Optimization of Oxygen Plasma Treatment on Ohmic Contact for AlGaN/GaN HEMTs on High-Resistivity Si Substrate

Abstract

:1. Introduction

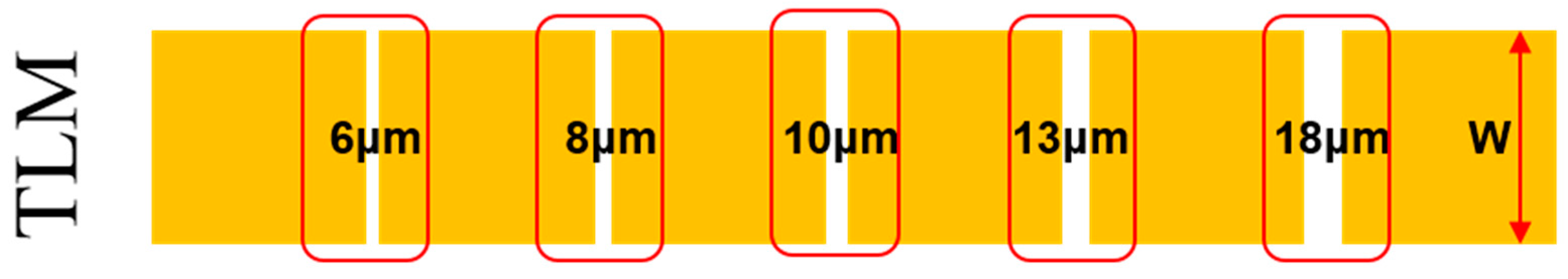

