Natural Polymers and Cosmeceuticals for a Healthy and Circular Life: The Examples of Chitin, Chitosan, and Lignin

Abstract

1. Introduction

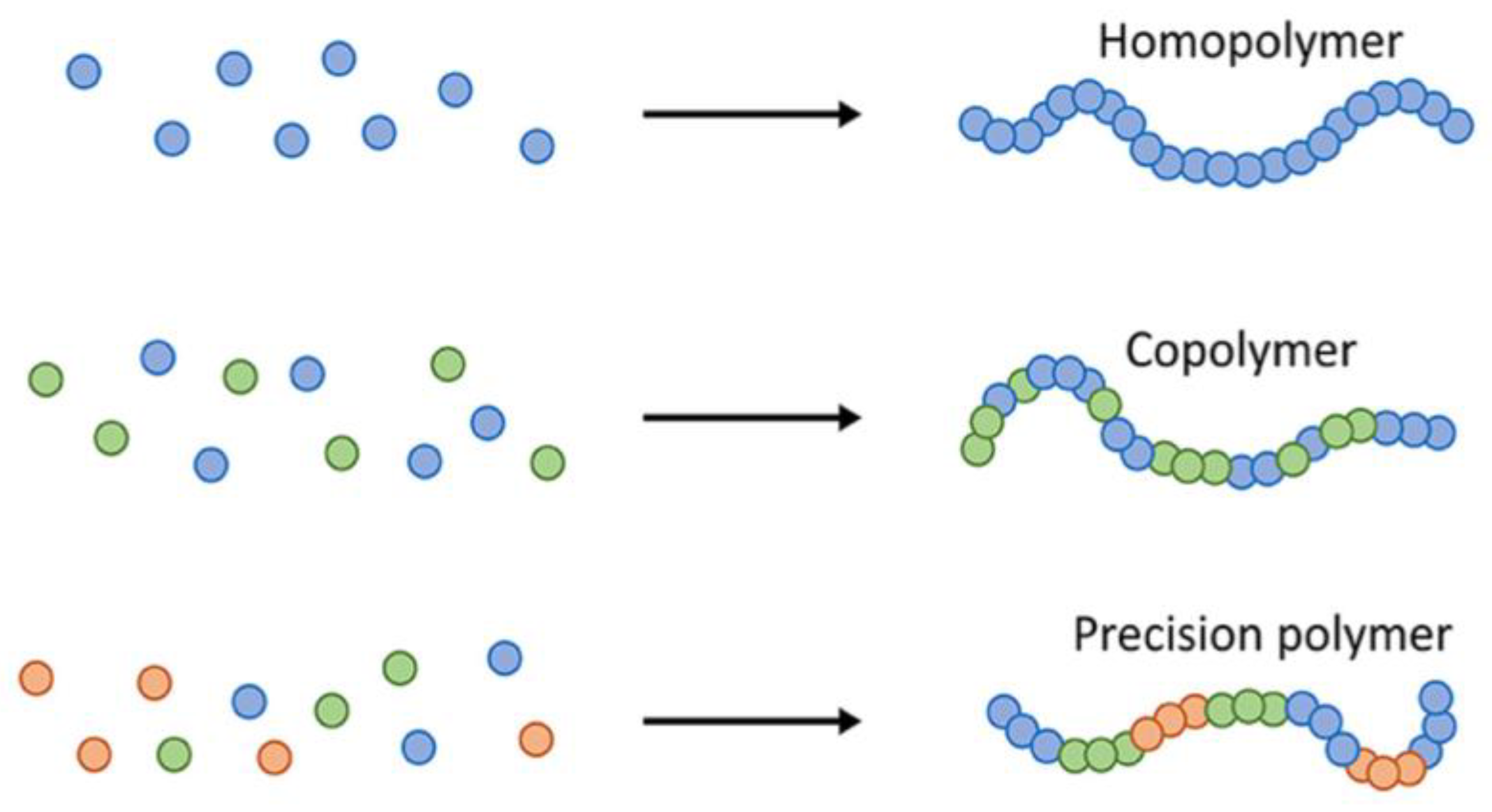

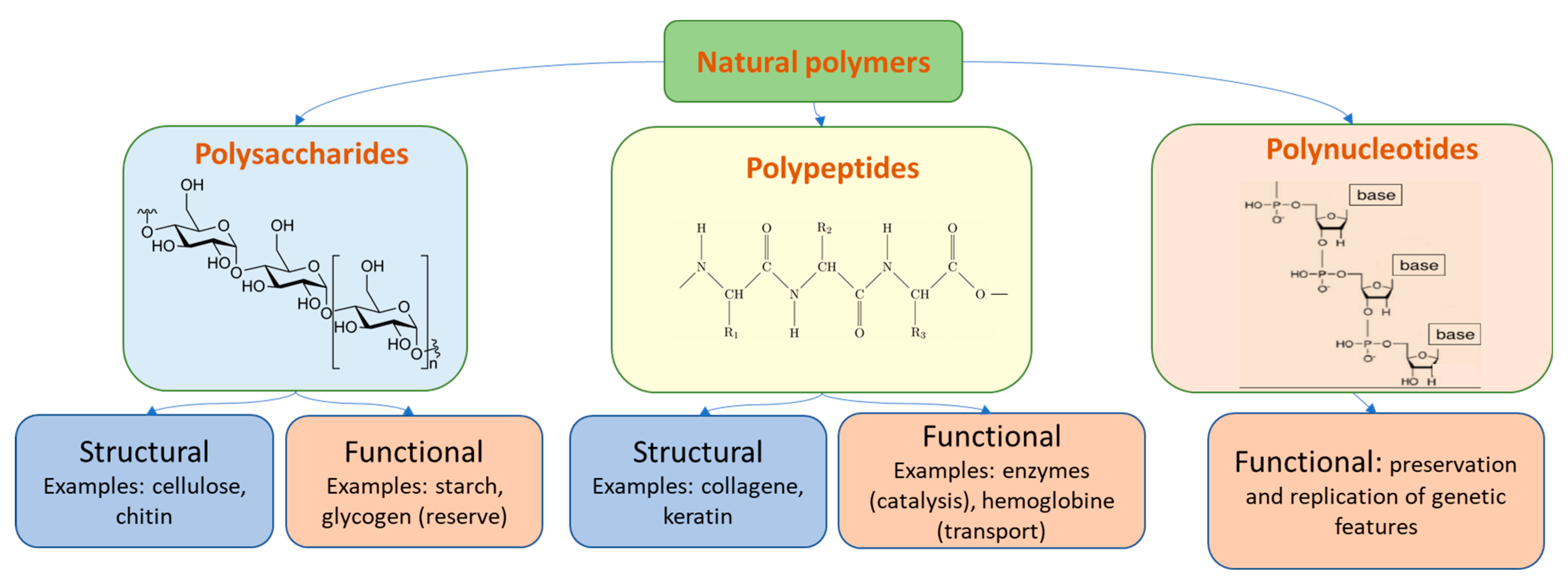

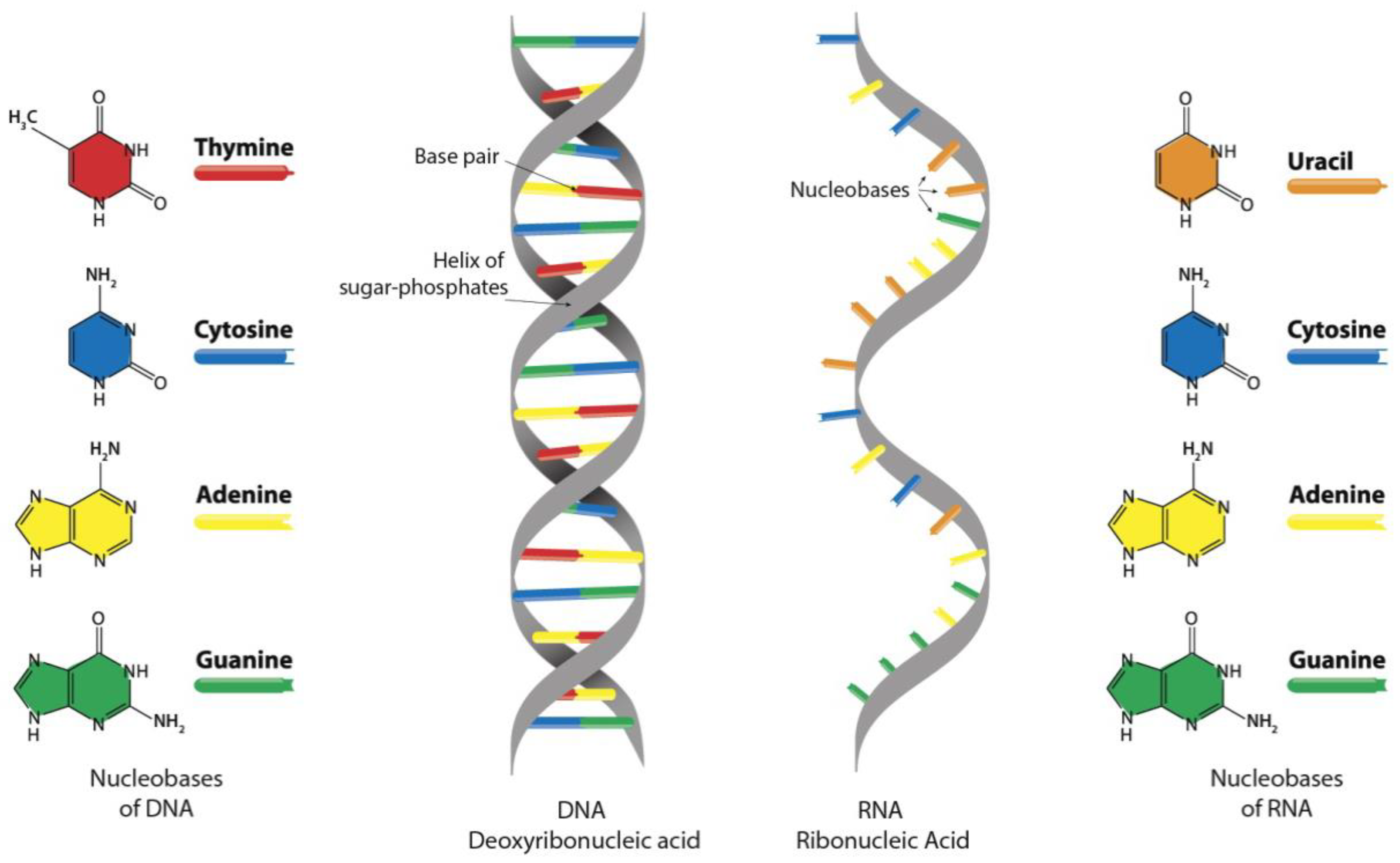

2. Nanobiotechnology and Biopolymers

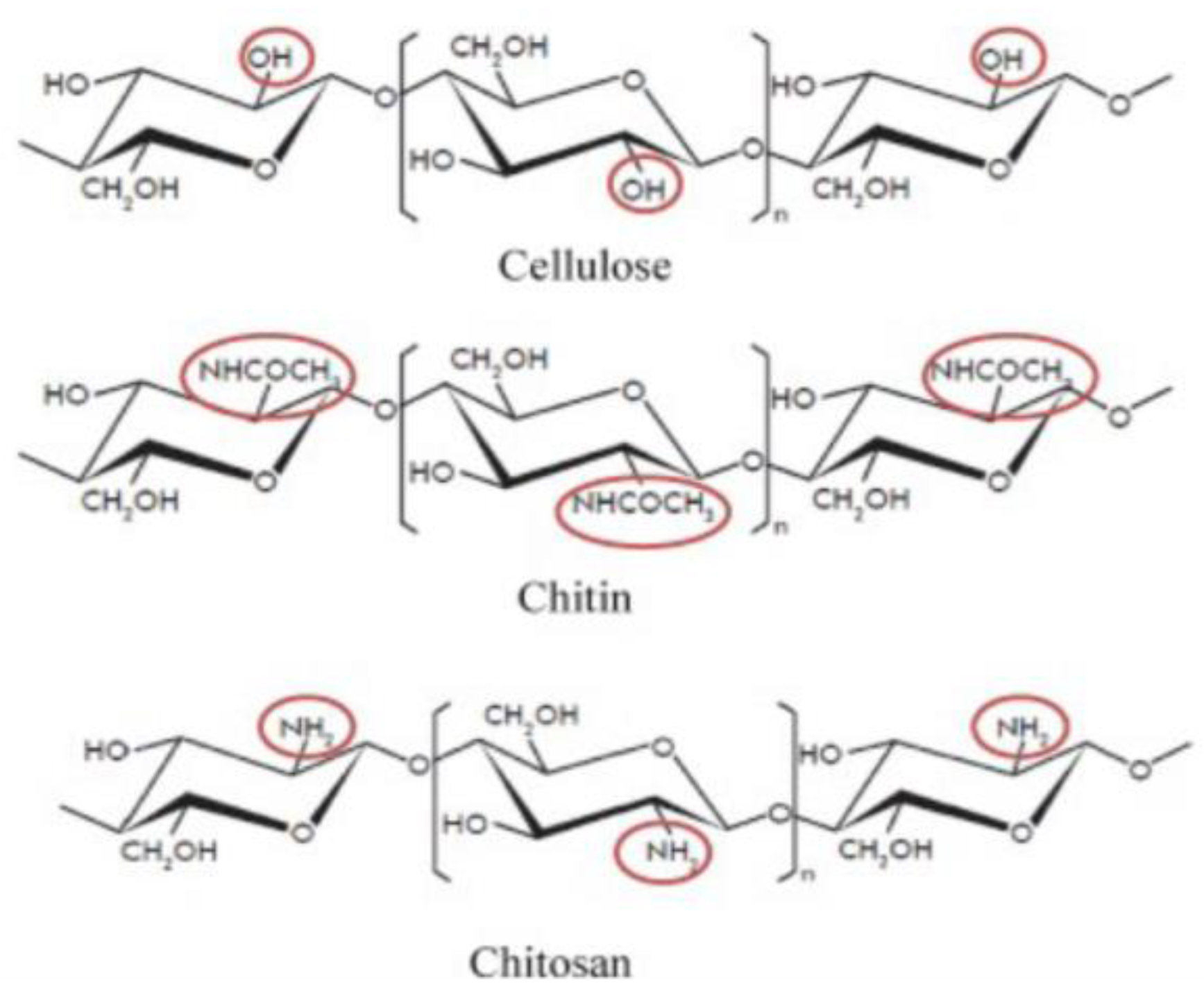

3. Sustainable Biopolymers

4. Chitin and Chitosan

