Rapid Thermal Annealing for Reduced Leakage and Enhanced Endurance of Reactive-Sputtered AlScN-Based Ferroelectric Memory Capacitors

Abstract

1. Introduction

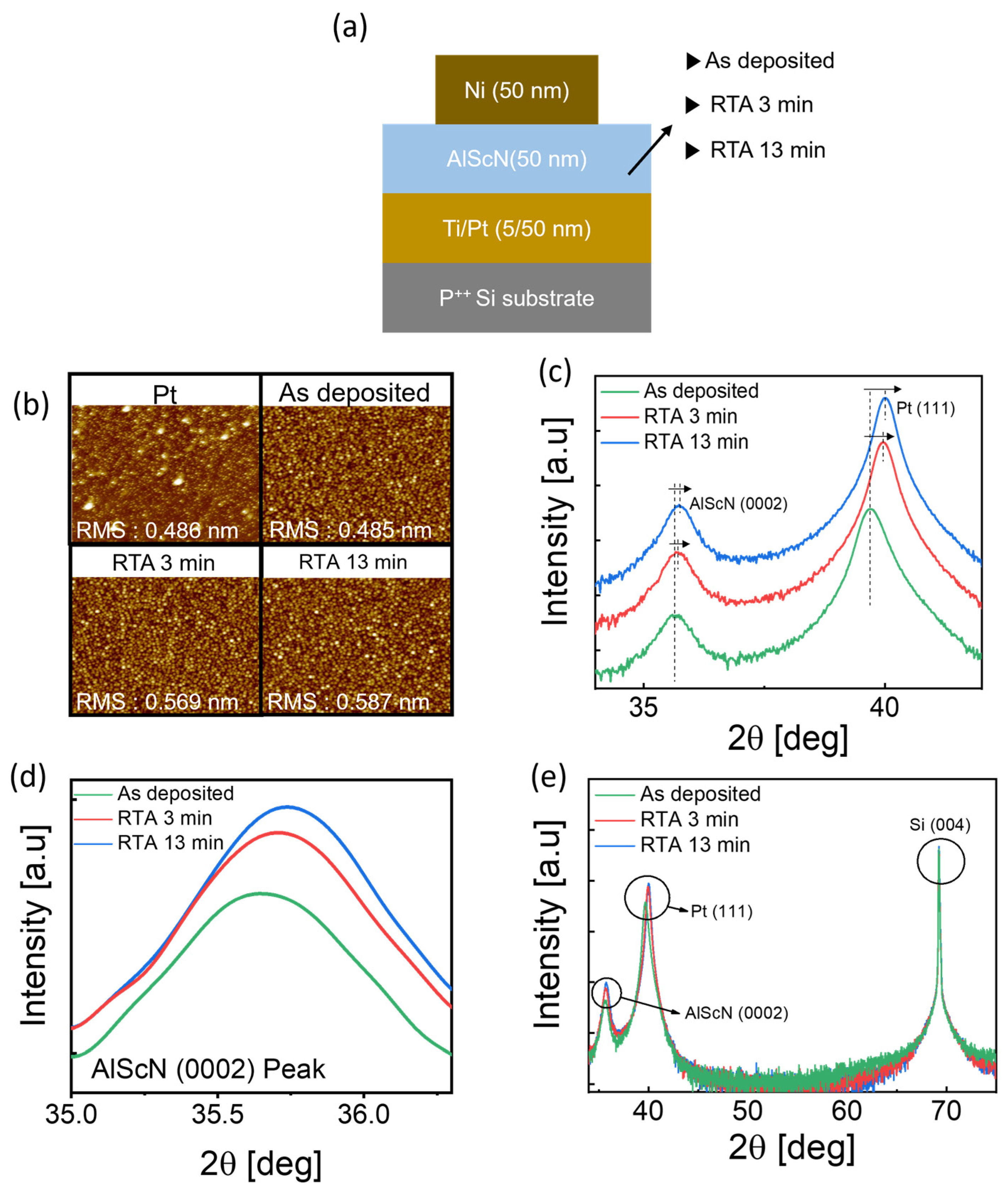

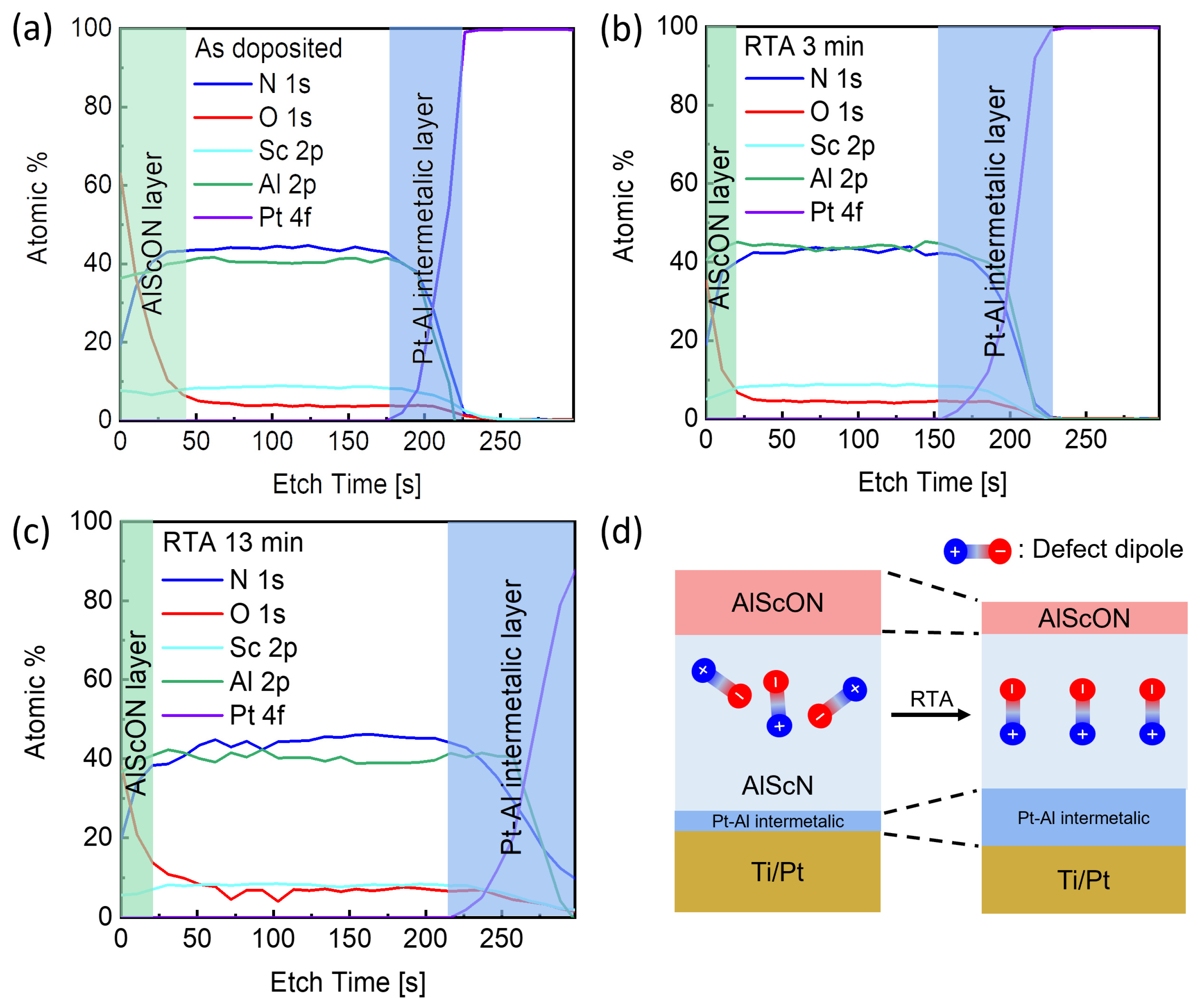

2. Materials and Methods

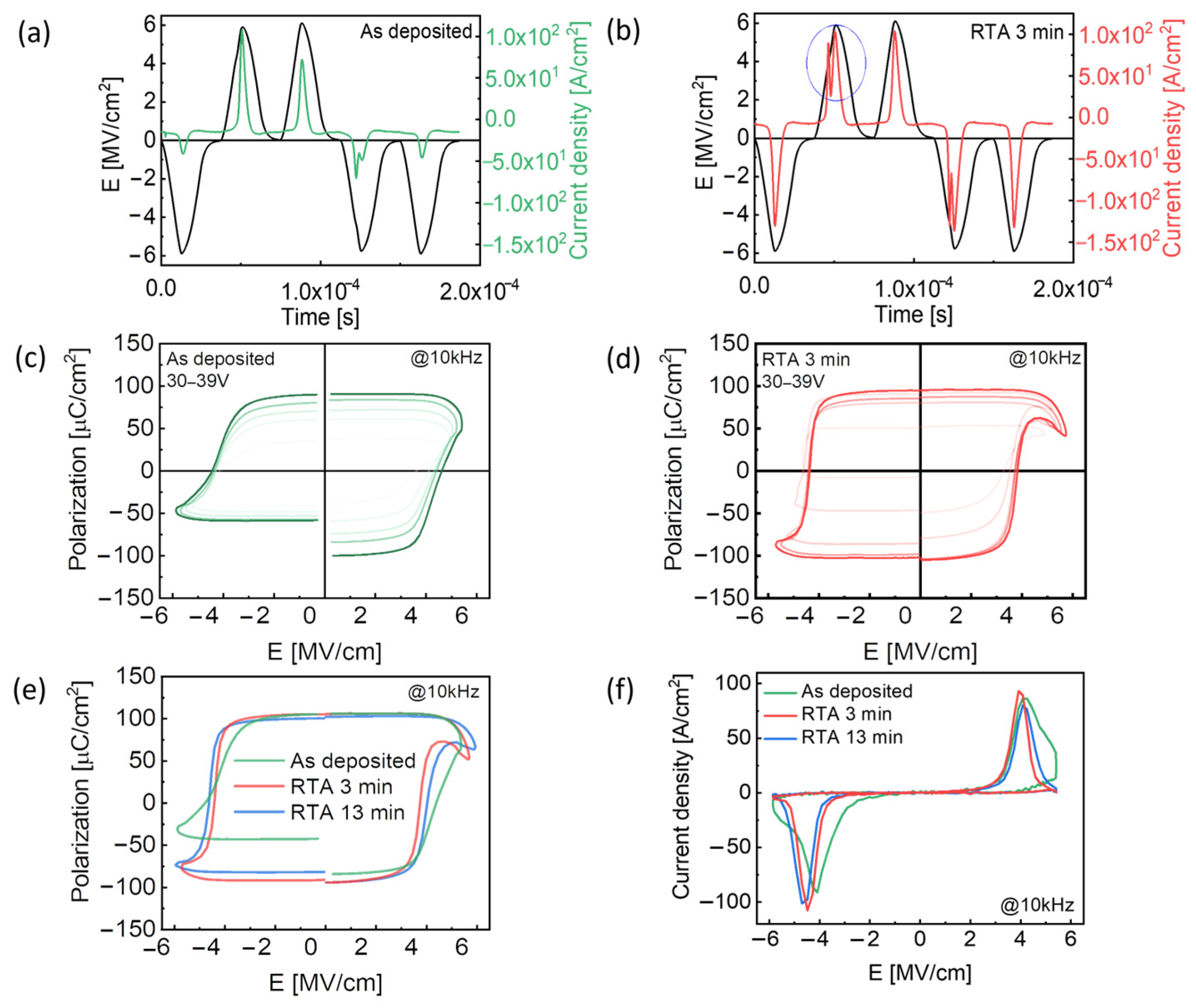

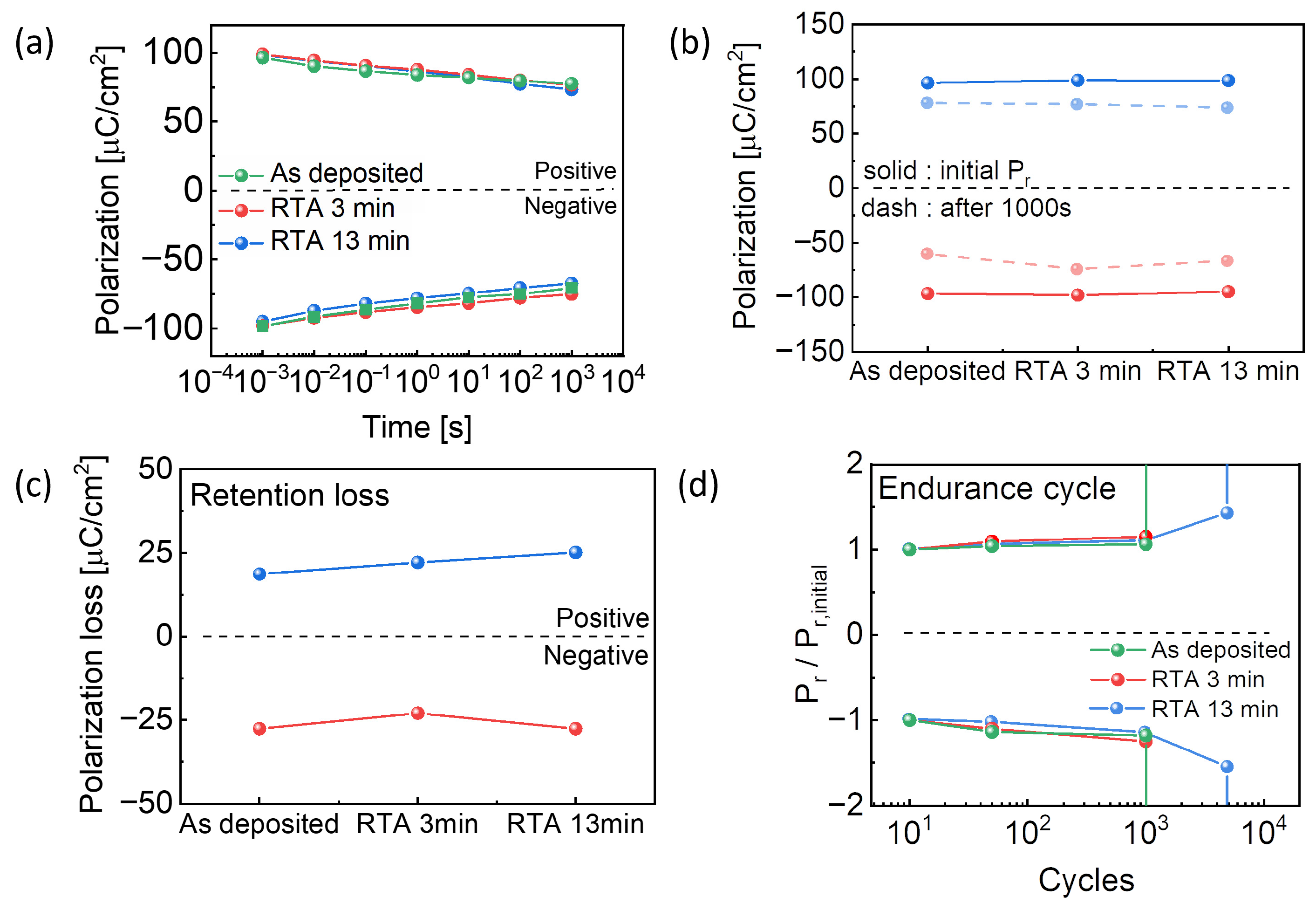

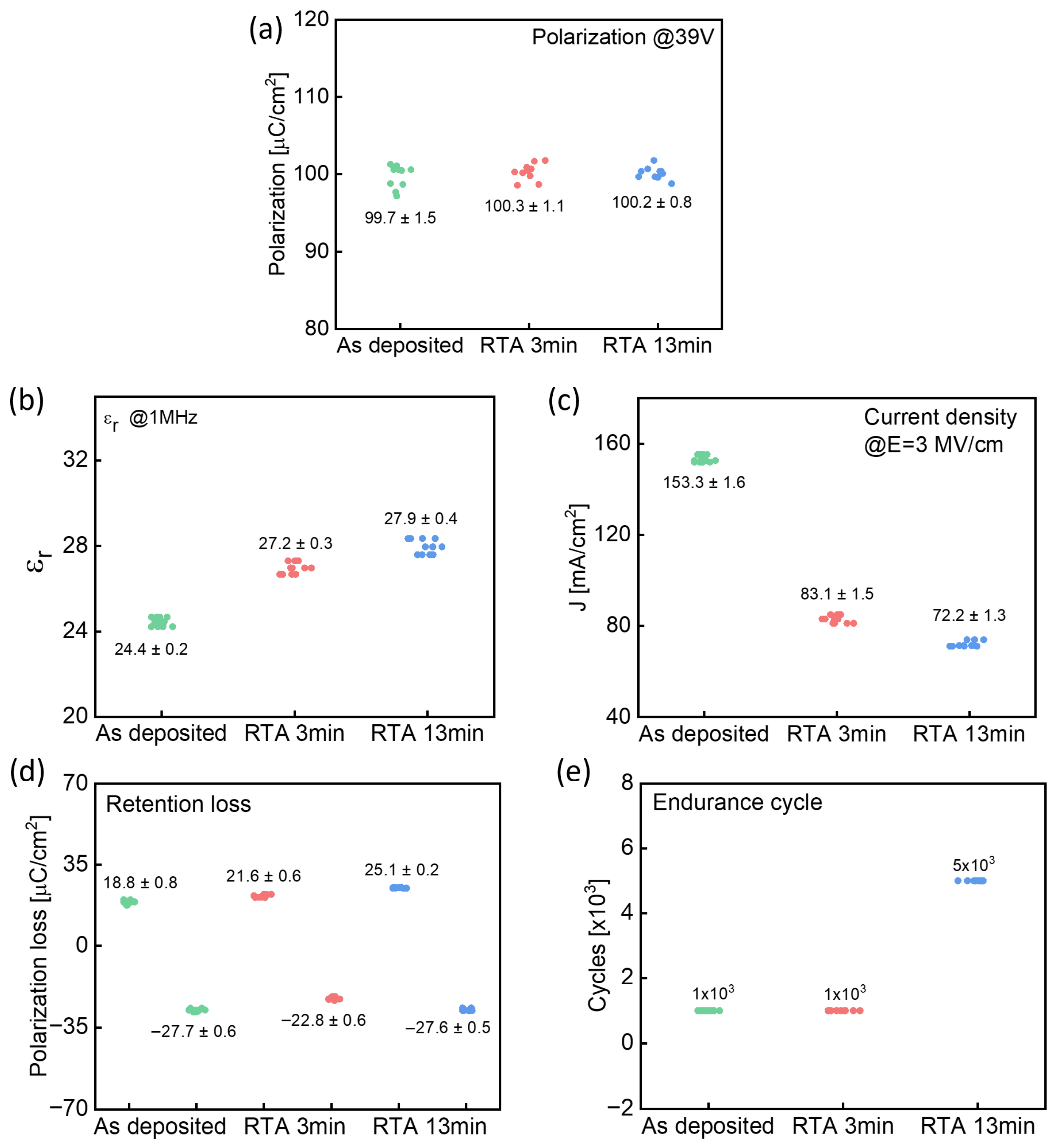

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Kuo, J.; Lal, A.; Sharma, J.; Singh, N. Characterization of Metal Effect on Solidly Mounted AlScN on