Ti/HfO2-Based RRAM with Superior Thermal Stability Based on Self-Limited TiOx

Abstract

:1. Introduction

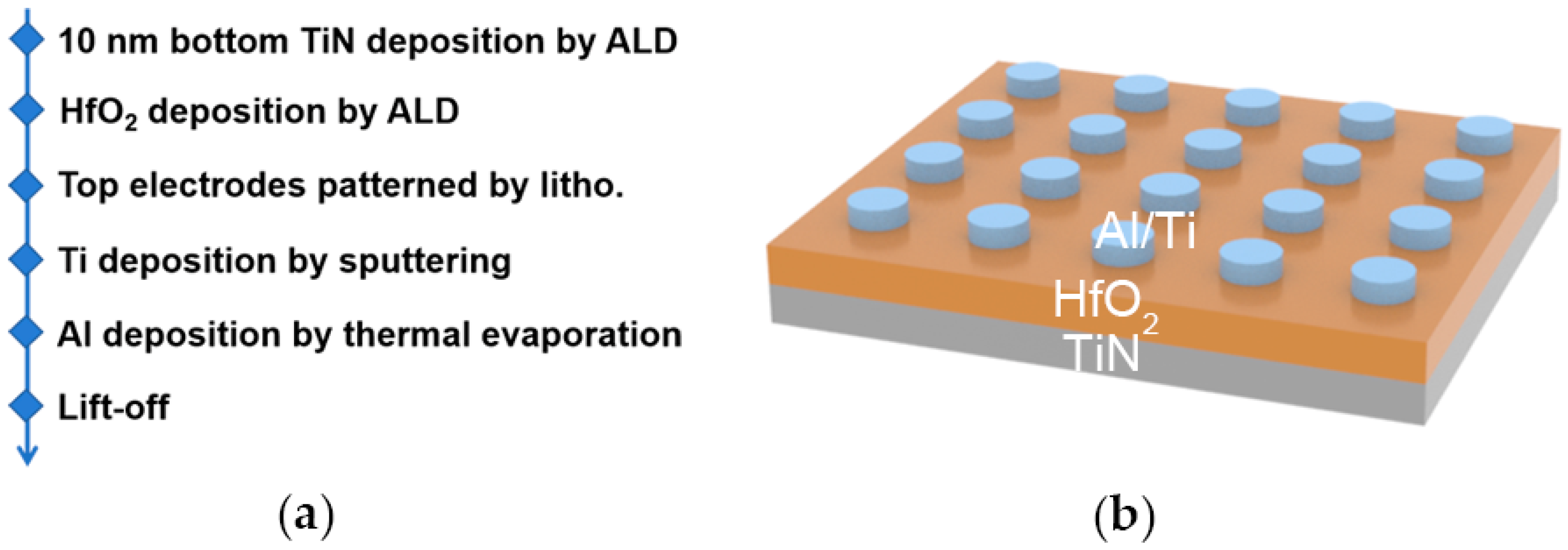

2. Materials and Methods

3. Results

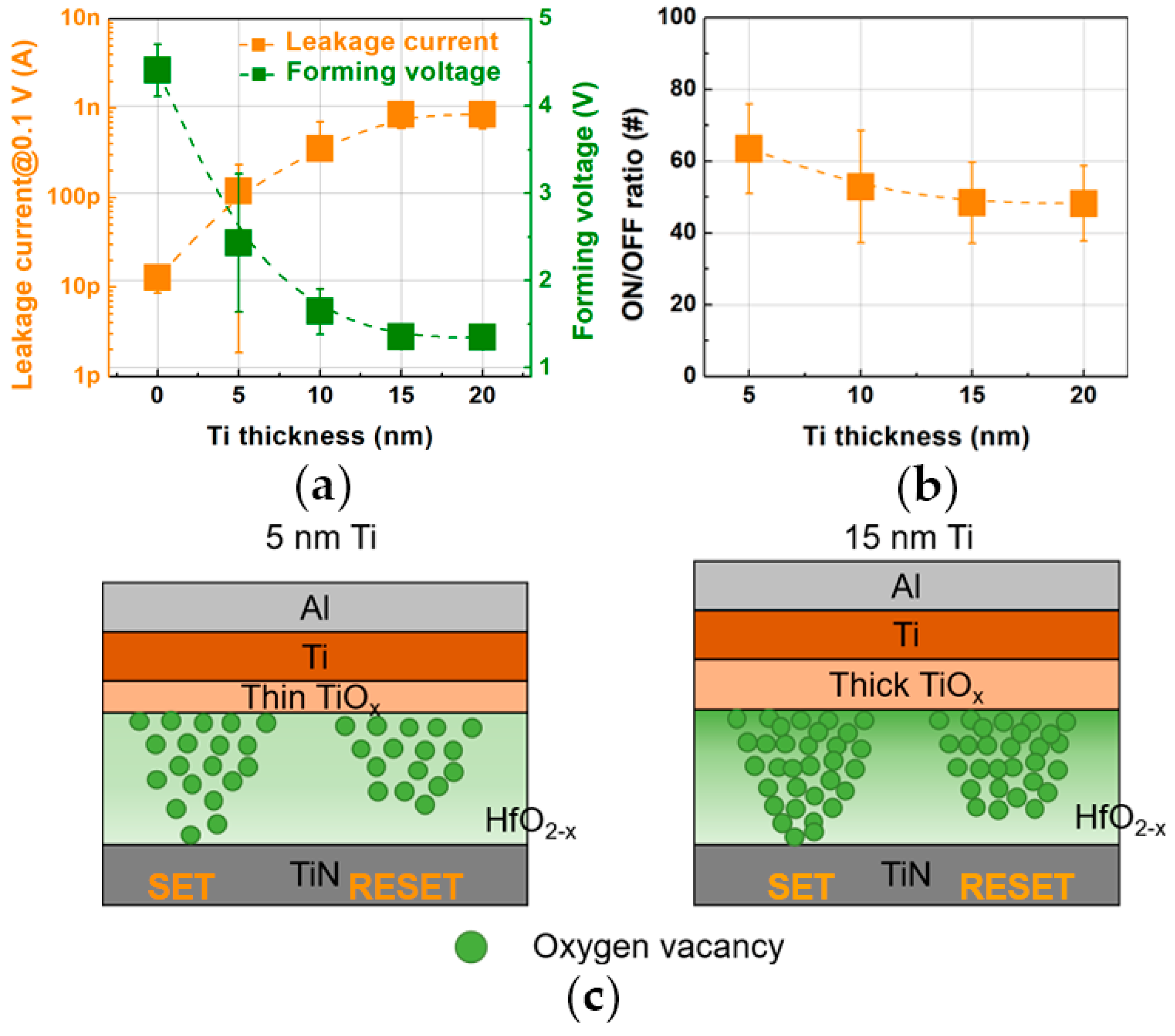

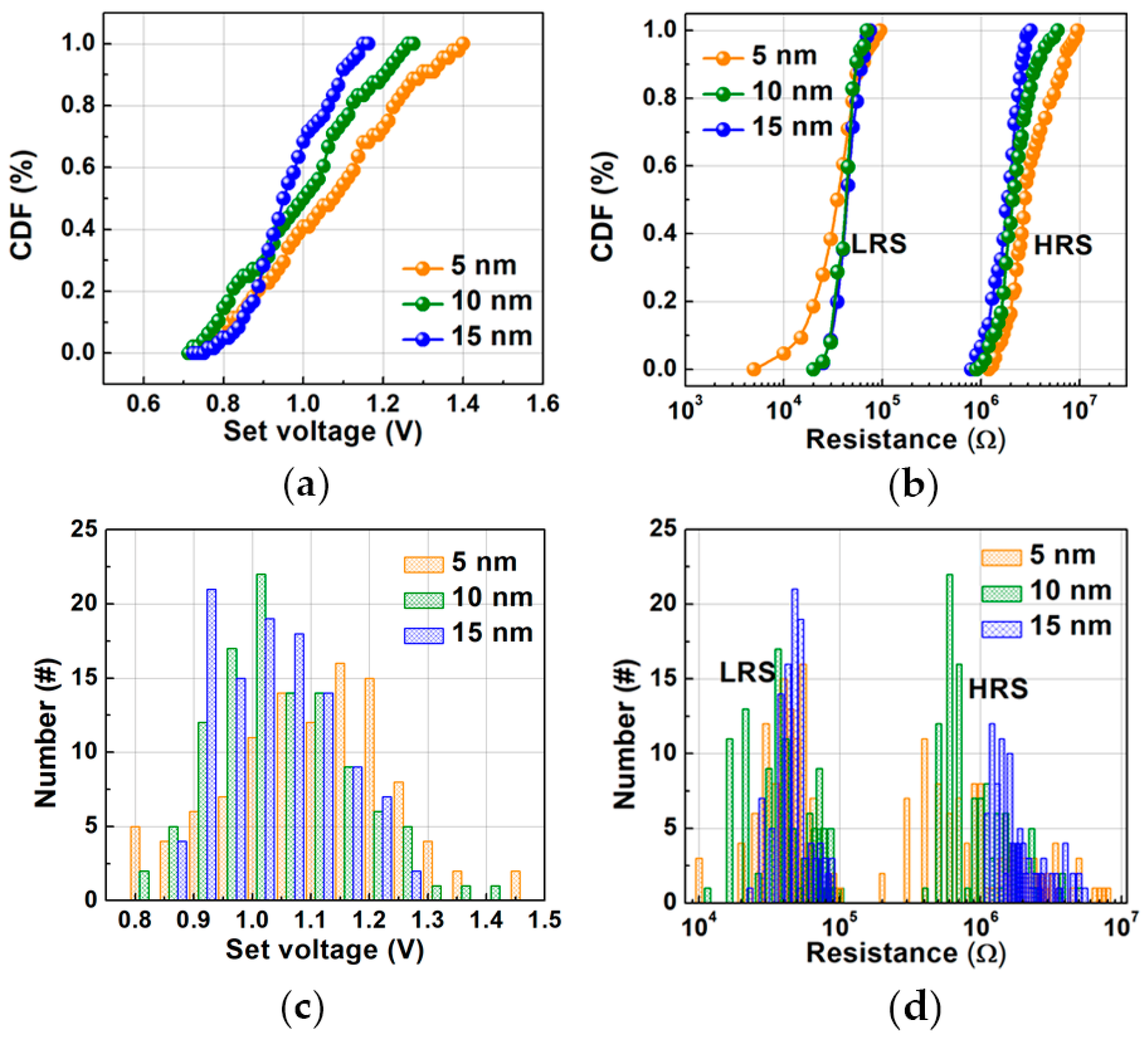

3.1. Ti Thickness-Dependent RS

