Low-Power GPS-Disciplined Oscillator Module for Distributed Wireless Sensor Nodes

Abstract

1. Introduction

GPSDO Commercial Availability

2. GPSDO Overview

2.1. GPSDO Requirements

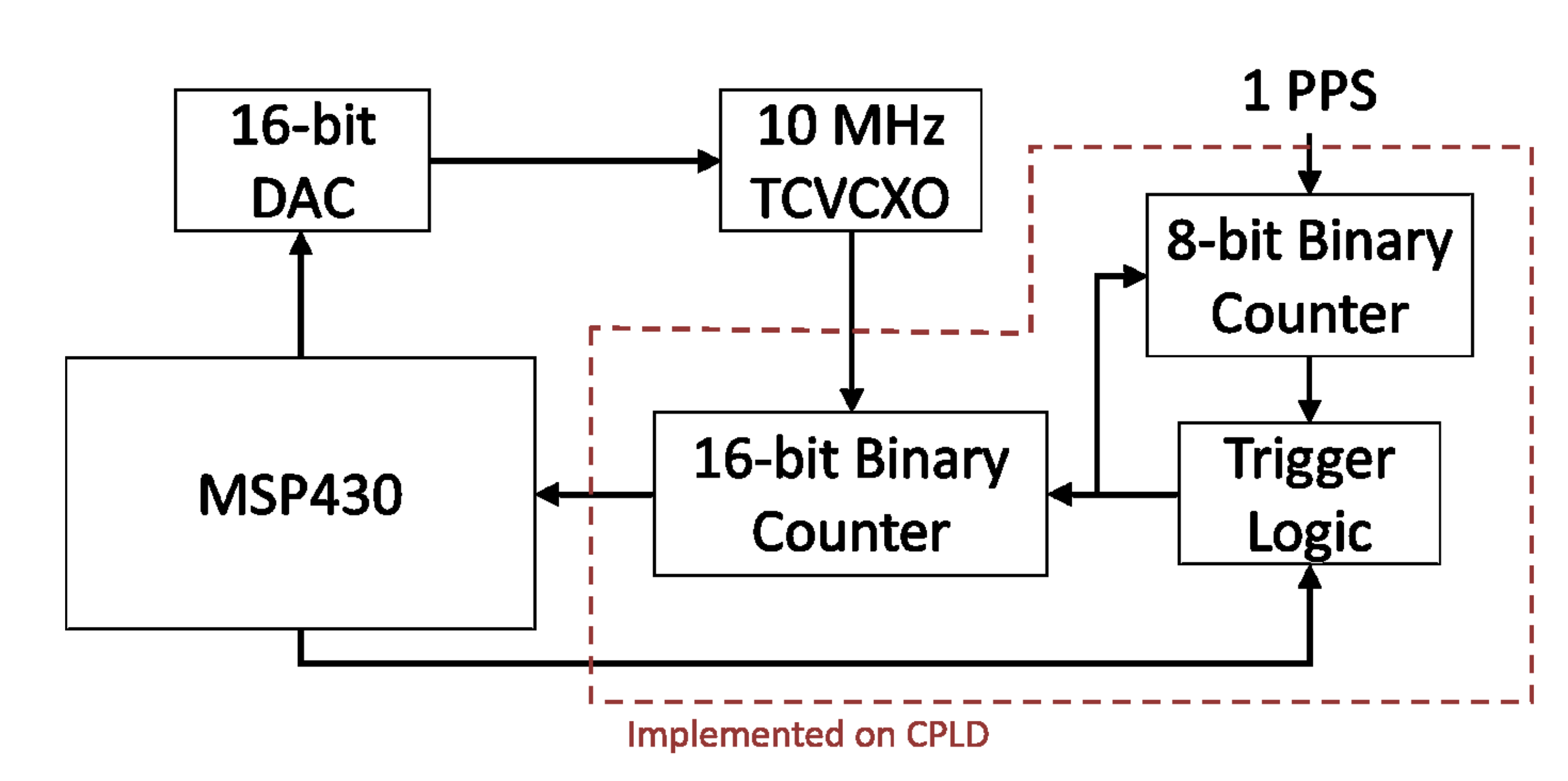

2.2. Hardware

2.3. Software

2.4. Oscillator Control

3. GPSDO Validation

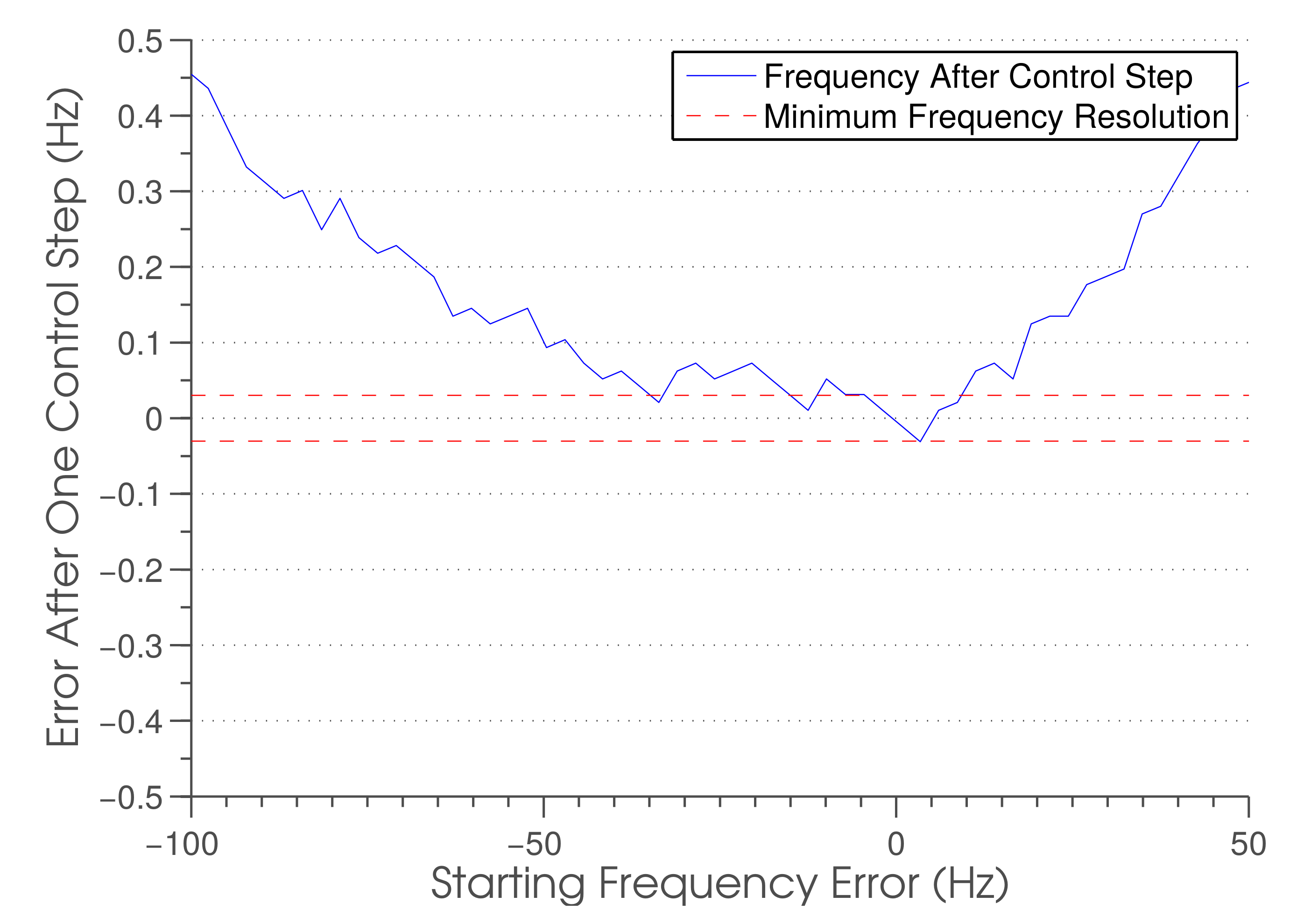

3.1. Control Linearity

