Effects of Active Layer Thickness on the Electrical Characteristics and Stability of High-Mobility Amorphous Indium–Gallium–Tin Oxide Thin-Film Transistors

Abstract

1. Introduction

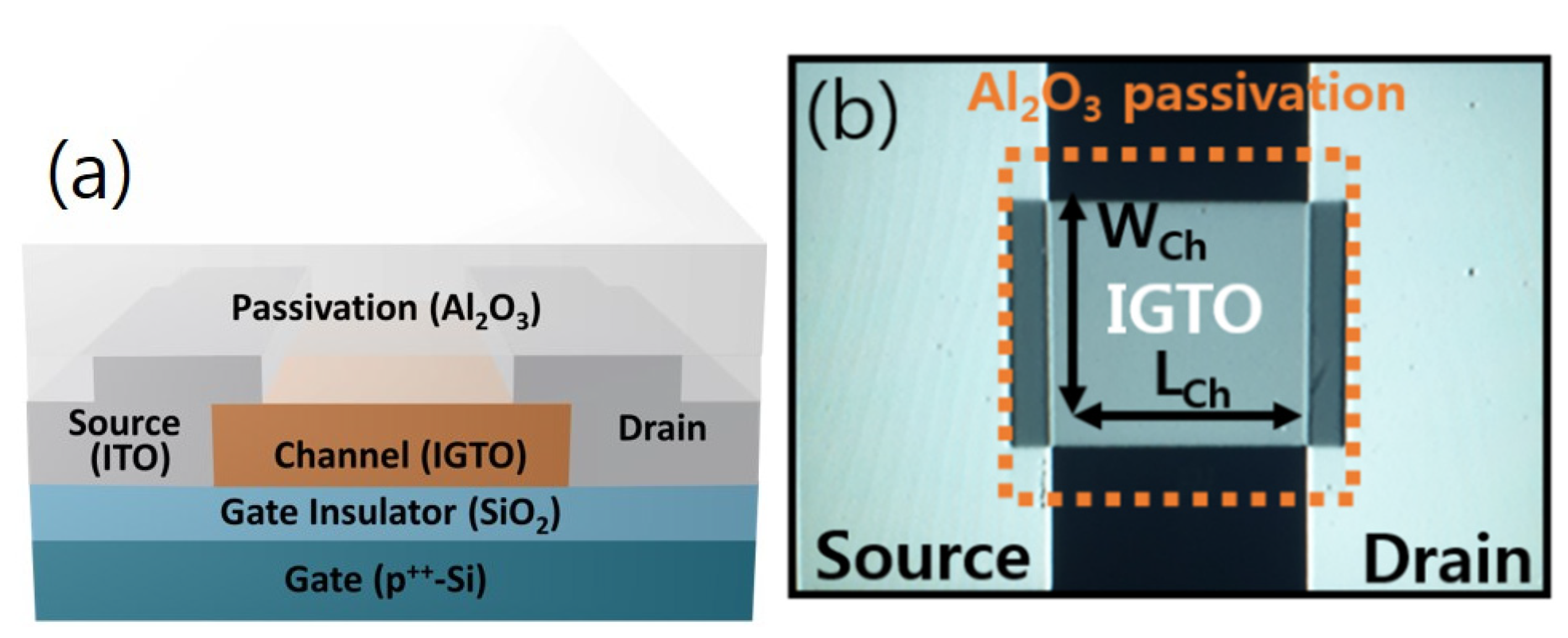

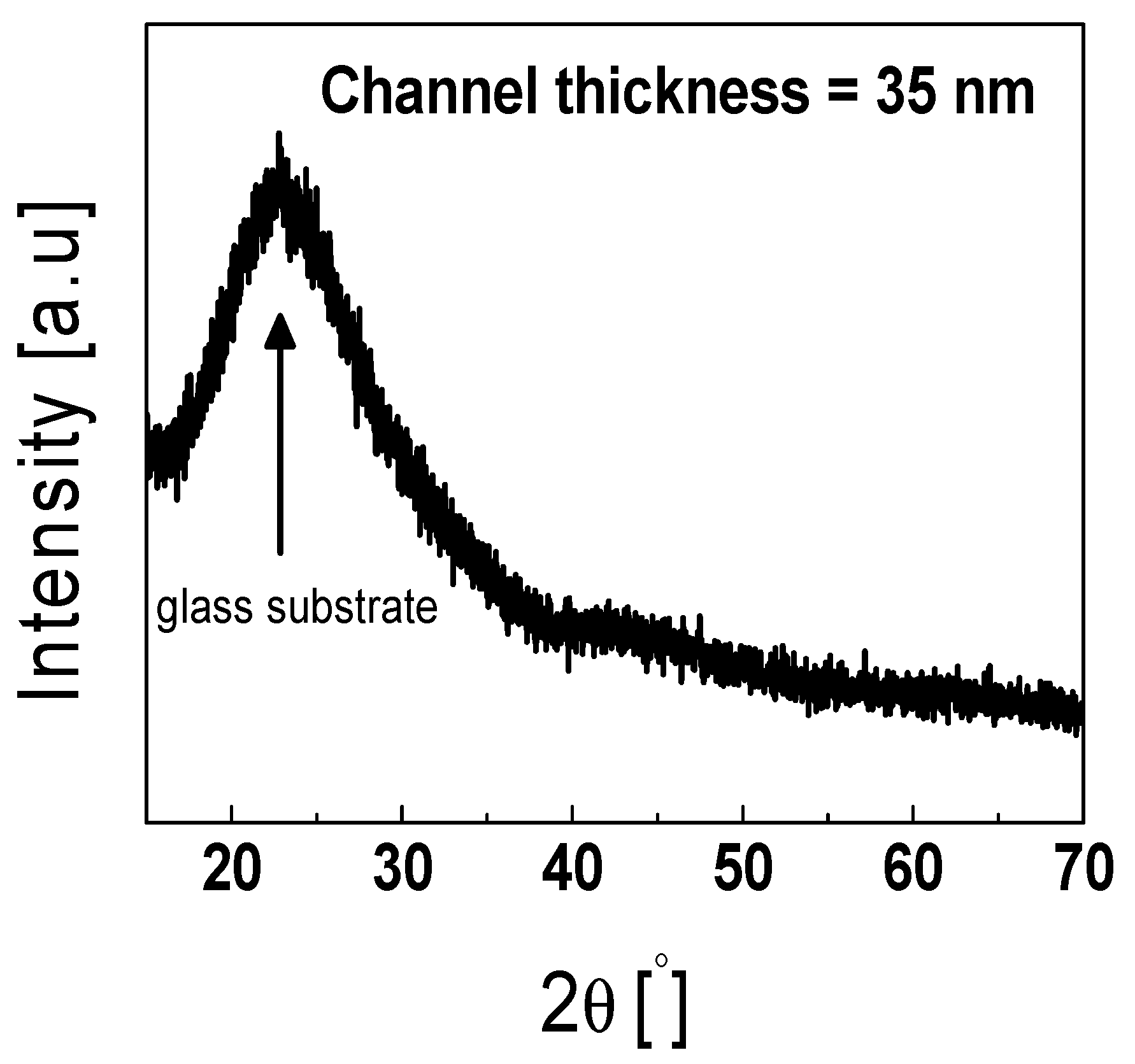

2. Materials and Methods

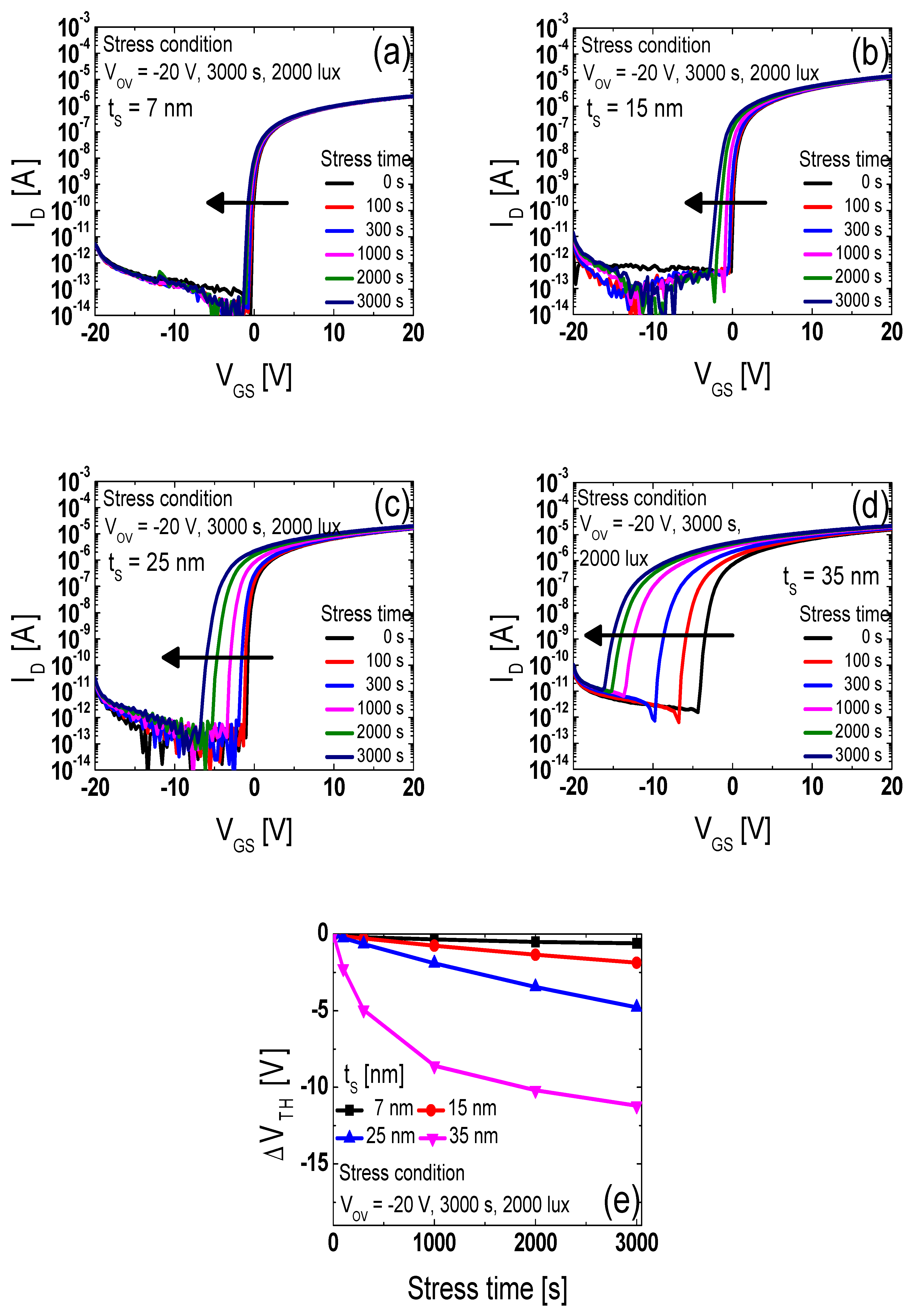

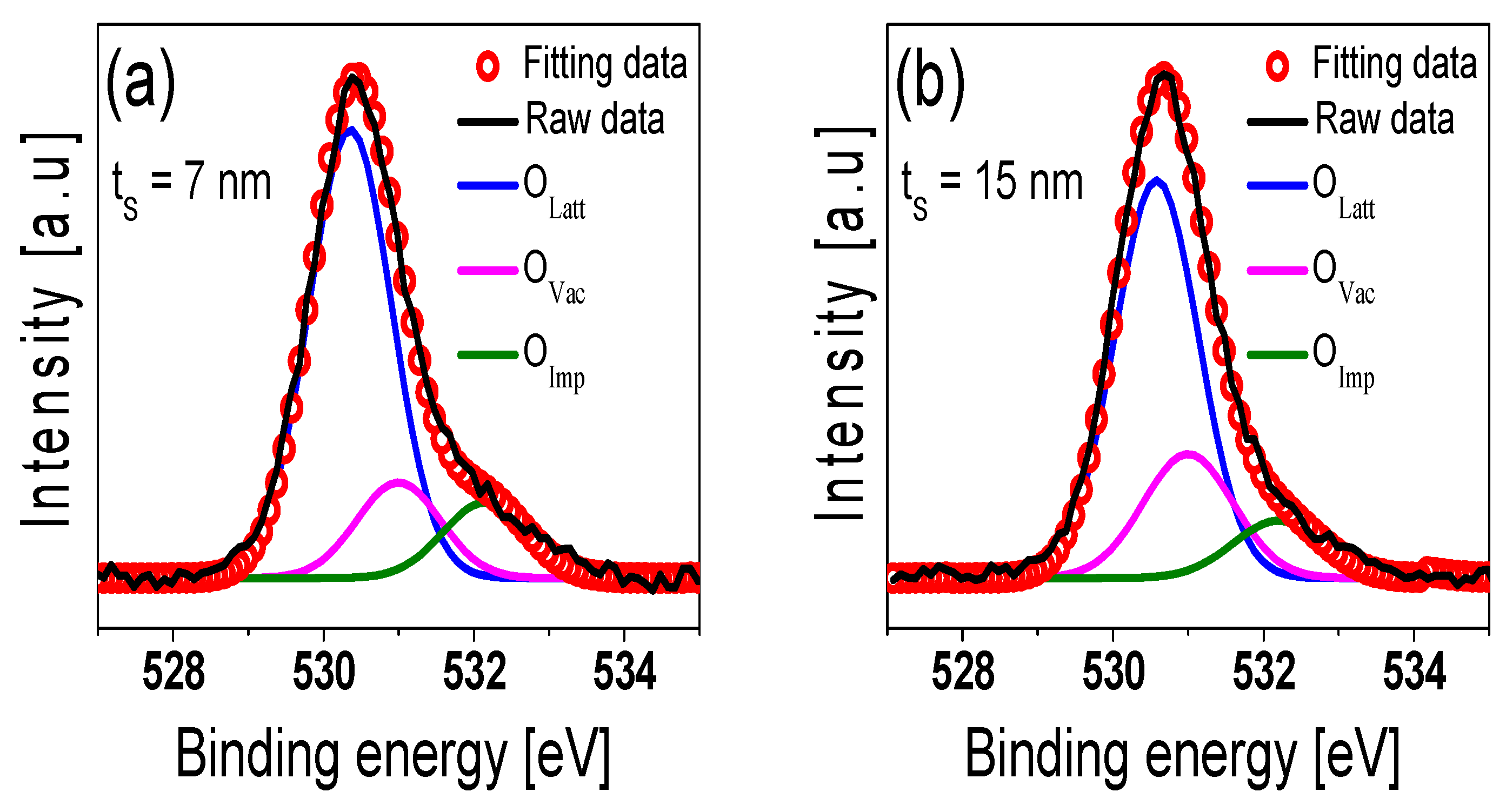

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef]

