Optically Transparent Antennas for 5G and Beyond: A Review

Abstract

1. Introduction

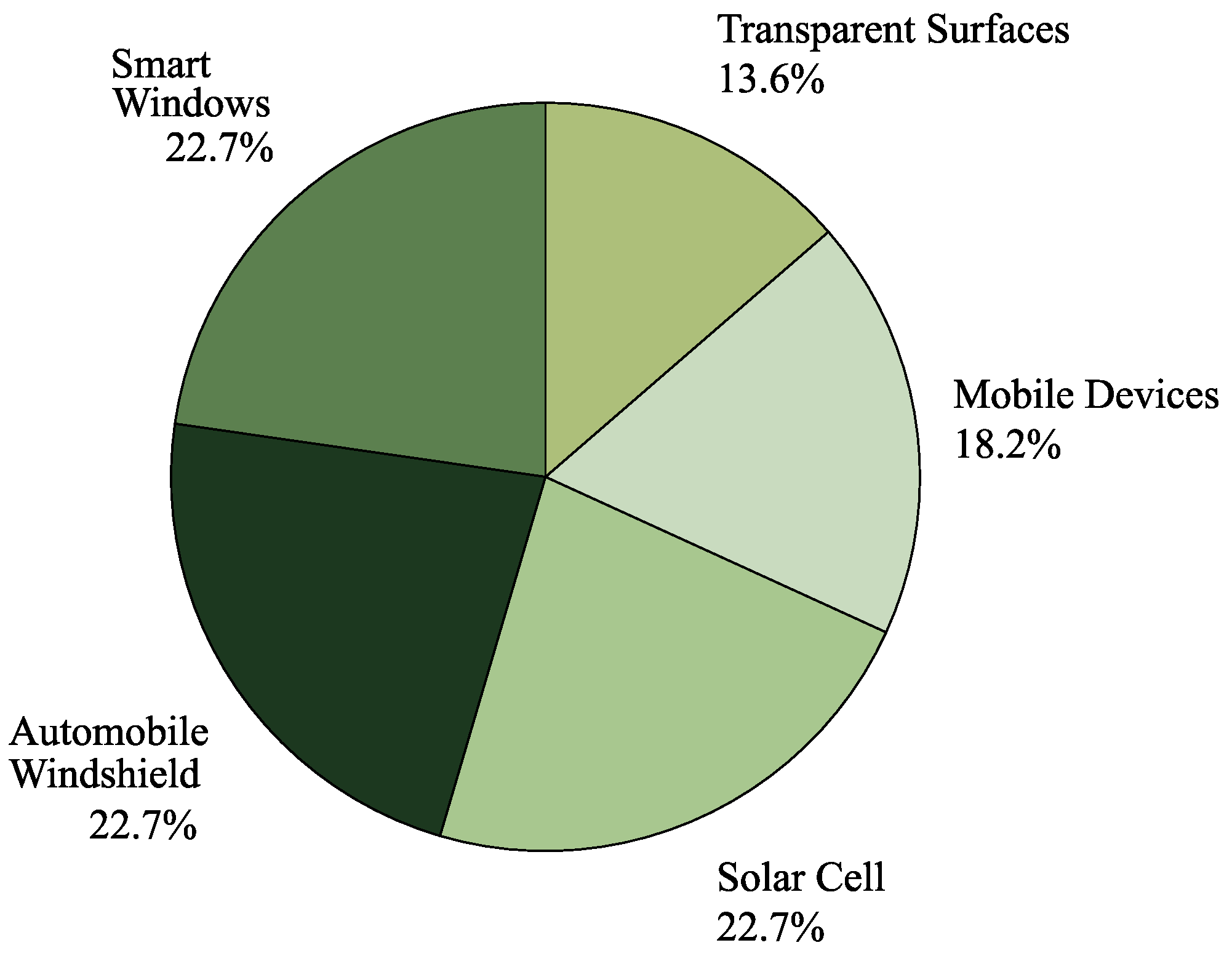

2. Optically Transparent Antennas

3. Manufacturing of Optically Transparent Antennas

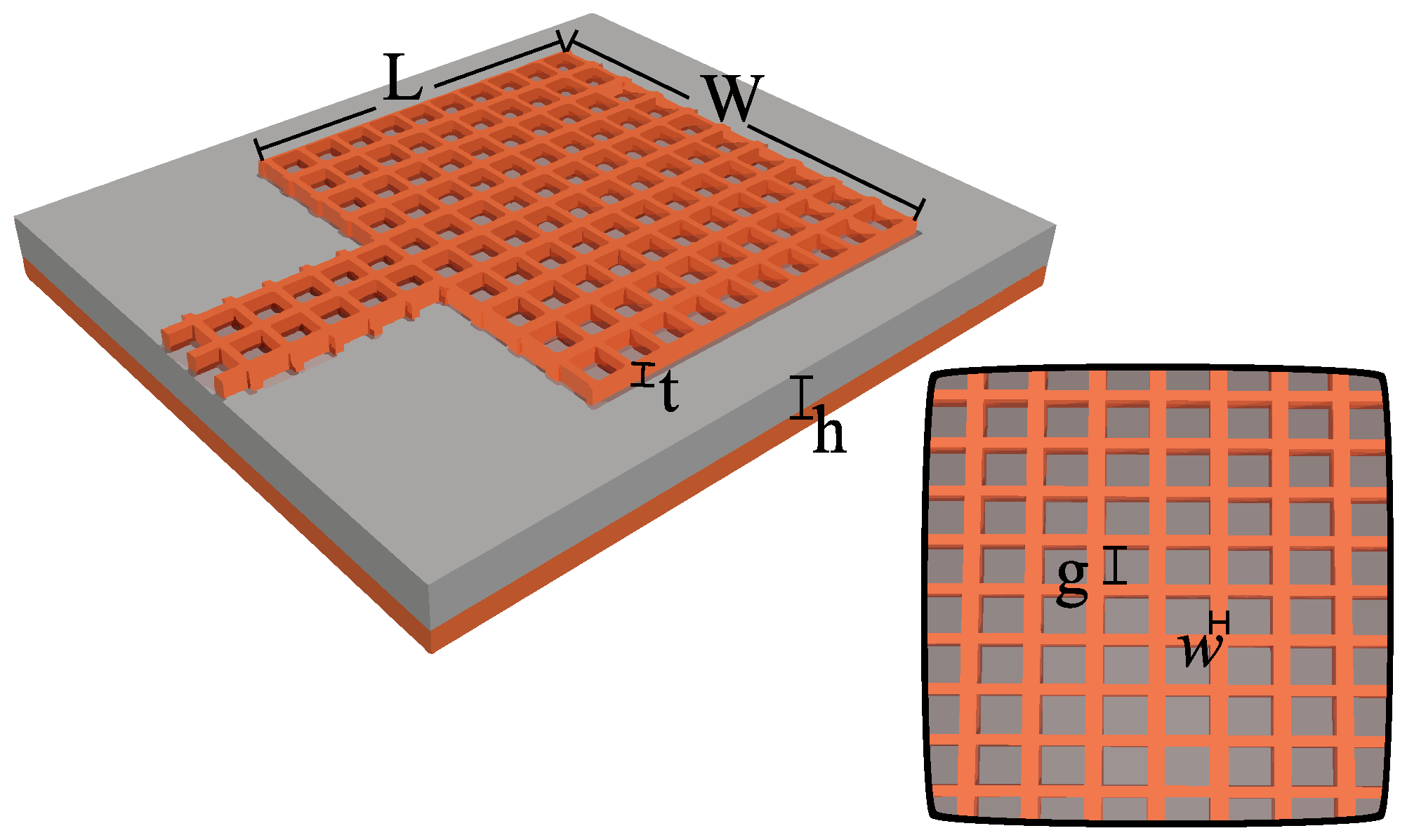

3.1. Metal Meshes

3.2. Transparent Conductive Films

3.2.1. Transparent Conductive Oxides

3.2.2. Multilayer Film

3.3. Transparent Substrates

3.3.1. Solid Substrates

3.3.2. Pre-Fabricated Substrates

3.3.3. Liquid Substrates

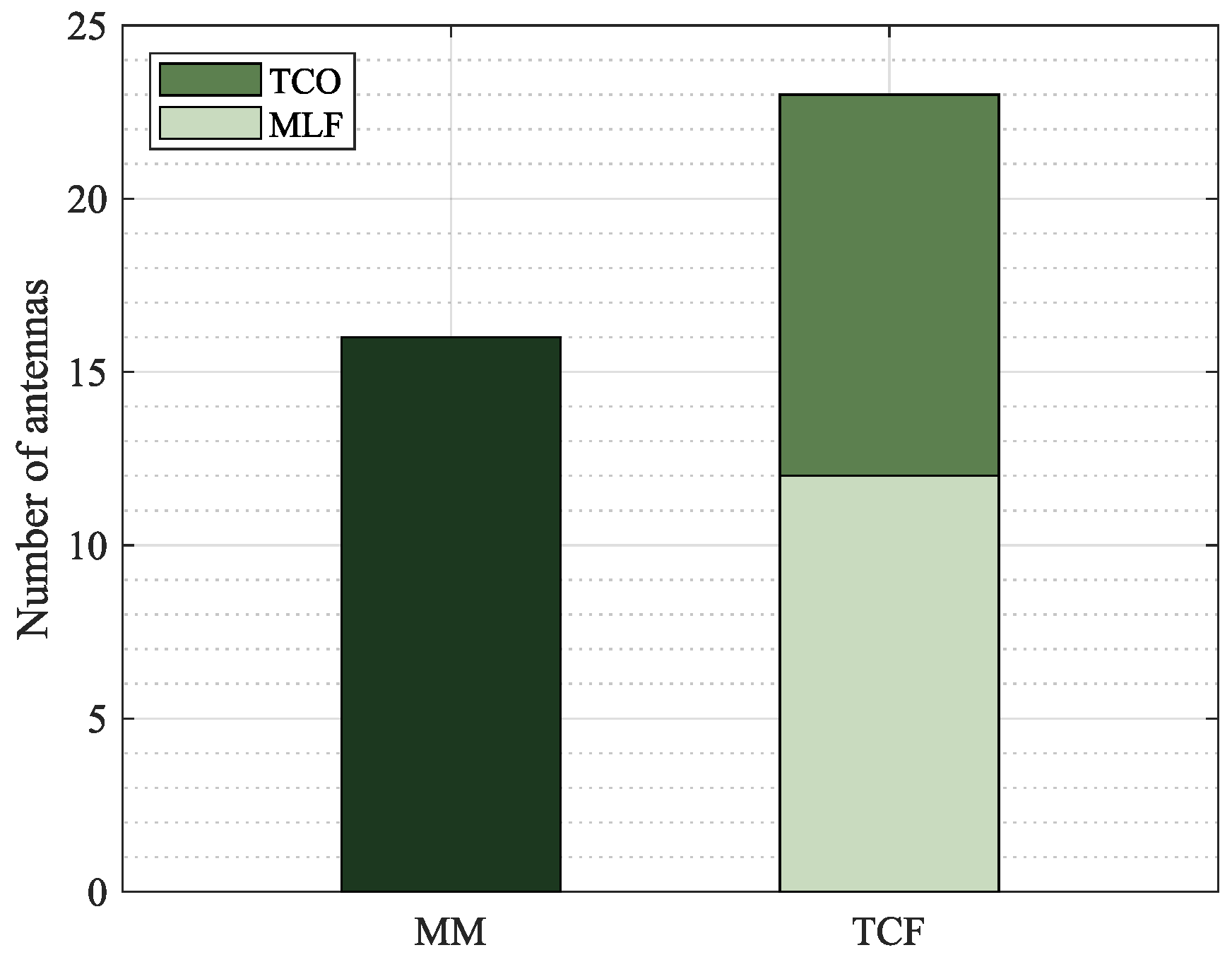

3.4. Technique Comparison

4. Analysis of Transparent Antennas

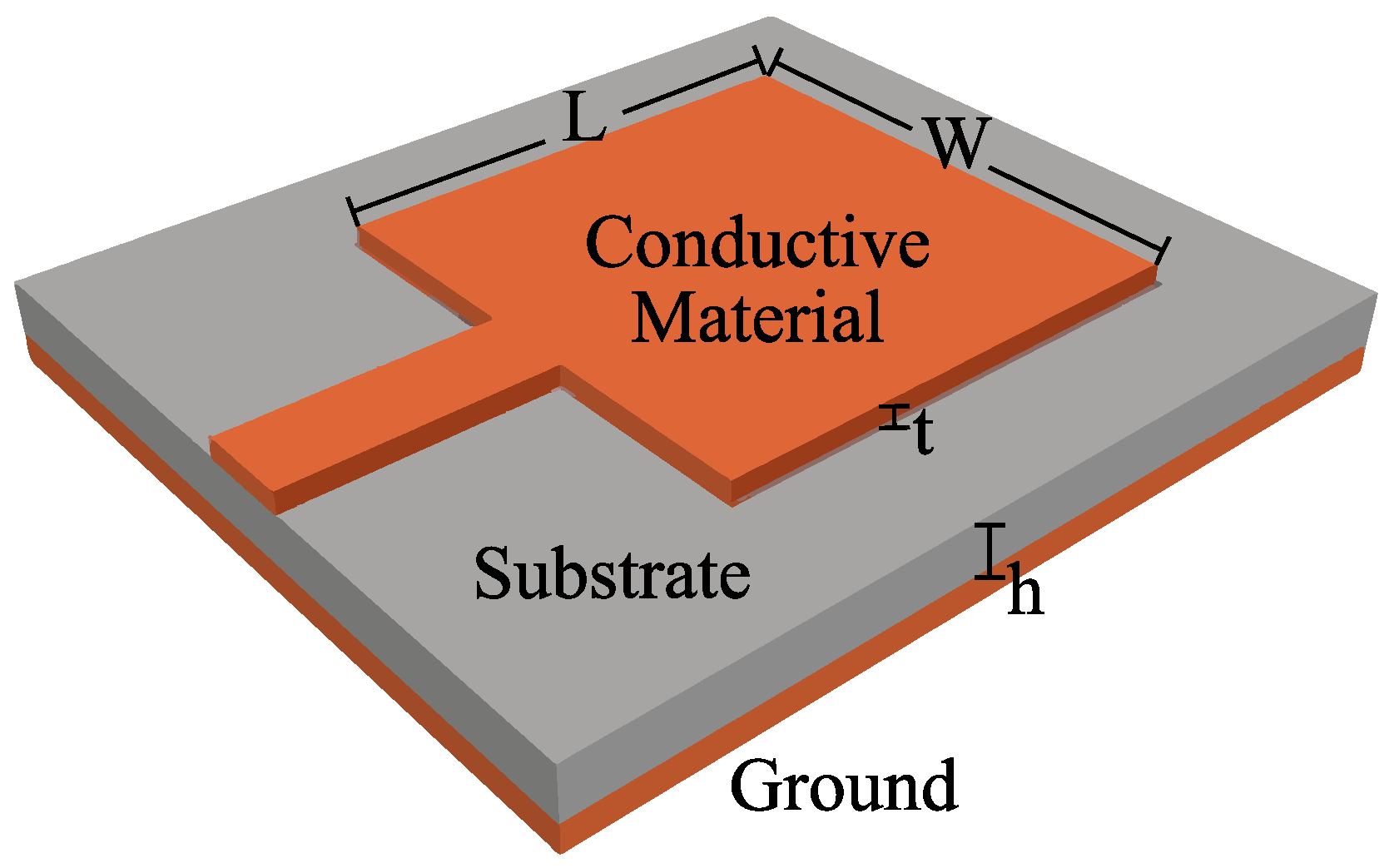

4.1. Metal Mesh Antenna

4.2. Transparent Conductive Films

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AgNW | Silver Nanowire |

| AiP | Antenna in Package |

| AoD | Antenna on Display |

| COP | Cyclic Olefin Polymer |

| CTF | Conductive Thin Film |

| FoM | Figure of Merit |

| FTO | Fluorine–Tin Oxide |

| IoT | Internet of Things |

| ITO | Indium–Tin Oxide |

| IZTO | Indium–Zinc–Tin Oxide |

| LCD | Liquid Crystal Display |

| LCL | Light Control Layer |

| LCP | Liquid Crystal Polymer |

| LED | Light Emitting Diode |

| LTCC | Low-Temperature Co-fired Ceramic |

| MM | Metal Mesh |

| MMMCF | Micro-Metal Mesh Conductive Film |

| MLF | Multilayer Film |

| mmWave | Millimeter Wave |

| OLED | Organic Light Emitting Diode |

| OT | Optical Transparency |

| OTA | Optically Transparent Antenna |

| OTC | Optical Transparency Conductor |

| PC | Polycarbonate |

| PDLC | Polymer Dispersed Liquid Crystal |

| PDMS | Polydimethylsiloxane |

| PET | Polyethylene Terephthalate |

| PEN | Polyethylene Naphthalate |

| PI | Polyimide |

| PMMA | Polymethyl Methacrylate |

| PVC | Poly Vinyl Chloride |

| PVD | Physical Vapor Deposition |

| RF | Radio Frequency |

| TCF | Transparent Conductive Film |

| TCO | Transparent Conductive Oxide |

| UWB | UltraWide Band |

References

- Wang, Y.; Potter, A.; Naim, M.; Vafeas, A.; Mavromatis, A.; Simeonidou, D. 5G Enabled Freeports: A Conceptual Framework. IEEE Access 2022, 10, 91871–91887. [Google Scholar] [CrossRef]

- Chakradhar, A.; G, S.K.; Devi Karunambiga, V.; Sristi, J.; Pavan Kumar, P.; Karthikraj. Evolution and Potential Application of 6G Wireless Communication in Smart Cities. In Proceedings of the 2023 10th IEEE Uttar Pradesh Section International Conference on Electrical, Electronics and Computer Engineering, Gautam Buddha Nagar, India, 1–3 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 536–540. [Google Scholar] [CrossRef]

