. Critical to the development of the system is the usage of the commercially available 5G network used as the bridge connecting the different development areas and supporting the real-time requirements of a production line. The monitoring system also implements the Software as a Service approach for all the software components which are hosted off-site. The goal of the system is to be utilized as a tool to provide key indicators regarding the status of the manufacturing process when it comes to certain phenomena that lead to damage to both the workpiece and the machine. The structure of this paper is as follows:

Section 2 consists of the literature review regarding the state-of-the-art understanding.

Section 3 describes the material and methods utilized for the system’s development.

Section 4 depicts the results of system implementation into a real production line.

Section 5 comments upon the presented results.

2. Literature Review

Typically, process-monitoring systems are integrated and deployed locally to (i) not compromise real-time prediction aspects and (ii) to not interfere with existing and possibly fragile IT infrastructure. Indicative examples include the work of Liu [

6], who implemented a chatter-detection strategy based on the Variational Mode Decomposition (VMD) and energy entropy of a processing unit located on the machine floor. Similarly, VMD was also used with the addition of energy ratio by Stavropoulos et al. [

7] to monitor the chatter occurrence mid-process, while M. Hossein et al. [

8] used pattern-recognizing algorithms in combination with convolutional neural networks (CNN) and energy-based features to create a hybrid on-line chatter detection model. Souflas et al. [

9] used an instrumented milling head that captures vibration and temperature data during milling, and utilizes these into a decision tree classifier and a random forest regressor to monitor tool wear.

Currently, most work involving monitoring systems that implement cloud solutions utilizing 5G is still limited to studies regarding the feasibility of implementing 5G in manufacturing. Cheng et al. [

10] try to map all areas where 5G currently stands in manufacturing and analyzes the communication requirements for various aspects of smart manufacturing, including machine-to-machine communication, the Industrial Internet of Things (IIoT), Cyber-Physical System (CPS)-based manufacturing, logistics and supply chains, industrial internet platforms, and digital twin-driven manufacturing. Furthermore, Liwen Hu et al. [

11] explored the feasibility of using 5G for process monitoring in milling operations, emphasizing its potential to revolutionize manufacturing through real-time data transmission, remote control, enhanced quality control, and increased efficiency. A novel 5G-enabled architecture was introduced to improve the efficiency, accuracy, and reliability of process monitoring.

On the application side, Yang et al. [

12] focused on a cloud manufacturing-based condition-monitoring platform that integrates 5G technology. The title suggests the work explores how 5G, along with a standard information model, supports real-time condition monitoring within a cloud manufacturing context, likely leveraging 5G’s capabilities for high data rates and low latency. Additionally, Mentes et al [

13] address the challenges of integrating sensors into Cyber-Physical Production Systems (CPPSs) for data collection and process monitoring, noting the limitations of existing wired and heterogeneous wireless infrastructures, which lead to high deployment and maintenance efforts. The study develops and implements a framework for 5G-enabled sensors for a machine tool, adapting an existing digital twin for a milling machine to support data-driven analysis. Real-time data transfer from a 5G-enabled accelerometer and a smartphone-based sensor was demonstrated for evaluation and visualization, aiming to elaborate the benefits, potential, and transferability of 5G sensors for future applications.

Prior studies have focused primarily on 5G-enabled data collection and local algorithm deployments for process monitoring. This study focuses on the feasibility of end-to-end communication between locations through the available commercial 5G network, meaning that real-time requirements are strictly limited due to the need to communicate feedback back to the facility where data originated from. To achieve this, artificial intelligence algorithms are also utilized, due to their ability to effectively resolve demanding phenomena in manufacturing.

3. Material and Methods

The methodology starts with the industrial requirements. The system aims to be a non-invasive, stand-alone solution that does not interfere with pre-existing IT infrastructure. It aims to provide a feasible alternative to local deployments, where all the processing is conducted on-site, aiming for a more cost-effective and easily deployable solution in a real manufacturing environment. For the manufacturing process that needs to be monitored, the best-fitting sensing unit is selected. The sensor is mounted on the machine and data are sent over 5G for evaluation. For each manufacturing issue an artificial intelligence model is developed. The model is hosted off-site and receives the information sampled during manufacturing. The developed algorithm assesses the sampled information and returns an output regarding the occurrence of the phenomenon under investigation. The answer is sent back to the facility for the operator to be informed. The aforementioned methodology is designed to operate in real-time.

