Design Space of GaN Vertical Trench Junction Barrier Schottky Diodes: Comprehensive Study and Analytical Modeling

Abstract

:1. Introduction

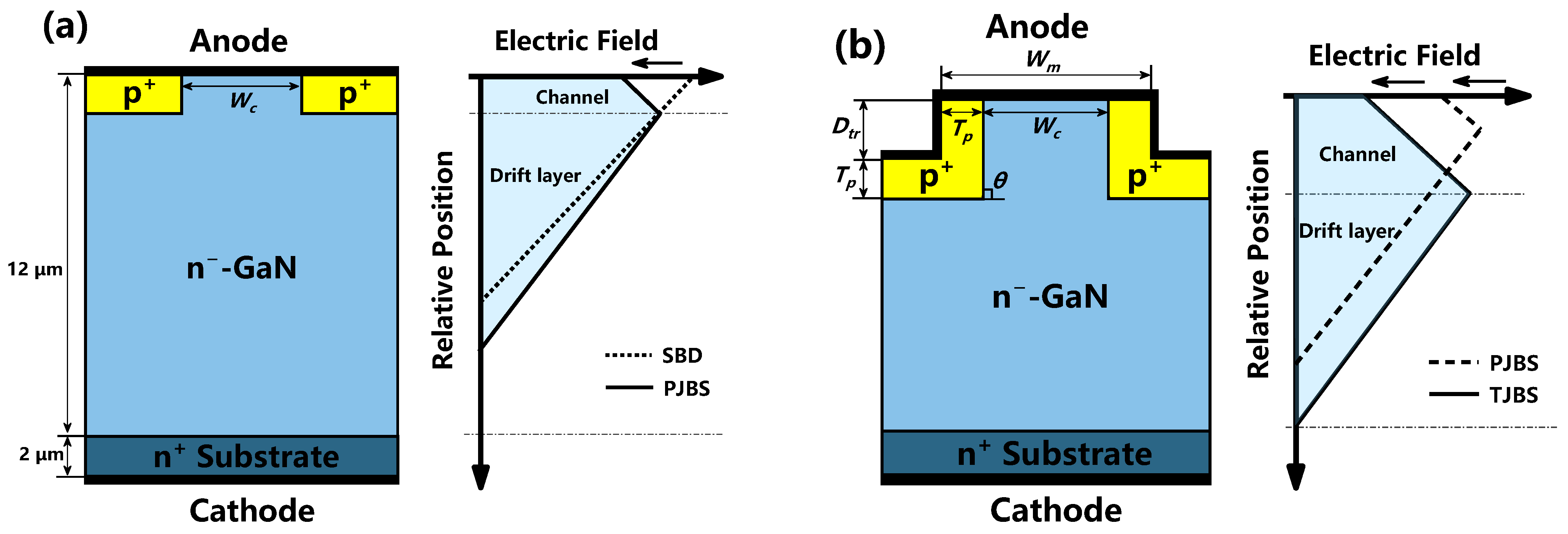

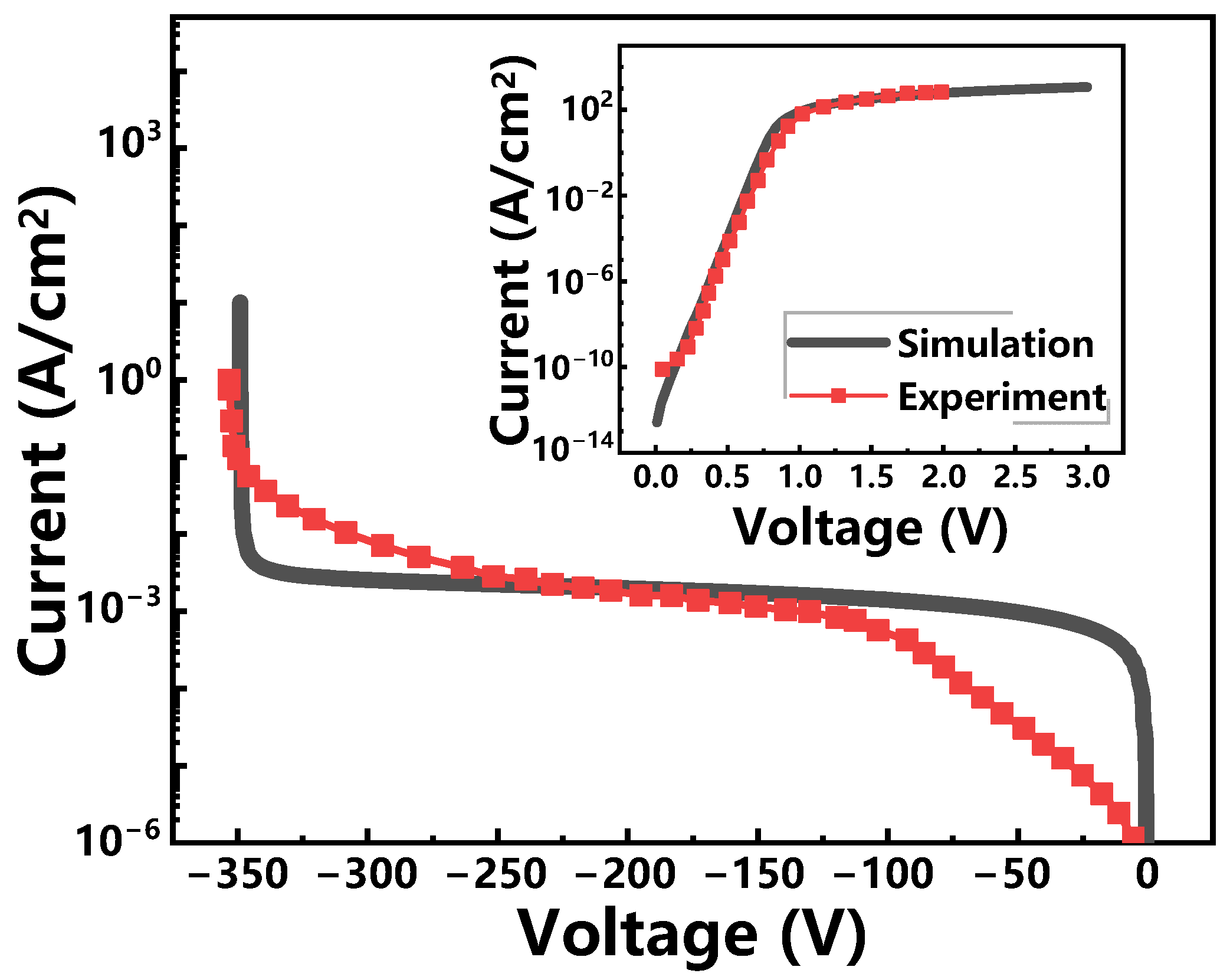

