A New Fabric Reinforced Geopolymer Mortar (FRGM) with Mechanical and Energy Benefits

Abstract

1. Introduction

2. Materials and Methods

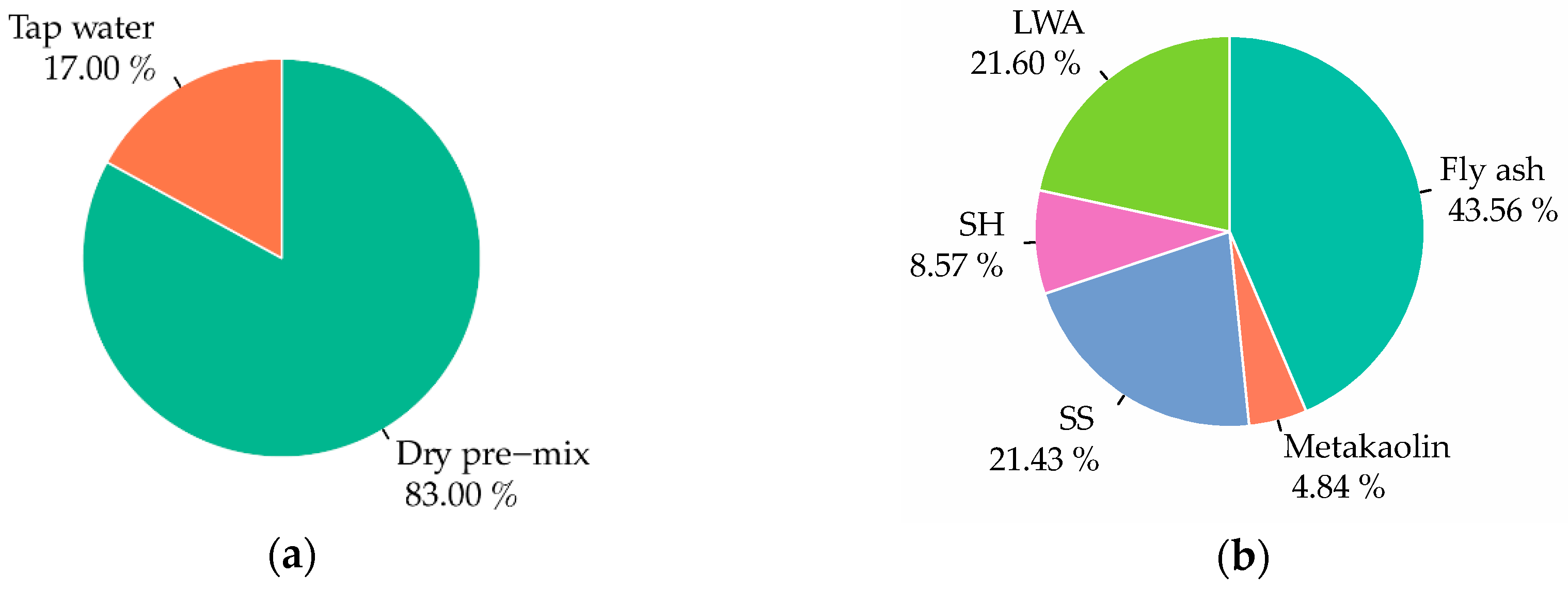

