Abstract

Driven by growing environmental concerns and regulations, cosmetic companies are seeking reliable methods to promptly assess the possibility of replacing high-impact ingredients with sustainable alternatives. In this work, we exploited rheological and texture analyses to evaluate the possibility of using natural and biodegradable raw materials for reformulating three commercial oil-in-water skin care emulsions from an eco-design perspective. Synthetic texturizers, like nylon-12 and PMMA, were replaced with starch, maltodextrin, and silica, while acrylic rheological modifiers were substituted with polysaccharide associations of sclerotium gum, xanthan gum, diutan gum, and carrageenan. Plant-based emollients and a biodegradable elastomer were used as alternatives to silicone oils. The flow and viscoelastic properties of the samples were characterized using rheological tests under continuous and oscillatory flow conditions. The immersion/de-immersion texture analysis allowed us to measure the mechanical properties of firmness, adhesiveness, and stringiness. A double-blind sensory test assessed the products’ application and sensory characteristics. The results revealed that rheology and texture analysis are complementary and correlated techniques, useful for predicting cosmetics’ sensory characteristics. While perfect replication of the original formulas might not be achievable, this protocol can aid formulators in selecting new eco-friendly ingredients ensuring the products’ desired application and sensory properties without compromising consumer experience.

1. Introduction

The heightened focus on sustainability has become a central imperative within the global cosmetics industry, compelling companies to develop innovative products that could minimize environmental impact [1]. This transition represents a considerable challenge, demanding in-depth research into eco-friendly materials and the integration of life cycle thinking throughout every stage of the product development process. Emerging as a powerful tool for fostering innovation in sustainable product development, eco-design formulation offers a comprehensive and systematic approach that prioritizes sustainability throughout the entire product life cycle [2]. By meticulously integrating environmental considerations into every step of the design and development, this approach allows us to significantly reduce cosmetics’ environmental impact without neglecting costs, processes, and regulatory aspects [3].

Cosmetics brands today face the dual challenge of meeting rising consumer expectations while acknowledging the complexities of sustainability, where “natural” or “green” formulations do not automatically guarantee environmental responsibility [4]. At the same time, functionality, efficacy, and sensory appeal remain non-negotiable, posing distinct challenges for formulators seeking to align their products with these demands [5,6,7]. In this context, a holistic, eco-design approach to cosmetic development is crucial [8,9].

One critical area for optimization lies in the selection of raw materials as it significantly influences the environmental impacts [10]. The primary environmental impacts differ between rinse-off and leave-on products. With rinse-off cosmetics, water usage and the downstream effects on aquatic ecosystems are crucial concerns. On the other hand, for leave-on products, the upstream phase and raw material sourcing hold greater environmental significance, underscoring the importance of sustainable ingredient selection [9].

This point presents unique hurdles. Conventional high-performance ingredients such as synthetic acrylic polymers, texturizing microplastics, and silicone emollients, whose ecological impacts are not negligible, should be replaced by natural-origin and biodegradable ingredients or synthetic substitutes derived from green chemistry principles, while safeguarding product excellence. Moreover, recent developments such as the restrictions on microplastic usage in leave-on products and the expansion of the microplastic definition proposed by the European Chemicals Agency are propelling manufacturers toward reformulations in this direction [11,12,13]. However, these substitutes may lack extensive application performance data, exhibit instabilities, or introduce esthetic-sensorial limitations [14].

Rheological and texture analyses are powerful tools for the characterization of cosmetic formulations [15,16,17]. They can be used to quickly assess the impact of formulation changes, including the replacement of commonly used raw materials with more sustainable alternatives [18]. Rheological tests, performed under both continuous and oscillatory flow conditions, provide a wealth of information about the structure, flow behavior, and viscoelastic properties of cosmetic samples [19,20,21]. Texture analysis can be used to further investigate the mechanical properties of these products, such as firmness, consistency, adhesiveness, and stringiness [22,23,24]. These data are essential for the development and quality control of new cosmetic products and the optimization of existing formulations. They can also be used to support marketing claims of application and sensorial properties in an objective and scientific way.

Following an eco-design approach, in this study, we reformulated three cosmetic products sold in the pharmaceutical sales channel by replacing some high environmental impact ingredients with eco-friendly alternatives. Synthetic texturizers, such as PMMA and nylon-12, which are considered microplastics with a toxicity profile for the marine fauna [25], have been replaced with natural organic and inorganic raw materials. The non-biodegradable acrylic rheological modifiers, whose persistence in the environment is problematic, have been replaced with associations of polysaccharides. The silicon emollients and film-forming polymers, whose impact is determined by their chemical synthesis which requires the consumption of many energy resources and determines significative CO2 emissions [26,27,28], have been replaced with plant-based emollients and a biodegradable elastomer.

After modifying the formulations as described above and after performing instrumental analyses to study their structural and application characteristics, a double-blind sensory test was conducted to verify whether these substitutions allowed us to preserve the sensory properties of the original products.

2. Materials and Methods

2.1. Materials

Three commercial skin care products provided by Unifarco S.p.A have been reformulated from an eco-design perspective: an acne-prone skin serum (F1), an eye contour gel-cream (F2), and a body butter (F3).

The product F1, whose formulative scheme is reported in Table 1, is a light-textured fluid emulsion, formulated with a lipidic complex with emulsifier properties and an anionic emulsifier. The structural properties are imparted by ammonium acryloyldimethyltaurate/VP copolymer as rheological modifiers. The lipidic phase is composed of fatty alcohols, esters, and dimethicone oil. Nylon-12 and PMMA have the function of texturizers and sensorial enhancers.

Table 1.

Formulation scheme of product F1.

The formula F2 is a gel/cream meant to uniform the under-eye area and ensure long-lasting hydration. The formulation scheme is shown in Table 2. The emulsifying system in this gel-cream is composed of a combination of two non-ionic emulsifiers. This formula is more structured than the previous one thanks to the presence of the cross-linked acrylic polymer carbomer. The silicones present in this formula are dimethicone, polysilicone-11, and dimethiconol, which work synergistically to form a film around the eye. Beyond the presence of silicone gums, the sensory and textural properties are provided by a combination of a synthetic esters, starch, and PMMA.

Table 2.

Formulation scheme of product F2.

The formula F3 is a body butter; this O/W emulsion has a high percentage of oil phase consisting of fatty alcohols, waxes, and nourishing emollients in combination with non-ionic and anionic emulsifiers (Table 3). The synthetic polymers sodium polyacrylate and acrylates/beheneth-25 methacrylate copolymer work together with the lipids to build the body butter structure. PMMA is the synthetic texturizing agent.

Table 3.

Formulation scheme of product F3.

The synthetic ingredients and the naturally derived alternatives chosen for the eco-design reformulation of the three commercial formulas are listed in Table 4. The synthetic texturizers of the formulas, i.e., nylon-12 (particle size of 20 µm) and polymethyl methacrylate (particle size of 6–10 µm) have been replaced using naturally derived organic or inorganic texturizers: Z (zea mays Starch, polyvinyl alcohol, and glycerin) whose particle size is 5–15 µm, M (maltodextrin) whose particle size is 2–20 µm, and S (sodium potassium aluminum silicate, titanium dioxide, and silica) whose particle size is 2–20 µm, H (Mica) whose particle size is 5–15 µm.

Table 4.

Synthetic raw materials and natural alternatives chosen for eco-design reformulation of cosmetic products.

The acrylic rheological modifiers present in the formulas have been replaced using polysaccharidic raw materials in combination: t (sclerotium gum), v (sclerotium gum and xanthan gum), k (Sphingomonas Ferment Extract), r (succynoglycan), and c (carrageenan).

Dimethicone emollients have been replaced using plant-based emollients: CU (undecane and tridecane), EG (C15-19 alkanes), DSG (ethyl olivate and triheptanoin), EP (palm/kernel alkanes), and P (coco-caprylate/caprate, triheptanoin, C9-12 alkane, dilinoleic acid/butanediol copolymer, and castor oil/IPDI copolymer).

2.2. Preparation of Emulsions

All of the emulsions were prepared following the same formulation procedure. The lipidic phase was prepared by dispersing the emulsifiers and the lipophile molecules in a mixture of emollients, and then heated at 75 °C. The water phase was prepared by dispersing the hydrophilic molecules (actives, humectants, chelating agents, and polymers) in water and heating at 70 °C. The oil phase was added to the water phase using a Silverson L5T laboratory mixer (Ghiaroni & C srl., Buccinasco, MI, Italy) and homogenized for 5 min at 4500 RPM. The texturizing powders were added after emulsification stirring at 2500 rpm. The pH of the emulsions prepared was set between 5 and 5.5 with the addition of citric acid as a buffering agent and measured with a pH-meter Basic 20 (Crison Instruments, Alella Barcelona, Spain).

