Real-Time Technique for Semiconductor Material Parameter Measurement Under Continuous Neutron Irradiation with High Integral Fluence

Abstract

1. Introduction

2. Materials and Methods

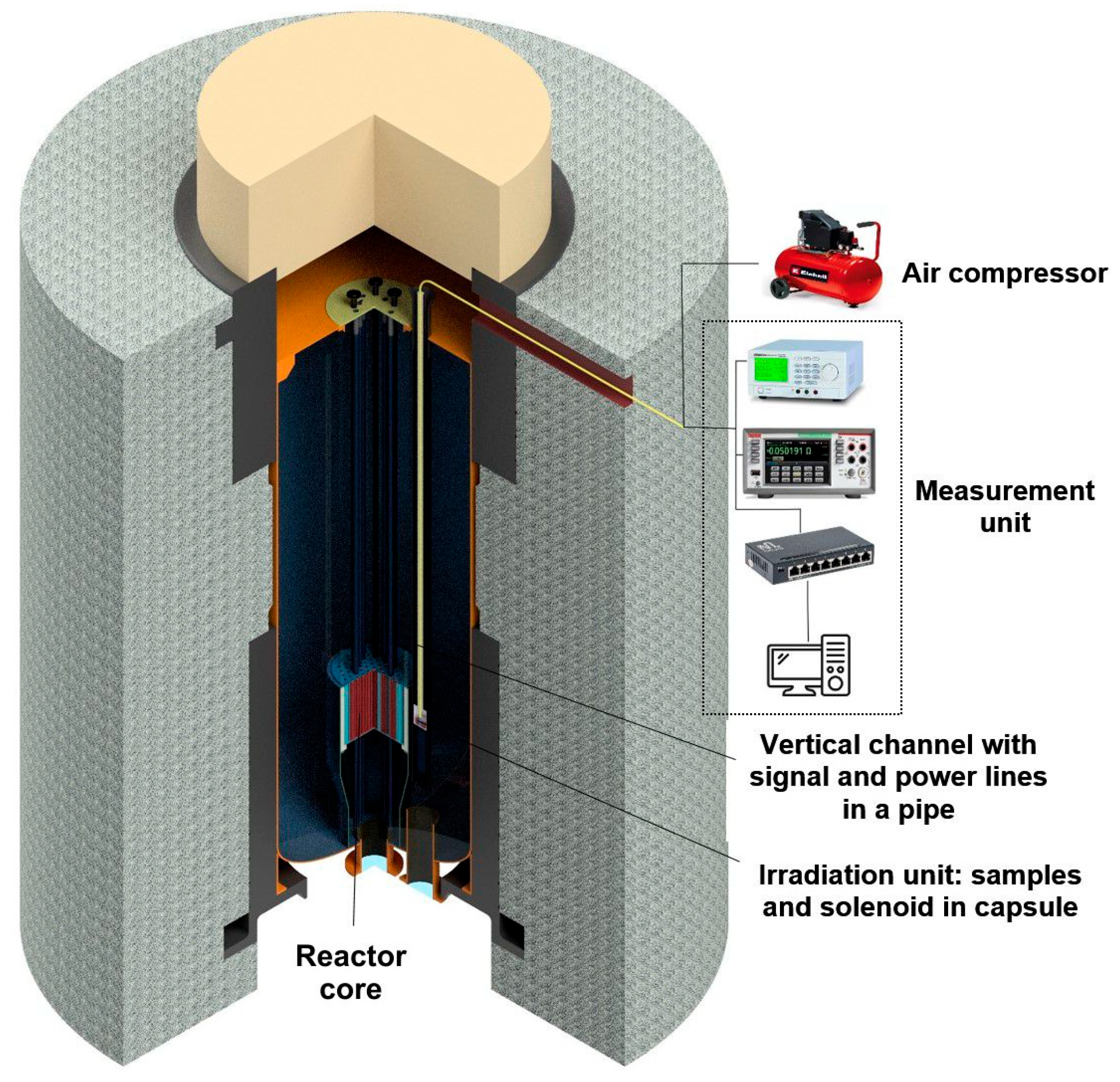

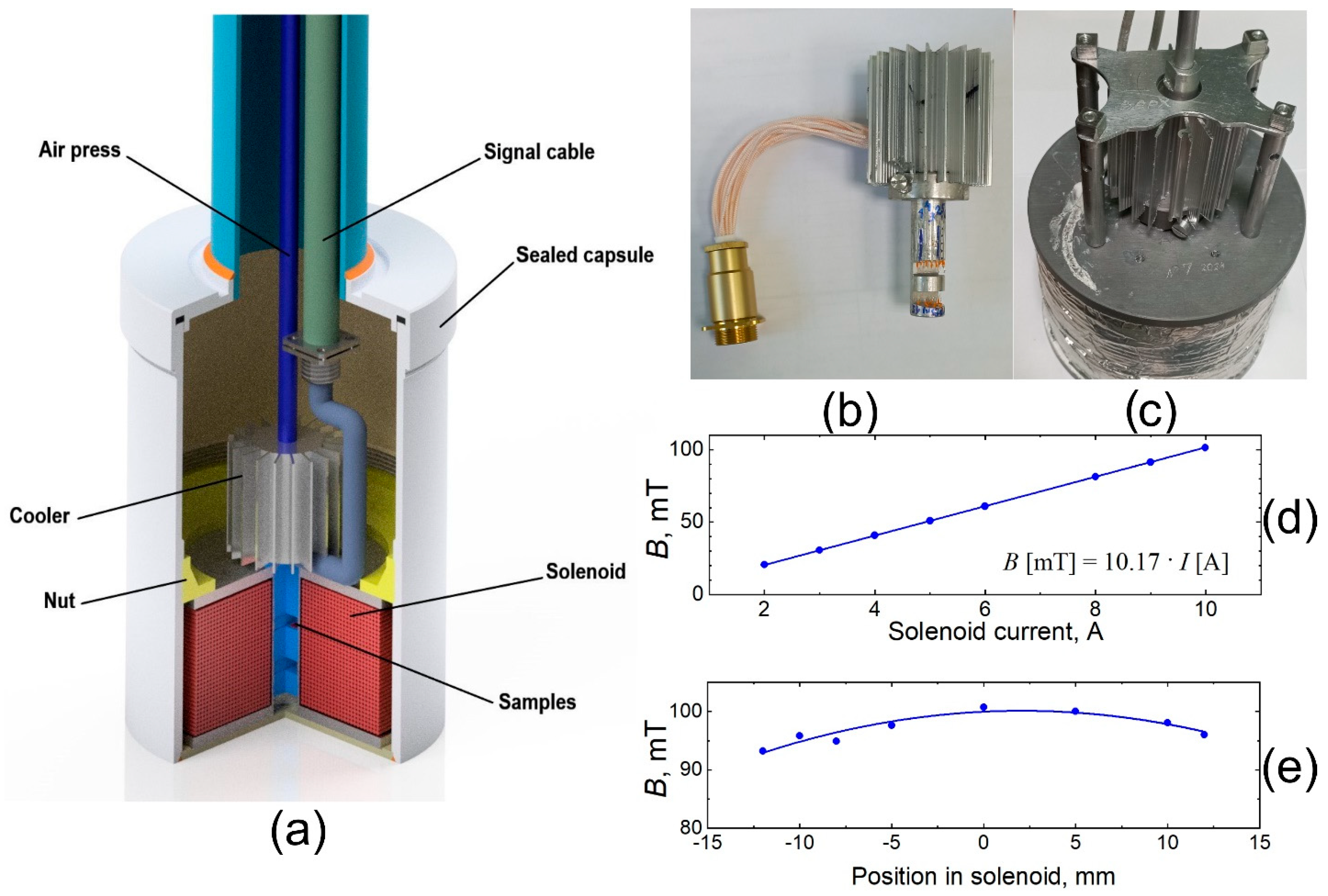

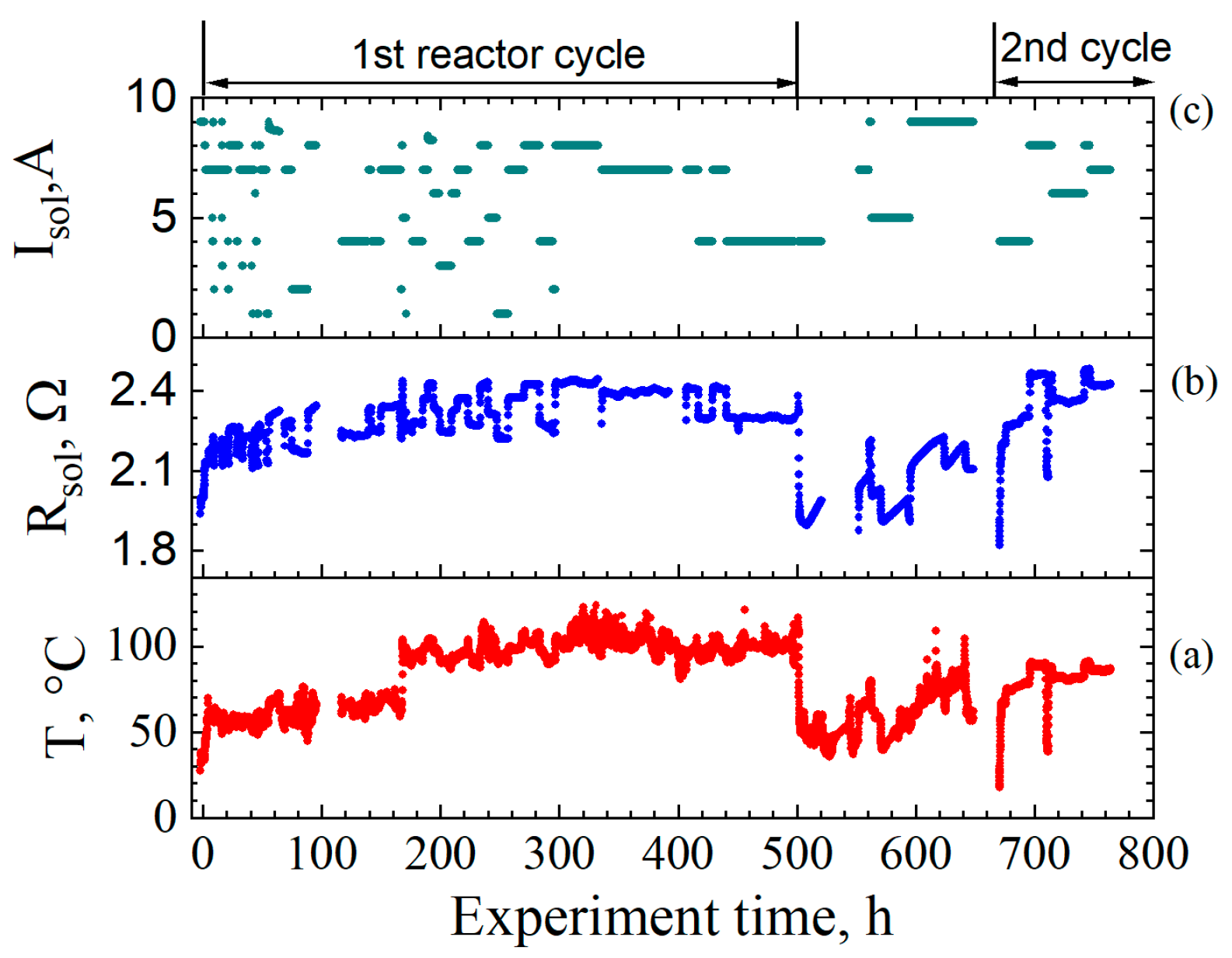

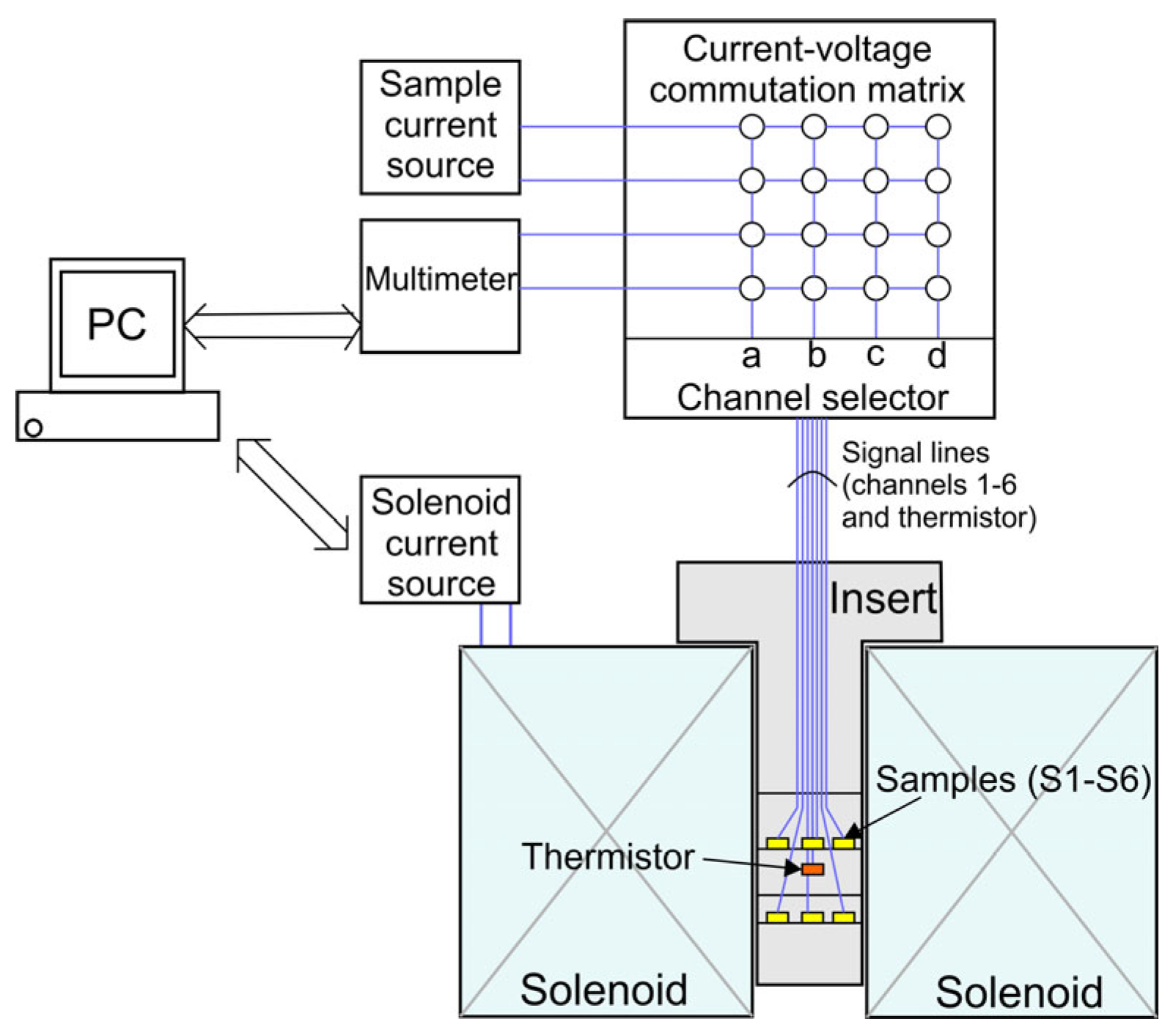

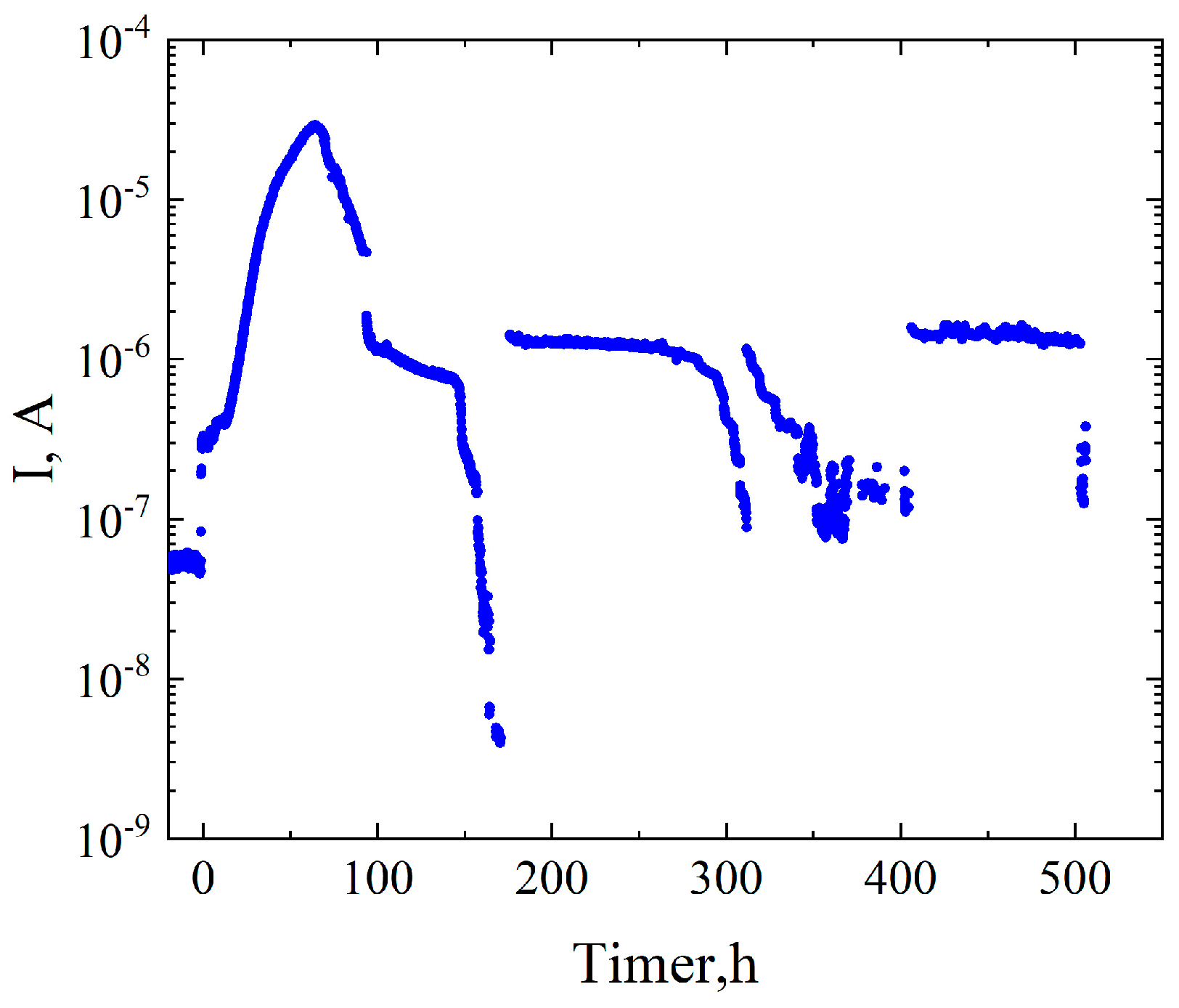

