Polarization-Charge Inversion at Al2O3/GaN Interfaces through Post-Deposition Annealing

Abstract

1. Introduction

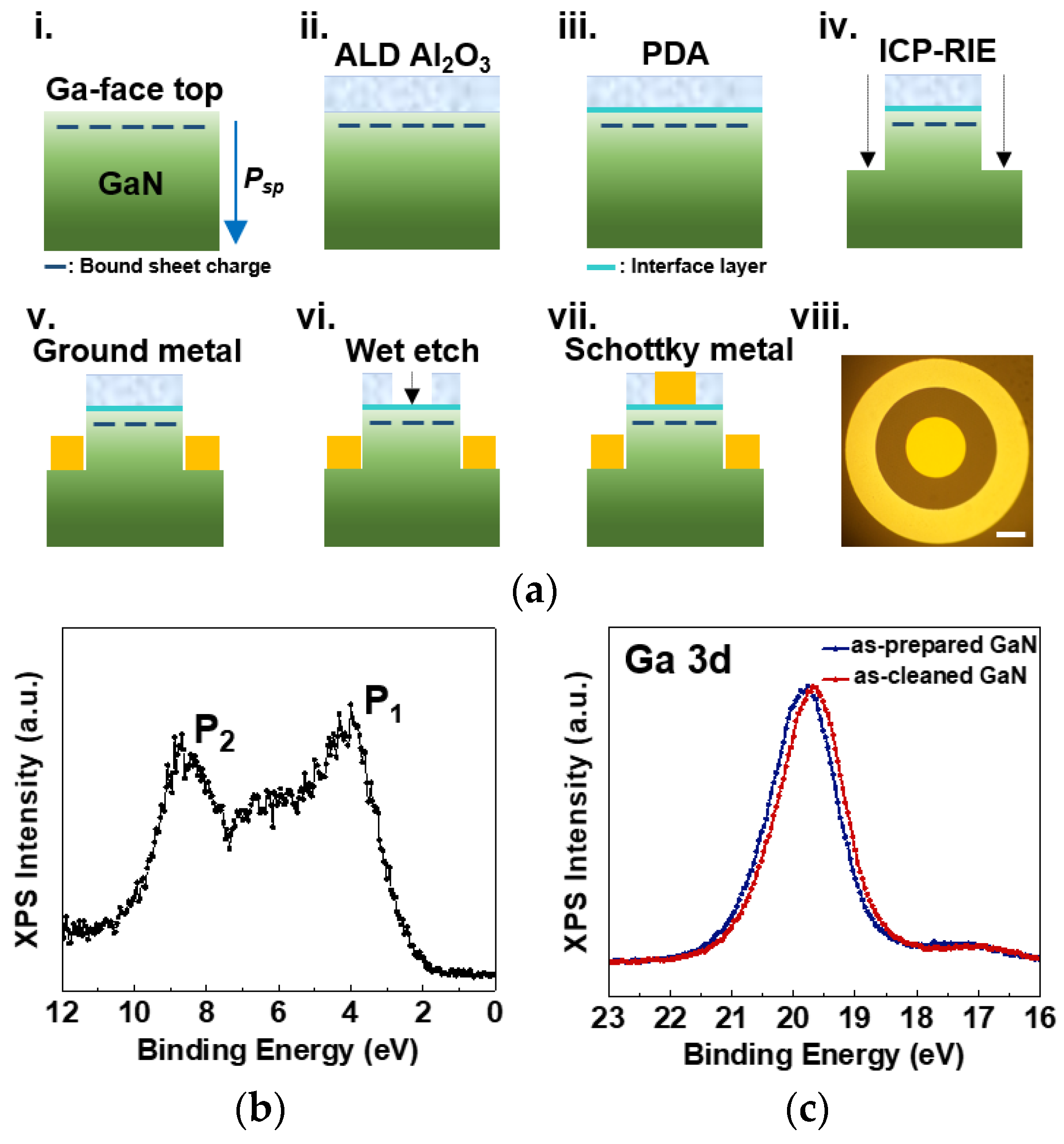

2. Materials and Methods

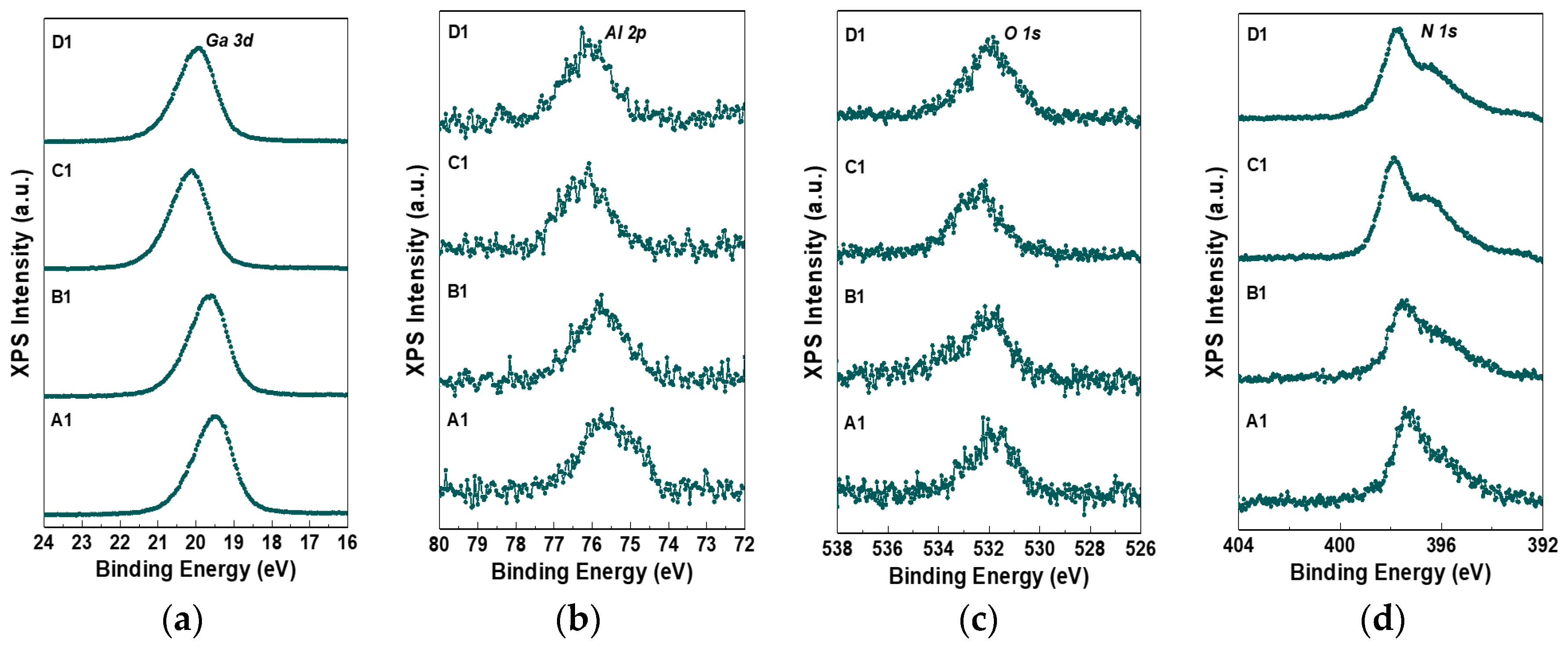