- Chishti, A.R.; Aziz, A.; Qureshi, M.A.; Abbasi, M.N.; Algarni, A.M.; Zerguine, A.; Hussain, N.; Hussain, R. Optically Transparent Antennas: A Review of the State-of-The-Art, Innovative Solutions and Future Trends. Appl. Sci. 2022, 13, 210. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Sun, H.; Su, J.; Zhang, B.; Liu, M.; Zhu, R. Software Defined Network based 5G and Time-Sensitive Network Fusion for Power services with Ultra-low Latency Requirements. In Proceedings of the 2021 International Conference on Wireless Communications and Smart Grid (ICWCSG), Hangzhou, China, 13–15 August 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 381–385. [Google Scholar] [CrossRef]

- Green, R.B.; Ding, K.; Avrutin, V.; Ozgur, U.; Topsakal, E. Optically Transparent Antenna Arrays for the Next Generation of Mobile Networks. IEEE Open J. Antennas Propag. 2022, 3, 538–548. [Google Scholar] [CrossRef]

- Karthi Raja, S.; Yeshwanth, P.; Indhumathi, K. Optically Transparent UWB Antennas for 6G Applications. In Proceedings of the 2024 10th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 14–15 March 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1282–1287. [Google Scholar] [CrossRef]

- Clerckx, B.; Mao, Y.; Yang, Z.; Chen, M.; Alkhateeb, A.; Liu, L.; Qiu, M.; Yuan, J.; Wong, V.W.S.; Montojo, J. Multiple Access Techniques for Intelligent and Multifunctional 6G: Tutorial, Survey, and Outlook. Proc. IEEE 2024, 112, 832–879. [Google Scholar] [CrossRef]

- Sayem, A.S.M.; Simorangkir, R.B.V.B.; Esselle, K.P.; Hashmi, R.M. Development of Robust Transparent Conformal Antennas Based on Conductive Mesh-Polymer Composite for Unobtrusive Wearable Applications. IEEE Trans. Antennas Propag. 2019, 67, 7216–7224. [Google Scholar] [CrossRef]

- Silva, Z.J.; Valenta, C.R.; Durgin, G.D. Optically Transparent Antennas: A Survey of Transparent Microwave Conductor Performance and Applications. IEEE Antennas Propag. Mag. 2020, 63, 27–39. [Google Scholar] [CrossRef]

- Koshiji, F.; Yasuda, Y.; Yamada, Y.; Yamada, K.; Uchida, T. Transparent Antenna with High Radiation Efficiency and High Optical Transmittance Using Dielectric-metal-dielectric Composite Materials Based on ITO/Ag/ITO Multilayer Film. Trans. Jpn. Inst. Electron. Packag. 2022, 15, E22-001-1–E22-001-7. [Google Scholar] [CrossRef]

- Kaya, C.; Akaoglu, B.; Er, U.; Bayram, Y. Transparent dielectric/metal/dielectric multilayer microstrip patch antennas for X and Ku-band. Opt. Commun. 2024, 564, 130620. [Google Scholar] [CrossRef]

- Silva, Z.J.; Valenta, C.R. Evaluating Optically Transparent Conductors at RF and Microwave Frequencies: A New Figure of Merit. IEEE Microw. Wirel. Compon. Lett. 2021, 31, 349–352. [Google Scholar] [CrossRef]

