Heterogeneous PLC-Based Distributed Controller with Embedded Logic-Monitoring Blackbox for Real-Time Failover

Abstract

1. Introduction

2. Components for Heterogeneous PLC I/O Error Detection

2.1. Hardware and Software Configuration of Heterogeneous PLCs

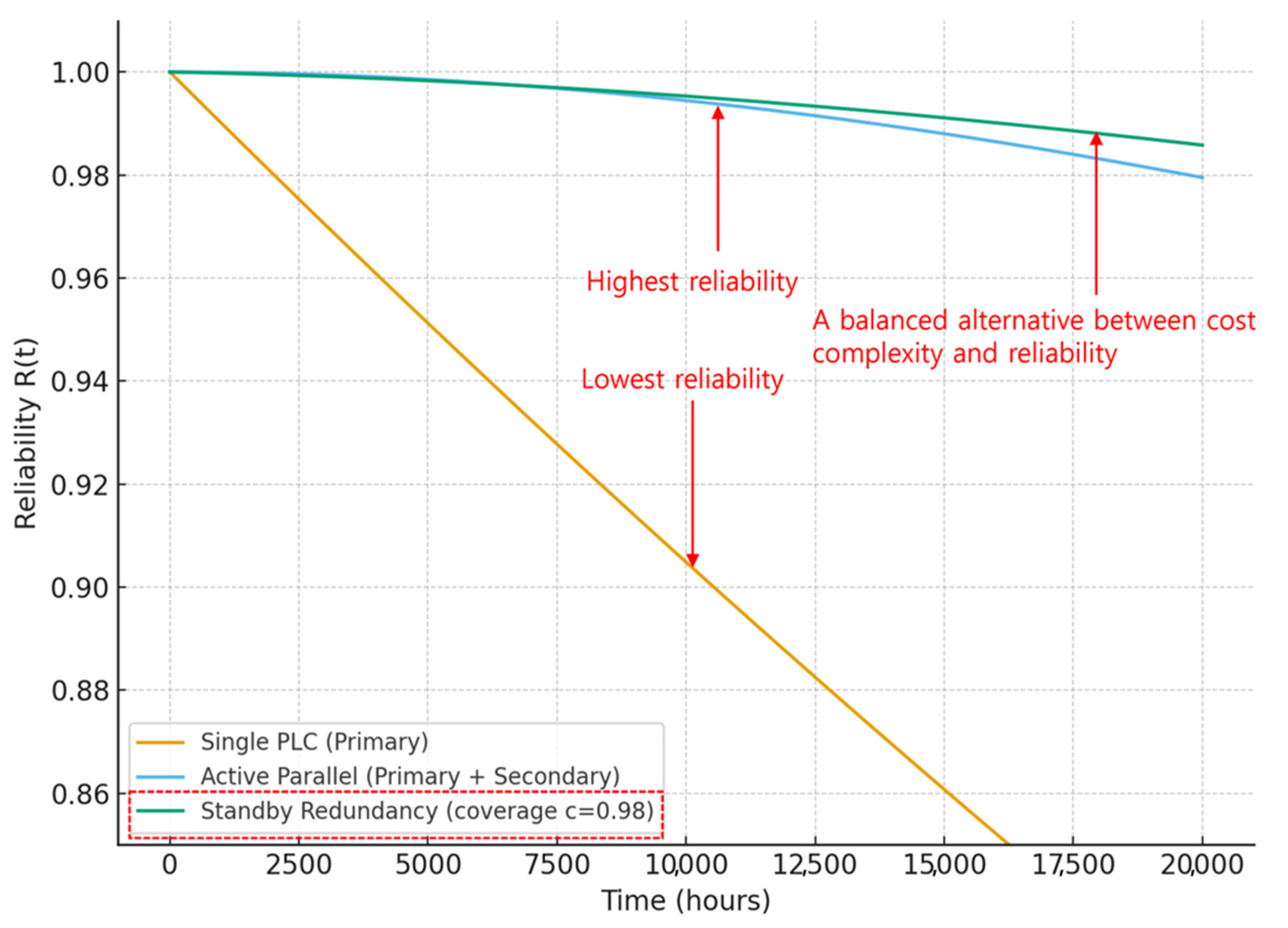

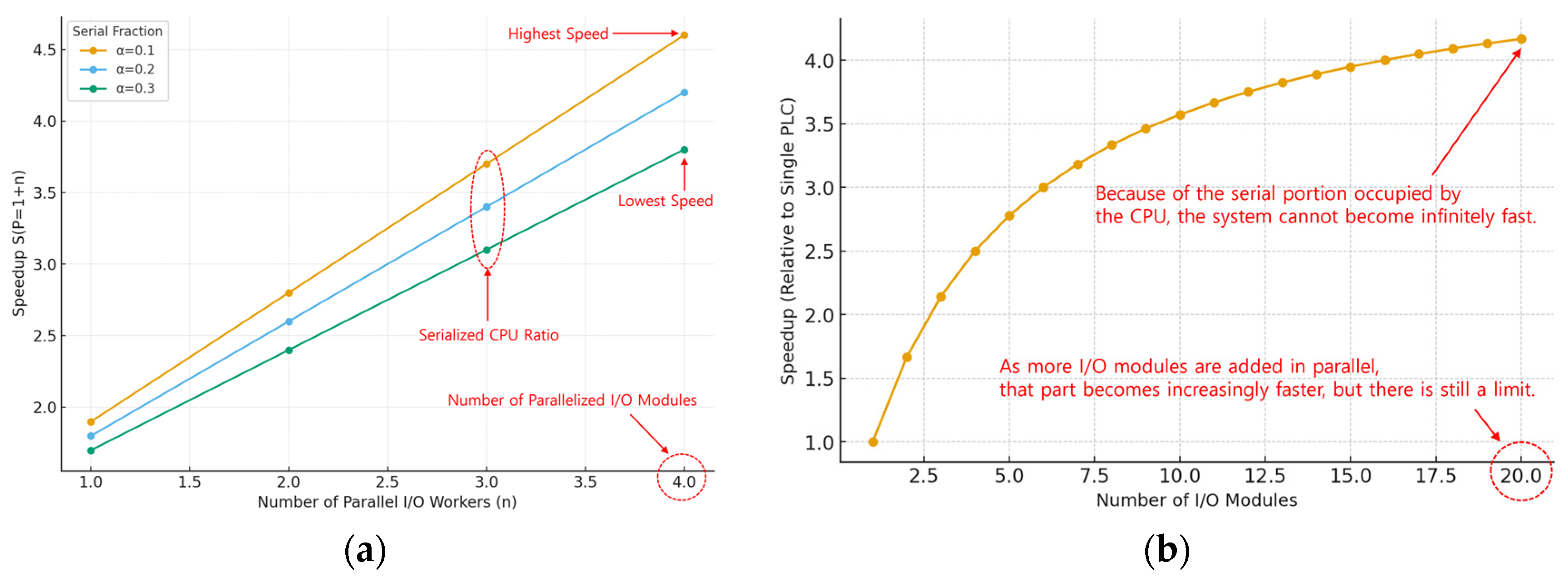

2.2. Reliability Analysis of Heterogeneous PLCs

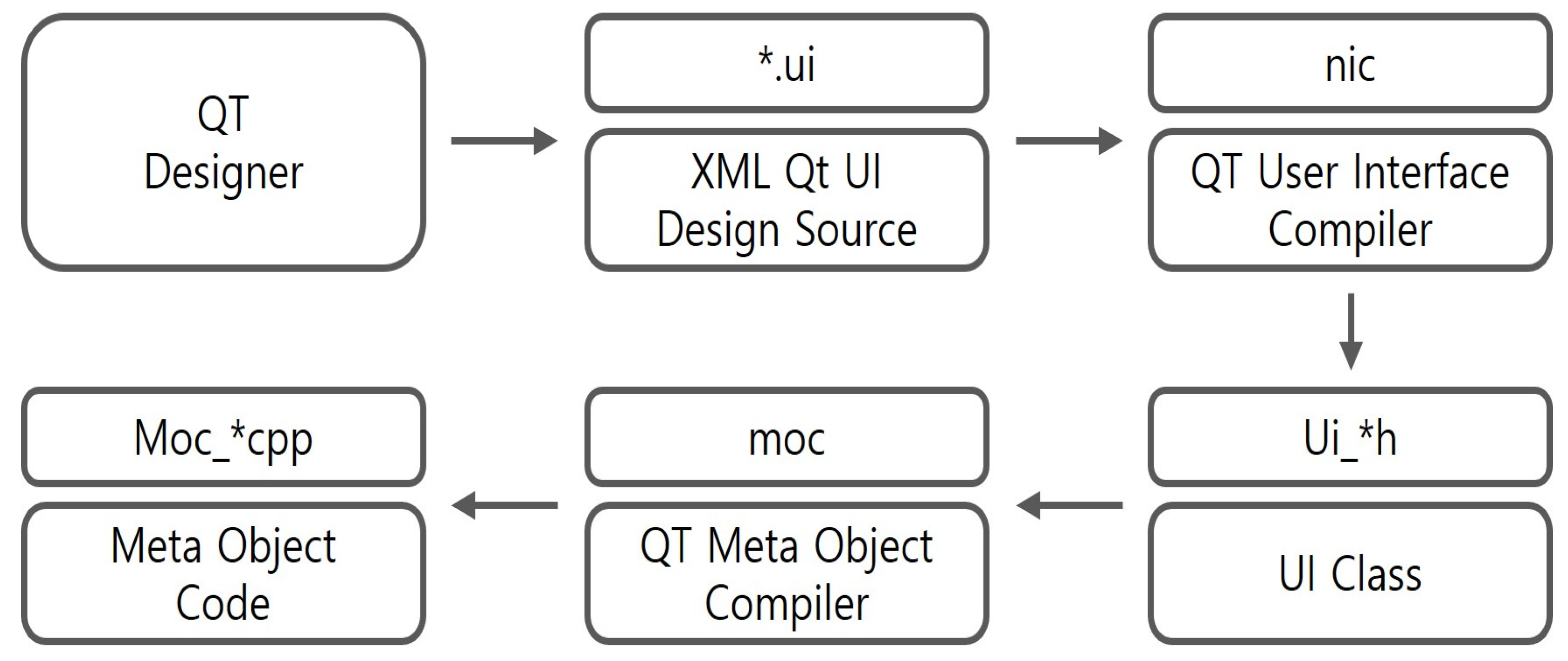

