1. Introduction

Generation expansion planning (GEP) aims to find the most economically feasible solution to install a combination of multiple power generation in the long-term planning process of the power system. GEP determines the capacity, timing, and technology of new generation plants to provide the required energy for a 10–30 year time horizon. The increasing power consumption of industrial development, especially in developing countries, significantly highlights the need for GEP [

1]. On one hand, considering the diverse and growing sources of renewable energy, wind power has valuable advantages, such as the capability to generate large quantities of cheap electricity, availability over a wide geographical area, and the possibility to create integrated wind-solar hybrid units [

2]. These factors have increased the importance of using this type of power plant. On the other hand, the use of wind power with intermittent production would significantly increase the complexities of the conventional GEP in which only thermal power plants are considered [

3]. GEP provides a mathematical model for an integer and constrained nonlinear optimization problem in which the objective function is satisfied if the constraints are met [

4]. To solve this optimization problem, two general mathematical and conceptual methods are used in [

1]. The goal is to obtain a simple model that can be used in GEP studies. In other types of power plants, the output at this design level is considered as a fixed number; however, in wind farms, it is necessary to obtain output as probabilities, and on the other hand, it should be as simple as possible so that it can be used in GEP. In the wind farm model, it is assumed that all farms will be under a specific regime at a time. With this assumption, the simplified wind farm model is obtained.

There are currently new conceptual optimization methods, such as the particle swarm optimization (PSO) algorithm [

2], the genetic algorithm (GA) [

3], the honey bee algorithm [

4], the taboo search (TS) [

5], and ant colony (AC) [

5], compared to mathematical methods such as linear programming (LP) [

6], dynamic programming (DP) [

7], and integer programming (IP) [

8]. In addition to the variety of GEP optimization problem-solving techniques, the objective functions and the network-imposed constraints widely vary among different design cases. For example, objective functions can be profit maximization of a generation company in the restructured power market [

9], maximizing reliability [

10,

11], minimizing operating costs [

12,

13], and minimizing environmental pollution [

14,

15]. In addition, constraints such as network security constraints [

16,

17,

18,

19,

20,

21], investment costs [

22,

23,

24], reliability [

25,

26,

27,

28,

29], and environmental pollution [

30] could be part of the constraints that are required to be considered in the GEP problem. Although less attention has been paid to the GEP problem in the presence of wind power plants in the literature, extensive studies have been carried out on GEP of traditional power plants with various objective functions and constraints [

31,

32]. From one side, the cost reduction of the initial investment in wind power plants over the past decade has led to a remarkable amount of renewable energy investment specifically allocated to this type of power plants [

33,

34]. From the other side, the power generation capacity of these units is significantly lower than the nominal amount due to some new challenges posed by the presence of these intermittent generations in the power grid [

35]. Planning for the expansion and operation of wind power plants for long-term intervals is a way to minimize these challenges. The use of the fast start-up power plants studied in [

36] is another solution to reduce the vulnerability of the power system subject to the increasing penetration of wind power generation.

GEP studies for wind power plants require proper modeling of wind turbines and wind farms. Numerous models of wind power plants have been presented in various papers [

37,

38]. In Reference [

39], the planning of combining generation units in the presence of wind units is investigated. In Reference [

40], for a short period of time, the operation and investment costs of wind farms are investigated in addition to the traditional power generation units. In Reference [

41], the penetration of wind power generation of different designs for various short-term economic incentives is examined. Another study aimed at minimizing the amount of carbon produced in GEP [

42]. Few studies of GEP in the last decade have focused on the costs of wind power plant investment in various projects. In this paper, the main objective is to investigate GEP in the presence of wind farms for a long-term target period. For this purpose, a model of the turbine and the wind farm is presented for long-term studies. The turbines’ type is assumed to be horizontal axis wind turbine (HAWT). The model considers the turbine’s forced outage rate (FOR), which is used as the input for GEP studies. The mathematical model of the GEP problem is presented by defining the objective functions and constraints. Finally, a proposed GEP model is solved using the Genetic Algorithm optimization method. The impact of decreasing initial investment due to the growth of wind units’ technology is demonstrated and discussed. Moreover, considering the importance of the maximum possible use of wind energy in the generation system, the maximum possible use of wind power in the GEP process subject to the constraints is investigated. It is worth noting that the impact of wind regimes on long-term planning studies using two different weak and strong wind regimes is illustrated in this paper.

Despite studies for wind power plants in GEP in the last decade, very limited number of studies have examined the cost of investment for various projects in system development planning. Consequently, the purpose of the present study is to investigate GEP with the presence of wind farms for a long time. It is worth mentioning that the difference between the present article and most of the extensive studies in this field is as follows:

The objective function of this paper is to minimize the sum of expansion costs by considering the four constraints of maximum unit capacity to build, refueling constraints, storage margin, and loss of load probability (LOLP).

In this paper, in addition to traditional power plants, the presence of wind power plants with a random generation nature is considered.

Due to the growth of technology for building wind farms, the initial investment required to make these units has decreased. In the present paper, the effect of this price reduction on the influence of wind units on the generation system for a long period of planning is studied.

Given the importance of the maximum possible use of wind energy in the production system, the maximum possible use of wind power in the GEP process is investigated, provided that the constraints are met.

The impact of the wind regime on long-term planning studies using two different wind regimes has been shown due to the development of wind unit technology and the increasing reliability of these units as well as different wind regimes. The type of wind regime is selected for two sample cities in Iran. Type 1 wind regime as a weak wind regime and type 2 wind regime as a strong wind regime have been used to obtain wind turbine output.

In the following section,

Section 2, turbine and wind farm modeling are discussed.