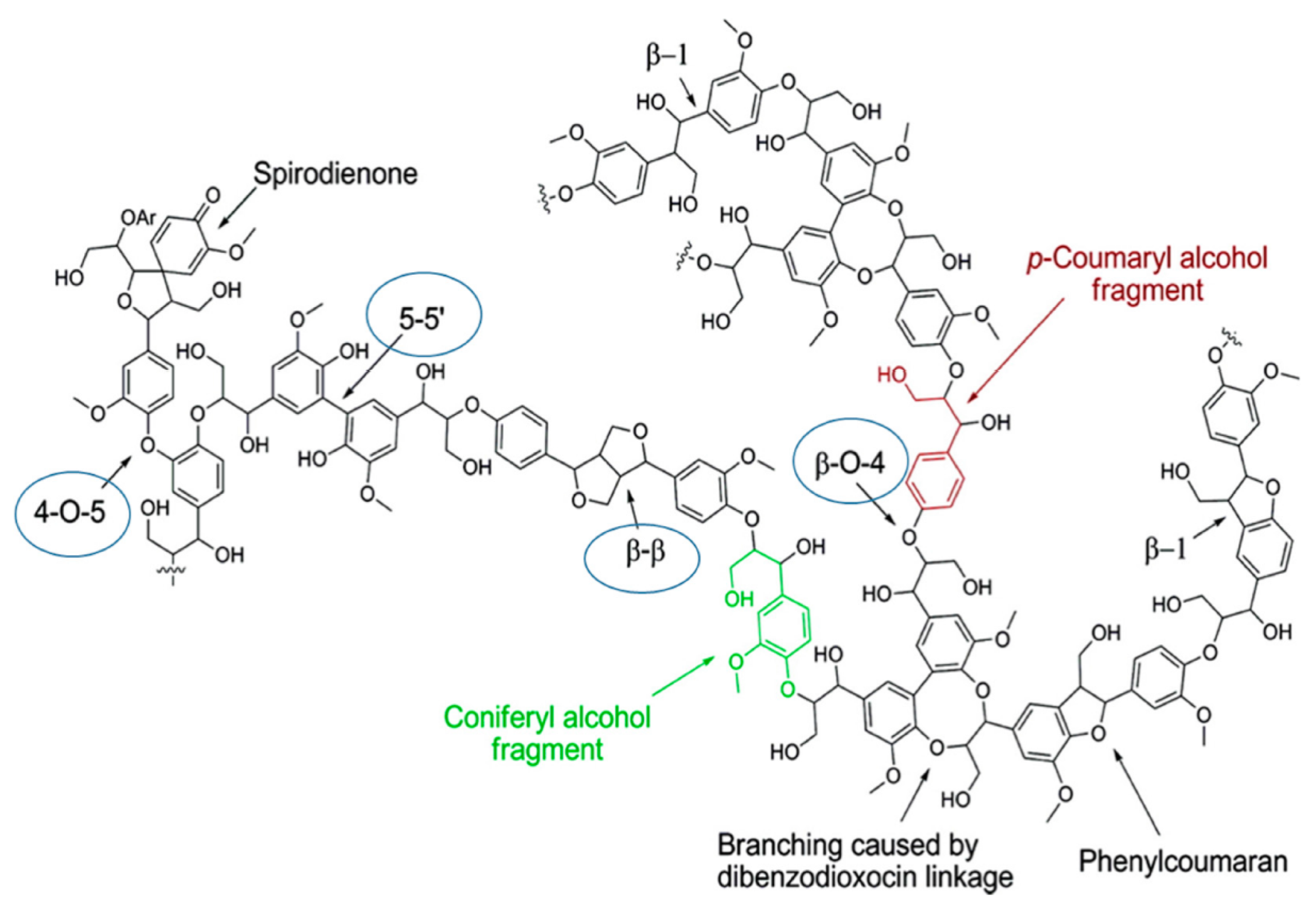

5. Lignin

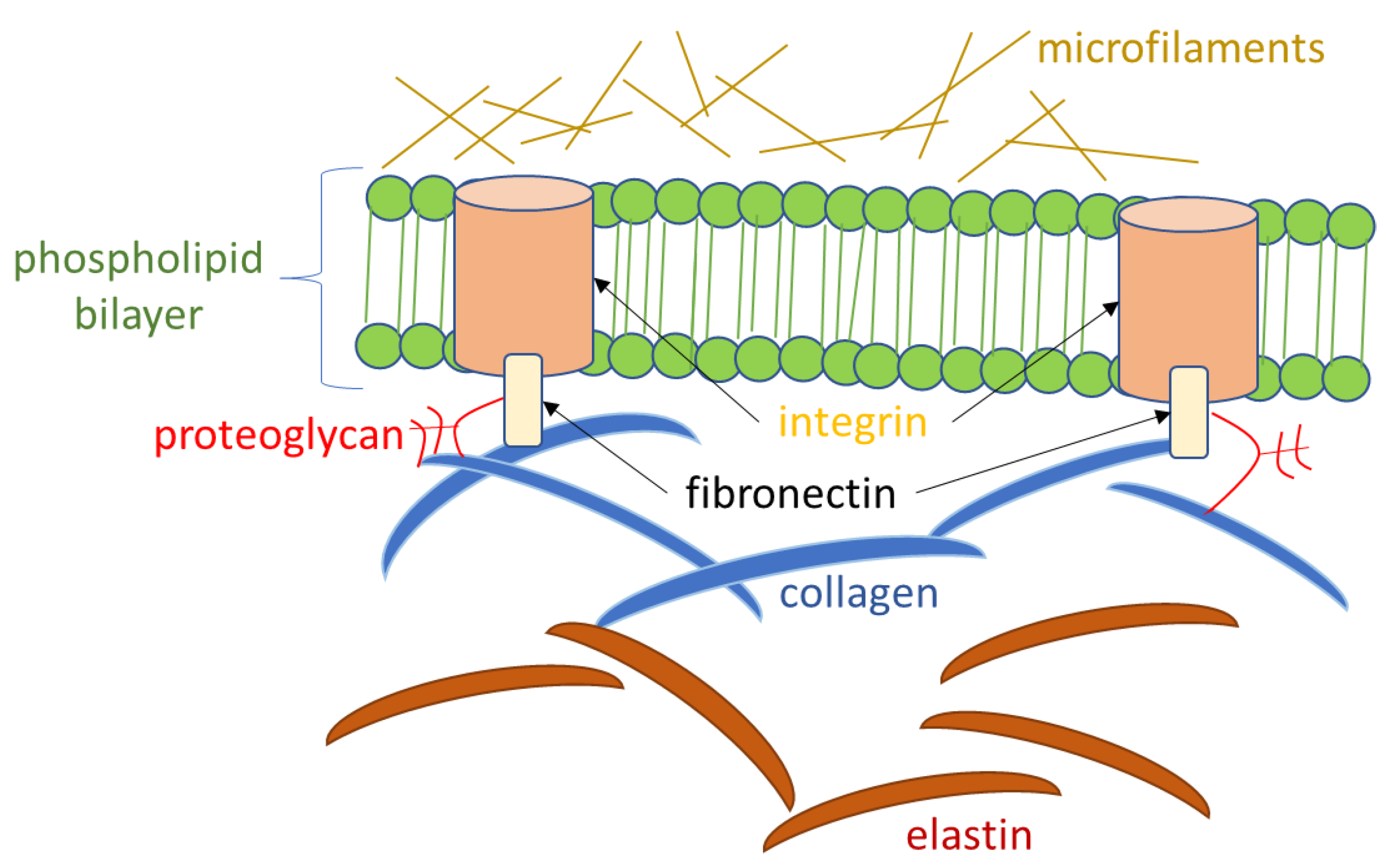

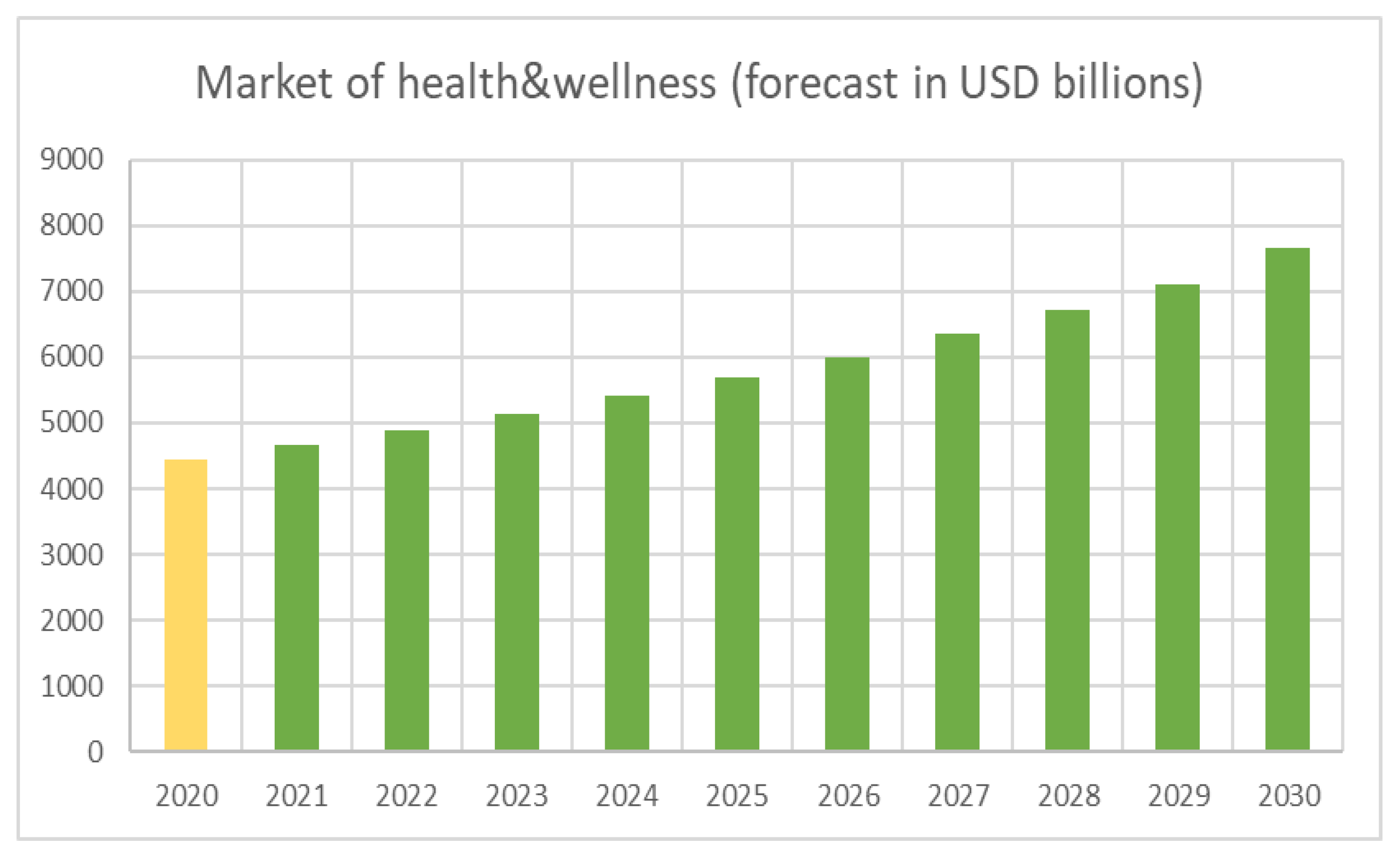

6. Cosmeceuticals

7. Discussion

8. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cook, A.B.; Bibic, L. Macromolecules, Actually: From Plastics to DNA. Front. Young Minds 2019, 7, 126. [Google Scholar] [CrossRef]

- Dong, R.; Liu, R.; Gaffney, P.R.J.; Schaepertoens, M.; Marchetti, P.; Williams, C.M.; Chen, R.; Livingston, A.G. Sequence-defined