2.1. Experimental System

2.2. Uncertainty and Validity Window

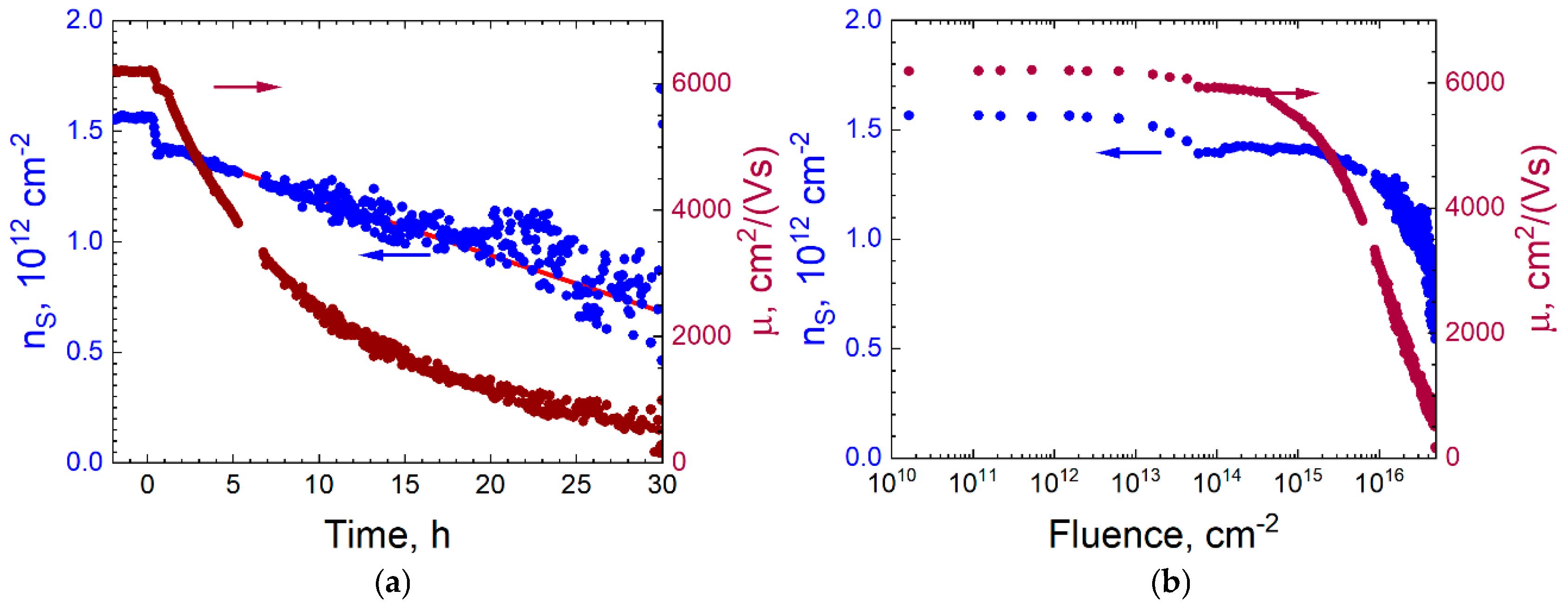

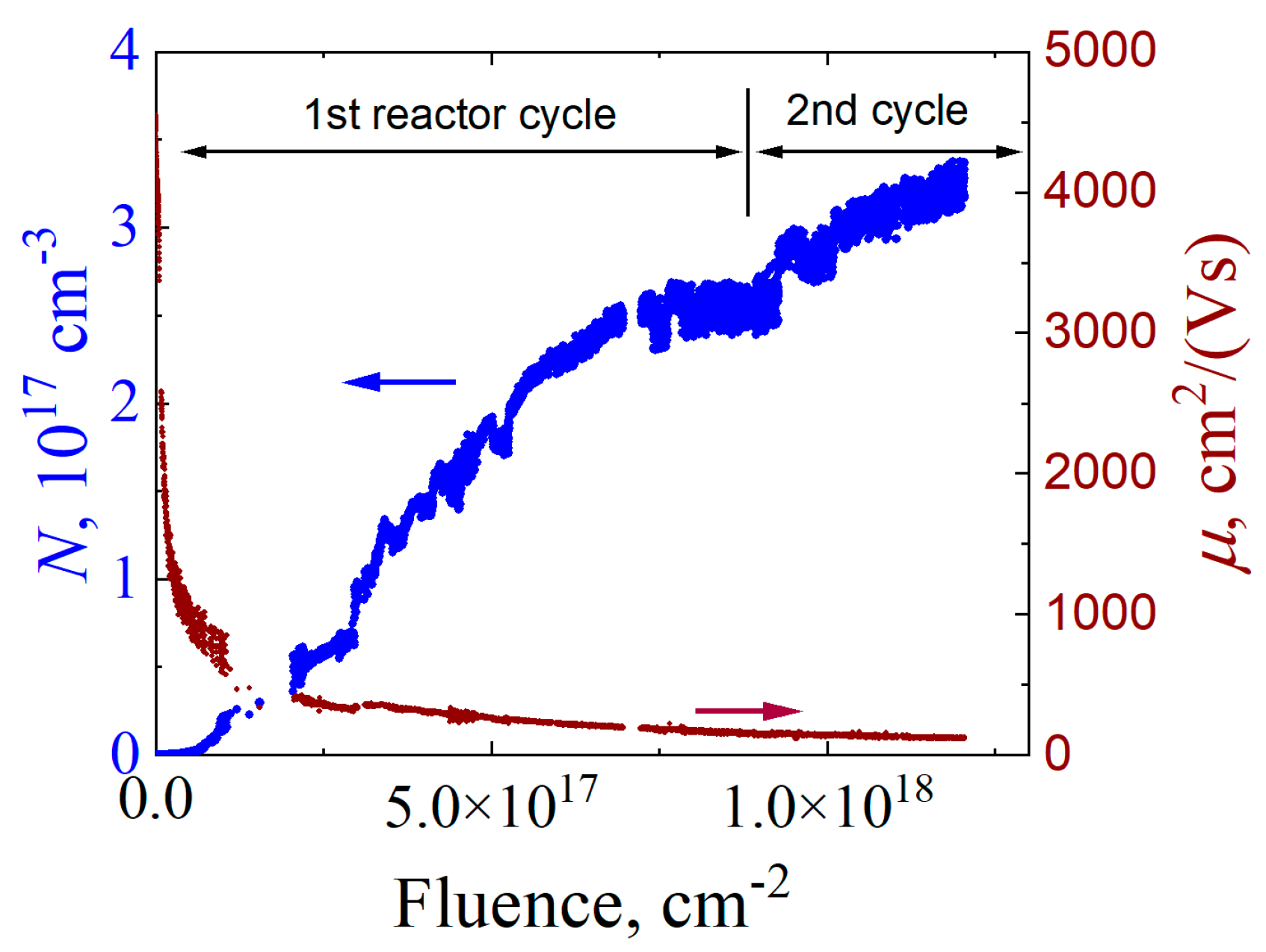

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Prinzie, J.; Simanjuntak, F.M.; Leroux, P.; Prodromakis, T. Low-power electronic technologies for harsh radiation environments. Nat. Electron. 2021, 4, 243–253. [Google Scholar] [CrossRef]