2.3. Port Forwarding of Heterogeneous PLC Input Data and DYTO Studio

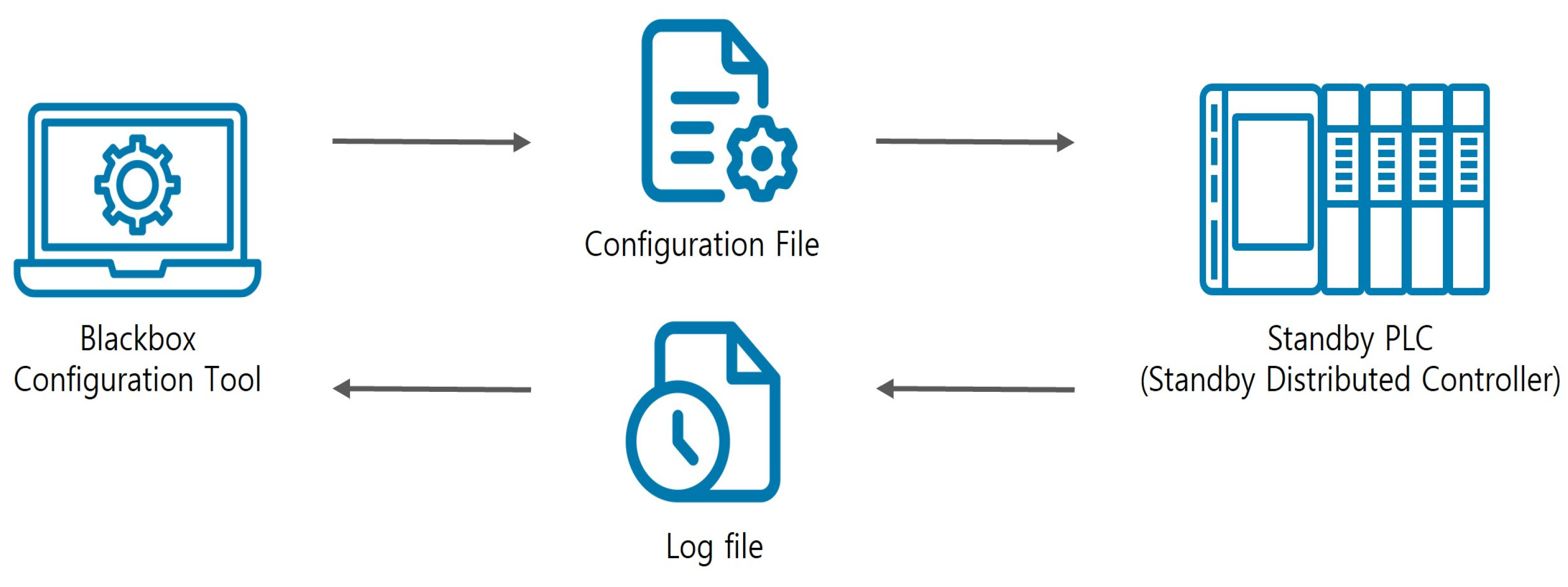

2.4. Logic State Monitoring and Blackbox

3. Design of Distributed Controller with Embedded Blackbox and I/O

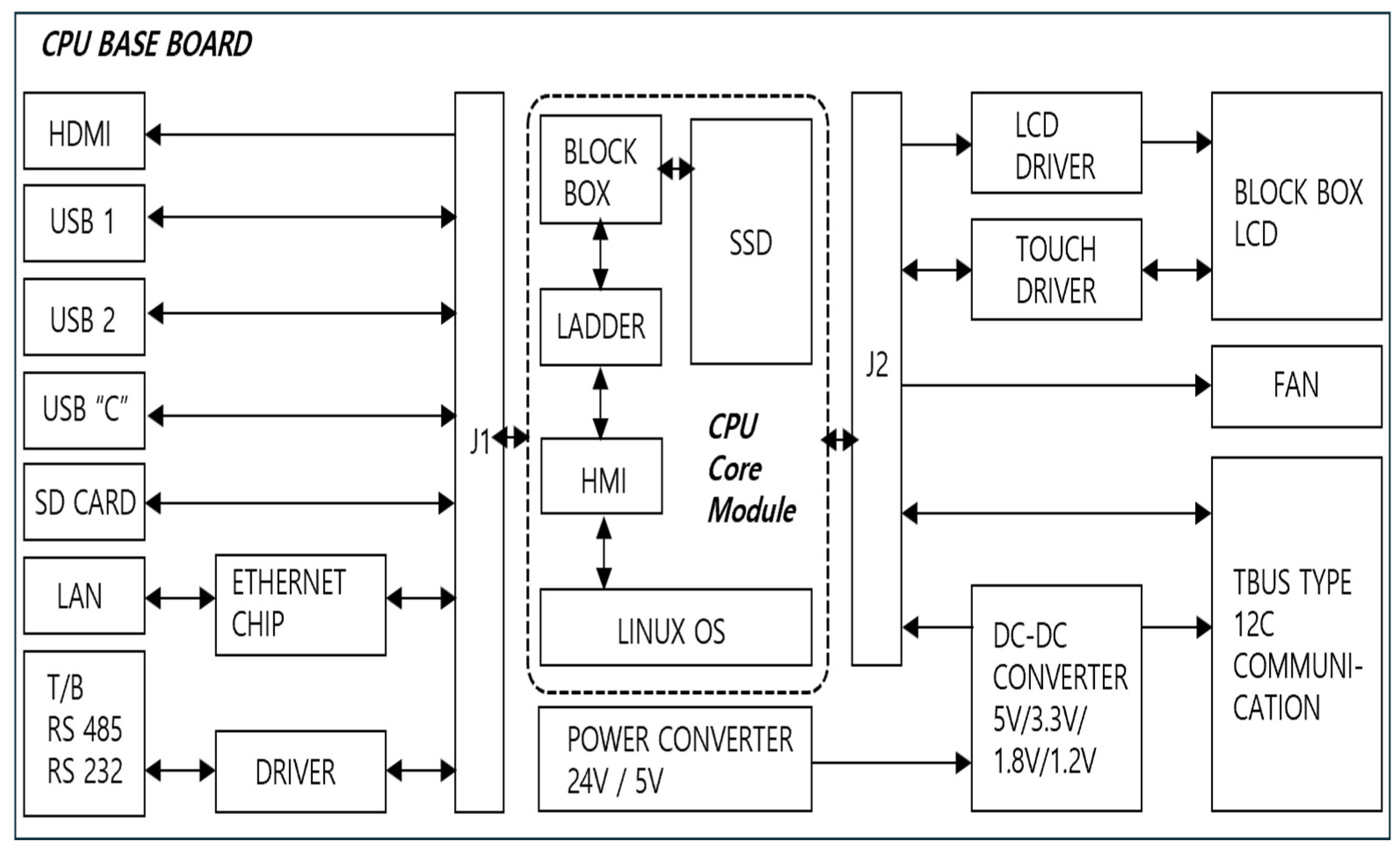

3.1. Hardware Design of Distributed Controller with Embedded Blackbox

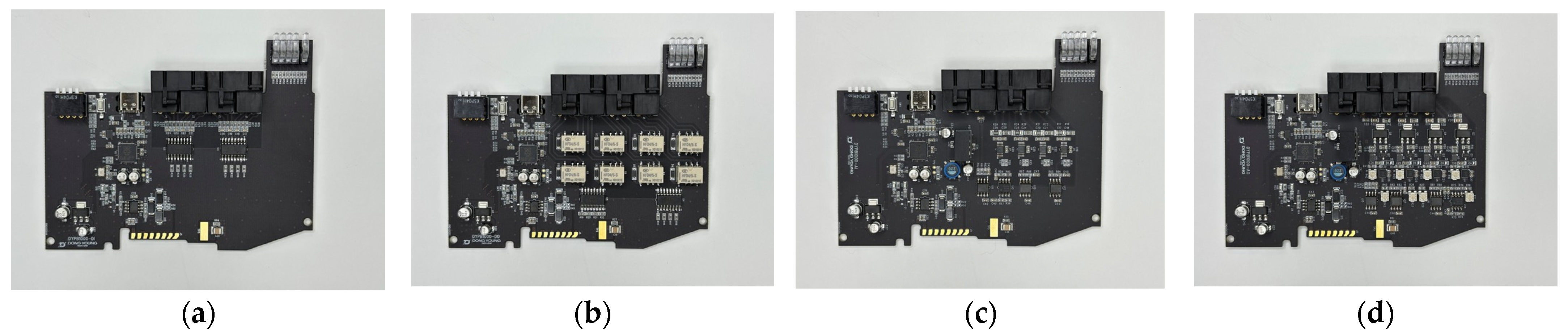

3.2. Distributed Controller I/O Hardware Design