- Wen, B.J.; Hsu, J.J. Thermomechanical Property Measurement of Flexible Transparent Conductive-Film Substrates Based on Whole Folding Test By Reflective- Type Common-Path Liquid-Crystal Modulating Interferometry. IEEE Trans. Instrum. Meas. 2022, 71, 1–11. [Google Scholar] [CrossRef]

- Maurya, S. Effect of Temperature Variation on Microstrip Patch Antenna and Temperature Compensation Technique. Int. J. Wirel. Commun. Mob. Comput. 2013, 1, 35. [Google Scholar] [CrossRef]

- Alobaidi, O.R.; Chelvanathan, P.; Tiong, S.K.; Bais, B.; Uzzaman, M.A.; Amin, N. Transparent Antenna for Green Communication Feature: A Systematic Review on Taxonomy Analysis, Open Challenges, Motivations, Future Directions and Recommendations. IEEE Access 2022, 10, 12286–12321. [Google Scholar] [CrossRef]

- Yasin, T.; Baktur, R.; Furse, C. A Comparative Study on Two Types of Transparent Patch Antennas. In Proceedings of the 2011 XXXth URSI General Assembly and Scientific Symposium, Istanbul, Turkey, 13–20 August 2011; IEEE: Piscataway, NJ, USA, 2011; Volume 52, pp. 1–4. [Google Scholar] [CrossRef]

- Yu, P.C.; Hong, C.C.; Liou, T.M. Bendable Transparent Conductive Meshes Based on Multi-Layer Inkjet-Printed Silver Patterns. J. Micromech. Microeng. 2016, 26, 035012. [Google Scholar] [CrossRef]

- Sun, Y.X.; Wu, D.; Fang, X.S.; Ren, J. On-Glass Grid Structure and Its Application in Highly-Transparent Antenna for Internet of Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 93–101. [Google Scholar] [CrossRef]

- Sharifi, H.; Song, H.J.; Yajima, M.; Kona, K.; Bekaryan, A.; Geary, K.; Bilik, I. Semi-Transparent and Conformal Antenna Technology for Millimeter-Wave Intelligent Sensing. In Proceedings of the 2018 IEEE MTT-S International Conference on Microwaves for Intelligent Mobility (ICMIM), Munich, Germany, 15–17 April 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Dao, Q.H.; Tchuigoua, R.; Geck, B.; Manteuffel, D.; von Witzendorff, P.; Overmeyer, L. Optically Transparent Patch Antennas Based on Silver Nanowires for Mm-Wave Applications. In Proceedings of the 2017 IEEE International Symposium on Antennas and Propagation and USNC/URSI National Radio Science Meeting, San Diego, CA, USA, 9–14 July 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2189–2190. [Google Scholar] [CrossRef]

- Yao, Y.; Shao, Y.; Zhang, J.; Zhang, J. A Transparent Antenna Using Metal Mesh for UWB MIMO Applications. IEEE Trans. Antennas Propag. 2023, 71, 3836–3844. [Google Scholar] [CrossRef]