2.3. Stability Assessment

To predict physical instability phenomena, samples were subjected to strong mechanical stress conditions by using the centrifuge MPW-56 (MPW Med. Instruments, Warsaw, Poland) at 4800 RPM for 30 min.

2.4. Rheological Analysis

The rheological measurements conducted both in continuous and oscillatory flow conditions were performed using a Rheometer Physica MCR e302 (Anton Paar GmbH, Graz, Austria), maintaining a temperature of 23 °C ± 0.05 °C. A PP50-P2 sensor (parallel plates with serrated surfaces) with a fixed gap of 1 mm was used. RheocompassTM software (version 1.32.258, Anton Paar GmbH, Graz, Austria) was used to collect and analyze the data. A controlled shear rate test (CSR) was performed to obtain the samples’ flow curves, which show the trend of viscosity (η) at an increasing shear rate, from 0.001 to 1000 s−1. The zero-shear viscosity , i.e., the viscosity of the material at rest, was calculated by fitting the flow curves with the Carreau−Yasuda mathematical model applicable to shear-thinning materials:

where is the shear stress, is the shear rate, is the infinite viscosity, i.e., asymptotic viscosity at a high shear rate, is the relaxation time, and is the power law index [29].

An amplitude sweep test (AS) was used to evaluate the products’ linear viscoelastic region (LVER) and the critical strain (γ G′ = G″). This test was performed at a fixed frequency of 1 Hz by increasing the amplitude strain (γ) from 0.01% to 1000%. A frequency sweep analysis allowed us to analyze the inner microstructure of the samples by considering the trend of the storage (G′) and the loss (G″) moduli. This test was conducted by fixing the oscillation strain within the LVER and decreasing at the same time the oscillation frequency from 10 Hz to 0.01 Hz.

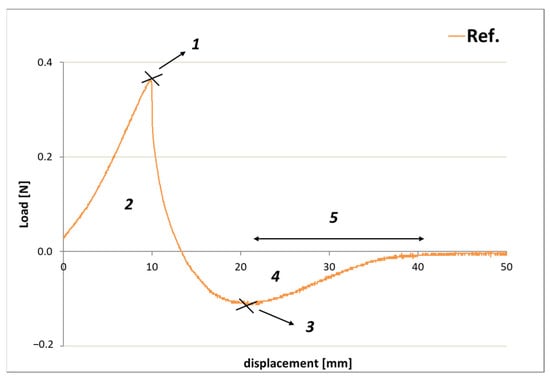

2.5. Texture Analysis

A texture analysis was performed using a Texture Analyzer TMS-Pro (Food Technology Corporation, Sterling, VA, USA) equipped with a 10-Newton load cell at room temperature. A spherical nylon probe with a diameter of 2 cm moved vertically at a speed of 80 mm/min to a depth of 10 mm into the emulsions contained in 50 mL containers with a diameter of 5.3 cm. The probe then returned to its original position. Texture Lab Pro software (version 1.1) was used to collect and analyze the data, generating a curve depicting load (N) versus cumulative displacement (mm) (Figure 1). Firmness or hardness (N) was defined as the maximum force recorded, consistency (N.mm) as the area under the positive portion of the curve, cohesiveness (N) as the negative peak, adhesiveness (N.mm) as the area under the negative portion of the curve, and stringiness (mm) as the distance that the sample stretched during the probe de-immersion phase [30,31].

Figure 1.

The curve obtained with an immersion/de-immersion test, performed with a texture analyzer, and the definitions of the calculated parameters are as follows: firmness (1), consistency (2), cohesiveness (3), adhesiveness (4), and stringiness (5). The data are plotted as load vs. cumulative displacement.

2.6. Sensory Analysis and Statistical Analysis

A double-blind sensory test was performed, where 33 healthy Caucasian volunteers of both sexes (age 23–45 years old) were asked to apply the final reformulated products and the original ones (1 mg cm−2) on each forearm. The products were evaluated by panelists in the same room with a controlled temperature and relative humidity. Each participant was provided with paper and cleaning gel to clean their hands and forearms before starting the test and between each evaluation session. The products, randomly coded with a two-letter code, unknown to panelists and to test administrators, were presented to them in neutral 30 mL jars to minimize the influence of external factors on their responses. The order of presentation of the samples was changed every session to avoid a bias in rating score. Panelists were shown how to pick up and apply the samples through circular movements until they disappeared on the skin. One minute after application, they were asked to fill out a seven-question survey concerning sensory parameters in four different phases of the application: color for the appearance at first sight; consistency at first touch; spreadability and rate of absorption for the application phase; greasiness, stickiness, and softness of the skin for the after-feel phase. Each parameter was evaluated on a scale from 1 to 7, where 1 stood for the lowest rating and 7 stood for highest rating:

- -

- Color: from 1 (yellowish) to 7 (greyish) through 4 (white);

- -

- Consistency at first touch: from 1 (fluid) to 7 (very consistent);

- -

- Spreadability: from 1 (not spreadable) to 7 (very spreadable);

- -

- Rate of absorption: from 1 (very slow) to 7 (very fast);

- -

- Greasiness: from 1 (not greasy) to 7 (very greasy);

- -

- Stickiness: from 1 (not sticky) to 7 (very sticky);

- -

- Softness of the skin after application: from (not soft) to 7 (very soft).

This study was conducted in accordance with the Declaration of Helsinki. All of the volunteers provided their informed consent for research analysis and the reporting of findings was anonymous, in accordance with Italian legal and ethical requirements. All participants were informed in detail about the aim of the study, the voluntary nature of their participation, and their right to withdraw from the study at any time without being penalized in any way.

The results and the data collected were elaborated with paired samples Student’s t-test statistical analysis at a significance level of p < 0.05 to determine the statistical differences between the cream samples, based on the characteristics described by the panelists.

3. Results and Discussions

The aim of this research study was to reformulate three commercially available cosmetic skin care oil-in-water emulsions through the lens of eco-design formulation. These three formulations, each distinct in their technological approach, were F1, a fluid and light-textured oil-in-water emulsion; F2, a firm cream/gel; F3, a rich emulsion boasting a high content of lipidic phases. Our systematic approach involved the progressive substitution of the synthetic and more impactful ingredients within each formula, beginning from texturizers, followed by acrylic rheological modifiers, and culminating in the replacement of silicone-based materials, where applicable. This comprehensive strategy aimed to optimize the formulations while adhering to eco-design principles, without interfering with their sensorial profile.

3.1. Reformulation of Product F1

3.1.1. Substitution of Synthetic Texturizers

The product F1 is a fluid emulsion with high spreadability and a light evanescent texture. It contains nylon-12 at 1% w/w and PMMA at 1.5% w/w as texturizers which confer the mattifying and anti-shine effect. A copolymer derived from acryloyldimethyltaurate acts as a stabilizer and rheological modifier. The emollient portion is composed of fatty alcohols, esters, and dimethicone oil.

In the first phase of this work, the synthetic texturizers nylon-12 and PMMA, which falling into the category of microplastics could be harmful to the aquatic environment, have been replaced with naturally derived and biodegradable powders proposed as more eco-friendly alternatives: two organic polymers, Z (a combination of zea mays starch powder, glycerin from olive oil, and biodegradable polyvinyl alcohol) and M (maltodextrin), and two inorganic polymers, H (mica) and S (a mixture of aluminum silicate, titanium dioxide, and silica). Four formulations were prepared, each containing these different natural texturizers to replace the synthetic ones at the same total concentration of 2.5% w/w.

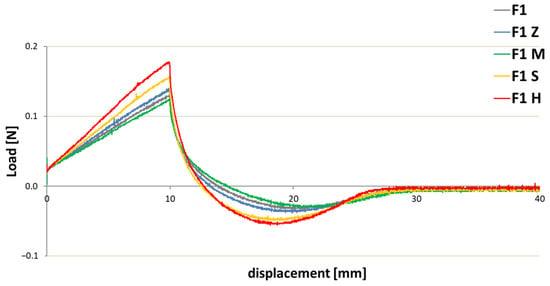

The texture curves in Figure 2 reveal that the parameters measured for the emulsions containing the organic polymers Z and M as texturizers (F1 Z and F1 M) did not show significant differences with those measured for the reference product F1 containing nylon-12 and PMMA. On the contrary, the samples formulated with the inorganic texturizers S and H (F1 S and F1 H) were characterized by higher values of firmness, consistency, cohesiveness, and adhesiveness (considering the absolute values), and lower values of stringiness. These two formulations, in fact, were less spreadable, since the force necessary to obtain a deformation was greater, and they left a stickier residue on the skin after the application phase [16].