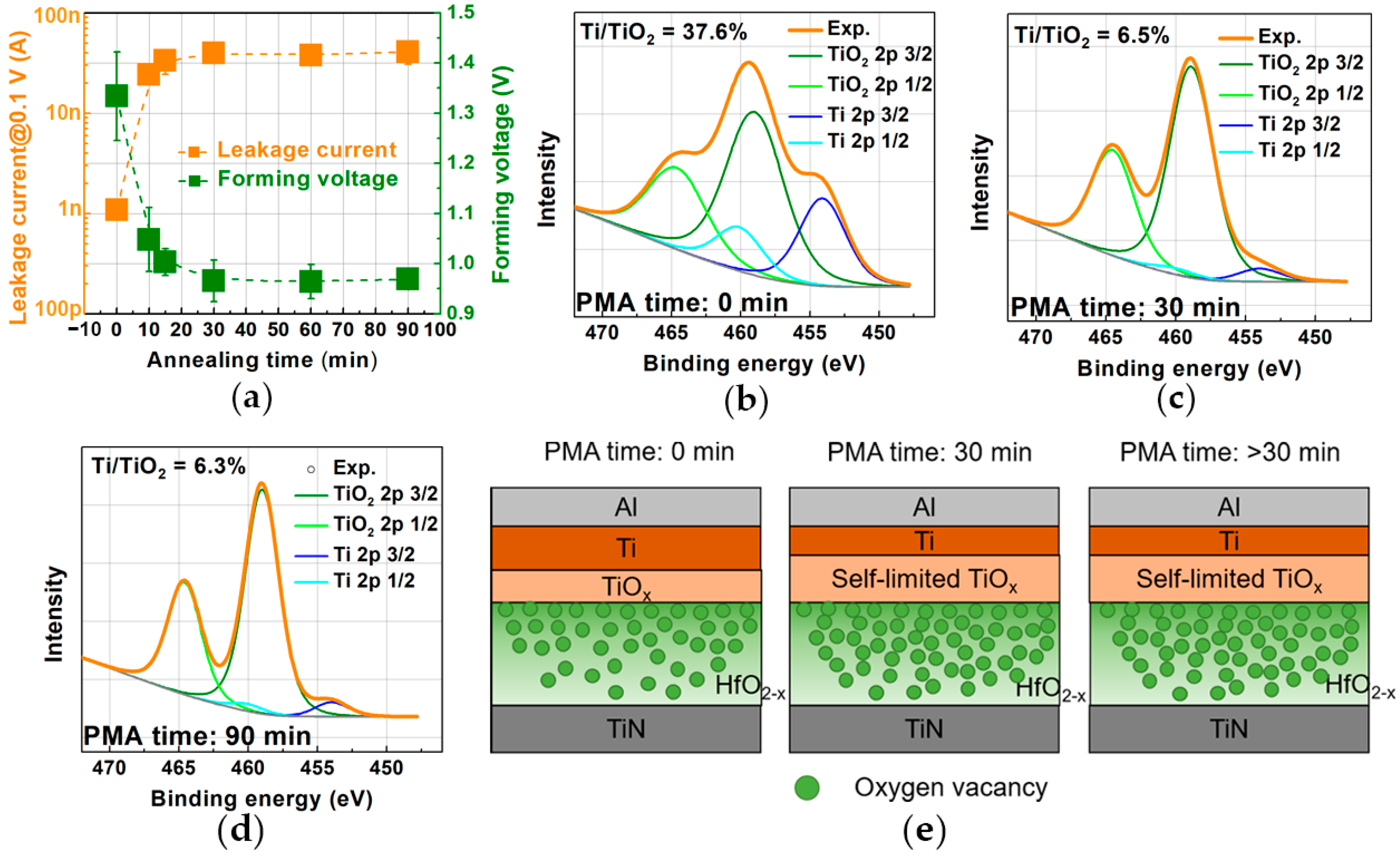

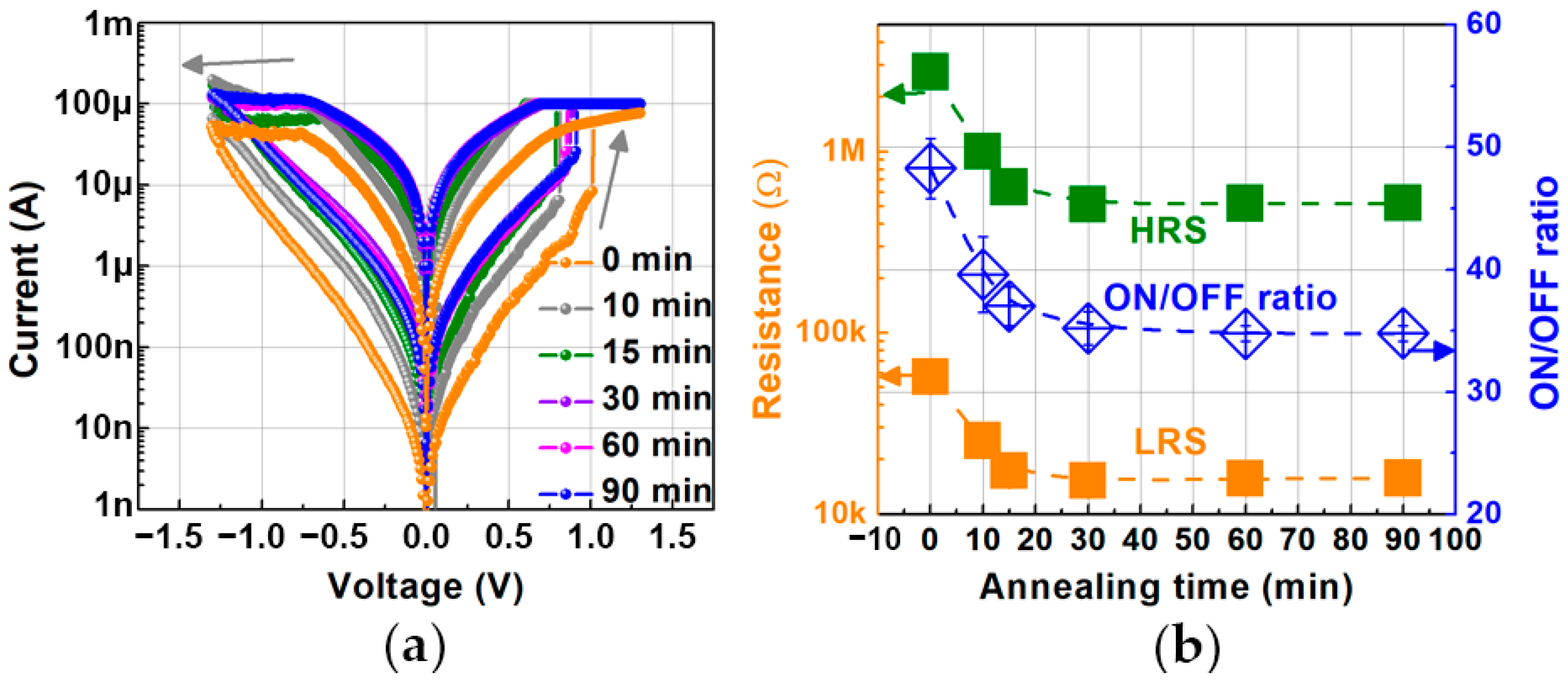

3.2. Systematic Thermal Degradation Research about the Effect of PMA Time on Oxygen Vacancy Distribution and RS Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- CHUA, L.O. Memristor-the missing circuit element. IEEE Trans. Circuit Theory 1971, 18, 507–519. [Google Scholar] [CrossRef]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The missing memristor found. Nature 2009, 459, 1154. [Google Scholar] [CrossRef]

- Yang, R.; Huang, H.M.; Guo, X. Memristive synapses and neurons for bio-inspired computing. Adv. Electron. Mater. 2019, 5, 1900287. [Google Scholar] [CrossRef]

- Pan, F.; Gao, S.; Chen, C.; Song, C.; Zeng, F. Recent Progress in Resistive Random Access Memories: Materials, Switching Mechanisms, and Performance. Mater. Sci. Eng. R Rep. 2014, 83, 1–59. [Google Scholar] [CrossRef]

- Wong, H.S.P.; Lee, H.Y.; Yu, S.; Chen, Y.S.; Wu, Y.; Chen, P.S.; Lee, B.; Chen, F.T.; Tsai, M.J. Metal-Oxide RRAM. Proc. IEEE 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Ielmini, D. Resistive Switching Memories Based on Metal Oxides: Mechanisms, Reliability and Scaling. Semicond. Sci. Technol. 2016, 31, 063002. [Google Scholar] [CrossRef]