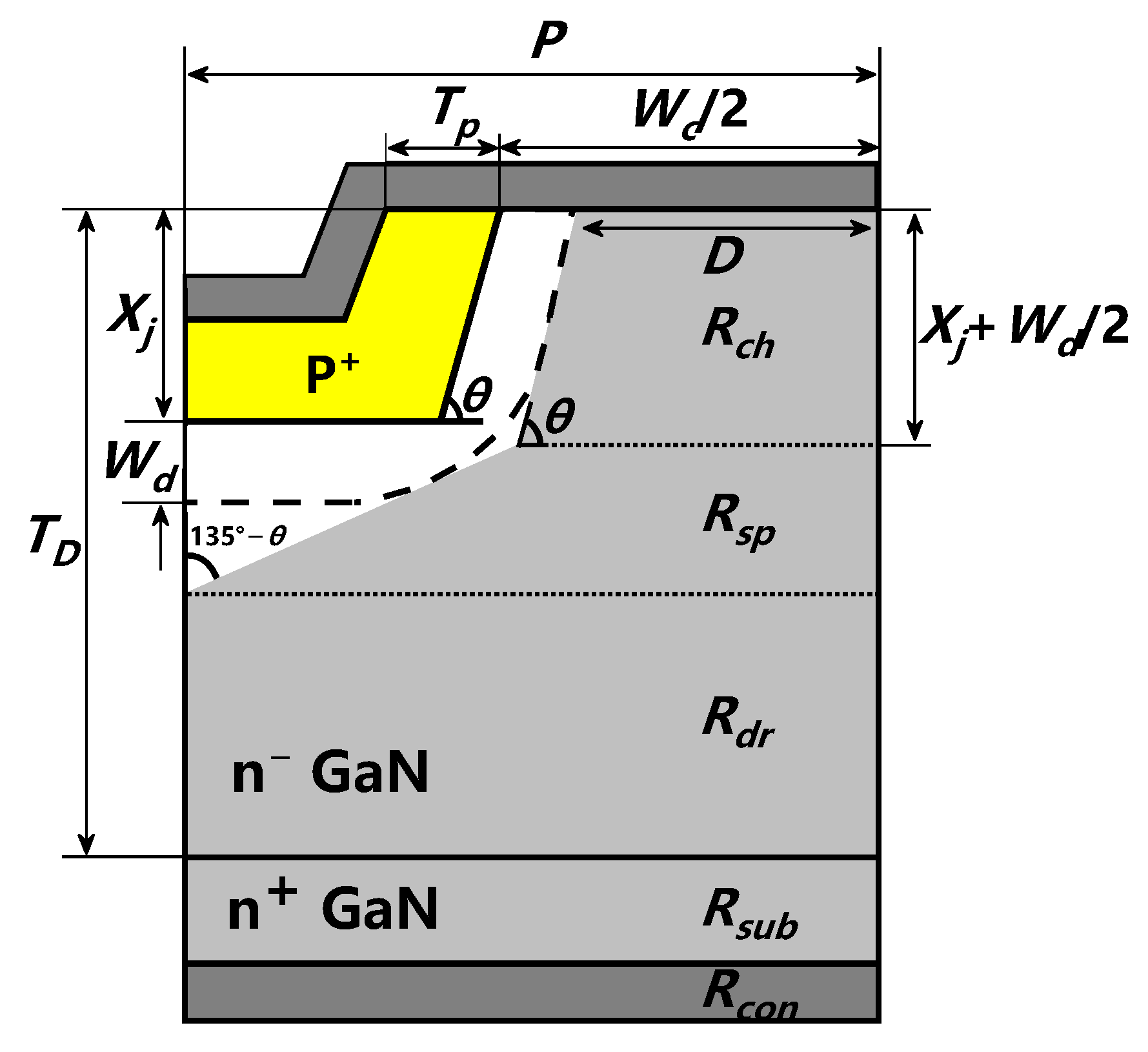

2. Device Architectures and Principles

3. Results and Discussion

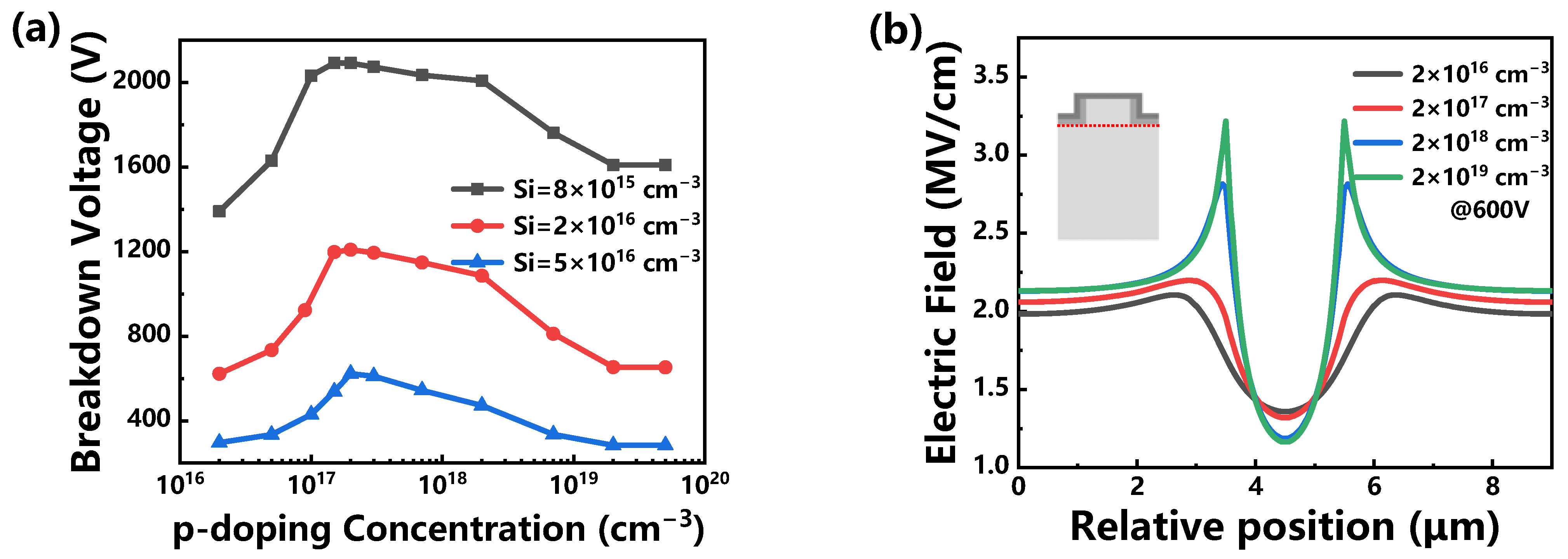

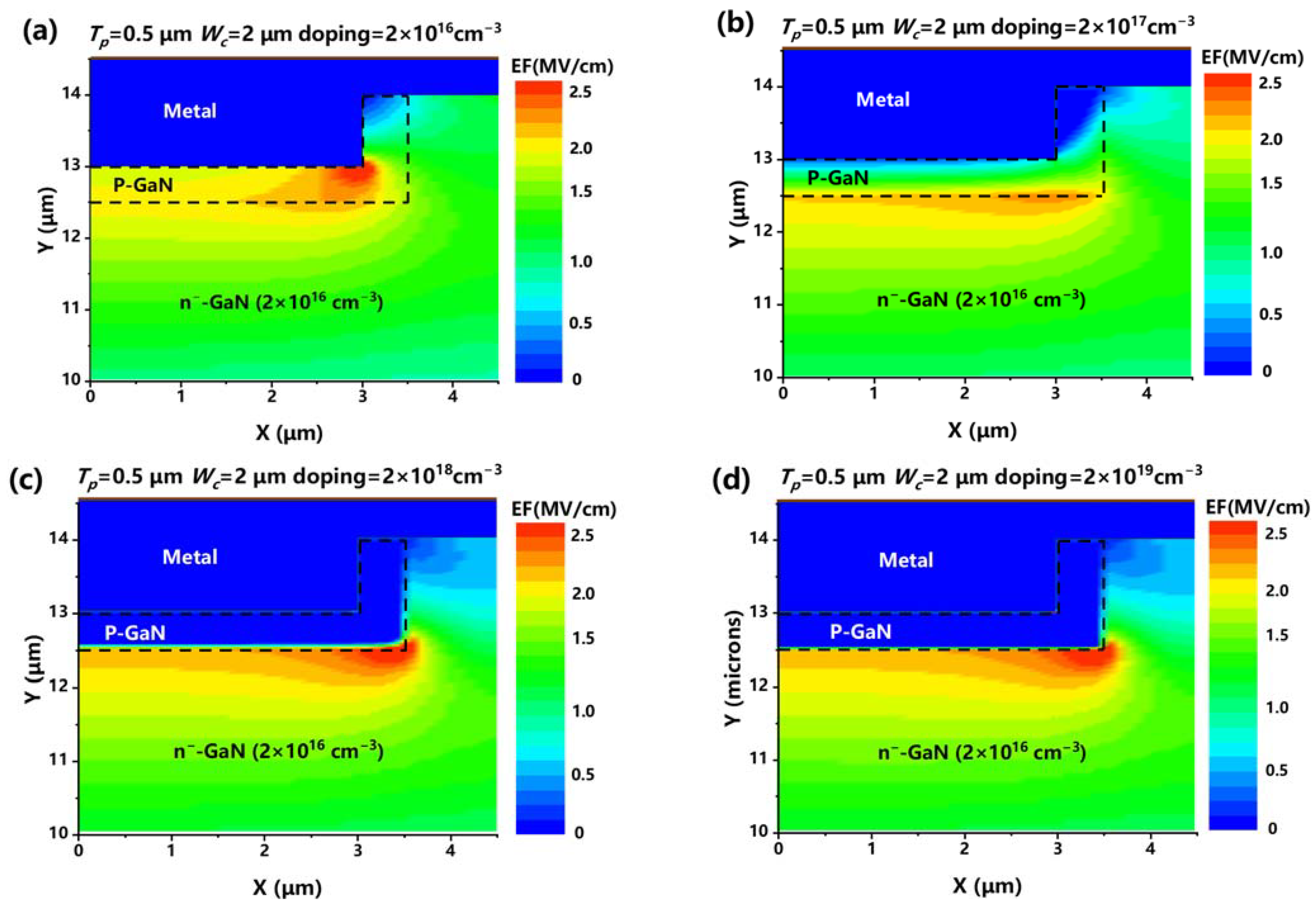

