Potential of LiDAR and Hyperspectral Sensing for Overcoming Challenges in Current Maritime Ballast Tank Corrosion Inspection

Abstract

1. Introduction

- Identify Shortcomings: highlight the limitations and challenges inherent in current inspection methods for detecting corrosion in maritime ballast tanks.

- Showcase Technology Potential: provide preliminary evidence and practical scenarios that illustrate how HSI, LiDAR, and RGB sensors, when used in tandem, could effectively address these gaps.

- Lay Groundwork for Future Research:employ this manuscript as a platform to initiate more focused and technical research, encouraging further exploration and development of integrated inspection methods.

2. Materials and Methods

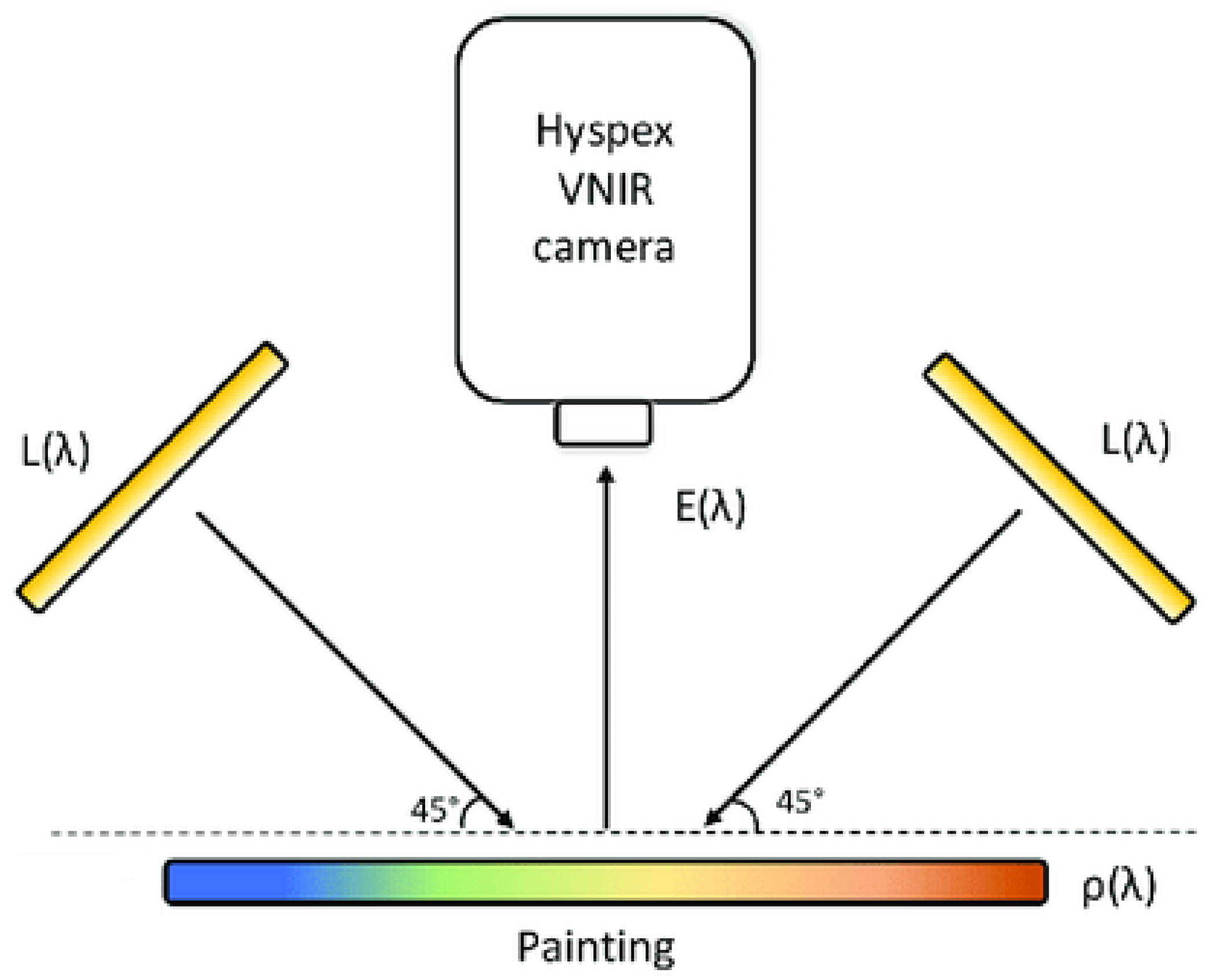

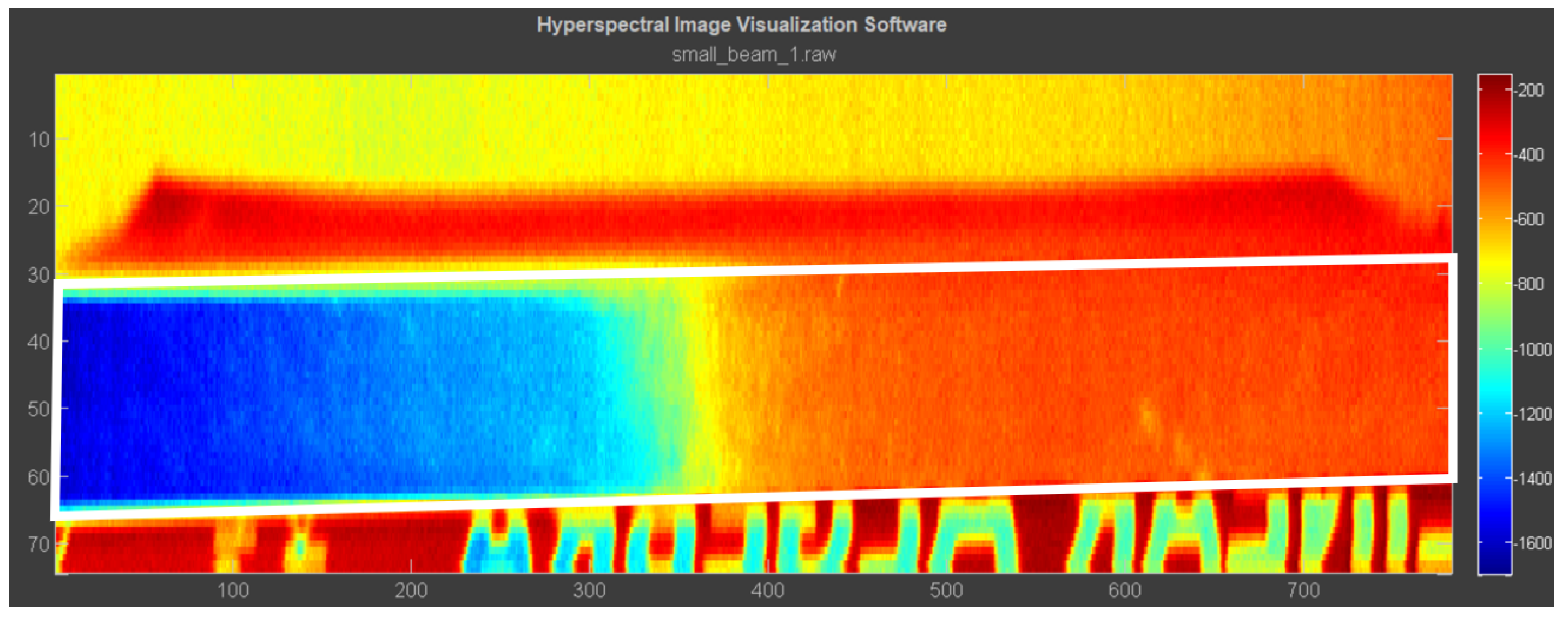

2.1. Hyperspectral Camera for Material Characterization