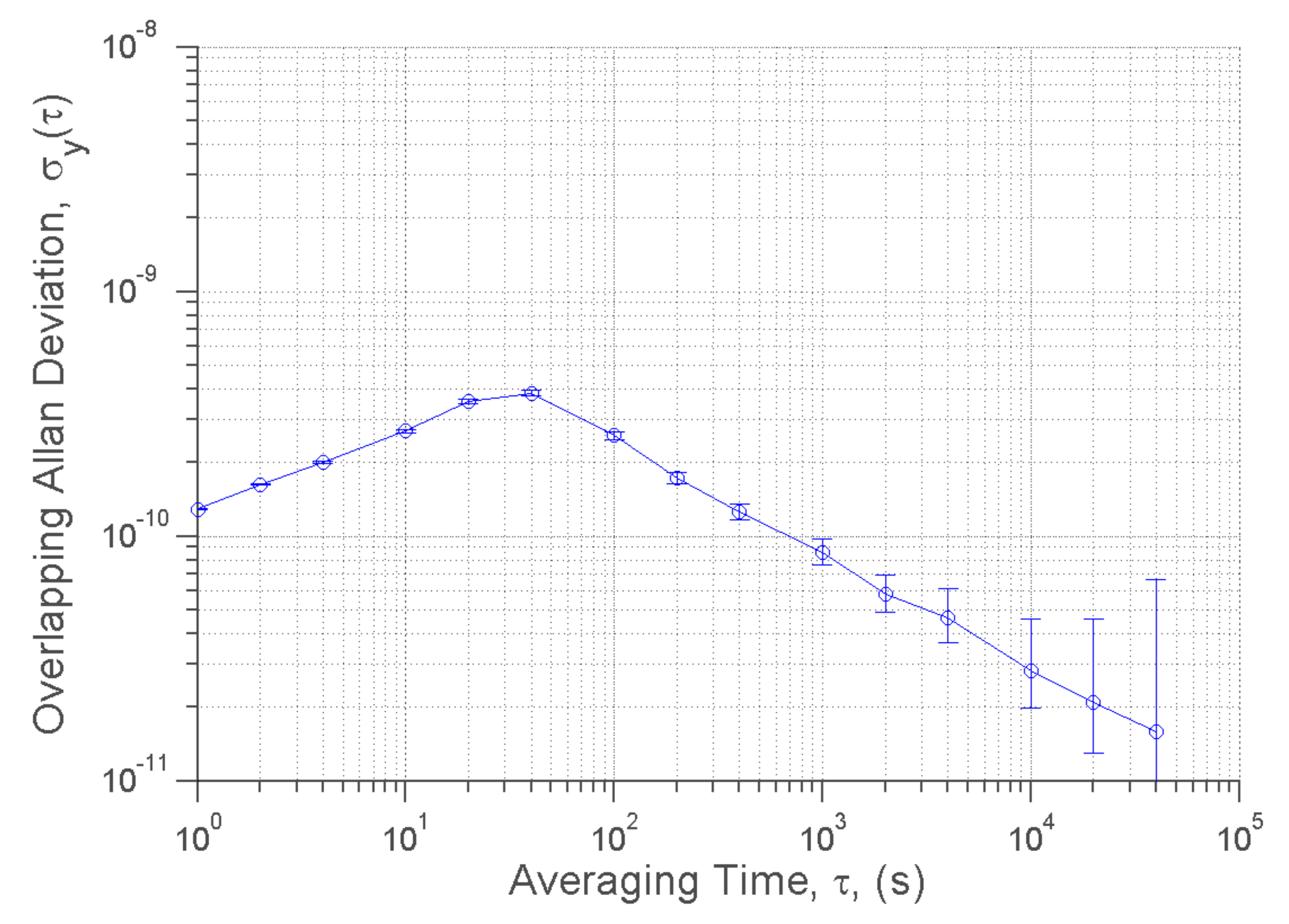

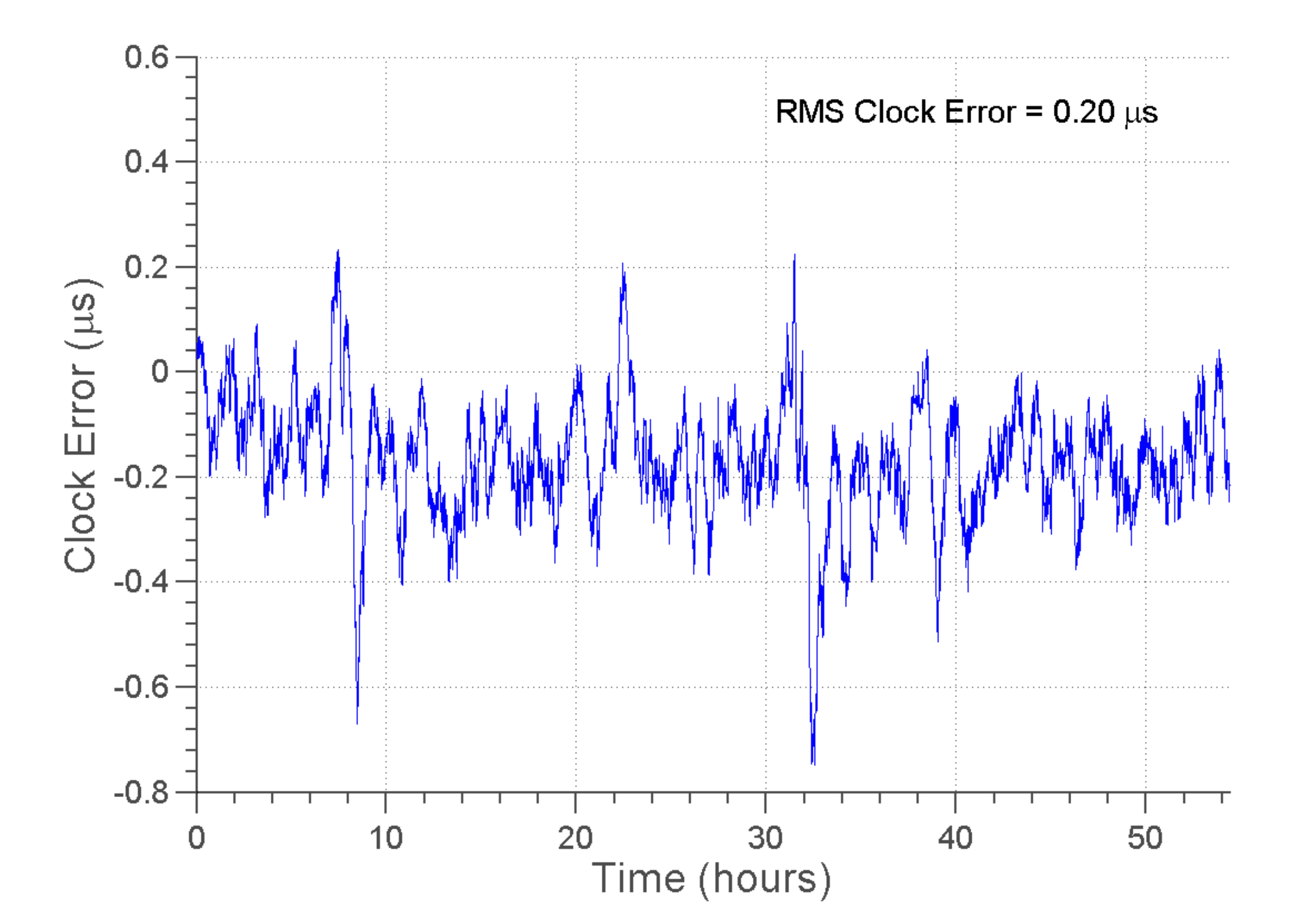

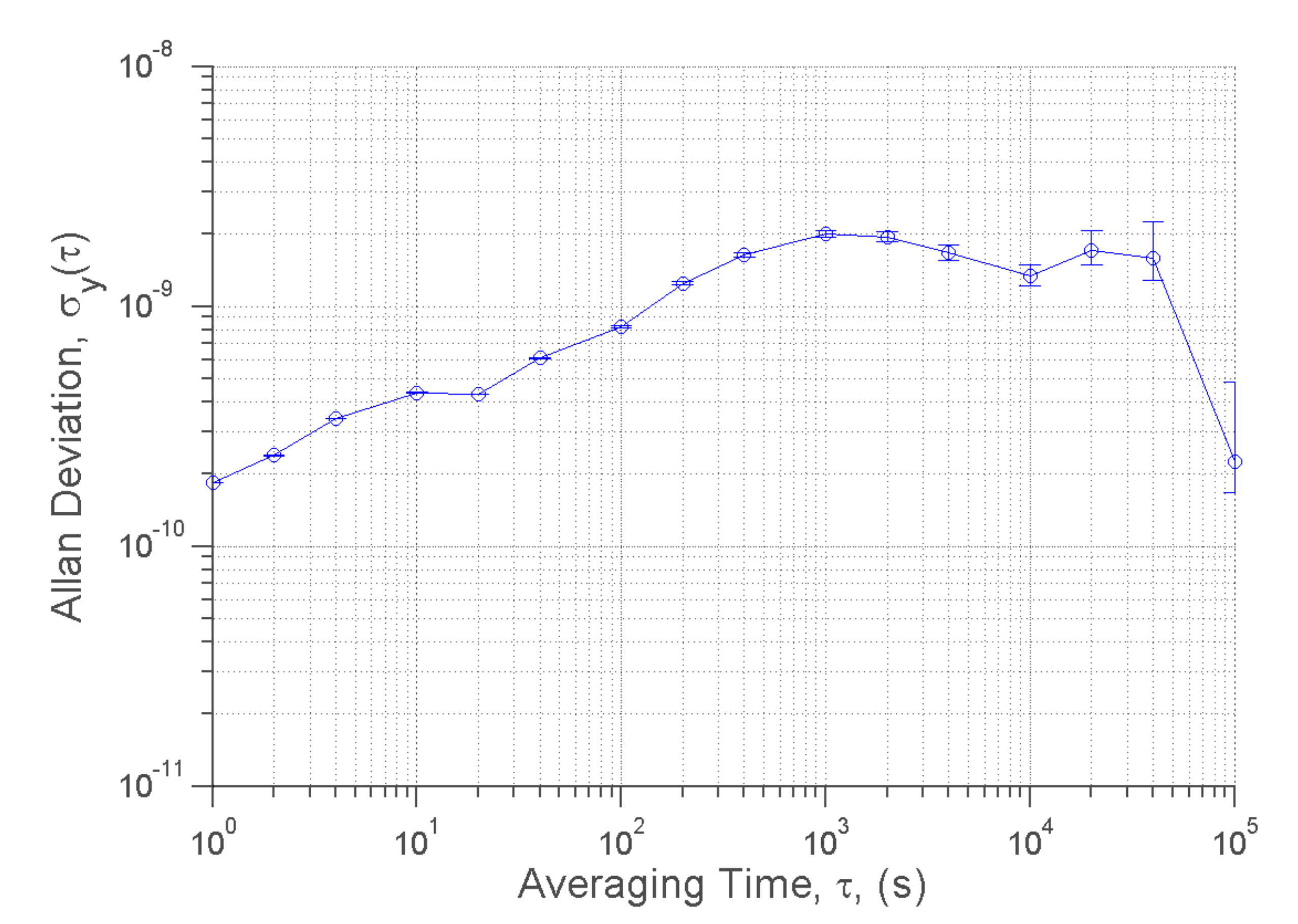

3.2. Continuous Operation

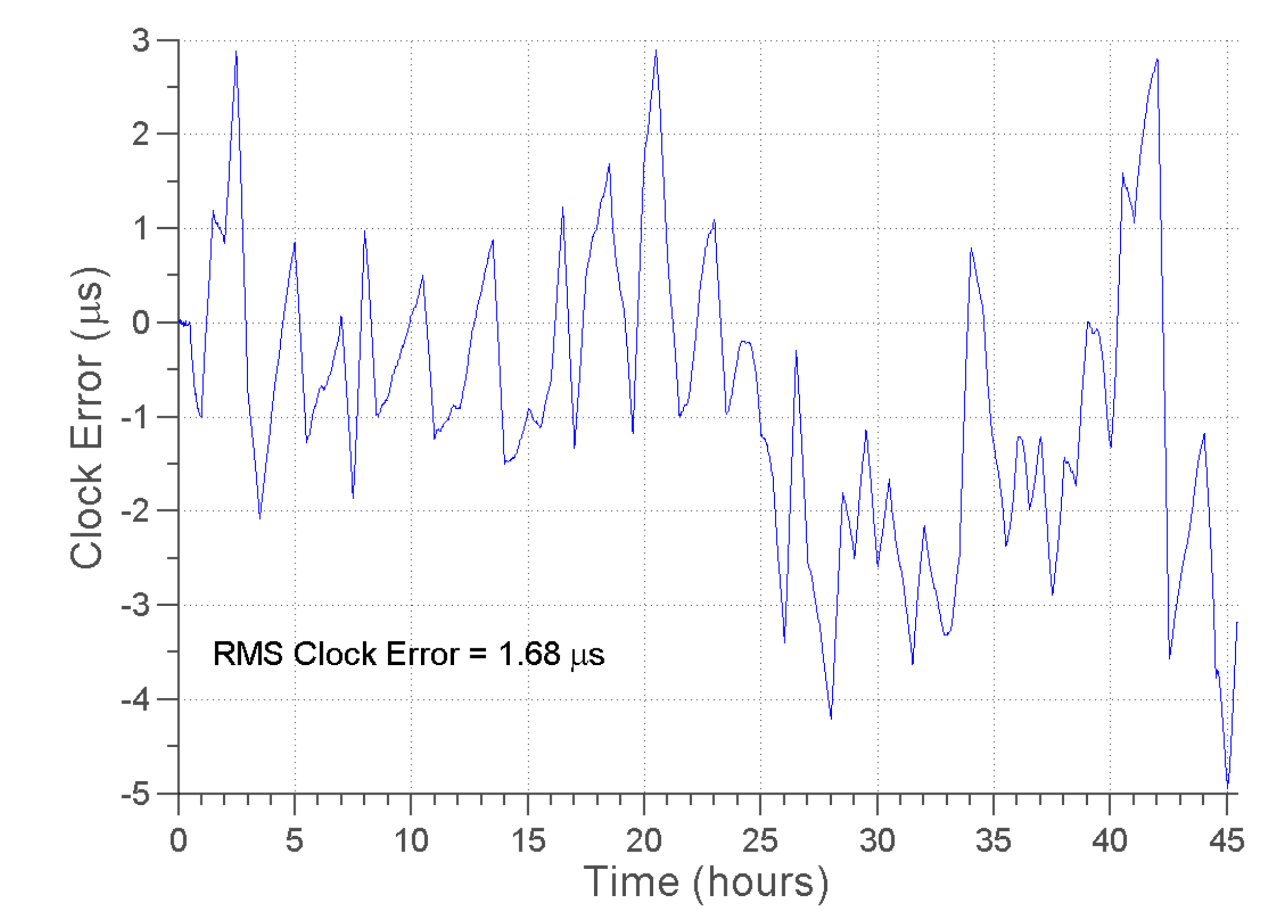