3.1. Effect of p-Doping Concentration and Thickness on the Reverse Blocking Performances of TJBS Diodes

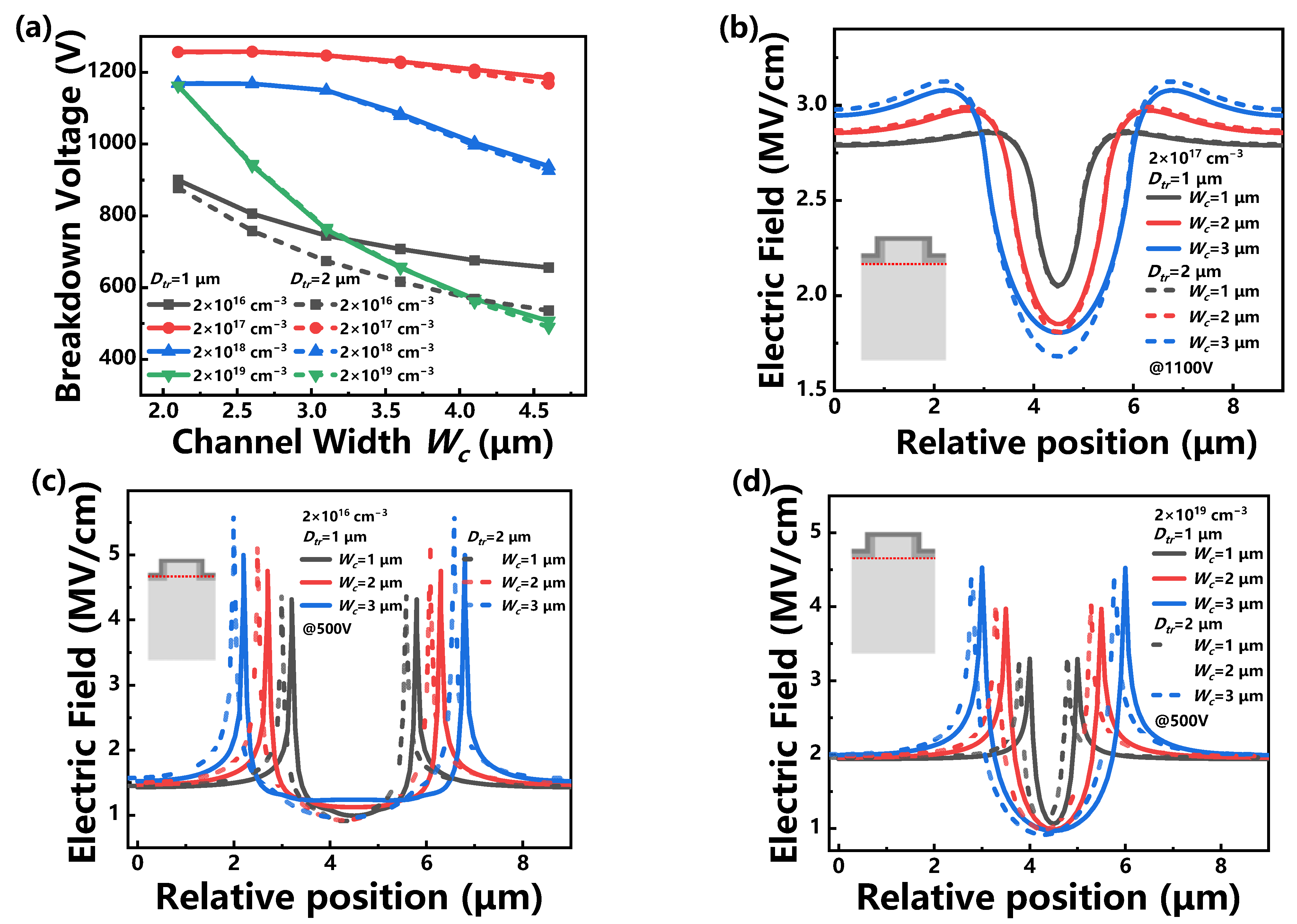

3.2. Effect of p-GaN Spacing and Trench Depth on the Reverse Blocking Performances of TJBS Diodes