CMOS. In Proceedings of the 2020 IEEE International Ultrasonics Symposium (IUS), Las Vegas, NV, USA, 7–11 September 2020. [Google Scholar] [CrossRef]

- Liu, X.; Wang, D.; Kim, K.-H.; Katti, K.; Zheng, J.; Musavigharavi, P.; Miao, J.; Stach, E.A.; Olsson, R.H., III; Jariwala, D. Post-CMOS Compatible Aluminum Scandium Nitride/2D Channel Ferroelectric Field-Effect-Transistor Memory. Nano Lett. 2021, 21, 3753–3761. [Google Scholar] [CrossRef]

- Kim, K.-H.; Oh, S.; Fiagbenu, M.M.A.; Zheng, J.; Musavigharavi, P.; Kumar, P.; Trainor, N.; Aljarb, A.; Wan, Y.; Kim, H.M.; et al. Scalable CMOS back-end-of-line-compatible AlScN/two-dimensional channel ferroelectric field-effect transistors. Nat. Nanotechnol. 2023, 18, 1044–1050. [Google Scholar] [CrossRef] [PubMed]

- Fichtner, S.; Wolff, N.; Lofink, F.; Kienle, L.; Wagner, B. AlScN: A III-V Semiconductor Based Ferroelectric. J. Appl. Phys. 2019, 125, 114103. [Google Scholar] [CrossRef]

- Oh, S.Y.; Kim, S.; Lee, G.; Park, J.-H.; Jeon, D.; Kim, S.; Yoo, G. Wide-Range Threshold Voltage Tunable β-Ga2O3 FETs with a Sputtered AlScN Ferroelectric Gate