- Fortunato, E.; Barquinha, P.; Martins, R. Oxide semiconductor thin-film transistors: A review of recent advances. Adv. Mater. 2012, 24, 2945–2986. [Google Scholar] [CrossRef] [PubMed]

- Kamiya, T.; Hosono, H. Material characteristics and applications of transparent amorphous Oxide semiconductors. NPG Asia Mater. 2010, 2, 15–22. [Google Scholar] [CrossRef]

- Jang, J.T.; Ahn, G.H.; Choi, S.-J.; Kim, D.M.; Kim, D.H. Control of the boundary between the gradual and abrupt modulation of resistance in the schottky barrier tunneling-modulated amorphous Indium-Gallium-Zinc-Oxide memristors for neuromorphic computing. Electronics 2019, 8, 1087. [Google Scholar] [CrossRef]

- Park, J.-S.; Maeng, W.-J.; Kim, H.-S.; Park, J.-S. Review of recent developments in amorphous Oxide semiconductor thin-film transistor devices. Thin Solid Films 2012, 520, 1679–1693. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Nomura, K.; Yanagi, H.; Kamiya, T.; Hirano, M.; Hosono, H. Device characteristics improvement of a-In–Ga–Zn–O TFTs by low-temperature annealing. Thin Solid Films 2010, 518, 3017–3021. [Google Scholar] [CrossRef]

- Rahaman, A.; Jeong, H.; Jang, J. A High-Gain CMOS Operational Amplifier Using Low-Temperature Poly-Si Oxide TFTs. IEEE Trans. Electron Devices 2020, 67, 524–527. [Google Scholar] [CrossRef]

- Jeong, D.Y.; Chang, Y.; Yoon, W.G.; Do, Y.; Jang, J. Low-Temperature Polysilicon Oxide Thin-Film Transistors with Coplanar Structure Using Six Photomask Steps Demonstrating High Inverter Gain of 264 V V−1. Adv. Eng. Mater. 2020, 22, 1901497. [Google Scholar] [CrossRef]