Section 3 presets the GEP mathematical model, including the objective function and constraints as well as the Genetic Algorithm method for optimization and problem-solving. In

Section 4, case studies based on real network data are shown by performing three experiments. These experiments include comparing the combined use of traditional power plants and wind farms with the ones with only traditional power plants, computing the maximum possible penetration of wind power plants, and computing the objective function sensitivity to the initial investment cost changes. Finally, in

Section 5, the results of this study are summarized with some remarks.

5. Case Studies

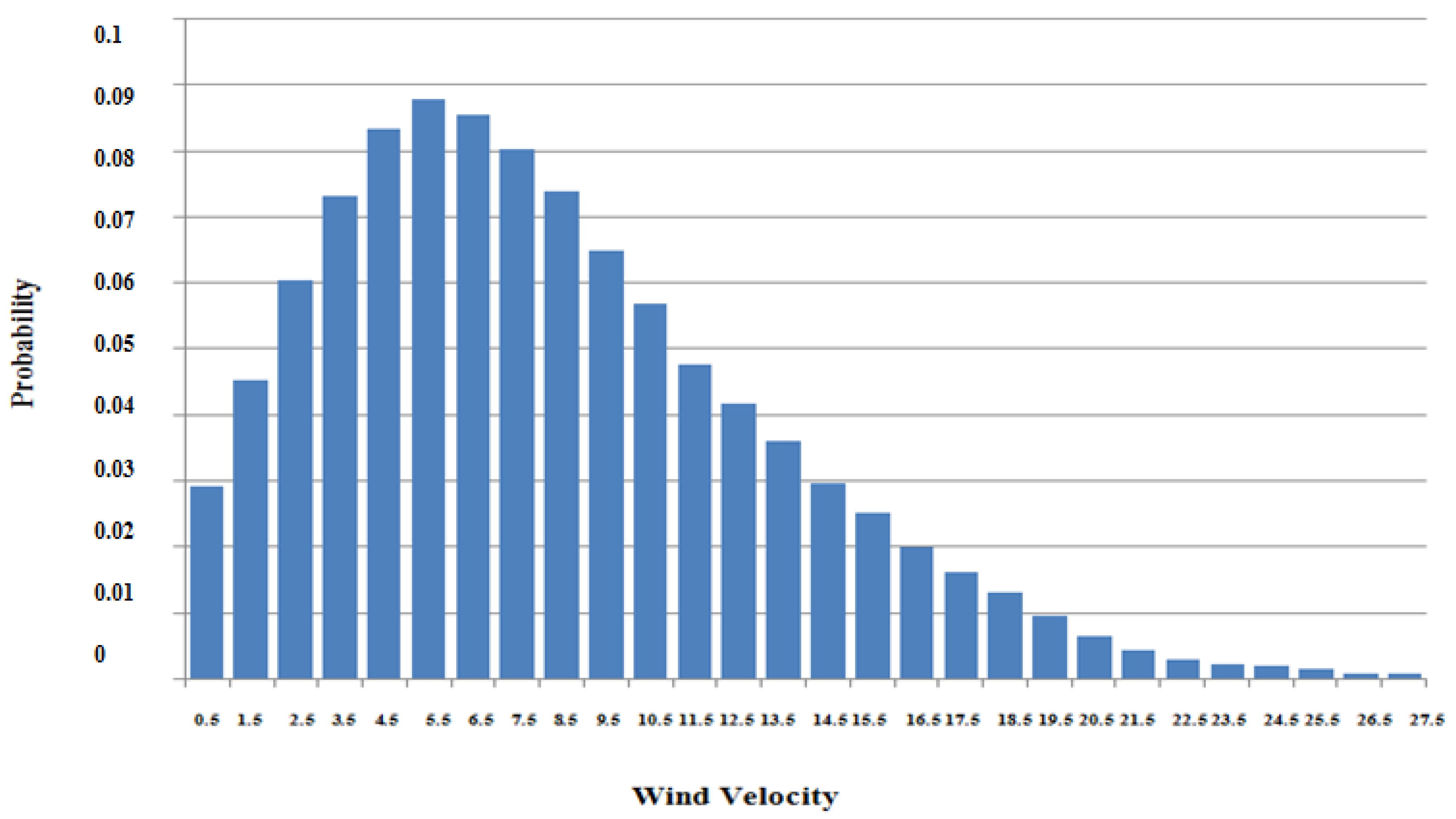

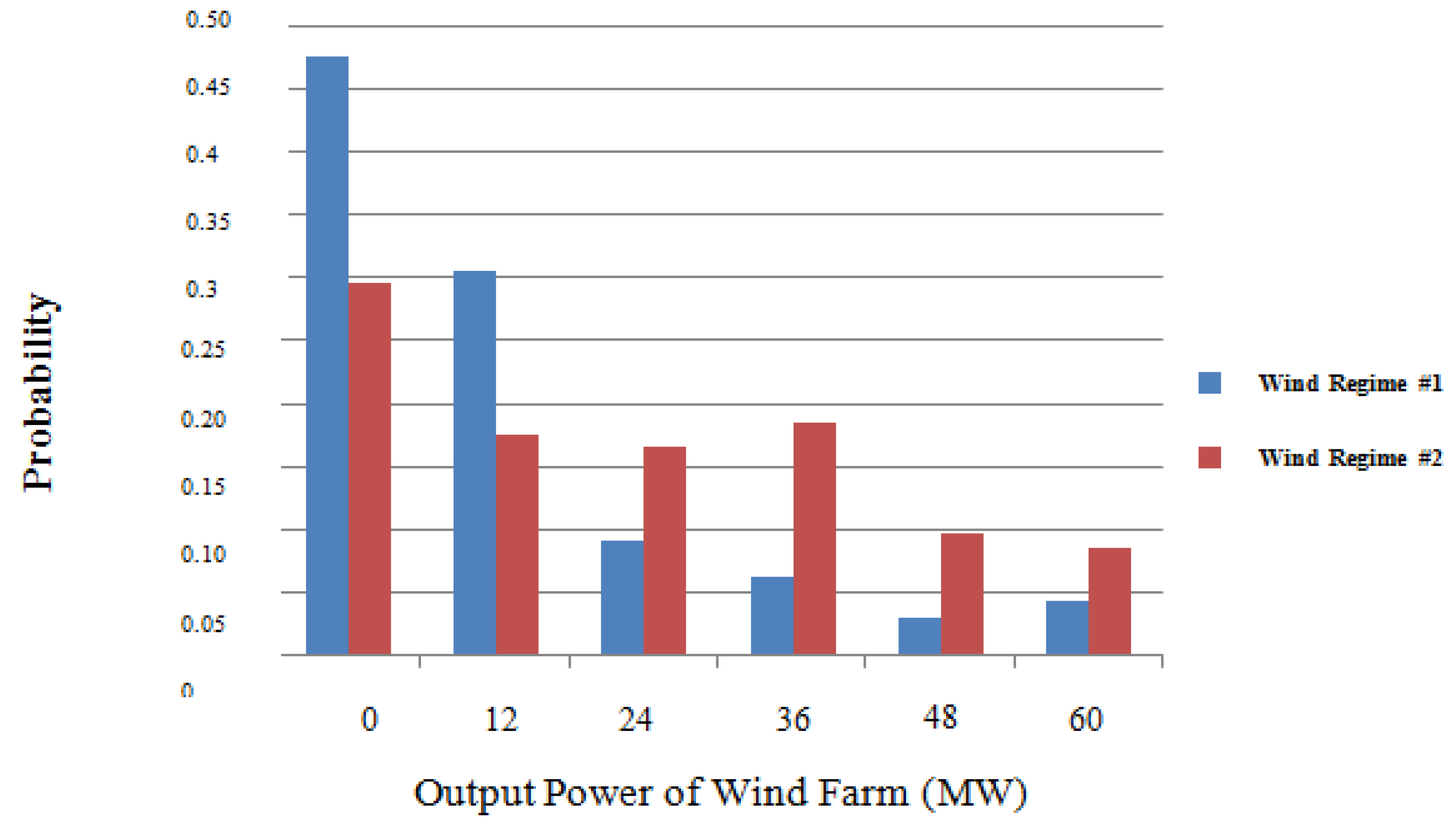

In this paper, two types of wind regime, including type 1 wind regime as the weak wind regime for Ardebil city in Iran, and type 2 wind regimes as a strong wind regime for a windy sample city, were used to obtain wind turbine output [

38]. The output power of a 2 MW turbine unit was divided into six parts, 0, 0.4, 0.8, 1.2, 1.6 and 2 MW and for FOR = 0.1, using the output model calculation procedure according to Equations (2)–(4), the output models classified for two farms consists of 30 turbine units calculated and is shown in

Table 9.

The required technical and economic data of the traditional power plants and wind farms studied in this article have been extracted entirely from references [

49] and [

11], respectively. In

Section 4, the technical and economic information of the system under study were introduced. The studies in this article are presented in the form of three experiments as follows:

5.1. GEP in the Presence of Wind Farm

In the first experiment, the planning was performed separately for two separate schemes. In plan 1, a 14-year planning interval, including seven 2-year planning stages, was implemented for the traditional power plant units. In plan 2, wind units were also considered as a selectable type of unit in the planning process. Thus, for plan 1, in the presence of five traditional unit types the study in conducted. Furthermore, in the 7-stage planning, each chromosome contains 35 genes, whereas for plan 2, which also includes the wind units as a selectable unit type in chromosome formation, each chromosome will have 42 genes.

For wind farms, the minimum number of constructions in each period is one unit, and the initial investment cost of wind farms is

$1485 per kWh. The results of the two selected optimal plans and the costs of each plan are presented in

Table 10 and

Table 11.

The results show that due to the high cost of initial investment of wind farms compared to other units, the total cost of investment increases, although the use of wind farms in planning reduces the operation cost.