- Desai, A.H.; Upadhyaya, T. Dual-Band Transparent and Non-Transparent Antennas for Wireless Application. Int. J. Electron. Lett. 2019, 8, 170–179. [Google Scholar] [CrossRef]

- Desai, A.; Upadhyaya, T.; Palandoken, M. Dual Band Slotted Transparent Resonator for Wireless Local Area Network Applications. Microw. Opt. Technol. Lett. 2018, 60, 3034–3039. [Google Scholar] [CrossRef]

- Koh, S.; Kosuga, S.; Suga, R.; Nagata, S.; Kuromatsu, S.; Watanabe, T.; Hashimoto, O. Graphene Transparent Antennas. Carbon Rep. 2023, 2, 23–30. [Google Scholar] [CrossRef]

- Liu, Y.; Luk, K.M. An Optically Transparent Magnetoelectric Dipole Antenna Design By Integrating Flexible Transparent Metal Mesh Film on Glass. IEEE Trans. Antennas Propag. 2024, 72, 5569–5577. [Google Scholar] [CrossRef]

- Li, L.; Zhang, P.; Cheng, F.; Chang, M.; Cui, T.J. An Optically Transparent Near-Field Focusing Metasurface. IEEE Trans. Microw. Theory Tech. 2021, 69, 2015–2027. [Google Scholar] [CrossRef]

- Hong, S.; Kim, Y.; Won Jung, C. Transparent Microstrip Patch Antennas with Multilayer and Metal-Mesh Films. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 772–775. [Google Scholar] [CrossRef]

- Hu, S.; Gu, J.; Zhao, W.; Ji, H.; Ma, X.; Wei, J.; Li, M. Silver-Nanowire Mesh-Structured Transparent Conductive Film with Improved Transparent Conductive Properties and Mechanical Performance. Adv. Mater. Technol. 2019, 4, 1900194. [Google Scholar] [CrossRef]

- Kosuga, S.; Nagata, S.; Kuromatsu, S.; Suga, R.; Watanabe, T.; Hashimoto, O.; Koh, S. Optically Transparent Antenna Based on Carrier-Doped Three-Layer Stacked Graphene. AIP Adv. 2021, 11, 035136. [Google Scholar] [CrossRef]

- Kosuga, S.; Suga, R.; Hashimoto, O.; Koh, S. Graphene-Based Optically Transparent Dipole Antenna. Appl. Phys. Lett. 2017, 110, 233102. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Yamada, Y.; Koshiji, F.; Yasuda, Y.; Uchida, T.; Yamada, K.; Koshiji, K. Analysis of Reflection Characteristics and Radiation Efficiency on Thickness and Conductivity of Monopole Antenna Using Transparent Conductive Film. In Proceedings of the 2021 International Conference on Electronics Packaging (ICEP), Tokyo, Japan, 12–14 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 185–186. [Google Scholar] [CrossRef]

- Bowrothu, R.; Kim, H.I.; Hwangbo, S.; Yoon, Y.K. High-Radiation Efficiency in Array Antennas Using Cu/Co Metaconductors. IEEE Trans. Antennas Propag. 2021, 69, 7993–7998. [Google Scholar] [CrossRef]

- Syed Feroze Hussain, S.; Thiripurasundari, D. A Review on Optically Transparent Antenna Fabricated with Conductive Nano-Material Oxides. J. Electron. Mater. 2022, 51, 6707–6734. [Google Scholar] [CrossRef]

- Zarbakhsh, S.; Akbari, M.; Farahani, M.; Ghayekhloo, A.; Denidni, T.A.; Sebak, A.R. Optically Transparent Subarray Antenna Based on Solar Panel for CubeSat Application. IEEE Trans. Antennas Propag. 2020, 68, 319–328. [Google Scholar] [CrossRef]

- Kawajiri, K.; Tahara, K.; Uemiya, S. Lifecycle Assessment of Critical Material Substitution: Indium Tin Oxide and Aluminum Zinc Oxide in Transparent Electrodes. Resour. Environ. Sustain. 2022, 7, 100047. [Google Scholar] [CrossRef]

- Green, R.B.; Toporkov, M.; Ullah, M.; Avrutin, V.; Ozgur, U.; Morkoc, H.; Topsakal, E. An Alternative Material for Transparent Antennas for Commercial and Medical Applications. Microw. Opt. Technol. Lett. 2017, 59, 773–777. [Google Scholar] [CrossRef]

- Shanmuganathan, S.; Kanagasabai, M.; Alsath, M.G.N.; Ramadoss, S.; Palaniswamy, S.K. Optically Transparent Coplanar Wideband Antenna for Vehicular Communication. Int. J. Commun. Syst. 2025, 38, e5968. [Google Scholar] [CrossRef]

- Lunca-Popa, P.; Chemin, J.B.; Adjeroud, N.; Kovacova, V.; Glinsek, S.; Valle, N.; El Hachemi, M.; Girod, S.; Bouton, O.; Maris, J.P. Study of Gallium-Doped Zinc Oxide Thin Films Processed by Atomic Layer Deposition and RF Magnetron Sputtering for Transparent Antenna Applications. ACS Omega 2023, 8, 5475–5485. [Google Scholar] [CrossRef] [PubMed]

- Varanytsia, A.; Weng, L.; Lin, T.C.; Yang, J.; Chien, L.C. High-Performance and Low-Cost Aluminum Zinc Oxide and Gallium Zinc Oxide Electrodes for Liquid Crystal Displays. J. Disp. Technol. 2016, 12, 1033–1039. [Google Scholar] [CrossRef]

- Sayem, A.S.M.; Esselle, K.P.; Hashmi, R.M. Increasing The Transparency of Compact Flexible Antennas Using Defected Ground Structure for Unobtrusive Wearable Technologies. IET Microw. Antennas Propag. 2020, 14, 1869–1877. [Google Scholar] [CrossRef]

- Kang, S.H.; Jung, C.W. Transparent Patch Antenna Using Metal Mesh. IEEE Trans. Antennas Propag. 2018, 66, 2095–2100. [Google Scholar] [CrossRef]

- Song, H.J.; Hsu, T.Y.; Sievenpiper, D.; Hsu, H.P.; Schaffner, J.; Yasan, E. A Method for Improving The Efficiency of Transparent Film Antennas. IEEE Antennas Wirel. Propag. Lett. 2008, 7, 753–756. [Google Scholar] [CrossRef]

- Ding, C.; Liu, L.; Luk, K.M. An Optically Transparent Dual-Polarized Stacked Patch Antenna with Metal-Mesh Films. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1981–1985. [Google Scholar] [CrossRef]

- Sayem, A.S.M.; Simorangkir, R.B.V.B.; Esselle, K.P.; Thalakotuna, D.N.; Lalbakhsh, A. An Electronically-Tunable, Flexible, and Transparent Antenna with Unidirectional Radiation Pattern. IEEE Access 2021, 9, 147042–147053. [Google Scholar] [CrossRef]

- Sayem, A.S.M.; Simorangkir, R.B.V.B.; Esselle, K.P.; Hashmi, R.M.; Liu, H. A Method To Develop Flexible Robust Optically Transparent Unidirectional Antennas Utilizing Pure Water, PDMS, and Transparent Conductive Mesh. IEEE Trans. Antennas Propag. 2020, 68, 6943–6952. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.Y.; Kim, Y.; Lee, J.; Hong, W. Hybrid Antenna Module Concept for 28 GHz 5G Beamsteering Cellular Devices. In Proceedings of the 2018 IEEE MTT-S International Microwave Workshop Series on 5G Hardware and System Technologies (IMWS-5G), Dublin, Ireland, 30–31 August 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, S.H.; Kim, D.; Jung, C.W. Transparent Dualband Monopole Antenna Using a μ-metal Mesh on the Rear Glass of an Automobile for Frequency Modulation/Digital Media Broadcasting Service Receiving. Microw. Opt. Technol. Lett. 2018, 61, 503–508. [Google Scholar] [CrossRef]