Dielectric. IEEE Electron Device Lett. 2024, 45, 1558–1561. [Google Scholar] [CrossRef]

- Chen, L.; Liu, C.; Li, M.; Song, W.; Wang, W.; Wang, Z.; Wang, N.; Zhu, Y. Scandium-Doped Aluminum Nitride for Acoustic Wave Resonators, Filters, and Ferroelectric Memory Applications. ACS Appl. Electron. Mater. 2023, 5, 612–622. [Google Scholar] [CrossRef]

- van Deurzen, L.; Nguyen, T.-S.; Casamento, J.; Xing, H.G.; Jena, D. Epitaxial Lattice-Matched AlScN/GaN Distributed Bragg Reflectors. Appl. Phys. Lett. 2023, 123, 241104. [Google Scholar] [CrossRef]

- Barth, S.; Bartzsch, H.; Gloess, D.; Frach, P.; Herzog, T.; Walter, S.; Heuer, H. Sputter Deposition of Stress-Controlled Piezoelectric AlN and AlScN Films for Ultrasonic and Energy Harvesting Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1329–1337. [Google Scholar] [CrossRef]

- Moe, C.G.; Leathersich, J.; Carlstrom, D.; Bi, F.; Kim, D.; Shealy, J.B. Metal–Organic Chemical Vapor Deposition-Grown AlScN for Microelectromechanical-Based Acoustic Filter Applications. Phys. Status Solidi A 2023, 220, 2200849. [Google Scholar] [CrossRef]