3.1. System Architecture

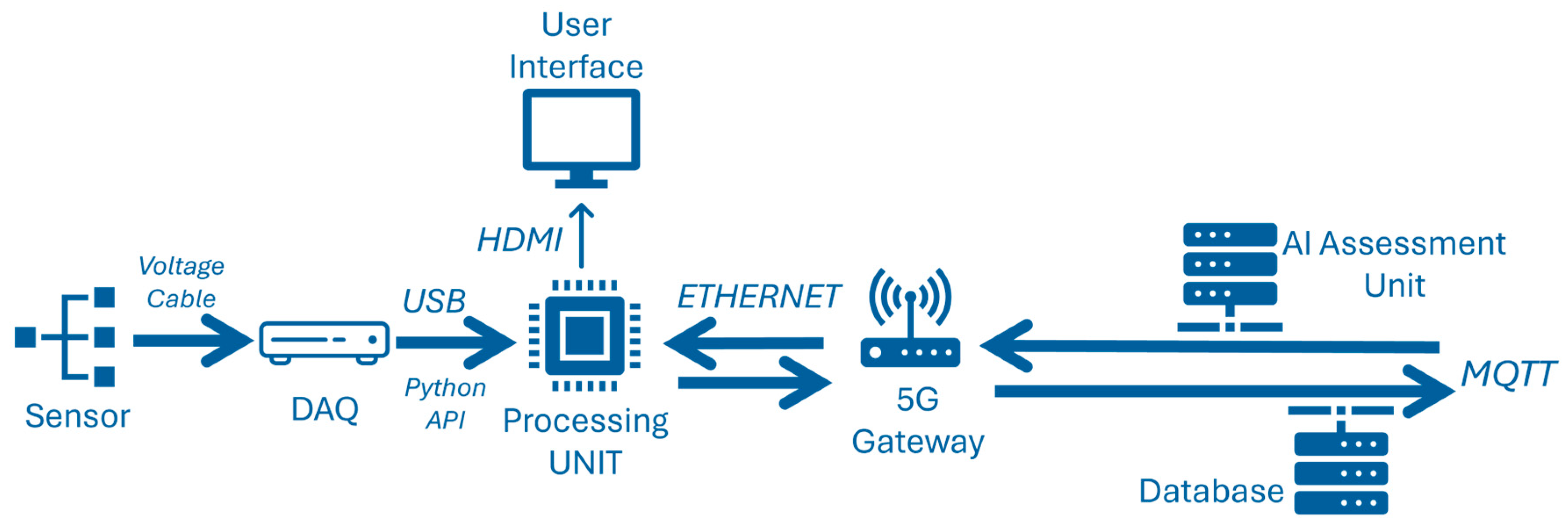

The monitoring system consists of three different entities. The first entity is the data sampling module. The data sampling module consists of the sensing element, the data acquisition device, the local processing unit, and the operator’s graphic interface (GUI). The sampled data are transferred through a local processing unit to a private communication bus that pushes the sampled information outside the facility for assessment and storage, utilizing the available 5G connection.

The system cooperates with a private bus infrastructure that makes messages available to all connected entities. Whenever a message is published to the bus, the receiving ends that assess the data are triggered. The second entity is the assessment unit. The assessment unit receives the data captured from the sampling module and runs them through a machine learning classification algorithm, which detects the occurrence of a specific phenomenon during manufacturing. Bus architecture allows for multiple iterations and different models to operate at the same time using the same raw data, allowing for easy model comparison on real operating conditions.

The third entity of the system is also connected to the bus infrastructure; it is a database which collects the raw data from the sampling module and any assessment result posted from the assessment unit. The collected data are stored as a time-series dataset for each machine that is on the network. The centralized data storage for the whole monitoring system makes data retrieval easier, compared to a local implementation where data retrieval may need to be performed on-site, making it a lengthy process, especially if machines from different areas are integrated on the same system. The architecture is visually represented in

Figure 1.

3.2. System Implementaion

As part of this work, the use case selected to test the methodology is chatter monitoring in CNC machining. Chatter is an uncontrollable and unattenuated vibration that results in large oscillations between the workpiece and the cutting tool and has a detrimental effect on the surface quality, the tool life, and the health of the machine tool components.