- Ren, Y.; Zhu, M.; Xu, D.; Liu, M.; Dai, X.; Wang, S.; Li, L. Overview on Radiation Damage Effects and Protection Techniques in Microelectronic Devices. Sci. Technol. Nucl. Install. 2024, 2024, 3616902. [Google Scholar] [CrossRef]

- Muhammad, Z.; Wang, Y.; Zhang, Y.; Vallobra, P.; Peng, S.; Yu, S.; Lv, Z.; Cheng, H.; Zhao, W. Radiation-Tolerant Electronic Devices Using Wide Bandgap Semiconductors. Adv. Mater. Technol. 2023, 8, 2200539. [Google Scholar] [CrossRef]

- Vayakis, G.; Walker, C. ITER International Team and Participant Teams Magnetic Diagnostics for ITER/BPX Plasmas (Invited). Rev. Sci. Instrum. 2003, 74, 2409–2417. [Google Scholar] [CrossRef]

- Quercia, A.; Pironti, A.; Bolshakova, I.; Holyaka, R.; Duran, I.; Murari, A.; Contributors, J. Long Term Operation of the Radiation-Hard Hall Probes System and the Path toward a High Performance Hybrid Magnetic Field Sensor. Nucl. Fusion 2022, 62, 106032. [Google Scholar] [CrossRef]

- Entler, S.; Duran, I.; Kocan, M.; Vayakis, G.; Kohout, M.; Sebek, J.; Sladek, P.; Grover, O.; Vyborny, K. Prospects for the Steady-State Magnetic Diagnostic Based on Antimony Hall Sensors for Future Fusion Power Reactors. Fusion Eng. Des. 2019, 146, 526–530. [Google Scholar] [CrossRef]