multifunctional polyethers via liquid-phase synthesis with molecular sieving. Nat. Chem. 2018, 11, 136–145. [Google Scholar] [CrossRef]

- Silva, A.C.Q.; Silvestre, A.J.D.; Vilela, C.; Freire, C.S.R. Natural Polymers-Based Materials: A Contribution to a Greener Future. Molecules 2021, 27, 94. [Google Scholar] [CrossRef]

- Maitz, M. Applications of synthetic polymers in clinical medicine. Biosurface Biotribol. 2015, 1, 161–176. [Google Scholar] [CrossRef]

- Hudson, W.; Ortlund, E. The structure, function and evolution of proteins that bind DNA and RNA. Nat. Rev. Mol. Cell Biol. 2014, 15, 749–760. [Google Scholar] [CrossRef]

- Consolino, F.; Iacobucci, I.; Monaco, V.; Monti, M. Protein- DNA/RNA Interactions: An overview of investigation methods in the—Omics era. J. Proteome Res. 2021, 20, 3018–3030. [Google Scholar]

- Coen, E. (Ed.) The Art of Genes: How Organisms Make Themselves; Oxford University Press: Oxford, UK, 1999. [Google Scholar]

- UNEP. Towards a Green Economy Pathways to Sustainable Development and Poverty Eradication; United Nations Environment Programme: New York, NY, USA, 2011; Available online: https://wedocs.unep.org/20.500.11822/9158 (accessed on 30 December 2022).