Figure 2.

Texture curves obtained from an immersion/de-immersion test performed on the product F1 with the synthetic texturizers and the products F1 Z, F1 M, F1 S, and F1 H with natural ones.

From the flow curves obtained with a rheological controlled shear rate test, the zero-shear viscosity of the samples was calculated with the Carreau–Yasuda equation in the so-called Newtonian plateau region where the viscosity remains almost constant. The calculated values are listed in Table 5. In accordance with the firmness and consistency data recorded in the texture analysis, the samples formulated with the starch-derived texturizers (Z and M) showed lower viscosity values than the samples formulated with the inorganic texturizers (S and H). The substitution of the microplastics with the organic texturizers did not cause drastic changes in the viscosity of the product.

Table 5.

The zero-shear viscosity (η0) values measured for the product F1 with the synthetic texturizers and the products F1 Z, F1 M, F1 S, and F1 H with natural ones.

The rheological curves obtained from a frequency sweep test are shown in Figure 3. The samples showed a weak gel pattern of the viscoelastic moduli, in which the storage G′ modulus was always greater than the loss G″ modulus in the whole frequency range investigated. The inorganic polymers S and H caused a slight increase in the elastic component (Figure 3b), whereas the use of M caused a decrease in both G′ and G″ (Figure 3a). The moduli of the sample containing the texturizer Z were superimposed on those of the original product formulated with the synthetic polymers, demonstrating that the natural polymer Z can be considered a valid alternative to the synthetic texturizers in this product. In this formulation which contains a high percentage of aqueous phases (more than 70% w/w), the starch-derived polysaccharides gave more balanced viscoelastic properties compared to the inorganic powders, being able to interact and bind with water through the formation of hydrogen bonds, but also able to efficiently absorb the oil phase, without feeling sticky or greasy, as demonstrated in the study conducted by Marku et al. in which starch-stabilized surfactant-free emulsions with a high oil content were found to be stable and pleasant during application on the skin [32].

Figure 3.

Trends of the elastic G′ and viscous G″ moduli in the function of the oscillation frequency for the product F1 compared with the samples formulated with the organic texturizers F1 Z and F1 M (a) and the samples formulated with the inorganic ones, F1 S and F1 H (b).

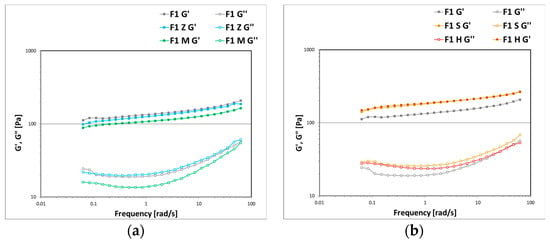

3.1.2. Substitution of Acrylic Rheological Modifiers

The acne-prone serum with Z as a texturizer (F1 Z) contains ammonium acryloyldimethyltaurate/VP copolymer at 0.9% w/w as a rheological modifier and has been reformulated using the following polysaccharidic raw materials at different concentrations: t (sclerotium gum), v (a combination of sclerotium gum and xanthan gum), and r (succinoglycan). These natural ingredients are polysaccharides obtained from bacterial fermentation proposed as cosmetic rheological modifiers, since, according to their chemical structure characterized by the presence of several hydroxyl groups, they can bind with water molecules and modulate the viscosity and mechanical properties of the systems [33]. Since the aim of this study was to replace the acrylic polymer while maintaining the physical–mechanical properties of the formula, the four polysaccharides were chosen among those that were found to be able to form weak gel-type structures, according to the results of our previous studies characterizing the rheological and texture properties of aqueous dispersions of naturally derived rheological modifiers [34,35]. The samples containing the microbe-derived ingredients at a concentration of 0.75% w/w were not stable in the centrifuge test conducted at 4800 rpm for 30 min, showing phase separation (Table 6). The samples that were stable in the centrifuge test were subjected to a controlled shear rate rheological test. By increasing the concentration of the polysaccharides t and v at 1% w/w, we obtained stable emulsions, but we registered high values of viscosity at rest, firmness, and consistency, which are parameters correlated with poor spreadability (Figure 4). In their work, Kulawik-Piorò et al. stated that too much firmness, which is strictly correlated with viscosity, could cause difficulties in spreading the product on the skin, since higher forces are needed to deform it, which would discourage consumers from regular and frequent use [16]. We therefore maintained the concentration of the polysaccharides t and v at 0.75% w/w and we introduced 0.1% w/w and 0.2% w/w of the polysaccharide k (diutan gum) known for its stabilizing properties even at low concentrations.

Table 6.

Mechanical stability test results for the formulation F1Z with the natural texturizer Z and different polysaccharides used at different concentrations to replace the synthetic acrylic rheological modifier. The samples that were stable in the centrifuge test were subjected to a controlled shear rate rheological test to measure the zero-shear viscosity (η0).

Figure 4.

Texture curves obtained from an immersion/de-immersion test performed on the product F1Z with the synthetic texturizer Z and the acrylic rheological modifier and the samples with the polysaccharidic rheological modifier and F1Z v1, F1Z t1, F1Z vk, and F1Z tk2.

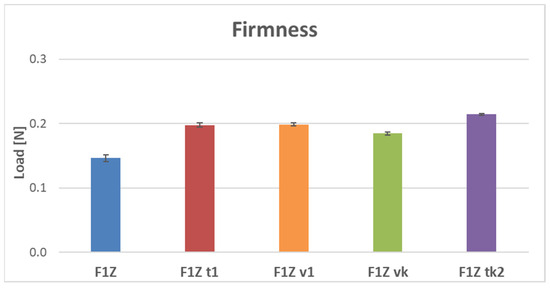

To stabilize the formula containing the polysaccharide t at 0.75% w/w, it was necessary to use a concentration of k of 0.2% w/w (sample F1Z tk2), leading to an increase in firmness at higher values than the formulation F1Z t1 with t at 1% w/w. As shown in Figure 5, the association between v at 0.75% w/w and k at 0.1% w/w (F1Z vk) stabilized the emulsion, producing the lowest increase in firmness.

Figure 5.

Firmness measured by means of an immersion/de-immersion test for the product F1Z by substituting the acrylic rheological modifier.

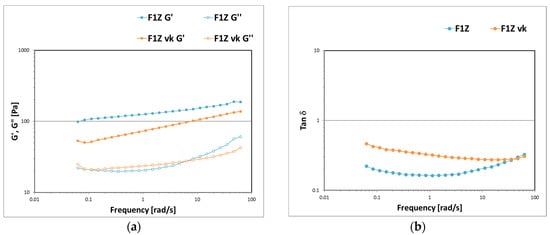

The frequency sweep rheological analyses showed that the substitution of the acrylic polymer with the polysaccharides determined a loss of the solid elastic component, since the formulation F1Z vk had a lower storage G′ modulus (Figure 6a) compared to the F1Z product and higher values of damping factor tanδ (Figure 6b), which is calculated from the ratio between the viscous modulus G″ and the elastic modulus G′.

Figure 6.

Trends of the elastic G’ and viscous G’’ moduli (a) and the damping factor tanδ (b) in the function of the oscillation frequency for samples F1Z with the acrylic polymer and F1Z vk with a combination of polysaccharides.

Despite the differences found between the products after the replacement of the acrylic polymer with polysaccharides of microbial origin, by combining the polysaccharide raw material v e at 0.75% and the diutan gum k at 0.1%, we managed to obtain a fluid product stable against mechanical stress, with high spreadability, modules that fall between the second and third decade, and a viscosity similar to that of the original product (η at 0.01 s−1 for F1 was 1173.3 Pa·s; for F1Z vk, it was 1145.4 Pa·s). Compared to the raw material t composed of only sclerotium gum, the raw material v is composed of a mixture of sclerotium gum and xanthan gum, which act synergistically with diutan gum to form a structured network in the aqueous phase, giving greater stability to the emulsion and a better balance of texture properties.