- Aghabeyki, P.; de la Rosa, P.; Caño-García, M.; Quintana, X.; Guirado, R.; Zhang, S. Optically Transparent Beam-Steering Reflectarray Antennas Based on a Liquid Crystal for Millimeter-Wave Applications. IEEE Trans. Antennas Propag. 2024, 72, 614–627. [Google Scholar] [CrossRef]

- Sun, J.; Luk, K.M. A Wideband Low Cost and Optically Transparent Water Patch Antenna with Omnidirectional Conical Beam Radiation Patterns. IEEE Trans. Antennas Propag. 2017, 65, 4478–4485. [Google Scholar] [CrossRef]

- Cai, H.; Wang, K. A Transparent MMW Liquid Fresnel Lens Antenna for 5G Communication. In Proceedings of the 2021 International Symposium on Antennas and Propagation (ISAP), Taipei, Taiwan, 19–22 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–2. [Google Scholar] [CrossRef]

- Sayem, A.S.M.; Lalbakhsh, A.; Esselle, K.P.; Moloudian, G.; Buckley, J.L.; Simorangkir, R.B.V.B. Advancements, Challenges, and Prospects of Water-Filled Antennas. IEEE Access 2023, 11, 8301–8323. [Google Scholar] [CrossRef]

- Li, W.; Meredov, A.; Shamim, A. Silver Nanowire Based Flexible, Transparent, Wideband Antenna for 5G Band Application. In Proceedings of the 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Atlanta, GA, USA, 7–12 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 275–276. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, W.J.; Hu, T.T. A Transparent SIW Cavity-Based Millimeter-Wave Slot Antenna for 5G Communication. IEEE Antennas Wirel. Propag. Lett. 2022, 21, 1105–1109. [Google Scholar] [CrossRef]

- Imam-Fulani, Y.O.; Faruk, N.; Sowande, O.A.; Abdulkarim, A.; Alozie, E.; Usman, A.D.; Adewole, K.S.; Oloyede, A.A.; Chiroma, H.; Garba, S.; et al. 5G Frequency Standardization, Technologies, Channel Models, and Network Deployment: Advances, Challenges, and Future Directions. Sustainability 2023, 15, 5173. [Google Scholar] [CrossRef]

- Park, S.H.; Park, C.K.; Yoo, H.; Kim, B.; Chae, C.B. Window-Type and AR Glass-Type Transparent Antenna Systems for B5G/6G. In Proceedings of the 2023 IEEE 20th Consumer Communications and Networking Conference (CCNC), Las Vegas, NV, USA, 8–11 January 2023; IEEE: Piscataway, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Chang, H.; Lai, F.P.; Chen, Y.S. Transparent Transmitarray Antenna with Large Aperture for Significant Gain Enhancement in Millimeter-Wave 5G Communication Networks. IEEE Antennas Wirel. Propag. Lett. 2024, 23, 663–667. [Google Scholar] [CrossRef]

- Park, J.; Hong, W. Antenna-on-Display (AoD) for Millimeter-Wave 5G Mobile Devices. In Proceedings of the 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Atlanta, GA, USA, 7–12 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 603–604. [Google Scholar] [CrossRef]

- El Halaoui, M.; Canale, L.; Asselman, A.; Zissis, G. An Optically Transparent Antenna Integrated in OLED Light Source for 5G Applications. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/ICPS Europe), Madrid, Spain, 9–12 June 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Halaoui, M.E.; Canale, L.; Asselman, A.; Zissis, G. Design and Analysis of Transparent and Non-Transparent Antennas Integrated in OLEDs At 3.5 GHz Band for 5G Applications. In Proceedings of the 2021 IEEE International Conference on Environment and Electrical Engineering and 2021 IEEE Industrial and Commercial Power Systems Europe (EEEIC / ICPS Europe), Bari, Italy, 7–10 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Magray, M.I.; Su, S.W. Optically Transparent Metasurface-Based Wideband Antenna for mmWave 5G Mobile Devices. In Proceedings of the 2022 Asia-Pacific Microwave Conference (APMC), Yokohama, Japan, 29 November–2 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 214–216. [Google Scholar] [CrossRef]

- Wawrzyniak, M.; Bras, J.; Denneulin, A.; Vuong, T.P. Development of Flexible and Quasi-Optically Transparent CPW Antennas for 5G by Meshing Construction. In Proceedings of the 2020 50th European Microwave Conference (EuMC), Utrecht, The Netherlands, 12–14 January 2021; pp. 372–375. [Google Scholar] [CrossRef]

- Li, Q.L.; Cheung, S.W.; Wu, D.; Yuk, T.I. Optically Transparent Dual-Band MIMO Antenna Using Micro-Metal Mesh Conductive Film for WLAN System. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 920–923. [Google Scholar] [CrossRef]

- Liu, X.; Jackson, D.R.; Chen, J.; Liu, J.; Fink, P.W.; Lin, G.Y.; Neveu, N. Transparent and Nontransparent Microstrip Antennas on a CubeSat: Novel Low-Profile Antennas for CubeSats Improve Mission Reliability. IEEE Antennas Propag. Mag. 2017, 59, 59–68. [Google Scholar] [CrossRef]

- Lee, S.Y.; Choi, D.; Youn, Y.; Hong, W. Electrical Characterization of Highly Efficient, Optically Transparent Nanometers-Thick Unit Cells for Antenna-on-Display Applications. In Proceedings of the 2018 IEEE/MTT-S International Microwave Symposium—IMS, Philadelphia, PA, USA, 10–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1043–1045. [Google Scholar] [CrossRef]

- Podilchak, S.K.; Comite, D.; Montgomery, B.K.; Li, Y.; Gomez-Guillamon Buendia, V.; Antar, Y.M.M. Solar-Panel Integrated Circularly Polarized Meshed Patch for CubeSats and Other Small Satellites. IEEE Access 2019, 7, 96560–96566. [Google Scholar] [CrossRef]

- Goliya, Y.; Rivadeneyra, A.; Salmeron, J.F.; Albrecht, A.; Mock, J.; Haider, M.; Russer, J.; Cruz, B.; Eschlwech, P.; Biebl, E.; et al. Next Generation Antennas Based on Screen-Printed and Transparent Silver Nanowire Films. Adv. Opt. Mater. 2019, 7, 1900995. [Google Scholar] [CrossRef]

- Wu, C.T.; Ho, Y.R.; Huang, D.Z.; Huang, J.J. AZO/Silver Nanowire Stacked Films Deposited By RF Magnetron Sputtering for Transparent Antenna. Surf. Coatings Technol. 2019, 360, 95–102. [Google Scholar] [CrossRef]

- Liu, X.; Jackson, D.R.; Ingram, E.; Chen, J.; Seko, M.H. Transparent Microstrip Antennas for CubeSats. In Proceedings of the 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Atlanta, GA, USA, 7–12 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 845–846. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.Y.; Kim, J.; Park, D.; Choi, W.; Hong, W. An Optically Invisible Antenna-on-Display Concept for Millimeter-Wave 5G Cellular Devices. IEEE Trans. Antennas Propag. 2019, 67, 2942–2952. [Google Scholar] [CrossRef]

- Kubwimana, J.L.; Kirsch, N.J.; Ziegler, C.; Kontopidis, G.; Tuner, B. Dual-Polarized 5.75 GHz Optically Transparent Antenna Arrays. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1512–1516. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, S.; Chiu, C.Y.; Murch, R. Hybrid RF-Solar Energy Harvesting Systems Utilizing Transparent Multiport Micromeshed Antennas. IEEE Trans. Microw. Theory Tech. 2019, 67, 4534–4546. [Google Scholar] [CrossRef]

- Duy Tung, P.; Jung, C.W. Optically Transparent Wideband Dipole and Patch External Antennas Using Metal Mesh for UHD TV Applications. IEEE Trans. Antennas Propag. 2020, 68, 1907–1917. [Google Scholar] [CrossRef]

- Xi, B.; Liang, X.; Chen, Q.; Wang, K.; Geng, J.; Jin, R. Optical Transparent Antenna Array Integrated with Solar Cell. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 457–461. [Google Scholar] [CrossRef]