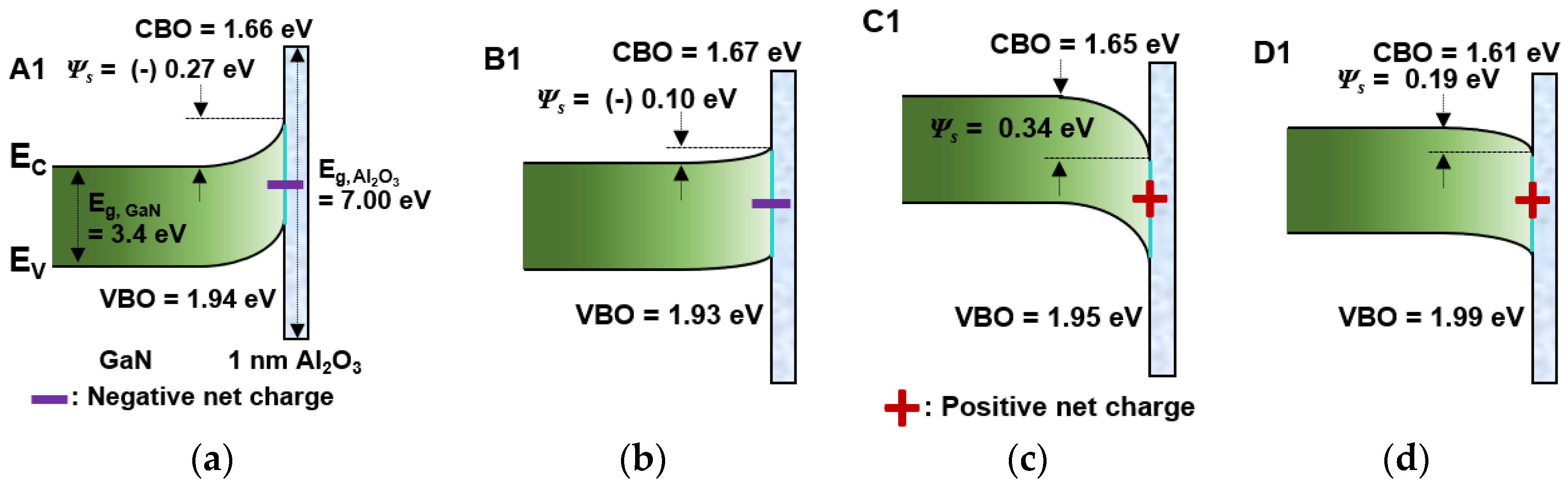

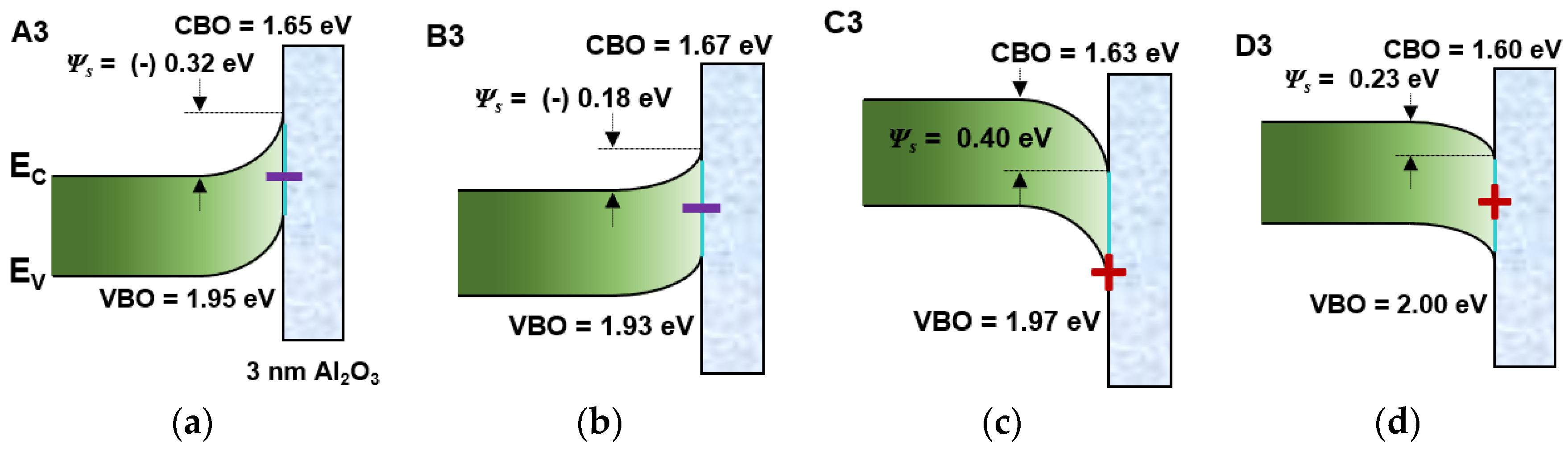

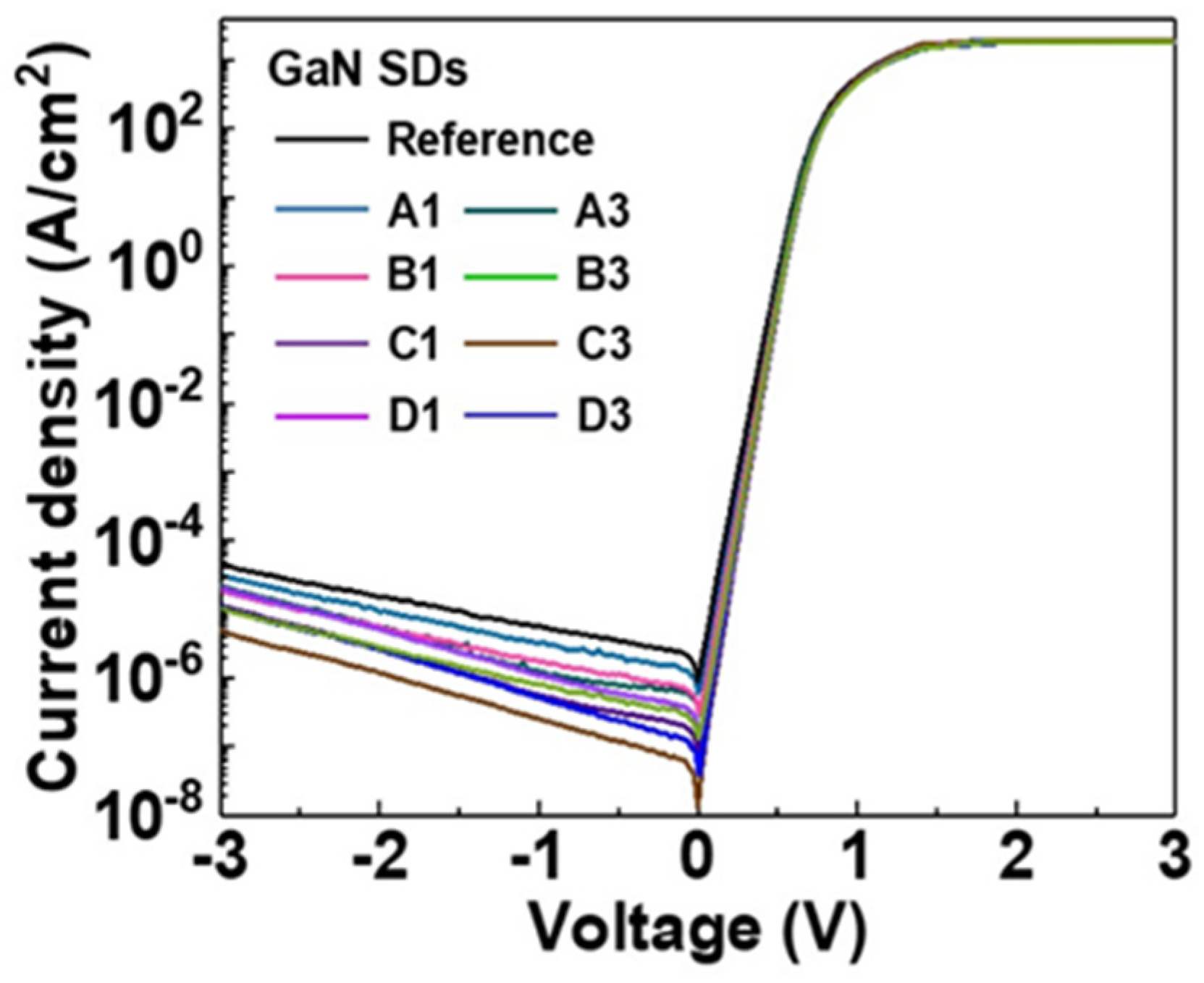

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Negara, M.A.; Kitano, M.; Long, R.D.; McIntyre, P.C. Oxide charge engineering of atomic layer deposited AlOxNy/Al2O3 gate dielectrics: A path to enhancement mode GaN devices. ACS Appl. Mater. Interfaces 2016, 8, 21089. [Google Scholar] [CrossRef]

- Zhernokletov, D.M.; Negara, M.A.; Long, R.D.; Aloni, S.; Nordlund, D.; McIntyre, P.C. Interface trap density reduction for Al2O3/GaN (0001) interfaces by oxidizing surface preparation prior to atomic layer deposition. ACS Appl. Mater. Interfaces 2015, 7, 12774. [Google Scholar] [CrossRef] [PubMed]

