Systematical Study of the Basic Properties of Surface Acoustic Wave Devices Based on ZnO and GaN Multilayers

Abstract

1. Introduction

2. Methods

3. Results

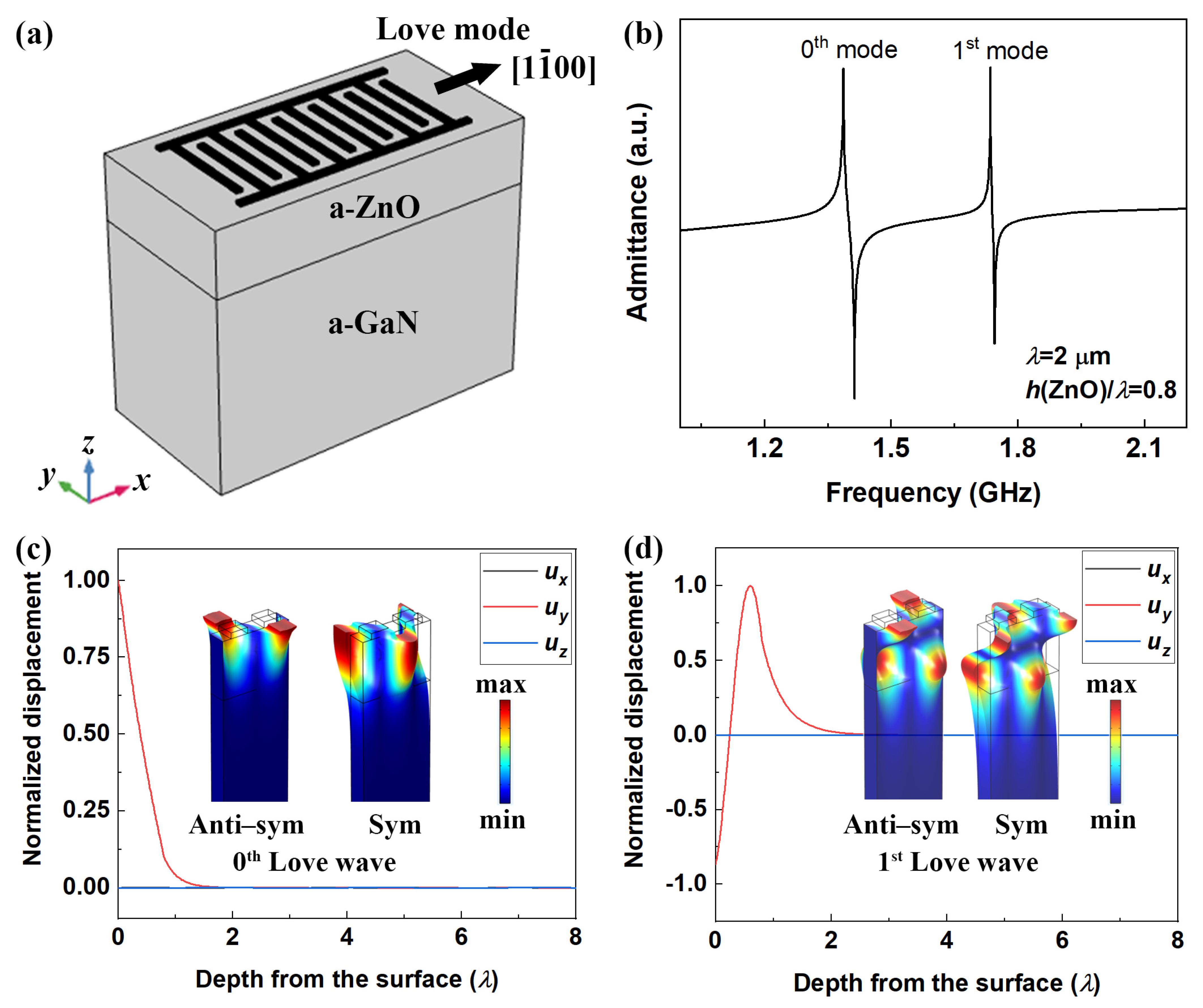

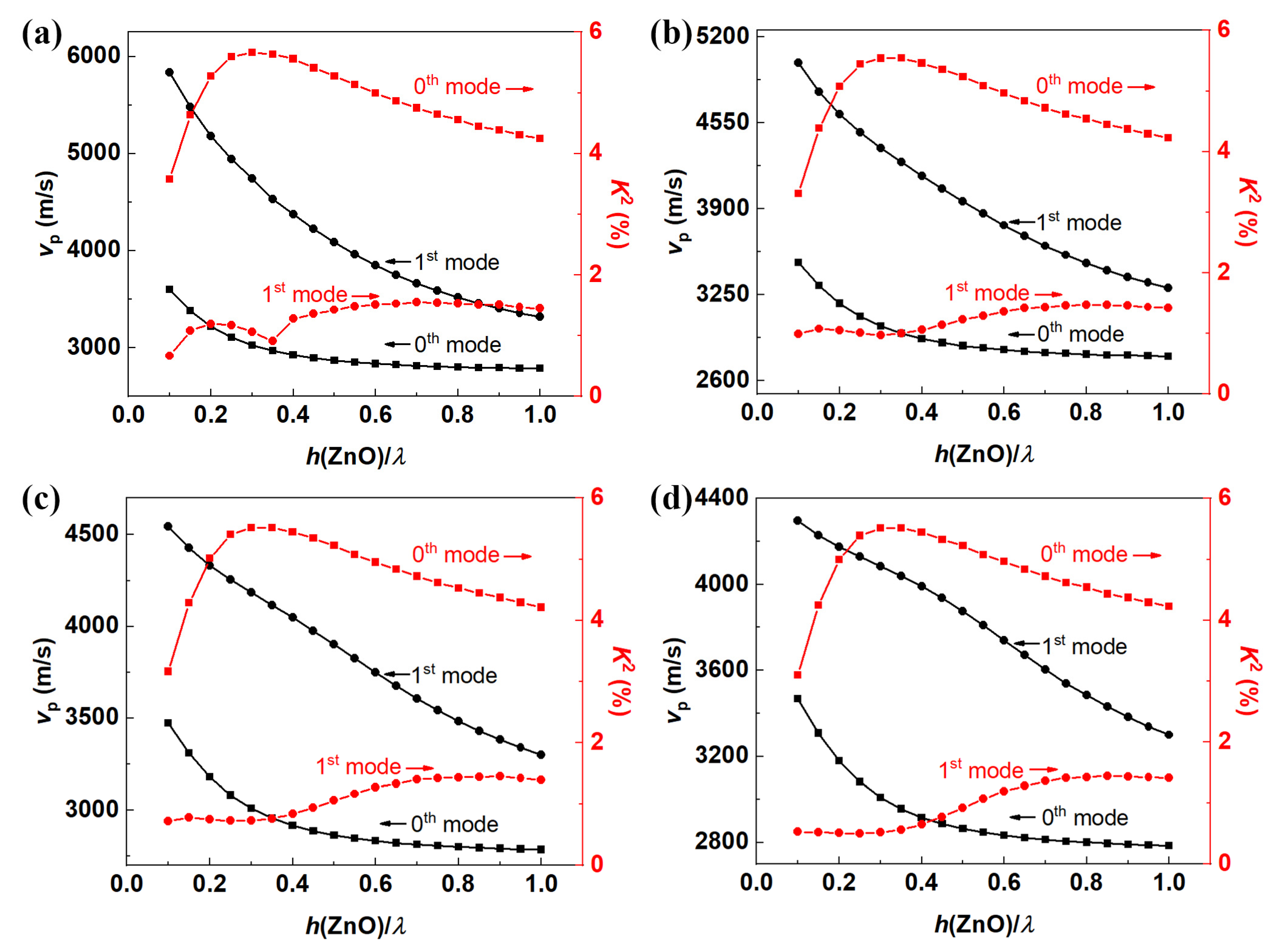

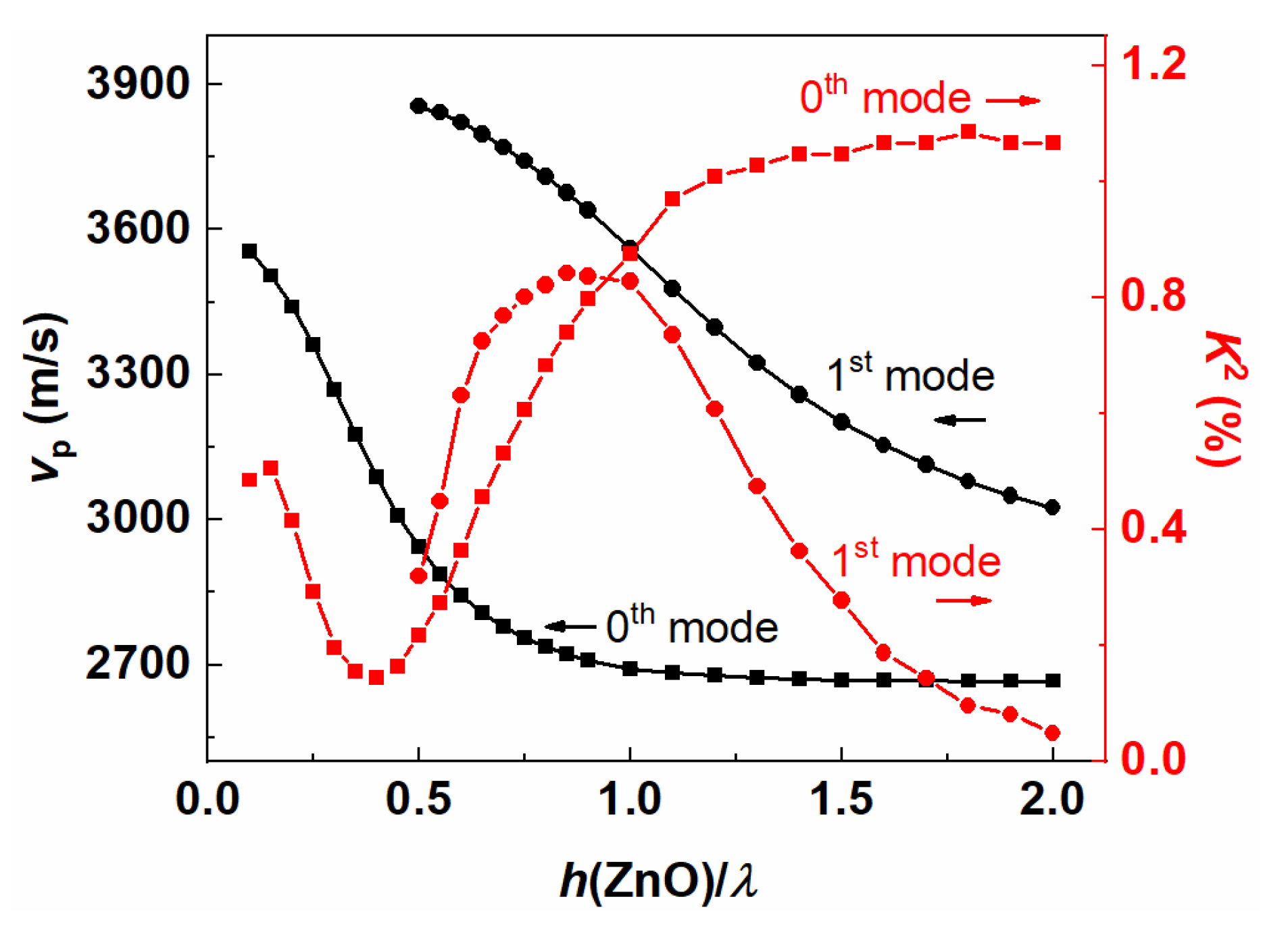

3.1. Devices Based on a-ZnO/a-GaN

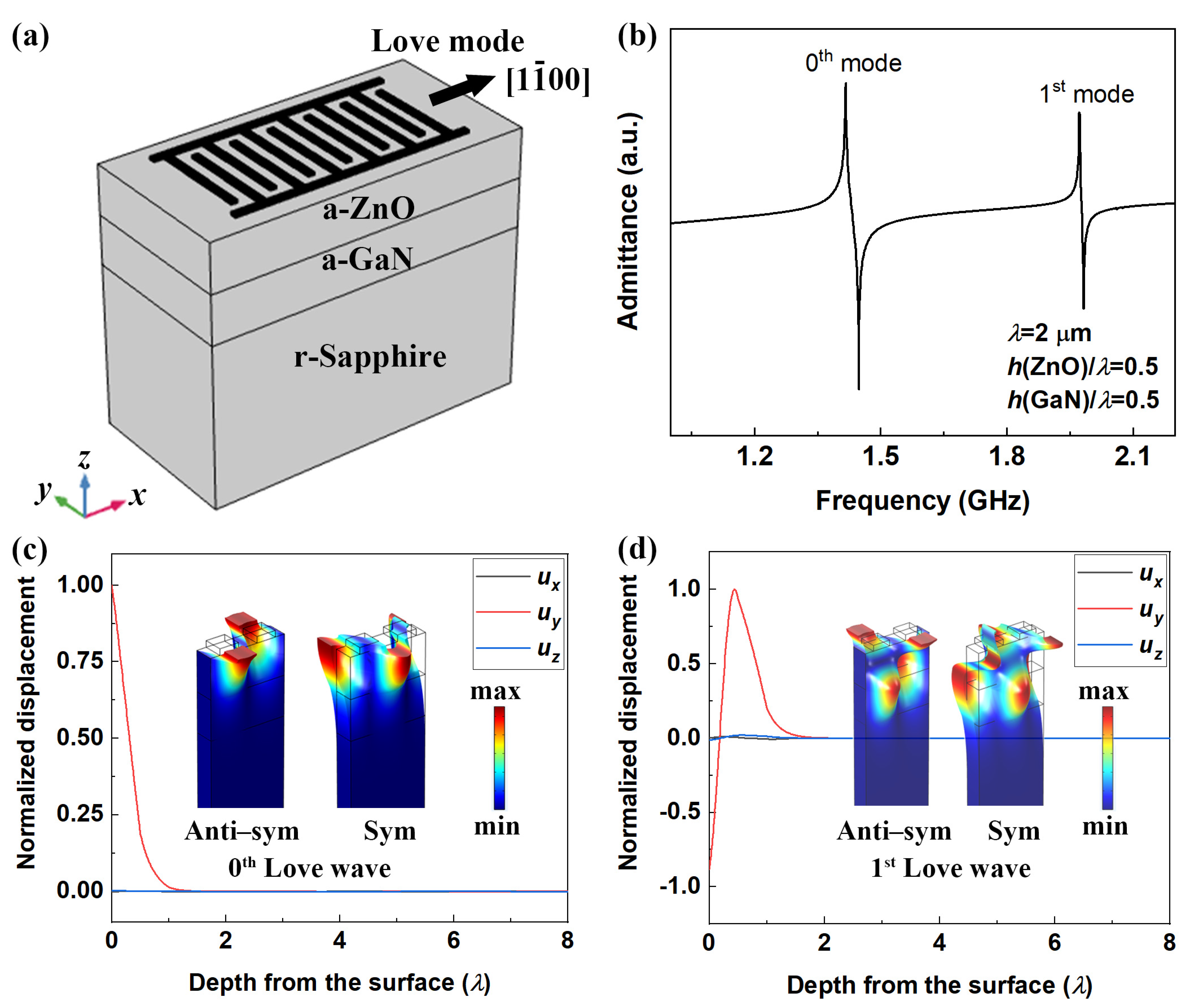