- Lanza, M.; Waser, R.; Ielmini, D.; Yang, J.J.; Goux, L.; Suñe, J.; Kenyon, A.J.; Mehonic, A.; Spiga, S.; Rana, V.; et al. Standards for the Characterization of Endurance in Resistive Switching Devices. ACS Nano 2021, 15, 17214–17231. [Google Scholar] [CrossRef] [PubMed]

- Sebastian, A.; Gallo, M.L.; Khaddam-Aljameh, R.; Eleftheriou, E. Memory devices and applications for in-memory computing. Nat. Nanotechnol. 2020, 15, 529–544. [Google Scholar] [CrossRef]

- Lanza, M.; Wong, H.-S.P.; Pop, E.; Ielmini, D.; Strukov, D.; Regan, B.C.; Larcher, L.; Villena, M.A.; Yang, J.J.; Goux, L.; et al. Recommended methods to study resistive switching devices. Adv. Electron. Mater. 2019, 5, 1800143. [Google Scholar] [CrossRef]

- Lee, H.Y.; Chen, P.S.; Wu, T.Y.; Chen, Y.S.; Wang, C.C.; Tzeng, P.J.; Lin, C.H.; Chen, F.; Lien, C.H.; Tsai, M.J. Low Power and High Speed Bipolar Switching with a Thin Reactive Ti Buffer Layer in Robust HfO2 Based RRAM. In Proceedings of the 2008 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 14–17 December 2008; pp. 297–300. [Google Scholar]

- Kwon, D.H.; Kim, K.M.; Jang, J.H.; Jeon, J.M.; Lee, M.H.; Kim, G.H.; Li, X.S.; Park, G.S.; Lee, B.; Han, S.; et al. Atomic Structure of Conducting Nanofilaments in TiO2 Resistive Switching Memory. Nat. Nanotechnol. 2010, 5, 148–153. [Google Scholar] [CrossRef]

- Torrezan, A.C.; Strachan, J.P.; Medeiros-Ribeiro, G.; Williams, R.S. Sub-Nanosecond Switching of a Tantalum Oxide Memristor. Nanotechnology 2011, 22, 485203. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Lee, B.; Wong, H.S.P. Al2O3-Based RRAM Using Atomic Layer Deposition (ALD) with 1-μA RESET Current. IEEE Electron. Device Lett. 2010, 31, 1449–1451. [Google Scholar] [CrossRef]

- Kim, D.C.; Seo, S.; Ahn, S.E.; Suh, D.S.; Lee, M.J.; Park, B.H.; Yoo, I.K.; Baek, I.G.; Kim, H.J.; Yim, E.K.; et al. Electrical Observations of Filamentary Conductions for the Resistive Memory Switching in NiO Films. Appl. Phys. Lett. 2006, 88, 202102. [Google Scholar] [CrossRef]

- Lin, C.Y.; Wu, C.Y.; Wu, C.Y.; Lee, T.C.; Yang, F.L.; Hu, C.; Tseng, T.Y. Effect of Top Electrode Material on Resistive Switching Properties of ZrO2 Film Memory Devices. IEEE Electron. Device Lett. 2007, 28, 366–368. [Google Scholar] [CrossRef]

- Yang, J.J.; Zhang, M.X.; Strachan, J.P.; Feng, F.M.; Pickett, M.D.; Kelley, R.D.; Ribeiro, G.M.; Williams, R.S. High switching endurance in TaOx memristive devices. Appl. Phys. Lett. 2010, 97, 232102. [Google Scholar] [CrossRef]