- Long, R.D.; McIntyre, P.C. Surface preparation and deposited gate oxides for gallium nitride based metal oxide semiconductor devices. Materials 2012, 5, 1297. [Google Scholar] [CrossRef]

- Kibria, M.G.; Zhao, S.; Chowdhury, F.A.; Wang, Q.; Nguyen, H.P.T.; Trudeau, M.L.; Guo, H.; Mi, Z. Tuning the surface Fermi level on p-type gallium nitride nanowires for efficient overall water splitting. Nat. Commun. 2014, 5, 3825. [Google Scholar] [CrossRef]

- Bilousov, O.V.; Carvajal, J.J.; Vilalta-Clemente, A.; Ruterana, P.; Diaz, F.; Aguilo, M.; O’Dwyer, C. Porous GaN and high-κ MgO–GaN MOS diode layers grown in a single step on silicon. Chem. Mater. 2014, 26, 1243. [Google Scholar] [CrossRef]

- Kim, K.; Ryu, J.H.; Kim, J.; Cho, S.J.; Liu, D.; Park, J.; Lee, I.-K.; Moody, B.; Zhou, W.; Albrecht, J.; et al. Band-bending of Ga-polar gan interfaced with Al2O3 through ultraviolet/ozone treatment. ACS Appl. Mater. Interfaces 2017, 9, 17576. [Google Scholar] [CrossRef]

- Duan, T.L.; Pan, J.S.; Ang, D.S. Interfacial chemistry and valence band offset between GaN and Al2O3 studied by X-ray photoelectron spectroscopy. Appl. Phys. Lett. 2013, 102, 201604. [Google Scholar] [CrossRef]

- Duan, T.L.; Pan, J.S.; Ang, D.S. Investigation of surface band bending of Ga-face GaN by angle-resolved X-ray photoelectron spectroscopy. ECS J. Solid State Sci. Technol. 2016, 5, P514. [Google Scholar] [CrossRef]

- Kocan, M.; Rizzi, A.; Luth, H.; Keller, S.; Mishra, U.K. Surface potential at as-grown GaN (0001) MBE layers. Phys. Status Solidi B 2002, 234, 773. [Google Scholar] [CrossRef]

- Palacios, T. Beyond the AlGaN/GaN HEMT: New concepts for high-speed transistors. Phys. Status Solidi A 2009, 206, 1145. [Google Scholar] [CrossRef]

- Tang, X.; Li, B.; Lu, Y.; Chen, K.J. On-chip addressable Schottky-on-heterojunction light-emitting diode arrays on AlGaN/GaN-on-Si platform. Phys. Status Solidi C 2016, 13, 365. [Google Scholar] [CrossRef]

- Kim, H.-S.; Han, S.-W.; Jang, W.-H.; Cho, C.-H.; Seo, K.-S.; Oh, J.; Cha, H.-Y. Normally-off GaN-on-Si MISFET using PECVD SiON gate dielectric. IEEE Electron Device Lett. 2017, 38, 1090. [Google Scholar] [CrossRef]

- Han, S.-W.; Lee, J.-G.; Cho, C.-H.; Cha, H.-Y. Dynamic on-resistance of normally-off recessed AlGaN/GaN-on-Si metal–oxide–semiconductor heterojunction field-effect transistor. Appl. Phys. Express 2014, 7, 111002. [Google Scholar] [CrossRef]

- Hsu, J.W.P.; Manfra, M.J.; Molnar, R.J.; Heying, B.; Speck, J. Direct imaging of reverse-bias leakage through pure screw dislocations in GaN films grown by molecular beam epitaxy on GaN templates. Appl. Phys. Lett. 2002, 81, 79. [Google Scholar] [CrossRef]

- Yan, D.; Jiao, J.; Ren, J.; Yang, G.; Gu, X.J. Forward current transport mechanisms in Ni/Au-AlGaN/GaN Schottky diodes. Appl. Phys. 2013, 114, 144511. [Google Scholar] [CrossRef]