3.2.1. Digital Input Module Design

3.2.2. Digital Output Module Design

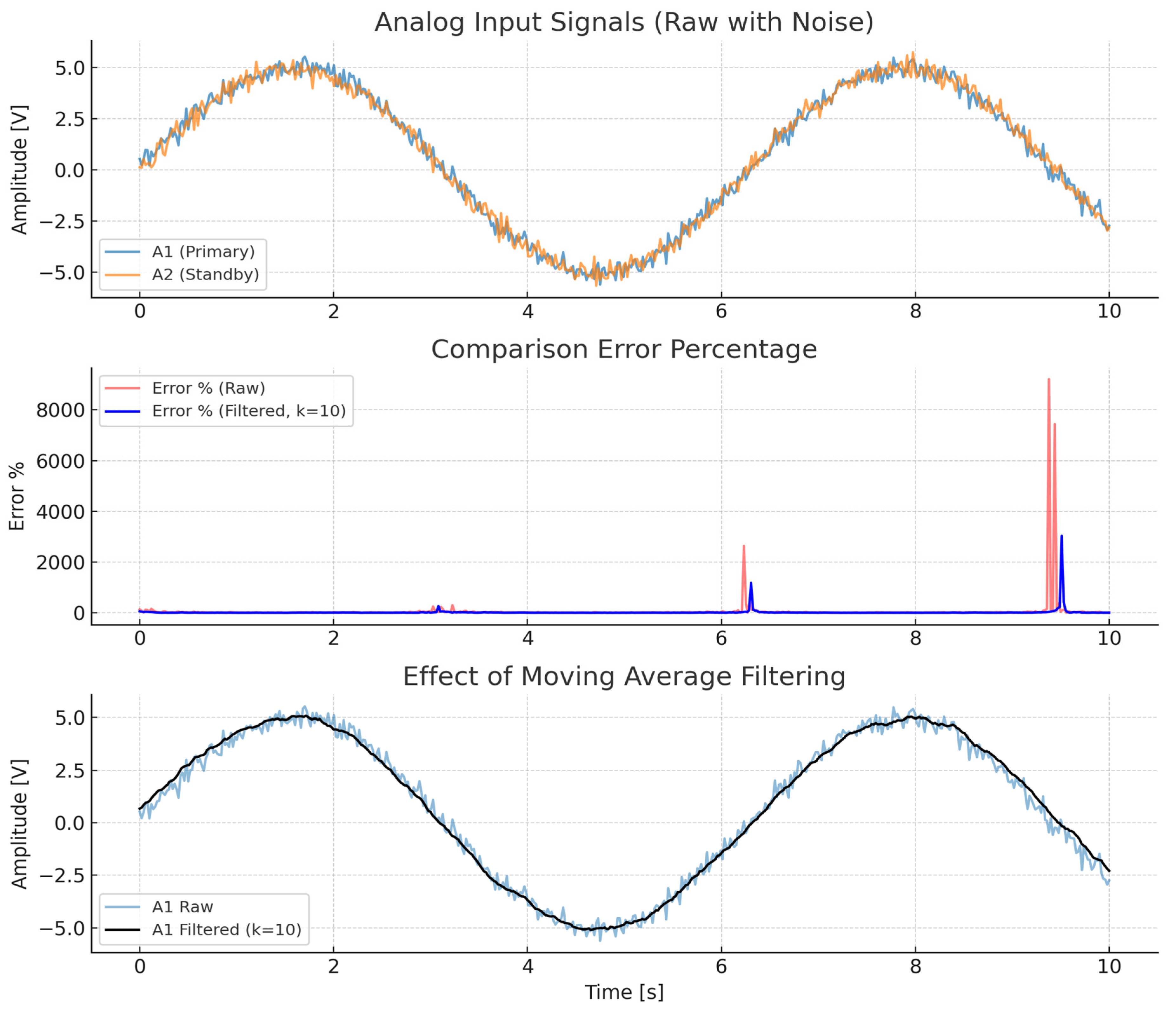

3.2.3. Analog Input Module Design

3.2.4. Analog Output Module Design

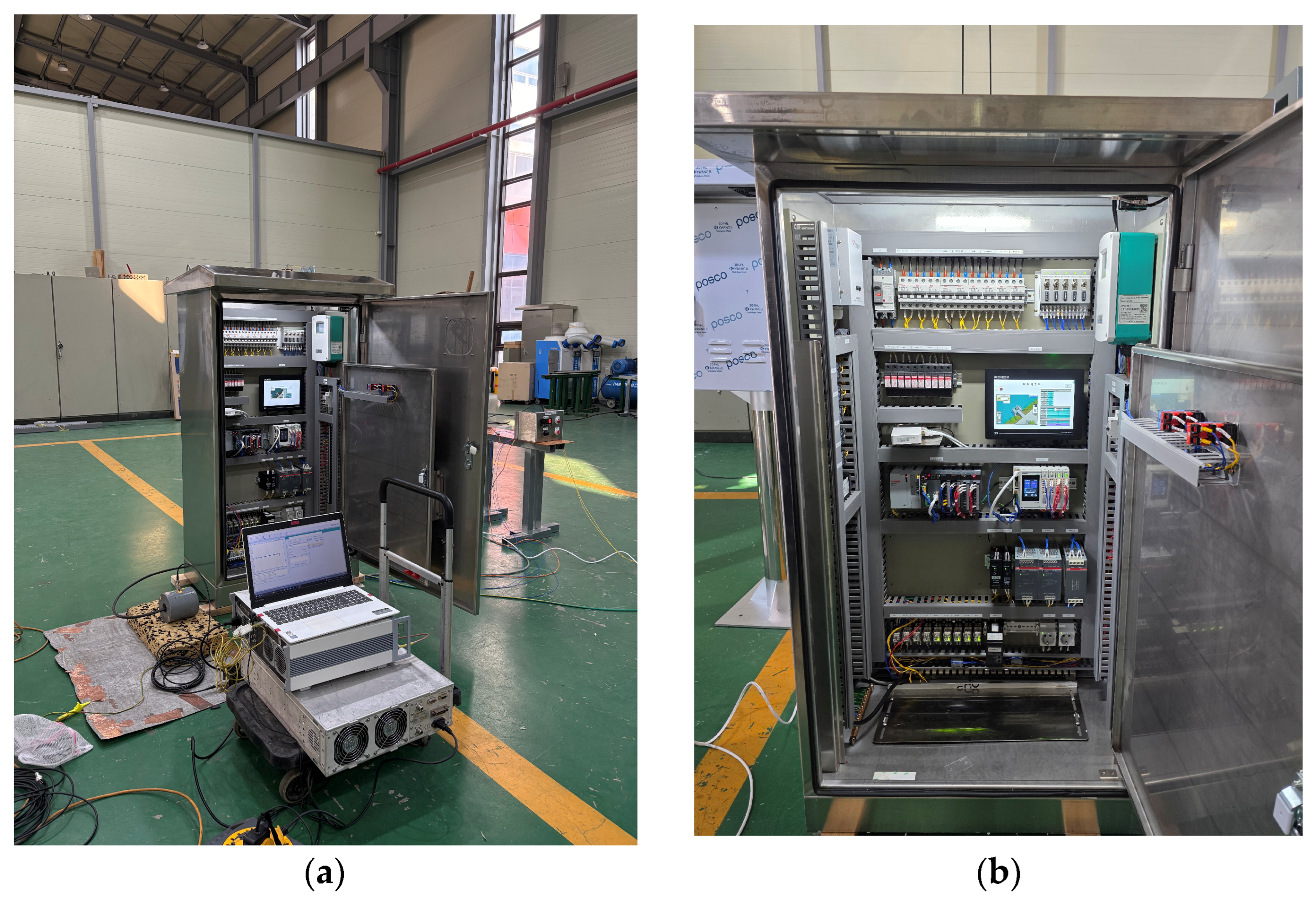

4. Implementation of a Distributed Controller with an Embedded Black-Box

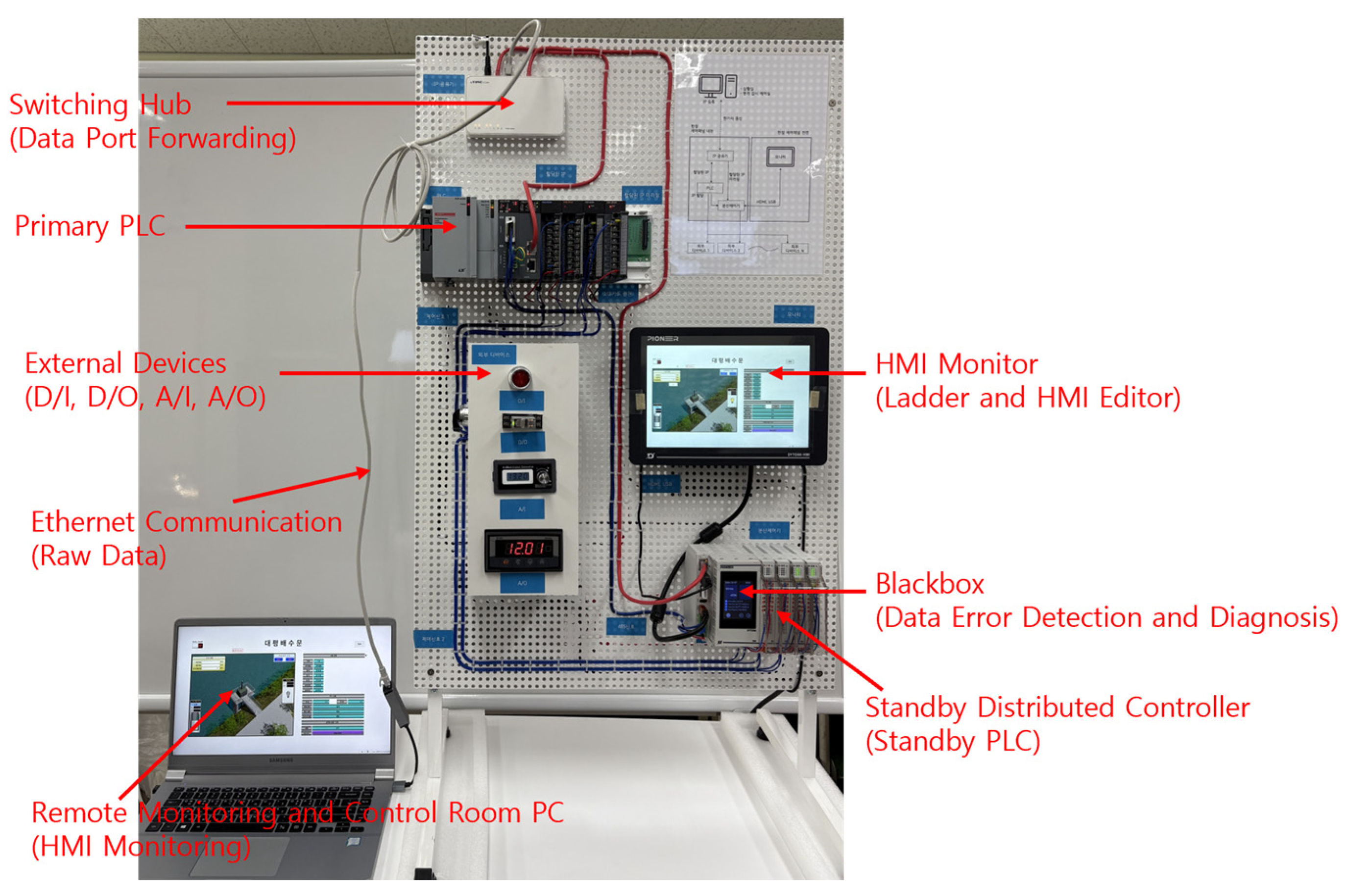

4.1. Implementation of the Black-Box Distributed Controller and HMI Monitor