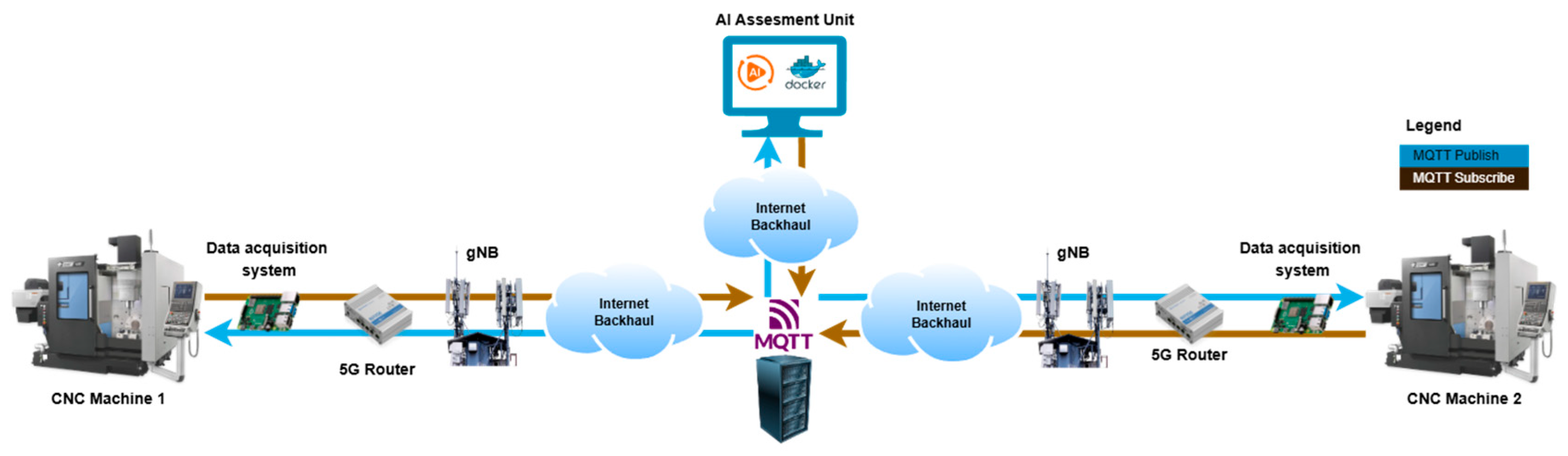

Figure 2 presents the implementation of the architecture in this use case.

