Device Design Assessment of GaN Merged P-i-N Schottky Diodes

Abstract

1. Introduction

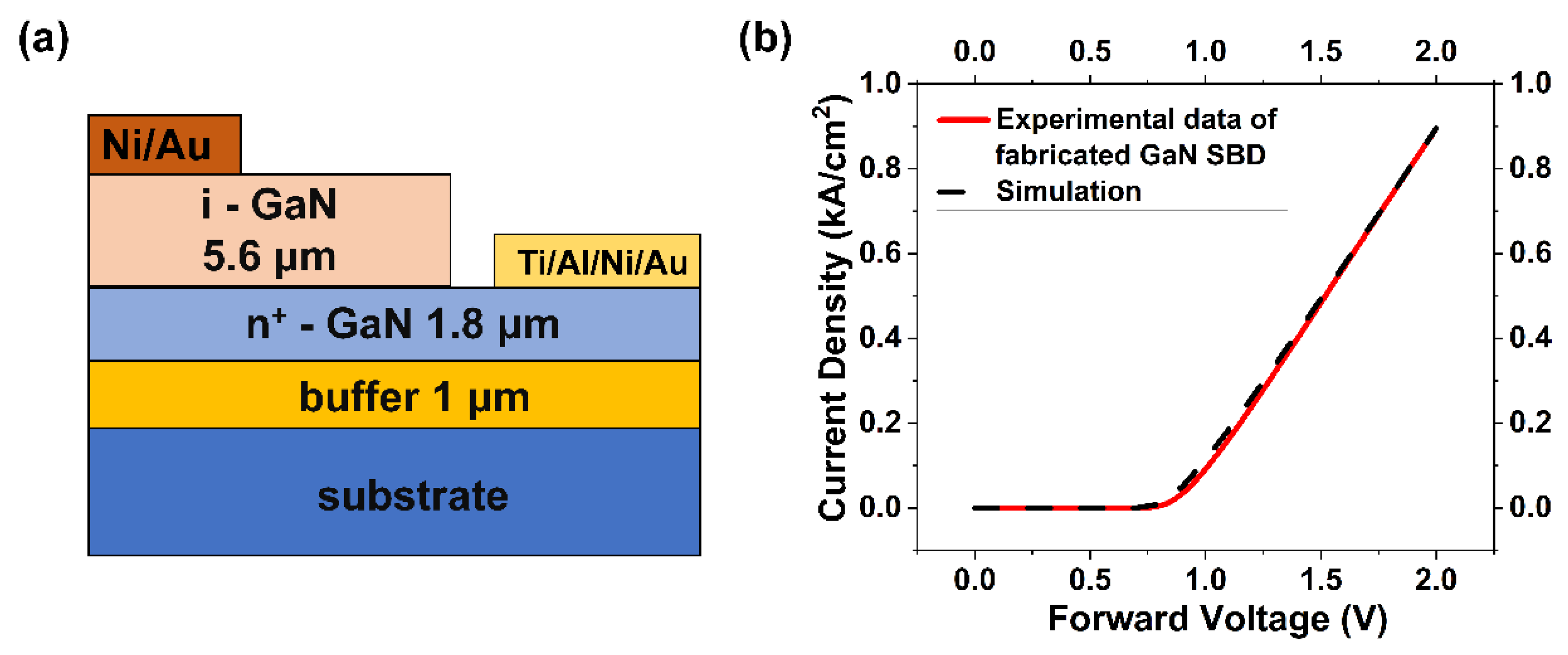

2. Materials and Methods

3. Results and Discussion

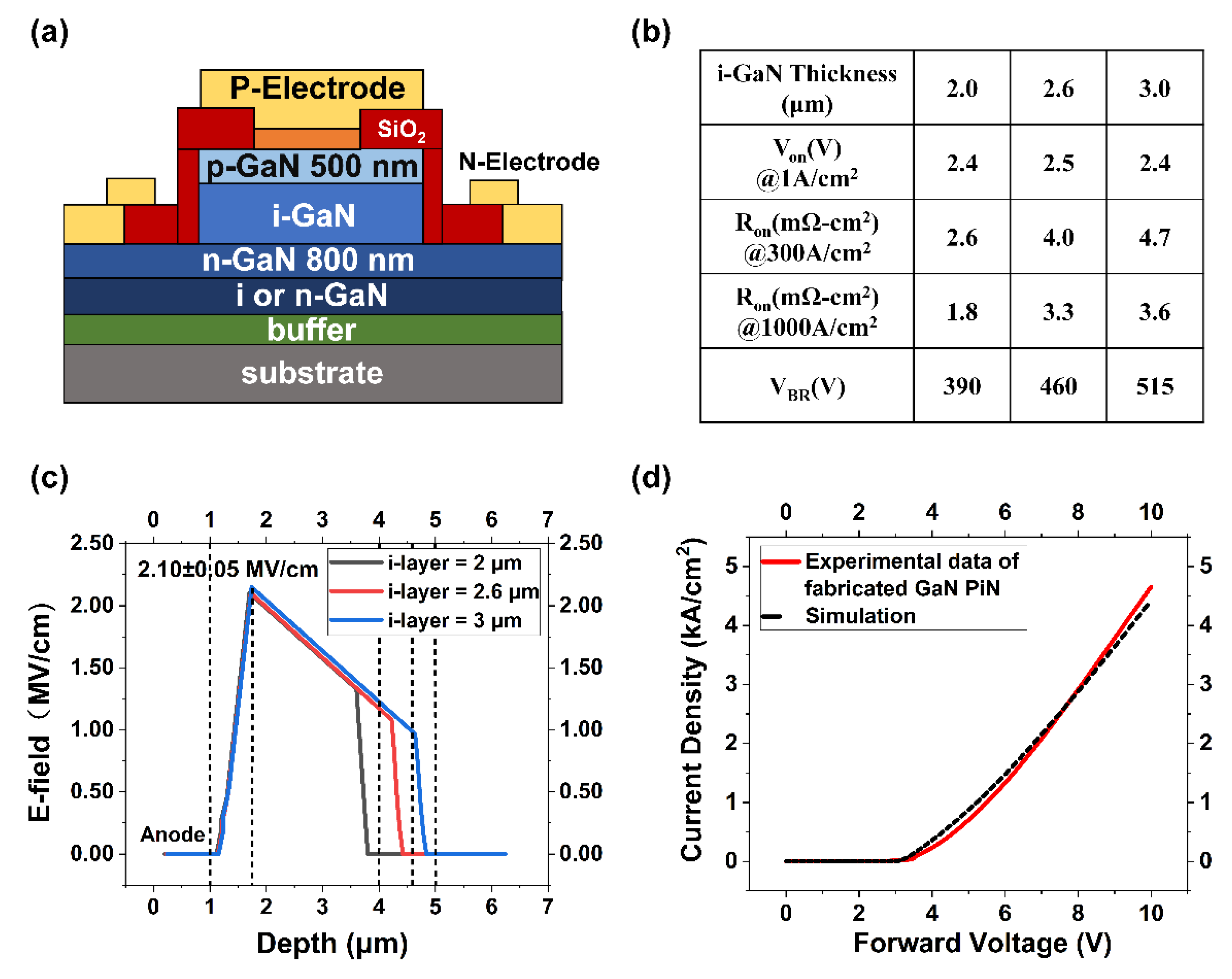

3.1. P-i-N Diode with 5 µm Drift Layer and MPS Diode Design Assessment

3.2. Forward and Reverse Characteristics of GaN MPSs