- Kim, S.-C.; Jeon, Y.-W.; Kim, Y.-S.; Kong, D.-S.; Jung, H.-K.; Bae, M.-K.; Lee, J.-H.; Ahn, B.-D.; Park, S.-Y.; Park, J.-H.; et al. Impact of oxygen flow rate on the instability under positive bias stresses in DC-sputtered amorphous InGaZnO thin-film transistors. IEEE Electron Device Lett. 2012, 33, 62–64. [Google Scholar] [CrossRef]

- Yabuta, H.; Sano, M.; Abe, K.; Aiba, T.; Den, T.; Kumomi, H.; Nomura, K.; Kamiya, T.; Hosono, H. High mobility thin-film transistor with amorphous InGaZnO4 channel fabricated by room temperature rf magnetron sputtering. Appl. Phys. Lett. 2006, 89, 112123. [Google Scholar] [CrossRef]

- Fan, C.L.; Tsao, H.Y.; Chen, C.Y.; Chou, P.C.; Lin, W.Y. New Low-Voltage Driving Compensating Pixel Circuit Based on HighMobility Amorphous Indium-Zinc-Tin-Oxide Thin-Film Transistors for High-Resolution Portable Active-Matrix OLED Displays. Coatings 2020, 10, 1004. [Google Scholar] [CrossRef]

- Fuh, C.-S.; Liu, P.-T.; Huang, W.-H.; Sze, S.M. Effect of annealing on defect elimination for high mobility amorphous Indium-Zinc-Tin-Oxide thin-film transistor. IEEE Electron Device Lett. 2014, 35, 1103. [Google Scholar] [CrossRef]

- Paine, D.-C.; Yaglioglu, B.; Beiley, Z.; Lee, S.-H. Amorphous IZO-based transparent thin film transistor. Thin Solid Films 2008, 516, 5894–5898. [Google Scholar] [CrossRef]

- Ruan, D.-B.; Liu, P.-T.; Chiu, Y.-C.; Kan, K.-Z.; Yu, M.-C.; Chien, T.-C.; Chen, Y.-H.; Kuo, P.-Y.; Sze, S.-M. Investigation of low operation voltage InZnSnO thin-film transistors with dierent high-k gate dielectric by physical vapor deposition. Thin Solid Films 2018, 660, 885–890. [Google Scholar] [CrossRef]

- Noh, J.-Y.; Kim, H.; Nahm, H.-H.; Kim, Y.-S.; Kim, D.H.; Ahn, B.-D.; Lim, J.-H.; Kim, G.H.; Lee, J.-H.; Song, J. Cation composition effects on electronic structures of In-Sn-Zn-O amorphous semiconductors. J. Appl. Phys. 2013, 113, 3706-1–3706-7. [Google Scholar] [CrossRef]

- Kim, B.K.; On, N.; Choi, C.H.; Kim, M.J.; Kang, S.; Lim, J.H.; Jeong, J.K. Polycrystalline Indium Gallium Tin Oxide Thin-Film Transistors With High Mobility Exceeding 100 cm2/V·s. IEEE Electron Device Lett. 2021, 42, 347–357. [Google Scholar] [CrossRef]

- Jeong, H.-S.; Cha, H.S.; Hwang, S.H.; Kwon, H.-I. Effects of annealing atmosphere on electrical performance and stability of high-mobility Indium-Gallium-Tin Oxide thin-film transistors. Electronics 2020, 9, 1875. [Google Scholar] [CrossRef]

- Hur, J.-S.; Kim, J.-O.; Kim, H.-A.; Jeong, J.-K. Stretchable polymer gate dielectric by ultraviolet-assisted Hafnium Oxide doping at low temperature for high-performance Indium Gallium Tin Oxide transistors. ACS Appl. Mater. Interfaces 2019, 11, 21675–21685. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-O.; Hur, J.-S.; Kim, D.-S.; Lee, B.-M.; Jung, J.-M.; Kim, H.-A.; Chung, U.-J.; Nam, S.-H.; Hong, Y.T.; Park, K.-S.; et al. Network structure modification-enabled hybrid polymer dielectric film with Zirconia for the stretchable transistor applications. Adv. Funct. Mater. 2020, 30, 1906647. [Google Scholar] [CrossRef]