- Khan, F.A. (Ed.) Biotechnology Fundamentals; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Drexler, E.; Peterson, C.; Pergamit, G. (Eds.) Unbounding the Future: The Nanotechnology Revolution; William Morrow & Co.: New York, NY, USA, 1991. [Google Scholar]

- Morganti, P. What does Cosmetic Dermatology mean. J. Appl. Cosmetol. 1996, 13, 51–54. [Google Scholar]

- Krishnan, U.M. Bioengineered Skin: Progress and Prospects. In Biomaterials and Nanotechnology for Tissue Engineering; Sethuraman, S., Krishnan, U.M., Subramanian, A., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 109–115. [Google Scholar]

- Rawling, A.V.; Leyden, J.J. (Eds.) Skin Moisturization, 2nd ed.; Marcel Dekker Inc.: New York, NY, USA, 2009; pp. 153–170. [Google Scholar]

- Markov, M.S. Contribution of water in the stabilization of biological membranes. In Interfacial Phenomena in Biological Systems; Bender, M., Ed.; Marcel Dekker: New York, NY, USA, 1991; pp. 153–170. [Google Scholar]

- Ramanathan, G.; Singaravela, S.; Raja, M.D.; Sivagnanam, U.T. Synthesis of highly interconnected 3D scaffold from Arothtrun stellatus skin collagen for tissue engineering application. Micron 2015, 78, 28–32. [Google Scholar] [CrossRef]

- Tangsadthakun, C.; Kanokpanont, S.; Sanchavanakit, N.; Banaprasert, T.; Damrongsakkul, S. Properties of collagen scaffolds for skin tissue engineering. J. Metal. Mater. Miner. 2006, 16, 37–44. [Google Scholar]

- Morganti, P.; Del Ciotto, P.; Morganti, G.; Fabien-Soulé, V. Application of Chitin Nanofibrils and Collagen of Marine Origin as Bioactive Ingredients. In Cosmeceuticals: Trends and Prospects; Kim, S.-K., Ed.; CRC: Boca Raton, FL, USA, 2011; pp. 267–290. [Google Scholar] [CrossRef]

- Garabska-Zielinska, S.; Siokowska, A. Surface properties of collagen, hyaluronic acid and chitosan films with neodymium laser. Polysaccharides 2022, 3, 178–187. [Google Scholar] [CrossRef]

- Pardue, E.L.; Ibrahim, S.; Ramamurti, A. Role of hyaluronan in angiogenesis and its ability to angiogenic tissue engineering. Organogenesis 2008, 4, 203–214. [Google Scholar] [CrossRef]

- Tucci, M.G.; Belmonte-Mattioli, M.; Ricotti, G.; Biagini, G. Polysaccharides: Health-Environment Binomial. J. Appl. Cosmetol. 1999, 17, 94–101. [Google Scholar]

- Verna, G.; Hassan, P.A. Self-assemble approach for biomaterials development. In Trends in Biomaterials; Kothiyal, G.P., Srinivasan, A., Eds.; Pan Stanford Publishing Ltd.: Singapore, 2016; pp. 49–84. [Google Scholar]

- Chang, W.; Shah, M.; Lee, P.; Rosa, R.; Kong, K.; Kandl, W.; Yu, X. Biomaterials and nanotechnology for tissue engineering: Neural regeneration. In Biomaterials and Nanotechnology for Tissue Engineering; Sethuraman, S., Krishnan, U.M., Subramanian, A., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 153–171. [Google Scholar]

- Murthy, C.S.K.; Mandal, B.B. Biomaterials based on natural and synthetic polymer fibers. In Trends in Biomaterials; Kothyal, G.P., Srinivasan, A., Eds.; Pan Stanford Publishing Ltd.: Singapore, 2016; pp. 121–174. [Google Scholar]

- Ozdil, D.; Aydin, H.M. Polymers for medical and tissue engineering applications. J. Chem. Technol. Biotechnol. 2014, 89, 1793–1810. [Google Scholar] [CrossRef]

- Sharma, P.; Sheets, K.; Elankumaran, S.; Nain, A.S. The mechanistic influence of aligned nanofibers on cell shape, migration and blebbing dynamics of glioma cells. Integr. Biol. 2013, 5, 1036–1044. [Google Scholar] [CrossRef]

- Hashimoto, M.; Maeda, K. New Functions of Low-Molecular-Weight Hyaluronic Acid on Epidermis Filaggrin Production and Degradation. Cosmetics 2021, 8, 118. [Google Scholar] [CrossRef]

- Eskens, O.; Villani, G.; Amin, S. Rheological Investigation of Thermoresponsive Alginate-Methylcellulose Gels for Epidermal Growth Factor Formulation. Cosmetics 2020, 8, 3. [Google Scholar] [CrossRef]

- Tafuro, G.; Costantini, A.; Baratto, G.; Francescato, S.; Busata, L.; Semenzato, A. Characterization of Polysaccharidic Associations for Cosmetic Use: Rheology and Texture Analysis. Cosmetics 2021, 8, 62. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Danti, S.; De Clerck, K.; Lazzeri, A.; Morganti, P. Pullulan for Advanced Sustainable Body- and Skin-Contact Applications. J. Funct. Biomater. 2020, 11, 20. [Google Scholar] [CrossRef]

- Oliveira, T.J.; Segato, T.C.M.; Machado, G.P.; Grotto, D.; Jozala, A.F. Evolution of Bacterial Cellulose in Cosmetic Applications: An Updated Systematic Review. Molecules 2022, 27, 8341. [Google Scholar] [CrossRef]

- Kazimierska, K.; Kalinowska-Lis, U. Milk Proteins—Their Biological Activities and Use in Cosmetics and Dermatology. Molecules 2021, 26, 3253. [Google Scholar] [CrossRef]

- Subramanian, A.; Swaminathan, S. Nanofibers design for guided cellular behavior. In Biomaterials and Nanotechnology for Tissue Nanoparticle Engineering; Sethuraman, S., Krishnan, U.M., Subramanian, A., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 17–31. [Google Scholar]

- Pillai, C.K.; Paul, W.; Sharma, C.P. Chitin and chitosan polymers. chemistry, solubility and fiber formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Ioelovich, M. Crystallinity and hydrophility of chitin and chitosan. J. Chem. 2014, 3, 7–14. [Google Scholar]