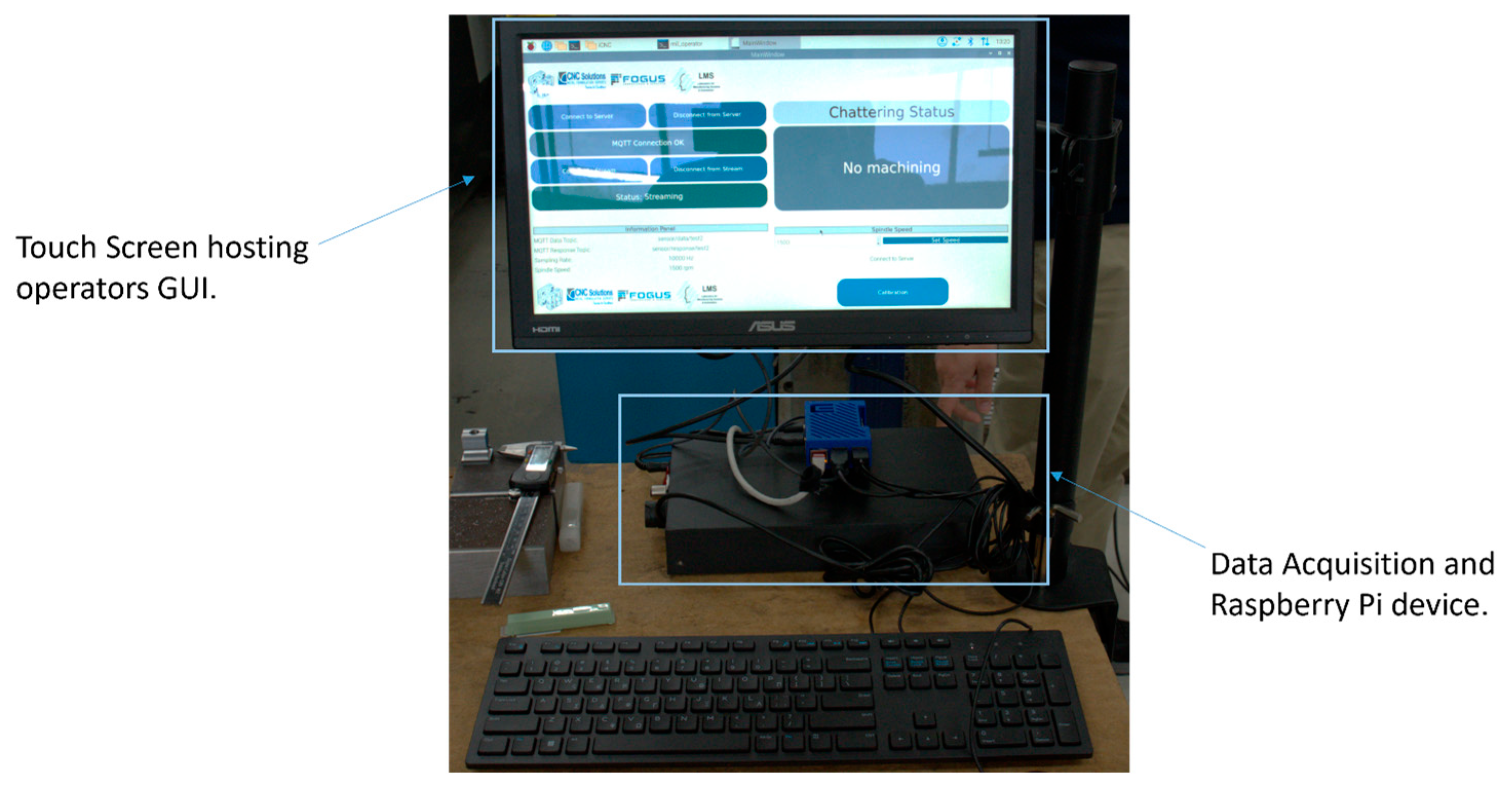

For the data sampling module, the components were chosen to ensure that the “chatter” is captured with sufficient fidelity for subsequent analysis. For the sensing element, the IAC-CM-U-03, tri-axial MEMS accelerometer, by Micromega (Fernemont, Belgium) was chosen as an industry-ready solution; with sufficient bandwidth (0–10 kHz) and sensitivity at 80 mV/g, it can effectively capture any vibrations that take place during milling. For the data acquisition system, the LabJack T8 was selected for being capable of the simultaneously sampling of up to 8 isolated inputs, differentiating it from the normal multiplexer approach to sampling different analog inputs. LabJack T8 offers 24-bit resolution and up to 40k samples per channel per second. The isolated simultaneous input sampling is ideal for a tri-axial accelerometer where all axes need to be sampled at the same time. The field-processing unit selected is a Raspberry Pi 5; the main purpose of the Pi is to collect and package the collected information to be pushed on the communication bus for assessment and storage. The Pi offers generous IO options to be able to connect a touch screen for hosting the operator’s graphic interface, the DAQ system, and is compact enough to be able to be fitted on the shop floor close to the milling machine without causing interference with the already-installed infrastructure, at a low cost. To transmit collected data out of the facility the RUTX-50 5G modem router by Teltonika was chosen. The RUTX 50 is mainly installed in industrial environments as it offers high throughput and offers many useful features like hosting a VPN server for enhancing data protection.

For the communication protocol between the interest areas, the MQTT protocol was selected. MQTT is a lightweight messaging protocol ideal for IIoT applications as it offers secure data transmission and an easy scalability path for integrating more nodes, utilizing the publish/ subscribe model. For the study, a private MQTT broker was developed, and two different milling machines were operating on the communication bus. The MQTT communication was tunneled through a VPN for enhanced security and network isolation.

