Study of Road Bitumen Operational Properties Modified with Phenol–Cresol–Formaldehyde Resin

Abstract

1. Introduction

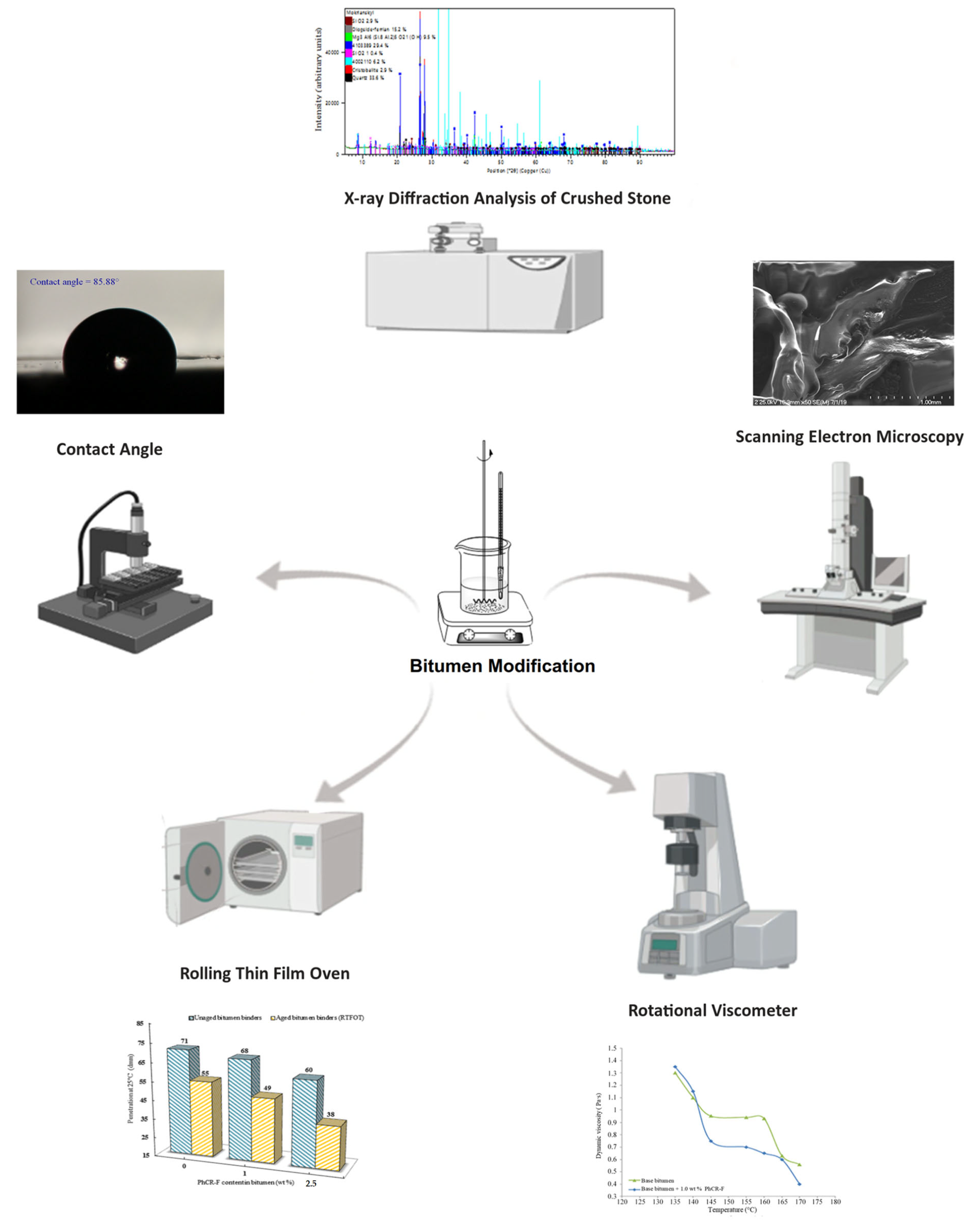

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.3. Methods of Analysis

2.3.1. Analysis of Physical Properties of Bitumen Binders

2.3.2. Analysis of Adhesive Properties of Bitumen Binders at Low Temperatures

- Preparation of 8 samples;

- Determination of the adhesive properties of the initial samples;

- Determination of the adhesive properties after one freeze–thaw cycle;

- Determination of the adhesive properties after four freeze–thaw cycles;

- Determination of the adhesive properties after four freeze–thaw cycles and four days of aging at −15 °C.