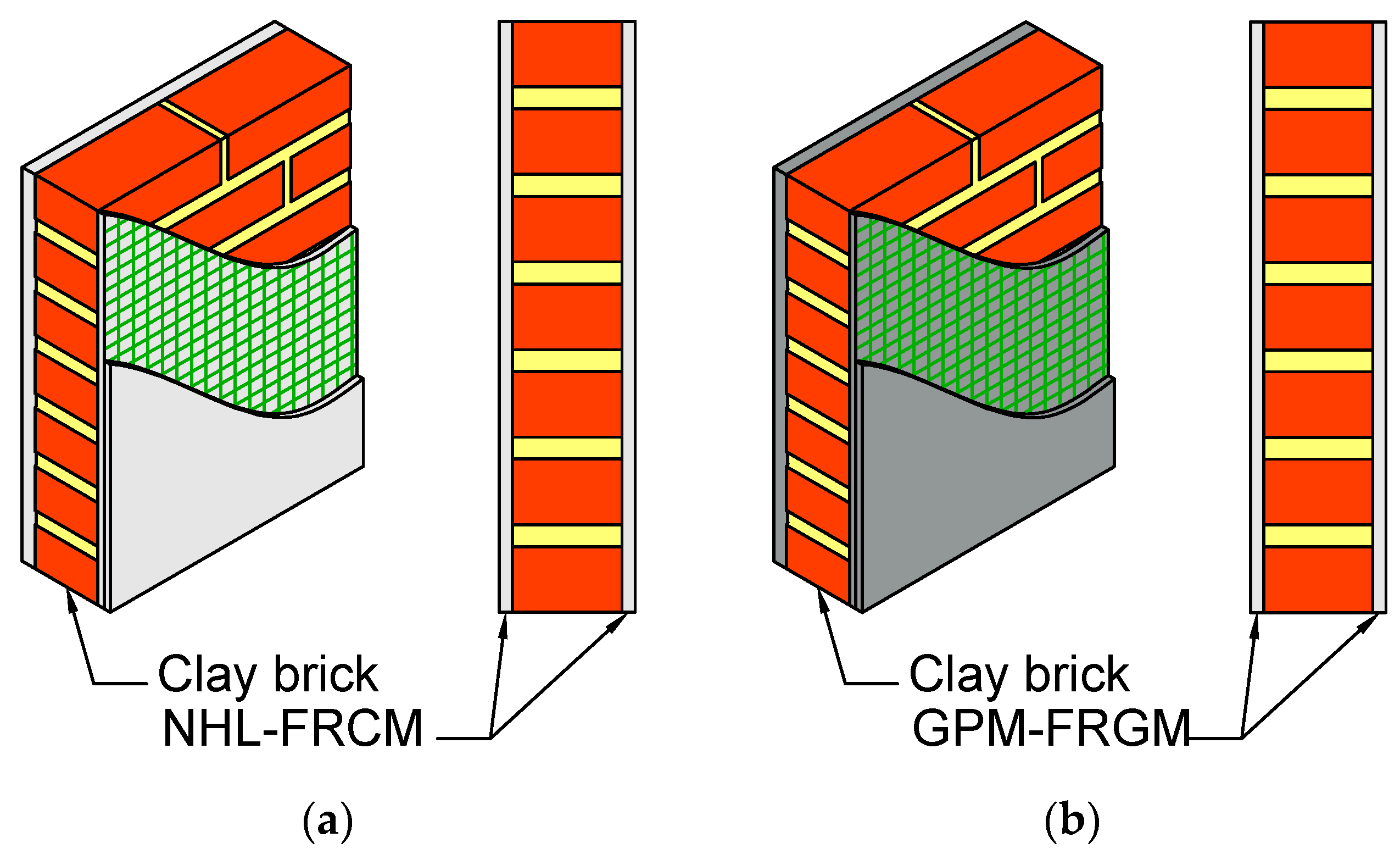

2.1. Materials and Sample Preparation

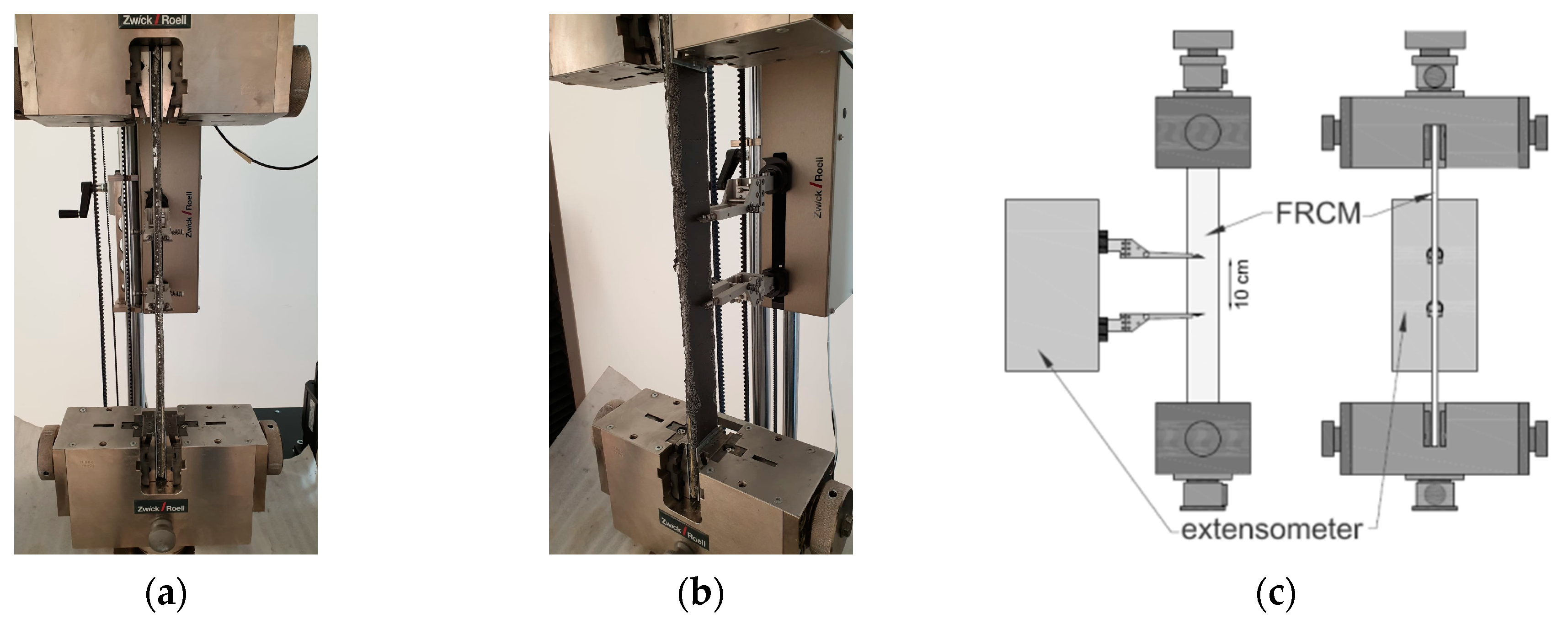