2. Materials and Methods

3. Results and Discussion

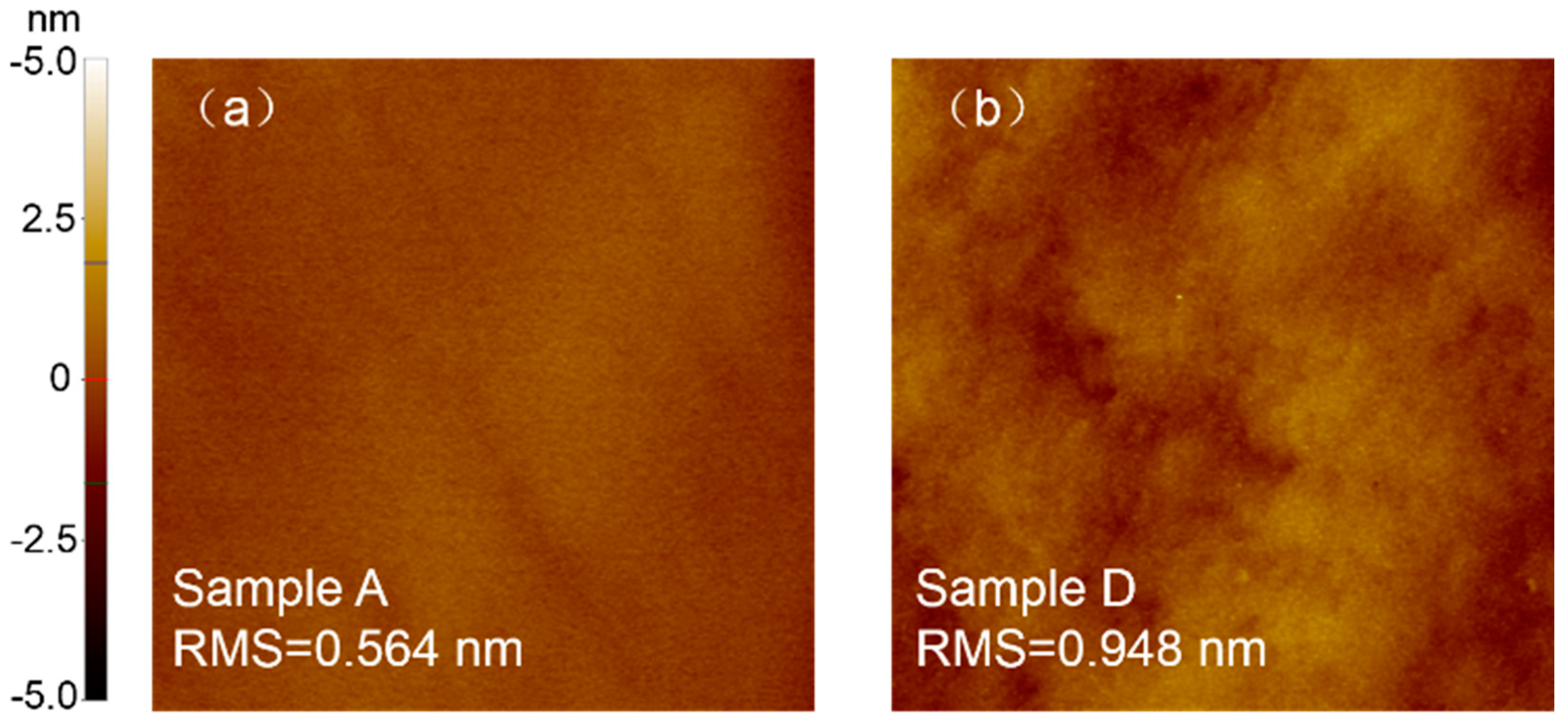

3.1. Material Characterization and Analysis

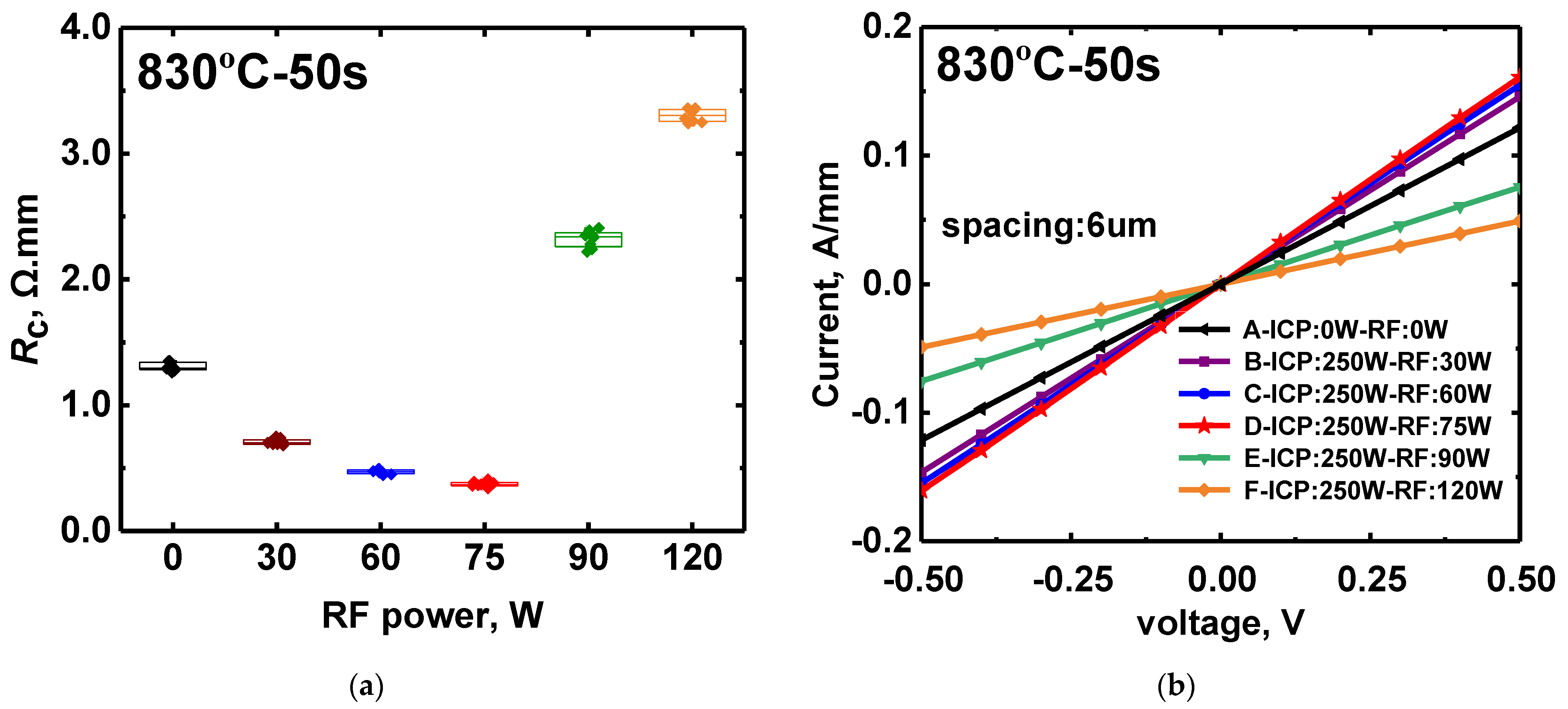

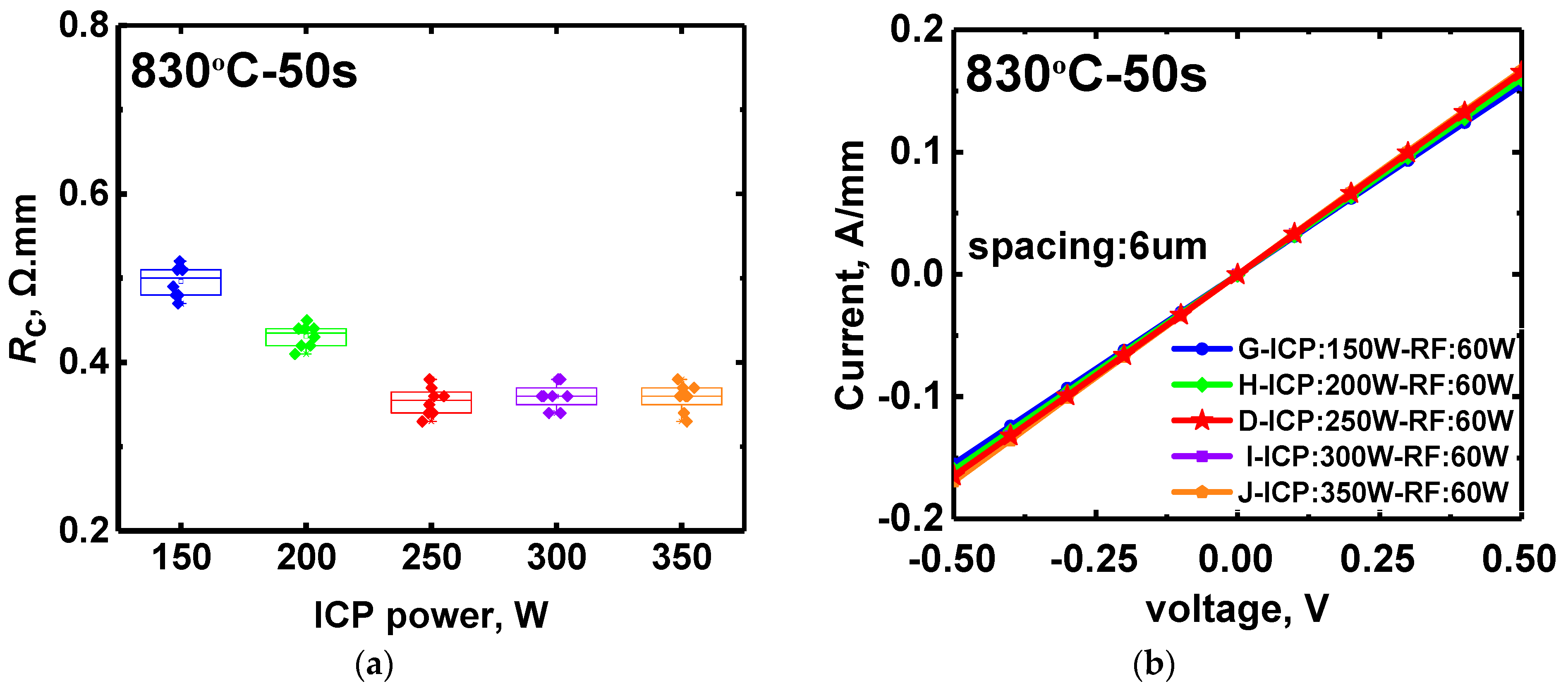