- Malafeev, K.V.; Moskalyuk, O.A.; Yudin, V.E.; Morganti, P.; Ivan’Kova, E.M.; Popova, E.N.; Elokhovskii, V.Y. Biodegradable polylactide/chitin composite fibers: Processing, structure and mechanical properties. J. Appl. Cosmetol. 2017, 35, 163–173. [Google Scholar]

- Morganti, P.; Coltelli, M.-B. A New Carrier for Advanced Cosmeceuticals. Cosmetics 2019, 6, 10. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.-B.; Buchignani, M.; Lazzeri, A. Chitosan and nano-structured chitin for biobased anti-microbial treatments onto cellulose based materials. Eur. Polym. J. 2019, 113, 328–339. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.-B.; Giangrandi, S.; Garrigós, M.C.; Hadrich, A.; Lazzeri, A.; Cinelli, P. Influence of Functional Bio-Based Coatings Including Chitin Nanofibrils or Polyphenols on Mechanical Properties of Paper Tissues. Polymers 2022, 14, 2274. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.-B.; Hadrich, A.; Braca, F.; Fiori, S.; Haviv, A.; Miketa, F.; Lazzeri, A.; Staebler, A.; Gigante, V.; et al. Antimicrobial and Gas Barrier Crustaceans and Fungal Chitin-Based Coatings on Biodegradable Bioplastic Films. Polymers 2022, 14, 5211. [Google Scholar] [CrossRef]

- Panariello, L.; Vannozzi, A.; Morganti, P.; Coltelli, M.-B.; Lazzeri, A. Biobased and Eco-Compatible Beauty Films Coated with Chitin Nanofibrils, Nanolignin and Vitamin E. Cosmetics 2021, 8, 27. [Google Scholar] [CrossRef]

- Gigante, V.; Panariello, L.; Coltelli, M.-B.; Danti, S.; Obisesan, K.A.; Hadrich, A.; Staebler, A.; Chierici, S.; Canesi, I.; Lazzeri, A.; et al. Liquid and Solid Functional Bio-Based Coatings. Polymers 2021, 13, 3640. [Google Scholar] [CrossRef]

- Triunfo, M.; Tafi, E.; Guarnieri, A.; Salvia, R.; Scieuzo, C.; Hahn, T.; Zibek, S.; Gagliardini, A.; Panariello, L.; Coltelli, M.B.; et al. Characterization of chitin and chitosan derived from Hermetia illucens, a further step in a circular economy process. Sci. Rep. 2022, 12, 6613. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Panariello, L.; Vannozzi, A.; Gigante, V.; Gagliardini, A.; Morganti, P.; Cinelli, P.; Lazzeri, A.; De Bonis, A.; Falabella, P. Chitin and Its Derivatives: Nanostructured Materials from Different Marine and Terrestrial Sources. Chem. Eng. Trans. 2022, 93, 295–300. [Google Scholar] [CrossRef]

- Teno, J.; Pardo-Figuerez, M.; Hummel, N.; Bonin, V.; Fusco, A.; Ricci, C.; Donnarumma, G.; Coltelli, M.-B.; Danti, S.; Lagaron, J.M. Preliminary Studies on an Innovative Bioactive Skin Soluble Beauty Mask Made by Combining Electrospinning and Dry Powder Impregnation. Cosmetics 2020, 7, 96. [Google Scholar] [CrossRef]

- Morganti, P.; Yudin, V.E.; Morganti, G.; Coltelli, M.-B. Trends in Surgical and Beauty Masks for a Cleaner Environment. Cosmetics 2020, 7, 68. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Yudin, V.E.; Chen, H.-D. Chitin and Lignin: Old Polymers and New Bio-Tissuecarriers. J. Dermatol. Dermat. 2021, 6, 1–11. [Google Scholar] [CrossRef]

- Morganti, P.; Gagliardini, A.; Morganti, G. Nanochitin and nanolignin: Activity and safeness. Dermal. J. Cosmet. Laser Ther. 2022, 1, 17–35. [Google Scholar]

- Lora, J.H. Industrial commercial lignins: Sources, properties and applications. In Monomers, Polymers and Composites from Renewable Resources; Belgacem, M., Gandini, A., Eds.; Elsevier: Oxford, UK, 2018; pp. 225–241. [Google Scholar]

- Nichols, J.A.; Katiyar, S.K. Skin photoprotection by natural polyphenols: Anti-inflammatory, antioxidant and DNA repair mechanisms. Arch. Dermatol. Res. 2009, 302, 71–83. [Google Scholar] [CrossRef]

- Morganti, P.; Carezzi, F.; Del Ciotto, P.; Morganti, P. Chitin nanoparticles as innovative delivery system. Pers. Care 2012, 5, 95–98. [Google Scholar]

- Morganti, P.; Palombo, M.; Tishchenko, G.; Yudin, V.E.; Guarneri, F.; Cardillo, M.; Del Ciotto, P.; Carezzi, F.; Morganti, G.; Fabrizi, G. Chitin-Hyaluronan Nanoparticles: A Multifunctional Carrier to Deliver Anti-Aging Active Ingredients through the Skin. Cosmetics 2014, 1, 140–158. [Google Scholar] [CrossRef]

- Lee, C.G.; Da Silva, C.A.; Lee, J.Y.; Hartl, D.; Elias, J.A. Chitin regulation of immune responses: An old molecule with new roles. Curr. Opin. Immunol. 2008, 20, 684–689. [Google Scholar] [CrossRef]

- Kligman, A.M. Cosmeceuticals: A Broad-Spectrum Category between Cosmetics and Drugs. In Cosmeceuticals and Active Cosmetics. Drugs versus Cosmetics, 2nd ed.; Elsner, P., Maibach, H., Eds.; TaILor & Francis Group: Oxford, UK, 2005; pp. 1–9. [Google Scholar]

- Morganti, P.; Morganti, G.; Gagliardini, A.; Lohani, A. From cosmetics to innovative cosmeceuticals-non-woven tissues. Cosmetics 2021, 8, 65. [Google Scholar] [CrossRef]