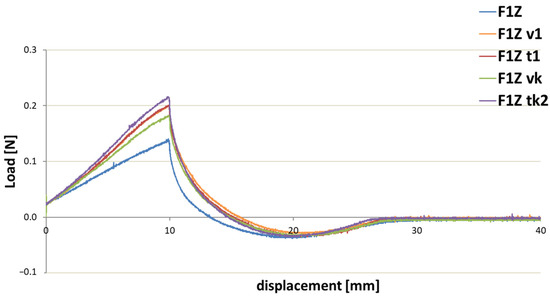

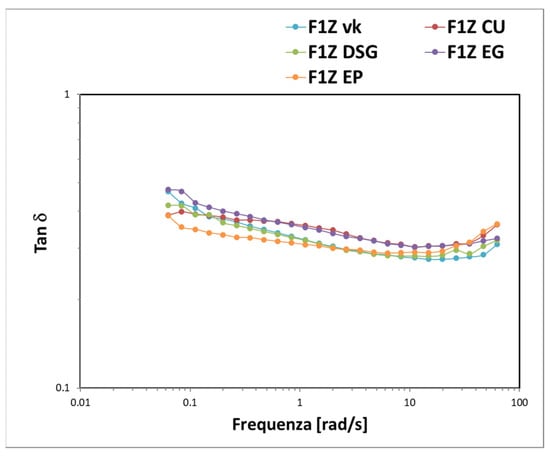

3.1.3. Substitution of Silicone Emollients

In the formula F1Z vk, where the texturizers and rheological modifier were replaced, we proceeded by replacing the emollient dimethicone, which was present at 1% w/w and whose production process has a high expenditure in terms of carbon dioxide and is, therefore, highly impactful on the environment. Silicones are highly appreciated in cosmetics for their sensorial properties, as they give a light, smooth, and silky texture to the formula. The raw materials chosen for the replacement were plant-based emollients proposed on the market as sustainable alternatives to silicones as they create a skin-like feel and a dry touch like those given by silicones [8]. These emollients were used at the same concentration of dimethicone (1% w/w): CU (undecane and tridecane), EG (C15-19 alkanes), DSG (ethyl olivate and triheptanoin), and EP (coconut/palm kernel alkanes). As shown from the values of the damping factor (tanδ) in the function of frequency (Figure 7 and Table 7), the formulation which was found to have the same viscoelastic properties as the formula F1Z vk was F1Z DSG (containing ethyl olivate and triheptanoin as a dimethicone-substitute emollient). These data highlight how the qualitative composition of the internal phase can influence the rheological and application properties of the emulsion. Even if the differences were not so marked, the ester-based raw material compared to that based on alkanes allowed us to obtain a good compromise between the polarity, mechanical properties, and sensoriality, bieng similar to those imparted by dimethicone.

Figure 7.

Trends of the damping factor tanδ in the function of the oscillation frequency for samples F1Z vk with dimethicone and samples F1Z DSG, F1Z CU, F1Z EG, and F1Z EP with naturally derived emollients.

Table 7.

Damping factor tanδ values registered at different frequencies (10 and 0.5 rad/s) and zero-shear viscosity values (η0) for samples F1Z v075 k01 with dimethicone and samples F1Z DSG, F1Z CU, F1Z EG, and F1Z EP with naturally derived emollients.

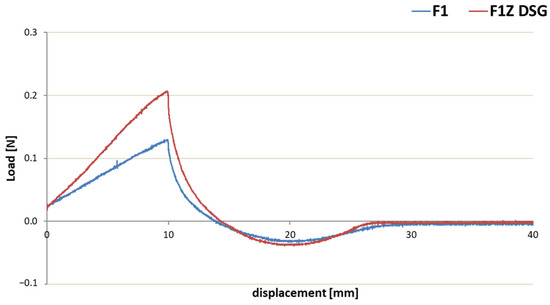

The graph of texture parameters in Figure 8 shows the comparison between the original commercial formula F1 and the final formula F1Z DSG reformulated using an eco-design approach by substituting the synthetic texturizers nylon-12 and PMMA with the starch-based raw material Z, the acrylic rheological modifier with the combination of sclerotium, xanthan (v), and diutan (k) gums, and dimethicone with the natural emollients ethyl olivate and triheptanoin (DSG). The formulations had similar values of cohesiveness (F1: −0.036 N ± 0.003; F1Z DSG: −0.039 N ± 0.001) and adhesiveness (F1: 0.413 N.mm ± 0.029; F1Z DSG: 0.363 N.mm ± 0.018), as the negative part of the curves are almost superimposed. On the other hand, F1Z DSG showed slightly higher values of firmness (F1: 0.139 N ± 0.001; F1Z DSG: 0.205 N ± 0.003) and consistency (F1: 0.982 N.mm ± 0.053; F1Z DSG: 1.395 N.mm ± 0.030) and significantly lower values of stringiness (F1: 8.91 mm ± 1.05; F1Z DSG: 6.57 mm ± 0.521), indicating that the substitution made resulted in a more structured emulsion with lower pick-up properties. These differences are mainly attributable to the replacement of the acrylic polymer with polysaccharides, which, in order to guarantee the mechanical stability of the formulation, must be used at high concentrations, resulting in an increase in firmness and consistency.

Figure 8.

Texture curves obtained from an immersion/de-immersion test performed on the original product F1 and the sample F1Z DSG reformulated using an eco-design approach by replacing the synthetic texturizers, the acrylic rheological modifier, and dimethicone.

We performed a double-blind sensory test comparing the original formula F1 and the reformulated one F1Z DSG. Differences were detected just for one parameter, that is, the consistency at first touch, in agreement with the texture parameters measured in the texture analysis. On a scale of values where 1 is fluid and 7 is compact, F1Z DSG was evaluated on average as μ = 2.61, while F1 was measured as μ = 1.73 [t (32) = 3.98 p < 0.01]. No differences were detected in terms of the spreadability, absorption rate, and after-feel phase.

3.2. Reformulation of Product F2

3.2.1. Substitution of Synthetic Texturizers

The product F2 is a firm gel-cream to be applied on the under-eye area, whose emulsified system is composed of two non-ionic emulsifiers and carbomer acts as a stabilizer and rheological modifier. The film-forming properties are provided by PMMA and a mixture of dimethicone, polysilicone-11, and dimethiconol, which also provide sensorial and texturizing properties.

The synthetic texturizer present in the formula at a concentration of 1% w/w has been replaced by natural texturizers at the same concentration, namely, Z, M, S, and H. Four formulations, each containing these different natural texturizers at 1% w/w, were prepared and analyzed through texture analysis and rheology.

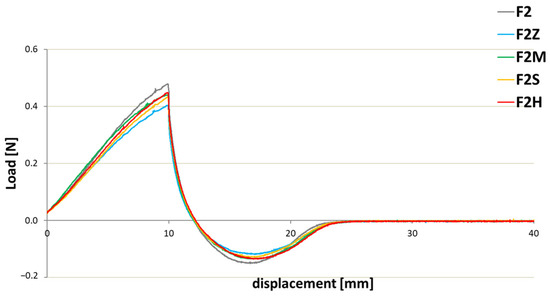

The texture curves in Figure 9 show that the incorporation of natural polymers instead of the synthetic ones caused a slight decrease in the emulsions’ firmness, consistency, and cohesiveness. The most significant decrease occurred when the synthetic texturizer was replaced with polymer Z.

Figure 9.

Texture curves obtained from an immersion/de-immersion test performed on the product F2 with the synthetic texturizers and the products F2 Z, F2 M, F2 S, and F2 H with the natural ones.

The values of zero-shear viscosity calculated with the Carreau–Yasuda model are listed in Table 8. The substitution of PMMA with the natural texturizers caused slight variation in the viscosity of the product. In accordance with the texture parameters, the sample containing Z had the lowest values of viscosity at rest.

Table 8.

Zero-shear viscosity (η0) values measured for the product F2 with the synthetic texturizers and the products F2 Z, F2 M, F2 S, and F2 H with the natural ones.

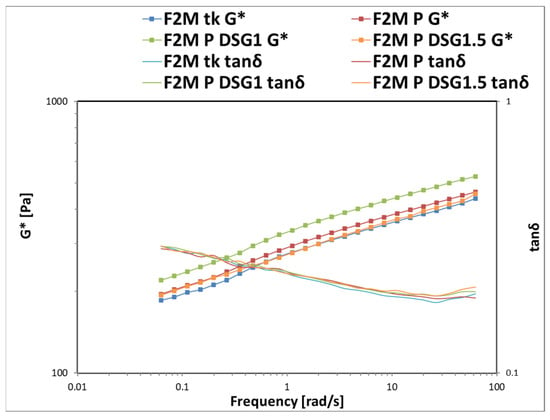

The samples showed a weak gel rheological pattern, with G′ always dominating over G″ in the entire frequency range investigated, whose values were settled between the second and third decades. Polymer Z caused a decrease in the complex G* modulus and an increase in the damping factor tanδ, thus indicating a less structured system with a lower elastic component than the other samples (Figure 10). Polymer M turned out to be the texturizer that caused fewer variations in the rheological and textural properties of the product.

Figure 10.