2.1.1. Sensor Specifications

2.1.2. Experimental Setup

2.1.3. Data Acquisition Approach

2.1.4. Rationale for Investigation

2.2. Samples for Testing

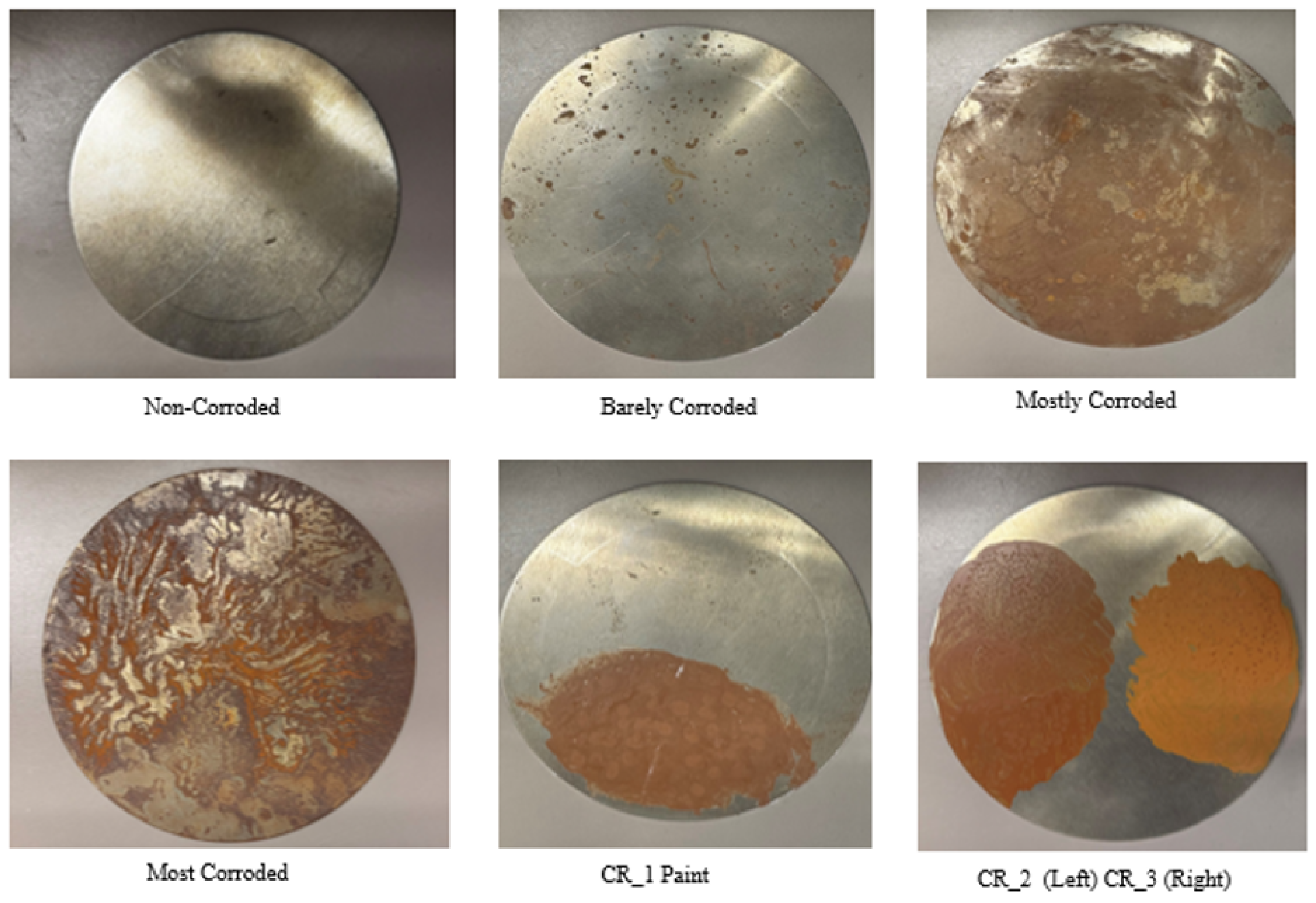

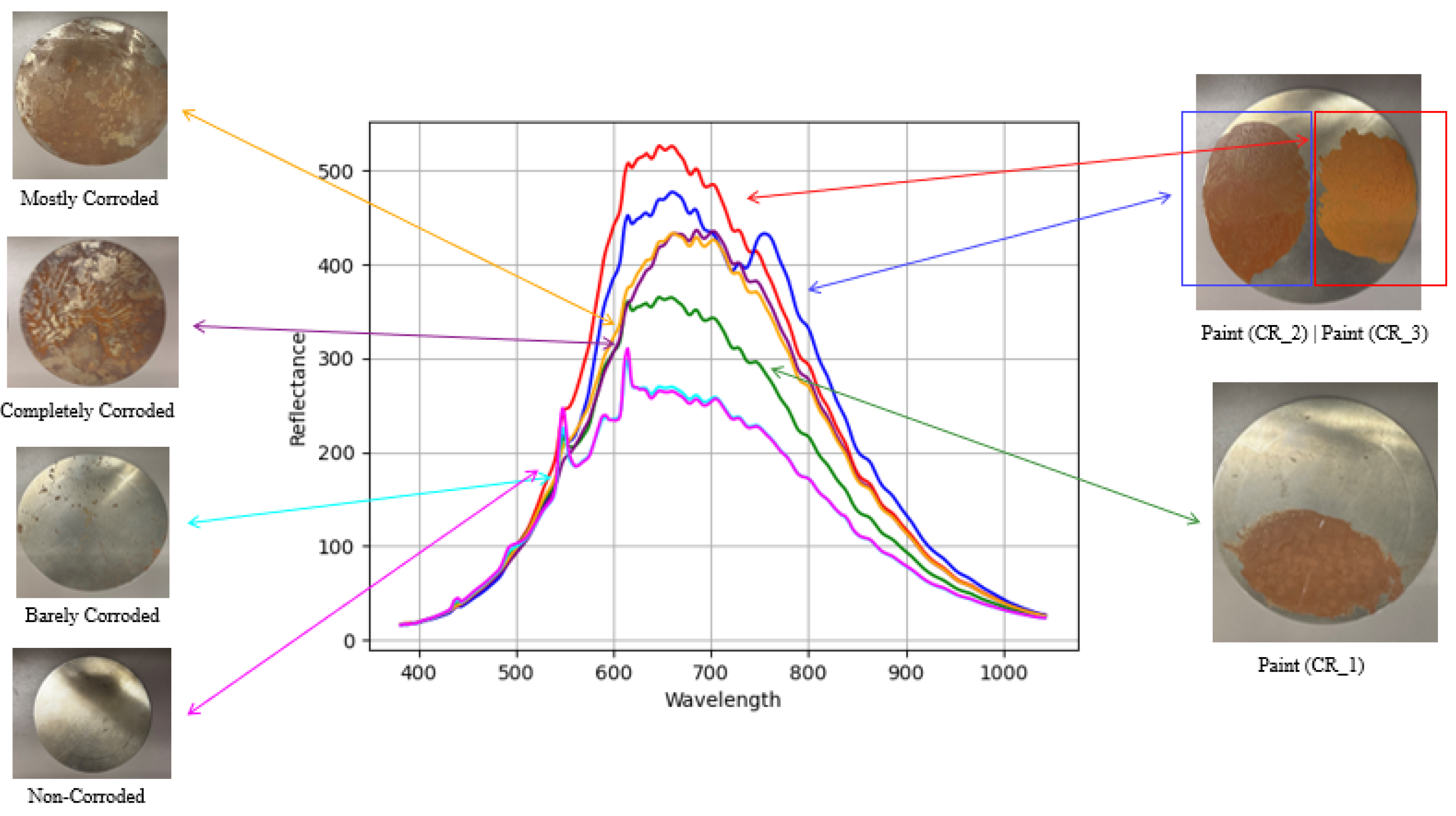

- Circular steel sheets were artificially corroded using saltwater exposure for varying durations to create samples with visually distinct levels of surface rust (see Figure 2).