- Zhuo, V.Y.Q.; Jiang, Y.; Zhao, R.; Shi, L.P.; Yang, Y.; Chong, T.C.; Robertson, J. Improved Switching Uniformity and Low-Voltage Operation in -Based RRAM Using Ge Reactive Layer. IEEE Electron. Device Lett. 2013, 34, 1130. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Goux, L.; Clima, S.; Govoreanu, B.; Degraeve, R.; Kar, G.S.; Fantini, A.; Groeseneken, G.; Wouters, D.J.; Jurczak, M. Endurance/retention trade-off on HfO2/metal cap 1T1R bipolar RRAM. IEEE Trans. Electron. Devices 2013, 60, 1114–1121. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Govoreanu, B.; Goux, L.; Degraeve, R.; Fantini, A.; Kar, G.S.; Wouters, D.J.; Groeseneken, G.; Kittl, J.A.; Jurczak, M.; et al. Balancing SET/RESET pulse for >1010 endurance in HfO2/Hf 1T1R bipolar RRAM. IEEE Trans. Electron. Devices 2012, 59, 3243–3249. [Google Scholar] [CrossRef]

- Govoreanu, B.; Kar, G.S.; Chen, Y.; Paraschiv, V.; Kubicek, S.; Fantini, A.; Radu, I.P.; Goux, L.; Clima, S.; Degraeve, R.; et al. 10 × 10 nm2 Hf/HfOx crossbar resistive RAM with excellent performance, reliability and low-energy operation. In Proceedings of the 2011 International Electron Devices Meeting (IEDM), Washington, DC, USA, 5–7 December 2011; pp. 31.6.1–31.6.4. [Google Scholar]

- Rahaman, S.Z.; Lin, Y.D.; Lee, H.Y.; Chen, Y.S.; Chen, P.S.; Chen, W.S.; Hsu, C.H.; Tsai, K.H.; Tsai, M.J.; Wang, P.H. The Role of Ti Buffer Layer Thickness on the Resistive Switching Properties of Hafnium Oxide-Based Resistive Switching Memories. Langmuir 2017, 33, 4654–4665. [Google Scholar] [CrossRef]

- Fang, Z.; Wang, X.P.; Sohn, J.; Weng, B.B.; Zhang, Z.P.; Chen, Z.X.; Tang, Y.Z.; Lo, G.-Q.; Provine, J.; Wong, S.S.; et al. The Role of Ti Capping Layer in HfOx-Based RRAM Devices. IEEE Electron. Device Lett. 2014, 35, 912–914. [Google Scholar] [CrossRef]

- Young-Fisher, K.G.; Bersuker, G.; Butcher, B.; Padovani, A.; Larcher, L.; Veksler, D.; Gilmer, D.C. Leakage Current–Forming Voltage Relation and Oxygen Gettering in HfOx RRAM Devices. IEEE Electron. Device Lett. 2013, 34, 750–752. [Google Scholar] [CrossRef]

- Tsai, T.; Chang, H.; Jiang, F.; Tseng, T. Impact of Post-Oxide Deposition Annealing on Resistive Switching in HfO2-Based Oxide RRAM and Conductive-Bridge RAM Devices. IEEE Electron. Device Lett. 2015, 36, 1146–1148. [Google Scholar] [CrossRef]

- Jiang, Y.; Tan, C.C.; Li, M.H.; Fang, Z.; Weng, B.B.; He, W.; Zhuo, V.Y.Q. Forming-Free TaOx Based RRAM Device with Low Operating Voltage and High On/Off Characteristics. ECS J. Solid State Sci. Technol. 2015, 4, 137–140. [Google Scholar] [CrossRef]

- Wu, L.; Liu, H.; Lin, J.; Wang, S. Self-compliance and high performance Pt/HfOx/Ti RRAM achieved through annealing. Nanomaterials 2020, 10, 457. [Google Scholar] [CrossRef]