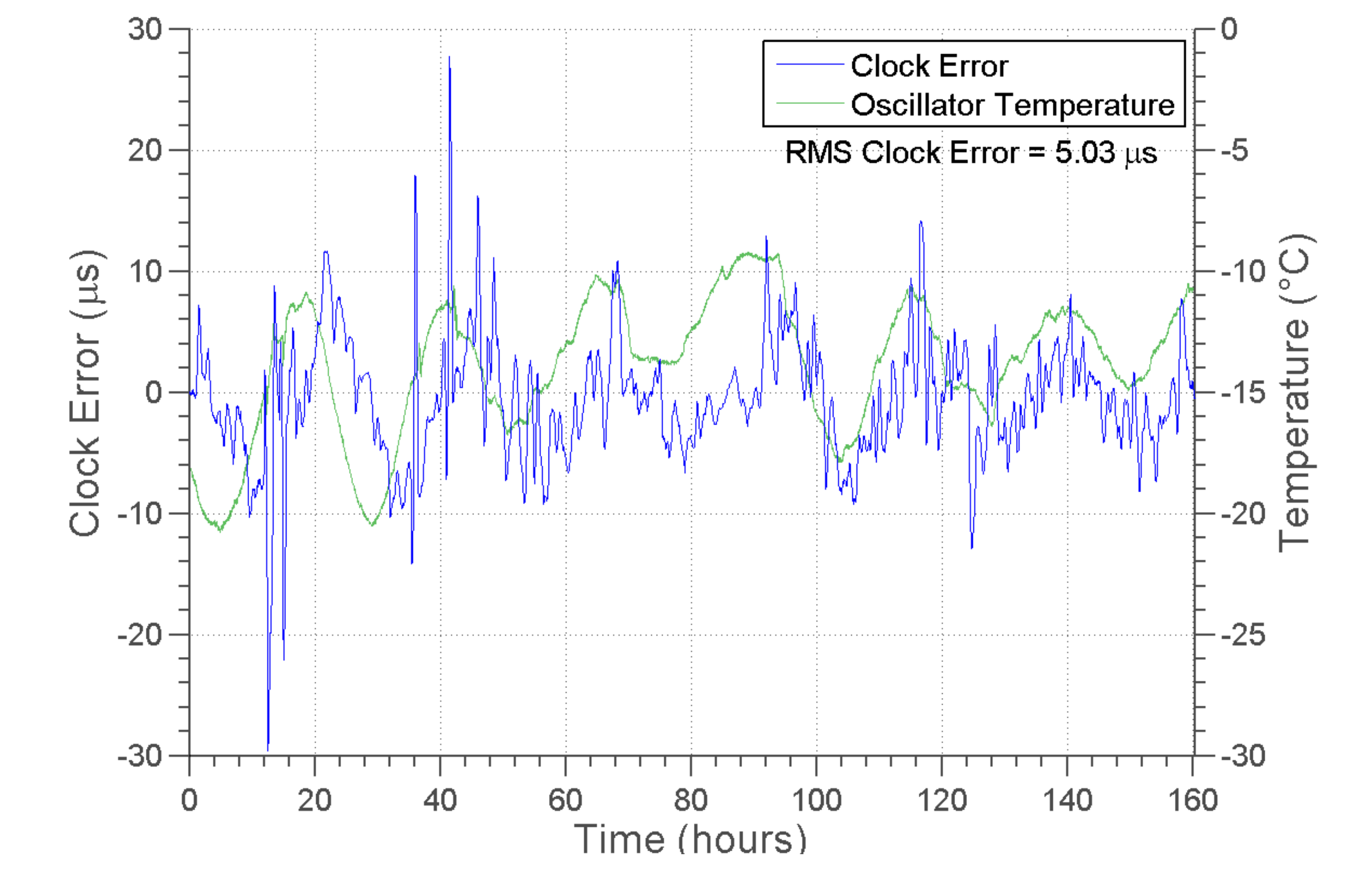

3.3. Duty-Cycled Operation

3.4. Oscillator Temperature Stability

Environmental Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AVAR | Allan variance |