3.2. Study the Influence of RF Power and ICP Power

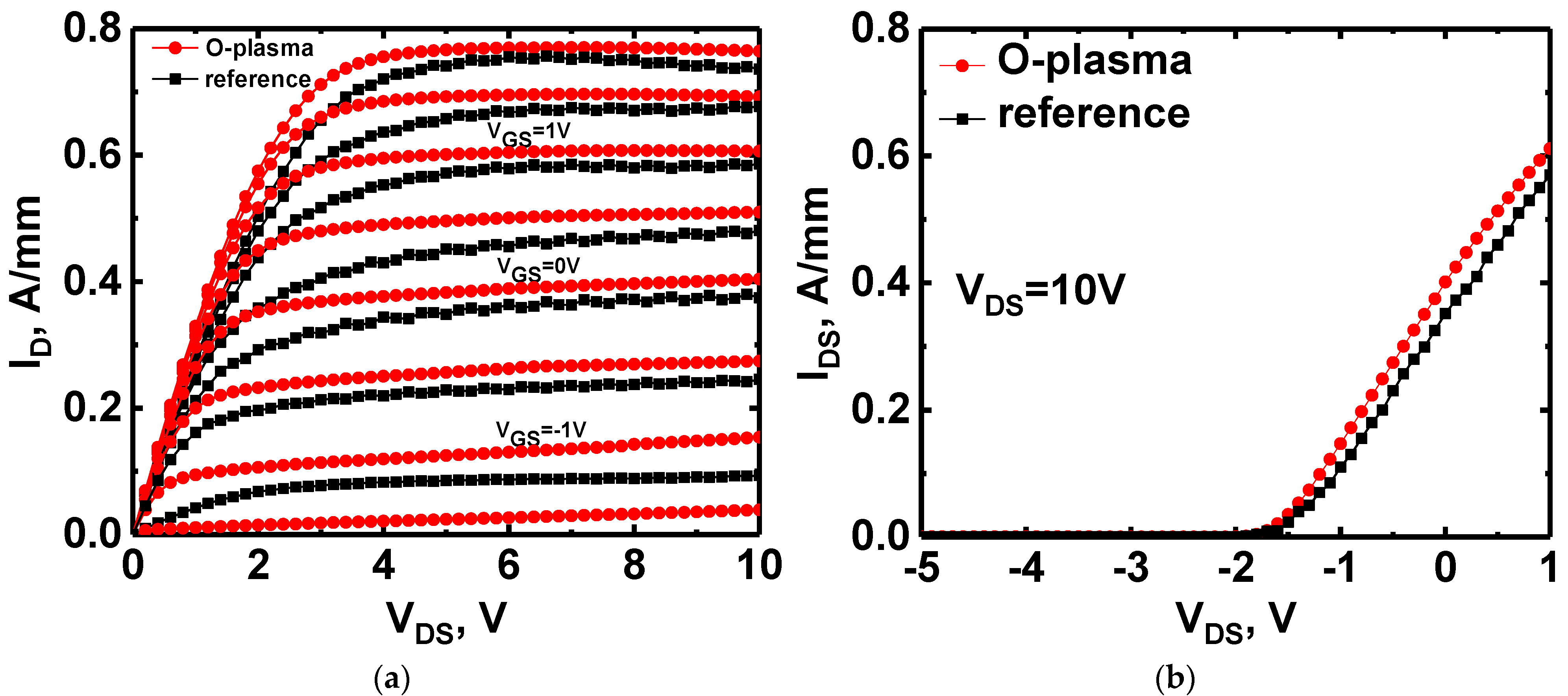

3.3. AlGaN/GaN HEMTs DC Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Asif Khan, M.; Bhattarai, A.; Kuznia, J.N.; Olson, D.T. High electron mobility transistor based on a GaN-AlxGa1−xN heterojunction. Appl. Phys. Lett. 1993, 63, 1214–1215. [Google Scholar] [CrossRef]