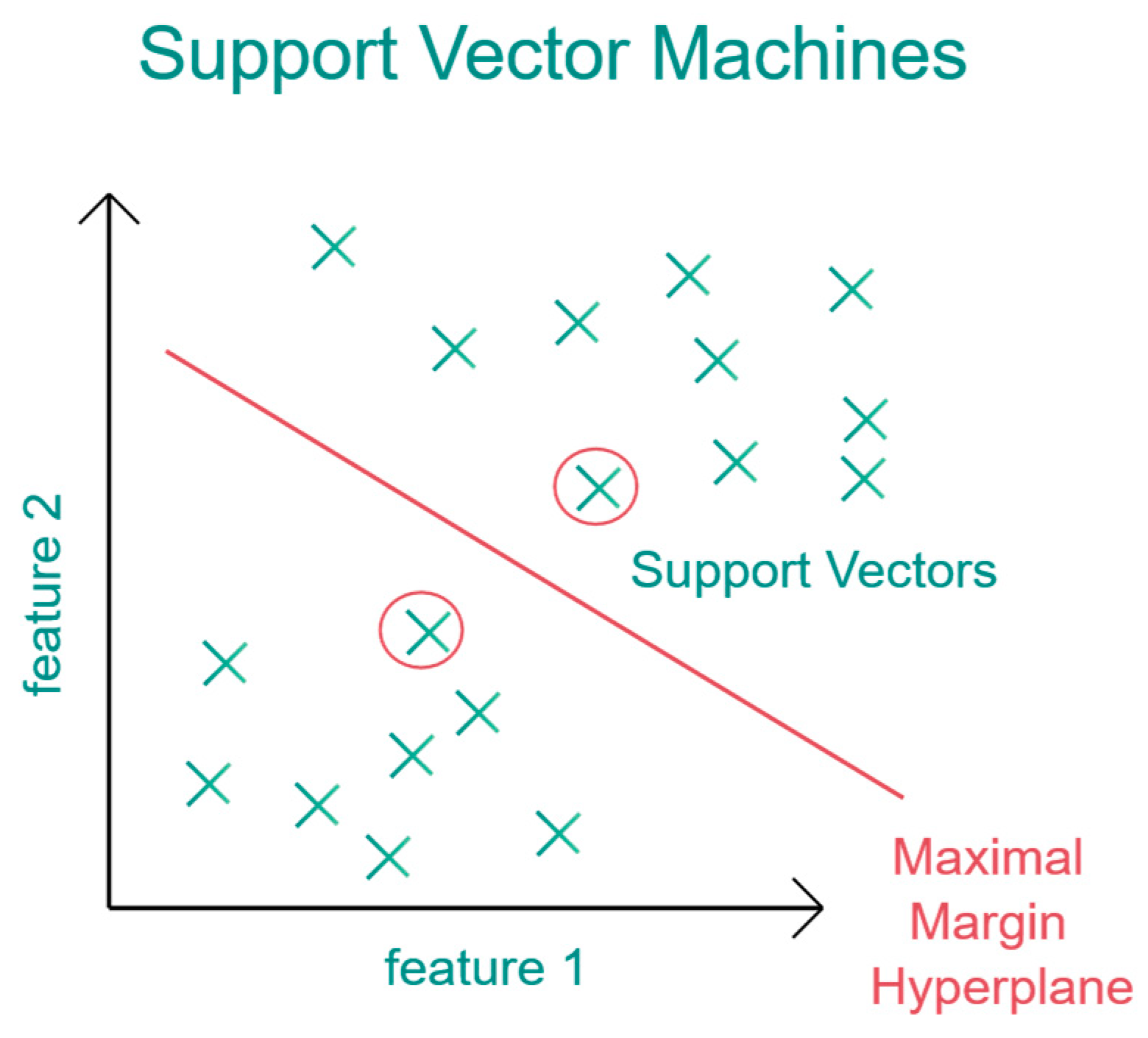

The assessment unit was developed by utilizing a support vector machine (SVM)-based machine learning model. SVMs are supervised learning models that are highly effective for binary classification. SVMs operate by identifying an optimal hyperplane that maximizes the margin between data points of the two classes in a high-dimensional Feature space as shown in

Figure 3. While deep learning approaches, such as Convolutional Neural Networks (CNNs), may also be employed for analyzing time-series data, such as vibrations, typically these require the labeling of more data and introduce more computational overhead, since the automated Feature extraction of CNNs is difficult to be interpreted or correlated with the physical mechanisms of the process. In terms of performance, the primary goal of the solution is achieving an accuracy level above 90% and meeting real-time prediction requirements at 150 ms. As such, the SVM approach has been selected as best fit, which allows for the definition and control of pre-engineered and domain-specific features. The model was trained using the sampled vibration data as its input and determines whether the chatter phenomenon occurs in machining in real time. The assessment unit is containerized to be able to be hosted easily on any cloud platform. Each machine has its own dedicated assessment unit and communication with the data sampling module though a dedicated set of MQTT messages.

For the data storage module, the implemented solution is an Influx DB time-series database. The database employs a Telegraph agent that connects to the communication bus and stores the raw data and assessment result in the database. Additionally, a Grafana dashboard that utilizes the stored information can provide clear insights regarding machine operation during milling. The dashboard provides a thorough review of all the machines connected to the network, beneficial for everyone that wants to be updated regarding the status of each machine without being present on the machine floor, as presented in

Figure 4.

4. Results

The test process conducted to measure the monitoring system’s performance was divided into two focus areas. The machine learning algorithm’s performance and the performance of the 5G network. The machine learning algorithm testing revolved around how accurately and how efficiently the algorithm can detect chatter occurrence on different milling machines. On the network side, the latency of the available 5G infrastructure was measured as well as the network and application round trip delays to assess whether the real-time machining requirements could be met.