Trends of the complex G* modulus and of the damping factor tanδ in the function of the oscillation frequency for the product F2 compared with the samples formulated with the organic texturizers F2 Z and F2 M (a) and the samples formulated with the inorganic ones, F2 S and F2 H (b).

3.2.2. Substitution of Acrylic Rheological Modifiers

Once the synthetic texturizer was replaced with the natural texturizer M, we proceeded with the substitution of the acrylic polymer. This product contains carbomer at 0.35% w/w and has been reformulated using three raw materials alone and in combination, t (sclerotium gum), r (succinoglycan), and k (diutan gum), which are polysaccharides with high elastic and film-forming properties. The polysaccharide concentration used to prepare the samples and the results of the centrifuge test are reported in Table 9.

Table 9.

Mechanical stability test results and zero-shear viscosity (η0) values for the formulation F2M with the natural texturizer M and different polysaccharides used at different concentrations to replace the synthetic acrylic rheological modifier.

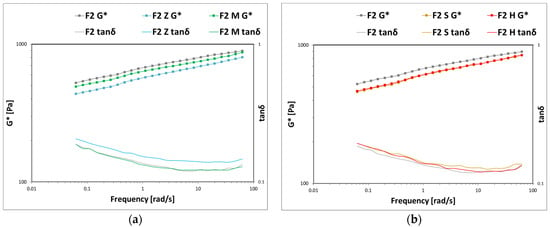

Even if the use of polysaccharide concentrations higher than 1.5% led to obtaining stable and structured systems, the emulsions were difficult to prepare and resulted in being non-homogeneous, sticky, and not very sensorial. It was therefore decided to compare the textural properties of the emulsions formulated with the different polysaccharides inserted in the water phase at 1.5% w/w (Figure 11). Compared to the F2M reference product, the F2M t, F2M r, and F2M k emulsions thus formulated showed lower firmness, consistency, cohesiveness, and adhesiveness values, demonstrating the difficulty of replicating the mechanical performance of the acrylic polymer through the use of a polysaccharide alone. Among the polysaccharides studied, t determined lower values of adhesiveness, r determined greater stringiness since the emulsion formed a longer filament during the de-immersion phase, which indicated greater pick-up properties, and k determined greater cohesiveness, which could reflect a more elastic and stiffer system. These different behaviors are linked to the different chemical structures of the polysaccharides which determine their application peculiarities. Sclerotium gum (t) is a non-ionic polysaccharide characterized by a linear chain of glucose with a single glucose branch at every third residue. Its molecular weight is about 1 million Dalton. In water, it assumes a triple-helix conformation which results in a rigid and pseudoplastic gel with a bouncy texture [36]. Succinoglycan (r) is an octasaccharide of 6 million Da consisting of seven glucose and one galactose with pyruvyl and succinyl substitutions. Its semi-flexible double-helix structure established in solution causes the formation of weak and soft gels [37]. Diutan gum (k) is a high-weight polysaccharide whose molecular weight is between 2.85 and 5.20 million Da. Its structure is characterized by a tetrasaccharide main chain with two rhamnose side chains, forming a rigid double-helix which enhances its stability in solution by forming a long-range ordered network [38].

Figure 11.

Firmness (a), consistency (b), cohesiveness (c), adhesiveness (d), and stringiness (e) measured by means of an immersion/de-immersion test for the product F2M by substituting the acrylic rheological modifier with polysaccharides t, r, and k alone and in combination.

By exploiting their different characteristics, it is possible to combine these polysaccharides together to obtain a wide range of textures and try to achieve the physical–mechanical properties imparted by acrylic polymers. Maintaining the total concentration of polysaccharides at 2% w/w, the textural properties of the associations between t at 1.5% w/w and r (formula F2M tr) or k (formula F2M tk) at 0.5% w/w were investigated (Figure 11). The formula F2M tk showed the texture parameters of firmness and consistency similar to those of the reference formula F2M. However, significant differences were found in terms of cohesiveness and adhesiveness, demonstrated by the negative part of the curve, which corresponds to the de-immersion phase, and could be related to the after-feel phase, i.e., the phase that follows the application of the product on the skin. Lower adhesiveness, in fact, corresponds to a smaller force needed to separate the product from the surface of the probe and could be attributable to lower film-forming properties.

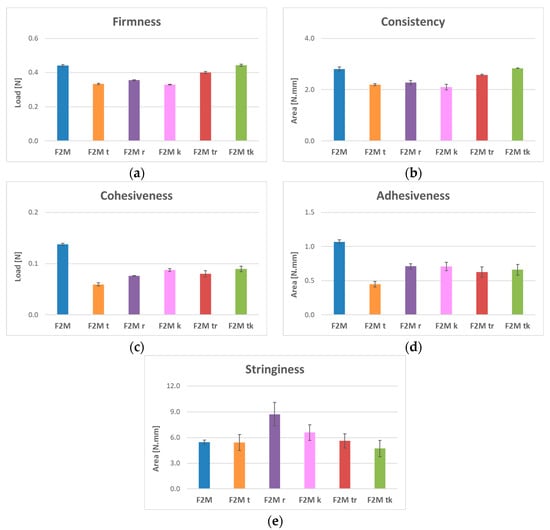

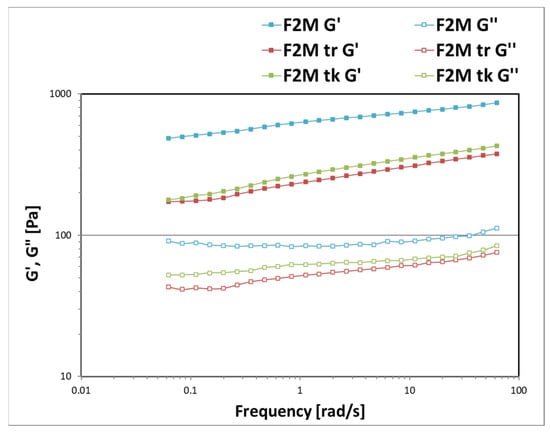

The mechanical spectra investigated by frequency sweep analyses (Figure 12) reflect the results of the texture data. The samples presented a weak gel-type pattern where the elastic modulus G′ dominated over the viscous modulus G″, keeping a parallel trend with each other. For all of the samples, the moduli were located between the second and third decades, even though the acrylic polymer’s replacement produced a significant reduction in their values.

Figure 12.

Trends of the elastic G′ and viscous G″ moduli in the function of the oscillation frequency for samples F2M with the acrylic polymer and F2M tr and F2M tk with combinations of polysaccharides.

3.2.3. Substitution of Silicone Emollients

The silicone ingredients were removed from the F2M tk formula: a five centistokes dimethicone oil at 3.5% w/w, dimethiconol at 0.5% w/w, and an elastomer composed of dimethicone and polysilicone-11 at 1.5% w/w. These raw materials were replaced by a natural ingredient (P), consisting of a polyurethane-based biodegradable elastomer dispersed in alkanes and esters of plant origin, used alone at 5.5% w/w in the formula F2M P or in combination with DSG (ethyl olivate and triheptanoin) at 1% in the formula F2M P DSG 1 and at 1.5% w/w in the formula F2M P DSG 1.5. All of the formulations were stable after the centrifuge test (Table 10).

Table 10.

Mechanical stability test results and zero-shear viscosity (η0) values for the formulations F2M tk with natural alternatives to silicones.

From the rheological curves obtained in the frequency sweep test (Figure 13), there were no differences between F2M P DSG1.5 and the sample F2M tk in terms of viscoelastic properties, since the G* and tanδ curves were superimposed. The samples F2M P and F2M P DSG1, on the other hand, showed a higher G* value, which was related to more structured emulsions.

Figure 13.

Trends of the complex G* modulus and of the damping factor tanδ in the function of the oscillation frequency for the product F2M tk formulated with silicones and the samples F2M P, F2M P DSG1, and F2M P DSG1.5 formulated with natural alternatives.