- Barth, S.; Schreiber, T.; Cornelius, S.; Zywitzki, O.; Modes, T.; Bartzsch, H. High Rate Deposition of Piezoelectric AlScN Films by Reactive Magnetron Sputtering from AlSc Alloy Targets on Large Area. Micromachines 2022, 13, 1561. [Google Scholar] [CrossRef]

- Lu, Y.; Reusch, M.; Kurz, N.; Ding, A.; Christoph, T.; Kirste, L.; Lebedev, V.; Žukauskaitė, A. Surface Morphology and Microstructure of Pulsed DC Magnetron Sputtered Piezoelectric AlN and AlScN Thin Films. Phys. Status Solidi A 2018, 215, 1700559. [Google Scholar] [CrossRef]

- Liu, H.Y.; Tang, G.S.; Zeng, F.; Pan, F. Influence of sputtering parameters on structures and residual stress of AlN films deposited by DC reactive magnetron sputtering at room temperature. J. Cryst. Growth 2013, 363, 80–85. [Google Scholar] [CrossRef]

- Jadoon, N.A.K.; Puvanenthiram, V.; Mosa, M.A.H.; Sharma, A.; Wang, K. Recent Advances in Aluminum Nitride (AlN) Growth by Magnetron Sputtering Techniques and Its Applications. Inorganics 2024, 12, 264. [Google Scholar] [CrossRef]

- Chen, L.; Li, M.; Varghese, B.; Wang, Z.; Song, W.; Lee, H.K.; Zhu, Y.; Liu, C.; Wang, W.; Lin, H. Leakage Mechanism of Ferroelectric Al0.7Sc0.3N Ultra-Thin Film. In Proceedings of the 2023 IEEE International Symposium on Applications of Ferroelectrics (ISAF), Cleveland, OH, USA, 23–27 July 2023. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Q.; Liu, C.; Li, M.; Song, W.; Wang, W.; Loke, D.K.; Zhu, Y. Leakage Mechanism and Cycling Behavior of Ferroelectric Al0.7Sc0.3N. Materials 2024, 17, 397. [Google Scholar] [CrossRef] [PubMed]

- Österlund, E.; Ross, G.; Caro, M.A.; Paulasto-Kröckel, M.; Hollmann, A.; Klaus, M.; Meixner, M.; Genzel, C.; Koppinen, P.; Pensala, T.; et al. Stability and residual stresses of sputtered wurtzite AlScN thin films. Phys. Rev. Mater. 2021, 5, 035001. [Google Scholar] [CrossRef]

- Kim, K.D.; Lee, Y.B.; Lee, S.H.; Lee, I.S.; Ryoo, S.K.; Byun, S.Y.; Lee, J.H.; Hwang, C.S. Impact of Operation Voltage and NH3 Annealing on the Fatigue Characteristics of Ferroelectric AlScN Thin Films Grown by Sputtering. Nanoscale 2023, 15, 16390–16402. [Google Scholar] [CrossRef] [PubMed]

- Sun, N.; Okamoto, K.; Yasuoka, S.; Doko, S.; Matsui, N.; Irisawa, T.; Tsunekawa, K.; Lu, H.; Gruverman, A.; Funakubo, H. Effect of H2 Heat Treatment on the Switching Behavior of Ferroelectric AlScN Capacitors. APL Mater. 2025, 13, 051106. [Google Scholar] [CrossRef]

- Liu, M.; Zang, H.; Jia, Y.; Jiang, K.; Ben, J.; Lv, S.; Li, D.; Sun, X.; Li, D. Effect and Regulation Mechanism of Post-deposition Annealing on the Ferroelectric Properties of AlScN Thin Films. ACS Appl. Mater. Interfaces 2024, 16, 16427–16435. [Google Scholar] [CrossRef]

- Wu, S.; Wu, M.Y.; Huang, J.-L.; Lii, D.-F. Characterization and Piezoelectric Properties of Reactively Sputtered (Sc,Al)N Thin Films on Diamond Structure. Int. J. Appl. Ceram. Technol. 2014, 11, 894–900. [Google Scholar] [CrossRef]

- Sigmund, P. Theory of Sputtering. I. Sputtering Yield of Amorphous and Polycrystalline Targets. Phys. Rev. 1969, 184, 383–416. [Google Scholar] [CrossRef]