- Qiu, H.; Liu, H.; Jia, X.; Jiang, Z.Y.; Liu, Y.H.; Xu, J.; Lu, T.; Shao, M.; Ren, T.L.; Chen, K.J. Compact, Flexible, and Transparent Antennas Based on Embedded Metallic Mesh for Wearable Devices in 5G Wireless Network. IEEE Trans. Antennas Propag. 2021, 69, 1864–1873. [Google Scholar] [CrossRef]

- Yu, S.; Lee, S.; Lee, H.; Park, Y.B. Study of Mesh Pattern for Optically Transparent Flexible Antenna with Feedline. Appl. Sci. 2021, 11, 10002. [Google Scholar] [CrossRef]

- Wu, B.; Sun, X.Y.; Zu, H.R.; Zhang, H.H.; Su, T. Transparent Ultrawideband Halved Coplanar Vivaldi Antenna with Metal Mesh Film. IEEE Antennas Wirel. Propag. Lett. 2022, 21, 2532–2536. [Google Scholar] [CrossRef]

- Abbasi, M.N.; Aziz, A.; Aljaloud, K.A.; Chishti, A.R.; Aladadi, Y.T.; Hussain, R. A Close Proximity 2-Element MIMO Antenna Using Optically Transparent Wired-Metal Mesh and Polyethylene Terephthalate Material. IEEE Access 2023, 11, 78811–78819. [Google Scholar] [CrossRef]

- Bark, S.; Kim, J.; Lee, M.; Lim, S. Optically Transparent Dual-Band Metamaterial Absorber Using Ag Nanowire Screen-Printed Second-Order Cross-Fractal Structures. Fractal Fract. 2024, 8, 153. [Google Scholar] [CrossRef]

- Myeong Heo, J.; Kim, K.; Choi, J.; Byun, G. Optically Transparent Series-Fed Microstrip Array with Small Inter-Element Spacing and Stepped Feed-Lines for Antenna-on-Display. IEEE Access 2024, 12, 99684–99692. [Google Scholar] [CrossRef]

- Heo, J.M.; Kim, K.; Choi, J.; Byun, G. Log-Periodic Patch Array with Coupled T-Probes for Broadband Dual-Polarized Antenna-on-Display. IEEE Trans. Antennas Propag. 2025, 73, 1435–1444. [Google Scholar] [CrossRef]

- Chen, S.; Jin, M.; Hao, X.; Zu, Z.; Li, Z.; Li, Y. Transparent CPW-Fed Antenna Array for 5G Communication Applications. In Proceedings of the 2024 IEEE 7th International Conference on Electronic Information and Communication Technology (ICEICT), Xi’an, China, 31 July–2 August 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 358–361. [Google Scholar] [CrossRef]

- Desai, A.; Palandoken, M.; Kulkarni, J.; Byun, G.; Nguyen, T.K. Wideband Flexible/Transparent Connected-Ground MIMO Antennas for Sub-6 GHz 5G and WLAN Applications. IEEE Access 2021, 9, 147003–147015. [Google Scholar] [CrossRef]

- Shao, T.; Liu, Y.; Sun, L.; Xu, Y.; Kong, S.; Liu, S.; Xia, B.; Li, M.; Shen, N.; Tian, S. A Dual Polarization Optical Transparent Antenna for 5G Communication Application. In Proceedings of the 2022 IEEE 10th Asia-Pacific Conference on Antennas and Propagation (APCAP), Xiamen, China, 4–7 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–2. [Google Scholar] [CrossRef]

- Ahmed, A.; Osman, S.A.; Mumin, A.R.; Salah, A.; Hussien, A.A.; Mohamud, Y. Design of A Compact Transparent Antenna for 5G Wireless Applications. In Proceedings of the 2023 9th International Conference on Computer and Communication Engineering (ICCCE), Kuala Lumpur, Malaysia, 15–16 August 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 18–23. [Google Scholar] [CrossRef]

- Suche, M.; Topsakal, E. Optically Transparent Materials for 5G High-Band. In Proceedings of the 2023 7th International Electromagnetic Compatibility Conference (EMC Türkiye), İstanbul, Türkiye, 17–20 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Fujita, K.; Takahashi, M. A Concept of Transparent Antenna Array on Touch Screen Panel for Sub-6 GHz Cellular Devices. In Proceedings of the 2021 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (APS/URSI), Singapore, 4–10 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 3–4. [Google Scholar] [CrossRef]

- Inomata, M.; Sayama, T.; Motegi, T.; Kagaya, O.; Shoji, H.; Takeuchi, S.; Nobuoka, K. Transparent Glass Antenna for 28 GHz and Its Signal Reception Characteristics In Urban Environment. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Elmobarak Elobaid, H.A.; Abdul Rahim, S.K.; Himdi, M.; Castel, X.; Abedian Kasgari, M. A Transparent and Flexible Polymer-Fabric Tissue UWB Antenna for Future Wireless Networks. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 1333–1336. [Google Scholar] [CrossRef]

- Stanley, M.; Huang, Y.; Wang, H.; Zhou, H.; Alieldin, A.; Joseph, S. A Transparent Dual-Polarized Antenna Array for 5G Smartphone Applications. In Proceedings of the 2018 IEEE International Symposium on Antennas and Propagation and USNC-URSI National Radio Science Meeting, Boston, MA, USA, 8–13 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 635–636. [Google Scholar] [CrossRef]

- Ourahou, O.; Abbaoui, H.; Ez-Zaki, F.; Bakouchi, R.J.E.; Belahrach, H.; Ghammaz, A. UWB Transparent Patch Antenna for 5G Millimeter-Wave Applications. In Proceedings of the 2023 6th International Conference on Advanced Communication Technologies and Networking (CommNet), Rabat, Morocco, 11–13 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Ourahou, O.; Abbaoui, H.; Ez-Zaki, F.; El Bakouchi, R.J.; Belahrach, H.; Ghammaz, A. A Novel UWB Pentagonal Transparent Antenna for Millimeter-Wave 5G Applications. In Proceedings of the 2024 International Conference on Global Aeronautical Engineering and Satellite Technology (GAST), Marrakesh, Morocco, 24–26 April 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, B.; Su, G.; Xue, F. A Novel Electromagnetic Transparent Antenna for 4G/5G Dual-Band Share-Aperture Array. IEEE Antennas Wirel. Propag. Lett. 2024, 23, 1171–1175. [Google Scholar] [CrossRef]

- Saeidi, T.; Mahmood, S.N.; Alani, S.; Ali, S.M.; Ismail, I.; Alhawari, A.R.H. Triple-Band Transparent Flexible Antenna for ISM Band and 5G Applications. In Proceedings of the 2020 IEEE International Black Sea Conference on Communications and Networking (BlackSeaCom), Odessa, Ukraine, 26–29 May 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Peter, T.; Rahman, T.A.; Cheung, S.W.; Nilavalan, R.; Abutarboush, H.F.; Vilches, A. A Novel Transparent UWB Antenna for Photovoltaic Solar Panel Integration and RF Energy Harvesting. IEEE Trans. Antennas Propag. 2014, 62, 1844–1853. [Google Scholar] [CrossRef]

- Zamudio, M.E.; Behzadirad, M.; Christodoulou, C.; Busani, T. Optimization of AZO Films for Integrating Optically Transparent Antennas with Photovoltaics. Appl. Phys. Lett. 2017, 110, 234101. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, W.; Chen, X.; Yu, J. Design of Optically Transparent Antenna with Directional Radiation Patterns. Int. J. Antennas Propag. 2017, 2017, 8125432. [Google Scholar] [CrossRef]

- Desai, A.; Upadhyaya, T.; Patel, R. Compact Wideband Transparent Antenna for 5G Communication Systems. Microw. Opt. Technol. Lett. 2018, 61, 781–786. [Google Scholar] [CrossRef]

- Cai, L. An on-Glass Optically Transparent Monopole Antenna with Ultrawide Bandwidth for Solar Energy Harvesting. Electronics 2019, 8, 916. [Google Scholar] [CrossRef]