3.2. Devices Based on a-ZnO/a-GaN/r-Sapphire

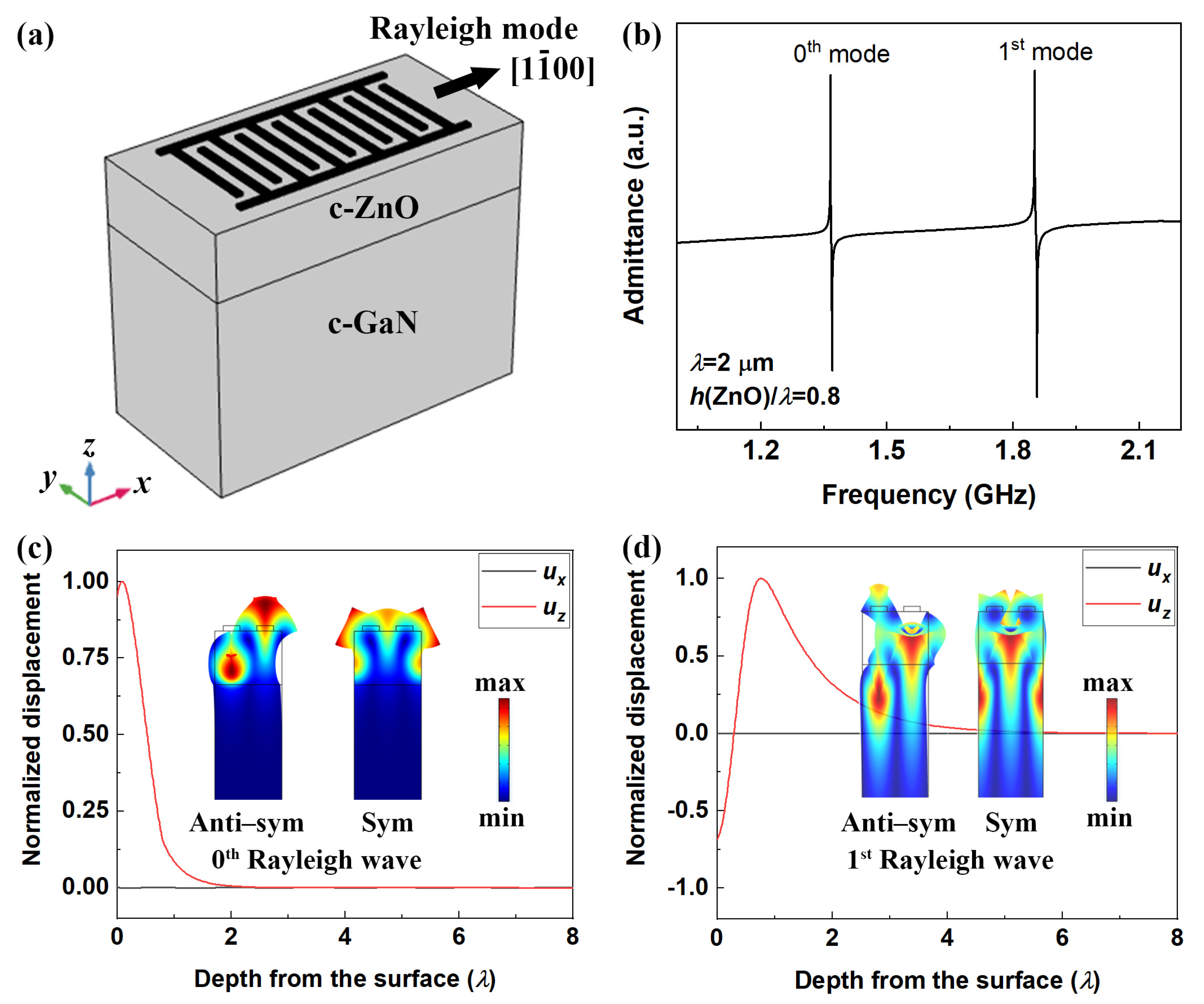

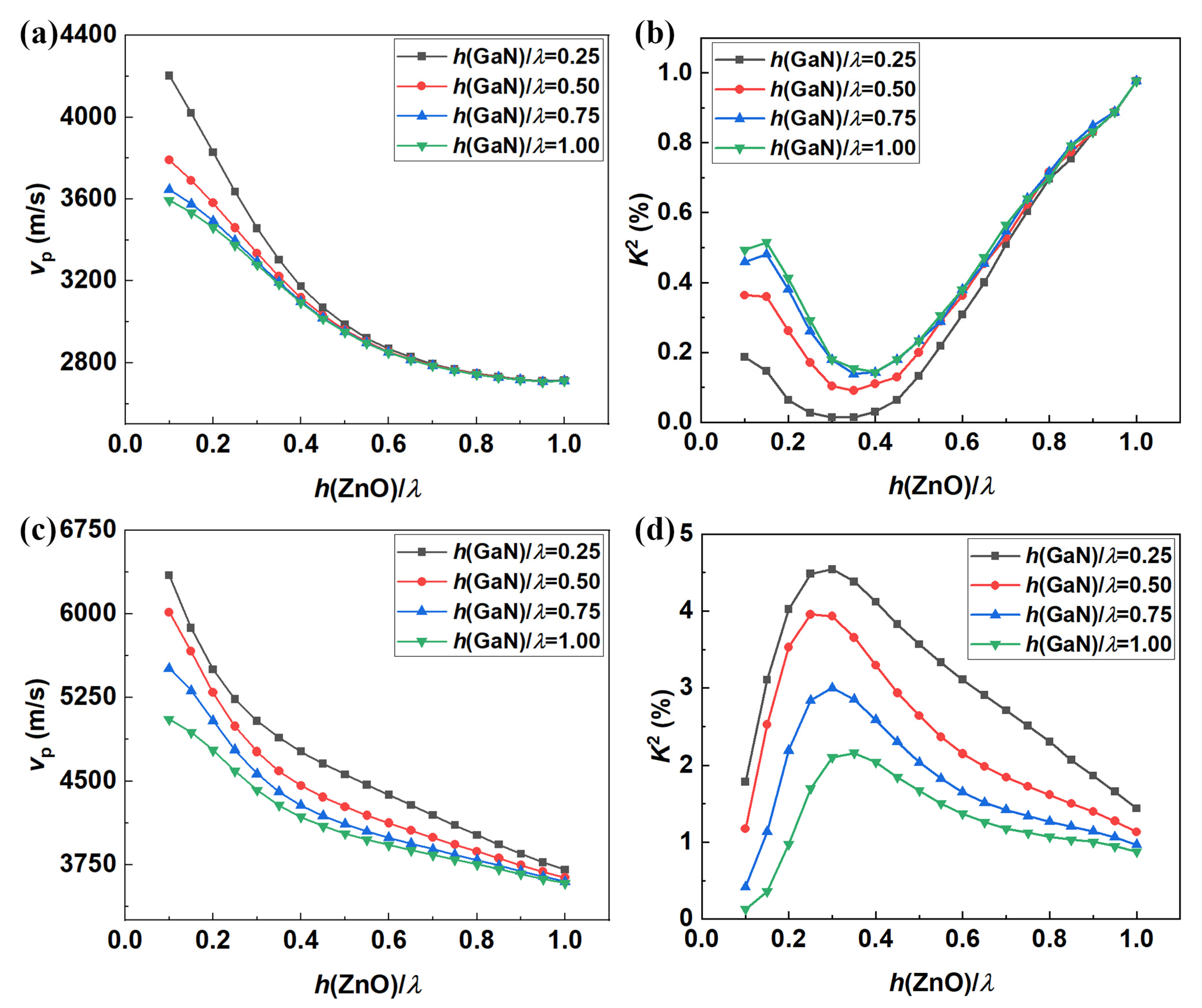

3.3. Devices Based on c-ZnO/c-GaN

3.4. Devices Based on c-ZnO/c-GaN/c-Sapphire

3.5. Other Devices with Sezawa-Mode Wave

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jeng, M.-J.; Sharma, M.; Li, Y.-C.; Lu, Y.-C.; Yu, C.-Y.; Tsai, C.-L.; Huang, S.-F.; Chang, L.-B.; Lai, C.-S. Surface acoustic wave sensor for c-reactive protein detection. Sensors 2020, 20, 6640. [Google Scholar] [CrossRef] [PubMed]