4.2. Implementation of Distributed Controller I/O

5. Experimental and Test Results

5.1. Experimental Bed Test of the Heterogeneous Redundant Distributed Controller

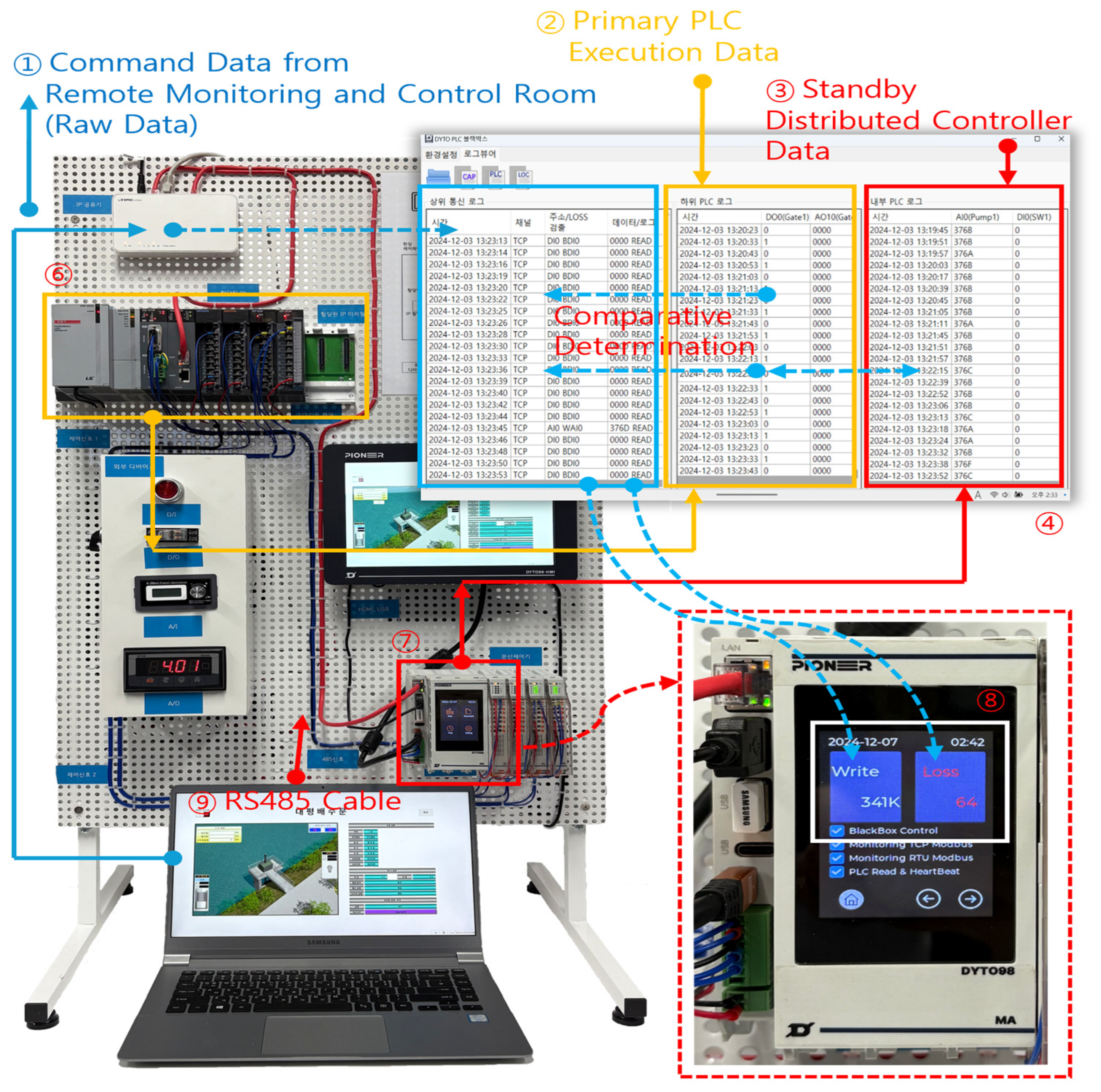

5.1.1. Command Data Synchronization Experiment

5.1.2. Black-Box Data Determination Experiment

- Write: counted when the command is executed successfully.

- Loss: counted when the command fails to be executed.