- Sowjanya, P.D.; Alsath, M.G.N.; Kirubaveni, S.; Govindaraj, R.; Santhosh, N. Design and Experimental Evaluation of A Proximity Coupled Transparent Patch Antenna for WLAN. IETE J. Res. 2019, 68, 77–84. [Google Scholar] [CrossRef]

- Desai, A.; Upadhyaya, T.; Palandoken, M.; Gocen, C. Dual Band Transparent Antenna for Wireless MIMO System Applications. Microw. Opt. Technol. Lett. 2019, 61, 1845–1856. [Google Scholar] [CrossRef]

- Eltresy, N.A.; Elsheakh, D.N.; Abdallah, E.A.; Elhennawy, H.M. RF Energy Harvesting Using Transparent Antenna for IoT Application. In Proceedings of the 2019 International Conference on Innovative Trends In Computer Engineering (ITCE), Aswan, Egypt, 2–4 February 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 287–291. [Google Scholar] [CrossRef]

- Paul, L.C.; Pramanik, R.K.; Ur Rashid, M.M.; Sarker, S.; Mahmud, M.Z.; Tariqul Islam, M. An ITO Based High Gain Optically Transparent Wide Band Microstrip Antenna for K Band Satellite Communication. In Proceedings of the 2019 International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 10–12 January 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 638–642. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, P.Y.; Zhang, C. High-Performance, Transparent and Flexible Antenna Based on Conductive Nanocomposites. In Proceedings of the 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting, Montreal, QC, Canada, 5–10 July 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1491–1492. [Google Scholar] [CrossRef]

- Peng, J.J.; Qu, S.W.; Xia, M. Optically Transparent Reflectarray Based on Indium Tin Oxide with Improved Efficiency. IEEE Trans. Antennas Propag. 2020, 68, 3289–3294. [Google Scholar] [CrossRef]

- Desai, A.; Bui, C.D.; Patel, J.; Upadhyaya, T.; Byun, G.; Nguyen, T.K. Compact Wideband Four Element Optically Transparent MIMO Antenna for mm-Wave 5G Applications. IEEE Access 2020, 8, 194206–194217. [Google Scholar] [CrossRef]

- Azizi, S.; Canale, L.; Ahyoud, S.; Zissis, G.; Asselman, A. Design of Transparent Antenna for 5G Wireless Applications. Proceedings 2020, 63, 54. [Google Scholar] [CrossRef]

- Alam, S.; Pinkey, R.; Haider, M.; Sagor, M.H. Comparative Analysis Between Copper and Transparent 60 GHz mmWave Antenna with Identical Geometry. In Proceedings of the 2021 IEEE-APS Topical Conference on Antennas and Propagation In Wireless Communications (APWC), Honolulu, HI, USA, 9–13 August 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 143–148. [Google Scholar] [CrossRef]

- Montisci, G.; Mura, G.; Muntoni, G.; Casula, G.A.; Chietera, F.P.; Aburish-Hmidat, M. A Curved Microstrip Patch Antenna Designed From Transparent Conductive Films. IEEE Access 2023, 11, 839–848. [Google Scholar] [CrossRef]

- Morimoto, Y.; Shiu, S.; Huang, I.W.; Fest, E.; Ye, G.; Zhu, J. Optically Transparent Antenna for Smart Glasses. IEEE Open J. Antennas Propag. 2023, 4, 159–167. [Google Scholar] [CrossRef]

- Tao, J.; Tang, P.; Yang, H.; Liao, D.; Jing, L.; Li, E.P.; Chen, H.; Wang, Z. Design of Electromagnetic Transparent Antennas Based on Drude Metasurface for High-Band Compatibility. IEEE Trans. Antennas Propag. 2024, 72, 4911–4919. [Google Scholar] [CrossRef]

- An, K.; Sun, P.; Chen, A. A High Gain and High Radiation Efficiency Optical Transparent Fabry–Perot Cavity Antenna. Electron. Lett. 2024, 60, e13203. [Google Scholar] [CrossRef]

- Wei, Z.; Xue, H.; Li, Y.; Zhao, S.; Chen, Z.; Li, L. A Hybrid RF and Solar Integrated Energy Harvesting System Using Optically Transparent Metasurface. IEEE Trans. Antennas Propag. 2025, 73, 920–927. [Google Scholar] [CrossRef]

- Dharshan, N.; S, S.B.; P, P. 5G Triband Transparent and Flexible Slotted Patch Antennae. In Proceedings of the 2024 5th International Conference on Circuits, Control, Communication and Computing (I4C), Bangalore, India, 4–5 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 166–171. [Google Scholar] [CrossRef]

- Varsha, J.; Prabhakar, P. Enhanced Soldier Terrain Visualization System Using Image Processing and Time of Flight Cameras with Transparent 5G Antenna. In Proceedings of the 2024 5th International Conference on Circuits, Control, Communication and Computing (I4C), Bangalore, India, 4–5 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 360–366. [Google Scholar] [CrossRef]

- Lee, H.; Nguyen, D.T.; Jung, C.W.; Kwon, D.H. A Transparent X-Band Leaky-Wave Antenna with A Sector Pattern for on-Glass Applications. IEEE Antennas Wirel. Propag. Lett. 2024, 23, 4792–4796. [Google Scholar] [CrossRef]

- Sayem, A.S.M.; Lalbakhsh, A.; Esselle, K.P.; Buckley, J.L.; OFlynn, B.; Simorangkir, R.B.V.B. Flexible Transparent Antennas: Advancements, Challenges, and Prospects. IEEE Open J. Antennas Propag. 2022, 3, 1109–1133. [Google Scholar] [CrossRef]

- Sissoko, A.; Sanogo, C.O.; Diourté, B. A Review on Conductive and Transparent Materials Used in the Design of Transparent Antennas. Open J. Antennas Propag. 2023, 11, 11–25. [Google Scholar] [CrossRef]

- Lee, S.Y.; Choo, M.; Jung, S.; Hong, W. Optically Transparent Nano-Patterned Antennas: A Review and Future Directions. Appl. Sci. 2018, 8, 901. [Google Scholar] [CrossRef]

- Zhang, H.; Meng, F. Exploiting The Skin Effect Using Radio Frequency Communication In Underwater Communication. In Proceedings of the 2012 International Conference on Industrial Control and Electronics Engineering, Xi’an, China, 23–25 August 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1150–1153. [Google Scholar] [CrossRef]

- Castel, X.; Himdi, M.; Colombel, F. Comparison of the Microwave Performance of Transparent Monopole Antennas Made of Different Transparent Conducting Films. In Proceedings of the 2018 IEEE Conference on Antenna Measurements & Applications (CAMA), Västerås, Sweden, 3–6 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

| Ref. | Date | Frequency [GHz] | Substrate | Substrate Thickness [mm] | Patch Material | Patch Thickness [m] | Gain [dBi] | Efficiency [%] | Transparency [%] |