- Wu, H.; Kang, X.; Zheng, Y.; Wei, K.; Sun, Y.; Li, P.; Liu, X.; Zhang, G. Analysis of reverse leakage mechanism in recess-free thin-barrier AlGaN/GaN Schottky barrier diode. Jpn. J. Appl. Phys. 2021, 60, 024002. [Google Scholar] [CrossRef]

- Lu, Y.; Ma, X.; Yang, L.; Hou, B.; Mi, M.; Zhang, M.; Hao, Y. High RF performance AlGaN/GaN HEMT fabricated by recess-arrayed ohmic contact technology. IEEE Electron Device Lett. 2018, 39, 811–814. [Google Scholar] [CrossRef]

- Kang, X.; Wang, X.; Huang, S.; Zhang, J.; Fan, J.; Yang, S.; Wang, Y.; Zheng, Y.; Wei, K.; Zhi, J.; et al. Recess-free AlGaN/GaN lateral Schottky barrier controlled Schottky rectifier with low turn-on voltage and high reverse blocking. In Proceedings of the 2018 IEEE 30th International Symposium on Power Semiconductor Devices and ICs, (ISPSD), Chicago, IL, USA, 13–17 May 2018. [Google Scholar]

- Zhang, J.; Kang, X.; Wang, X.; Huang, S.; Chen, C.; Wei, K.; Liu, X. Ultralow-contact-resistance Au-free ohmic contacts with low annealing temperature on AlGaN/GaN heterostructures. IEEE Electron Device Lett. 2018, 39, 847–850. [Google Scholar] [CrossRef]

- Li, X.; Gao, S.; Zhou, Q.; Liu, X.; Hu, W.; Wang, H. Fabrication and performance of Ti/Al/Ni/TiN Au-free ohmic contacts for undoped AlGaN/GaN HEMT. IEEE Trans. Electron Devices 2020, 67, 1959–1964. [Google Scholar] [CrossRef]

- Fan, M.Y.; Yang, G.Y.; Zhou, G.N.; Jiang, Y.; Li, W.M.; Jiang, Y.L.; Yu, H.Y. Ultra-Low Contact Resistivity of <0.1 Ω∙mm for Au-Free TixAly Alloy Contact on Non-Recessed i-AlGaN/GaN. IEEE Electron Device Lett. 2019, 41, 143–146. [Google Scholar]

- Van Daele, B.; Van Tendeloo, G.; Ruythooren, W.; Derluyn, J.; Leys, M.R.; Germain, M. The role of Al on Ohmic contact formation on n-type GaN and AlGaN/GaN. Appl. Phys. Lett. 2005, 87, 061905. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, S.; Bao, Q.; Wang, X.; Wei, K.; Zheng, Y.; Zhang, B. Mechanism of Ti/Al/Ti/W Au-free ohmic contacts to AlGaN/GaN heterostructures via pre-ohmic recess etching and low temperature annealing. Appl. Phys. Lett. 2015, 107, 262109. [Google Scholar] [CrossRef]

- Benakaprasad, B.; Eblabla, A.M.; Li, X.; Crawford, K.G.; Elgaid, K. Optimization of ohmic contact for AlGaN/GaN HEMT on low-resistivity silicon. IEEE Trans. Electron Devices 2020, 67, 863–868. [Google Scholar] [CrossRef]

- Lau, W.S.; Tan, J.B.; Singh, B.P. Formation of Ohmic contacts in AlGaN/GaN HEMT structures at 500°C by Ohmic contact recess etching. Microelectron. Reliab. 2009, 49, 558–561. [Google Scholar] [CrossRef]

- Yanxu, Z.; Weiwei, C.; Yuyu, F.; Ye, D.; Chen, X. Effects of rapid thermal annealing on ohmic contact of AlGaN/GaN HEMTs. J. Semicond. 2014, 35, 026004. [Google Scholar]

- Zhang, L.Q.; Shi, J.S.; Huang, H.F.; Liu, X.Y.; Zhao, S.X.; Wang, P.F.; Zhang, D.W. Low-temperature Ohmic contact formation in GaN high electron mobility transistors using microwave annealing. IEEE Electron Device Lett. 2015, 36, 896–898. [Google Scholar] [CrossRef]