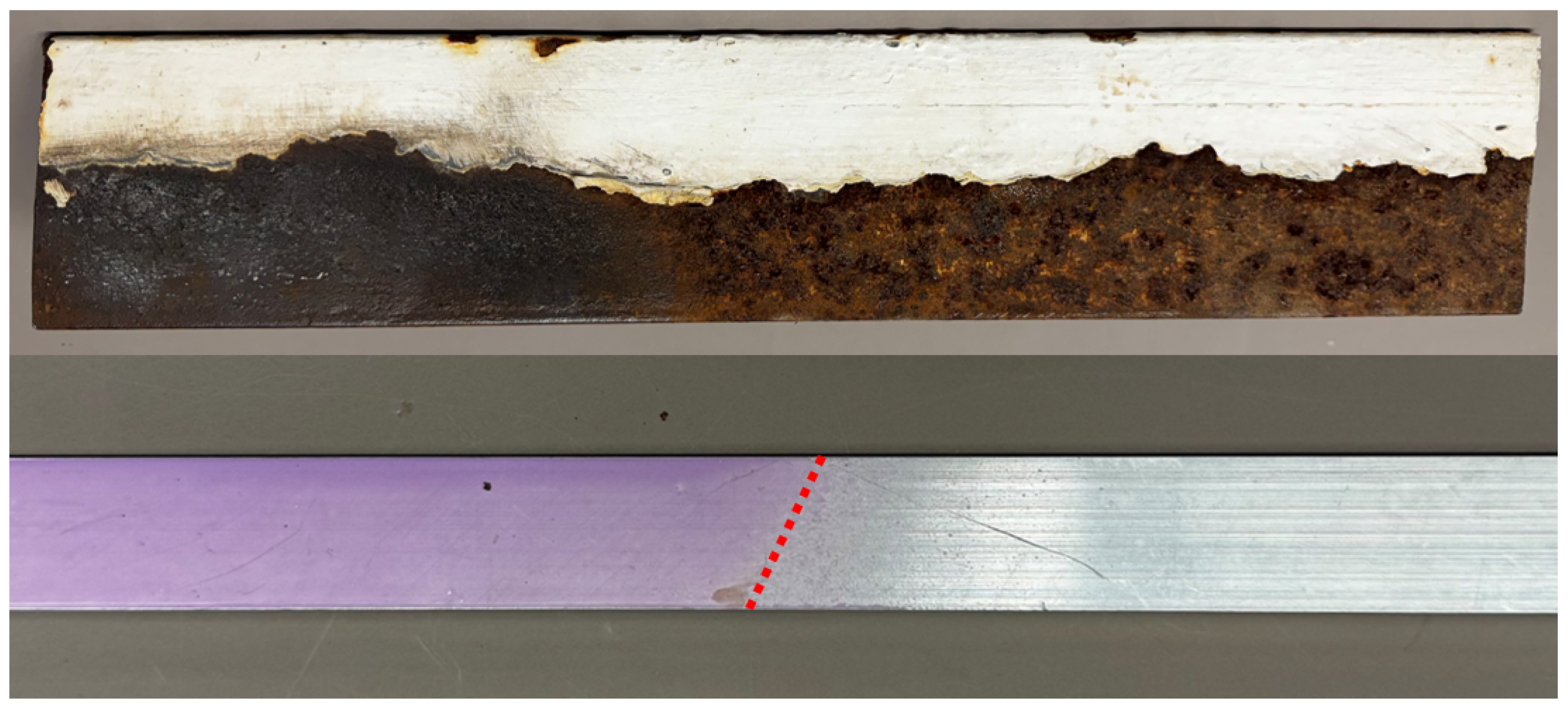

- Steel beams exhibiting naturally occurring corrosion, varying levels of residual coating, and areas of bare metal were sourced from scrapyards. These provided non-homogeneous surfaces characteristic of real-world scenarios (see Figure 3).

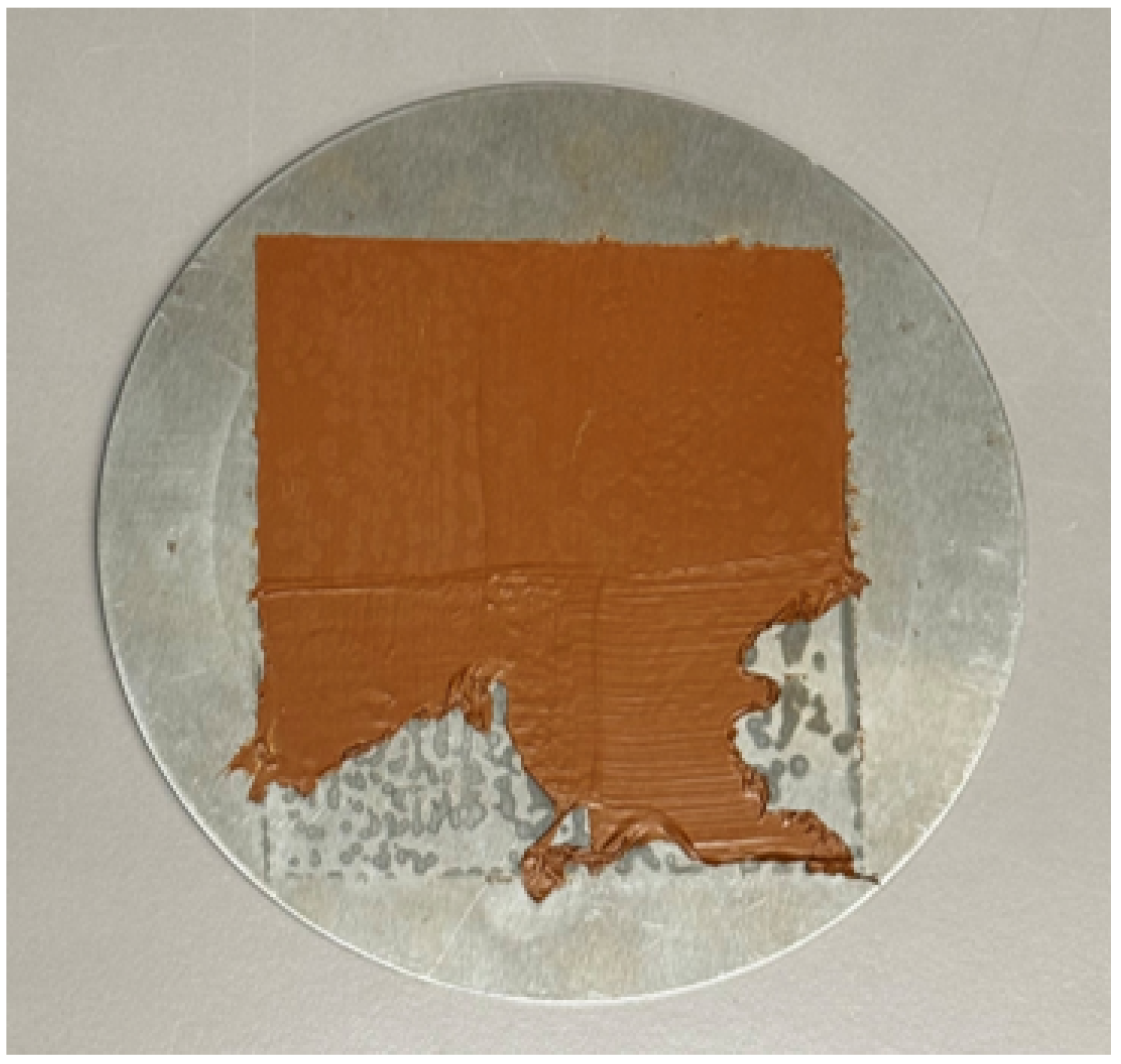

- A steel plate was prepared with varying numbers of paint layers applied using commercially available spray paint to test the ability to differentiate coating thicknesses (see Figure 4). Coating layers were controlled and recorded; for this purpose, paint was chosen due to its similarity in thickness with commercial maritime coatings and color-matched to the existing steel plate corrosion samples. Coating layers were measured to be the same thickness.

