Agrivoltaic Impact on Some Lettuce Quality Attributes and Photovoltaic Power Generation

Abstract

1. Introduction

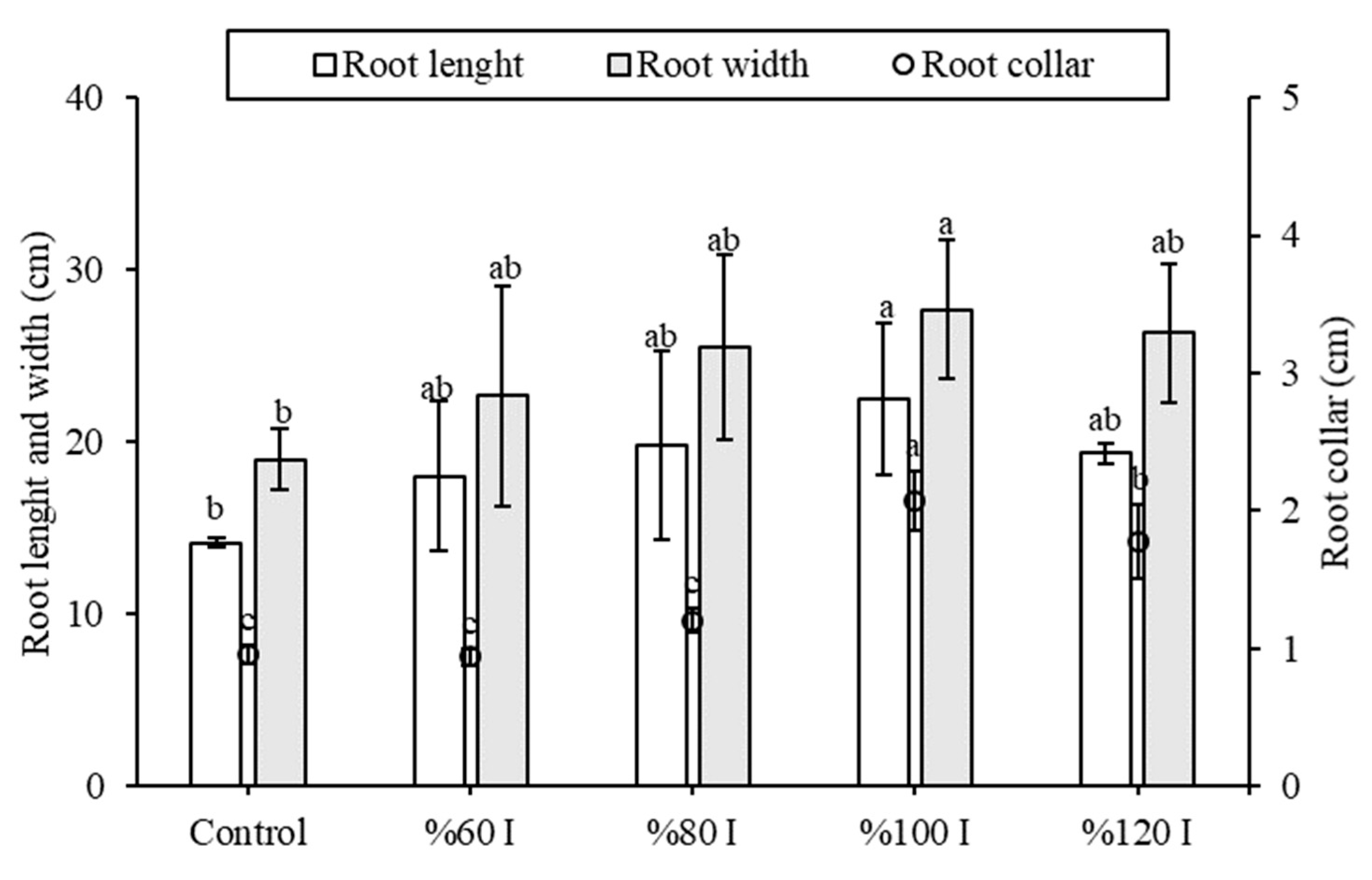

2. Results and Discussion

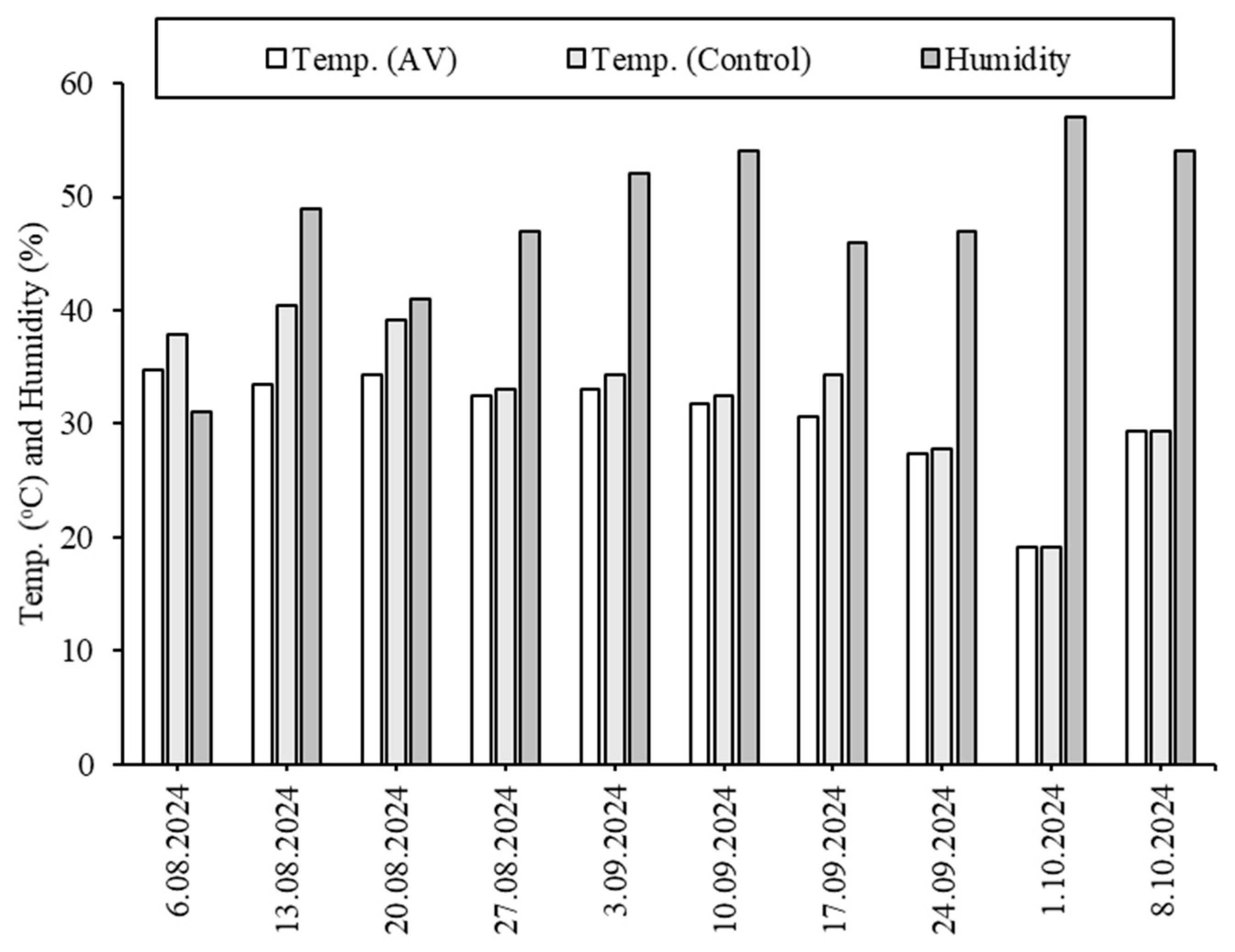

2.1. Climatic Conditions During the Experimental Period

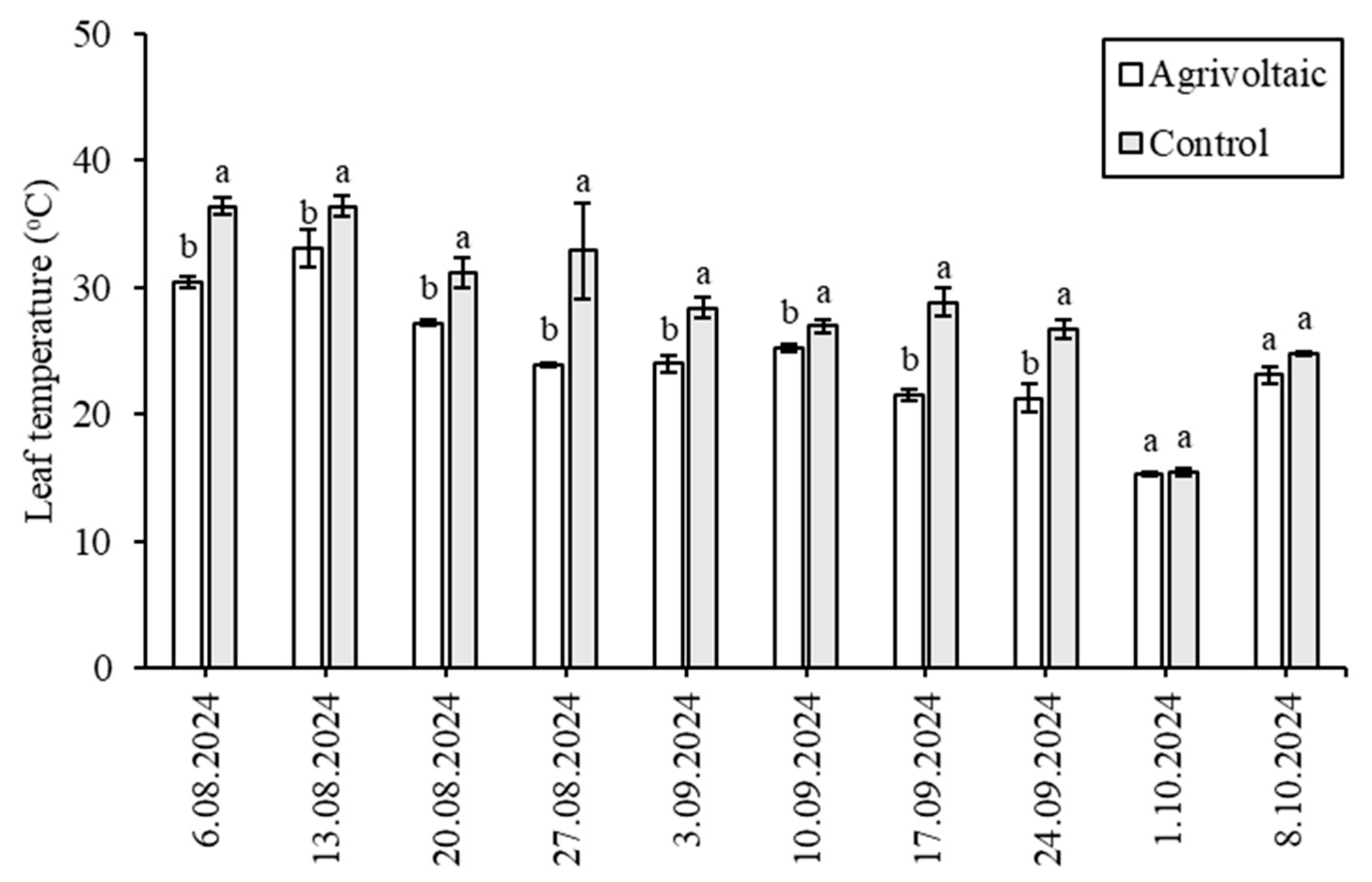

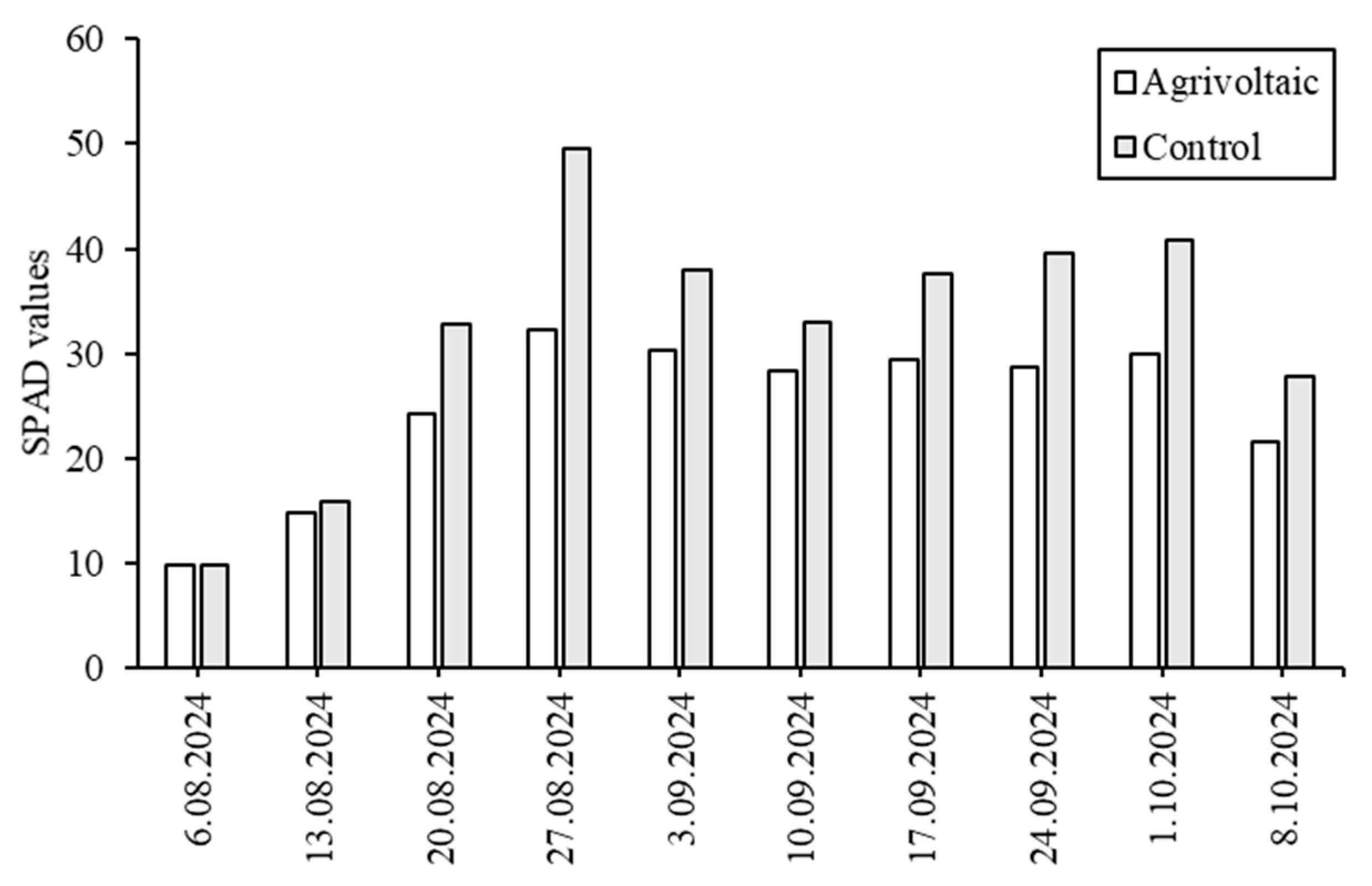

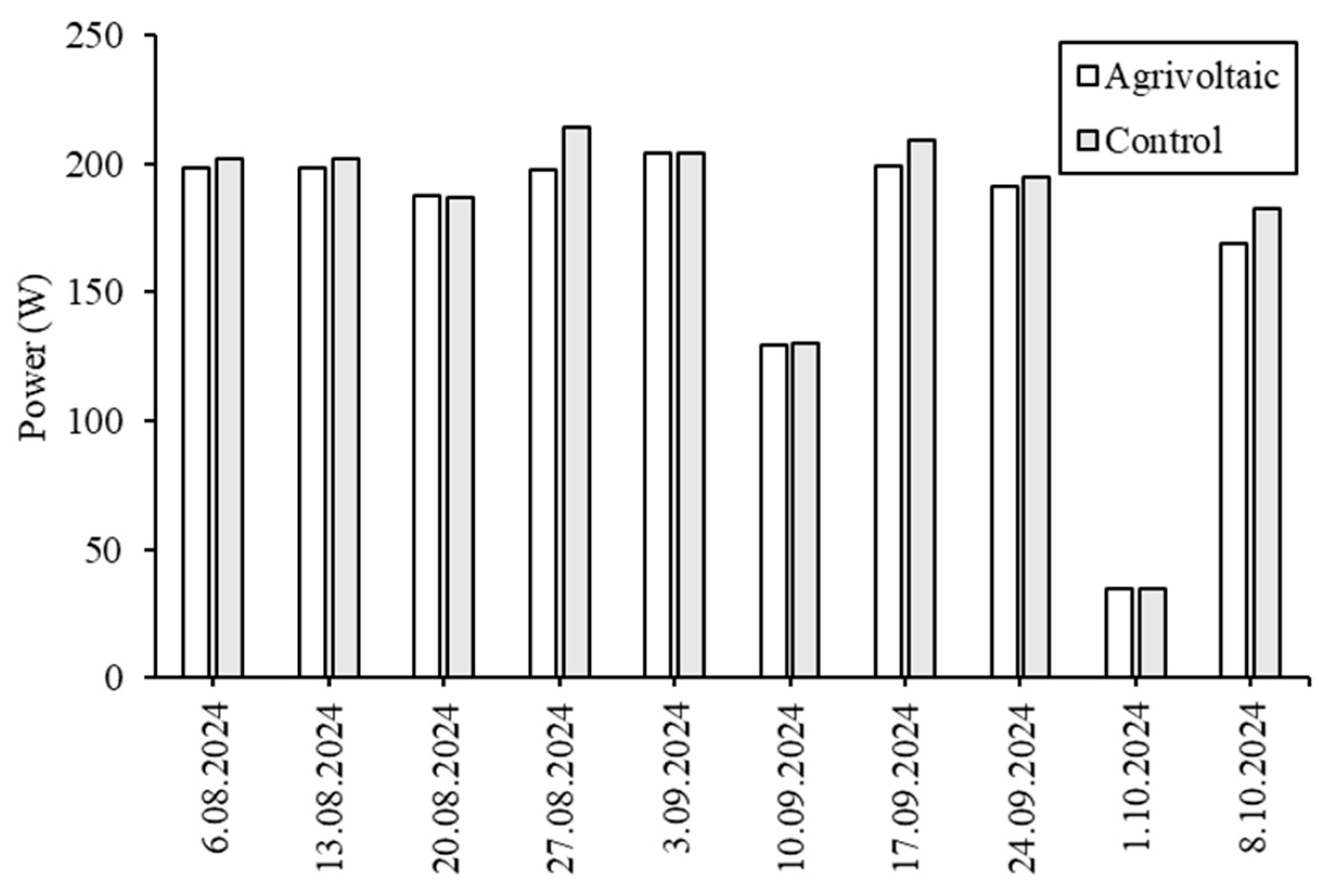