- Rhoderick, E.H.; Williams, R.H. Metal-Semiconductor Contacts; Clarendon: Oxford, UK, 1988. [Google Scholar]

- Aydin, M.E.; Yakuphanoglu, F.; Eom, J.-H.; Hwang, D.-H. Electrical characterization of Al/MEH-PPV/p-Si Schottky diode by current–voltage and capacitance–voltage methods. Physica B 2007, 387, 239. [Google Scholar] [CrossRef]

- Cetin, H.; Sahin, B.; Ayyildiz, E.; Turut, A. Ti/p-Si Schottky barrier diodes with interfacial layer prepared by thermal oxidation. Physica B 2005, 364, 133. [Google Scholar] [CrossRef]

- Wei, W.; Qin, Z.; Fan, S.; Li, Z.; Shi, K.; Zhu, Q.; Zhang, G. Valence band offset of β-Ga2O3/wurtzite GaN heterostructure measured by X-ray photoelectron spectroscopy. Nanoscale Res. Lett. 2012, 7, 562. [Google Scholar] [CrossRef]

- Liu, B.-Q.; Wang, L.; Gao, D.-Y.; Zou, J.-H.; Ning, H.-L.; Peng, J.-B.; Cao, Y. Extremely high-efficiency and ultrasimplified hybrid white organic light-emitting diodes exploiting double multifunctional blue emitting layers. Light Sci. Appl. 2016, 5, e16137. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Nie, H.; Zhou, X.; Hu, S.; Luo, D.; Gao, D.; Zou, J.; Xu, M.; Wang, L.; Zhao, Z.; et al. Manipulation of charge and exciton distribution based on blue aggregation-induced emission fluorophors: A novel concept to achieve high-performance hybrid white organic light-emitting diodes. Adv. Funct. Mater. 2016, 26, 776–783. [Google Scholar] [CrossRef]

- Luo, D.; Chen, Q.; Gao, Y.; Zhang, M.; Liu, B. Extremely simplified, high-performance, and doping-free white organic light-emitting diodes based on a single thermally activated delayed fluorescent emitter. ACS Energy Lett. 2018, 3, 1531–1538. [Google Scholar] [CrossRef]

- Liu, B.; Altintas, Y.; Wang, L.; Shendre, S.; Sharma, M.; Sun, H.; Mutlugun, E.; Demir, H.V. Record high external quantum efficiency of 19.2% achieved in light-emitting diodes of colloidal quantum wells enabled by hot-injection shell growth. Adv. Mater. 2020, 32, 1905824. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Eller, B.S.; Nemanich, R.J.J. Surface band bending and band alignment of plasma enhanced atomic layer deposited dielectrics on Ga-and N-face gallium nitride. Appl. Phys. 2014, 116, 123702. [Google Scholar] [CrossRef]

- Yang, J.B.; Eller, S.; Zhu, C.; England, C.; Nemanich, R.J.J. Comparative band alignment of plasma-enhanced atomic layer deposited high-k dielectrics on gallium nitride. Appl. Phys. 2012, 112, 053710. [Google Scholar] [CrossRef]

- Eller, B.S.; Yang, J.; Nemanich, R.J.J. Electronic surface and dielectric interface states on GaN and AlGaN. Vac. Sci. Technol. A 2013, 31, 050807. [Google Scholar] [CrossRef]

- Strite, S.; Morkoc, H.J. GaN, AlN, and TiN: A review. Vac. Sci. Technol. B 1992, 10, 1237. [Google Scholar] [CrossRef]

- Skuridina, D.; Dinh, D.V.; Lacroix, B.; Ruterana, P.; Hoffmann, M.; Sitar, Z.; Pristovsek, M.; Kneissl, M.; Vogt, P.J. Polarity determination of polar and semipolar (112¯2) InN and GaN layers by valence band photoemission spectroscopy. Appl. Phys. 2013, 114, 173503. [Google Scholar] [CrossRef]

- Lambrecht, W.R.L.; Segall, B.; Strite, S.; Martin, G.; Agarwal, A.; Morkoc, H.; Rockett, A. X-ray photoelectron spectroscopy and theory of the valence band and semicore Ga 3d states in GaN. Phys. Rev. B 1994, 50, 14155. [Google Scholar] [CrossRef]