- Park, J.; Park, E.; Kim, S.G.; Jin, D.G.; Yu, H.Y. Analysis of the thermal degradation effect on a HfO2-based memristor synapse caused by oxygen affinity of a top electrode metal and on a neuromorphic system. ACS Appl. Electron. Mater. 2021, 3, 5584. [Google Scholar] [CrossRef]

- Chen, H.; Li, L.; Wang, J.; Zhao, G.; Li, Y.; Lan, J.; Tay, B.K.; Zhong, G.; Li, J.; Huang, M. Performance Optimization of Atomic Layer Deposited HfOx Memristor by Annealing With Back-End-of-Line Compatibility. IEEE Electron. Device Lett. 2022, 43, 1141–1144. [Google Scholar] [CrossRef]

- Chuang, K.C.; Lin, K.Y.; Luo, J.D.; Li, W.S.; Li, Y.S.; Chu, C.Y.; Cheng, H.C. Effects of Post-Metal Annealing on the Electrical Characteristics of HfOx-Based Resistive Switching Memory Devices. Jpn. J. Appl. Phys. 2017, 56, 06GF10. [Google Scholar] [CrossRef]

- Yang, L.; Wang, C.Z.; Lin, S.; Cao, Y.; Liu, X. Early stage of oxidation on titanium surface by reactive molecular dynamics simulation computers. Comput. Mater. Contin. 2018, 55, 177–188. [Google Scholar]

- Sun, J.; Tan, J.B.; Chen, T. HfOx-Based RRAM Device With Sandwich-Like Electrode for Thermal Budget Requirement. IEEE Trans. Electron. Devices 2020, 67, 4193–4200. [Google Scholar] [CrossRef]

- Yang, J.J.; Strachan, J.P.; Xia, Q.; Ohlberg, D.A.A.; Kuekes, P.; D.Kelley, J.R.; Stickle, W.F.; Stewart, D.R.; Medeiros-Ribeiro, G.; Williams, R.S. In-operando and non-destructive analysis of the resistive switching in the Ti/HfO2/TiN-based system by hard X-ray photoelectron spectroscopy. Adv. Mater. 2010, 22, 4036. [Google Scholar]

| Structure | Forming Voltage | Temp. | Time | Ref. |

|---|---|---|---|---|

| Ta/TaOx/Pt | Forming free | 400 °C | 30 s | [25] |

| Pt/Ti/HfO2/Pt | Forming free | 500 °C | 10 min | [26] |

| Al/Ta/HfO2/Pt | 8.79 V | 400 °C | 60 min | [27] |

| Pt/Ti/HfO2/Pt | Forming free | 300 °C | 60 s | [28] |

| TiN/Ti/HfO2/TiN | 3.8 V | 400 °C | 60 min | [29] |

| TiN/Ti/TiN/ HfO2/TiN | 1.2 V | 400 °C | 180 min | [31] |

| Al/Ti/HfO2/TiN | Forming free | 400 °C | 90 min | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, H.; Tan, Y.; Lee, C.; Zhao, Y. Ti/HfO2-Based RRAM with Superior Thermal Stability Based on Self-Limited TiOx. Electronics 2023, 12, 2426. https://doi.org/10.3390/electronics12112426

He H, Tan Y, Lee C, Zhao Y. Ti/HfO2-Based RRAM with Superior Thermal Stability Based on Self-Limited TiOx. Electronics. 2023; 12(11):2426. https://doi.org/10.3390/electronics12112426

Chicago/Turabian StyleHe, Huikai, Yixin Tan, Choonghyun Lee, and Yi Zhao. 2023. "Ti/HfO2-Based RRAM with Superior Thermal Stability Based on Self-Limited TiOx" Electronics 12, no. 11: 2426. https://doi.org/10.3390/electronics12112426

APA StyleHe, H., Tan, Y., Lee, C., & Zhao, Y. (2023). Ti/HfO2-Based RRAM with Superior Thermal Stability Based on Self-Limited TiOx. Electronics, 12(11), 2426. https://doi.org/10.3390/electronics12112426