- An aluminum piece was also coated with varying paint thicknesses for comparative analysis (see Figure 3).

2.3. Methodology for Preliminary Coating Assessment Experiments

2.4. LiDAR Sensor for Spatial Mapping

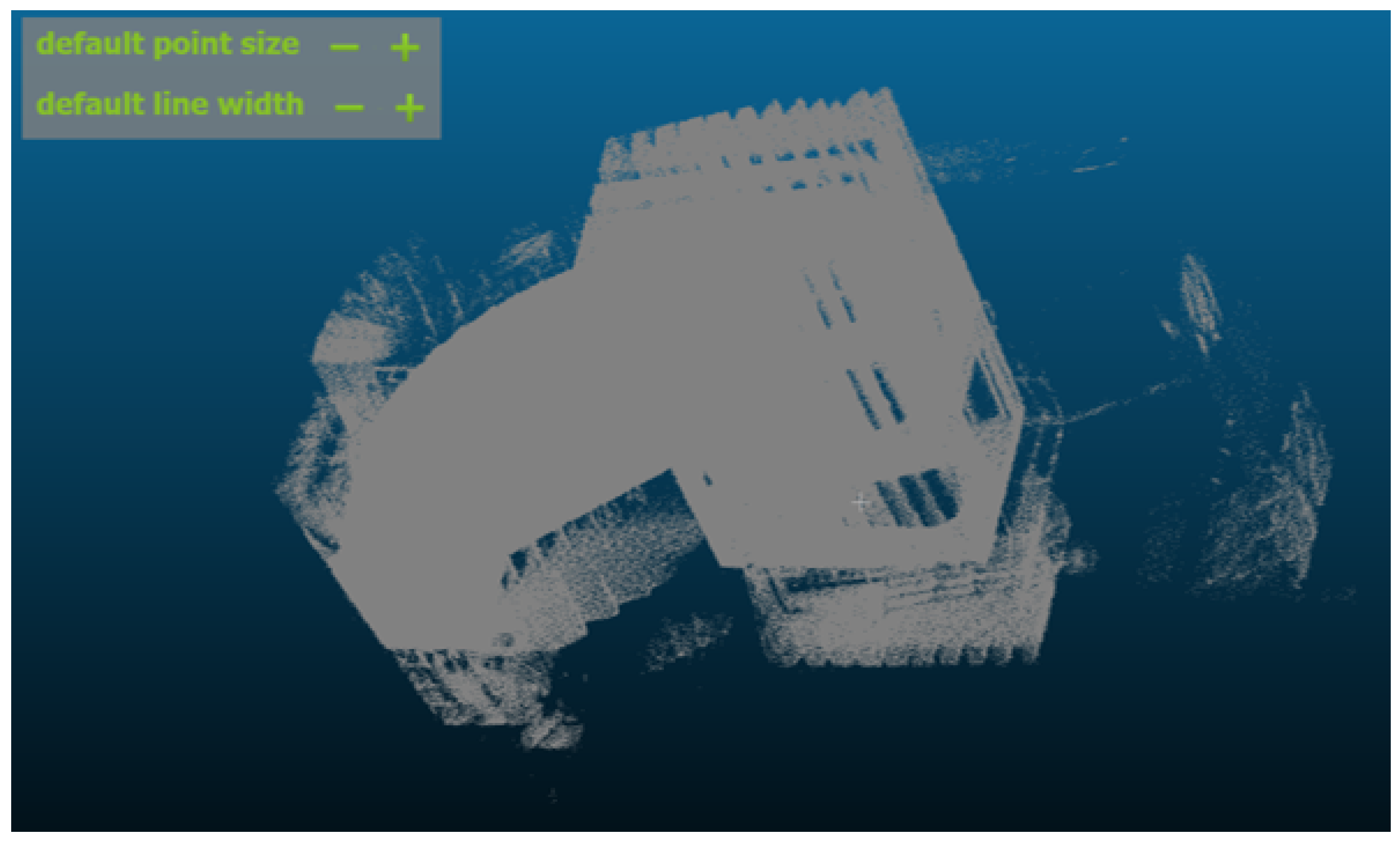

- Geometric Mapping: Creating accurate 3D models of the complex internal tank structure, essential for understanding the environment and documenting its condition.

- Navigation Aid: Providing spatial awareness for a mobile platform (like a UAV), potentially enabling autonomous or semi-autonomous navigation in the confined GPS-denied environment [34].

- Data Integration Framework: Serving as a common 3D reference frame onto which data from other sensors (like HSI or RGB cameras) can be accurately georeferenced and fused, creating comprehensive multi-modal maps [35].

- Anomaly Detection: While not primary for fine corrosion detection, the high-resolution geometric data might reveal large-scale deformations, buckling, or significant build-up indicative of structural issues or severe corrosion requiring further investigation [28].