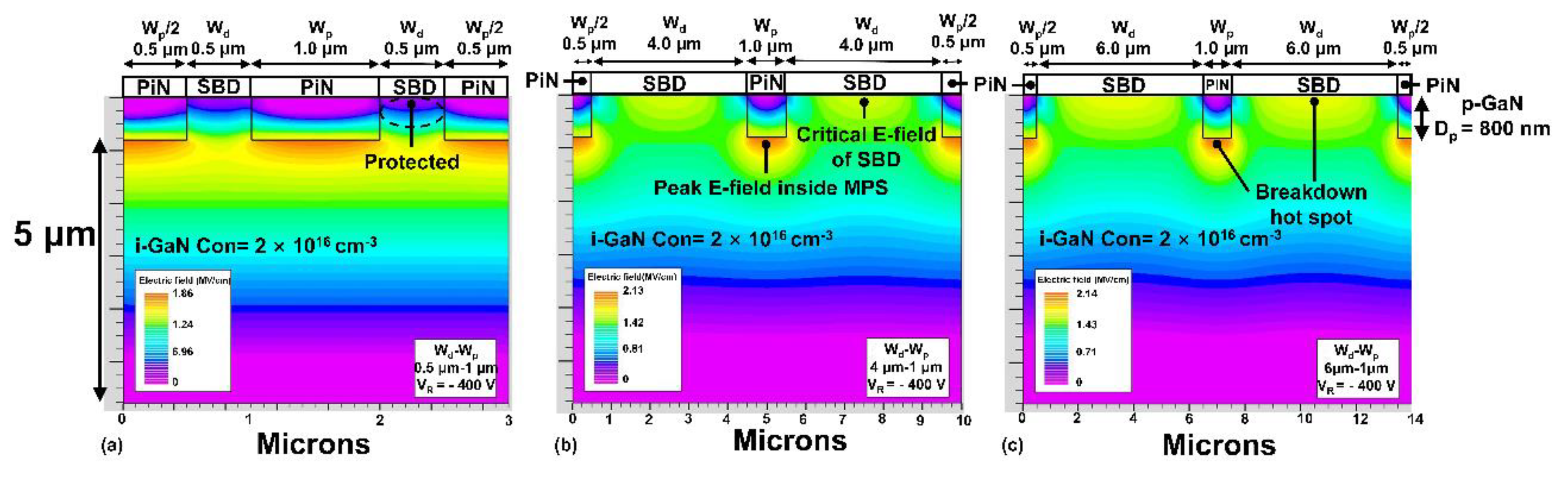

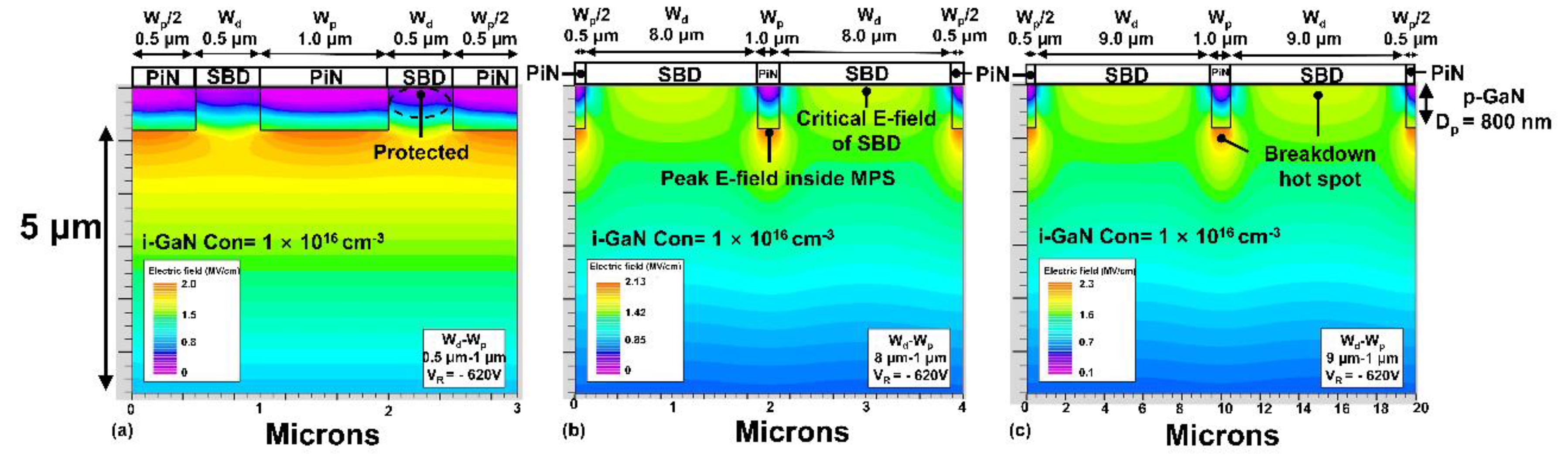

3.2.1. Reverse Characteristics

3.2.2. Forward Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, U.K.; Shen, L.; Kazior, T.E.; Wu, Y. GaN-Based RF Power Devices and Amplifiers. Proc. IEEE 2008, 96, 287–305. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mishra, U.K. Lateral and Vertical Transistors Using the AlGaN/GaN Heterostructure. IEEE Trans. Electron Devices 2013, 60, 3060–3066. [Google Scholar] [CrossRef]

- Mohammad, S.N.; Salvador, A.A.; Morkoc, H. Emerging gallium nitride based devices. Proc. IEEE 1995, 83, 1306–1355. [Google Scholar] [CrossRef]