| CPLD | complex programmable logic device |

| DAC | digital-to-analog converter |

| FM | frequency modulation |

| FFM | flicker-noise frequency modulation |

| FPGA | field-programmable gate array |

| GPS | Global Positioning System |

| GSPDO | GPS-disciplined oscillator |

| MAVAR | modified Allan variance |

| PM | phase modulation |

| ppb | parts per billion |

| ppm | parts per million |

| pps | pulse per second |

| ppt | parts per trillion |

| PWM | pulse-width modulated |

| RFWM | random walk frequency modulation |

| rms | root mean square |

| TCVCXO | temperature-compensated voltage-controlled crystal oscillator |

| TCXO | temperature-compensated crystal oscillator |

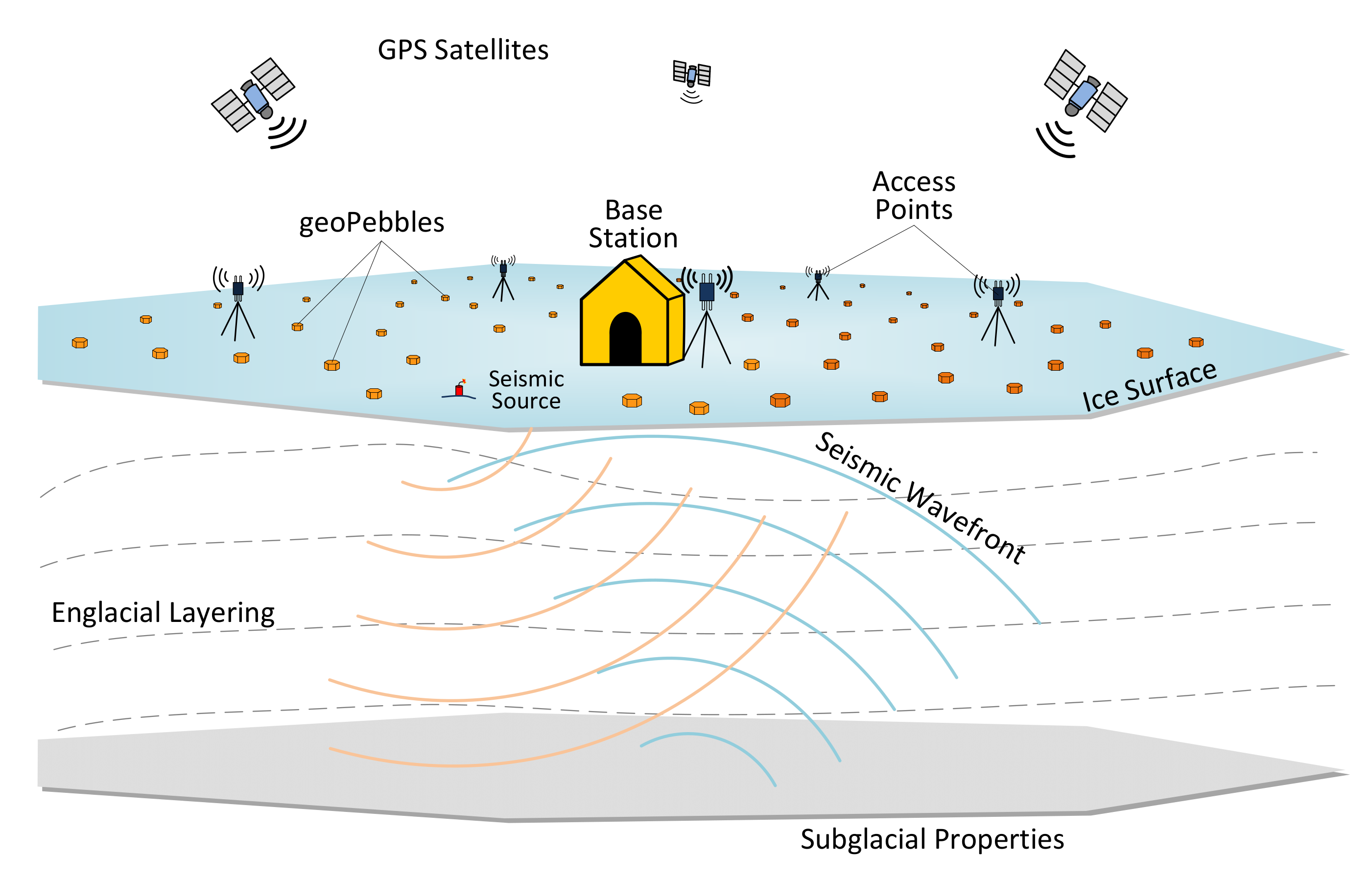

Appendix A. geoPebble System

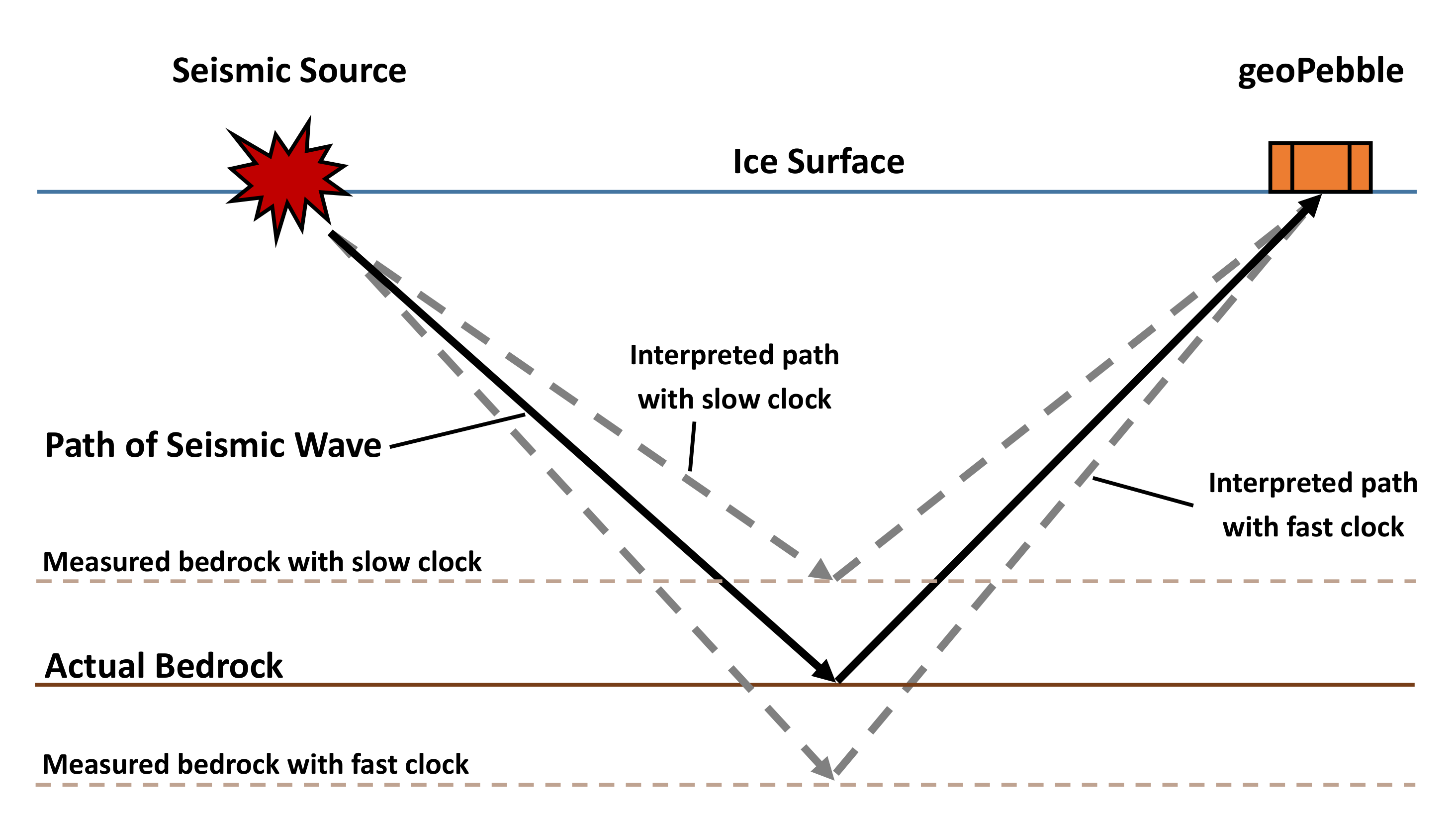

Appendix A.1. Requirement for Accurate Timing

Appendix B. GPSDO Implementation in the geoPebble System

Appendix C. Clock and Timing Fundamentals

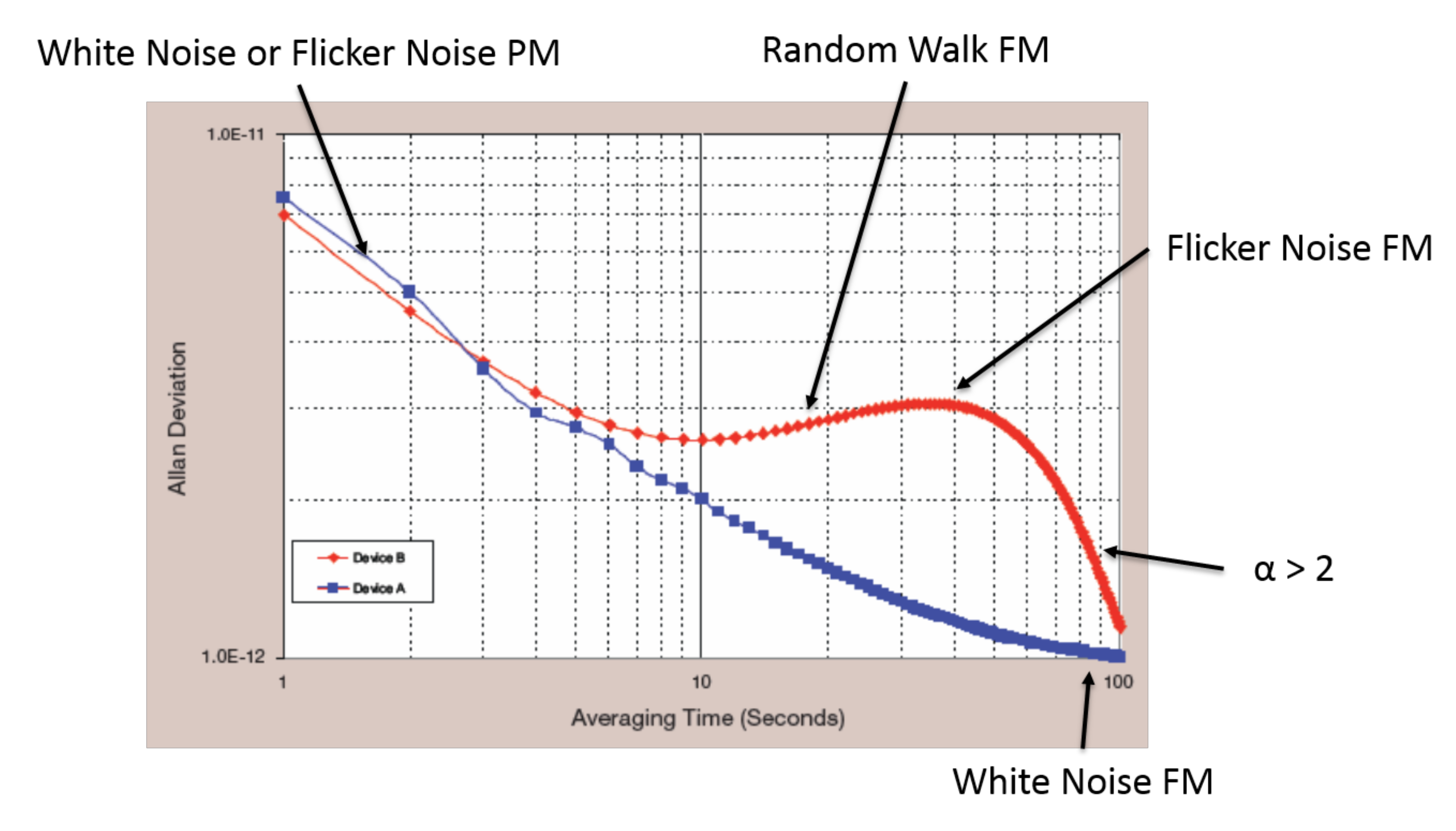

Appendix C.1. Allan Variance Theory

| Noise Process | |

|---|---|

| 2 | White-Noise Phase Modulation |

| 1 | Flicker-Noise Phase Modulation |

| 0 | White-Noise Frequency Modulation (Random Walk Phase) |

| Flicker-Noise Frequency Modulation | |

| Random Walk Frequency Modulation |

Appendix C.2. Time Error Estimation Using the Allan Variance