- Cho, E.N.; Kang, J.H.; Yun, I. Effects of channel thickness variation on bias stress instability of InGaZnO thin-film transistors. Microelectron. Reliab. 2011, 51, 1792–1795. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, J.; Meng, T.; Qu, M.; Zhang, Q. Influence of channel layer thickness on the stability of amorphous indium zinc oxide thin film transistors. Mater. Lett. 2016, 166, 46–50. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, D.H.; Chong, E.; Jeon, Y.W.; Kim, D.H. Effect of channel thickness on density of states in amorphous InGaZnO thin film transistors. Appl. Phys. Lett. 2011, 98, 122105-1–122105-3. [Google Scholar] [CrossRef]

- Li, G.T.; Yang, B.R.; Liu, C.; Lee, C.Y.; Tseng, C.Y.; Lo, C.C.; Lien, A.; Deng, S.Z.; Shieh, H.P.D.; Xu, N.S. Positive gate bias instability alleviated by self-passivation effect in amorphous InGaZnO thin-film transistors. J. Phys. D Appl. Phys. 2015, 48, 475107. [Google Scholar] [CrossRef]

- Jung, S.H.; Moon, H.J.; Ryu, M.K.; Cho, K.I.; Bae, B.S.; Yun, E.-J. The effects of high-energy electron beam irradiation on the properties of IGZO thin films prepared by rf magnetron sputtering. J. Ceram. Process. Res. 2012, 13, s246–s250. [Google Scholar]

- Shin, M.-G.; Hwang, S.-H.; Cha, H.-S.; Jeong, H.-S.; Kim, D.-H.; Kwon, H.-I. Effects of proton beam irradiation on the physical and chemical properties of IGTO thin films with different thicknesses for thin-film transistor applications. Surf. Interfaces 2021, 23, 100990. [Google Scholar] [CrossRef]

- Barquinha, P.; Pimentel, A.; Marques, A.; Pereira, L.; Martins, R.; Fortunato, E. Influence of the semiconductor thickness on the electrical properties of transparent TFTs based on indium zinc oxide. J. Non-Cryst. Solids 2006, 352, 1749–1752. [Google Scholar] [CrossRef]

- Li, J.; Ding, X.W.; Zhang, J.H.; Zhang, H.; Jiang, X.Y.; Zhang, Z.L. Improving electrical performance and bias stability of HfInZnO-TFT with optimizing the channel thickness. AIP Adv. 2013, 3, 102132. [Google Scholar] [CrossRef]

- Park, H.-W.; Park, K.; Kwon, J.-Y.; Choi, D.; Chung, K.-B. Effect of active layer thickness on device performance of tungsten-doped InZnO thin-film transistor. IEEE Trans. Electron Dev. 2016, 64, 159–163. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, X.W.; Goh, G.K.L.; Demir, H.V.; Yu, H.Y. Influence of Channel Layer Thickness on the Electrical Performances of Inkjet-Printed In-Ga-Zn Oxide Thin-Film Transistors. IEEE Trans. Electron. Dev. 2011, 58, 480–485. [Google Scholar] [CrossRef]

- Nguyen, C.P.T.; Raja, J.; Kim, S.; Jang, K.; Le, A.H.T.; Lee, Y.-J.; Yi, J. Enhanced electrical properties of oxide semiconductor thin-film transistors with high conductivity thin layer insertion for the channel region. Appl. Surf. Sci. 2014, 396, 1472–1477. [Google Scholar] [CrossRef]

- Lee, E.; Kim, T.H.; Lee, S.W.; Kim, J.H.; Kim, J.; Jeong, T.G.; Ahn, J.-H.; Cho, B. Improved Electrical Performance of a Sol-Gel IGZO Transistor with High-k Al2O3 Gate Dielectric Achieved by Post Annealing. Nano Converg. 2019, 6, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Ji, H.; Hwang, A.Y.; Lee, C.K.; Yun, P.S.; Bae, J.U.; Park, K.-S.; Jeong, J.K. Improvement in Field-Effect Mobility of Indium Zinc Oxide Transistor by Titanium Metal Reaction Method. IEEE Trans. Electron Devices 2015, 62, 1009–1013. [Google Scholar]

- Kumaran, S.; Liu, M.-T.; Lee, K.-Y.; Tai, Y. The Impact of Solvents on the Performances of Solution-Processed Indium Gallium Zinc Oxide Thin-Film Transistors Using Nitrate Ligands. Adv. Eng. Mater. 2020, 22, 1901053. [Google Scholar] [CrossRef]