- Fichtner, S.; Lofink, F.; Wagner, B.; Schönweger, G.; Kreutzer, T.-N.; Petraru, A.; Kohlstedt, H. Ferroelectricity in AlScN: Switching, Imprint and sub-150 nm Films. In Proceedings of the 2020 Joint Conference of the IEEE International Frequency Control Symposium and International Symposium on Applications of Ferroelectrics (IFCS-ISAF), Keystone, CO, USA, 19–23 July 2020. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, H.; Lin, K.; Deng, J.; Chen, J.; Xing, X. Defect dipoles-induced domain reorientation of NdFeO3-PbTiO3 thin films. Inorg. Chem. Front. 2018, 5, 1214–1220. [Google Scholar] [CrossRef]

- Cao, D.; Cheng, X.; Xie, Y.-H.; Zheng, L.; Wang, Z.; Yu, X.; Wang, J.; Shen, D.; Yu, Y. Effects of Post-Deposition Vacuum Annealing on the Piezoelectric Properties of AlScN Thin Films Sputtered on 200 mm Production Wafers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 1576–1584. [Google Scholar] [CrossRef]

- Shi, Y.; Lan, Y. Effect of working pressure and annealing temperature on single-phase AlN films. Mater. Lett. 2018, 213, 1–3. [Google Scholar] [CrossRef]

- Kim, S.-K.; Jeong, S.-Y.; Cho, C.-R. Structural reconstruction of hexagonal to cubic ZnO films on substrate by annealing. Appl. Phys. Lett. 2003, 82, 562–564. [Google Scholar] [CrossRef]

- Cao, D.; Cheng, X.; Xie, Y.-H.; Zheng, L.; Wang, Z.; Yu, X.; Wang, J.; Shen, D.; Yu, Y. Effects of Rapid Thermal Annealing on the Properties of AlN Films Deposited by PEALD on AlGaN/GaN Heterostructures. RSC Adv. 2015, 5, 37881–37887. [Google Scholar] [CrossRef]

- Li, M.; Song, W.; Liu, C.; Chen, L.; Lin, H.; Zhu, Y. Thermal Assisted Intermixing at AlScN/Pt Interfaces. In Proceedings of the 2023 IEEE International Symposium on Applications of Ferroelectrics (ISAF), Cleveland, OH, USA, 23–27 July 2023. [Google Scholar]

- Li, D.; Chen, Y.; Zhou, C.; Shi, C.; Xu, Z.; Miao, Z.; Xi, Z.; Han, J. XPS Depth Profiling of Functional Materials: Applications of Ion Beam Etching Techniques. Mater. Chem. Front. 2024, 8, 715–731. [Google Scholar] [CrossRef]

- Rácz, A.S.; Menyhárd, M. XPS Depth Profiling of Nano-Layers by a Novel Trial-and-Error Evaluation Procedure. Sci. Rep. 2024, 14, 18497. [Google Scholar] [CrossRef]

- Won, S.S.; Seo, H.; Kawahara, M.; Glinsek, S.; Lee, J.; Kim, Y.; Jeong, C.K.; Kingon, A.I.; Kim, S.-H. Flexible Vibrational Energy Harvesting Devices Using Strain-Engineered Perovskite Piezoelectric Thin Films. Nano Energy 2019, 55, 182–192. [Google Scholar] [CrossRef]

- Pedan, R.; Makushko, P.; Yavorskyi, Y.; Dubikovskyi, O.; Bodnaruk, A.; Burmak, A.; Golub, V.; Voloshko, S.; Hübner, R.; Makarov, D.; et al. Low-temperature diffusion in thin-film Pt-(Au-)-Co heterostructures: A structural and magnetic characterization. Nanotechnology 2024, 35, 195707. [Google Scholar] [CrossRef]

- Rehm, O.; Holzapfel, M.; Reisinger, H.; Ambacher, O. Long-Term Stability and Oxidation of Ferroelectric AlScN Thin Films. Phys. Status Solidi RRL 2024, 18, 2400307. [Google Scholar] [CrossRef]

- Gogi, V.K.; Chae, C.; Hwang, J.; Jha, R. Impact of Electrodes and Interfaces on Ferroelectric Switching of Al1−xScxN. MRS Commun. 2025, 15, 285–291. [Google Scholar] [CrossRef]

- Park, M.H.; Hyun, S.D.; Lee, S.Y.; Lee, C.; Kwon, J.; Kim, Y.; Jeon, S. Improved Leakage Currents and Polarity Control through O-Doping in AlScN Films. Adv. Electron. Mater. 2024, 10, 2400874. [Google Scholar] [CrossRef]

- Fichtner, S.; Schönweger, G.; Lee, C.-W.; Yazawa, K.; Gorai, P.; Brennecka, G.L. Polarization and Domains in Wurtzite Ferroelectrics: Fundamentals and Applications. Appl. Phys. Rev. 2025, 12, 021310. [Google Scholar] [CrossRef]