|---|---|---|---|---|---|---|---|---|---|

| [63] | 2017 | Glass | MMMCF | 5 | 0.74 | 43 | 75 | ||

| 2.3 | 46 | ||||||||

| [64] | 2017 | Quartz | Ag Epoxy | - | 7.23 | - | 94.2 | ||

| [27] | 2017 | 2.45 | Acrylic | 1 | Cu | 5 | 2.63 | 42.69 | 61.46 |

| [48] | 2018 | Glass | - | 5 | 1.1 | - | 61.6 | ||

| 8.8 | |||||||||

| [65] | 2018 | * | Glass | Ag | - | 3.2 | 68 | 88 | |

| [42] | 2018 | 2.44 | Acrylic | Cu | 35 | 5.28 | 50.93 | 68.63 | |

| 2.49 | 4.38 | 49.18 | 77.77 | ||||||

| [44] | 2019 | PET + PMMA | 9 | Ag/Cu/Ni | 100 | 75 | 80 | ||

| [66] | 2019 | * | Borosilicate Glass | MM | 200 | 5 * | - | - | |

| [67] | 2019 | 2.45 | PET | AgNWs | - | 52 | 85 | ||

| [68] | 2019 | * | Glass | - | AZO | - | - | - | 80.28 |

| AgNWs | |||||||||

| [69] | 2019 | 2.4 | Quartz | - | MM | - | - | 90 | 95 |

| - | - | - | 90 | 78 | |||||

| [70] | 2019 | LCP | Cu | - | 9.16 | 41.21 | 88 | ||

| 6.66 | 24.15 | ||||||||

| [8] | 2019 | PDMS | 3 | Zn/Ni/Cu | 1520 | 3.2 | 48 | 52 | |

| 3.5 | 46 | ||||||||

| [71] | 2019 | Lexan | - | 84.50 | 77.80 | ||||

| [53] | 2019 | - | 0.05 | - | - | 1.45 | 55 | 90 | |

| [72] | 2019 | Glass | 6 | Cu | 1000 | 5 | 72.40 | 92.40 | |

| [73] | 2020 | PET | Cu | 5 | 6.2 | 83.80 | 70 | ||

| [74] | 2020 | Glass | 2 | Ag | - | 20.14 | 38.70 | 88 | |

| [41] | 2020 | PDMS | 1.6 | VeilShield | 7 | 3.2 | 56 | 66 | |

| [75] | 2021 | PET | Ni | 5 | 3.8 | 85 | 93 | ||

| 26 & 27 | 10 | 9.70 | 61 | 86 | |||||

| [76] | 2021 | * | Polyimide | Cu | 18 | 3.56 | - | 85 | |

| 3.6 | |||||||||

| [77] | 2022 | PET | Cu | 10.4 | - | 72 | |||

| [29] | 2022 | 9.8 | Quartz Glass | - | Graphene | - | * | 52.50 | 90.10 |

| [18] | 2023 | * | Glass | 1 | Ni/Cu/Sn(Tin) | 7500 | 5.01 | 71.90 | 69.80 |

| [21] | 2023 | FR-4 | MM | - | 77 | ||||

| [56] | 2023 | 3.5 | Glass | - | - | - | 5.81 | - | 90 |

| [78] | 2023 | PET | 1 | Metal | - | 3.55 | 64.50 | 83 | |

| [79] | 2024 | 6.40 & 20.96 | PET | Ag NWs | - | - | 97.48 & 98.20 | 63 | |

| [80] | 2024 | COP | Cu | 100 | 7.02 | - | 85.10 | ||

| [81] | 2024 | COP | Cu | 2 | 7.65 | 44.20 | 86.80 | ||

| [57] | 2024 | Glass | 1 | - | 0.06 | 37.5 | - | 70 | |

| [82] | 2024 | Quartz Glass | Ag | - | 7.9 | 85 | 92 |

| Research Articles | Date | Frequency [GHz] | Substrate | Substrate Thickness [mm] | Material | Gain [dBi] | Efficiency [%] | Transparency [%] |

|---|---|---|---|---|---|---|---|---|

| [43] | 2008 | * | Glass | 3 | AgHT-4 | 5 | 68 | 70 |

| [95] | 2014 | Glass | 2 | AgHT-4 | 9.8 | - | - | |

| [37] | 2017 | Sapphire | GZO | 2.10 | 43 | 85 | ||

| [27] | 2017 | * | Acrylic | 1 | IZTO/Ag/IZTO | −4.23 | 7.76 | 80.78 |

| [96] | 2017 | * | Poly-Si | - | AZO | 4.7 | 60 | 86 |

| [30] | 2017 | * | Quartz | 1 | Graphene | - | - | - |

| [97] | 2017 | Glass | 1 | ITO | - | 80 | ||

| [89] | 2017 | PDMS | 2 | Polyester | - | 75 | 90 | |

| [98] | 2018 | Plexiglass | AgHT-8 | |||||

| [90] | 2018 | Glass | 0.3 | ITO | 12.1 | - | 80 | |

| [23] | 2018 | Borosilicate Glass | 2 | AgHT-8 | 0.64 1.2 | 62 83 | - | |

| [99] | 2019 | Glass | ITO | * | - | 95 | ||

| [100] | 2019 | Soda Lime Glass | FTO | 5.16 | 90 | 80 | ||

| [101] | 2019 | Plexiglass | AgHT-8 | 3.6 | 74 | - | ||

| 7.1 | 84 | - | ||||||

| [102] | 2019 | * | Glass | ITO | −3.9 | 14 | 90 | |

| [69] | 2019 | 2.4 | Soda-Lime Glass | - | ITO | - | 64 | 85 |

| [103] | 2019 | Pyrex Glass | 3 | ITO | 11.5 | 92.30 | - | |

| [104] | 2020 | * | PDMS | NCM | 0.8 | - | - | |

| * | Acrylic | 13.6 | - | - | ||||

| [22] | 2020 | * & * | Glass | 2 | AgHT-8 | - | 48.02 & 53.14 | - |

| * & * | AgHT-4 | - | 59.25 & 49.20 | - | ||||

| [105] | 2020 | Glass | ITO | 25.8 | 37.3 | - | ||

| [94] | 2020 | & & | Polyimide | 0.125 | ITO | - | 83 | - |

| [106] | 2020 | Plexiglass | AgHT-8 | 3 | 75 | - | ||

| [107] | 2020 | * | Glass | 2 | AgHT-8 | 5.5 | - | - |

| [88] | 2020 | Glass | - | - | 1.5 | - | - | |

| [105] | 2020 | * | Glass | ITO | 73 | 81 | ||

| [26] | 2021 | 5.8 | Soda Lime Glass | ITO | - | - | 63 | |

| [83] | 2021 | Melinex | 0.635 | AgHT-4 | 0.53 | 41 | - | |

| [87] | 2021 | PET | - | FTO | −6 | - | - | |

| [108] | 2021 | * | PET | AgHT-8 | 7.5 | 63.7 | - | |

| [84] | 2022 | PMMA | 7.5 | - | 6 | - | - | |

| [86] | 2023 | * | Glass | 0.4 | ITO | −3.70 | - | - |

| [85] | 2023 | * | FR4 | 1.6 | - | 2.11 | - | - |

| [109] | 2022 | * | PET | In203/Au/Ag | 2.57 | 72.3 | 71 | |

| [110] | 2023 | * | PDLC | LCL | −4.40 | 40 | - | |

| [38] | 2023 | * | Soda Lime Glass | FTO | 4.34 | 70 | 82 | |

| * | 95 | |||||||

| [111] | 2024 | * | F4BM220 | 1 | DM | - | - | - |

| [112] | 2024 | * | Glass | FPC | 14.2 | 67.10 | 81 | |

| [113] | 2024 | * | PC | 2 | ITO | 6.7 | 68.70 | 81 |

| [114] | 2024 | 3.54 & 5.4 & 6.82 | PVC | 4 | AgHT-8 | 4.88 & 4.23 & 4.37 | - | 90 |

| ITO | 5.87 & 3.7 & 4.66 | - | - | |||||

| [93] | 2024 | - | - | - | 0.5 | - | - | |

| [92] | 2024 | Plexiglass | 1.48 | AgHT-8 | 6 | - | - | |

| [115] | 2024 | 2.4 3.6 5.4 | Plexiglass | 2.35 | ITO | - | - | - |

| [116] | 2024 | 10 | PET | 2 | Metasurface | 10.8 | - | 54.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominguez, B.; Silva, F.; Baghel, A.; Albuquerque, D.; Pinho, P. Optically Transparent Antennas for 5G and Beyond: A Review. Electronics 2025, 14, 1616. https://doi.org/10.3390/electronics14081616

Dominguez B, Silva F, Baghel A, Albuquerque D, Pinho P. Optically Transparent Antennas for 5G and Beyond: A Review. Electronics. 2025; 14(8):1616. https://doi.org/10.3390/electronics14081616

Chicago/Turabian StyleDominguez, Bernardo, Fábio Silva, Amit Baghel, Daniel Albuquerque, and Pedro Pinho. 2025. "Optically Transparent Antennas for 5G and Beyond: A Review" Electronics 14, no. 8: 1616. https://doi.org/10.3390/electronics14081616

APA StyleDominguez, B., Silva, F., Baghel, A., Albuquerque, D., & Pinho, P. (2025). Optically Transparent Antennas for 5G and Beyond: A Review. Electronics, 14(8), 1616. https://doi.org/10.3390/electronics14081616