- Sharma, C.; Visvkarma, A.K.; Laishram, R.; Kumar, A.; Rawal, D.S.; Vinayak, S.; Singh, R. Effect of γ-ray irradiation on Schottky and ohmic contacts on AlGaN/GaN hetero-structures. Microelectron. Reliab. 2020, 105, 113565. [Google Scholar] [CrossRef]

- Van Daele, B.; Van Tendeloo, G.; Derluyn, J.; Shrivastava, P.; Lorenz, A.; Leys, M.R.; Germain, M. Mechanism for Ohmic contact formation on Si3N4 passivated AlGaN/GaN high-electron-mobility transistors. Appl. Phys. Lett. 2006, 89, 201908. [Google Scholar] [CrossRef]

- Onojima, N.; Hirose, N.; Mimura, T.; Matsui, T. Effects of Si deposition on AlGaN barrier surfaces in GaN heterostructure field-effect transistors. Appl. Phys. Express 2008, 1, 071101. [Google Scholar] [CrossRef]

- Yu, H.; McCarthy, L.; Rajan, S.; Keller, S.; Denbaars, S.; Speck, J.; Mishra, U. Ion implanted AlGaN-GaN HEMTs with nonalloyed ohmic contacts. IEEE Electron Device Lett. 2005, 26, 283–285. [Google Scholar]

- Song, B.; Zhu, M.; Hu, Z.; Qi, M.; Nomoto, K.; Yan, X.; Xing, H.G. Ultralow-leakage AlGaN/GaN high electron mobility transistors on Si with non-alloyed regrown ohmic contacts. IEEE Electron Device Lett. 2015, 37, 16–19. [Google Scholar] [CrossRef]

- Song, L.; Fu, K.; Zhao, J.; Yu, G.; Hao, R.; Zhang, X.; Zhang, B. Influence factors and temperature reliability of ohmic contact on AlGaN/GaN HEMTs. AIP Adv. 2018, 8, 035213. [Google Scholar] [CrossRef]

- Greco, G.; Iucolano, F.; Roccaforte, F. Ohmic contacts to Gallium Nitride materials. Appl. Surf. Sci. 2016, 383, 324–345. [Google Scholar] [CrossRef]

- Sun, C.; Hao, R.; Xu, N.; He, T.; Shi, F.; Yu, G.; Zhang, B. Normally-off p-GaN/AlGaN/GaN high-electron-mobility transistors using oxygen plasma treatment. Appl. Phys. Express 2019, 12, 051001. [Google Scholar] [CrossRef]

- Lee, J.H.; Im, K.S. Effects of Al Composition and High-Temperature Atomic Layer-Deposited Al2O3 Layer on the Leakage Current Characteristics of AlGaN/GaN Schottky Barrier Diodes. Crystals 2021, 11, 87. [Google Scholar] [CrossRef]

- Zhao, Z.; Kang, X.; Yang, B.; Zhang, J.; Wu, H.; Sun, Y.; Zheng, Y.; Wei, K. Reduction of isolation current by annealing treatment for AlGaN/GaN mesa region. Semicond. Technol. 2020, 45, 293–297. [Google Scholar]

- Xu, H.Z.; Bell, A.; Wang, Z.G.; Okada, Y.; Kawabe, M.; Harrison, I.; Foxon, C.T. Competition between band gap and yellow luminescence in undoped GaN grown by MOVPE on sapphire substrate. J. Cryst. Growth 2001, 222, 96–103. [Google Scholar] [CrossRef]

- Julkarnain, M.; Kamata, N.; Fukuda, T.; Arakawa, Y. Yellow luminescence band in undoped GaN revealed by two-wavelength excited photoluminescence. Opt. Mater. 2016, 60, 481–486. [Google Scholar] [CrossRef]

- Mattila, T.; Nieminen, R.M. Point-defect complexes and broadband luminescence in GaN and AlN. Phys. Rev. B. 1997, 55, 9571. [Google Scholar] [CrossRef] [Green Version]

- Neugebauer, J.; Van de Walle, C.G. Gallium vacancies and the yellow luminescence in GaN. Appl. Phys. Lett. 1996, 69, 503–505. [Google Scholar] [CrossRef] [Green Version]