- Kim, K.D.; Lee, Y.B.; Lee, S.H.; Lee, I.S.; Ryoo, S.K.; Byun, S.Y.; Lee, J.H.; Kim, H.; Park, H.W.; Hwang, C.S. Evolution of the Ferroelectric Properties of AlScN Film by Electrical Cycling with an Inhomogeneous Field Distribution. Adv. Electron. Mater. 2023, 9, 2201142. [Google Scholar] [CrossRef]

- Tsai, S.-L.; Hoshii, T.; Wakabayashi, H.; Tsutsui, K.; Chung, T.-K.; Chang, E.Y.; Kakushima, K. Field Cycling Behavior and Breakdown Mechanism of Ferroelectric Al0.78Sc0.22N Films. Jpn. J. Appl. Phys. 2022, 61, SJ1005. [Google Scholar] [CrossRef]

- Drury, D.; Yazawa, K.; Zakutayev, A.; Hanrahan, B.; Brennecka, G. High-Temperature Ferroelectric Behavior of Al0.7Sc0.3N. Micromachines 2022, 13, 887. [Google Scholar] [CrossRef]

- Joo, H.J.; Yoon, S.S.; Oh, S.Y.; Lim, Y.; Lee, G.H.; Yoo, G. Temperature-Dependent Ferroelectric Behaviors of AlScN-Based Ferroelectric Capacitors with a Thin HfO2 Interlayer for Improved Endurance and Leakage Current. Electronics 2024, 13, 4515. [Google Scholar] [CrossRef]

- Chen, S.-M.; Hoshii, T.; Wakabayashi, H.; Tsutsui, K.; Chang, E.Y.; Kakushima, K. Reactive sputtering of ferroelectric AlScN films with H2 gas flow for endurance improvement. Jpn. J. Appl. Phys. 2024, 63, 03SP45. [Google Scholar] [CrossRef]

- Tsai, S.-L.; Hoshii, T.; Wakabayashi, H.; Tsutsui, K.; Chung, T.-K.; Chang, E.Y.; Kakushima, K. Room-temperature deposition of a poling-free ferroelectric AlScN film by reactive sputtering. Appl. Phys. Lett. 2021, 118, 082902. [Google Scholar] [CrossRef]

| Ferroelectric | Structure | Leakage Current Density (A/cm2) | Cycles |

|---|---|---|---|

| Al0.7Sc0.3N [39] | Pt/AlScN/Pt | n/a | 2.7 × 105 |

| Al0.72Sc0.28N [40] | Pt/AlScN/Ni | 2 × 10−2 to 10−7 | 1 × 104 |

| Al0.72Sc0.28N [40] | Pt/HfO2/AlScN/Ni | 3 × 10−4 to 10−7 | 1 × 105 |

| Al0.88Sc0.12N [41] | TiN/AlScN/TiN | 1 × 10−7 | 2 × 107 |

| Al0.78Sc0.22N [42] | Mo/TiN/HZO/Mo | n/a | Under 1 × 104 |

| This work | Pt/AlScN/Ni | 7 × 10−2 | 5 × 103 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, J.; Lim, Y.; Park, J.M.; Joo, H.J.; Yoo, G. Rapid Thermal Annealing for Reduced Leakage and Enhanced Endurance of Reactive-Sputtered AlScN-Based Ferroelectric Memory Capacitors. Electronics 2025, 14, 4353. https://doi.org/10.3390/electronics14214353

Bae J, Lim Y, Park JM, Joo HJ, Yoo G. Rapid Thermal Annealing for Reduced Leakage and Enhanced Endurance of Reactive-Sputtered AlScN-Based Ferroelectric Memory Capacitors. Electronics. 2025; 14(21):4353. https://doi.org/10.3390/electronics14214353

Chicago/Turabian StyleBae, Juno, Yoojin Lim, Jong Min Park, Hyeong Jun Joo, and Geonwook Yoo. 2025. "Rapid Thermal Annealing for Reduced Leakage and Enhanced Endurance of Reactive-Sputtered AlScN-Based Ferroelectric Memory Capacitors" Electronics 14, no. 21: 4353. https://doi.org/10.3390/electronics14214353

APA StyleBae, J., Lim, Y., Park, J. M., Joo, H. J., & Yoo, G. (2025). Rapid Thermal Annealing for Reduced Leakage and Enhanced Endurance of Reactive-Sputtered AlScN-Based Ferroelectric Memory Capacitors. Electronics, 14(21), 4353. https://doi.org/10.3390/electronics14214353