- Khadka, D.B.; Kuo, Y.-C.; Li, Y.Z.; Waqas, M.; Xu, Y.-J.; Yanagida, M.; Nishihara, H.; Tsukagoshi, K.; Chou, M.M.C.; Shirai, Y.; et al. Coordination Nanosheets Stabilizing Efficient Tin-Based Perovskite Solar Cells, ACS Appl. Mater. Interfaces 2025, 17, 26813–26822. [Google Scholar] [CrossRef]

- Antuzevics, A.; Elsts, E.; Kemere, M.; Lushchik, A.; Moskina, A.; Scherer, T.A.; Popov, A.I. Thermal annealing of neutron irradiation generated paramagnetic defects in transparent Al2O3 ceramics. Opt. Mater. 2023, 135, 113250. [Google Scholar] [CrossRef]

- León, M.; Martín, P.; Vila, R.; Molla, J.; Ibarra, A. Neutron irradiation effects on optical absorption of KU1 and KS-4V quartz glasses and Infrasil 301. Fusion Eng. Des. 2009, 84, 1174–1178. [Google Scholar] [CrossRef]

- Duran, I.; Hron, M.; Stockel, J.; Viererbl, L.; Vsolak, R.; Cerva, V.; Bolshakova, I.; Holyaka, R.; Vayakis, G. Stability of the Hall Sensors Performance under Neutron Irradiation. In Proceedings of the 12 International Congress on Plasma Physics—ICPP, Nice, France, 25–29 October 2004. [Google Scholar]

- Kiseleva, E.V. Stability of Quasi-Ballistic MESFETs with Various Buffer Layer Structures under Irradiation with Neutrons Possessing Different Energy Spectra. Tech. Phys. Lett. 2005, 31, 881–884. [Google Scholar] [CrossRef]

- Brudnyi, V.N.; Boiko, V.M.; Kolin, N.G.; Kosobutsky, A.V.; Korulin, A.V.; Brudnyi, P.A.; Ermakov, V.S. Neutron Irradiation-Induced Modification of Electrical and Structural Properties of GaN Epifilms Grown on Al2O3 (0001) Substrate. Semicond. Sci. Technol. 2018, 33, 095011. [Google Scholar] [CrossRef]

- Boiko, V.M.; Brudnii, V.N.; Ermakov, V.S.; Kolin, N.G.; Korulin, A.V. On the Electronic Properties of GaSb Irradiated with Reactor Neutrons and Its Charge Neutrality Level. Semiconductors 2015, 49, 763–766. [Google Scholar] [CrossRef]

- Vesaghi, M.A. Electrical Properties of Neutron-Transmutation-Doped GaAs below 450 K. Phys. Rev. B 1982, 25, 5436–5450. [Google Scholar] [CrossRef]

- Kuriyama, K.; Yokoyama, K.; Satoh, A. Thermally Stimulated Current in Neutron-Transmutation-Doped Semi-Insulating GaAs. Appl. Phys. Lett. 1991, 59, 1326–1328. [Google Scholar] [CrossRef]

- Brudnyi, V.N.; Krivov, M.A. Radiation Defects in Gallium Arsenide. Sov. Phys. J. 1980, 23, 45–54. [Google Scholar] [CrossRef]

- Goltzené, A.; Schwab, C.; David, J.P.; Roizes, A. Electrical Behavior of Fast Neutron Irradiated Semi-Insulating GaAs during Thermal Recovery. Appl. Phys. Lett. 1986, 49, 862–864. [Google Scholar] [CrossRef]

- Bolshakova, I.A.; Boiko, V.M.; Brudnyi, V.N.; Kamenskaya, I.V.; Kolin, N.G.; Makido, E.Y.; Moskovets, T.A.; Merkurisov, D.I. The Effect of Neutron Irradiation on the Properties of N-InSb Whisker Microcrystals. Semiconductors 2005, 39, 780–785. [Google Scholar] [CrossRef]

- Bolshakova, I.; Belyaev, S.; Bulavin, M.; Brudnyi, V.; Chekanov, V.; Coccorese, V.; Duran, I.; Gerasimov, S.; Holyaka, R.; Kargin, N.; et al. Experimental Evaluation of Stable Long Term Operation of Semiconductor Magnetic Sensors at ITER Relevant Environment. Nucl. Fusion 2015, 55, 083006. [Google Scholar] [CrossRef]

- Jankowski, J.; Prokopowicz, R.; Pytel, K.; El-Ahmar, S. Toward the Development of an InSb-Based Neutron-Resistant Hall Sensor. IEEE Trans. Nucl. Sci. 2019, 66, 926–931. [Google Scholar] [CrossRef]

- Gerstenberg, H.; Muller, P. Shubnikov-de Haas Effect Study of InAs after Transmutation Doping at Low Temperatures. J. Phys. Condens. Matter 1990, 2, 6945–6951. [Google Scholar] [CrossRef]

- Entler, S.; Soban, Z.; Duran, I.; Kovarik, K.; Vyborny, K.; Sebek, J.; Tazlaru, S.; Strelecek, J.; Sladek, P. Ceramic-Chromium Hall Sensors for Environments with High Temperatures and Neutron Radiation. Sensors 2021, 21, 721. [Google Scholar] [CrossRef]

- Kocan, M.; Duran, I.; Entler, S.; Vayakis, G.; Agostinetti, P.; Brombin, M.; Carmona, J.M.; Gambetta, G.; Jirman, T.; Marconato, N.; et al. Steady State Magnetic Sensors for ITER and beyond: Development and Final Design (Invited). Rev. Sci. Instrum. 2018, 89, 10J119. [Google Scholar] [CrossRef] [PubMed]

- Duran, I.; Entler, S.; Kočan, M.; Kohout, M.; Viererbl, L.; Mušálek, R.; Chráska, T.; Vayakis, G. Development of Bismuth Hall Sensors for ITER Steady State Magnetic Diagnostics. Fusion Eng. Des. 2017, 123, 690–694. [Google Scholar] [CrossRef]