2.2. Leaf Temperature, SPAD, and Panel Power Under Agrivoltaic and Control Conditions

2.3. Size, Weight, and Number of Leaf Parameters of Lettuce

2.4. Leaf Color Characteristics

3. Materials and Methods

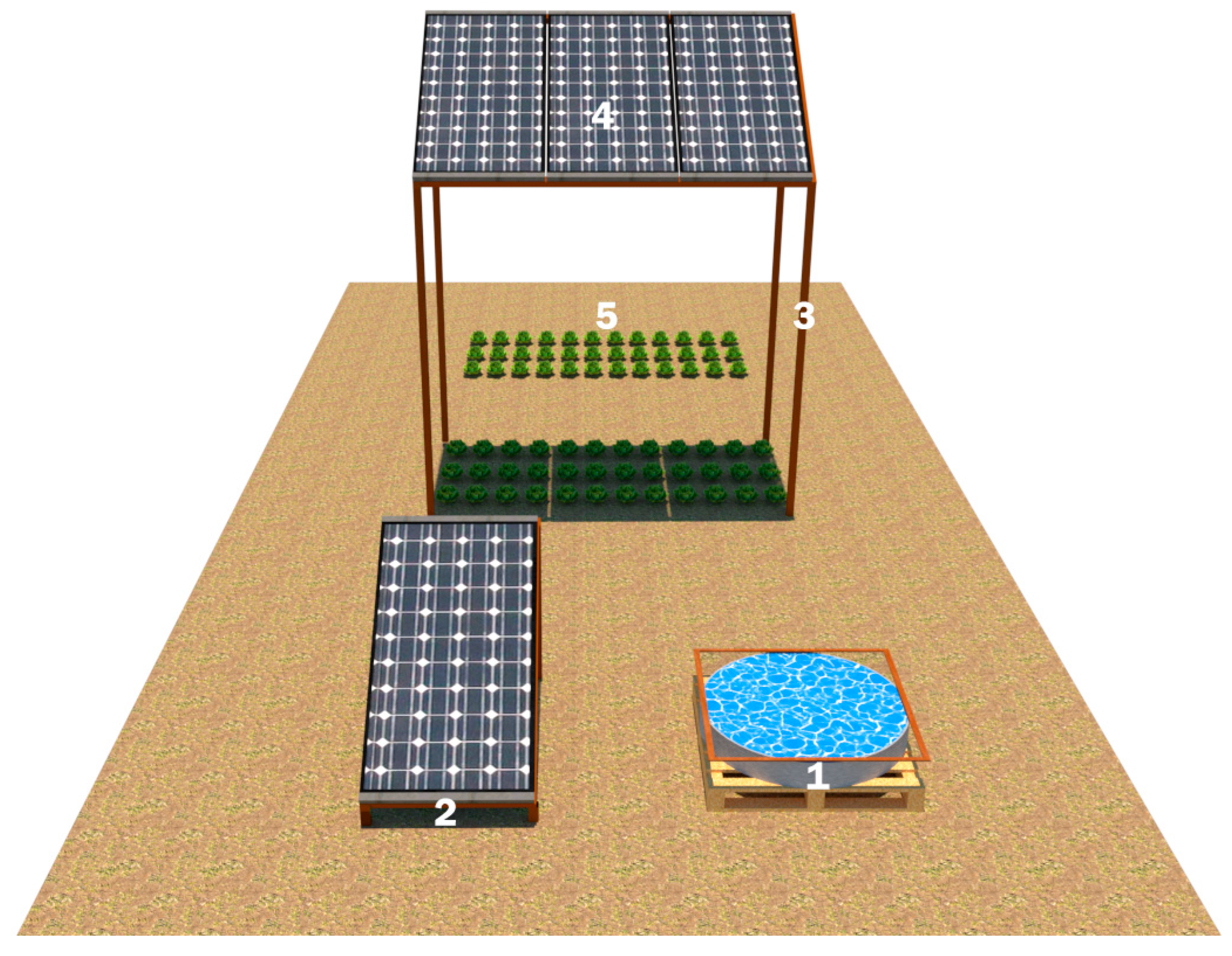

3.1. Experimental Site and Setup Description

3.2. Test Procedure

- I: Irrigation water amount (liters/plant);

- Epan: Evaporation amount from the evaporation pan (mm);