2.2. Test Methods

3. Results

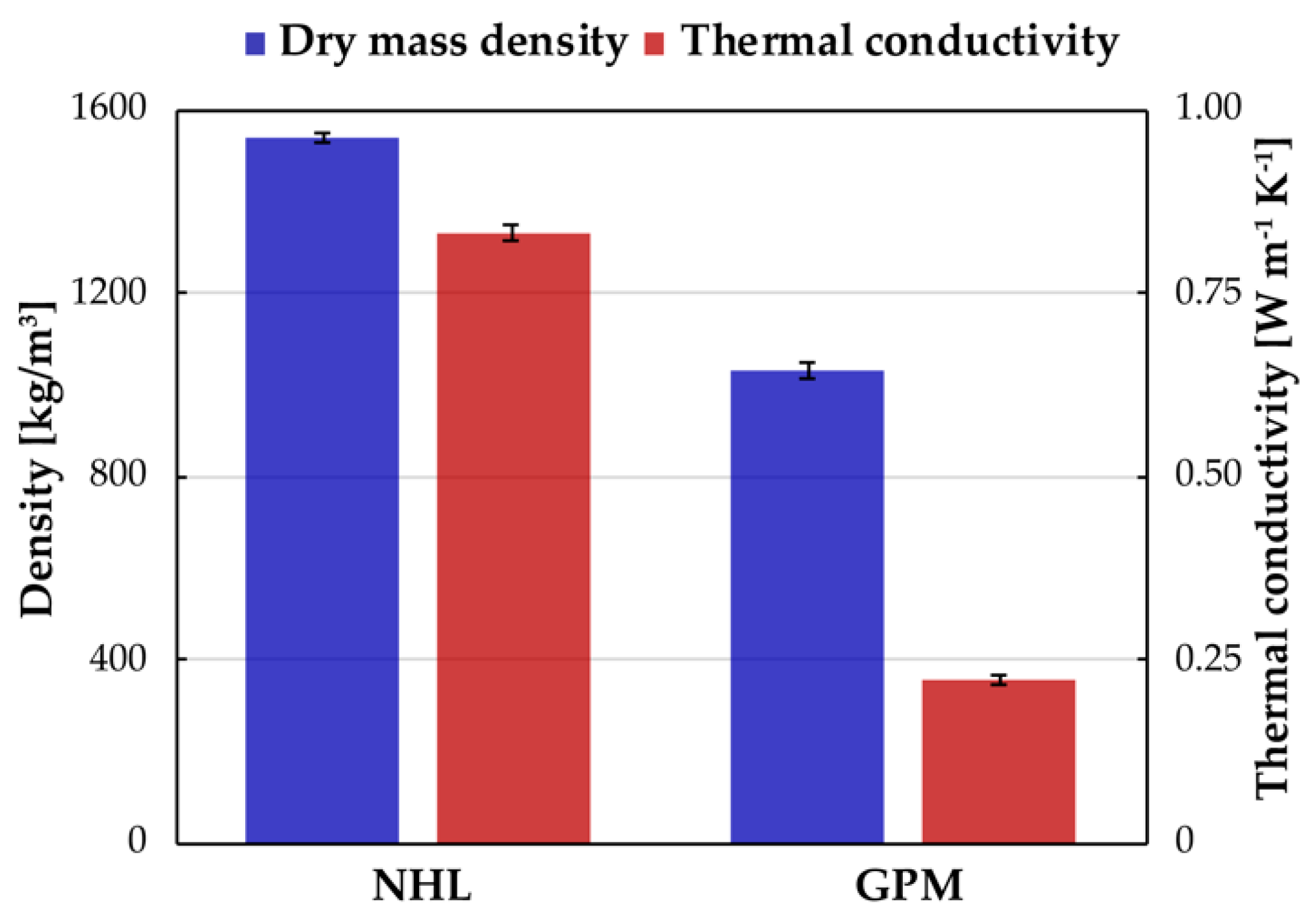