- Constantinoiu, I.; Viespe, C. ZnO metal oxide semiconductor in surface acoustic wave sensors: A review. Sensors 2020, 20, 5118. [Google Scholar] [CrossRef] [PubMed]

- Lo, X.-C.; Li, J.-Y.; Lee, M.-T.; Yao, D.-J. Frequency shift of a SH-SAW biosensor with glutaraldehyde and 3-aminopropyltriethoxysilane functionalized films for detection of epidermal growth factor. Biosensors 2020, 10, 92. [Google Scholar] [CrossRef] [PubMed]

- Ruppel, C.C.W. Acoustic wave filter technology-a review. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2017, 64, 1390–1400. [Google Scholar] [CrossRef] [PubMed]

- Takai, T.; Iwamoto, H.; Takamine, Y.; Fuyutsume, T.; Nakao, T.; Hiramoto, M.; Toi, T.; Koshino, M. High-performance SAW resonator with simplified LiTaO3/SiO2 double layer structure on Si substrate. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2019, 66, 1006–1013. [Google Scholar] [CrossRef] [PubMed]

- Holm, A.; Sturzer, Q.; Xu, Y.; Weigel, R. Investigation of surface acoustic waves on LiNbO3, quartz, and LiTaO3 by laser probing. Microelectron. Eng. 1996, 31, 123–127. [Google Scholar] [CrossRef]

- Look, D.C.; Farlow, G.C.; Reunchan, P.; Limpijumnong, S.; Zhang, S.B.; Nordlund, K. Evidence for native-defect donors in n-type ZnO. Phys. Rev. Lett. 2005, 95, 4. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, W.; Xu, S.; Wang, Z. Enhancing light emission of ZnO microwire-based diodes by piezo-phototronic effect. Nano Lett. 2011, 11, 4012–4017. [Google Scholar] [CrossRef]

- Wang, T.; Wu, H.; Wang, Z.; Chen, C.; Liu, C. Improvement of optical performance of ZnO/GaN p-n junctions with an InGaN interlayer. Appl. Phys. Lett. 2012, 101, 161905. [Google Scholar] [CrossRef]

- Luo, J.; Zeng, F.; Pan, F.; Li, H.; Niu, J.; Jia, R.; Liu, M. Filtering performance improvement in V-doped ZnO/diamond surface acoustic wave filters. Appl. Surf. Sci. 2010, 256, 3081–3085. [Google Scholar] [CrossRef]

- Didenko, I.S.; Hickernell, F.S.; Naumenko, N.F. The experimental and theoretical characterization of the SAW propagation properties for zinc oxide films on silicon carbide. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 179–187. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.; Wang, W.; Qian, L.; Li, Q.; Lu, Z.; Shen, J.; Song, C.; Zeng, F.; Pan, F. High-frequency surface acoustic wave devices based on ZnO/SiC layered structure. IEEE Electron. Device Lett. 2019, 40, 103–106. [Google Scholar] [CrossRef]

- Harding, G.L.; Du, J. Design and properties of quartz-based Love wave acoustic sensors incorporating silicon dioxide and PMMA guiding layers. Smart Mater. Struct. 1997, 6, 716–720. [Google Scholar] [CrossRef]

- Barie, N.; Stahl, U.; Rapp, M. Vacuum-deposited wave-guiding layers on STW resonators based on LiTaO3 substrate as Love wave sensors for chemical and biochemical sensing in liquids. Ultrasonics 2010, 50, 606–612. [Google Scholar] [CrossRef]

- Matatagui, D.; Fontecha, J.; Fernandez, M.J.; Oliver, M.J.; Hernando-Garcia, J.; Sanchez-Rojas, J.L.; Gracia, I.; Cane, C.; Santos, J.P.; Horrillo, M.C. Comparison of two types of acoustic biosensors to detect immunoreactions: Love-wave sensor working in dynamic mode and QCM working in static mode. Sens. Actuator B Chem. 2013, 189, 123–129. [Google Scholar] [CrossRef]