4.1. Machine Learning Results

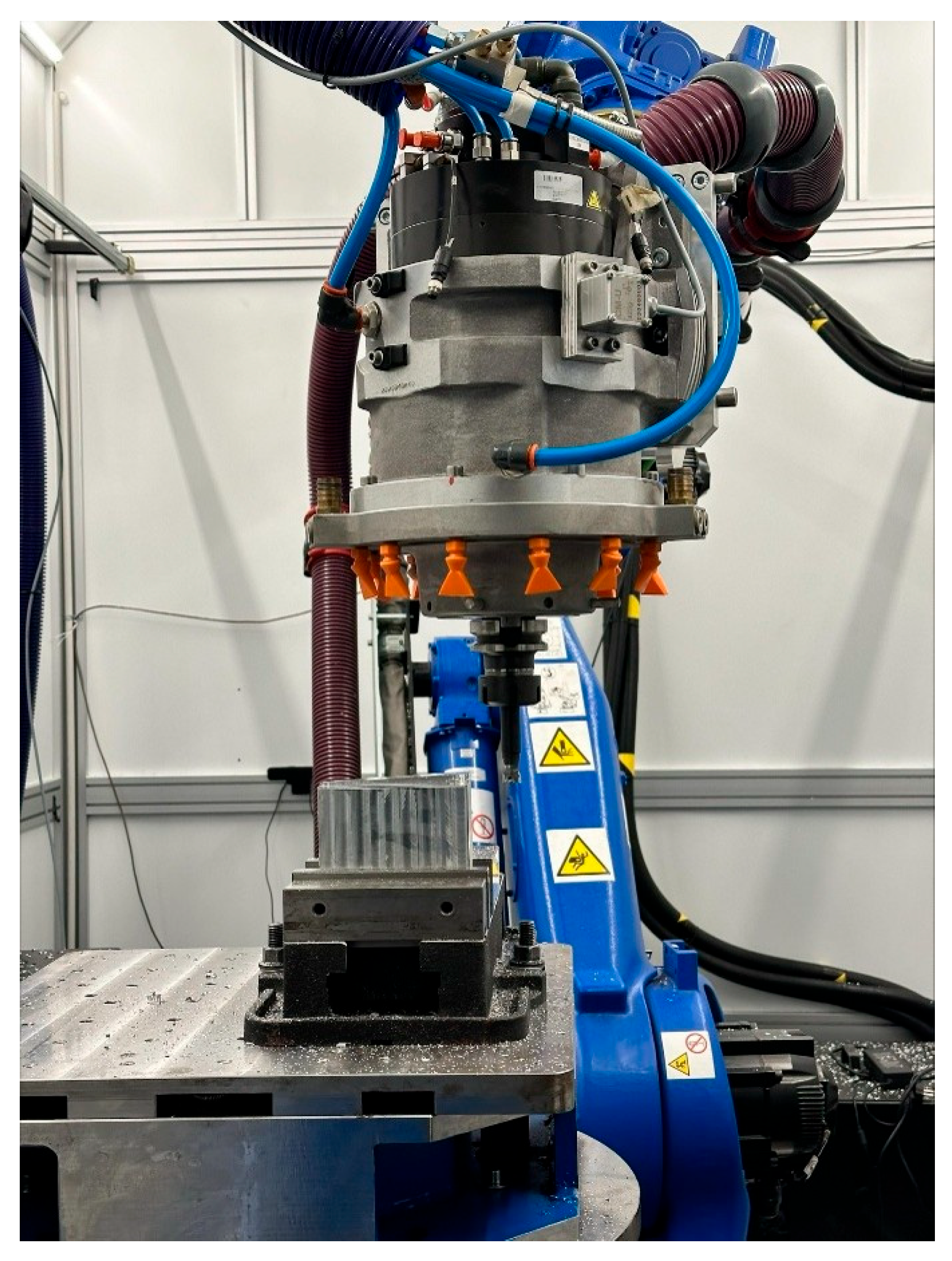

Starting with the machine learning algorithm, vibration data were collected from two distinct milling systems: a conventional HAAS CNC machine and an experimental hybrid robotic cell. These systems were selected due to their differing dynamic behaviors, stiffness, and operational characteristics, ensuring that the dataset would capture a wide range of vibration responses associated with both stable cutting and chatter conditions.

For the development of the machine learning algorithms, the approach and methodology of Souflas et al. [

14] formed the basis. The adaptations made to fit the 5G-based infrastructure needed to be lightweight and able to be deployed as a container to a local server and a cloud service. This resulted in a completely different input–output interface, as well as the way that the model handles potential errors, since both the IT administrator and operator need to be informed. The developed solution was tested locally at first and then deployed on a dedicated server.