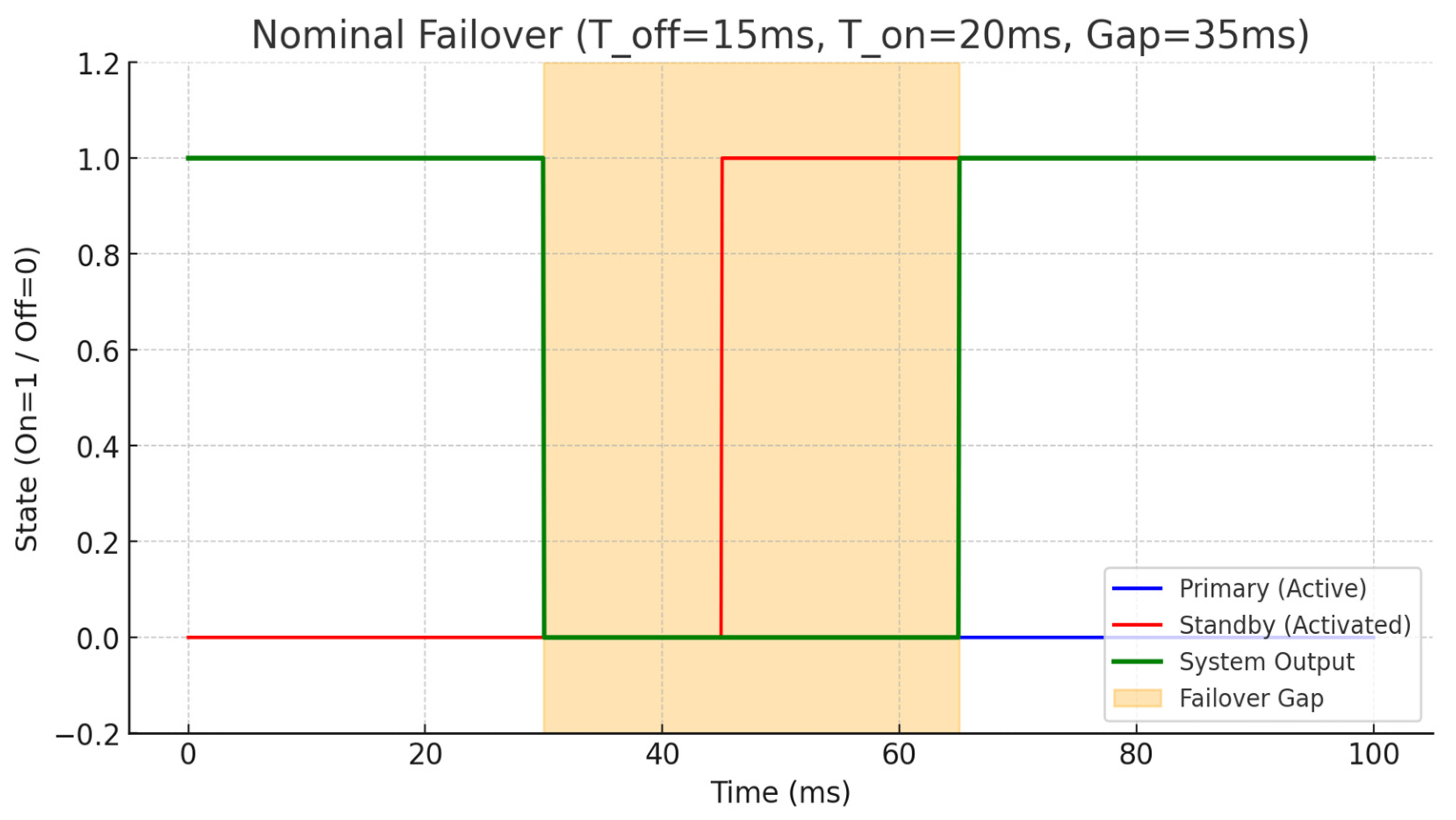

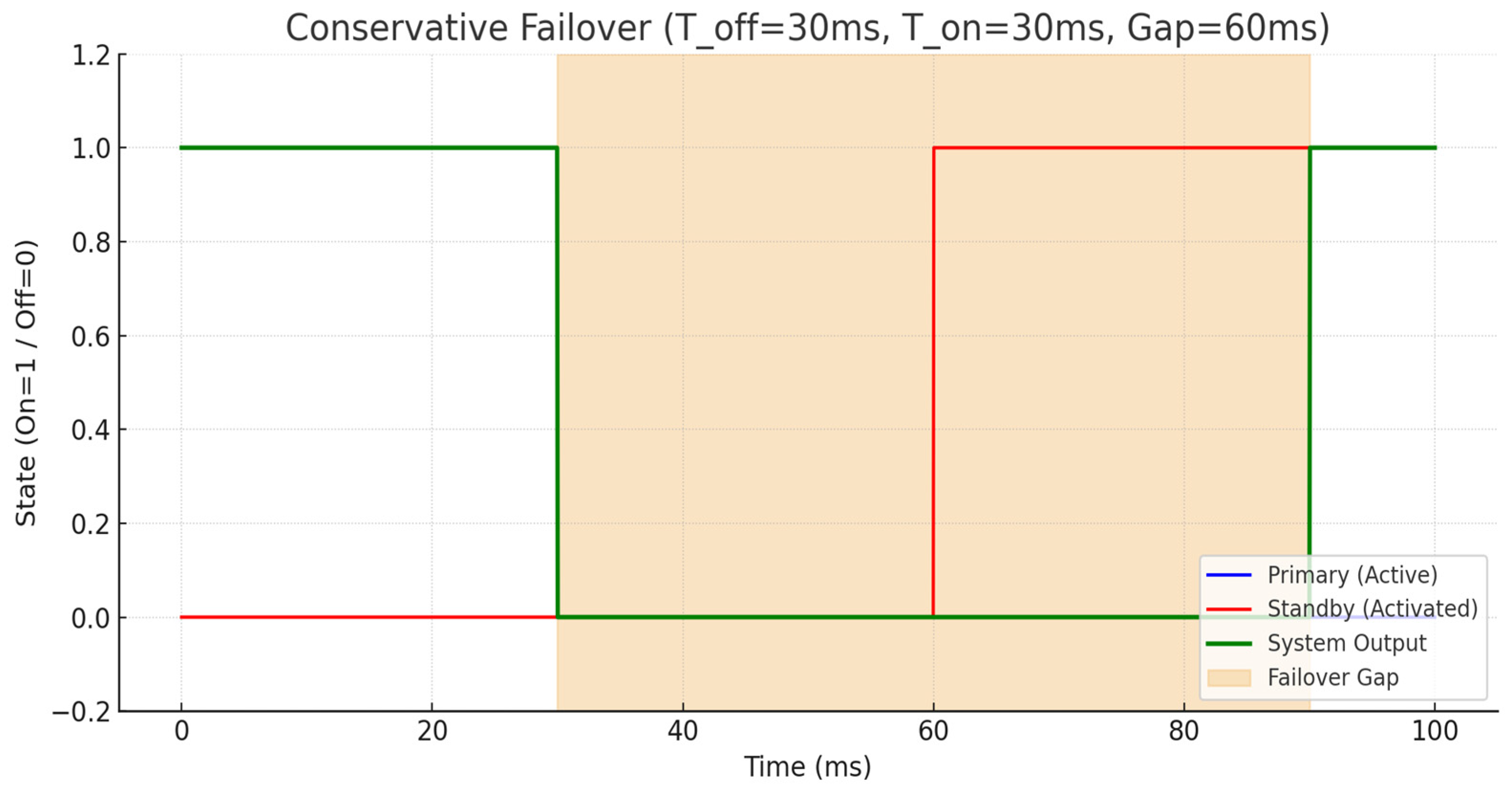

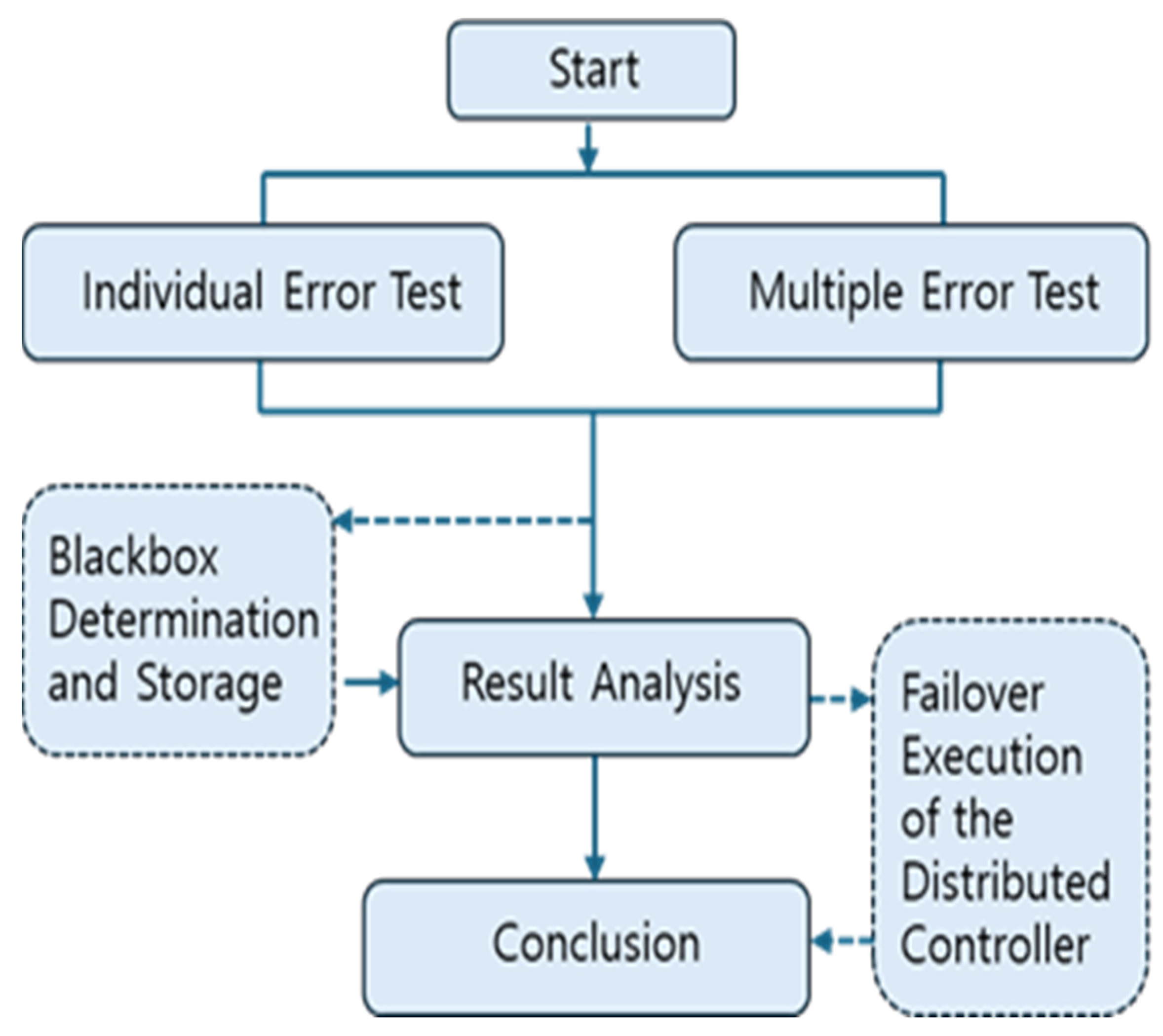

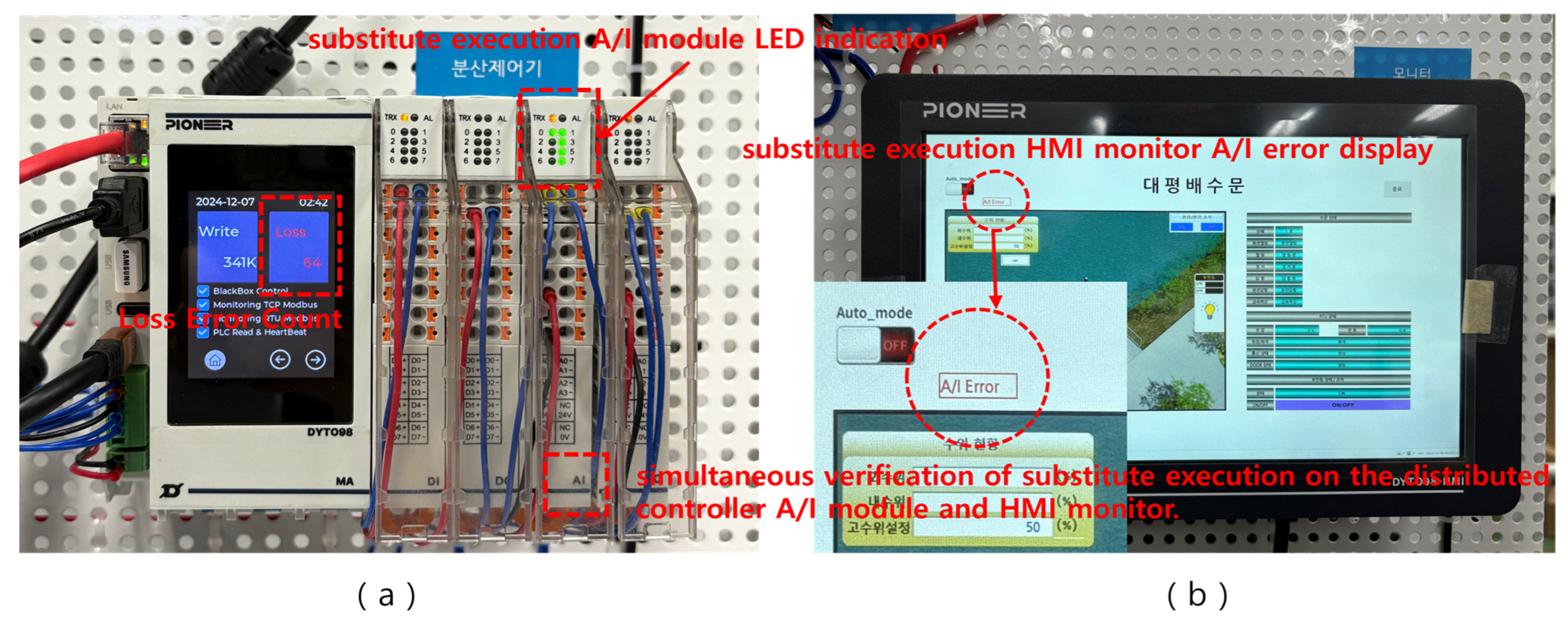

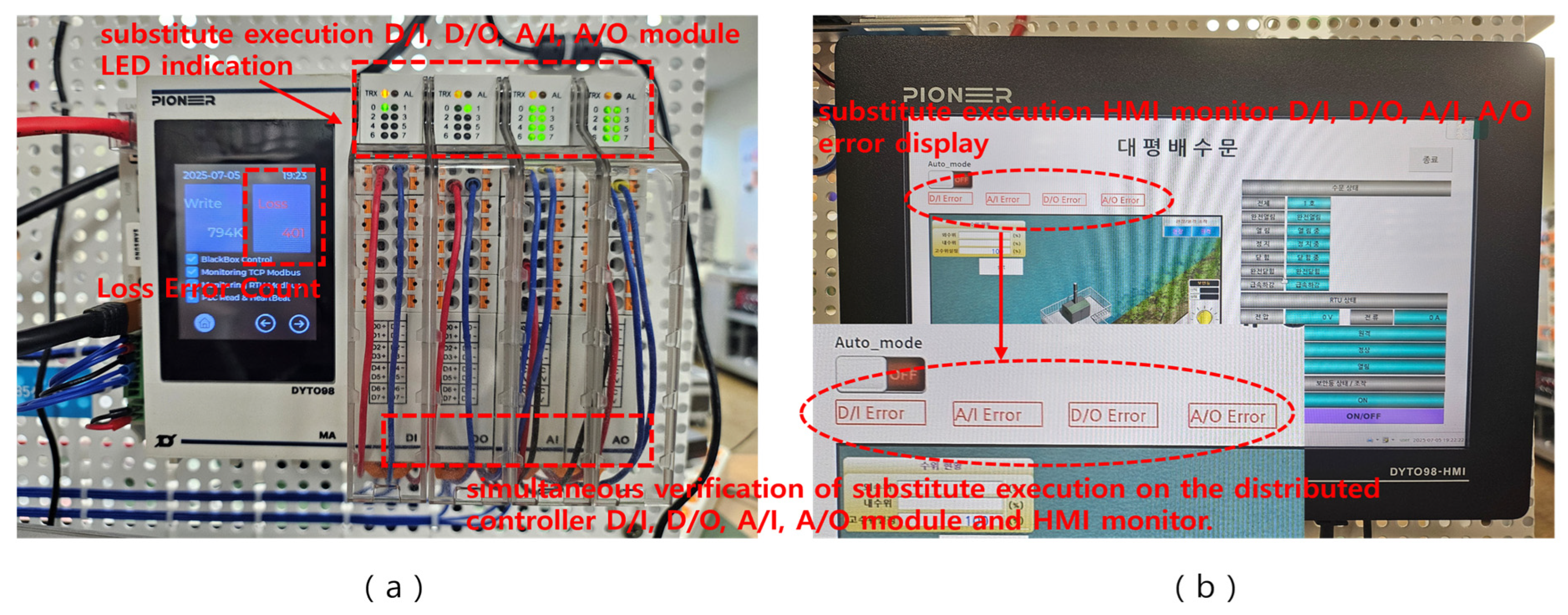

5.1.3. Failover Execution and Error Notification Test

- Individual Error Test: verifies whether the standby distributed controller’s I/O module can successfully execute failover when a single I/O channel in the primary PLC fails.

- Multiple Error Test: simulates simultaneous failures of multiple I/O channels in the primary PLC and evaluates whether the standby distributed controller can reliably handle them concurrently.