5.2. Investigating the Impact of Wind Penetration on GEP

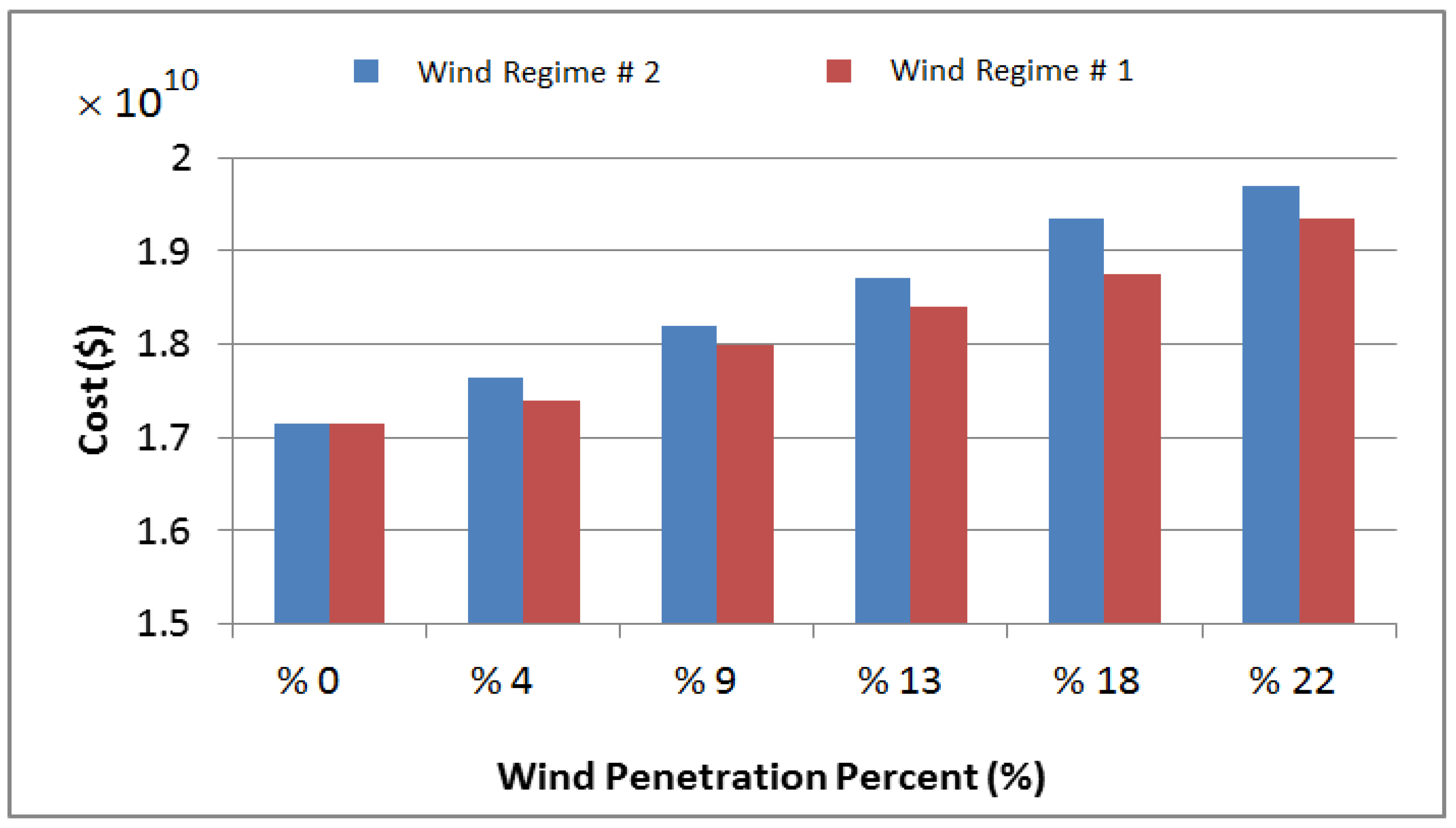

The scenario that was considered in the second experiment was aimed at investigating the impact of adding wind to the system in a step-by-step manner. A certain number of fixed wind farm steps were added to the system at each stage. For example, to achieve 4% wind penetration in the generation system, two wind units must be constantly added to the production system at each planning stage—atthe end of the 7-stage planning, there will be 14 wind farm installations that have a capacity equivalent to 4% of the total peak load available in the generation system. To achieve 9%, 13%, 18%, and 22% wind penetration, 4, 6, 8, and 10 wind farms must be constructed in each 2-year design period, respectively. Since the number of wind units added in this scenario is initially fixed and constant, the number of chromosome genes is 35. In the process of problem-solving, the effect of the added wind units at each stage should be considered in the constraints of the problem. The process of adding stairwells continued until the LOLP constraint was violated. This scenario was implemented for both types of wind regime, and the results were obtained.

Figure 3 illustrates the cost function changes as the wind farm penetrates the system. Although using a wind farm as shown in

Figure 4 reduces the Operational Cost of the system due to its low operating cost compared to other types of power plants, since the cost of building these units is high, adding these units to the production system increases the overall cost of the project.

The effective amount of wind farm output power is the expected value of farm output power. For wind regimes 1 and 2 this is 11.8652 MW and 22.4075 MW, respectively. Due to the small cost of variable operating and maintenance of wind farms, these units were used in the process of calculating the operating cost to support the load. However, due to the low effective power output, the impact of increasing the cost of building these units was far greater than the cost of operating these units and increased the overall cost of the project.

The effective amount of wind farm output with wind regime 1 is less than regime 2. For this reason, the amount of reduction in operating costs for regime 2 is higher than that of regime 1.