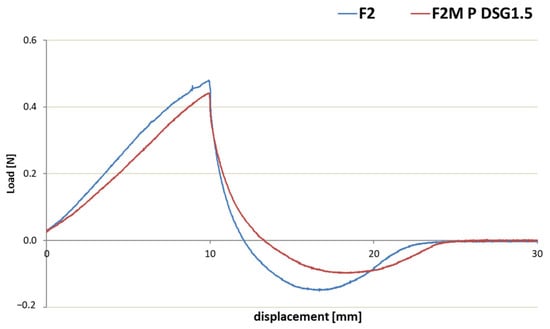

The texture curve in Figure 14 shows the comparison between the original commercial formula F2 and the final formula F2M P DSG1.5 reformulated using an eco-design approach by substituting the synthetic texturizer PMMA with the maltodextrin powder M, the acrylic rheological modifier with a combination of sclerotium (t) and diutan (k) gums, and the silicone ingredients with the biodegradable elastomer P and natural emollients ethyl olivate and triheptanoin (DSG). The formulations showed quite similar values of firmness (F2: 0.496 N ± 0.014; F2M P DSG1.5: 0.440 N ± 0.003), consistency (F2: 3.073 N.mm ± 0.066; F2M P DSG1.5: 2.746 N.mm ± 0.023), and stringiness (F2: 5.28 mm ± 0.32; F2M P DSG1.5: 5.43 mm ± 0.42). The main differences were found in the negative part of the curve: the new formula had lower values of cohesiveness (F2: −0.159 N ± 0.007; F2M P DSG1.5: −0.101 N ± 0.003) and adhesiveness (F2: 1.184 N.mm ± 0.094; F2M P DSG1.5: 0.768 N.mm ± 0.044). These differences indicated that the substitution made resulted in a more spreadable emulsion with lower film-forming properties. These differences were mainly attributable to the replacement of the acrylic polymer with polysaccharides, resulting in a decrease in the structure of the systems.

Figure 14.

Texture curves obtained from an immersion/de-immersion test performed on the original product F2 and the sample F2M P DSG1.5 reformulated using an eco-design approach by replacing the synthetic texturizer, the acrylic rheological modifier, and the silicone ingredients.

We conducted the consumer sensory test to compare the original formula F2 and the reformulated sample F2M P DSG1.5. Differences were detected for three parameters, even if the numerical data registered were limited and not so marked. For consistency at first touch, on a scale where 1 was fluid and 7 was very consistent, F2 had an average rating μ = 2.94, while F2M P DSG1.5 had an average rating μ = 4.39 [t (32) = 6.31 p < 0.01]. For spreadability, on a scale from 1—low to 7—high, F2 had an average rating μ = 5.91, while F2M P DSG1.5 had an average rating μ = 4.85 [t (32) = 4.79 p < 0.01]. For the rate of absorption, on a scale from 1—slow to 7—fast, F2 had an average rating μ = 4.85, while F2M P DSG1.5 had an average rating μ = 4.21 [t (32) = 2.18 p < 0.04].

3.3. Reformulation of Product F3

3.3.1. Substitution of Synthetic Texturizers

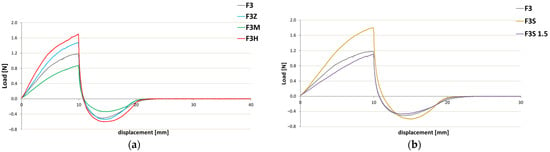

The product F3 is an O/W body butter characterized by a high percentage of lipidic phases composed of synthetic esters and triglycerides, natural waxes, and fatty alcohols. The emulsifying system is a combination of non-ionic and anionic emulsifiers. The semi-solid structure is held up by the synthetic polymers sodium polyacrylate and acrylates/beheneth-25 methacrylate copolymer. PMMA is the synthetic texturizing agent at 3% w/w, which has been replaced by natural ones at the same concentration: Z, M, S, and H. Four formulations, each containing these different natural texturizers at 1% w/w, were prepared and analyzed through texture analysis and rheology. From the texture curves, one can immediately see how the inorganic texturizers S and H increased the mechanical properties of the emulsion significantly (Figure 15a,b). The inorganic texturizers showed better performance in the formulations with a greater oil phase, thanks to their better wettability compared to organic texturizers. Reducing the silica concentration from 3% to 1.5% resulted in texture parameters similar to those of the reference product (Figure 15b).

Figure 15.

Texture curves obtained from an immersion/de-immersion test performed on the product F3 with the synthetic texturizer and the formula with the natural ones F3 Z, F3 M, F3 H (a), F3 S, and F3S 1.5 (b).

The rheological values obtained from the analysis conducted both in continuous and oscillatory flow conditions confirmed that the substitution of the synthetic texturizer with the inorganic polymer S at 1.5% w/w allowed us to obtain an emulsion with viscosity and elasticity parameters closer to those of the reference emulsion F3 (Table 11).

Table 11.

Zero-shear viscosity η0 values and damping factor tanδ values measured for the product F3 with the synthetic texturizers and the products F3 Z, F3 M, F3 H, and F3 S with the natural ones.

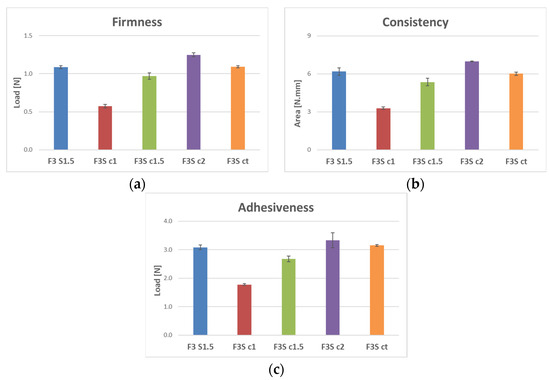

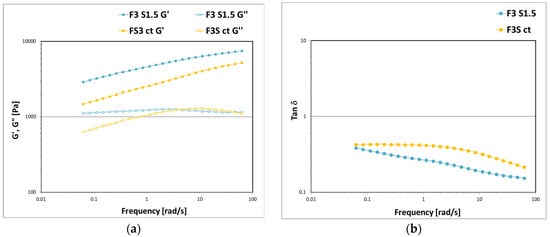

3.3.2. Substitution of Acrylic Rheological Modifiers

The body butter with silica at 1.5% w/w as natural texturizer, F3 S1.5, contained two synthetic rheological modifiers, sodium polyacrylate at 0.3% w/w and acrylates/beheneth-25 methacrylate copolymer at 1% w/w, which have been replaced with c (iota carrageenan) alone at increasing concentrations (1–1.5–2% w/w) or in a binary combination with t (sclerotium gum). All of the formulations were stable after the centrifuge test (Table 12).

Table 12.

Mechanical stability test results and zero-shear viscosity (η0) values for the formulations F3S and polysaccharides used at different concentrations to replace the synthetic acrylic rheological modifiers.

Iota carrageenan, once dispersed in water, can form soft and elastic gels. This ability is due to its chemical structure characterized by galactose dimers with acidic sulfate groups that lead, in the presence of bivalent cations, to a double-helix-type conformation, stabilized by cationic bridges between the negatively charged sulfate groups [39]. For these reasons, this algae-derived polysaccharide was selected to replace the synthetic polymers and maintain the rich, consistent, and bouncy texture typical of a body butter. As the concentration of carrageenan increased, the texture parameters of firmness (Figure 16a), consistency (Figure 16b), and adhesiveness (Figure 16c) increased. However, the sample with the highest concentration (F3S c2), despite having texture parameters closer to the F3S sample, was not homogeneous from an organoleptic point of view. At this point, the carrageenan was associated with another structuring polysaccharide with a weak gel rheology, sclerotium gum (t) at 0.5% w/w. The sample thus formulated as F3S ct showed high firmness, consistency, and adhesiveness, similar to those of F3S.

Figure 16.

Firmness (a), consistency (b), and adhesiveness (c) measured by means of an immersion/de-immersion test for the product F3 S1.5 by substituting the acrylic rheological modifiers with polysaccharide c alone and in combination with t.

The sample F3S ct containing a combination of c at 1.5% w/w and t at 0.5% w/w showed a weak gel rheological pattern, as did the sample F3 S1.5 with the acrylic polymers, but the mechanical spectra showed some qualitative and quantitative differences as the moduli values were lower (Figure 17a) and more dependent on the applied frequency, and the damping factor values were higher than those of F3 S1.5 (Figure 17b), indicating a decrease in the solid elastic properties.

Figure 17.

Trends of the elastic G′ and viscous G″ moduli (a) and the damping factor tanδ (b) in the function of the oscillation frequency for samples F3 S1.5 with the acrylic polymer and F3S ct with a combination of polysaccharides.