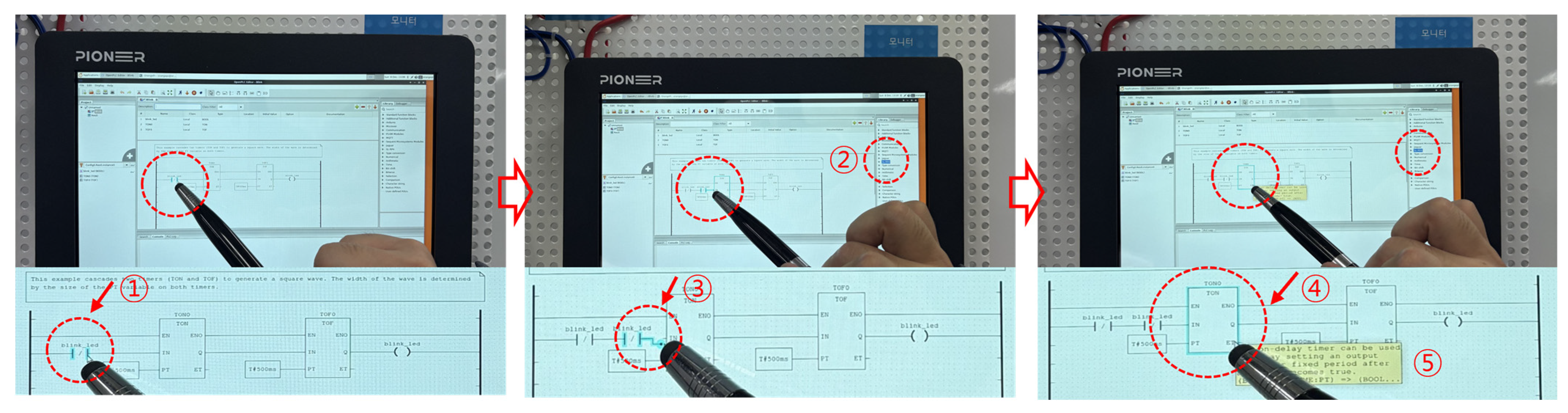

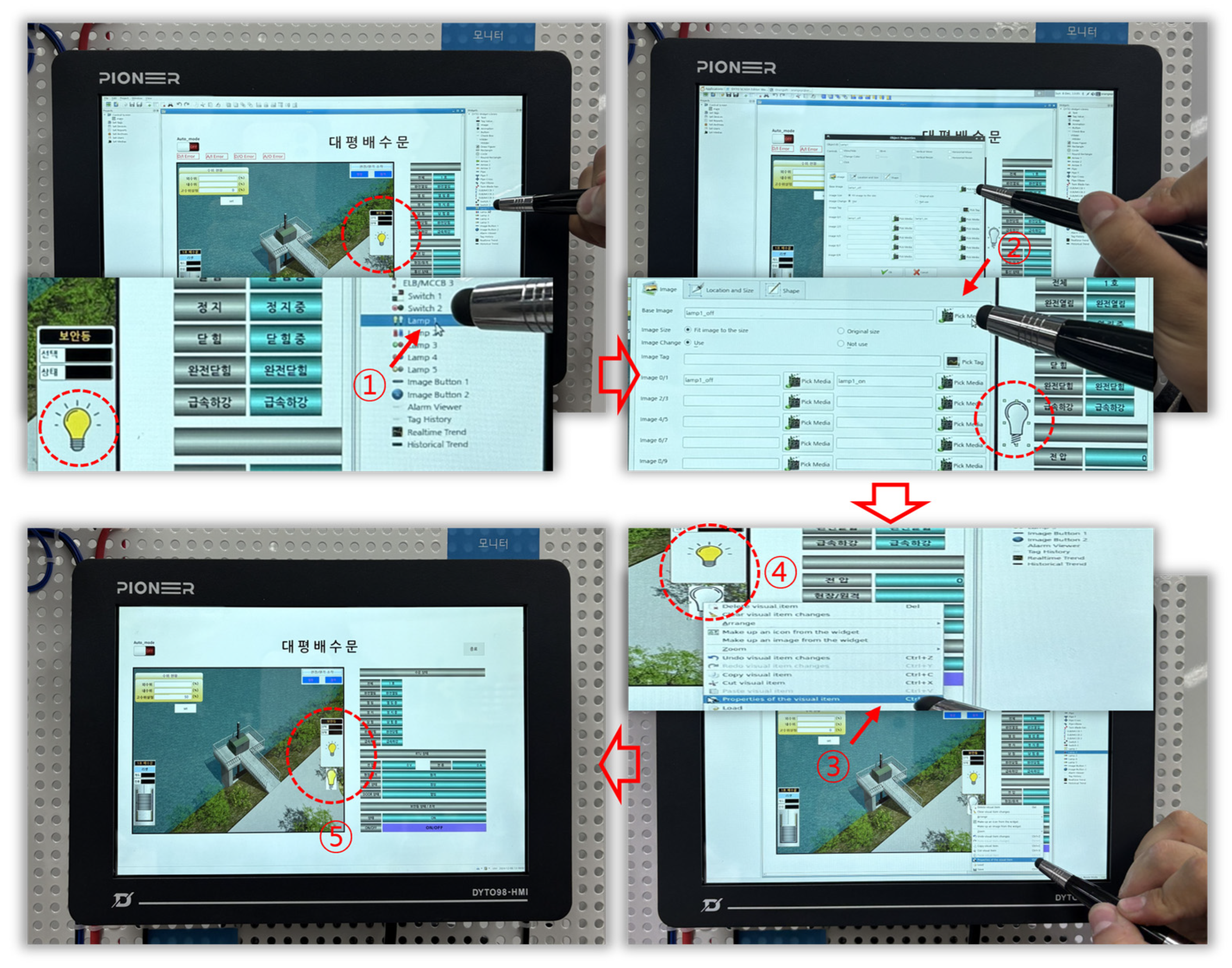

5.1.4. Program Modification and Editing Test

5.2. Certification Tests by Authorized Institutions

- Main power conducted emission test (0.15–30 MHz): The measured interference levels remained within CISPR 32 Class A limits, including peak bands at 0.5 MHz, 5 MHz, and 10 MHz.

- Communication port conducted emission test (RS232, RS485, LAN): Both peak and average detection values satisfied the KS C9610-6-4 requirements, with no data loss or transmission errors observed.

- Radiated emission below 1 kHz band (30 MHz–1 GHz): All results remained within CISPR 32 Class A limits, and no functional degradation was observed even at peak frequencies.

- Radiated emission above 1 kHz band (1–6 GHz): Peak and average detection values were all below the allowable limits, verifying stable performance under high-frequency EMI conditions.

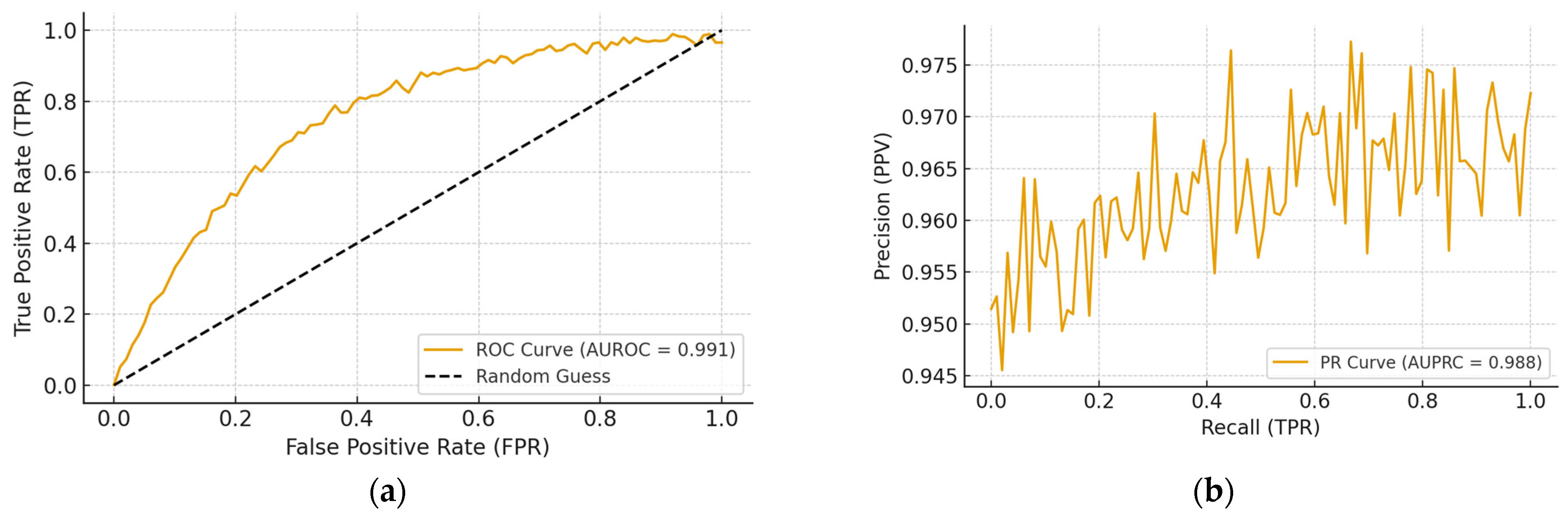

5.3. Statistical Evaluation and Comparative Analysis

6. Conclusions

- Redundant data structure validation: implemented a port-forwarding-based configuration ensuring that the remote monitoring room, primary PLC, and standby distributed controller receive identical data.

- Blackbox recording and display functionality: experimentally confirmed that normal data (Write) and error data (Loss) are recorded and displayed on the LCD, providing intuitive execution results.

- Detailed log analysis: verified that execution details such as date, time, I/O information, addresses, and data logs can be stored and examined.

- Error detection and remote verification: demonstrated that D/I, D/O, A/I, and A/O errors can be consistently identified both in the blackbox and the remote monitoring room.

- On-site modification capability: verified that ladder logic and HMI editing can be performed directly on the local HMI monitor without additional equipment or software, ensuring rapid field response.

- Industrial validation and patent registration: the developed system has been registered under Korean Patent No. 10-2733771 (“Logic Monitoring Blackbox-Integrated Distributed Controller”) and has been applied in real-world water treatment facilities (e.g., flood control automation systems in Jinju City and Hapcheon County), where it is currently under field operation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Empowered Automation. Understanding Automation PLC: A Comprehensive Guide. Available online: https://www.empoweredautomation.com/understanding-automation-plc-a-comprehensive-guide?utm_source (accessed on 10 April 2025).

- Zhang, H. Optimization and Innovation of Industrial Control Systems Based on PLC. Int. J. Res. Pract. Robot. 2024, 3, 45–74. [Google Scholar]

- Alphonsus, E.R.; Abdullah, M.O. A Review on the Applications of Programmable Logic Controllers (PLCs). Renew. Sustain. Energy Rev. 2016, 60, 1185–1205. [Google Scholar] [CrossRef]

- Market Research Future. Programmable Logic Controller (PLC) Market Research Report—Forecast 2025 to 2030; Market Research Future: Pune, India, 2024. [Google Scholar]

- Allied Market Research. Global Programmable Logic Controller (PLC) Market Size, Share & Forecast 2024–2034; Allied Market Research: Portland, OR, USA, 2024. [Google Scholar]

- Doe, J. Trends in Industrial Automation and PLC Redundancy. Int. J. Autom. Eng. 2023, 15, 101–112. [Google Scholar]

- Siemens, A.G. Redundant PLC System Design Manual; Siemens Technical Documentation: Nuremberg, Germany, 2022. [Google Scholar]

- Rockwell Automation. ControlLogix Redundancy System Reference Manual; Rockwell Automation: Milwaukee, WI, USA, 2021. [Google Scholar]

- Lee, K.; Park, H. Triple Modular Redundancy in PLC Systems for Critical Industrial Applications. IEEE Trans. Ind. Electron. 2022, 69, 8123–8132. [Google Scholar]

- Smith, M. Virtual PLCs for Flexible and Secure Automation. J. Ind. Control Syst. 2023, 10, 55–67. [Google Scholar]

- IEC 61508; Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- Dong Young Tech One (DYTO). DYTO Studio Program Manual; Internal Technical Documentation: Busan, Republic of Korea, 2023. [Google Scholar]

- Ogata, K. Modern Control Engineering, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010; pp. 1–968. [Google Scholar]

- Lee, J.; Kim, H. Design of Industrial PC-Based Control Systems for Flexible Manufacturing. J. Ind. Autom. 2022, 32, 215–227. [Google Scholar]

- Park, S.; Choi, Y. Analysis of PLC–HMI Integration for Smart Factory Applications. IEEE Access 2021, 9, 120351–120364. [Google Scholar]

- NIST. Reliability Block Diagram (RBD) Overview; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2021. Available online: https://www.nist.gov (accessed on 27 September 2025).

- IEC 61078; Analysis Techniques for Dependability—Reliability Block Diagrams (RBD). International Electrotechnical Commission: Geneva, Switzerland, 2016.

- ReliaSoft. Reliability Block Diagrams (RBDs) Tutorial; ReliaSoft/Weibull.com: Tucson, AZ, USA, 2020; Available online: https://www.weibull.com (accessed on 27 September 2025).