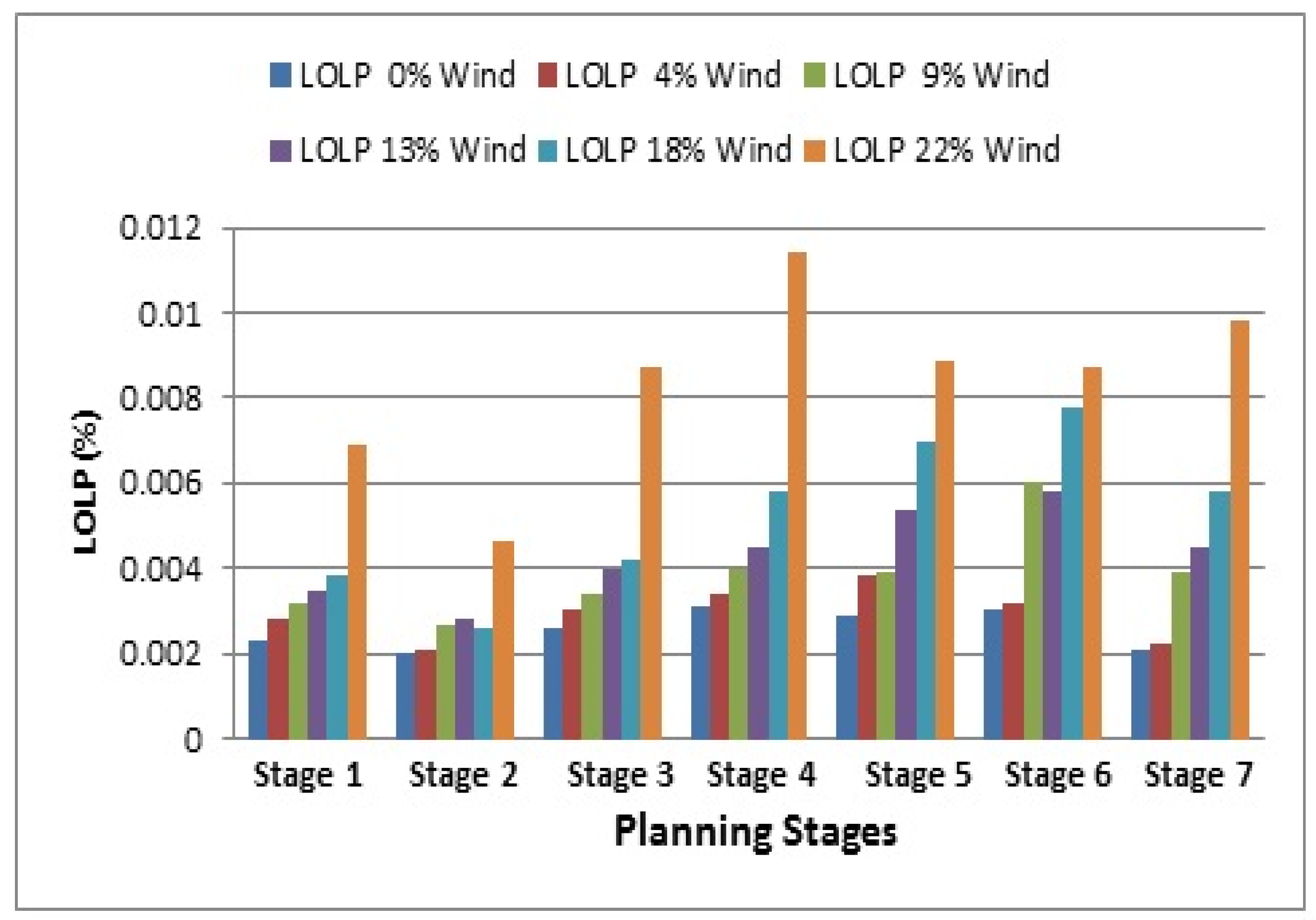

As mentioned, the addition of wind farms can continue as long as the LOLP constraint is not violated, even if the increased cost incurred by the system is used. For the studied system, the LOLP constraint was violated in exchange for 22% penetration of wind farms with the type 1 wind regime. Therefore, it is possible to install wind farms in the system if the wind regime type is one, with 8 farms at each planning stage.

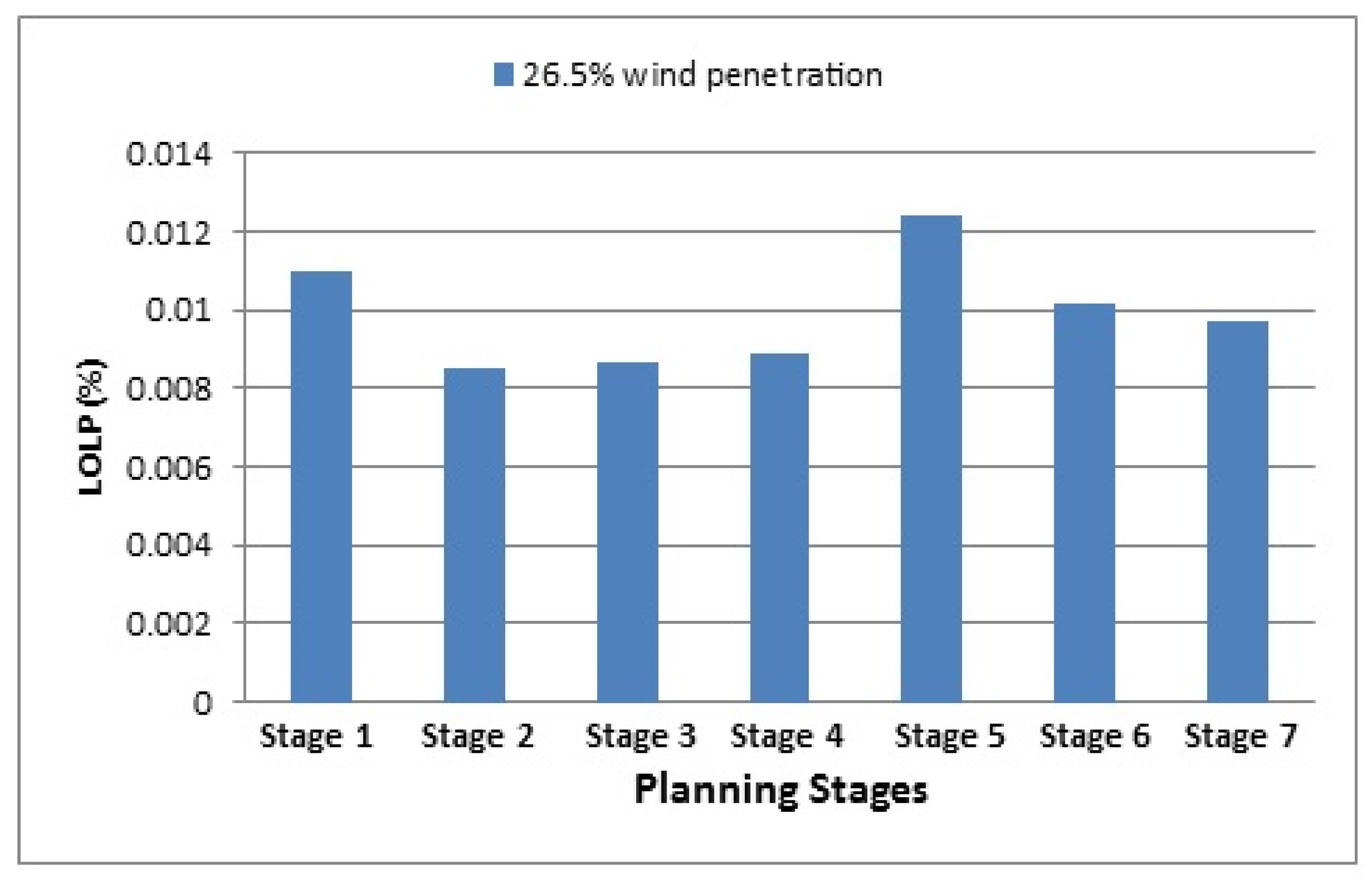

Figure 5 shows the different values of LOLP at different planning stages for different wind permeation values with the Type 1 regime.