- Donnarumma, G.; Fusco, A.; Morganti, P.; Palombo, M.; Anniboletti, T.; Del Ciotto, P.; Baroni, A.; Chianese, A. Advanced medications made by green nanocomposites. Int. J. Res. Nano Sci. 2018, 5, 261–270. [Google Scholar]

- Anniboletti, T.; Palombo, M.; Moroni, S.; Bruno, S.; Palombo, P.; Morganti, P. Clinical activity of innovative polymeric nanoparticles and non-woven tissues. In Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 340–360. [Google Scholar]

- Mezzana, P. Clinical efficacy of a new chitin nanofibrils-based gel in wound healing. Acta Chir. Plast. 2008, 50, 81–84. [Google Scholar]

- Morganti, P.; Morganti, G.; Coltelli, M.B. Chitin nanomaterials and nanocomposites for tissue repair. In Marine-Derived Biomaterials for Tissue Engineering Applications; Coi, A.H., Ben-Nissan, B., Eds.; Springer: Singapore, 2019; pp. 523–544. [Google Scholar]

- Morganti, P.; Morganti, G.; Colao, C. Biofuntional textiles for aged skin. Biomedicines 2019, 7, 51. [Google Scholar] [CrossRef] [PubMed]

- Danti, S.; Trombi, L.; Fusco, A.; Azimi, B.; Lazzeri, A.; Morganti, P.; Coltelli, M.-B.; Donnarumma, G. Chitin Nanofibrils and Nanolignin as Functional Agents in Skin Regeneration. Int. J. Mol. Sci. 2019, 20, 2669. [Google Scholar] [CrossRef] [PubMed]

- Morganti, P.; Morganti, G. Natural polymers for natural hair: The smart use of innovative carrier. In Nanocosmetics: Fundamentals, Applications and Toxicity; Nanda, A., Nanda, S., Nguyen, T.A., Rajendran, S., Slimani, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 267–286. [Google Scholar]

- Morganti, P.; Morganti, G.; Coltelli, M.-B. Smart and Sustainable Hair Products Based on Chitin-Derived Compounds. Cosmetics 2021, 8, 20. [Google Scholar] [CrossRef]

- GWI. Wellness Industry Statistics & Facts; Global Wellness Industry: Miami, FL, USA, 2022; Available online: https://globalwellnessinstitute.org/press-room/statistics-and-facts/ (accessed on 30 December 2022).

- Precedence Research. Health and Wellness Market-Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2021–2030; 2022 Report; Ottawa, ON, Canada. Available online: www.precedenceresearch.com (accessed on 29 December 2022).

- Osborne, R.; Hakozaki, T.; Laughlin, T.; Finlay, D. Application of genomics to breakthroughs in the cosmetic treatment of skin ageing and discoloration. Br. J. Dermatol. 2012, 166, 16–19. [Google Scholar] [CrossRef]

- Gilbert, P.M.; Havenstrite, K.L.; Magnusson, K.E.G.; Sacco, A.; Leonardi, N.A.; Kraft, P.; Nguyen, N.K.; Thrun, S.; Lutolf, M.P.; Blau, H.M. Substrate Elasticity Regulates Skeletal Muscle Stem Cell Self-Renewal in Culture. Science 2010, 329, 1078–1081. [Google Scholar] [CrossRef] [PubMed]

- Peoples, J.E.; Ferland, C.A. The New Generation of Cosmetics, 1990–2000; Decision Resources Report: Burlington, MA, USA, 1991. [Google Scholar]

- UN. Climate Action 2022, United Nations Report; UN: New York, NY, USA. Available online: https://www.un.org/en/climatechange/reports (accessed on 29 December 2022).

- Gerhardt, C.; Hubbert, J. Innovation, Sustainability and the “Triple Botton Line”; Marketing & Communications Report; A Kearney Inc.: Chicago, IL, USA, 2009. [Google Scholar]

- Velez, M.J.; Velez, J.J. The eminent need for an academic program in universities to teach nanomedicine. Int. J. Nanomed. 2011, 6, 1733–1738. [Google Scholar] [CrossRef]

- Deafen, M.E.; Walsh, D.J.; Audus, D.J.; Kroenlein, K.; De Pablo, J.J.; Aou, K. Wetworks an Interfaces as Catalysts for Polymer Materials Innovation. Cell Rep. Phys. Sci. 2022, 3, 101126. [Google Scholar]

- Morganti, P.; Coltelli, M.B. (Eds.) An Introduction to the Circular Economy; Nova Science: Hauppauge, NY, USA, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morganti, P.; Morganti, G.; Coltelli, M.-B. Natural Polymers and Cosmeceuticals for a Healthy and Circular Life: The Examples of Chitin, Chitosan, and Lignin. Cosmetics 2023, 10, 42. https://doi.org/10.3390/cosmetics10020042

Morganti P, Morganti G, Coltelli M-B. Natural Polymers and Cosmeceuticals for a Healthy and Circular Life: The Examples of Chitin, Chitosan, and Lignin. Cosmetics. 2023; 10(2):42. https://doi.org/10.3390/cosmetics10020042

Chicago/Turabian StyleMorganti, Pierfrancesco, Gianluca Morganti, and Maria-Beatrice Coltelli. 2023. "Natural Polymers and Cosmeceuticals for a Healthy and Circular Life: The Examples of Chitin, Chitosan, and Lignin" Cosmetics 10, no. 2: 42. https://doi.org/10.3390/cosmetics10020042

APA StyleMorganti, P., Morganti, G., & Coltelli, M.-B. (2023). Natural Polymers and Cosmeceuticals for a Healthy and Circular Life: The Examples of Chitin, Chitosan, and Lignin. Cosmetics, 10(2), 42. https://doi.org/10.3390/cosmetics10020042