- Millán, J.; Godignon, P.; Perpiñà, X.; Pérez-Tomás, A.; Rebollo, J. A Survey of Wide Bandgap Power Semiconductor Devices. IEEE Trans. Power Electron. 2014, 29, 2155–2163. [Google Scholar] [CrossRef]

- Han, S.; Yang, S.; Sheng, K. High-Voltage and High-ION/IOFF Vertical GaN-on-GaN Schottky Barrier Diode With Nitridation-Based Termination. IEEE Electron Device Lett. 2018, 39, 572–575. [Google Scholar] [CrossRef]

- Tsou, C.; Wei, K.; Lian, Y.; Hsu, S.S.H. 2.07-kV AlGaN/GaN Schottky Barrier Diodes on Silicon With High Baliga’s Figure-of-Merit. IEEE Electron Device Lett. 2016, 37, 70–73. [Google Scholar] [CrossRef]

- Zhu, M.; Song, B.; Qi, M.; Hu, Z.; Nomoto, K.; Yan, X.; Cao, Y.; Johnson, W.; Kohn, E.; Jena, D.; et al. 1.9-kV AlGaN/GaN Lateral Schottky Barrier Diodes on Silicon. IEEE Electron Device Lett. 2015, 36, 375–377. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, M.; Piedra, D.; Azize, M.; Zhang, X.; Fujishima, T.; Palacios, T. GaN-on-Si Vertical Schottky and p-n Diodes. IEEE Electron Device Lett. 2014, 35, 618–620. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Hao, Y.; Luo, X.; Fang, J.; Ma, Y.; Yu, C.; Cao, F. Evaluation by Simulation of AlGaN/GaN Schottky Barrier Diode (SBD) With Anode-Via Vertical Field Plate Structure. IEEE Trans. Electron Devices 2018, 65, 2552–2557. [Google Scholar] [CrossRef]

- Ohta, H.; Asai, N.; Mishima, T.; Horikiri, F.; Narita, Y.; Yoshida, T. Stable Fabrication of High Breakdown Voltage Mesa-Structure Vertical GaN p-n Junction Diodes Using Electrochemical Etching. In Proceedings of the IEEE International Meeting for Future of Electron Devices, Kansai (IMFEDK), Kyoto, Japan, 21–22 June 2018; pp. 1–2. [Google Scholar] [CrossRef]

- Yu, C.J.; Lu, J.Y.; Shan, L.W.; Chen, C.J.; Liao, J.H.; Wu, M.C. Over 1 GW/cm2 for high-power GaN p-i-n diodes with edge termination structure and laser annealing. J. Vac. Sci. Technol. B 2019, 37, 5. [Google Scholar] [CrossRef]

- Maeda, T.; Narita, T.; Ueda, H.; Kanechika, M.; Uesugi, T.; Kachi, T.; Kimoto, T.; Horita, M.; Suda, J. Parallel-Plane Breakdown Fields of 2.8–3.5 MV/cm in GaN-on-GaN p-n Junction Diodes with Double-Side-Depleted Shallow Bevel Termination. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Nomoto, K.; Qi, M.; Li, W.S.; Zhu, M.D.; Gao, X.; Jena, D.; Xing, H.G. 1.1-kV Vertical GaN p-n Diodes With p-GaN Regrown by Molecular Beam Epitaxy. IEEE Electron Device Lett. 2017, 38, 1071–1074. [Google Scholar] [CrossRef]

- Nomoto, K.; Song, B.; Hu, Z.; Zhu, M.; Qi, M.; Kaneda, N.; Mishima, T.; Nakamura, T.; Jena, D.; Xing, H.G. 1.7-kV and 0.55-mΩ·cm2 GaN p-n Diodes on Bulk GaN Substrates With Avalanche Capability. IEEE Electron Device Lett. 2016, 37, 161–164. [Google Scholar] [CrossRef]

- Limb, J.B.; Yoo, D.; Ryou, J.; Shen, S.; Dupuis, R.D. Low on-resistance GaN pin rectifiers grown on 6H-SiC substrates. Electron. Lett. 2007, 43, 67–68. [Google Scholar] [CrossRef]

- Liu, W.K.; Xu, W.Z.; Zhou, D.; Ren, F.F.; Chen, D.J.; Yu, P.; Zhang, R.; Zheng, Y.D.; Lu, H. Avalanche Ruggedness of GaN p-i-n Diodes Grown on Sapphire Substrate. Phys. Status Solidi A Appl. Mater. 2018, 215, 6. [Google Scholar] [CrossRef]