As shown in

Figure 6, for the penetration of regime-1 wind farms on the generation system, the LOLP constraint approaches the limit value of 0.01, and for the 22% penetration of this constraint in the 4-th planning stage, it was violated. However, if the LOLP constraint in

Figure 5 is examined for wind regime 2, it is found that for the 26.5% wind penetration in the system, this constraint is violated due to the more appropriate wind. Nonetheless, the higher reliability of the ratio to the wind regime is reported to be 1. Hence, the maximum possible installation of a wind farm with 2 wind regimes at each planning stage is 10 farms.

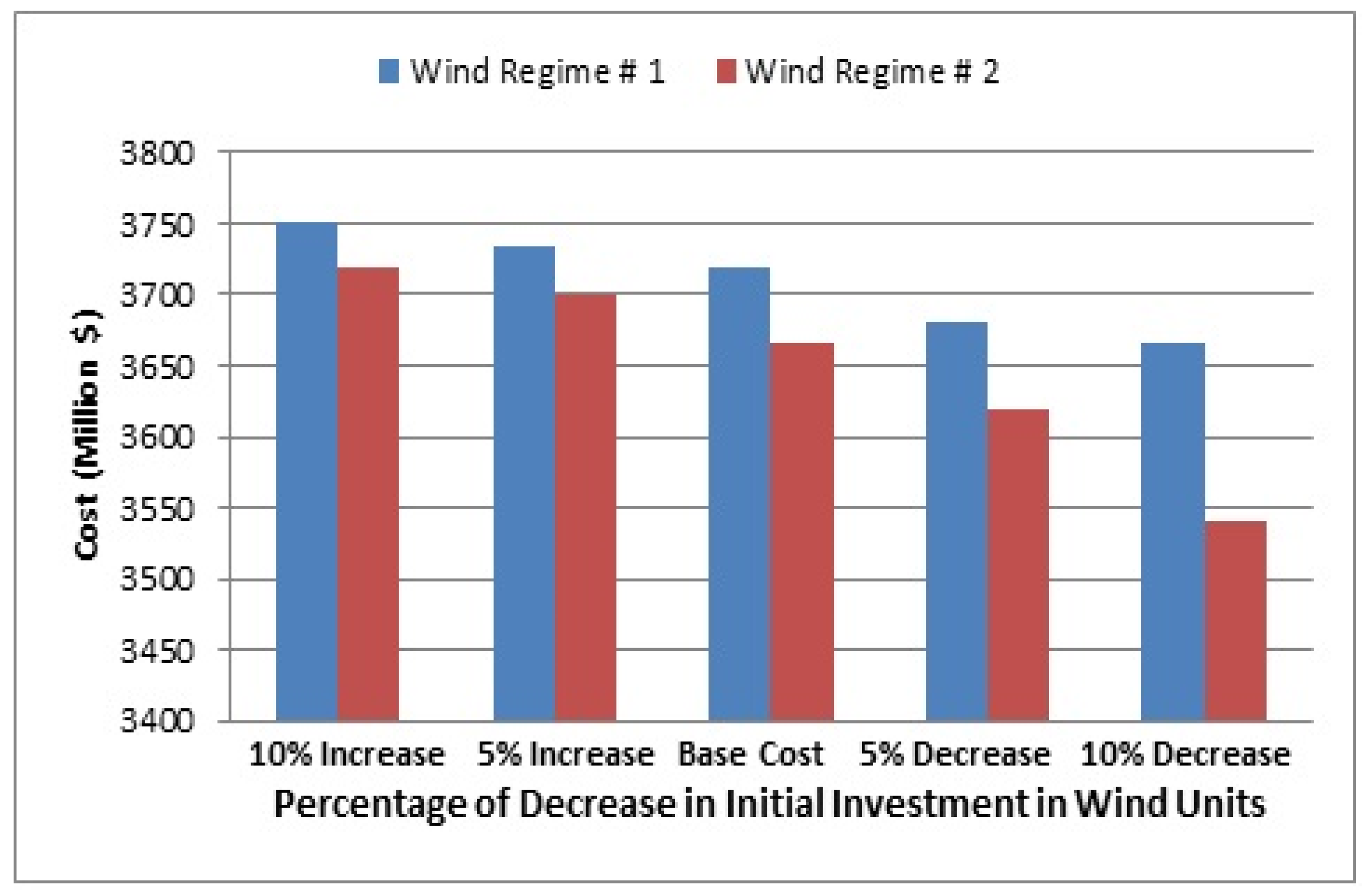

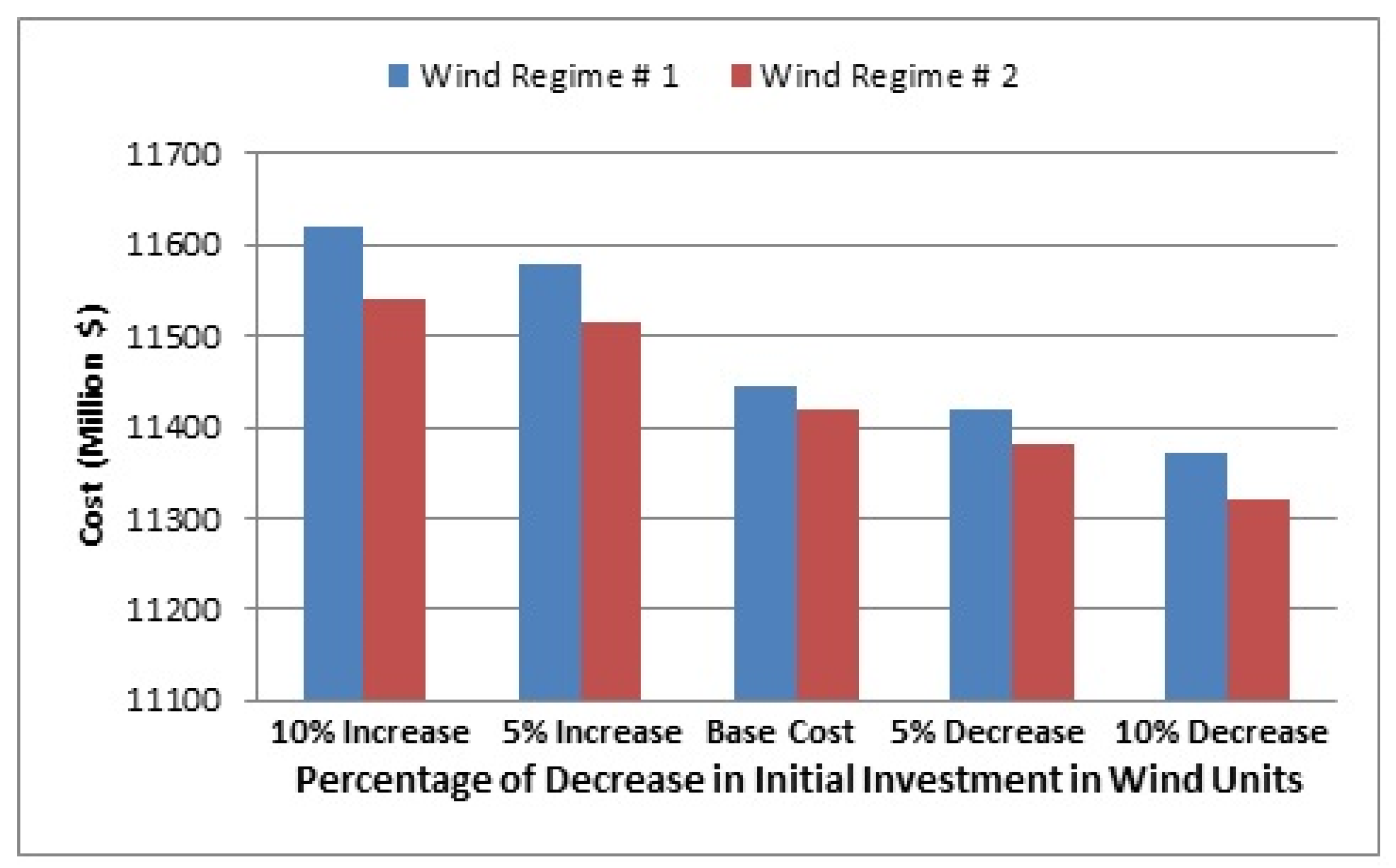

5.3. Investigating the Sensitivity of the Problem of Initial Investment in Wind Farms

In the third experiment, wind farms are considered as one of the types of power plant units to be selected. The minimum number of wind farm options for both types of wind regime is 1 unit and the maximum for type 1 wind regime is 8 units and for wind 2 regimes is 10 units. This experiment was conducted to determine the sensitivity of the objective function to the initial investment cost of the wind units using two turbine output power models derived from two different wind regimes. For this purpose, for each of the two initial investment amounts less than

$1485 (1402 and 1320, respectively), and for the higher initial investment amounts of 1575 and 1650, different design costs are compared. As shown in

Figure 7, by reducing the initial investment cost of the wind units, the cost of the required designs is reduced and by increasing the investment cost of these units, the total cost of the optimal design increases.