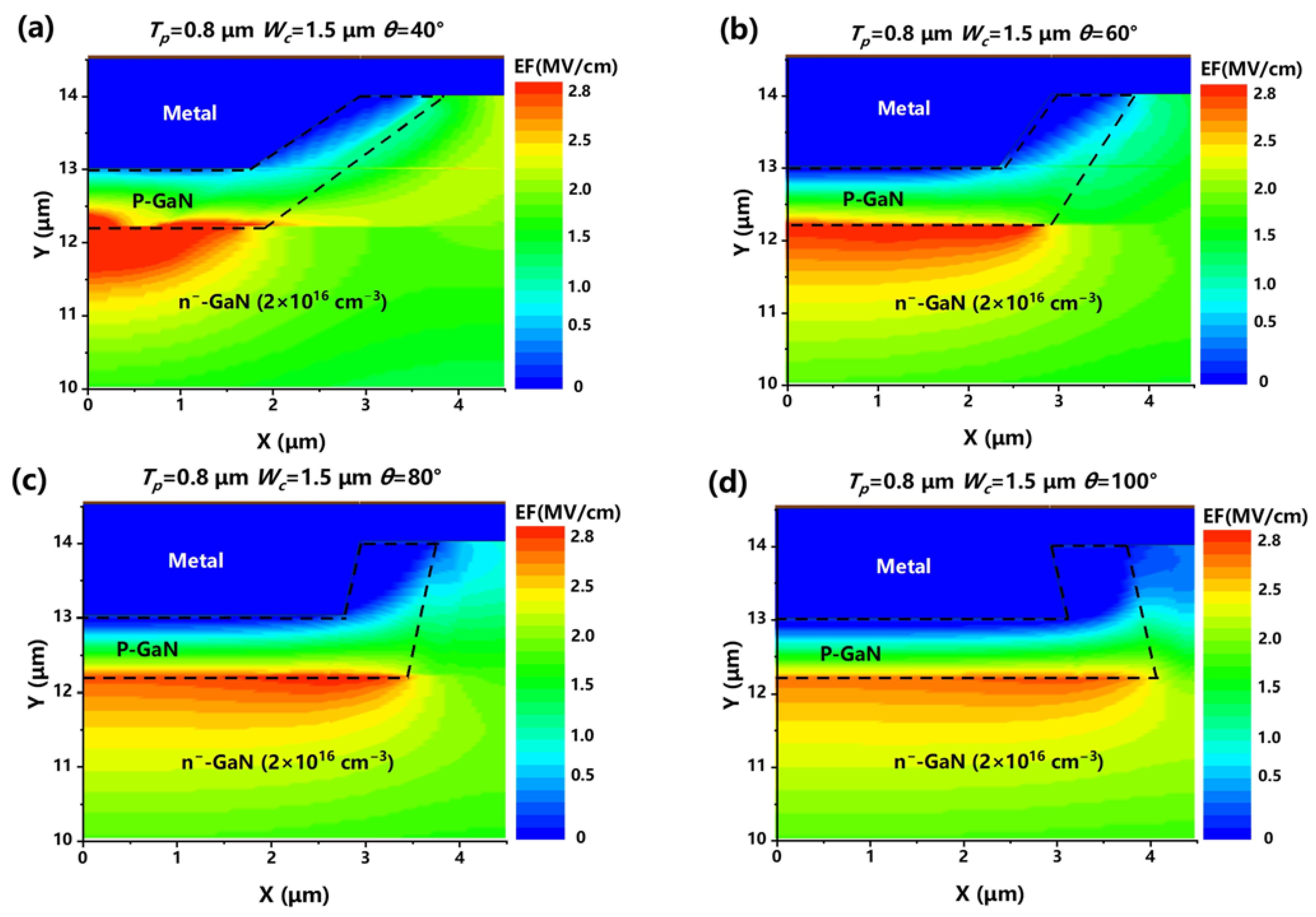

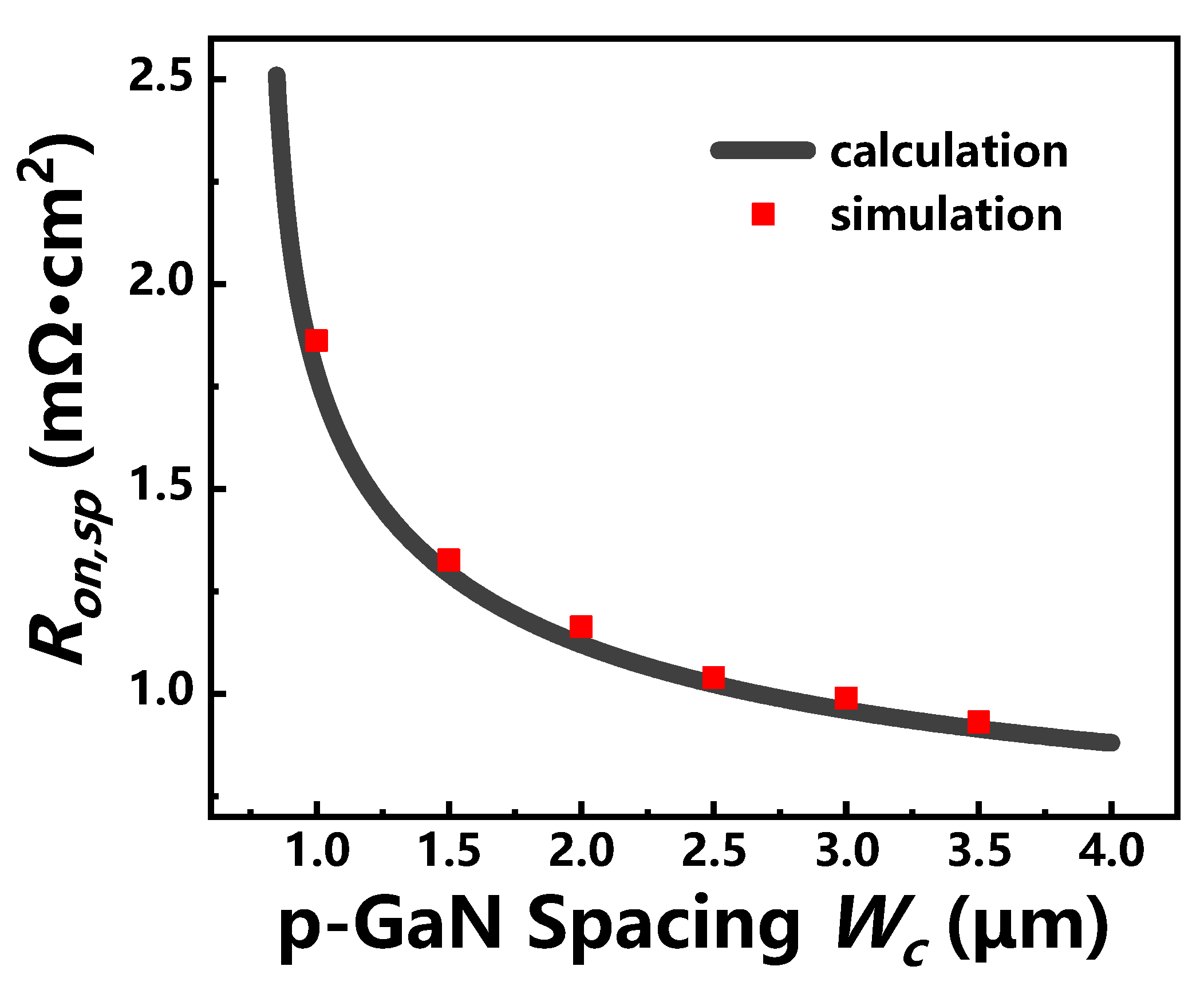

3.3. Effect of Trench Bevel on the Blocking Performances and Forward Characteristics of TJBS Diodes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Millán, J.; Godignon, P.; Perpiñà, X.; Pérez-Tomás, A.; Rebollo, J. A Survey of Wide Bandgap Power Semiconductor Devices. IEEE Trans. Power Electron. 2014, 29, 21553. [Google Scholar] [CrossRef]

- Roccaforte, F.; Fiorenza, P.; Greco, G.; Nigro, R.L.; Giannazzo, F.; Iucolano, F.; Saggio, M. Emerging trends in wide band gap semiconductors (SiC and GaN) technology for power devices. Microelectron. Eng. 2018, 187, 66–77. [Google Scholar] [CrossRef]