- Shan, L.W.; Liu, Z.Y.; Lin, M.P.; Yu, C.J.; Hsieh, K.C.; Wu, M.C. Electrical analyses of GaN PIN diodes grown on patterned sapphire substrates. J. Vac. Sci. Technol. B 2017, 35, 4. [Google Scholar] [CrossRef]

- Harrison, S.E.; Shao, Q.; Frye, C.D.; Voss, L.F.; Nikolić, R.J. 1.1 kV vertical p-i-n GaN-on-sapphire diodes. In Proceedings of the 76th Device Research Conference (DRC), Santa Barbara, CA, USA, 24–27 June 2018; pp. 1–2. [Google Scholar] [CrossRef]

- Khadar, R.A.; Liu, C.; Zhang, L.Y.; Xiang, P.; Cheng, K.; Matioli, E. 820-V GaN-on-Si Quasi-Vertical p-i-n Diodes With BFOM of 2.0 GW/cm(2). IEEE Electron Device Lett. 2018, 39, 401–404. [Google Scholar] [CrossRef]

- Zou, X.; Zhang, X.; Lu, X.; Tang, C.W.; Lau, K.M. Fully Vertical GaN p-i-n Diodes Using GaN-on-Si Epilayers. IEEE Electron Device Lett. 2016, 37, 636–639. [Google Scholar] [CrossRef]

- Mase, S.; Hamada, T.; Freedsman, J.J.; Egawa, T. Effect of Drift Layer on the Breakdown Voltage of Fully-Vertical GaN-on-Si p-n Diodes. IEEE Electron Device Lett. 2017, 38, 1720–1723. [Google Scholar] [CrossRef]

- Mase, S.; Urayama, Y.; Hamada, T.; Freedsman, J.J.; Egawa, T. Novel fully vertical GaN p-n diode on Si substrate grown by metalorganic chemical vapor deposition. Appl. Phys. Express 2016, 9, 4. [Google Scholar] [CrossRef]

- Ohta, H.; Kaneda, N.; Horikiri, F.; Narita, Y.; Yoshida, T.; Mishima, T.; Nakamura, T. Vertical GaN p-n Junction Diodes With High Breakdown Voltages Over 4 kV. IEEE Electron Device Lett. 2015, 36, 1180–1182. [Google Scholar] [CrossRef]

- Zhang, X.; Zou, X.; Lu, X.; Tang, C.W.; Lau, K.M. Fully- and Quasi-Vertical GaN-on-Si p-i-n Diodes: High Performance and Comprehensive Comparison. IEEE Trans. Electron Devices 2017, 64, 809–815. [Google Scholar] [CrossRef]

- Pribytny, P.; Donoval, D.; Chvala, A.; Marek, J.; Molnar, M. Electro-thermal analysis and optimization of edge termination of power diode supported by 2D numerical modeling and simulation. Microelectron. Reliab. 2012, 52, 463–468. [Google Scholar] [CrossRef]

- Feng, G.; Suda, J.; Kimoto, T. Space-Modulated Junction Termination Extension for Ultrahigh-Voltage p-i-n Diodes in 4H-SiC. IEEE Trans. Electron Devices 2012, 59, 414–418. [Google Scholar] [CrossRef]

- Slobodyan, O.; Smith, T.; Flicker, J.; Sandoval, S.; Matthews, C.; van Heukelom, M.; Kaplar, R.; Atcitty, S. Hard-switching reliability studies of 1200 V vertical GaN PiN diodes. MRS Commun. 2018, 8, 1413–1417. [Google Scholar] [CrossRef]

- Matthews, C.; Flicker, J.; Kaplar, R.; Heukelom, M.V.; Attcity, S.; Kizilyalli, I.C.; Aktas, O. Switching characterization of vertical GaN PiN diodes. In Proceedings of the IEEE 4th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Fayetteville, AR, USA, 7–9 November 2016; pp. 135–138. [Google Scholar] [CrossRef]

- Baliga, B.J. Analysis of a high-voltage merged p-i-n/Schottky (MPS) rectifier. Electron Device Lett. 1987, 8, 407–409. [Google Scholar] [CrossRef]