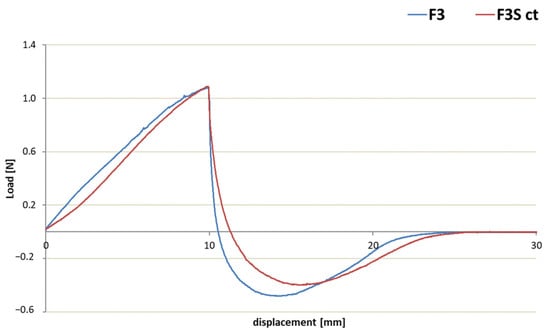

The texture curve in Figure 18 shows the comparison between the original commercial body butter F3 and the final formula F3S ct reformulated using an eco-design approach by substituting the synthetic texturizer PMMA with the silica powder S and the acrylic rheological modifiers with a combination of carrageenan (c) and sclerotium gum (t). The formulations showed close values of firmness (F3: 1.090 N ± 0.089; F3S ct: 1.091 N ± 0.014) and consistency (F3: 6.715 N.mm ± 0.951; F3S ct: 6.016 N.mm ± 0.132). The new formula had lower values of cohesiveness (F3: −0.484 N ± 0.025; F3S ct: −0.399 N ± 0.002) and adhesiveness (F3: 3.597 N.mm ± 0.171; F3S ct: 3.149 N.mm ± 0.031), and higher values of stringiness (F3: 4.73 mm ± 0.97; F3S ct: 5.31 mm ± 0.49). These differences indicated that the substitution made resulted in a body butter with similar mechanical–structural properties to the original product, with lower adhesiveness and greater pick-up properties.

Figure 18.

Texture curves obtained from an immersion/de-immersion test performed on the original product F3 and the sample F3S ct reformulated using an eco-design approach by replacing the synthetic texturizer, the acrylic rheological modifier, and the silicone ingredients.

In the double-blind sensory test performed on the F3 product and the formula F3S ct, differences were perceived for only two parameters. For consistency at first touch, on a scale of values where 1 was fluid and 7 was very consistent, F3 had an average rating μ = 5.33, while F3S ct had an average rating μ = 6.24 [t (32) = 5.71 p < 0.01]. For spreadability, on a scale where 1 was low spreadability and 7 was high spreadability, F3 had an average rating μ = 5.21 and F3S ct had an average rating μ = 4.12 [t (32) = 3.31 p < 0.01].

4. Conclusions

Replacing synthetic ingredients without affecting the applicative properties of a product is a hard challenge for the formulator. Synthetic materials like acrylic polymers and silicones are meticulously engineered to deliver specific functionalities—impacting the product’s structure, application characteristics, and sensory experience. When replacing those ingredients with nature-derived raw materials, factors like choosing the right material, calibrating its concentration, and exploring synergistic combinations become crucial in order to achieve the desired performance. Eco-design focuses on selecting environmentally friendly raw materials without compromising the product’s stability, ease of application, or the sensorial aspects to which consumers are accustomed. This study proposes a novel formulation approach that leverages combined rheology and texture analysis to identify the optimal concentration and ingredient combinations, facilitating effective comparisons between products. The studies present in the literature that include the combined use of rheology and texture analysis exploit instrumental techniques to comprehensively describe the physical–mechanical characteristics of raw materials and finished products in order to predict the sensorial characteristics perceived by consumers. Kulawik-Pióro et al. in their paper [16] investigated the relationship between rheological, textural, and sensorial properties to assess the effectiveness of barrier creams, finding good correlations between viscosity, firmness, and spreadability. Callixto and Maia Campos, analyzing the physical and textural properties of skin care products, found a strong correlation between the concentration of UV filters, spreadability, and cohesiveness. In the study by Gilbert et al. [19], they concluded that sensory attributes used to describe cosmetic products during the pick-up and rub-out phases can be foreseen through instrumental rheological and texture analyses. Terscensco et al. [21] set up an instrumental protocol to investigate the influence of emollients on the structural properties and the rheological behavior of emulsions, discovering that the formation of larger oil droplets led to enhanced elastic behavior and spreading properties. Correlations existing between the textural and sensory parameters determined by the use of different cosmetic ingredients, such as butters, oils, and starch, were highlighted by Vieira et al., in which [27] fluidity and consistency were found to be inversely correlated. In this work, the instrumental protocol is incorporated into the concept of eco-design formulation, with the aim of identifying the correct combinations of natural ingredients that can effectively replace synthetic raw materials with a high environmental impact and ensuring that the final consumer does not notice these formulation changes.

The replacement of the rheological modifiers in the three formulas highlighted how the use of polysaccharides resulted in a decrease in the elastic properties together with a reduction in cohesiveness and adhesiveness. On the other hand, the replacement of silicone emollients, highly appreciated in terms of sensory properties as they give a light, flowing, and silky texture to products, with different naturally derived emollients caused different interactions with the skin, which are difficult to detect with instrumental characterization, having an impact on the after-feel phase of the product after application.

In F1, an acne-prone skin serum, the substitution of the microplastics with a starch-based texturizer, the substitution of the acrylic polymer with a combination of sclerotium gum, xanthan gum, and diutan gum, and the substitution of dimethicone with a mixture of ethyl olivate and triheptanoin allowed us to obtain a stable and fluid system with good pick-up properties, and with a skin feel almost equal to that of the original formula, according to the consumer sensory evaluation.

In F2, an eye-contour gel-cream, the substitution of PMMA with maltodextrin, the substitution of the acrylic polymers with a binary combination of sclerotium gum and diutan gum, and the substitution of the silicone ingredients with a raw material containing a biodegradable elastomer allowed us to produce a stable and smooth system without increasing the stiffness. However, in the final formula, we were not able to reach the same adhesiveness and cohesiveness of the original product, as shown by the different trend of viscoelastic moduli that reflected the differences detected during the sensory test.

In F3, a body butter, the substitution of the synthetic texturizer with silica and the substitution of the acylates with a combination of carrageenan and sclerotium gum allowed us to reproduce the rigid structure and the low pick-up value of the original formula. However, the reformulated emulsion was perceived to be less spreadable and to have a thicker consistency than the commercial one.

The differences recorded were limited and not so marked, being inevitably due to the specificity of the raw materials used and the intrinsic performances of the selected polysaccharides. Although perfectly replicating the structural and application properties of existing formulas with natural alternatives might be impractical, combining rheology and texture analyses allows for the selection of the most suitable natural ingredients that closely resemble the performance of their synthetic counterparts. This instrumental protocol offers a significant advantage over traditional trial-and-error methods, facilitating the development of viable solutions with reduced costs and development time. This proves particularly valuable when reformulating cosmetic products from a green and sustainable perspective.

The replacement of unsustainable ingredients and the reformulation of products represents the first step of the eco-design approach. Life cycle assessment studies are required to have objective data on the sustainability of cosmetic products. Future steps must consider the entire life cycle of the product, taking into account the emissions during the production processes and the choice of materials that will make up the packaging.

Author Contributions

Conceptualization, A.S.; investigation, G.T., M.P. and S.L.; resources, L.B.; project administration G.T.; formal analyses, M.P.; writing—original draft preparation, G.T.; writing—review and editing, A.S.; supervision, A.C., G.B. and S.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to acknowledge Antonio Gion from Unired S.r.l. for the creation of the double-blind sensory test and the statistical elaboration of the data.

Conflicts of Interest

Stefano Francescato, Laura Busata, Giovanni Baratto are working in Unifarco S.p.A. and other authors declare no conflicts of interest.

References

- Schneiders, B.; Anklin, F. The social impact of a cosmetics company. In Sustainability: How the Cosmetics Industry Is Greening up; Sahota, A., Ed.; John Wiley & Sons, Ltd.: London, UK, 2014; pp. 47–68. [Google Scholar]

- L’Haridon, J.L.; Martz, P.; Chenéble, J.C.; Campion, J.F.; Colombe, L. Ecodesign of cosmetic formulae: Methodology and application. Int. J. Cosmet. Sci. 2018, 40, 165–177. [Google Scholar] [CrossRef] [PubMed]

- ISO/TR 14006:2020 Environmental Management Systems—Guidelines for Incorporating Ecodesign. 2020. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14006:ed-2:v1:en (accessed on 15 March 2024).