- Liu, C.; Khadar, R.A.; Matioli, E. GaN-on-Si Quasi-Vertical Power MOSFETs. IEEE Electron Device Lett. 2018, 39, 71–74. [Google Scholar] [CrossRef]

- Khadar, R.A.; Floriduz, A.; Liu, C.; Soleimanzadeh, R.; Matioli, E. Quasi-vertical GaN-on-Si reverse blocking power MOSFETs. Appl. Phys. Express 2021, 14, 046503. [Google Scholar] [CrossRef]

- Liu, C.; Khadar, R.A.; Matioli, E. Vertical GaN-on-Si MOSFETs with Monolithically Integrated Freewheeling Schottky Barrier Diodes. IEEE Electron Device Lett. 2018, 39, 1034–1037. [Google Scholar] [CrossRef]

- Fu, H.; Huang, X.; Chen, H.; Lu, Z.; Baranowski, I.; Zhao, Y. Ultra-low turn-on voltage and on-resistance vertical GaN-on-GaN Schottky power diodes with high mobility double drift layers. Appl. Phys. Lett. 2017, 111, 152102. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.; Xu, W.; Ren, F.; Zhou, D.; Chen, D.; Zhang, R.; Zheng, Y.; Zhu, T.; Lu, H. High-Voltage Quasi-Vertical GaN Junction Barrier Schottky Diode with Fast Switching Characteristics. IEEE Electron Device Lett. 2021, 42, 974–977. [Google Scholar] [CrossRef]

- Khadar, R.A.; Floriduz, A.; Wang, T.; Matioli, E. p-NiO junction termination extensions for GaN power devices. Appl. Phys. Express 2021, 14, 071006. [Google Scholar] [CrossRef]

- Bian, Z.; Zhang, T.; Zhang, J.; Zhao, S.; Zhou, H.; Xue, J.; Duan, X.; Zhang, Y.; Chen, J.; Dang, K. Leakage mechanism of quasi-vertical GaN Schottky barrier diodes with ultra-low turn-on voltage. Appl. Phys. Express 2019, 12, 084004. [Google Scholar] [CrossRef]

- Hasegawa, K.; Nishio, G.; Yasunishi, K.; Tanaka, N.; Murakami, N.; Oka, T. Vertical GaN trench MOS barrier Schottky rectifier maintaining low leakage current at 200 °C with blocking voltage of 750 V. Appl. Phys. Express 2017, 10, 121002-1–121002-3. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, M.; Liu, Z.; Piedra, D.; Pan, M.; Gao, X.; Lin, Y.; Zubair, A.; Yu, L.; Palacios, T. Novel GaN trench MIS barrier Schottky rectifiers with implanted field rings. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; pp. 10.2.1–10.2.4. [Google Scholar]

- Chen, S.; Chen, H.; Qiu, Y.; Liu, C. Systematic Design and Parametric Analysis of GaN Vertical Trench MOS Barrier Schottky Diode with p-GaN Shielding Rings. IEEE Trans. Electron Devices. 2021, 68, 5707–5713. [Google Scholar] [CrossRef]

- Hayashida, T.; Nanjo, T.; Furukawa, A.; Yamamuka, M. Vertical GaN merged PiN Schottky diode with a breakdown voltage of 2 kV. Appl. Phys. Express 2017, 10, 061003-1–061003-3. [Google Scholar] [CrossRef]

- Li, W.; Nomoto, K.; Pilla, M.; Pan, M.; Gao, X.; Jena, D.; Xing, H.G. Design and Realization of GaN Trench Junction-Barrier-Schottky-Diodes. IEEE Trans. Electron Devices 2017, 64, 1635–1641. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.H.; Tadjer, M.J.; Sun, M.; Hatem, D.P.C.; Anderson, T.J.; Luna, L.E.; Nath, A.; Koehler, A.D.; Okumura, H.; et al. Vertical GaN Junction Barrier Schottky Rectifiers by Selective Ion Implantation. IEEE Electron Device Lett. 2017, 38, 1097–1100. [Google Scholar] [CrossRef]

- Koehler, A.D.; Anderson, T.J.; Tadjer, M.J.; Nath, A.; Feigelson, B.N.; Shahin, D.I.; Hobart, K.D.; Kub, F.J. Vertical GaN junction barrier Schottky diodes. ECS J. Solid State Sci. Technol. 2016, 6, Q10–Q12. [Google Scholar] [CrossRef]

- Zhou, F.; Xu, W.; Ren, F.; Zhou, D.; Chen, D.; Zhang, R.; Zheng, Y.; Zhu, T.; Lu, H. Demonstration of Avalanche and Surge Current Robustness in GaN Junction Barrier Schottky Diode with 600-V/10-A Switching Capability. IEEE Trans. Power Electron. 2021, 36, 12163–12167. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, Y.; Sun, M.; Piedra, D.; Piedra, N.; Chowdhury, N.; Palacios, T. Materials and processing issues in vertical GaN power electronics. Mater. Sci. Semicond. Process 2018, 78, 75–84. [Google Scholar] [CrossRef] [Green Version]