| Noise Process | Optimum Prediction rms | Time Error: Asymptotic Form | |

|---|---|---|---|

| 2 | White-Noise PM | constant | |

| 1 | Flicker-Noise PM | ||

| 0 | White-Noise FM | ||

| Flicker-Noise FM | |||

| Random Walk FM |

Appendix C.3. Using the Allan Variance

References

- Allan, D.; Weiss, M.; Peppler, T. In search of the best clock. In Proceedings of the Precision Electromagnetic Measurements (CPEM 88), Tsukuba, Japan, 7–10 June 1988; pp. 78–79. [Google Scholar] [CrossRef]

- Allan, D.; Weiss, M.; Peppler, T. In search of the best clock. IEEE Trans. Instrum. Meas. 1989, 38, 624–630. [Google Scholar] [CrossRef]

- Sichitiu, M.; Veerarittiphan, C. Simple, accurate time synchronization for wireless sensor networks. In Proceedings of the Wireless Communications and Networking (WCNC 2003), New Orleans, LA, USA, 16–20 March 2003; Volume 2, pp. 1266–1273. [Google Scholar] [CrossRef]

- Gezici, S.; Tian, Z.; Giannakis, G.; Kobayashi, H.; Molisch, A.; Poor, H.; Sahinoglu, Z. Localization via ultra-wideband radios: A look at positioning aspects for future sensor networks. Signal Process. Mag. 2005, 22, 70–84. [Google Scholar] [CrossRef]

- Sayed, A.; Tarighat, A.; Khajehnouri, N. Network-based wireless location: Challenges faced in developing techniques for accurate wireless location information. Signal Process. Mag. 2005, 22, 24–40. [Google Scholar] [CrossRef]