- Hino, T.; Tomiya, S.; Miyajima, T.; Yanashima, K.; Hashimoto, S.; Ikeda, M. Characterization of threading dislocations in GaN epitaxial layers. Appl. Phys. Lett. 2000, 76, 3421–3423. [Google Scholar] [CrossRef]

- Wang, C.; He, Y.; Zheng, X.; Zhao, M.; Mi, M.; Li, X.; Hao, Y. Low ohmic-contact resistance in AlGaN/GaN high electron mobility transistors with holes etching in ohmic region. Electron. Lett. 2015, 51, 2145–2147. [Google Scholar] [CrossRef]

- Cao, X.A.; Piao, H.; LeBoeuf, S.F.; Li, J.; Lin, J.Y.; Jiang, H.X. Effects of plasma treatment on the Ohmic characteristics of Ti/Al/Ti/Au contacts to n-AlGaN. Appl. Phys. Lett. 2006, 89, 082109. [Google Scholar] [CrossRef]

- Yan, J.; Kappers, M.J.; Barber, Z.H.; Humphreys, C.J. Effects of oxygen plasma treatments on the formation of ohmic contacts to GaN. Appl. Surf. Sci. 2004, 234, 328–332. [Google Scholar] [CrossRef]

- Wetzel, C.; Suski, T.; Ager Iii, J.W.; Weber, E.R.; Haller, E.E.; Fischer, S.; Perlin, P. Pressure induced deep gap state of oxygen in GaN. Phys. Rev. Lett. 1997, 78, 3923. [Google Scholar] [CrossRef]

- Greco, G.; Fiorenza, P.; Giannazzo, F.; Alberti, A.; Roccaforte, F. Nanoscale electrical and structural modification induced by rapid thermal oxidation of AlGaN/GaN heterostructures. Nanotechnology 2013, 25, 025201. [Google Scholar] [CrossRef] [PubMed]

- Nakano, Y.; Kachi, T.; Jimbo, T. n-type doping characteristics of O-implanted GaN. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2003, 21, 2602–2604. [Google Scholar] [CrossRef]

| Sample | Treatment | RF Power (W) | ICP Power (W) |

|---|---|---|---|

| A | reference | 0 | 0 |

| B–F | O-plasma | 30/60/75/90/120 | 250 |

| G–J | O-plasma | 75 | 150/200/300/350 |

| Sample | xGa,3d /% | xN,1s /% | n (xN,1s/xGa,3d) |

|---|---|---|---|

| A | 48.1 | 37.6 | 0.78 |

| D | 47.8 | 8.6 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Wei, S.; Kang, X.; Zheng, Y.; Zhang, J.; Wu, H.; Wei, K.; Yan, J.; Liu, X. Optimization of Oxygen Plasma Treatment on Ohmic Contact for AlGaN/GaN HEMTs on High-Resistivity Si Substrate. Electronics 2021, 10, 855. https://doi.org/10.3390/electronics10070855

Li P, Wei S, Kang X, Zheng Y, Zhang J, Wu H, Wei K, Yan J, Liu X. Optimization of Oxygen Plasma Treatment on Ohmic Contact for AlGaN/GaN HEMTs on High-Resistivity Si Substrate. Electronics. 2021; 10(7):855. https://doi.org/10.3390/electronics10070855

Chicago/Turabian StyleLi, Pengfei, Shuhua Wei, Xuanwu Kang, Yingkui Zheng, Jing Zhang, Hao Wu, Ke Wei, Jiang Yan, and Xinyu Liu. 2021. "Optimization of Oxygen Plasma Treatment on Ohmic Contact for AlGaN/GaN HEMTs on High-Resistivity Si Substrate" Electronics 10, no. 7: 855. https://doi.org/10.3390/electronics10070855

APA StyleLi, P., Wei, S., Kang, X., Zheng, Y., Zhang, J., Wu, H., Wei, K., Yan, J., & Liu, X. (2021). Optimization of Oxygen Plasma Treatment on Ohmic Contact for AlGaN/GaN HEMTs on High-Resistivity Si Substrate. Electronics, 10(7), 855. https://doi.org/10.3390/electronics10070855