- Narita, T.; Yoshida, H.; Tomita1, K.; Kataoka, K.; Sakurai, H.; Horita, M.; Bockowski, M.; Ikarashi, N.; Suda, J.; Kachi, T.; et al. Progress on and challenges of p-type formation for GaN power devices. J. Appl. Phys. 2020, 128, 090901. [Google Scholar] [CrossRef]

- Dou, W.; Song, Q.; Yuan, H.; Tanga, X.; Zhang, Y.; Zhang, Y.; Xiao, L.; Wang, L. Design and fabrication of high performance 4H-SiC TJBS diodes. J. Cryst. Growth 2020, 533, 125421. [Google Scholar] [CrossRef]

- Ren, N.; Wang, J.; Sheng, K. Design and Experimental Study of 4H-SiC Trenched Junction Barrier Schottky Diodes. IEEE Trans. Electron Devices 2014, 61, 2459–2465. [Google Scholar] [CrossRef]

- Konishi, K.; Kameshiro, N.; Yokoyama, N.; Shima, A.; Shimamoto, Y. Effect of trench structure on reverse characteristics of 4H-SiC junction barrier Schottky diodes. Jpn. J. Appl. Phys. 2017, 56, 121301-1–121301-6. [Google Scholar] [CrossRef]

- Oikawa, T.; Saijo, Y.; Kato, S.; Mishima, T.; Nakamura, T. Formation of definite GaN p-n junction by Mg-ion implantation to n--GaN epitaxial layers grown on a high-quality free-standing GaN substrate. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms. 2015, 365, 168–170. [Google Scholar] [CrossRef]

- He, Y.; Lv, H.; Tang, X.; Song, Q.; Zhang, Y.; Han, C.; Zhang, Y.; Zhang, Y. Experimental study on the 4H-SiC-based VDMOSFETs with lightly doped P-well field-limiting rings termination. Solid-State Electron. 2017, 129, 175–181. [Google Scholar] [CrossRef]

- Crosslight Software Inc. APSYS 2018 and APSYS Technical Manuals. Available online: http://www.crosslight.com (accessed on 1 September 2020).

- Chynoweth, A.G. Ionization rates for electrons and holes in silicon. Phys. Rev. 1958, 109, 1537–1540. [Google Scholar] [CrossRef]

- Sundaramoorthy, V.K.; Nistor, I. Study of edge termination structures for high power GaN Schottky diodes. Phys. Status Solidi 2011, 8, 2270–2272. [Google Scholar] [CrossRef]

- Kozodoy, P.; DenBaars, S.P.; Mishra, U.K. Depletion region effects in Mg-doped GaN. J. Appl. Phys. 1999, 87, 770–775. [Google Scholar] [CrossRef]

- Han, S.; Yang, S.; Sheng, K. High-voltage and high-Ion/Ioff vertical GaN-on-GaN Schottky barrier diode with nitridation-based termination. IEEE Electron Device Lett. 2018, 39, 572–575. [Google Scholar] [CrossRef]

- Zhu, L.; Chow, T.P. Analytical Modeling of High-Voltage 4H-SiC Junction Barrier Schottky (JBS) Rectifiers. IEEE Trans. Electron Devices 2008, 55, 1857–1863. [Google Scholar] [CrossRef]

- Liu, H.; Fu, H.; Fu, K.; Alugubelli, S.R.; Su, P.-Y.; Zhao, Y.; Ponce, F.A. Non-uniform Mg distribution in GaN epilayers grown on mesa structures for applications in GaN power electronics. Appl. Phys. Lett. 2019, 114, 082102. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Chen, S.; Chen, H.; Li, S.; Fu, H.; Liu, C. Design Space of GaN Vertical Trench Junction Barrier Schottky Diodes: Comprehensive Study and Analytical Modeling. Electronics 2022, 11, 1972. https://doi.org/10.3390/electronics11131972

Yin J, Chen S, Chen H, Li S, Fu H, Liu C. Design Space of GaN Vertical Trench Junction Barrier Schottky Diodes: Comprehensive Study and Analytical Modeling. Electronics. 2022; 11(13):1972. https://doi.org/10.3390/electronics11131972

Chicago/Turabian StyleYin, Jian, Sihao Chen, Hang Chen, Shuti Li, Houqiang Fu, and Chao Liu. 2022. "Design Space of GaN Vertical Trench Junction Barrier Schottky Diodes: Comprehensive Study and Analytical Modeling" Electronics 11, no. 13: 1972. https://doi.org/10.3390/electronics11131972

APA StyleYin, J., Chen, S., Chen, H., Li, S., Fu, H., & Liu, C. (2022). Design Space of GaN Vertical Trench Junction Barrier Schottky Diodes: Comprehensive Study and Analytical Modeling. Electronics, 11(13), 1972. https://doi.org/10.3390/electronics11131972