2.3.3. Spectral Analysis of Crushed Stone

2.3.4. Application of Scanning Electron Microscopy in the Analysis of Bitumen Binders

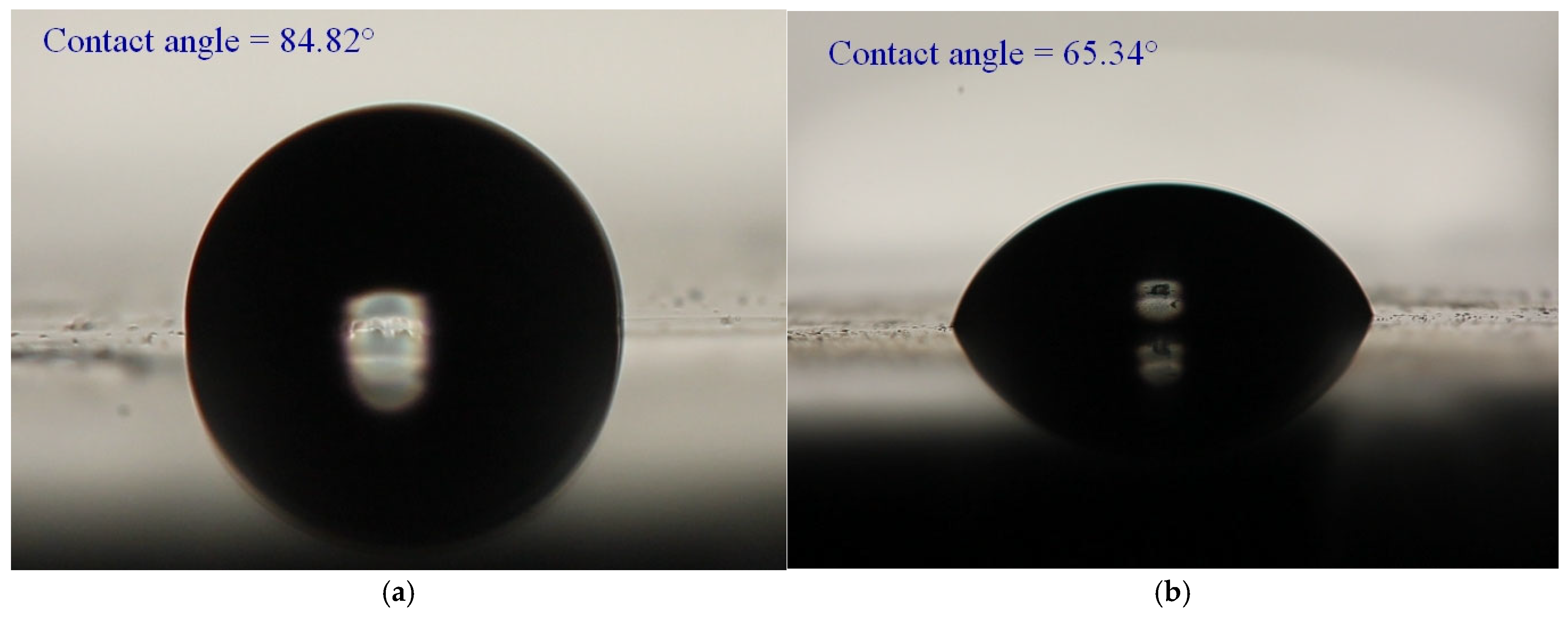

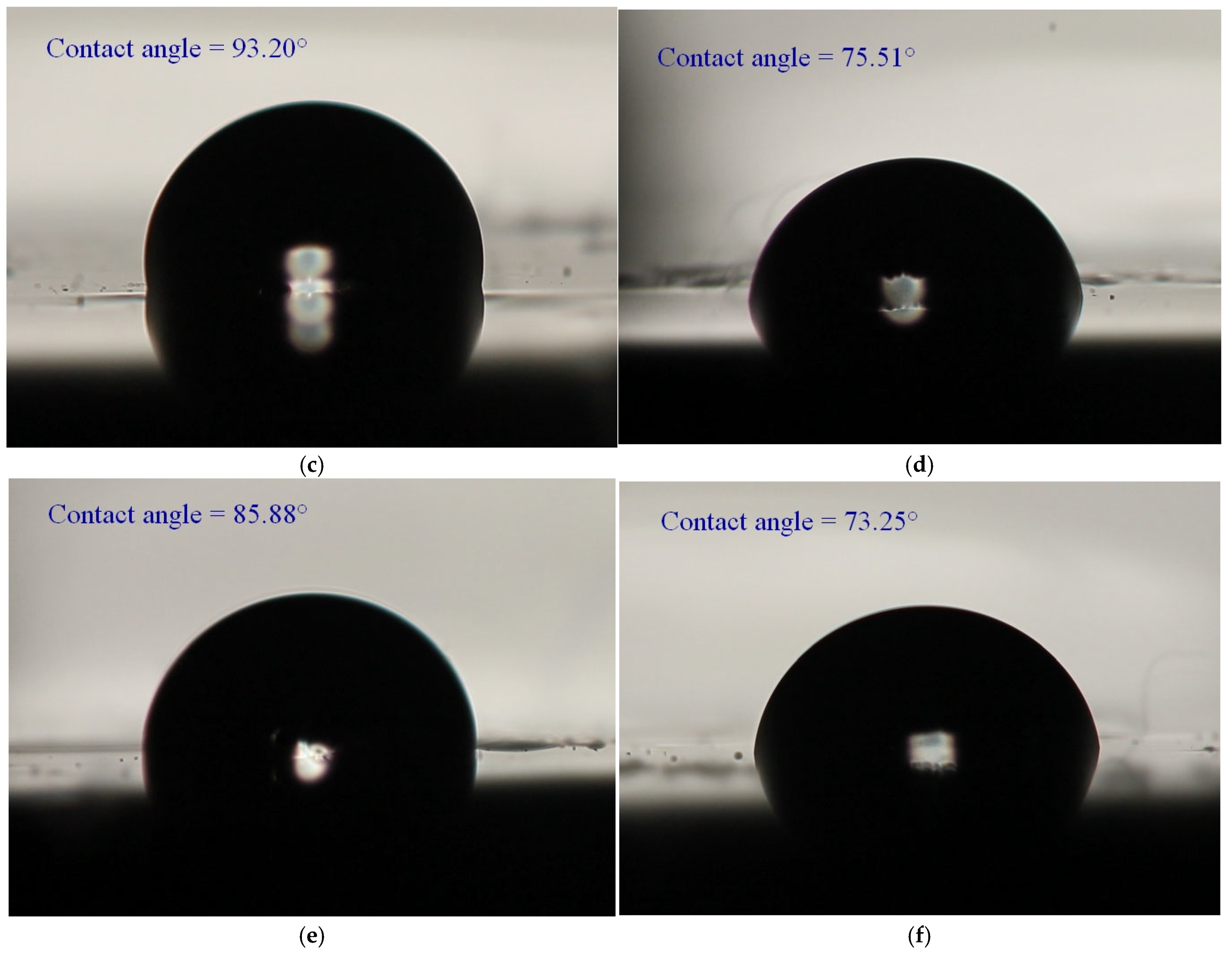

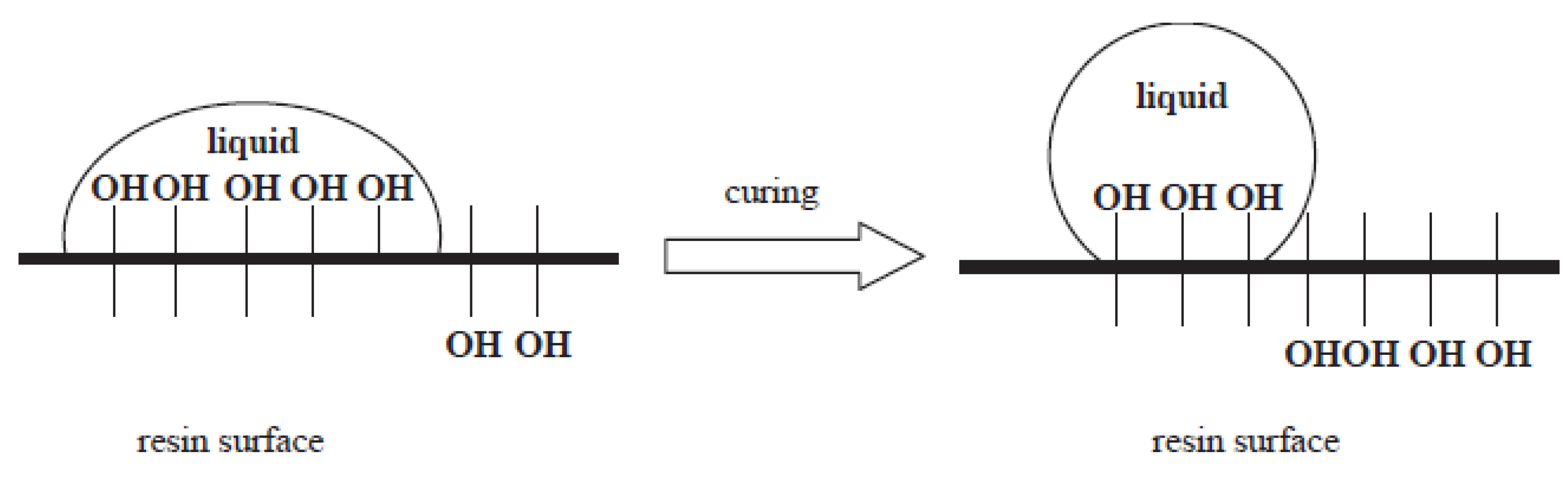

2.3.5. Surface Free Energy of Bitumen Binders

3. Results and Discussion

3.1. Definition of the Main Characteristics for Bitumen Modified with PhCR-F

3.2. Storage Stability and Scanning Electron Microscopy (SEM) Studies of Bitumen Modified with PhCR-F

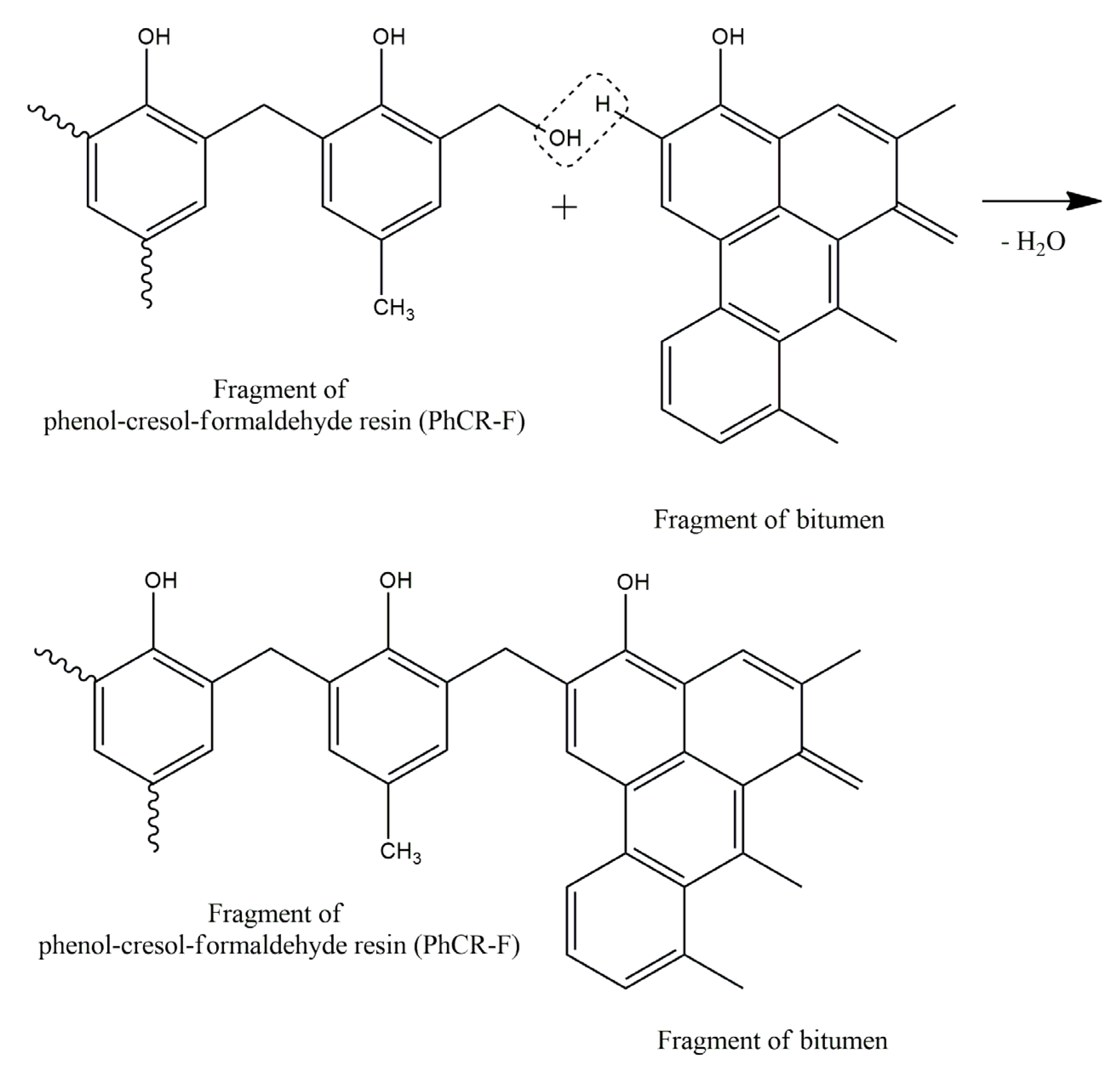

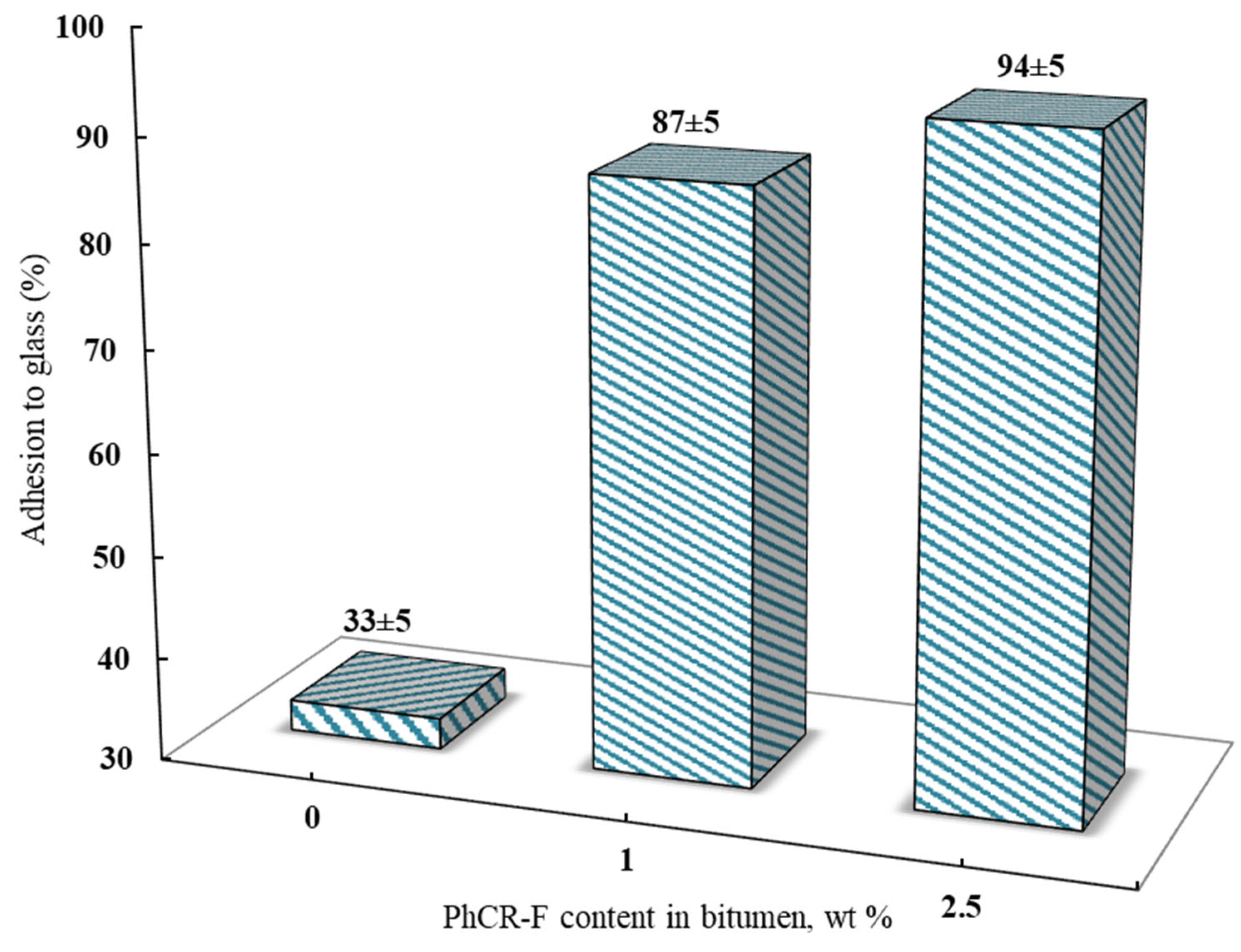

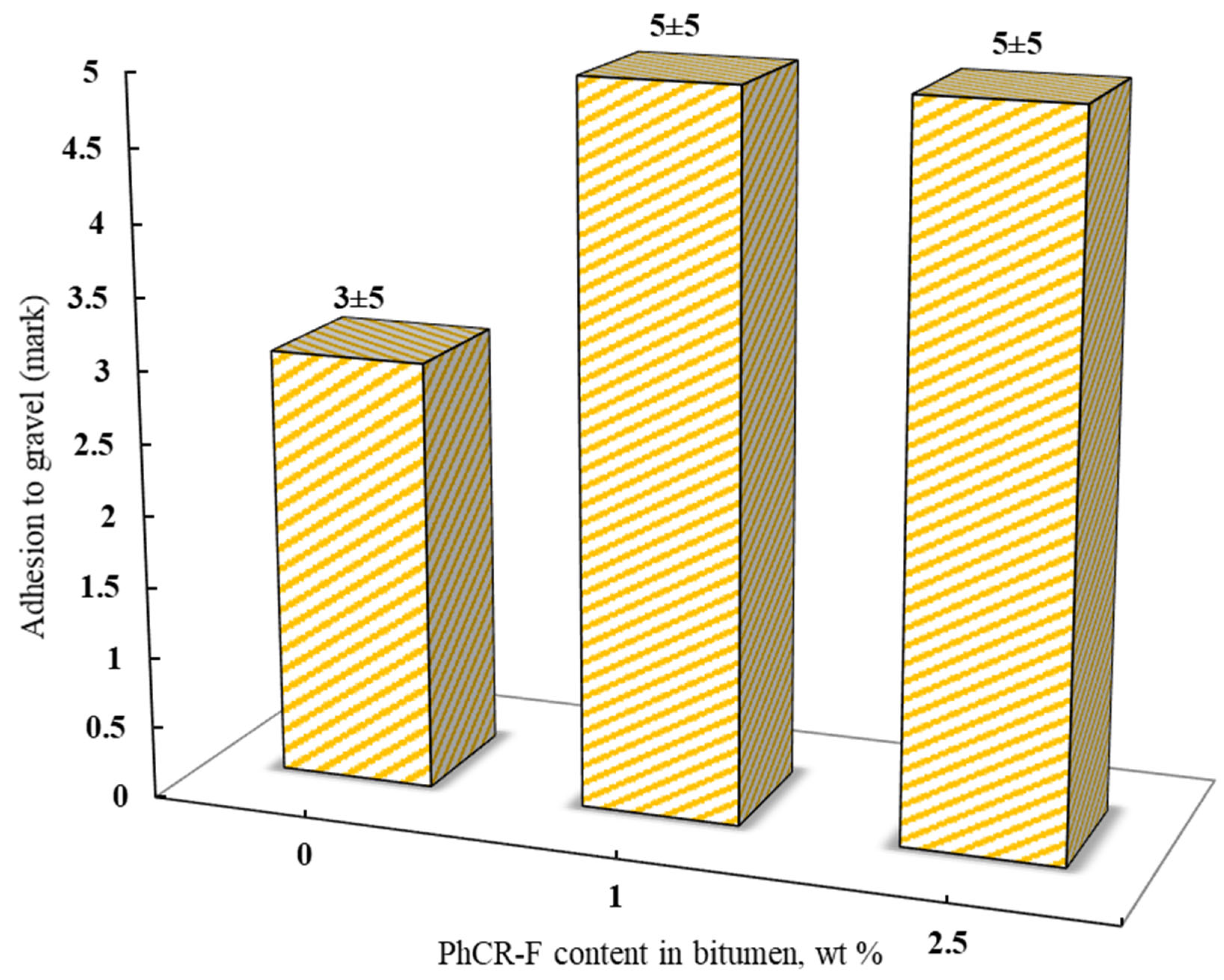

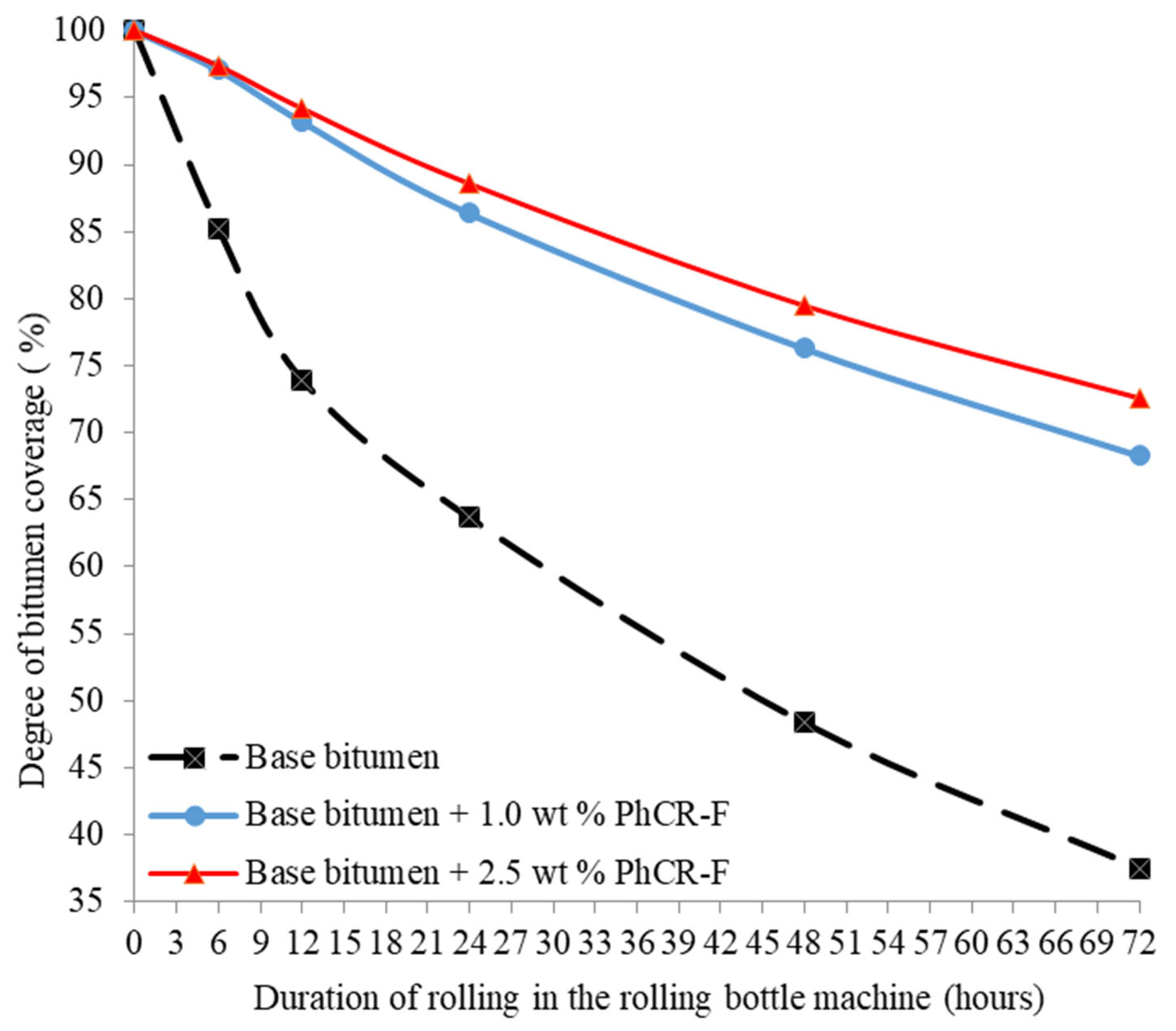

3.3. Adhesive Properties and Surface Free Energy (SFE) of Bitumen Modified with PhCR-F

3.4. Viscosity Test of Bitumen Modified with PhCR-F

3.5. Comparison of the Effectiveness of PhCR-F with Industrial Adhesive Modifier Wetfix BE

3.6. Assessment of the Economic Feasibility of the PhCR-F Bitumen Modification Process

4. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CA | contact angle (°) |

| FBP | Fraass breaking point (°C) |

| PhCR-F | phenol–cresol–formaldehyde resin |

| PMB | polymer-modified bitumen |

| RTFOT | rolling thin film oven test |

| SEM | scanning electron microscopy |

| SFE | surface free energy (mJ/m2) |

| SP | softening point (°C) |