- Kolin, N.G.; Merkurisov, D.I.; Solov’ev, S.P. Electrical Properties of Nuclear-Doped Indium Antimonide. Semiconductors 1999, 33, 712–715. [Google Scholar] [CrossRef]

- El-Ahmar, S.; Przychodnia, M.; Jankowski, J.; Prokopowicz, R.; Ziemba, M.; Szary, M.J.; Reddig, W.; Jagiełło, J.; Dobrowolski, A.; Ciuk, T. The Comparison of InSb-Based Thin Films and Graphene on SiC for Magnetic Diagnostics under Extreme Conditions. Sensors 2022, 22, 5258. [Google Scholar] [CrossRef]

- Bolshakova, I.; Dyuzhkov, D.; Kost, Y.; Radishevskiy, M.; Shurigin, F.; Vasyliev, A.; Wang, Z.; Otto, M.; Neumaier, D.; Bulavin, M.; et al. Graphene and Prospects of Radiation-Hard Hall Sensors. In Proceedings of the 2017 IEEE 7th International Conference Nanomaterials: Application & Properties (NAP), Odessa, Ukraine, 10–15 September 2017; pp. 03CBN15-1–03CBN15-5. [Google Scholar]

- Klochkov, A.N.; Yskakov, A.; Vinichenko, A.N.; Safonov, D.A.; Kargin, N.I.; Bulavin, M.V.; Galushko, A.V.; Yamurzin, V.R.; Vasil’evskii, I.S. Effect of Neutron Irradiation on the Electronic and Optical Properties of AlGaAs/InGaAs-Based Quantum Well Structures. Materials 2023, 16, 6750. [Google Scholar] [CrossRef]

- Fauzi, A.; Rashid, M.; Zin, M.R.M.; Hasbullah, N.F. Neutron Radiation Effects on the Electrical Characteristics of InAs/GaAs Quantum Dot-in-a-Well Structures. IEEE Trans. Nucl. Sci. 2015, 62, 3324–3329. [Google Scholar] [CrossRef]

- Fortuna, S.A.; Hughes, E.T.; Chow, W.W.; Addamane, S.; Alford, C.; Vizkelethy, G.; Bowers, J.E.; Skogen, E.J. Radiation-Resilient InAs Quantum Dot Lasers. APL Photonics 2025, 10, 041301. [Google Scholar] [CrossRef]

- Volkova, N.S.; Gorshkov, A.P.; Trufanov, A.N.; Istomin, L.A.; Levichev, S. Influence of Neutron Irradiation on Optoelectronic Properties of Structures with the InAs/GaAs Quantum Dots. J. Phys. Conf. Ser. 2019, 1410, 012137. [Google Scholar] [CrossRef]

- Papaioannou, G.J.; Papastamatiou, M.; Arpatzanis, N.; Dimitrakis, P.; Papastergiou, C. Neutron Radiation Effects in HEMTs. In Proceedings of the RADECS 93. Second European Conference on Radiation and Its Effects on Components and Systems (Cat. No.93TH0616-3), St. Malo, France, 13–16 September 1993; pp. 207–212. [Google Scholar]

- Duran, I.; Oszwaldowski, M.; Kovarík, K.; Jankowski, J.; El-Ahmar, S.; Viererbl, L.; Lahodová, Z. Investigation of Impact of Neutron Irradiation on Properties of InSb-Based Hall Plates. J. Nucl. Mater. 2011, 417, 846–849. [Google Scholar] [CrossRef]

- Papastamatiou, M.; Arpatzanis, N.; Papaioannou, G.J.; Papastergiou, C.; Christou, A. Neutron Radiation Effects in High Electron Mobility Transistors [AlGaAs/GaAs]. IEEE Trans. Electron Devices 1997, 44, 364–372. [Google Scholar] [CrossRef]

- Baramidze, N.V.; Bonch-Bruevich, V.L.; Giorgadze, M.P.; Kurdiani, N.I. Electrical Properties of InSb Irradiated with Fast Neutrons. Phys. Status Solidi B 1982, 110, 33–37. [Google Scholar] [CrossRef]

- Paccagnella, A.; Del Papa, C.; Chitussi, P.; Fuochi, P.G.; Benetti, P. Radiation Induced Degradation of Electrical Characteristics of III-V Devices. In Proceedings of the Gallium Arsenide Applications Symposium (GAAS), Turin, Italy, 28–30 April 1994. [Google Scholar] [CrossRef]

- Ohyama, H.; Simoen, E.; Kuroda, S.; Claeys, C.; Takami, Y.; Hakata, T.; Kobayashi, K.; Nakabayashi, M.; Sunaga, H. Degradation and Recovery of AlGaAs/GaAs p-HEMT Irradiated by High-Energy Particle. Microelectron. Reliab. 2001, 41, 79–85. [Google Scholar] [CrossRef]

- Aitkulov, M.T.; Dyussambayev, D.S.; Romanova, N.K.; Gizatulin, S.H.; Shaimerdenov, A.A.; Bugybay, Z.T.; Kisselyov, K.S.; Beisebayev, A.O. Measurement of the spatial-energy distribution of neutrons in the irradiation channel of the critical facility. J. Phys. Conf. Ser. 2022, 2155, 012021. [Google Scholar] [CrossRef]

- Shaimerdenov, A.; Gizatulin, S.; Dyussambayev, D.; Askerbekov, S.; Kenzhina, I. The WWR-K Reactor Experimental Base for Studies of the Tritium Release from Materials Under Irradiation. Fusion Sci. Technol. 2020, 76, 304–313. [Google Scholar] [CrossRef]