Sensor Considerations

3. Results

3.1. Hyperspectral Differentiation of Surface Conditions

3.2. LiDAR-Based 3D Mapping and Data Framework

4. Discussion

4.1. Deployment Platform Considerations: UAV

4.1.1. Platform Requirements

- Stability and Motion Control: HSI sensors require stable controlled motion to capture accurate spectral data without distortions caused by drone vibrations and movements. LiDAR and RGB sensors could probably work in a less sophisticated platform. However, advanced stabilization systems, such as gimbals, are crucial for maintaining data quality within the system as a whole [40].

- Environmental Conditions: The harsh conditions of maritime environments, including high humidity and salt spray, can impact sensor performance and longevity, necessitating robust protective measures [41].

- Data Volume and Processing: HSI generates large volumes of data, presenting challenges for real-time onboard processing and efficient data transmission [42].

- Power Consumption: The significant power requirements of HSI sensors can reduce the total flight time and operational efficiency, highlighting the importance of power management strategies [43].

- Integration with Other Sensors: Seamless integration with other sensors, such as LiDAR and RGB cameras, is essential for effective data fusion but requires precise synchronization [44].

- Distance and Field of View: Maintaining a consistent distance and field of view from surfaces is critical for accurate data collection, especially in confined spaces like ballast tanks [45].

- Lighting Conditions: Ensuring adequate and consistent lighting is essential for capturing high-quality hyperspectral data, particularly in low-light conditions typical of tank interiors [46].

4.1.2. Operational Approach and Automation Potential

- Conducting field trials within actual ballast tanks to assess sensor performance under realistic environmental conditions.

- Developing and validating robust data processing and machine learning algorithms for automated classification and analysis of fused LiDAR and HSI data.

- Addressing the engineering challenges of integrating the required sensor suite onto a UAV platform suitable for confined space operations (balancing payload, agility, endurance, and safety).

- Establishing a reliable workflow for hyperspectral data acquisition that is applicable to diverse environments.

- Performing quantitative comparisons against established non-destructive methods (NDT) methods to benchmark the performance of any proposed system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moore, J.D., III. Long-term corrosion processes of iron and steel shipwrecks in the marine environment: A review of current knowledge. J. Marit. Archaeol. 2015, 10, 191–204. [Google Scholar] [CrossRef]

- Almadhoun, R.; Taha, T.; Seneviratne, L.; Dias, J.; Cai, G. A survey on inspecting structures using robotic systems. Int. J. Adv. Robot. Syst. 2016, 13, 1729881416663664. [Google Scholar] [CrossRef]

- Hung, M.L.; Gucunski, N.; Dana, K.; Seong-Hoon, K. Development of an autonomous bridge deck inspection robotic system. J. Field Robot. 2017, 34, 1489–1504. [Google Scholar] [CrossRef]

- Gudze, M.T.; Melchers, R.E. Operational based corrosion analysis in naval ships. Corros. Sci. 2008, 50, 3296–3307. [Google Scholar] [CrossRef]

- Qi, Z.; Eames, I.; Greig, A. Flushing ballast tanks. Ocean Eng. 2014, 89, 157–172. [Google Scholar] [CrossRef]

- Lakshmi, E.; Priya, M.; Achari, V.S. An overview on the treatment of ballast water in ships. Ocean Coast. Manag. 2021, 199, 105296. [Google Scholar] [CrossRef]

- David, M. Vessels and Ballast Water. In Global Maritime Transport and Ballast Water Management; Invading Nature—Springer Series in Invasion Ecology; David, M., Gollasch, S., Eds.; Springer: Dordrecht, The Netherlands, 2015; Volume 8. [Google Scholar]

- Paik, J.K.; Thayamballi, A.K.; Park, Y.I.; Hwang, J.S. A time-dependent corrosion wastage model for seawater ballast tank structures of ships. Corros. Sci. 2004, 46, 471–486. [Google Scholar] [CrossRef]

- Wang, Y.; Li, B.; Chen, L.; Jiang, Z. Region segmentation based radiographic detection of defects for gas turbine blades. In Proceedings of the 2015 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 2–5 August 2015. [Google Scholar]

- Kaess, M.; Hover, F.S.; Leonard, J.J.; Teixeira, P.V. Underwater inspection using sonar-based volumetric submaps. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016. [Google Scholar]

- Ok, D. The Effects of Corrosions and Fatigue Induced Cracks on Strength Degradation in Ageing Ships. Ph.D. Thesis, Newcastle University, Newcastle, UK, 2006. [Google Scholar]

- Agarwala, V.S.; Reed, P.L.; Ahmad, S. Corrosion Detection and Monitoring—A Review. In Proceedings of the CORROSION 2000 Conference, Orlando, FL, USA, 26–31 March 2000; Available online: https://onepetro.org/NACECORR/proceedings-pdf/CORR00/All-CORR00/NACE-00271/1915423/nace-00271.pdf (accessed on 15 September 2024).

- Kerf, T.D.; Gestels, A.; Janssens, K.; Scheuders, P.; Steenackers, G.; Vanlanduit, S. Quantitative detection of corrosion minerals in carbon steel using shortwave infrared hyperspectral imaging. RSC Adv. 2022, 12, 32775–32783. [Google Scholar] [CrossRef]

- Koch, G. 1—Cost of corrosion. In Trends in Oil and Gas Corrosion Research and Technologies; El-Sherik, A., Ed.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2017; pp. 3–30. [Google Scholar]

- Brogaard, R.Y.; Andersen, R.E.; Kovac, L.; Zajaczkowski, M.; Boukas, E. Towards an Autonomous, Visual Inspection-aware 3D Exploration and Mapping System for Water Ballast Tanks of Marine Vessels. In Proceedings of the 2021 IEEE International Conference on Imaging Systems and Techniques (IST), Kaohsiung, Taiwan, 24–26 August 2021; pp. 1–6. [Google Scholar]