| VAT | value added tax (%) |

| XRD | X-ray diffraction |

References

- Vargas, C.; Hanandeh, A.E. Features Importance and Their Impacts on the Properties of Asphalt Mixture Modified with Plastic Waste: A Machine Learning Modeling Approach. Int. J. Pavement Res. Technol. 2022, 16, 1555–1582. [Google Scholar] [CrossRef]

- Ibrahim, H.; Desidery, L.; Lanotte, M. Devulcanized Tire Rubber–Waste Plastic Compounds: A Solution to Improve Storage Stability of Plastic-Modified Bitumen. Int. J. Pavement Res. Technol. 2023, 18, 667–681. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Le, V.P.; Nguyen, T.P. Performance Evaluation of Waste High Density Polyethylene as a Binder Modifier for Hot Mix Asphalt. Int. J. Pavement Res. Technol. 2023, 18, 102–113. [Google Scholar] [CrossRef]

- Mahida, S.; Shah, Y.U.; Mehta, S.; Mehta, P. Rheological evaluation of bitumen binders with polystyrene waste. Int. J. Pavement Res. Technol. 2023, 16, 1352–1363. [Google Scholar] [CrossRef]

- Paliukaitė, M.; Vorobjovas, V.; Bulevičius, M.; Andrejevas, V. Evaluation of different test methods for bitumen adhesion properties. Transport. Res. Proced. 2016, 14, 724–731. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Teltayev, B.; Angelico, R. Adhesion promoters in bituminous road materials: A review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