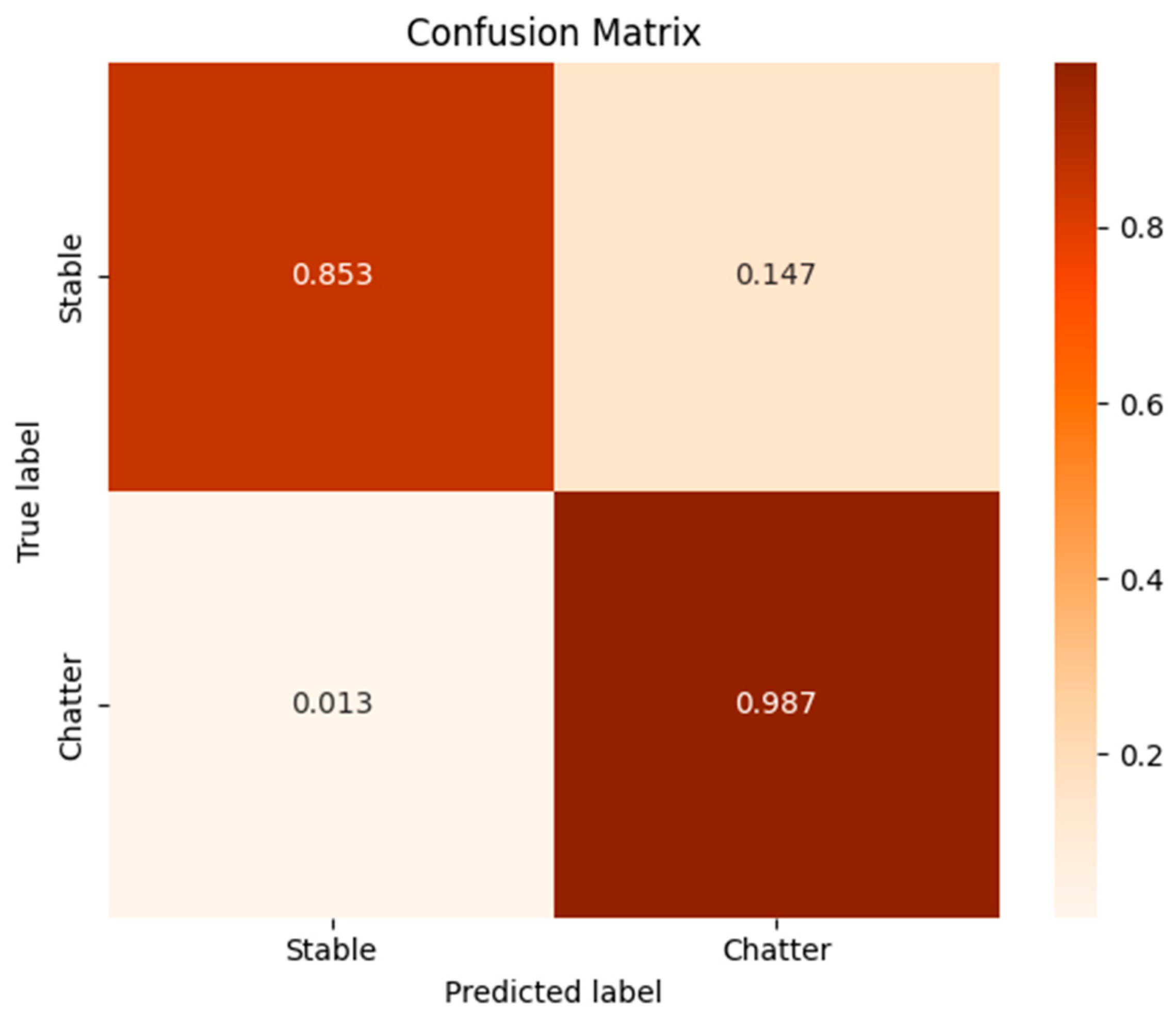

The performance of the trained model was evaluated using standard classification metrics.

Figure 5 presents the normalized confusion matrix obtained on the test dataset, depicting the classifier’s ability to distinguish stable cutting from chatter events with high reliability. The model achieved excellent performance, with most chatter events correctly identified and minimal false positives, demonstrating its applicability for real-time monitoring in industrial settings.

4.2. Networking Results

The performance of the available commercial 5G network was measured to assess if the real-time requirements were achievable. The desired network round-trip delay was set at 100 milliseconds, based on the ITU requirements for real-time communication [

15]. The method selected for this test was ICMP echo requests to assess the network latency and packet loss. To observe how latency scales compared to the packet size, differently sized messages were sent. The setup used for these tests utilized the RUTX50 router by Teltonika. For network round-trip latency, measurements were taken for data transferring between two reference points of the platform, namely the MQTT broker and the 5G Router in the machine shop floor room.

Table 1 depicts network-level round-trip delay measurements. The payload sizes started at 32 and scaled to 128, 256, and 512 bytes. Router placement in the industrial environment was also challenging, as the high volume of concrete and steel caused frequent signal interference.