- Higashiyama, T.; Katsuyama, A.; Otori, H.; Kamimura, T.; Uehara, A.; Kainuma, M.; Takumi, R.; Kudo, Y.; Ebina, M.; Mochitate, K.; et al. Detection of cellular damage by hydrogen peroxide using SV40-T2 cells on shear horizontal surface acoustic wave (SH-SAW) sensor. Ultrasonics 2014, 54, 1430–1438. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Xu, J.; Xie, Y.; Lan, X. Characteristics of surface acoustic waves in (1120) ZnO film/R-sapphire substrate structures. Sci. China Phys. Mech. Astron. 2018, 61, 024311. [Google Scholar] [CrossRef]

- Emanetoglu, N.W.; Patounakis, G.; Liang, S.H.; Gorla, C.R.; Wittstruck, R.; Lu, Y.C. Analysis of SAW properties of epitaxial ZnO films grown on R-Al2O3 substrates. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2001, 48, 1389–1394. [Google Scholar] [CrossRef]

- Tjeung, R.T.; Maurya, D.K.; Yeo, L.Y.; Friend, J.R.; Kandasamy, S. ZnO/sapphire Based Layered Surface Acoustic Wave Devices for Microfluidic Applications. In Proceedings of the 2011 6th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Kaohsiung, Taiwan, 20–23 February 2011. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Fan, L.; Shui, X.; Zhang, Z.; Wasa, K. Characteristics of surface acoustic waves excited by (1120) ZnO films deposited on r-sapphire substrates. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 1213–1218. [Google Scholar] [CrossRef]

- Lan, X.; Zhang, S.; Fan, L.; Wang, Y. Simulation of SAW humidity sensors based on (1120) ZnO/r-sapphire structures. Sensors 2016, 16, 1112. [Google Scholar] [CrossRef]

- Cui, J.; Duan, Y.; Wang, X.; Zeng, Y. Strain status in ZnO film on sapphire substrate with a GaN buffer layer grown by metal-source vapor phase epitaxy. Microelectron. J. 2008, 39, 1542–1544. [Google Scholar] [CrossRef]

- Hong, S.K.; Ko, H.J.; Chen, Y.; Hanada, T.; Yao, T. ZnO/GaN heterointerfaces and ZnO films grown by plasma-assisted molecular beam epitaxy on (0001) GaN/Al2O3. J. Vac. Sci. Technol. B 2000, 18, 2313–2321. [Google Scholar] [CrossRef]

- Zhao, B.; Yang, H.; Du, G.; Miao, G.; Zhang, Y.; Gao, Z.; Yang, T.; Wang, J.; Li, W.; Ma, Y.; et al. High-quality ZnO/GaN/Al2O3 heteroepitaxial structure grown by LP-MOCVD. J. Cryst. Growth 2003, 258, 130–134. [Google Scholar] [CrossRef]

- Parmenter, R.H. The acousto-electric effect. Phys. Rev. 1953, 89, 990–998. [Google Scholar] [CrossRef]

- Rocke, C.; Manus, S.; Wixforth, A.; Sundaram, M.; English, J.H.; Gossard, A.C. Voltage tunable acoustoelectric interaction in GaAs/AlGaAs heterojunctions. Appl. Phys. Lett. 1994, 65, 2422–2424. [Google Scholar] [CrossRef]

- Wixforth, A.; Scriba, J.; Wassermeier, M.; Kotthaus, J.P.; Weimann, G.; Schlapp, W. Surface acoustic-waves on GaAs AlxGa1-xAs heterostructures. Phys. Rev. B 1989, 40, 7874–7887. [Google Scholar] [CrossRef] [PubMed]

- Rotter, M.; Ruile, V.; Wixforth, A.; Kotthaus, J.P. Voltage controlled SAW velocity in GaAs/LiNbO3-hybrids. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1999, 46, 120–125. [Google Scholar] [CrossRef] [PubMed]

- Pedros, J.; Calle, F.; Cuerdo, R.; Grajal, J.; Bougrioua, Z. Voltage tunable surface acoustic wave phase shifter on AlGaN/GaN. Appl. Phys. Lett. 2010, 96, 123505. [Google Scholar] [CrossRef]

- Li, R.; Reyes, P.I.; Ragavendiran, S.; Shen, H.; Lu, Y.C. Tunable surface acoustic wave device based on acoustoelectric interaction in ZnO/GaN heterostructures. Appl. Phys. Lett. 2015, 107, 5. [Google Scholar] [CrossRef]

- Bahamonde, J.A.; Kymissis, I. A Reconfigurable surface acoustic wave filter on ZnO/AlGaN/GaN heterostructure. IEEE Trans. Electron. Devices 2020, 67, 4507–4514. [Google Scholar] [CrossRef]