- Fan, Z.; Hong, B.; Lin, J.; Chen, C.; Wang, D.; Oeser, M. Understanding the wetting and water-induced dewetting behaviors of bitumen on rough aggregate surfaces. Langmuir 2021, 37, 3420–3427. [Google Scholar] [CrossRef]

- Zaidi, S.B.A.; Airey, G.D.; Grenfell, J.; Alfaqawi, R.M.; Ahmed, I.; Ahmad, N.; Haynes, M. Moisture susceptibility of hydrated lime modified mastics using adhesion test methods and surface free energy techniques. Int. J. Pavement Eng. 2021, 22, 829–841. [Google Scholar] [CrossRef]

- Mo, L.T.; Huurman, M.; Wu, S.P.; Molenaar, A.A. Bitumen–stone adhesive zone damage model for the meso-mechanical mixture design of ravelling resistant porous asphalt concrete. Int. J. Fatigue 2011, 33, 1490–1503. [Google Scholar] [CrossRef]

- Caputo, P.; Miriello, D.; Bloise, A.; Baldino, N.; Mileti, O.; Ranieri, G.A. A comparison and correlation between bitumen adhesion evaluation test methods, boiling and contact angle tests. Int. J. Adhes. Adhes. 2020, 102, 102680. [Google Scholar] [CrossRef]

- Xu, Y.; Zheng, C.; Feng, Y.; Guo, X. Low-temperature cohesive and adhesive strength testing of contact surface between bitumen and mineral aggregates by image analysis. Constr. Build. Mater. 2018, 183, 95–101. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Effect of filler on the bitumen-aggregate adhesion in asphalt mix. Int. J. Pavement Eng. 2020, 21, 1482–1490. [Google Scholar] [CrossRef]