- Allan, D.W. An Ultra-Precise Time Synchronization System Designed by Computer Simulation; Technical Report; National Bureau of Standards: Gaithersburg, MD, USA, 1968.

- Allan, D.W.; Gray, J.E.; Machlan, H. The National Bureau of Standards atomic time scales: Generation, dissemination, stability, and accuracy. IEEE Trans. Instrum. Meas. 1972, 21, 388–391. [Google Scholar] [CrossRef][Green Version]

- Allan, D.W.; Davis, D.D.; Weiss, M.; Clements, A.; Guinot, B.; Granveaud, M.; Dorenwendt, K.; Fischer, B.; Hetzel, P.; Aoki, S.; et al. Accuracy of international time and frequency comparisons via Global Positioning System satellites in common-view. IEEE Trans. Instrum. Meas. 1985, 34, 118–125. [Google Scholar] [CrossRef]

- Lombardi, M.A. The use of GPS disciplined oscillators as primary frequency standards for calibration and metrology laboratories. NCSLI Measure. 2008, 3, 56–65. [Google Scholar] [CrossRef]

- u blox. LEA-6T Module with Precision Timing. Available online: https://www.u-blox.com/en/product/neolea-6t (accessed on 17 March 2021).

- Microsemi. Chip Scale Atomic Clock (CSAC)—SA.45s. Available online: http://https://www.microsemi.com/product-directory/clocks-frequency-references/3824-chip-scale-atomic-clock-csac (accessed on 17 March 2021).