- Esposto, M.; Krishnamoorthy, S.; Nath, D.N.; Bajaj, S.; Hung, T.-H.; Rajan, S. Electrical properties of atomic layer deposited aluminum oxide on gallium nitride. Appl. Phys. Lett. 2011, 99, 133503. [Google Scholar] [CrossRef]

- Hung, T.-H.; Krishnamoorthy, S.; Esposto, M.; Nath, D.N.; Park, P.S.; Rajan, S. Interface charge engineering for enhancement-mode GaN MISHEMTs. Appl. Phys. Lett. 2013, 102, 072105. [Google Scholar] [CrossRef]

- Kubo, T.; Miyoshi, M.; Egawa, T. Post-deposition annealing effects on the insulator/semiconductor interfaces of Al2O3/AlGaN/GaN structures on Si substrates. Semicond. Sci. Technol. 2017, 32, 065012. [Google Scholar] [CrossRef]

- Hori, Y.; Mizue, C.; Hashizume, T. Process conditions for improvement of electrical properties of Al2O3/n-GaN structures prepared by atomic layer deposition. Jpn. J. Appl. Phys. 2010, 49, 080201. [Google Scholar] [CrossRef]

- Ye, G.; Wang, H.; Ng, S.L.G.; Ji, R.; Arulkumaran, S.; Ng, G.I.; Li, Y.; Liu, Z.H.; Ang, K.S. Band alignment of HfO2/AlN heterojunction investigated by X-ray photoelectron spectroscopy. Appl. Phys. Lett. 2014, 105, 152104. [Google Scholar] [CrossRef]

- Brennan, B.; Qin, X.; Dong, H.; Kim, J.; Wallace, R.M. In situ atomic layer deposition half cycle study of Al2O3 growth on AlGaN. Appl. Phys. Lett. 2012, 101, 211604. [Google Scholar] [CrossRef]

- Duan, T.L.; Pan, J.S.; Ang, D.S. Effect of post-deposition annealing on the interface electronic structures of Al2O3-capped GaN and GaN/AlGaN/GaN heterostructure. ECS J. Solid State Sci. Technol. 2015, 4, P364–P368. [Google Scholar] [CrossRef]

| Sample No. | Al2O3 (nm) | PDA (3 min) | Ga 3d (eV) | Al 2p (eV) | O 1s (eV) | N 1s (eV) |

|---|---|---|---|---|---|---|

| A1 | 1 nm | N. A. | 19.55 | 75.60 | 531.52 | 397.27 |

| B1 | 1 nm | 500 °C | 19.70 | 75.74 | 531.65 | 397.41 |

| C1 | 1 nm | 700 °C | 20.16 | 76.22 | 532.13 | 397.85 |

| D1 | 1 nm | 900 °C | 20.01 | 76.11 | 532.02 | 397.68 |

| A3 | 3 nm | N. A. | 19.50 | 75.56 | 531.48 | 397.23 |

| B3 | 3 nm | 500 °C | 19.64 | 75.68 | 531.58 | 397.38 |

| C3 | 3 nm | 700 °C | 20.22 | 76.30 | 532.26 | 397.97 |

| D3 | 3 nm | 900 °C | 20.05 | 76.16 | 532.14 | 397.81 |

| No | Sample | Al2O3 Thickness (nm) | Anneal Condition (°C, min) | GaN Polarity (ND, cm−3) | Method | Net Charge Density (cm−2) | Interface Charge Density (cm−2) | Ref. |

|---|---|---|---|---|---|---|---|---|

| 1 | A1 | 1 | - | Ga-face (5 × 1017) | XPS | −1.19 × 1012 | 1.69 × 1013 | This work |

| 2 | B1 | 1 | PDA (500, 3) | Ga-face (5 × 1017) | XPS | −7.79 × 1011 | 1.73 × 1013 | This work |

| 3 | C1 | 1 | PDA (700, 3) | Ga-face (5 × 1017) | XPS | 2.55 × 1014 | 2.73 × 1014 | This work |

| 4 | D1 | 1 | PDA (900, 3) | Ga-face (5 × 1017) | XPS | 1.38 × 1013 | 3.19 × 1013 | This work |