- Vinet-Cantot, J.; Gaudefroy, V.; Delfosse, F.; Chailleux, E.; Crews, E. Stripping at the bitumen–aggregate interface: A laboratory method to assess the loss of chemical adhesion. Energy Fuels 2019, 33, 2641–2650. [Google Scholar] [CrossRef]

- Cihlářová, D.; Fencl, I.; Cápayová, S.; Pospíšil, P. Use of adhesion promoters in asphalt mixtures. Slovak J. Civ. Eng. 2018, 26, 19–24. [Google Scholar] [CrossRef]

- Guo, F.; Pei, J.; Zhang, J.; Xue, B.; Sun, G.; Li, R. Study on the adhesion property between asphalt binder and aggregate: A state-of-the-art review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; Baldino, N.; Szerb, E.I.; Teltayev, B. Quantitative evaluation of organosilane-based adhesion promoter effect on bitumen-aggregate bond by contact angle test. Int. J. Adhes. Adhes. 2017, 72, 117–122. [Google Scholar] [CrossRef]

- Rossi, C.O.; Caputo, P.; Baldino, N.; Lupi, F.R.; Miriello, D.; Angelico, R. Effects of adhesion promoters on the contact angle of bitumen-aggregate interface. Int. J. Adhes. Adhes. 2016, 70, 297–303. [Google Scholar] [CrossRef]

- Çubuk, M.; Gürü, M.M.; Çubuk, K.; Arslan, D. Rheological properties and performance evaluation of phenol formaldehyde modified bitumen. J. Mater. Civil. Eng. 2014, 26, 04014015. [Google Scholar] [CrossRef]