- Knappe, S.; Shah, V.; Schwindt, P.D.D.; Hollberg, L.; Kitching, J.; Liew, L.A.; Moreland, J. A microfabricated atomic clock. Appl. Phys. Lett. 2004, 85, 1460–1462. [Google Scholar] [CrossRef]

- Bilén, S.G.; Anandakrishnan, S.; Burkett, P.; Fleishman, A.; Urbina, J. Design and implementation of a wireless sensor network of GPS-enabled seismic sensors for the study of glaciers and ice sheets. In Proceedings of the 2012 AGU Fall Meeting, San Francisco, CA, USA, 3–7 December 2012. [Google Scholar]

- Anandakrishnan, S.; Urbina, J.; Bilén, S.G.; Fleishman, A.; Burkett, P. Penn State geoPebble system: Design, implementation, and initial results. In Proceedings of the 2014 AGU Fall Meeting, San Francisco, CA, USA, 15–19 December 2014. [Google Scholar]

- Lim, J.; Lee, K.; Cho, K. Ultra low power RC oscillator for system wake-up using highly precise auto-calibration technique. In Proceedings of the 2010 Proceedings of ESSCIRC, Sevilla, Spain, 13–17 September 2010; pp. 274–277. [Google Scholar] [CrossRef]

- Ali, I.; Asif, M.; Rehman, M.R.U.; Khan, D.; Yingge, H.; Kim, S.J.; Pu, Y.; Yoo, S.S.; Lee, K.Y. A highly reliable, 5.8 GHz DSRC wake-up receiver with an intelligent digital controller for an ETC system. Sensors 2020, 20, 4012. [Google Scholar] [CrossRef] [PubMed]

- Apparatus for Correcting the Timing Function in a Nodal Seismic Data Acquisition Unit. U.S. Patent US9465124B2, 11 October 2016.

- Jackson Labs Technologies, Inc. GPSOCXO. Available online: http://www.jacksonlabs.com/index.php/products/gps_ocxo (accessed on 17 March 2021).

- Tejado, I.; Vinagre, B.M.; Traver, J.E.; Prieto-Arranz, J.; Nuevo-Gallardo, C. Back to basics: Meaning of the parameters of fractional order PID controllers. Mathematics 2019, 7, 530. [Google Scholar] [CrossRef]

- William Riley, D.A.H. Handbook of Frequency Stability Analysis; National Institutes of Standards and Technology: Gaithersburg, MD, USA, 2008.

- Bramwell, M. Glaciers and Ice Caps; Franklin Watts: Hachette, UK, 1986. [Google Scholar]

- Vogt, C.; Laihem, K.; Wiebusch, C. Speed of sound in bubble-free ice. J. Acoust. Soc. Am. 2008, 124, 3613–3618. [Google Scholar] [CrossRef] [PubMed]

- Allan, D.W. Statistics of atomic frequency standards. Proc. IEEE 1966, 54, 221–230. [Google Scholar] [CrossRef]

- Allan, D.; Barnes, J. A Modified “Allan Variance” with increased oscillator characterization ability. In Proceedings of the Thirty Fifth Annual Frequency Control Symposium, Philadelphia, PA, USA, 27–29 May 1981; pp. 470–475. [Google Scholar] [CrossRef]

- Barnes, J. Tables of Bias Functions, B1 and B2, for Variances Based on Finite Samples of Processes with Power Law Spectral Densities; Technical Report; National Bureau of Standards: Gaithersburg, MD, USA, 1969.

- Allan, D.W. Time and frequency (time-domain) characterization, estimation, and prediction of precision clocks and oscillators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 1987, 34, 647–654. [Google Scholar] [CrossRef] [PubMed]

- Howe, D.; Allan, D.; Barnes, J. Properties of signal sources and measurement methods. In Proceedings of the Thirty Fifth Annual Frequency Control Symposium, Philadelphia, PA, USA, 27–29 May 1981; pp. 669–716. [Google Scholar] [CrossRef]

| Frequency Source | Long-Term Accuracy (1000 s) | Power Consumption | Cost |

|---|---|---|---|

| Quartz Crystal Oscillator | Low | Low | Low |

| Ovenized Oscillator | Medium | Medium to High | Medium |

| Rubidium | High | High | High |

| Cesium | High | High | High |

| Chip-Scale Atomic Clock (CSAC) | High | Low | High |

| GPS-Disciplined Oscillator (GPSDO) | High | Medium | Medium |

| GPSDO in This Paper | High | Low | Low |

| Manufacturer | Model | Rated Power Consumption | Rated Accuracy From UTC |

|---|---|---|---|

| Jackson Labs Technologies | GPSTCXO | <0.5 W | ns |

| Jackson Labs Technologies | GPSOCXO | 0.7 W | ns |

| Jackson Labs Technologies | FireFly-1B GPSTCXO | <0.75 W | ns |

| Symmetricom/Microsemi | GPS-1000 | <1.8 W | ns |

| Symmetricom/Microsemi | GPS-2700/2750 | <1.4 W | ns |

| Symmetricom/Microsemi | GPS-3300/3550 | <5.6 W | ns |

| Connor Winfield | FTS250 | 0.66 W | ns |

| Connor Winfield | Wi125 | 0.6 W | ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boehmer, T.J.; Bilén, S.G. Low-Power GPS-Disciplined Oscillator Module for Distributed Wireless Sensor Nodes. Electronics 2021, 10, 716. https://doi.org/10.3390/electronics10060716

Boehmer TJ, Bilén SG. Low-Power GPS-Disciplined Oscillator Module for Distributed Wireless Sensor Nodes. Electronics. 2021; 10(6):716. https://doi.org/10.3390/electronics10060716

Chicago/Turabian StyleBoehmer, Tyler J., and Sven G. Bilén. 2021. "Low-Power GPS-Disciplined Oscillator Module for Distributed Wireless Sensor Nodes" Electronics 10, no. 6: 716. https://doi.org/10.3390/electronics10060716

APA StyleBoehmer, T. J., & Bilén, S. G. (2021). Low-Power GPS-Disciplined Oscillator Module for Distributed Wireless Sensor Nodes. Electronics, 10(6), 716. https://doi.org/10.3390/electronics10060716