- Szaban, R. Internal factors influencing customer attitude, purchase intention and purchase behaviour with regard to green personal care products. A literature review. Argum. Oeconomica 2023, 2, 233–262. [Google Scholar] [CrossRef]

- Suphasomboon, T.; Vassanadumrongdee, S. Toward Sustainable Consumption of Green Cosmetics and Personal Care Products: The Role of Perceived Value and Ethical Concern. Sustain. Prod. Consum. 2022, 33, 230–243. [Google Scholar] [CrossRef]

- Fonseca-Santos, B.; Antonio Corrêa, M.; Chorilli, M. Sustainability, Natural and Organic Cosmetics: Consumer, Products, Efficacy, Toxicological and Regulatory Considerations. Braz. J. Pharm. Sci. 2015, 51, 17–26. [Google Scholar] [CrossRef]

- Amberg, N.; Fogarassy, C. Green Consumer Behavior in the Cosmetics Market. Resources 2019, 8, 137. [Google Scholar] [CrossRef]

- Bom, S.; Fitas, M.; Martins, A.M.; Pinto, P.; Ribeiro, H.M.; Marto, J. Replacing Synthetic Ingredients by Sustainable Natural Alternatives: A Case Study Using Topical O/W Emulsions. Molecules 2020, 25, 4887. [Google Scholar] [CrossRef]

- Fresneda, M.; Trujillo-Cayado, L.A.; García, M.C.; Alfaro-Rodriguez, M.C.; Muñoz, J. Production of more sustainable emulsions formulated with eco-friendly materials. J. Clean. Prod. 2020, 243, 118661. [Google Scholar] [CrossRef]

- Bom, S.; Ribeiro, H.M.; Marto, J. Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products. Sustainability 2020, 12, 1437. [Google Scholar] [CrossRef]

- Faraca, G.; Vidal Abarca Garrido, C.; Kaps, R.B.; Fernandez Carretero, A.; Wolf, O. Revision of EU Ecolabel Criteria for Cosmetic Products and Animal Care Products (Previously Rinse-Off Cosmetic Products); EUR 30724 EN; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- European Chemical Agency. ECHA Proposes to Restrict Intentionally Added Microplastics. 2019. Available online: https://echa.europa.eu/it/-/echa-proposes-to-restrict-intentionally-added-microplastics#:~:text=ECHA’s%20proposed%20restriction%20targets%20intentionally,that%20resist%20(bio)degradation (accessed on 15 March 2024).

- Rochman, C.M.; Kross, S.M.; Armstrong, J.B.; Bogan, M.T.; Darling, E.S.; Green, S.J.; Smyth, A.R.; Veríssimo, D. Scientific Evidence Supports a Ban on Microbeads. Environ. Sci. Technol. 2015, 49, 10759–10761. [Google Scholar] [CrossRef]

- Scudo, A.; Liebmann, B.; Corden, C.; Tyrer, D.; Kreissig, J.; Warwick, O. Intentionally Added Microplastics in Products; Amec Foster Wheeler Environ. & Infrastruct.: London, UK, 2017. [Google Scholar]

- Zheng, Y.J.; Loh, X.J. Natural Rheological Modifiers for Personal Care. In Polymers for Personal Care Products and Cosmetics; Loh, X.J., Ed.; Royal Society of Chemistry: London, UK, 2016; pp. 60–89. [Google Scholar]

- Kulawik-Pióro, A.; Ptaszek, A.; Kruk, G. Effective tool for assessment of the quality of barrier creams—Relationships between rheological, textural and sensory properties. Regul. Toxicol. Pharmacol. 2019, 103, 113–123. [Google Scholar] [CrossRef]

- Calixto, M.S.; Maia Campos, P.M.B.G. Physical–Mechanical characterization of cosmetic formulations and correlation between instrumental measurements and sensorial properties. Int. J. Cosmet. Sci. 2017, 39, 527–534. [Google Scholar] [CrossRef] [PubMed]

- de Araujo Silva, R.; Morais Ruela, A.L.; de Oliveira Mamede, M.E.; de Paula Pereira, N. Preparation and sensory evaluation of gels based on silicone copolymers/acrylic copolymers incorporating different vegetable oils. Ind. Crops Prod. 2023, 193, 116147. [Google Scholar] [CrossRef]

- Gilbert, L.; Picard, C.; Savary, G.; Grisel, M. Rheological and textural characterization of cosmetic emulsions containing natural and synthetic polymers: Relationships between both data. Colloids Surf. A Physiochem. Eng. Asp. 2013, 421, 150–163. [Google Scholar] [CrossRef]

- Tadros, T. Application of rheology for assessment and prediction of the long-term physical stability of emulsions. Adv. Colloid Interface Sci. 2004, 108–109, 227–258. [Google Scholar] [CrossRef] [PubMed]

- Terescenco, D.; Picard, C.; Clemenceau, F.; Grisel, M.; Savary, G. Influence of the emollient structure on the properties of cosmetic emulsion containing lamellar liquid crystals. Colloids Surf. A Physicochem. Eng. Asp. 2018, 536, 10–19. [Google Scholar] [CrossRef]

- Adejokun, D.A.; Dodou, K. Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics 2020, 7, 2. [Google Scholar] [CrossRef]

- Vieira, G.S.; Lavarde, M.; Fréville, V.; Rocha-Filho, P.A.; Pensé-Lhéritier, A. Combining sensory and texturometer parameters to characterize different type of cosmetic ingredients. Int. J. Cosmet. Sci. 2020, 42, 156–166. [Google Scholar] [CrossRef]

- César, F.C.S.; Campos, P.M.B.G.M. Influence of vegetable oils in the rheology, texture profile and sensory properties of cosmetic formulations based on organogel. Int. J. Cosmet. Sci. 2020, 42, 494–500. [Google Scholar] [CrossRef] [PubMed]

- Imbart, S.; Laplanche, A.; Ruzic, C.; Lavarde, M.; Marull-Tufeu, S.; Bernard, C.; Pensé-Lhéritier, A.-M. Aoussat Design of a Sensorial-Instrumental Correlation Methodology for a Category of Cosmetic Products: O/W Emulsions. Cosmetics 2022, 9, 84. [Google Scholar] [CrossRef]

- Bashir, S.M.; Kimiko, S.; Mak, C.W.; Fang, J.K.H.; Gonçalves, D. Personal Care and Cosmetic Products as a Potential Source of Environmental Contamination by Microplastics in a Densely Populated Asian City. Front. Mar. Sci. 2021, 8, 683482. [Google Scholar] [CrossRef]

- Georgalas, A. Are Silicones Safe and Sustainable? What Are the Alternatives? Cosmet. & Toilet.: Northbrook, IL, USA, 2014; p. 129. [Google Scholar]

- Martins, A.M.; Marto, J.M. A sustainable life cycle for cosmetics: From design and development to post-use phase. Sustain. Chem. Pharm. 2023, 35, 101178. [Google Scholar] [CrossRef]

- Yasuda, K.; Armstrong, R.C.; Cohen, R.E. Shear flow properties of concentrated solutions of linear and star branched poly-styrenes. Rheol. Acta 1981, 20, 163–178. [Google Scholar] [CrossRef]

- Tai, A.; Bianchini, R.; Jachowicz, J. Texture analysis of cosmetic/pharmaceutical raw materials and formulations. Int. J. Cosmet. Sci. 2014, 36, 291–304. [Google Scholar] [CrossRef] [PubMed]

- Estanqueiro, M.; Amarak, M.H.; Sousa Lobo, J.M. Comparison between sensory and instrumental characterization of topical formulations: Impact of thickening agent. Int. J. Cosmet. Sci. 2016, 38, 389–398. [Google Scholar] [CrossRef] [PubMed]

- Marku, D.; Wahlgren, M.; Rayner, M.; Sjöö, M.; Timgren, A. Characterization of starch Pickering emulsions for potential applications in topical formulations. Int. J. Pharm. 2012, 428, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Lapasin, R.; Pricl, S. Rheology of Industrial Polysaccarides, Theory and Application; Blackie Academic & Professional: London, UK, 1995. [Google Scholar]

- Tafuro, G.; Costantini, A.; Baratto, G.; Francescato, S.; Busata, L.; Semenzato, A. Characterization of Polysaccharidic Associations for Cosmetic Use: Rheology and Texture Analysis. Cosmetics 2021, 8, 62. [Google Scholar] [CrossRef]

- Pressi, G.; Barbieri, E.; Rizzi, R.; Tafuro, G.; Costantini, A.; Di Domenico, E.; Semenzato, A. Formulation and Physical Characterization of a Polysaccharidic Gel for the Vehiculation of an Insoluble Phytoextract for Mucosal Application. Polysaccharides 2022, 3, 728–744. [Google Scholar] [CrossRef]

- Lapasin, R.; Abrami, M.; Grassi, M.; Sebenik, U. Rheology of laponite-scleroglucan hydrogels. Carbohydr. Polym. 2017, 168, 290–300. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.; Kim, Y.; Hu, Y.; Jung, S. Bacterial Succinoglycans: Structure, Physical Properties, and Applications. Polymers 2022, 14, 276. [Google Scholar] [CrossRef]

- Xu, L.; Gong, H.; Dong, M.; Li, Y. Rheological properties and thickening mechanism of aqueous diutan gum solution: Effects of temperature and salts. Carbohydr. Polym. 2015, 132, 620–629. [Google Scholar] [CrossRef]

- Blakemore, W.R.; Harpell, A.R. Carrageenan. In Food Stabilizers, Thickeners and Gelling Agents; Imeson, A., Ed.; Wiley-Blackwell: Oxford, UK, 2010; pp. 73–94. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).