- Gunka, V.; Demchuk, Y.; Pyshyev, S.; Starovoit, A.; Lypko, Y. The selection of raw materials for the production of road bitumen modified by phenol-cresol-formaldehyde resins. Pet. Coal 2018, 60, 1199–1206. [Google Scholar]

- Demchuk, Y.; Donchenko, M.; Astakhova, O.; Gunka, V.; Drapak, I.; Sulyma, M.; Palianytsia, L.; Bratychak, M. Effect of Bisphenol-Formaldehyde Resin on Physico-Mechanical Properties of Road Bitumen. Chem. Chem. Technol. 2024, 18, 23–29. [Google Scholar] [CrossRef]

- Gunka, V.; Demchuk, Y.; Sidun, I.; Miroshnichenko, D.; Nyakuma, B.B.; Pyshyev, S. Application of phenol-cresol-formaldehyde resin as an adhesion promoter for bitumen and asphalt concrete. Road Mater. Pavement Des. 2021, 22, 2906–2918. [Google Scholar] [CrossRef]

- Pyshyev, S.; Demchuk, Y.; Poliuzhyn, I.; Kochubei, V. Obtaining and use adhesive promoters to bitumen from the phenolic fraction of coal tar. Int. J. Adhes. Adhes. 2022, 118, 103191. [Google Scholar] [CrossRef]

- Prysiazhnyi, Y.; Borbeyiyong, G.I.; Pyshyev, S. Preparation and Application of Coumarone-Indene-Carbazole Resin as a Modifier of Road Petroleum Bitumen 1. Influence Of Carbazole: Raw Materials Ratio. Chem. Chem. Technol. 2022, 16, 284–294. [Google Scholar] [CrossRef]

- Astakhova, O.; Shved, M.; Zubal, O.; Shyshchak, O.; Prysiazhnyi, Y.; Bruzdziak, P.; Bratychak, M. Obtaining of coumarone-indene resins based on light fraction of coal tar 4. Bitumen-polymer blends with participation of coumarone-indene resins with epoxy groups Chem. Chem. Technol. 2019, 13, 112–120. [Google Scholar] [CrossRef]

- Bratychak, M.; Astakhova, O.; Shyshchak, O.; Namiesnik, J.; Ripak, O.; Pyshyev, S. Obtaining of Coumarone-Indene Resins Based on Light Fraction of Coal Tar. 1. Coumarone-Indene Resins with Carboxy Groups. Chem. Chem. Technol. 2017, 11, 509–516. [Google Scholar] [CrossRef]

- Pyshyev, S.; Prysiazhnyi, Y.; Sidun, I.; Shved, M.; Borbeyiyong, G.I.; Korsh, D. Obtaining of Resins Based on Model Mixtures with Indene, Coumarone and Styrene and their Usage as Bitumen Modifiers. Pet. Coal 2020, 62, 341–346. [Google Scholar]

- Pyshyev, S.; Demchuk, Y.; Gunka, V.; Sidun, I.; Shved, M.; Bilushchak, H.; Obshta, A. Development of mathematical model and identification of optimal conditions to obtain phenol-cresol-formaldehyde resin. Chem. Chem. Technol. 2019, 13, 212–217. [Google Scholar] [CrossRef]

- Pyshyev, S.; Prysiazhnyi, Y.; Demchuk, Y.; Borbeyiyong, G.I.; Vytrykush, N. Adhesive modifiers for bitumen obtained from coumarone-indene fractions of liquid coal coking products. Int. J. Adhes. Adhes. 2025, 138, 103933. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, H.; Ban, X.; Liu, X.; Guo, Y.; Sun, J.; Lei, J. Thermosetting resin modified asphalt: A comprehensive review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 1001–1036. [Google Scholar] [CrossRef]

- Mahdi, S.N.; Imjai, T.; Wattanapanich, C.; Garcia, R.; Kaur, H.; Musarat, M.A. Life cycle cost analysis of flexible pavements reinforced with geosynthetics: A case study of new construction or repair overlays in Thailand’s Roads. Eng. Sci. 2023, 28, 1071. [Google Scholar] [CrossRef]

- Aitkaliyeva, G.; Azat, S.; Baidullayev, I.; Mangazbayeva, R.; Amitova, A.; Yelubay, M.; Abutalip, M. Using Oil Sludge as a Rejuvenator for Reclaimed Asphalt Pavement: Improving Sustainability in Road Maintenance. ES Mater. Manuf. 2024, 26, 1291. [Google Scholar] [CrossRef]

- Coking Coal & Coke in Ukraine: Production & Imports in 2013–2024. Available online: https://gmk.center/en/infographic/due-to-the-war-ukraine-has-lost-74-of-coking-coal-production/ (accessed on 29 January 2025).

- Road Construction: How the Bitumen Market in Ukraine Has Changed Over the Past 10 Years. Available online: https://www.slovoidilo.ua/2021/02/10/infografika/biznes/budivnycztvo-dorih-yak-zminyuvavsya-rynok-bitumu-ukrayini-ostanni-10-rokiv (accessed on 10 February 2021).

- Doran, P.M. Bioprocess Engineering Principles, 2nd ed.; Mixing; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; Chapter 8; pp. 255–332. [Google Scholar] [CrossRef]

- Cullen, P.J. Food Mixing: Principles and Applications; John Wiley & Sons. Ltd. Publication: Hoboken, NJ, USA, 2009; p. 320. [Google Scholar]

- Standard EN 1426:2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=78299 (accessed on 1 June 2019).

- Standard EN 1427:2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=78301 (accessed on 1 June 2019).

- Standard EN 13398:2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=79270 (accessed on 1 December 2019).

- Standard EN 12593:2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=78305 (accessed on 1 June 2019).

- Standard EN 12607-1:2015. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=63683 (accessed on 1 July 2016).

- Standard EN 13399:2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=78553 (accessed on 1 October 2019).

- Standard EN 12697-11:2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=81760 (accessed on 1 January 2020).

- Standard EN 13302:2019. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=82165 (accessed on 1 January 2020).

- Ukrainian State Standard DSTU 9169:2021. Available online: https://online.budstandart.com/ua/catalog/doc-page?id_doc=97049 (accessed on 1 August 2022).

- Ukrainian State Standard DSTU 8787:2018. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=4917 (accessed on 1 April 2003).

- Stalder, A.R.; Melchior, T.; Muller, M.; Sage, D.; Blu, T.; Unser, M. Low-Bond Axisymmetric Drop Shape Analysis for Surface Tension and Contact Angle Measurements of Sessile Drops. Colloids Surf. A 2010, 364, 72–81. [Google Scholar] [CrossRef]

- Brugnara, M. Using the ESEM for the measurement of contact angles on flat samples. Microsc. Anal. 2007, 3, 17–19. [Google Scholar]

- Williams, D.; Kuhn, A.; Amann, M.; Hausinger, M.; Konarik, M.; Nesselrode, E. Computerized Measurement of Contact Angles. Galvanotechnik 2010, 10, 2502. [Google Scholar]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Molina, R.; Esquena, J.; Erra, P. Interfacial processes in textile materials: Relevance to adhesion. J. Adhes. Sci. Technol. 2010, 24, 7–33. [Google Scholar] [CrossRef]

- Ukrainian State Standard SOU 45.2-00018112-067:2011. Available online: http://online.budstandart.com/ua/catalog/doc-page.html?id_doc=69813 (accessed on 1 June 2017).