Having established the round-trip latency floor for the network, the application latency was also measured. The application round-trip delay is measured as the amount of time it takes for the assessment result to return to the data sampling module and be displayed in the operator’s GUI, since the data package is published for the data sampling module in the MQTT bus. The set target for the application round-trip latency is set at 150 milliseconds, based on the application requirements. The size of the data message was measured at 168 Kbytes containing the sampled accelerometer data and the MQTT headers. Three different networks were tested to measure the difference in latency between different approaches. The first network tested was establishing communication though the RUTX50 5G modem built into the MQTT broker. This measurement was conducted to establish the latency baseline since no network limitations apply. The second set of measurements were performed using the laboratory’s network infrastructure as a high-speed, high-bandwidth, symmetric connection establishing a baseline for the disseminated communication between modules. The last set of measurements were performed using the available commercial 5G network. In this case the test was conducted at the University of Patras campus. Three variations of the same test were conducted. First, using a public MQTT broker, then using a dedicated MQTT broker, and lastly using the dedicated MQTT broker and a VPN for tunneling all of the connections on the MQTT bus. The results of the tests are listed below in

Table 2.

The initial results did not fulfil the established KPIs. Thus, modifications were conducted to improve the latency. Since the commercial 5G network is asymmetric [

16] and providers prioritize download speeds over upload speed to reduce the latency and achieve the target threshold, focus was given to the data that are uploaded, meaning the sampled acceleration data. To reduce the size of the data, a compression algorithm was applied, namely the G-ZIP algorithm that compressed the size of the MQTT message from the original 168 Kbytes to approximately 30 Kbytes. After implementing the compression protocol and conducting a new set of tests, the test was conducted using the final network, featuring a private MQTT broker with an incorporated VPN service. The final solution managed an application round-trip latency delay of 140 milliseconds. Lastly, there is also the option of hosting the assessment unit outside the existing infrastructure, meaning deploying the assessment container on a cloud service (e.g., aws, azure) or a different server location. Although this can add versatility in deployment and improve redundancy even more, it also adds another step to the information path from and to the MQTT bus, and thus the total application round-trip delay was measured at 195 milliseconds.

Regarding the deployment of the solution for data acquisition and validation,

Figure 6 presents the industrial deployment that was conducted on the shopfloor of CNC solutions, while

Figure 7 presents the user interface of the developed software along with the data acquisition module. Next, in

Figure 8, the sensorized robot machining cell is presented.

5. Discussion

Starting from the digitization process, an industrial environment where milling processes (or others) take place is much more demanding than a laboratory environment, due to the harsh conditions (e.g., cutting fluids). Τo integrate such systems into industry, they must be inexpensive to acquire and require minimal maintenance. This extends from the selected sensing elements to the selected connectors, enclosures, routing across the machine, etc., so that wear resistance must also be considered. Special attention must be taken when calibrating sensors, since the operation of one neighboring machine can interfere with another.

Incorporating user feedback, in the case of manufacturing-related technologies, is of high importance for the acceptance of such solutions. The operator’s graphical interface was iterated and designed to be as simplified as possible based on the operator’s feedback to be as non-invasive as possible so that it is not distractive for other operations.

Moving to the use of AI algorithms for monitoring manufacturing processes, the chatter phenomenon was initially selected as a very demanding case with a high sampling frequency and real-time prediction requirement which stress-tested the 5G-based system. Running the algorithm on an off-site system was especially useful during development, as it allowed multiple containerized versions, each with different hyperparameters, to be tested at the same time. This approach is much more efficient than testing locally, where limited hardware usually means running models one after another and comparing results. The system performed as expected on both machines (laboratory–industrial machine shop), highlighting the system’s ability to perform on different milling machines, each with fundamentally different characteristics and dynamic behavior (e.g., stiffness). This shows that AI models can be successfully integrated into manufacturing through implementation architectures that are non-invasive to the existing IT infrastructures of manufacturers.

Regarding the available 5G infrastructure, the current deployments (in the target area) are mainly based on NSA mode. Also, the signals had to penetrate walls full of steel and cement to reach the area where industrial 5G routers were set. Beyond these links, VPN and MQTT services were set to safely and synchronously transfer data from each CNC machine centrally for assessment. The overall 5G performance managed to support the target use case, even though the real network-level measurements were below the theoretically expected ones. Also, the related round-trip values at the network and application level came very close to the set limit on using a 5G connection. Overall, the network managed to support the ambitious target of moving in real-time to cloud infrastructures processes that conventionally are performed locally next to the CNC machines. However, the results indicated the need for 5G NPN (non-public networks) deployment, especially for industrial environments.

Regarding the approach, the implementation of 5G to enable scalable digitization in a non-invasive way of an already established infrastructure was successful overall. System integration on both milling machines was straightforward. The service availability was sufficient without network disconnections, and data transmission was adequate to provide real tome connection between locations. A complete implementation like this can be considered as proof of concept for implementing similar systems to other demanding processes (e.g., extrusion, additive manufacturing).