- Rausand, M.; Høyland, A. System Reliability Theory: Models, Statistical Methods, and Applications, 2nd ed.; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Ebeling, C.E. An Introduction to Reliability and Maintainability Engineering; McGraw-Hill: New York, NY, USA, 1997. [Google Scholar]

- Trivedi, K.S. Probability and Statistics with Reliability, Queuing, and Computer Science Applications, 2nd ed.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Shooman, M.L. Reliability of Computer Systems and Networks; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar]

- Lala, P.K. Fault-Tolerant Systems; Morgan Kaufmann: San Francisco, CA, USA, 2001. [Google Scholar]

- Standard Bank Co., Ltd. Test Report for Electromagnetic Compatibility of Logic Monitoring Blackbox-Embedded Distributed Controller for Broadcasting and Communication Equipment; Test Report No. E25KR-0309; Standard Bank Co., Ltd.: Shanghai, China, 6 February 2025. (In Korea) [Google Scholar]

- WonTech Co., Ltd. Electromagnetic Compatibility Test Report for Logic Monitoring Blackbox-Embedded Distributed Instrumentation and Control Device; Test Report No. OT-252-RED-023; WonTech Co., Ltd.: Shenzhen, China, 5 February 2025. (In Korea) [Google Scholar]

- Korea Testing Certification Institute (KTC). Q-Mark Test Report for Instrumentation Control Device; Test Report No. GT2025-00742; Korea Testing Certification Institute (KTC): Gunpo, Republic of Korea, 20 January 2025. (In Korean) [Google Scholar]

- Korea Testing Certification Institute (KTC). Test Report for Logic Monitoring Blackbox-Embedded Distributed Instrumentation and Control Device for Water Treatment; Test Report No. 2025-00068; Korea Testing Certification Institute (KTC): Gunpo, Republic of Korea, 6 January 2025. (In Korean) [Google Scholar]

- Cisco Systems. Configuring SPAN and RSPAN: Port Mirroring in Ethernet Switches; Cisco Networking Documentation: San Jose, CA, USA, 2022; Available online: https://www.cisco.com (accessed on 12 April 2025).

- Rockwell Automation. EtherNet/IP Networks Design Guide; Publication ENET-RM002; Rockwell Automation: Milwaukee, WI, USA, 2023. [Google Scholar]

- Netfilter.org. Netfilter/Iptables Documentation; Linux Foundation: San Francisco, CA, USA, 2022; Available online: https://netfilter.org (accessed on 12 April 2025).

- Kim, S.; Lee, J.; Park, Y. A Redundancy-Based Reliability Model for Industrial Control Systems. Reliab. Eng. Syst. Saf. 2020, 197, 106803. [Google Scholar]

- Smith, D.J. Reliability, Maintainability and Risk: Practical Methods for Engineers, 9th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Gustafson, J.L. Reevaluating Amdahl’s Law. Commun. ACM 1988, 31, 532–533. [Google Scholar] [CrossRef]

- Proakis, J.G.; Salehi, M. Digital Communications, 5th ed.; McGraw-Hill: New York, NY, USA, 2007. [Google Scholar]

- Sklar, B. Digital Communications: Fundamentals and Applications, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Isermann, R. Fault-Diagnosis Systems: An Introduction from Fault Detection to Fault Tolerance; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Zio, E. An Introduction to the Basics of Reliability and Risk Analysis; World Scientific: Singapore, 2007. [Google Scholar]

- Iung, B.; Levrat, E. Advanced Maintenance Services for Promoting Sustainability. Procedia CIRP 2014, 22, 15–22. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J. Reliability Modeling of Redundant PLC I/O Modules for Industrial Automation. IEEE Trans. Ind. Electron. 2020, 67, 4813–4824. [Google Scholar]

- Lyu, M.R. Handbook of Software Reliability Engineering; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Tanenbaum, A.S.; Van Steen, M. Distributed Systems: Principles and Paradigms; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Hwang, I.; Kim, S.; Kim, Y.; Seah, C.E. A Survey of Fault Detection, Isolation, and Reconfiguration Methods. IEEE Trans. Control Syst. Technol. 2010, 18, 636–653. [Google Scholar] [CrossRef]

- Hall, S.H.; Hall, G.W.; McCall, J.A. High-Speed Digital System Design: A Handbook of Interconnect Theory and Design Practices; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar]

- IEC 61131-2; Programmable Controllers—Equipment Requirements and Tests. International Electrotechnical Commission: Geneva, Switzerland, 2007.

- Liu, J.; Zhang, W. Application of Moving Average Filtering in Industrial Signal Processing. Int. J. Signal Process. Image Process. Pattern Recognit. 2016, 9, 101–112. [Google Scholar]

- Peng, Y.; Dong, M.; Zuo, M.J. Current Status of Machine Prognostics in Condition-Based Maintenance: A Review. Int. J. Adv. Manuf. Technol. 2010, 50, 297–313. [Google Scholar] [CrossRef]

- IEC 61511; Functional Safety—Safety Instrumented Systems for the Process Industry Sector. International Electrotechnical Commission: Geneva, Switzerland, 2016.

| Redundancy Type | Fault Coverage (c) | Switchover Latency | Implementation Cost (Relative) | Reference |

|---|---|---|---|---|

| Isomorphic Redundancy | 0.93–0.96 | 80–100 ms | High | IEC 61508 [11] |

| Virtual PLC | 0.90–0.94 | 60–70 ms | Medium | Control Eng. Practice (2023) [10] |

| Triple-Mode Redundancy | 0.95–0.97 | 45–60 ms | High | IEEE Trans. Ind. Informat. (2022) [9] |

| Proposed Heterogeneous Redundancy | 0.98 | 41 ms | Medium | This Work |

| No | Name | Product Specifications |

|---|---|---|

| 1 | Main Unit | Main CPU Board (Black Box LCD)/Fan Board/I2C Interface Board |

| 2 | Communication Board (LAN, HDMI, USB 2.0, USB 3.0, USB Type-C) Connection Terminal: (RS232, RS485, DC24V) | |

| 3 | ||

| 4 | D/I Module | D/I CPU Board, 8 Ports/DC24V Input (Sink Source Type) |

| 5 | D/O Module | D/O CPU Board, 8-Port Relay Output (0.5 A) |

| 6 | A/I Module | A/I CPU Board, 4-Port/4–20 mA Input |

| 7 | A/O Module | A/O CPU Board, 4-Port/4–20 mA Output |

| Component | Function | Description |

|---|---|---|

| HMI Monitor | Real-time monitoring and editing | Provides logic and HMI visualization; supports on-site editing via external display |

| I/O Modules (D/I, D/O, A/I, A/O) | Redundant execution | TBUS and I2C based modular expansion; executes I/O replacement during PLC faults |

| 2.4-inch LCD (Blackbox display) | Data indication | Displays real-time status of normal and error data on the front panel |

| LAN Port | Remote communication | Ensures real-time connection with the remote monitoring room |

| HDMI Port | Screen transmission | Sends graphical interface to the HMI monitor |

| USB Port | Touchscreen input | Allows for interactive control and editing |

| RS485/RS232 Ports | Execution data monitoring | Monitors execution data from the primary PLC |

| and provides it to the black-box |

| Experiment | Detailed Description | |

|---|---|---|

| Command Data Synchronization Test | Objective | To verify that critical command and event data transmitted from the remote monitoring control room can be simultaneously delivered to both the primary PLC and the standby distributed controller. |

| Method | Command data transmitted from the remote-control PC are forwarded through the LAN port to a switching hub and then IP-mirrored to both the primary PLC and the standby distributed controller. | |

| Verification Items | Confirm that both controllers receive identical input data simultaneously, ensuring proper redundancy and synchronization. | |

| Black-Box Data Discrimination Test | Objective | To test whether the black box correctly monitors and classifies the execution results of the primary PLC. |

| Method | When important command or event data are transmitted, the primary PLC drives the I/O, and the results are sent to the standby distributed controller via RS485. The black box records the execution status. | |

| Verification Items | Verify that normal execution results are categorized under the Write item and error results are recorded under the Loss item. Confirm that detailed error information is accessible from the black box. | |

| Substitute Execution and Error Notification Test | Objective | To verify whether the standby distributed controller can immediately perform substitute execution and notify errors in the event of a primary PLC I/O fault. |

| Method | An intentional error is induced to prevent the primary PLC from operating the external device. | |

| Verification Items | Confirm that the standby controller immediately executes the corresponding I/O and that errors are displayed in red on the remote monitoring PC and HMI monitor via RS232 and HDMI interfaces. | |

| Program Modification and Editing Test | Objective | To verify whether operators can immediately modify and edit programs on-site in case of errors. |

| Method | Ladder and HMI programs are modified and edited through the HMI monitor’s touchscreen. The HDMI port is used for screen transmission, and the USB port is used for the touch interface. | |

| Verification Items | Confirm that operators can edit programs in real time during error situations. | |

| Metric | Proposed System (Mean ± SD) | Conventional Redundant PLC | Improvement |

|---|---|---|---|

| Failover Latency (s) | 2.46 ± 0.12 | 3.01 ± 0.19 | −18.3% |

| Fault Detection Accuracy (%) | 97.8 ± 0.7 | 86.9 ± 1.2 | +12.5% |

| False Positive Rate (%) | 2.3 ± 0.5 | 5.9 ± 0.8 | −61.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, C.K.; Lee, M.C.; Hong, I.H.; Park, J.H.; Lee, J.D.; Choi, S.Y. Heterogeneous PLC-Based Distributed Controller with Embedded Logic-Monitoring Blackbox for Real-Time Failover. Electronics 2025, 14, 4359. https://doi.org/10.3390/electronics14224359

Ryu CK, Lee MC, Hong IH, Park JH, Lee JD, Choi SY. Heterogeneous PLC-Based Distributed Controller with Embedded Logic-Monitoring Blackbox for Real-Time Failover. Electronics. 2025; 14(22):4359. https://doi.org/10.3390/electronics14224359

Chicago/Turabian StyleRyu, Chi Kook, Min Cheol Lee, In Ho Hong, Jun Hyuk Park, Jae Deuk Lee, and Su Yeon Choi. 2025. "Heterogeneous PLC-Based Distributed Controller with Embedded Logic-Monitoring Blackbox for Real-Time Failover" Electronics 14, no. 22: 4359. https://doi.org/10.3390/electronics14224359

APA StyleRyu, C. K., Lee, M. C., Hong, I. H., Park, J. H., Lee, J. D., & Choi, S. Y. (2025). Heterogeneous PLC-Based Distributed Controller with Embedded Logic-Monitoring Blackbox for Real-Time Failover. Electronics, 14(22), 4359. https://doi.org/10.3390/electronics14224359