- Ukrainian State Standard DSTU 9116:2021. Available online: http://online.budstandart.com/ua/catalog/doc-page.html?id_doc=96264 (accessed on 1 March 2022).

- Standard EN 14023:2010. Available online: https://online.budstandart.com/ua/catalog/doc-page.html?id_doc=105146 (accessed on 1 June 2024).

- Mazumder, M.; Ahmed, R.; Ali, A.W.; Lee, S.J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

- Gupta, R.; Kaur, V.; Maharishi, V.; Guru, N. Characterization of Bitumen and Modified Bitumen (e-PMB) using FT-IR, Thermal and SEM techniques. Res. J. Chem. Sci. 2012, 2, 31–36. [Google Scholar]

- Azam, A.M.; El-Badawy, S.M.; Alabasse, R.M. Evaluation of asphalt mixtures modified with polymer and wax. Innov. Infrastruct. Solut. 2019, 4, 43. [Google Scholar] [CrossRef]

- Grönniger, J.; Wistuba, M.P.; Renken, P. Adhesion in bitumen-aggregate-systems: New technique for automated interpretation of rolling bottle tests. Road Mater. Pavement Des. 2010, 11, 881–898. [Google Scholar] [CrossRef]

- Brożyna, D.; Kowalski, K.J. Assessment of polyethylen-modified bitumen adhesion using computer image analysis. Arch. Civ. Eng. 2016, LXII, 3–18. [Google Scholar] [CrossRef]

- Mei, A.; Fusco, R.; Moroni, M.; Fiore, N.; Fontinovo, G.; D’Andrea, A. Affinity between Bitumen and Aggregate in Hot Mix Asphalt by Hyperspectral Imaging and Digital Picture Analysis. Coatings 2021, 11, 648. [Google Scholar] [CrossRef]

- Komačka, J.; Budjačová, E.; Remišová, E. Colour-histogram-based assessment procedure of the rolling bottle test considering the drawbacks in the digital image analysis of bitumen–aggregate systems. Mater. Struct. 2019, 52, 59. [Google Scholar] [CrossRef]

- Little, D.N.; Bhasin, A. Final Report for NCHRP RRD 316: Using surface energy measurements to select materials for asphalt pavement. Transport. Res. Board. 2006, 9–37. [Google Scholar] [CrossRef]

- Martínez-Rodríguez, M.; Esquena, J. Wetting and interfacial properties of bitumen at room temperature, and the role of naturally present ionic molecules. Colloids Surf. A 2021, 609, 125575. [Google Scholar] [CrossRef]

- Salou, M.; Siffert, B.; Jada, A. Study of the stability of bitumen emulsions by application of DLVO theory. Colloids Surf. A 1998, 142, 9–16. [Google Scholar] [CrossRef]

- Cantin, S.; Bouteau, M.; Benhabib, F.; Perrot, F. Surface free energy evaluation of well-ordered langmuir-blodgett surfaces: Comparison of different approaches. Colloids Surf. A 2006, 276, 107–115. [Google Scholar] [CrossRef]

- Lee, Y.K.; Kim, H.J.; Rafailovich, M.; Sokolov, J. Curing monitoring of phenolic resol resins via atomic force microscope and contact angle. Int. J. Adhes. Adhes. 2002, 22, 375–384. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Moghadas Nejad, F. Using energy parameters based on the surface free energy concept to evaluate the moisture susceptibility of hot mix asphalt. Road Mater. Pavement Des. 2015, 16, 239–255. [Google Scholar] [CrossRef]

- Akbari, A.; Modarres, A. Fatigue response of HMA containing modified bitumen with nano-clay and nano-alumina and its relationship with surface free energy parameters. Road Mater. Pavement Des. 2020, 21, 1490–1513. [Google Scholar] [CrossRef]

- Kuoshiken, U.; Tileuberdi, Y.; Shi, Q.; Ongarbayev, Y.; Li, S.; Zhanbekov, K.; Kanzharkan, E.; Imanbayev, Y. Electrospray Ionization FT-ICR MS Analysis of Polar Compounds in Natural Bitumen of Munaily-Mola Oil Sands and Its Asphaltenes. ES Mater. Manuf. 2024, 25, 1240. [Google Scholar] [CrossRef]

- Vega, A.D.L.; Santos, J.; Martinez-Arguelles, G. Life cycle assessment of hot mix asphalt with recycled concrete aggregates for road pavements construction. Int. J. Pavement Eng. 2022, 23, 923–936. [Google Scholar] [CrossRef]

- Sarnowski, M.; Kowalski, K.J.; Król, J.B.; Radziszewski, P. Influence of overheating phenomenon on bitumen and asphalt mixture properties. Materials 2019, 12, 610. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Penetration at 25 °C (dmm), measurement error ± 2 | 70 |

| Softening point (°C), measurement error ± 1 | 46 |

| Ductility at 25 °C (cm), measurement error ± 4 | 63 |

| Adhesion to glass (%), measurement error ± 5 | 33 |

| Adhesion to crushed stone (mark), measurement error ± 0.5 | 3.0 |

| Fraass breaking point (°C), measurement error ± 1 | −18 |

| Plasticity range (°C), measurement error ± 1 | 64 |

| Resistance to hardening at 163 °C (RTFOT method): | |

| Change in mass (%), measurement error ± 2 | 0.030 |

| Softening point after RTFOT (°C), measurement error ± 1 | 52 |

| Penetration at 25 °C after RTFOT (dmm), measurement error ± 2 | 55 |

| Increase in softening point (°C), measurement error ± 1 | 6 |

| Retained penetration (%), measurement error ± 2 | 79 |

| Property | Value |

|---|---|

| Appearance (−) | Brown powder |

| Softening point (°C), measurement error ± 1 | 110 |

| Free phenol (%), measurement error ± 1 | 8–12 |

| Solubility in ketones (−) | Soluble |

| Resistance to bases (−) | Decomposes |

| Compound Name | Chemical Formula | Content (wt.%) |

|---|---|---|

| Quartz | Si6O6 | 33.6 |

| Periclase | Mg4O4 | 9.5 |

| Potassium iron silicate | FeSi2KO8 | 15.2 |

| Cristobalite | Si4O8 | 6.2 |

| Aluminum oxide carbide | AlC8O5; Al2C23O10 | 35.6 |

| Liquid | , mJ/m2 | , mJ/m2 | , mJ/m2 |

|---|---|---|---|

| Water | 21.80 | 51.00 | 72.80 |

| Ethylene glycol | 29.00 | 19.00 | 48.00 |

| Property | Base Bitumen | Comparison of the Characteristics of Bitumens with the Requirements of Regulatory Documents for Bitumens Modified with Adhesive Additives | Comparison of the Characteristics of Bitumens with the Requirements of Regulatory Documents for Bitumens Modified with Polymer Additives | ||