- Kpc: Evaporation pan coefficient;

- A: Area per plant (m2/plant).

3.3. Measurements of Leaf Temperature, SPAD, and Panel Power

3.4. Determination of the Size of Root and Plant, Plant Weight, and Number of Leaves

3.5. Leaf Color Analysis

3.6. Statictics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zahrawi, A.A.; Aly, A.M. A review of agrivoltaic systems: Addressing challenges and enhancing sustainability. Sustainability 2024, 16, 8271. [Google Scholar] [CrossRef]

- Reher, T.; Lavaert, C.; Willockx, B.; Huyghe, Y.; Bisschop, J.; Martens, J.A.; Van de Poel, B. Potential of sugar beet (Beta vulgaris) and wheat (Triticum aestivum) production in vertical bifacial, tracked, or elevated agrivoltaic systems in Belgium. Appl. Energy 2024, 359, 122679. [Google Scholar] [CrossRef]

- Ramos-Fuentes, I.A.; Elamri, Y.; Cheviron, B.; Dejean, C.; Belaud, G.; Fumey, D. Effects of shade and deficit irrigation on maize growth and development in fixed and dynamic AgriVoltaic systems. Agric. Water Manag. 2023, 280, 108187. [Google Scholar] [CrossRef]

- Özden, T. Tarım ve Güneş. In Proceedings of the in 6th SolarVision2023 Energy Transition Summit and Fair, İstanbul, Türkiye, 11 December 2023. [Google Scholar]

- Aćamović-Djoković, G.; Pavlović, R.; Mladenović, J.; Djurić, M. Vitamin C content of different types of lettuce varieties. Acta Agric. Serb. 2011, 16, 83–89. [Google Scholar]

- Food and Agriculture Organization. Food and Agriculture Organization of the United Nations-Classifications and Standards. 2024. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 10 December 2024).