- Baliga, B.J. Advanced Power Rectifier Concepts; Springer: New York, NY, USA, 2009; pp. 195–285. [Google Scholar]

- Baliga, B.J. Gallium Nitride and Silicon Carbide Power Devices; World Scientific: Singapore, 2017. [Google Scholar]

- Jiang, Y.F.; Sung, W.; Baliga, J.; Wang, S.Z.; Lee, B.; Huang, A. Electrical Characteristics of 10-kV 4H-SiC MPS Rectifiers with High Schottky Barrier Height. J. Electron. Mater. 2018, 47, 927–931. [Google Scholar] [CrossRef]

- Wu, J.P.; Ren, N.; Wang, H.Y.; Sheng, K. 1.2-kV 4H-SiC Merged PiN Schottky Diode With Improved Surge Current Capability. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 1496–1504. [Google Scholar] [CrossRef]

- Wu, J.; Fursin, L.; Li, Y.Z.; Alexandrov, P.; Weiner, M.; Zhao, J.H. 4.3 kV 4H-SiC merged PiN/Schottky diodes. Semicond. Sci. Technol. 2006, 21, 987–991. [Google Scholar] [CrossRef]

- Tone, K.; Zhao, J.H.; Weiner, M.; Pan, M. Fabrication and Testing of 1000 V–60 A 4H-SiC MPS Diodes in an Inductive Half-Bridge Circuit. In Silicon Carbide and Related Materials—1999 Pts, 1 & 2; Carter, C.H., Devaty, R.P., Rohrer, G.S., Eds.; Trans Tech Publications Ltd.: Zurich-Uetikon, Switzerland, 2000; Volume 338-3, pp. 1187–1190. [Google Scholar] [CrossRef]

- Palanisamy, S.; Fichther, S.; Lutz, J.; Basler, T.; Rupp, R. Various structures of 1200 V SiC MPS diode models and their simulated surge current behavior in comparison to measurement. In Proceedings of the 28th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Prague, Czech Republic, 12–16 June 2016; pp. 235–238. [Google Scholar] [CrossRef]

- Heinze, B.; Lutz, J.; Neumeister, M.; Rupp, R.; Holz, M. Surge current ruggedness of silicon carbide Schottky- and merged-pin-Schottky diodes. In Proceedings of the20th International Symposium on Power Semiconductor Devices and IC’s, Orlando, FL, USA, 18–22 May 2008; p. 245. [Google Scholar] [CrossRef]

- Sawant, S.; Baliga, B.J. 4 kV merged PiN Schottky (MPS) rectifiers. In Proceedings of the10th International Symposium on Power Semiconductor Devices and ICs. ISPSD’98 (IEEE Cat. No. 98CH36212), Kyoto, Japan, 3–6 June 1998; pp. 297–300. [Google Scholar] [CrossRef]

- Li, W.; Nomoto, K.; Pilla, M.; Pan, M.; Gao, X.; Jena, D.; Xing, H.G. Design and Realization of GaN Trench Junction-Barrier-Schottky-Diodes. IEEE Trans. Electron Devices 2017, 64, 1635–1641. [Google Scholar] [CrossRef]

- Irokawa, Y.; Kim, J.; Ren, F.; Baik, K.H.; Gila, B.P.; Abernathy, C.R.; Pearton, S.J.; Pan, C.C.; Chen, G.T.; Chyi, J.I.; et al. Si+ ion implanted MPS bulk GaN diodes. Solid State Electron. 2004, 48, 827–830. [Google Scholar] [CrossRef]

- Hayashida, T.; Nanjo, T.; Furukawa, A.; Yamamuka, M. Vertical GaN merged PiN Schottky diode with a breakdown voltage of 2 kV. Appl. Phys. Express 2017, 10. [Google Scholar] [CrossRef]

- TCAD World Leader, Silvaco Inc., USA. Available online: https://www.silvaco.com.cn/tech_lib_TCAD/tech_info/devicesimulation/pdf/TCADWL_May2010.pdfA (accessed on 29 July 2019).