|---|---|---|---|---|---|

| Base Bitumen + 1.0 wt.% PhCR-F | Requirements According to SOU 45.2-00018112-067:2011 1 [51] | Base Bitumen + 2.5 wt.% PhCR-F | Requirements According to DSTU 9116:2021 2 [52] | ||

| Penetration at 25 °C (dmm), measurement error ± 2 | 70 | 68 | 61–90 | 60 | 71–100 |

| Softening point (°C), measurement error ± 1 | 46 | 48 | 47–53 | 49 | ≥55 |

| Ductility at 25 °C (cm), measurement error ± 4 | 63 | 58 | ≥55 | 52 | ≥8 |

| Fraass breaking point (°C), measurement error ± 1 | −18 | −18 | ≤−13 | −18 | ≤−18 |

| Elastic recovery at 25 °C (%) 3, measurement error ± 2 | – | – | Not applicable | – | ≥55 |

| Adhesion to crushed stone (mark), measurement error ± 0.5 | 3.0 | 5.0 | ≥5.0 | 5.0 | ≥4.5 |

| Adhesion to glass (%), measurement error ± 5 | 33 | 87 | ≥75 | 94 | ≥75 |

| Low-temperature adhesion A–15, (%), measurement error ± 2 | 24 | 82 | Not applicable | 89 | Not applicable |

| Plasticity range (°C), measurement error ± 1 | 64 | 66 | 67 | ||

| Homogeneity (–) | – | Homogeneous | Not applicable | Homogeneous | Polymer clots and particles should not be observed in BMP |

| Property | Base Bitumen | Base Bitumen + PhCR-F | ||||

|---|---|---|---|---|---|---|

| 1.0 wt.% | 2.5 wt.% | |||||

| Unaged | RTFOT | Unaged | RTFOT | Unaged | RTFOT | |

| Softening point (°C), measurement error ± 1 | 46 | 52 | 48 | 54 | 49 | 56 |

| Increase in softening point (°C), measurement error ± 1 | – | 6 | – | 6 | – | 7 |

| Penetration at 25 °C (dmm), measurement error ± 2 | 70 | 55 | 68 | 49 | 60 | 38 |

| Retained penetration (%), measurement error ± 1 | – | 78 | – | 72 | – | 63 |

| Change in mass (%), measurement error ± 0.05 | – | 0.030 | – | 0.085 | – | 0.114 |

| Property | Base Bitumen | Base Bitumen + 1.0 wt.% PhCR-F | ||

|---|---|---|---|---|

| Top | Bottom | Top | Bottom | |

| Softening point (°C), measurement error ± 1 | 46.1 | 46.0 | 48.4 | 48.2 |

| Softening point change (°C) | 0.1 | 0.2 | ||

| Penetration at 25 °C (dmm), measurement error ± 2 | 70 | 71 | 68 | 67 |

| Penetration change (%) | 1.4 | 1.5 | ||

| Bitumen Film Samples | Contact Angle (°) * | Surface Energy Components (mJ/m2) | Total Surface Energy (mJ/m2) | ||

|---|---|---|---|---|---|

| Water | Ethylene Glycol | ||||

| Base bitumen | 84.82 | 65.34 | 14.90 | 9.21 | 24.11 |

| Base bitumen + 1.0 wt.% PhCR-F | 93.20 | 75.51 | 12.68 | 6.18 | 18.85 |

| Base bitumen + 2.5 wt.% PhCR-F | 85.88 | 73.25 | 7.85 | 13.19 | 21.04 |

| Composition of Polymer Modified Bitumen, wt.% | Penetration at 25 °C (dmm), Measurement Error ± 2 | Softening Point (°C), Measurement Error ±1 | Ductility at 25 °C (cm), Measurement Error ± 4 | Adhesion to Glass (%), Measurement Error ± 5 | Adhesion to Crushed Stone (Mark), Measurement Error ± 0.5 | ||

|---|---|---|---|---|---|---|---|

| Bitumen 70/100 | Wetfix BE | PhCR-F | |||||

| 100.0 | – | – | 70 | 46 | 63 | 33 | 3 |

| 99.5 | 0.5 | – | 87 | 46 | >100 | 92 | 5 |

| 99.0 | – | 1.0 | 68 | 48 | 58 | 87 | 5 |

| Requirements according to SOU 45.2-00018112-067:2011 1 [51] | – | – | 61–90 | 47–53 | ≥55 | ≥75 | 5 |

| Property | Quantity, Ton | Cost per Ton, USD | Cost, USD |

|---|---|---|---|

| 1. Reagents: 1 | – | – | 1208 |

| “Raw” (technical) phenols | 1.05 | 875 | 919 |

| Formalin | 0.54 | 518 | 280 |

| Catalyst (HCl) | 0.03 | 314 | 9 |

| 2. Production costs (25% of point 1) | – | – | 302 |

| 3. Profit (20% of points 1–2) | – | – | 302 |

| 4. Cost without VAT 2 (points 1–3) | – | – | 1812 |

| VAT—20% | – | – | 362 |

| Total cost of 1 ton of PhCR-F | – | – | 2174 |

| Component | Amount, wt.% | Quantity, ton | Cost per Ton, USD | Total Cost |

|---|---|---|---|---|

| Modified bitumen with PhCR-F | ||||

| Bitumen | 99.0 | 0.990 | 518 | 513 |

| PhCR-F | 1.0 | 0.010 | 2174 | 22 |

| Total | 100.0 | 1.000 | – | 535 |

| Modified bitumen with Wetfix BE | ||||

| Bitumen | 99.5 | 0.995 | 518 | 515 |

| Wetfix BE | 0.5 | 0.005 | 5428 | 28 |

| Total | 100.0 | 1.000 | – | 543 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demchuk, Y.; Gunka, V.; Sidun, I.; Korchak, B.; Donchenko, M.; Drapak, I.; Poliuzhyn, I.; Pyshyev, S. Study of Road Bitumen Operational Properties Modified with Phenol–Cresol–Formaldehyde Resin. Resources 2025, 14, 91. https://doi.org/10.3390/resources14060091

Demchuk Y, Gunka V, Sidun I, Korchak B, Donchenko M, Drapak I, Poliuzhyn I, Pyshyev S. Study of Road Bitumen Operational Properties Modified with Phenol–Cresol–Formaldehyde Resin. Resources. 2025; 14(6):91. https://doi.org/10.3390/resources14060091

Chicago/Turabian StyleDemchuk, Yuriy, Volodymyr Gunka, Iurii Sidun, Bohdan Korchak, Myroslava Donchenko, Iryna Drapak, Ihor Poliuzhyn, and Serhiy Pyshyev. 2025. "Study of Road Bitumen Operational Properties Modified with Phenol–Cresol–Formaldehyde Resin" Resources 14, no. 6: 91. https://doi.org/10.3390/resources14060091

APA StyleDemchuk, Y., Gunka, V., Sidun, I., Korchak, B., Donchenko, M., Drapak, I., Poliuzhyn, I., & Pyshyev, S. (2025). Study of Road Bitumen Operational Properties Modified with Phenol–Cresol–Formaldehyde Resin. Resources, 14(6), 91. https://doi.org/10.3390/resources14060091