- Kim, S.T.; Shin, Y.; Yun, P.S.; Bae, J.U.; Chung, I.J.; Jeong, J.K. Achieving High Carrier Mobility Exceeding 70 cm2/V·s in Amorphous Zinc Tin Oxide Thin-Film Transistors. Electron. Mater. Lett. 2017, 13, 406–411. [Google Scholar] [CrossRef]

- Mativenga, M.; Um, J.G.; Jang, J. Reduction of Bias and Light Instability of Mixed Oxide Thin-Film Transistors. Appl. Sci. 2017, 7, 885. [Google Scholar] [CrossRef]

- Khan, S.A. Amorphous Metal-Oxide Based Thin Film Transistors on Metal Foils: Materials, Devices and Circuits Integration. Ph.D. Thesis, Deptartment Electrical Engineering, University Lehigh, Bethlehem, PA, USA, 2018. [Google Scholar]

- Jeong, H.-J.; Lee, H.-M.; Oh, K.-T.; Park, J.; Park, J.-S. Enhancement of In–Sn–Ga–O TFT performance by the synergistic combination of UV + O3 radiation and low temperature annealing. J. Electroceram. 2016, 37, 158–162. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hirano, M.; Hosono, H. Electronic structure of oxygen deficient amorphous oxide semiconductor a-InGaZnO4–x: Optical analyses and first-principle calculations. Phys. Stat. Sol. 2008, 5, 3098–3100. [Google Scholar]

- Kim, J.H.; Park, E.-K.; Kim, M.S.; Cho, H.J.; Lee, D.-H.; Kim, J.-H.; Khang, Y.; Park, K.; Kim, Y.-S. Bias and illumination instability analysis of solution-processed a-InGaZnO thin-film transistors with different component ratios. Thin Solid Films 2018, 645, 154–159. [Google Scholar] [CrossRef]

- Oh, H.; Yoon, S.M.; Ryu, M.K.; Hwang, C.S.; Yang, S.; Park, S.H. Photon-accelerated negative bias instability involving subgap states creation in amorphous In–Ga–Zn–O thin film transistor. Appl. Phys. Lett. 2010, 97, 183502. [Google Scholar] [CrossRef]

| tS [nm] | VTH [V] | μFE [cm2·V−1·S−1] | SS [V/decade] | IOFF [A] |

|---|---|---|---|---|

| 7 | 1.3 | 6.5 | 0.16 | |

| 15 | 0.3 | 26.5 | 0.16 | |

| 25 | −0.7 | 26.9 | 0.20 | |

| 35 | −3.1 | 27.8 | 0.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-H.; Cha, H.-S.; Jeong, H.-S.; Hwang, S.-H.; Kwon, H.-I. Effects of Active Layer Thickness on the Electrical Characteristics and Stability of High-Mobility Amorphous Indium–Gallium–Tin Oxide Thin-Film Transistors. Electronics 2021, 10, 1295. https://doi.org/10.3390/electronics10111295

Kim D-H, Cha H-S, Jeong H-S, Hwang S-H, Kwon H-I. Effects of Active Layer Thickness on the Electrical Characteristics and Stability of High-Mobility Amorphous Indium–Gallium–Tin Oxide Thin-Film Transistors. Electronics. 2021; 10(11):1295. https://doi.org/10.3390/electronics10111295

Chicago/Turabian StyleKim, Dae-Hwan, Hyun-Seok Cha, Hwan-Seok Jeong, Seong-Hyun Hwang, and Hyuck-In Kwon. 2021. "Effects of Active Layer Thickness on the Electrical Characteristics and Stability of High-Mobility Amorphous Indium–Gallium–Tin Oxide Thin-Film Transistors" Electronics 10, no. 11: 1295. https://doi.org/10.3390/electronics10111295

APA StyleKim, D.-H., Cha, H.-S., Jeong, H.-S., Hwang, S.-H., & Kwon, H.-I. (2021). Effects of Active Layer Thickness on the Electrical Characteristics and Stability of High-Mobility Amorphous Indium–Gallium–Tin Oxide Thin-Film Transistors. Electronics, 10(11), 1295. https://doi.org/10.3390/electronics10111295