- Marrou, H.; Wéry, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agron. 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Carreño-Ortega, A.; Do Paço, T.A.; Díaz-Pérez, M.; Gómez-Galán, M. Lettuce production under mini-PV modules arranged in patterned designs. Agronomy 2021, 11, 2554. [Google Scholar] [CrossRef]

- Cossu, M.; Tiloca, M.T.; Cossu, A.; Deligios, P.A.; Pala, T.; Ledda, L. Increasing the agricultural sustainability of closed agrivoltaic systems with the integration of vertical farming: A case study on baby-leaf lettuce. Appl. Energy 2023, 344, 121278. [Google Scholar] [CrossRef]

- Elamri, Y.; Cheviron, B.; Lopez, J.M.; Dejean, C.; Belaud, G. Water budget and crop modelling for agrivoltaic systems: Application to irrigated lettuces. Agric. Water Manag. 2018, 208, 440–453. [Google Scholar] [CrossRef]

- Ko, D.Y.; Chae, S.H.; Moon, H.W.; Kim, H.J.; Seong, J.; Lee, M.S.; Ku, K.M. Agrivoltaic farming insights: A case study on the cultivation and quality of kimchi cabbage and garlic. Agronomy 2023, 13, 2625. [Google Scholar] [CrossRef]

- Patel, U.R.; Chauhan, P.M. Studies of climatic parameters under agrivoltaic structure. Renew. Sustain. Energy Int. J. 2009, 1, 87–97. [Google Scholar]

- Disciglio, G.; Frabboni, L.; Tarantino, A.; Stasi, A. Association between dynamic agrivoltaic system and cultivation: Viability, yields and qualitative assessment of medical plants. Sustainability 2023, 15, 16252. [Google Scholar] [CrossRef]

- Oleskewicz, K. The Effect of Gap Spacing Between Solar Panel Clusters on Crop Biomass Yields, Nutrients and the Microenvironment in a Dual-Use Agrivoltaic System. Master’s Thesis, University of Massachusetts Amherst, Amherst, MA, USA, 2020. [Google Scholar]

- Potenza, E.; Croci, M.; Colauzzi, M.; Amaducci, S. Agrivoltaic system and modelling simulation: A case study of soybean (Glycine max L.) in Italy. Horticulturae 2022, 8, 1160. [Google Scholar] [CrossRef]

- Liu, W.; Omer, A.A.A.; Li, M. Agrivoltaic: Challenge and progress. Agronomy 2023, 13, 1934. [Google Scholar] [CrossRef]

- Trommsdorff, M.; Kang, J.; Reise, C.; Schindele, S.; Bopp, G.; Ehmann, A.; Obergfell, T. Combining food and energy production: Design of an agrivoltaic system applied in arable and vegetable farming in Germany. Renew. Sustain. Energy Rev. 2021, 140, 110694. [Google Scholar] [CrossRef]

- Modi, V.V.; Patel, S.K. Performance evaluation of agrivoltaic system for the synergy among greengram (Vigna radiata L. Wilczek) production and solar electric power generation. Energy Sci. Eng. 2024, 12, 5385–5397. [Google Scholar] [CrossRef]

- Kostik, N.; Bobyl, A.; Rud, V.; Salamov, I. The potential of agrivoltaic systems in the conditions of southern regions of Russian Federation. IOP Conf. Ser. Earth Environ. Sci. 2020, 578, 012047. [Google Scholar] [CrossRef]

- Zheng, J.; Meng, S.; Zhang, X.; Zhao, H.; Ning, X.; Chen, F.; Liu, W. Increasing the comprehensive economic benefits of farmland with Even-lighting Agrivoltaic Systems. PLoS ONE 2021, 16, e0254482. [Google Scholar] [CrossRef]

- Jamil, U.; Rahman, M.M.; Hayibo, K.S.; Alrayes, L.; Fordjour, E.; Thomas, R.; Pearce, J.M. Impacts of Transparency in Agrivoltaics Lettuce Cultivation Using Uniform or Non-Uniform Semitransparent Solar Photovoltaic Modules. Available at SSRN 4954023. 2024. Available online: https://ssrn.com/abstract=4954023 (accessed on 27 July 2025).