- Su, R.; Fu, S.; Shen, J.; Chen, Z.; Lu, Z.; Yang, M.; Wang, R.; Zeng, F.; Wang, W.; Song, C.; et al. Enhanced performance of ZnO/SiO2/Al2O3 surface acoustic wave devices with embedded electrodes. ACS Appl. Mater. Interfaces 2020, 12, 42378–42385. [Google Scholar] [CrossRef] [PubMed]

- Stefanescu, A.; Muller, A.; Dinescu, A.; Konstantinidis, G.; Cismaru, A.; Stavrinidis, A.; Neculoiu, D.; Society, I.E.D. FEM Analysis of GaN Based Surface Acoustic Wave Resonators. In Proceedings of the 2011 International Semiconductor Conference, Sinaia, Romania, 17–19 October 2011. [Google Scholar] [CrossRef]

- Goto, T.; Anderson, O.L.; Ohno, I.; Yamamoto, S. Elastic-constants of corundum up to 1825K. J. Geophys. Res. 1989, 94, 7588–7602. [Google Scholar] [CrossRef]

- Zhang, Q.; Han, T.; Wang, W.; Hashimoto, K.; Chen, J. Surface Acoustic Wave Propagation Characteristics of ScAlN/diamond Structure with Buried Electrode. In Proceedings of the 2014 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications, Beijing, China, 30 October–2 November 2014. [Google Scholar] [CrossRef]

- Shen, J.; Luo, J.; Fu, S.; Su, R.; Wang, W.; Zeng, F.; Song, C.; Pan, F. 3D layout of interdigital transducers for high frequency surface acoustic wave devices. IEEE Access 2020, 8, 123262–123271. [Google Scholar] [CrossRef]

- Salim, Z.T.; Hashim, U.; Arshad, M.K.M. FEM Modeling and Simulation of A Layered SAW Device Based on ZnO/128° YX LiNbO3. In Proceedings of the 2016 IEEE International Conference on Semiconductor Electronics, Kaula Lumpur, Malaysia, 17–19 August 2016. [Google Scholar] [CrossRef]

- Muller, A.; Giangu, I.; Stavrinidis, A.; Stefanescu, A.; Stavrinidis, G.; Dinescu, A.; Konstantinidis, G. Sezawa propagation mode in GaN on Si surface acoustic wave type temperature sensor structures operating at GHz frequencies. IEEE Electron. Device Lett. 2015, 36, 1299–1302. [Google Scholar] [CrossRef]

- Talbi, A.; Sarry, F.; Le Brizoual, L.; Elmazria, O.; Alnot, P. Sezawa mode SAW pressure sensors based on ZnO/Si structure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2004, 51, 1421–1426. [Google Scholar] [CrossRef]

- Fu, S.; Wang, W.; Li, Q.; Lu, Z.; Chen, Z.; Luo, J.; Shen, J.; Wang, R.; Song, C.; Zeng, F.; et al. High-frequency V-doped ZnO/SiC surface acoustic wave devices with enhanced electromechanical coupling coefficient. Appl. Phys. Lett. 2019, 114, 5. [Google Scholar] [CrossRef]

| Items | Details | Items | Details |

|---|---|---|---|

| Number of electrodes | 2 | Shape of unit cell | Quadrangle or quadrangular prism |

| Thickness of electrodes | 0.08λ | Width of unit cell | Less than 0.2λ |

| Terminal voltage | 1 V | Height of unit cell at surface | Less than 0.2λ |

| Boundary condition | Periodic | Depth of 3D models | 0.25λ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Fu, S.; Su, R.; Xu, H.; Zeng, F.; Song, C.; Pan, F. Systematical Study of the Basic Properties of Surface Acoustic Wave Devices Based on ZnO and GaN Multilayers. Electronics 2021, 10, 23. https://doi.org/10.3390/electronics10010023

Shen J, Fu S, Su R, Xu H, Zeng F, Song C, Pan F. Systematical Study of the Basic Properties of Surface Acoustic Wave Devices Based on ZnO and GaN Multilayers. Electronics. 2021; 10(1):23. https://doi.org/10.3390/electronics10010023

Chicago/Turabian StyleShen, Junyao, Sulei Fu, Rongxuan Su, Huiping Xu, Fei Zeng, Cheng Song, and Feng Pan. 2021. "Systematical Study of the Basic Properties of Surface Acoustic Wave Devices Based on ZnO and GaN Multilayers" Electronics 10, no. 1: 23. https://doi.org/10.3390/electronics10010023

APA StyleShen, J., Fu, S., Su, R., Xu, H., Zeng, F., Song, C., & Pan, F. (2021). Systematical Study of the Basic Properties of Surface Acoustic Wave Devices Based on ZnO and GaN Multilayers. Electronics, 10(1), 23. https://doi.org/10.3390/electronics10010023