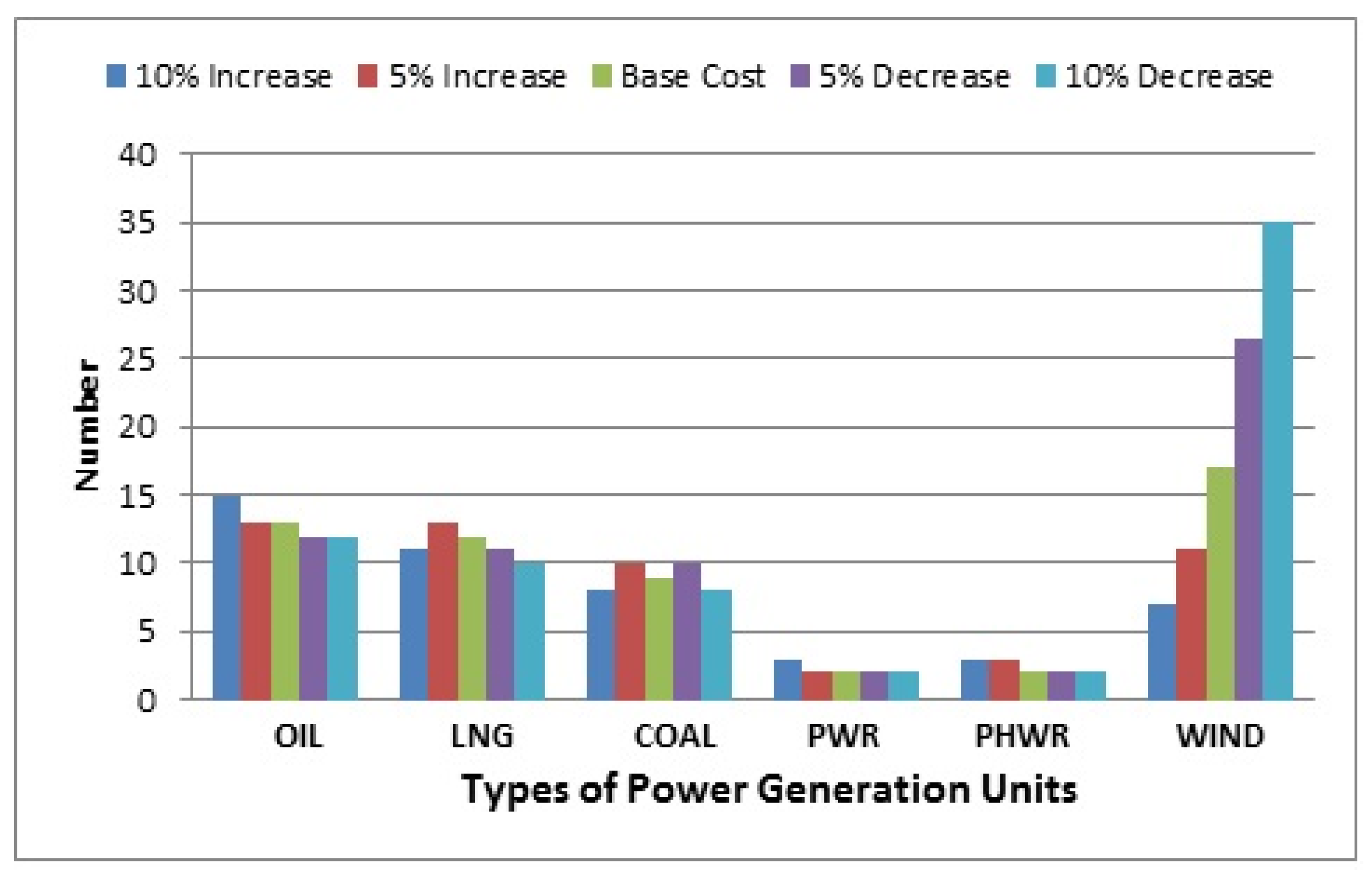

When the initial investment cost of wind units ($/KW) is 1650, the number of wind units in the optimally selected plan will yield the minimum designated number one. By reducing the cost of the initial investment in optimizing the layout, more wind farms are selected. Interestingly, in order to reduce the cost of investing wind farms to ($/kW) 1320, the final design selected has a lower cost than one that is not used in any wind farm system. In other words, if the cost of initial investment required for wind farms is reduced to less than ($/kW) 1320, plans are selected that, despite the use of wind farms, cost less than the total cost of not using wind farms.

In the system under study, a plan with 8% wind penetration was chosen as the optimal design for reduction of the initial investment required for wind farms to (

$/kW) 1320 for the type 1 regime and for farms with wind regime 2, the selected plan has 11% wind penetration.

Figure 8 and

Figure 9 illustrate the amount of variation in the initial investment cost and operating cost of the selected designs for different amounts of initial unit investment cost reduction.

Figure 10 shows the change in the number of units selected in different plans for regime 2.

Due to the number of oil units selected in different plans, it can be said that with the increase in the possibility of using wind units, the system is moving towards using a lower number of oil units. Due to the cost of investment required for oil units, it is determined that by reducing the initial investment cost of wind farms and making the price competitive for oil units, the operating costs of the wind units will be lower and plans use fewer oil units.

6. Conclusions

In this paper, a GA was used to model GEP in the presence of wind power plants. A six-state model was used to obtain the wind farm output power model. The method of calculating the six-state wind farm output model with the FOR of wind farm units for use in long-term GEP calculations is described. In the first experiment of GEP using GA, an optimized plan was obtained. In the second experiment, depending on the importance of knowing the maximum utilization of wind farms in plans for system planning, the maximum possible penetration was calculated by increasing the number of wind units in steps. Due to the existence of different wind regimes in different regions, two models of power output were developed for strong and weak wind regimes. The outcomes of the models were studied and compared. It was observed that by increasing the capacity utilization of wind farms, the cost of the plans increases. The growth for the areas with a strong wind regime is reported less significant compared to the areas with a less stronger wind regime.

In addition, by installing wind farms in areas with strong wind regimes, the maximum amount of capacity which is available is increased, subject to all constrains. Due to the growth of technology associated with the construction of wind farms and the reduction in construction cost per kW of wind, the sensitivity of the objective function to the change in construction cost was tested in the third experiment. It was found that for a 10% reduction in cost, the construction of these units can be found in a combination of generating units that, while using wind farms, cost less than the total plan cost.

Finally, the studies presented in this paper show that by reducing the cost of initial investment due to the improvement of wind turbine and wind farm technology, the competitive potential of wind power plants is significantly increased compared to other power plants. This justifies the increase in the number and capacity of wind power plants. It is worth mentioning that the problem of generation expansion planning was investigated with some assumptions that by revising these assumptions we can re-examine the effect of these factors. The following can be suggested to complement the research:

A model with a higher number of scenarios for the wind farm can be used to increase the accuracy of the calculations.

In this study, the predicted two-piece linear model was used, while a more accurate model can be used to make the results more realistic.

Uncertainties in both forecasted load and costs can also be included in the calculations and its effect can be examined.

Given the problem with the HL1 level, the transmission system is assumed to be quite reliable, which can be considered the transmission network.

Models can be used to simultaneously consider wind, solar, and other types of renewable energy sources and address the issue.

In the issue of generation expansion planning, which was examined in this study, only the type of unit, the number and time of units being added to the final design are specified.

Running the problem by considering the network can determine the location of the units and the impact of the location on the reliability of the system. In this case, different regimes of wind can be applied to different regions, making the results closer to reality.

This study is conducted as a single bus, therefore the network is not considered. At the next level of system planning so-called transmission expansion planning (TEP), the network should be studied, hence the role of increasing reactive power and low power factor due to the expansion of wind power can be investigated.