- Fontana, L.; Rossi, C.A.; Hubinger, S.Z.; Ferreira, M.D.; Spoto, M.H.; Sala, F.C.; Verruma-Bernardi, M.R. Physicochemical characterization and sensory evaluation of lettuce cultivated in three growing systems. Hortic. Bras. 2018, 36, 20–26. [Google Scholar] [CrossRef]

- Anonymous. Lettuce. 2024. Available online: www.serene.com.tr/marul (accessed on 12 December 2024).

- Şahin, M.; Al-Bayati, Y.F.A. Determination of water-yield parameters of lettuce plant in Konya open field conditions. J. Soil Water 2018, 7, 38–45. [Google Scholar]

- Ozsoy, G.; Aksoy, E. Soils of the Uludag University campus area, their genesis and classification. In Proceedings of the International Soil Congress on Natural Resources Management for Sustainable Development, Erzurum, Turkey, 7–10 June 2004. [Google Scholar]

- Esmaeili, M.; Mashal, M.; Azadegan, B.; Seif, M. Dependency of growth, water use efficiency, chlorophyll fluorescence, and stomatal characteristics of lettuce plants to light intensity. J. Plant Growth Regul. 2021, 40, 2191–2207. [Google Scholar]

- Mohamoud, S.S. Effects of Different Water Stress Conditions on Yield and Quality of Some Curly (Lactuca sativa var. Crispa) and Cos (Lactuca sativa var. Longifolia) Lettuce Varieties. Master’s Thesis, Akdeniz University, Antalya, Türkiye, 2019. [Google Scholar]

- Taskin, O. Efficiency measurements on defective solar panel (PV). Uludağ Univ. J. Fac. Eng. 2019, 24, 289–298. [Google Scholar] [CrossRef]

| L* | a* | b* | C | α | ∆E | |

|---|---|---|---|---|---|---|

| Control | 49.09 ± 1.97 ab | −8.87 ± 0.53 ab | 27.04 ± 2.76 a | 28.46 ± 2.78 a | 108.20 ± 0.70 ab | - |

| %60 I | 47.26 ± 2.12 ab | −8.45 ± 0.62 a | 27.52 ± 3.25 a | 28.80 ± 3.15 a | 107.18 ± 1.99 b | 5.35 ± 1.13 a |

| %80 I | 46.24 ± 2.63 b | −8.99 ± 0.79 ab | 24.64 ± 4.37 a | 26.23 ± 4.36 a | 110.25 ± 1.87 a | 6.30 ± 0.65 a |

| %100 I | 47.21 ± 1.42 ab | −10.39 ± 0.85 c | 28.79 ± 2.75 a | 30.61 ± 2.87 a | 109.87 ± 0.45 a | 6.40 ± 1.11 a |

| %120 I | 50.29 ± 2.69 a | −9.87 ± 0.86 bc | 28.06 ± 3.22 a | 29.75 ± 3.32 a | 109.42 ± 0.53 ab | 6.69 ± 2.47 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gunhan, Y.; Taskin, O. Agrivoltaic Impact on Some Lettuce Quality Attributes and Photovoltaic Power Generation. Plants 2025, 14, 2853. https://doi.org/10.3390/plants14182853

Gunhan Y, Taskin O. Agrivoltaic Impact on Some Lettuce Quality Attributes and Photovoltaic Power Generation. Plants. 2025; 14(18):2853. https://doi.org/10.3390/plants14182853

Chicago/Turabian StyleGunhan, Yasin, and Onur Taskin. 2025. "Agrivoltaic Impact on Some Lettuce Quality Attributes and Photovoltaic Power Generation" Plants 14, no. 18: 2853. https://doi.org/10.3390/plants14182853

APA StyleGunhan, Y., & Taskin, O. (2025). Agrivoltaic Impact on Some Lettuce Quality Attributes and Photovoltaic Power Generation. Plants, 14(18), 2853. https://doi.org/10.3390/plants14182853