- Silvaco Data System Inc. Atlas User Manual; Santa: Clara, CA, USA, 2009. [Google Scholar]

- Chaudhuri, R.; Bader, S.J.; Chen, Z.; Muller, D.A.; Xing, H.G.; Jena, D. A polarization-induced 2D hole gas in undoped gallium nitride quantum wells. Science 2019, 365, 1454. [Google Scholar] [CrossRef] [PubMed]

- Sabui, G.; Parbrook, P.J.; Arredondo-Arechavala, M.; Shen, Z.J. Modeling and simulation of bulk gallium nitride power semiconductor devices. AIP Adv. 2016, 6, 14. [Google Scholar] [CrossRef]

- Yates, L.; Pavlidis, G.; Graham, S.; Usami, S.; Nagamatsu, K.; Honda, Y.; Amano, H. Electrical and Thermal Analysis of Vertical GaN-on-GaN PN Diodes. In Proceedings of the 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; pp. 831–837. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Piedra, D.; Sun, M.; Hennig, J.; Dadgar, A.; Yu, L.L.; Palacios, T. High-Performance 500 V Quasi- and Fully-Vertical GaN-on-Si pn Diodes. IEEE Electron Device Lett. 2017, 38, 248–251. [Google Scholar] [CrossRef]

- Dharmarasu, N.; Karthikeyan, G.S.; Agrawal, M.; Alex, S.T.L.; Radhakrishnan, K. AlGaN/GaN HEMT grown on SiC with carbon doped GaN buffer by MOCVD. In Proceedings of the Electron Devices Technology and Manufacturing Conference (EDTM), Singapore, 12–15 March 2019; pp. 434–436. [Google Scholar] [CrossRef]

| Parameters | Quantity | Unit | Description |

|---|---|---|---|

| Eg (300) | 3.42 | eV | Direct band gap at 300 K |

| Affinity | 4.1 | eV | Affinity |

| Permittivity | 9.5 | - | Permittivity |

| Workf | 5.2 | eV | Work function |

| Mun | 400/100 | cm2/V·s | Electron mobility |

| Mup | 10 | cm2/V·s | Hole mobility |

| Vstan | 1.9 × 107 | cm/s | Electron saturation velocity |

| Vstap | 7 × 106 | cm/s | Hole saturation velocity |

| Taun0 | 0.7 × 10−9 | s | Electron lifetime |

| Taup0 | 2 × 10−9 | s | Hole lifetime |

| Nsrhn | 4 × 1018 | cm−3 | Shockley-Read-Hall concentration-dependent lifetime model for electrons |

| Nsrhp | 4 × 1018 | cm−3 | Shockley-Read-Hall concentration-dependent lifetime model for holes |

| Augn | 3 × 10−31 | cm6/s | Auger recombination parameter for electrons |

| Augp | 3 × 10−31 | cm6/s | Auger recombination parameter for holes |

| Wd–Wp | Applying Voltage | E-Field at Schottky Contact (MV/cm) | Peak E-Field Inside MPS (MV/cm) |

|---|---|---|---|

| 0.5–1 μm | −550 V | 0.4 | 2.1 |

| 2–1 μm | −430 V | 1.34 | 2.12 |

| 4–1 μm | −400 V | 1.61 | 2.11 |

| 5–1 μm | −370 V | 1.60 | 2.05 |

| 6–1 μm | −355 V | 1.60 | 2.01 |

| Wd–Wp | Applying Voltage | E-Field at Schottky Contact (MV/cm) | Peak E-Field Inside MPS (MV/cm) |

|---|---|---|---|

| 0.5–1 μm | −800 V | 0.2 | 2.11 |

| 2–1 μm | −660 V | 1.22 | 2.1 |

| 4–1 μm | −635 V | 1.5 | 2.1 |

| 8–1 μm | −620 V | 1.605 | 2.117 |

| 9–1 μm | −610 V | 1.597 | 2.086 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lu, X.; Zou, X. Device Design Assessment of GaN Merged P-i-N Schottky Diodes. Electronics 2019, 8, 1550. https://doi.org/10.3390/electronics8121550

Zhang Y, Lu X, Zou X. Device Design Assessment of GaN Merged P-i-N Schottky Diodes. Electronics. 2019; 8(12):1550. https://doi.org/10.3390/electronics8121550

Chicago/Turabian StyleZhang, Yuliang, Xing Lu, and Xinbo Zou. 2019. "Device Design Assessment of GaN Merged P-i-N Schottky Diodes" Electronics 8, no. 12: 1550. https://doi.org/10.3390/electronics8121550

APA StyleZhang, Y., Lu, X., & Zou, X. (2019). Device Design Assessment of GaN Merged P-i-N Schottky Diodes. Electronics, 8(12), 1550. https://doi.org/10.3390/electronics8121550