- Lindemuth, J. Hall Effect Measurement Handbook: A Fundamental Tool for Semiconductor Material Characterization; Lake Shore Cryotronics: Westerville, OH, USA, 2020. [Google Scholar]

- Bolshakova, I.; Quercia, A.; Coccorese, V.; Murari, A.; Holyaka, R.; Duran, I.; Viererbl, L.; Konopleva, R.; Yerashok, V. Magnetic Measuring Instrumentation With Radiation-Resistant Hall Sensors for Fusion Reactors: Experience of Testing at JET. IEEE Trans. Nucl. Sci. 2012, 59, 1224–1231. [Google Scholar] [CrossRef]

- Bolshakova, I.A.; Kost, Y.Y.; Radishevskyi, M.I.; Shurygin, F.M.; Vasyliev, O.V.; Wang, Z.; Neumaier, D.; Otto, M.; Bulavin, M.V.; Kulikov, S.A. Resistance of Hall Sensors Based on Graphene to Neutron Radiation. In Nanomaterials in Biomedical Application and Biosensors (NAP-2019); Pogrebnjak, A., Pogorielov, M., Viter, R., Eds.; Springer: Singapore, 2020; pp. 199–209. [Google Scholar] [CrossRef]

- Bolshakova, I.; Holyaka, R.; Marusenkova, T.; Shurygin, F. Radiation-Resistant Hall Magnetic Field Sensors and Instrumentations; Primedia Elaunch LLC: Dallas, TX, USA, 2022; p. 148. [Google Scholar] [CrossRef]

- Safonov, D.A.; Klochkov, A.N.; Vinichenko, A.N.; Sibirmovsky, Y.D.; Kargin, N.I.; Vasil’evskii, I.S. Electron Effective Masses, Nonparabolicity and Scattering Times in One Side Delta-Doped PHEMT AlGaAs/InGaAs/GaAs Quantum Wells at High Electron Density Limit. Phys. E Low Dimens. Syst. Nanostructures 2021, 133, 114787. [Google Scholar] [CrossRef]

- Kolin, N.G.; Merkurisov, D.I.; Solov’ev, S.P. Electrical Properties of Transmutation-Doped Indium Phosphide. Semiconductors 2000, 34, 150–154. [Google Scholar] [CrossRef]

- Yoon, J.; Ro, T.; Lee, S.; Yamamoto, S.; Kobayashi, K. Measurement of neutron capture cross-section of indium in the energy region from 0.003 eV to 30 keV. Ann. Nucl. Energy 2002, 29, 1157–1169. [Google Scholar] [CrossRef]

- Boudart, B.; Marí, B.; Prévot, B.; Schwab, C. Efficiency of neutron transmutation doping of InP investigated by optical and electrical methods. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1992, 63, 101–105. [Google Scholar] [CrossRef]

- Mari, B.; Prevot, B.; Schwab, C. Effective n-type doping of InP by the neutron transmutation technique. Mater. Sci. Eng. B 1993, 20, 113–116. [Google Scholar] [CrossRef]

- Najda, S.P.; Holmes, S.; Stradling, R.A.; Kuchar, F. Donor identification in neutron-transmutation-doped GaAs and InP. Semicond. Sci. Technol. 1989, 4, 791–796. [Google Scholar] [CrossRef]

| Neutrons | Energy | Neutron Flux Density, cm−2s−1 | Percentage of Total Flux, % |

|---|---|---|---|

| Thermal | 0 ÷ 0.683 eV | 2.56·1011 | 52 |

| Epithermal | 0.683 eV ÷ 1 MeV | 1.71·1011 | 34 |

| Fast | >1 MeV | 6.84·1010 | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasil’evskii, I.S.; Klochkov, A.N.; Nekrasov, P.V.; Vinichenko, A.N.; Kargin, N.I.; Yskakov, A.; Bulavin, M.V.; Galushko, A.V.; Bekbayev, A.; Mukhametuly, B.; et al. Real-Time Technique for Semiconductor Material Parameter Measurement Under Continuous Neutron Irradiation with High Integral Fluence. Electronics 2025, 14, 3802. https://doi.org/10.3390/electronics14193802

Vasil’evskii IS, Klochkov AN, Nekrasov PV, Vinichenko AN, Kargin NI, Yskakov A, Bulavin MV, Galushko AV, Bekbayev A, Mukhametuly B, et al. Real-Time Technique for Semiconductor Material Parameter Measurement Under Continuous Neutron Irradiation with High Integral Fluence. Electronics. 2025; 14(19):3802. https://doi.org/10.3390/electronics14193802

Chicago/Turabian StyleVasil’evskii, Ivan S., Aleksey N. Klochkov, Pavel V. Nekrasov, Aleksander N. Vinichenko, Nikolay I. Kargin, Almas Yskakov, Maksim V. Bulavin, Aleksey V. Galushko, Askhat Bekbayev, Bagdaulet Mukhametuly, and et al. 2025. "Real-Time Technique for Semiconductor Material Parameter Measurement Under Continuous Neutron Irradiation with High Integral Fluence" Electronics 14, no. 19: 3802. https://doi.org/10.3390/electronics14193802

APA StyleVasil’evskii, I. S., Klochkov, A. N., Nekrasov, P. V., Vinichenko, A. N., Kargin, N. I., Yskakov, A., Bulavin, M. V., Galushko, A. V., Bekbayev, A., Mukhametuly, B., Myrzabekova, E., Shegebayev, N., Kulikbayeva, D., Nurulin, R., Nurkasova, A., & Baitugulov, R. (2025). Real-Time Technique for Semiconductor Material Parameter Measurement Under Continuous Neutron Irradiation with High Integral Fluence. Electronics, 14(19), 3802. https://doi.org/10.3390/electronics14193802