- Veleva, L. Protective Coatings and Inorganic Anti-Corrosive Pigments (Chapter 28). In ASTM MNL; ASTM: West Conshohocken, PA, USA, 2012; Volume 122. [Google Scholar]

- Mulla, D.J. Twenty-five years of remote sensing in precision agriculture: Key advances and remaining knowledge gaps. Biosyst. Eng. 2013, 114, 358–371. [Google Scholar] [CrossRef]

- Lang, M.; Forkuor, G.; Kuemmerle, T. Mapping South African savannah with hyperspectral data and machine learning. Remote Sens. 2019, 11, 1245. [Google Scholar]

- Kruse, F.A. Mapping surface mineralogy using imaging spectrometry. Geomorphology 2012, 137, 41–56. [Google Scholar] [CrossRef]

- VanDerMeer, F.; de Jong, S.M. Imaging spectrometry for local seismic hazard assessment in mining. Int. J. Appl. Earth Obs. Geoinf. 2012, 14, 95–104. [Google Scholar]

- Clark, M.R.; McCann, D.M.; Forde, M.C. Applications of remote sensing techniques to civil and structural engineering. Surv. Eng. 2004, 32, 201–210. [Google Scholar]

- Del Pozo, S.; Herrero-Pascual, J.; Felipe-García, B.; Hernández-López, D.; Rodríguez-Gonzálvez, P.; González-Aguilera, D. Multispectral Radiometric Analysis of Façades to Detect Pathologies from Active and Passive Remote Sensing. Remote Sens. 2016, 8, 80. [Google Scholar] [CrossRef]

- Schwertmann, U.; Cornell, R.M. Iron Oxides in the Laboratory: Preparation and Characterization; Wiley-VCH: Weinheim, Germany, 1998. [Google Scholar]

- Hunt, G.R. Spectral properties of rocks and related materials—A short course. In Economics and the Reflectance Spectra of Minerals, Presented at the Geological Society of America Meeting, Washington, DC, USA, 29–31 October 1971; CRC Press: Boca Raton, FL, USA, 1971. [Google Scholar]

- Hu, J.Y.; Zhang, S.S.; Chen, E.; Li, W.G. A review on corrosion detection and protection of existing reinforced concrete (RC) structures. Constr. Build. Mater. 2022, 325, 126718. [Google Scholar] [CrossRef]

- Naik, D.; Sakid, H.U.; Kiran, R.; Sun, X. Hyperspectral Imaging for the Elimination of Visual Ambiguity in Corrosion Detection and Identification of Corrosion Sources. Struct. Health Monit. 2022, 21, 1678–1693. [Google Scholar]

- Lattanzi, D.; Miller, G. Review of robotic infrastructure inspection systems. J. Infrastruct. Syst. 2017, 23, 04017004. [Google Scholar] [CrossRef]

- Sharma, V.B. Automatic Identification of Deformations in Buildings and Pipelines Using 3D Point Cloud Data for Structural Health Monitoring with LiDAR Technology. Ph.D. Thesis, Rajiv Gandhi Institute of Petroleum Technology, Amethi, India, 2023. [Google Scholar]

- Bhargava, A.; Sachdeva, A.; Sharma, K.; Alsharif, M.H.; Uthansakul, P.; Uthansakul, M. Hyperspectral imaging and its applications: A review. Heliyon 2024, 10, e33208. [Google Scholar] [CrossRef] [PubMed]

- Noomen, M. Hyperspectral Reflectance of Vegetation Affected by Underground Hydrocarbon Gas Seepage; Wageningen University and Research: Wageningen, The Netherlands, 2007. [Google Scholar]

- Dingemans, L.M.; Papadakis, V.M.; Liu, P.; Adam, A.J.L.; Groves, R.M. Quantitative Coating Thickness Determination Using a Coefficient-Independent Hyperspectral Scattering Model. J. Eur. Opt. Soc.-Rapid Publ. 2017, 13, 40. [Google Scholar] [CrossRef]

- Thomas, D.; Gündel, M. Hyperspectral imaging systems for corrosion detection from remotely operated vehicles. ce/Papers 2023, 6, 934–938. [Google Scholar] [CrossRef]

- Zabalza, J.; Murray, P.; Bennett, S.; Campbell, A.J.; Marshall, S.; Ren, J. Hyperspectral Imaging Based Corrosion Detection in Nuclear Packages. IEEE Sens. J. 2023, 23, 25607–25617. [Google Scholar] [CrossRef]

- Rodríguez-Gonzálvez, P.; Fernández-Palacios, B.J.; Muñoz-Nieto, A.L.; Arias, P.; González-Aguilera, D. Mobile lidar system: New possibilities for the documentation and dissemination of large cultural heritage sites. Remote Sens. 2017, 9, 189. [Google Scholar] [CrossRef]

- Buckley, S.J.; Kurz, T.H.; Howell, J.A.; Schneider, D. Terrestrial lidar and hyperspectral data fusion products for geological outcrop analysis. Comput. Geosci. 2013, 54, 249–258. [Google Scholar] [CrossRef]

- Flyability. ELIOS 3—Digitizing the Inaccessible. Available online: https://www.flyability.com/elios-3 (accessed on 31 October 2024).

- CloudCompare: 3D Point Cloud and Mesh Processing Software. Available online: https://www.cloudcompare.org/ (accessed on 1 November 2023).