| 5 | A3 | 3 | - | Ga-face (5 × 1017) | XPS | −1.28 × 1012 | 1.68 × 1013 | This work |

| 6 | B3 | 3 | PDA (500, 3) | Ga-face (5 × 1017) | XPS | −9.98 × 1011 | 1.71 × 1013 | This work |

| 7 | C3 | 3 | PDA (700, 3) | Ga-face (5 × 1017) | XPS | 8.20 × 1014 | 8.38 × 1014 | This work |

| 8 | D3 | 3 | PDA (900, 3) | Ga-face (5 × 1017) | XPS | 3.00 × 1013 | 4.81 × 1013 | This work |

| 9 | S1 | - | - | Ga-face (4 × 1017) | XPS | 2.09 × 1012 | 2.01 × 1013 | Ref. [8] |

| 10 | S2 | - | - | Ga-face (4 × 1017) | XPS | −1.0 × 1012 | 1.7 × 1013 | Ref. [8] |

| 11 | - | 6, 12, 18 | PDA (600, 3), PMA (400, 5) | Ga-face (1 × 1018) | C-V | 4.60 × 1012 | 2.27 × 1013 | Ref. [26] |

| 12 | - | 6, 12, 18 | PDA (700, 1) | Ga-face (1 × 1018) | C-V | 9.5 × 1012 | 2.7 × 1013 | Ref. [27] |

| 13 | - | 6, 12, 18 | PDA (700, 1), PMA (400, 5) | Ga-face (1 × 1018) | C-V | 4.1 × 1012 | 2.2 × 1013 (estimated) | Ref. [27] |

| 14 | - | 6, 12, 18 | PDA (700, 1), PMA (450, 5) | Ga-face (1 × 1018) | C-V | 2.2 × 1012 | 2.0 × 1013 (estimated) | Ref. [27] |

| 15 | - | 6, 12, 18 | PDA (700, 1), PMA (500, 5) | Ga-face (1 × 1018) | C-V | 1.1 × 1012 | 1.9 × 1013 | Ref. [27] |

| 16 | - | 6, 12, 18 | PDA (700, 1), PMA (400, 5) | N-face (1 × 1018) | C-V | 9.2 × 1012 | 2.7 × 1013 (estimated) | Ref. [27] |

| 17 | - | 6, 12, 18 | PDA (700, 1), PMA (450, 5) | N-face (1 × 1018) | C-V | 5.9 × 1012 | 2.4 × 1013 (estimated) | Ref. [27] |

| 18 | - | 6, 12, 18 | PDA (700, 1), PMA (500, 5) | N-face (1 × 1018) | C-V | 2.8 × 1012 | 2.0 × 1013 (estimated) | Ref. [27] |

| 19 | - | 6, 12, 18 | PDA (700, 1), PMA (550, 5) | N-face (1 × 1018) | C-V | 9.0 × 1011 | 1.9 × 1013 (estimated) | Ref. [27] |

| 20 | - | 6, 12, 18 | PDA (700, 1) | m-plane (6 × 1016) | C-V | 7.8 × 1012 | 2.5 × 1013 (estimated) | Ref. [27] |

| 21 | - | 6, 12, 18 | PDA (700, 1), PMA (400, 5) | m-plane (6 × 1016) | C-V | 2.5 × 1012 | 2.0 × 1013 (estimated) | Ref. [27] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Jang, J. Polarization-Charge Inversion at Al2O3/GaN Interfaces through Post-Deposition Annealing. Electronics 2020, 9, 1068. https://doi.org/10.3390/electronics9071068

Kim K, Jang J. Polarization-Charge Inversion at Al2O3/GaN Interfaces through Post-Deposition Annealing. Electronics. 2020; 9(7):1068. https://doi.org/10.3390/electronics9071068

Chicago/Turabian StyleKim, Kwangeun, and Jaewon Jang. 2020. "Polarization-Charge Inversion at Al2O3/GaN Interfaces through Post-Deposition Annealing" Electronics 9, no. 7: 1068. https://doi.org/10.3390/electronics9071068

APA StyleKim, K., & Jang, J. (2020). Polarization-Charge Inversion at Al2O3/GaN Interfaces through Post-Deposition Annealing. Electronics, 9(7), 1068. https://doi.org/10.3390/electronics9071068