- Ayamga, M.; Akaba, S.; Nyaaba, A.A. Multifaceted applicability of drones: A review. Technol. Forecast. Soc. Change 2021, 167, 120677. [Google Scholar] [CrossRef]

- Menendez, E.; Victores, G.V.; Montero, R.; Martinez, S.; Balaguer, C. Tunnel structural inspection and assessment using an autonomous robotic system. Autom. Constr. 2018, 87, 117–126. [Google Scholar] [CrossRef]

- Kopačková, V.; Alfoldi, T.T.; Yilmaz-Onen, F. UAV-based hyperspectral sensing of soil washes. Remote Sens. 2018, 10, 1428. [Google Scholar]

- Harwin, S.; Lucieer, A. Assessing the accuracy of georeferenced point clouds produced via multi-view stereopsis from unmanned aerial vehicle (UAV) imagery. Remote Sens. 2012, 4, 1573–1599. [Google Scholar] [CrossRef]

- Gašparović, M.; Zrinjski, M.; Galić, I.; Balenović, I. The Cost-Effectiveness of Hyperspectral and LIDAR Data on Pre-Harvest Volume Estimation of Riparian Forests. Remote Sens. 2016, 8, 638. [Google Scholar]

- Burkart, A.; Hecht, V.L.; Kraska, T.; Rascher, U.; Aigner, J. A novel UAV-based ultra-light weighting frame for hyperspectral field measurements. Comput. Electron. Agric. 2015, 119, 195–209. [Google Scholar]

- Aasen, H.; Bolten, A. Multi-temporal high-resolution imaging spectroscopy with hyperspectral 2D framework: An approach for plant phenotyping. Remote Sens. Environ. 2018, 206, 212–222. [Google Scholar]

- Turner, D.; Lucieer, A.; Malenovský, Z.; King, D.H.; Robinson, S.A. Assessment of Antarctic moss health from multi-sensor UAV imagery. Sensors 2014, 14, 7692–7710. [Google Scholar]

- Zhang, C.; Kovacs, J.M. The application of small unmanned aerial systems for precision agriculture: A review. Precis. Agric. 2012, 13, 693–712. [Google Scholar] [CrossRef]

- Headwall. Nano HP (400–1000 nm) Hyperspectral Imaging Package HyperSpectral Imaging Package. Available online: https://headwallphotonics.com/products/remote-sensing/nano-hp-400-1000nm-hyperspectral-imaging-package (accessed on 31 October 2024).

- Fabris, A.; Kirchgeorg, S.; Mintchev, S. A Soft Drone with Multi-modal Mobility for the Exploration of Confined Spaces. In Proceedings of the 2021 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), New York City, NY, USA, 25–27 October 2021; pp. 48–54. [Google Scholar]

- Puente-Castro, A.; Rivero, D.; Pazos, A.; Fernandez-Blanco, E. A review of artificial intelligence applied to path planning in UAV swarms. Neural Comput. Appl. 2022, 34, 153–170. [Google Scholar] [CrossRef]

- Conte, C.; de Alteris, G.; Lo Moriello, R.S.; Accardo, D.; Rufino, G. Drone Trajectory Segmentation for Real-Time and Adaptive Time-of-Flight Prediction. Drones 2021, 5, 62. [Google Scholar] [CrossRef]

| Challenge | Description |

|---|---|

| Confined Spaces | Drones must navigate tight enclosed environments that limit maneuverability and increase the risk of collisions. GPS signal reception is often poor, complicating navigation. |

| Lighting Conditions | Poor lighting affects visual data acquisition, necessitating onboard lighting systems, which increase power consumption. Reflective surfaces can create shadows and glare. |

| Environmental Conditions | High humidity and saltwater can impact drone operation and sensor functionality, requiring protective measures for electronic components. |

| Sensor Integration | Integrating multiple sensors (e.g., LiDAR, HSI, Visual RGB) requires careful calibration and synchronization for accurate data fusion, with constraints on payload capacity. |

| Data Processing | High-resolution sensors generate large data volumes, necessitating robust onboard processing or efficient transmission for post-processing. |

| Autonomy and Control | Real-time data processing for navigation and obstacle avoidance is complex. Autonomous systems require sophisticated algorithms. |

| Power Management | High power requirements reduce flight duration, necessitating energy-efficient designs and potential solutions for battery swapping or recharging. |

| Communication Constraints | Signal loss is possible in metallic environments. Reliable communication systems are needed to maintain control and data links. |

| Collision Avoidance | Advanced systems are needed for real-time collision avoidance. Sensors must reliably detect obstacles in cluttered environments. |

| Maintenance and Reliability | Harsh conditions demand regular maintenance. Reliability is crucial to prevent system failures during inspections. |

| Data Security and Privacy | Ensuring compliance with data privacy laws and securing sensitive data collected during operations is necessary. |

| Training and Human Factors | Operators require specialized training for effective drone use, particularly in manual or semi-automated modes. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enguita, S.P.; Jiang, J.; Chen, C.-H.; Kovacic, S.; Lebel, R. Potential of LiDAR and Hyperspectral Sensing for Overcoming Challenges in Current Maritime Ballast Tank Corrosion Inspection. Electronics 2025, 14, 3065. https://doi.org/10.3390/electronics14153065

Enguita SP, Jiang J, Chen C-H, Kovacic S, Lebel R. Potential of LiDAR and Hyperspectral Sensing for Overcoming Challenges in Current Maritime Ballast Tank Corrosion Inspection. Electronics. 2025; 14(15):3065. https://doi.org/10.3390/electronics14153065

Chicago/Turabian StyleEnguita, Sergio Pallas, Jiajun Jiang, Chung-Hao Chen, Samuel Kovacic, and Richard Lebel. 2025. "Potential of LiDAR and Hyperspectral Sensing for Overcoming Challenges in Current Maritime Ballast Tank Corrosion Inspection" Electronics 14, no. 15: 3065. https://doi.org/10.3390/electronics14153065

APA StyleEnguita, S. P., Jiang, J., Chen, C.-H., Kovacic, S., & Lebel, R. (2025). Potential of LiDAR and Hyperspectral Sensing for Overcoming Challenges in Current Maritime Ballast Tank Corrosion Inspection. Electronics, 14(15), 3065. https://doi.org/10.3390/electronics14153065