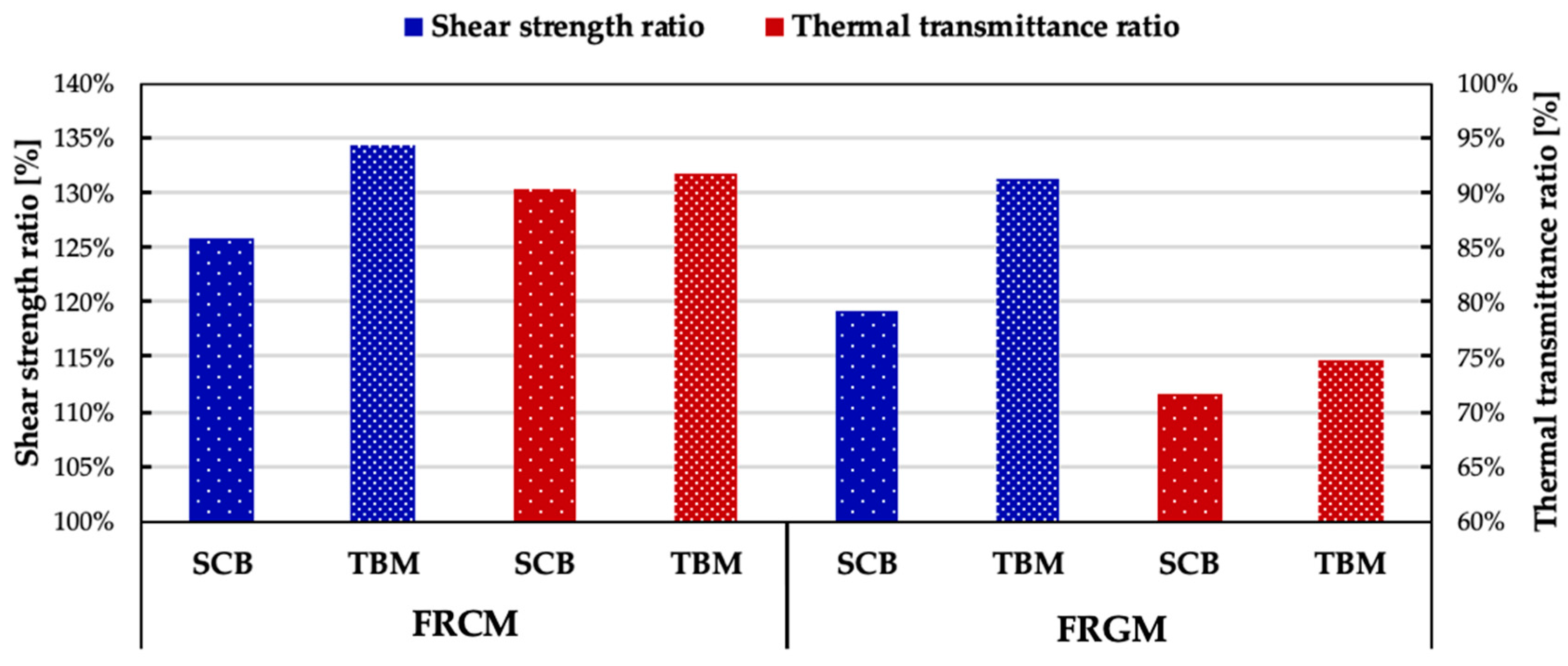

3.1. Energy Performance

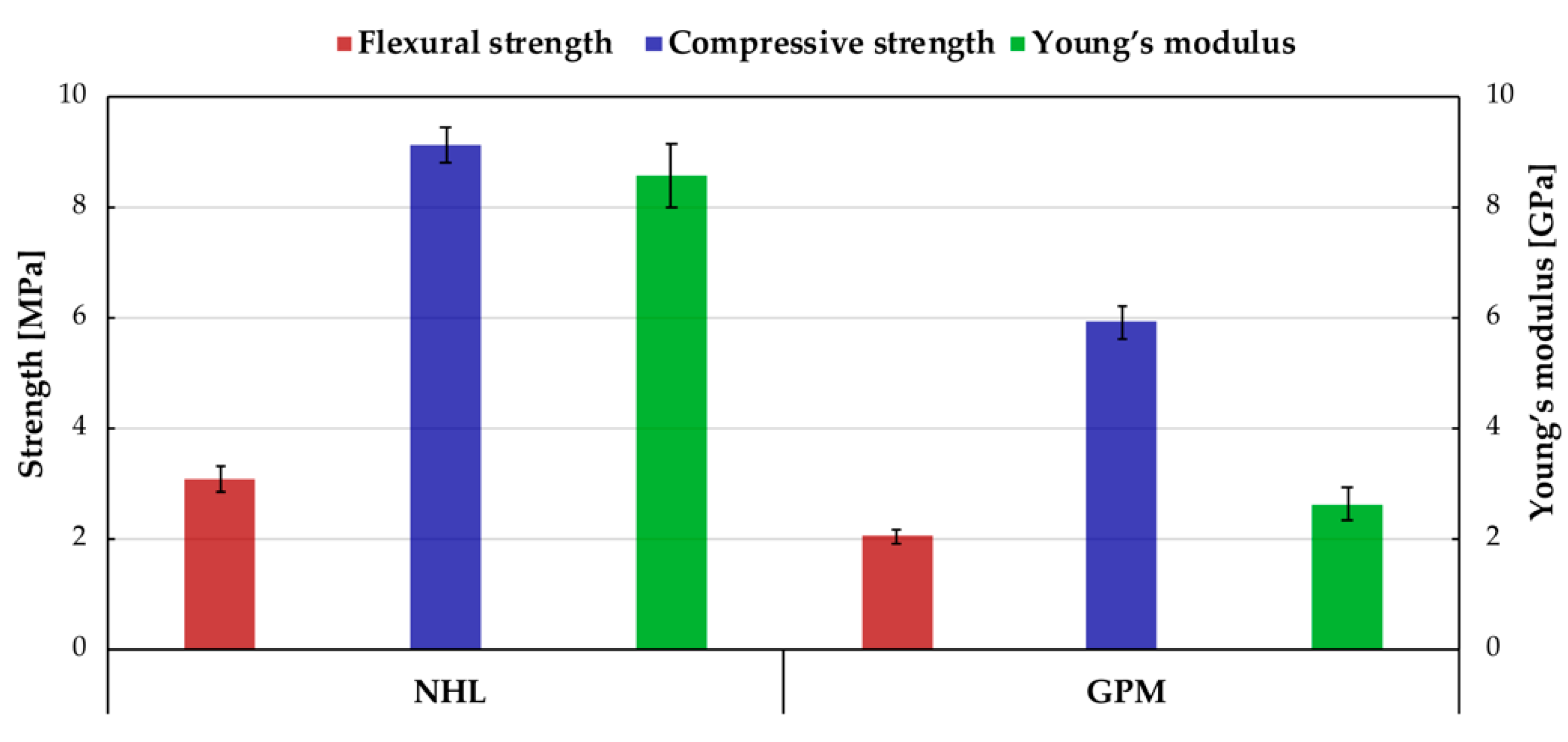

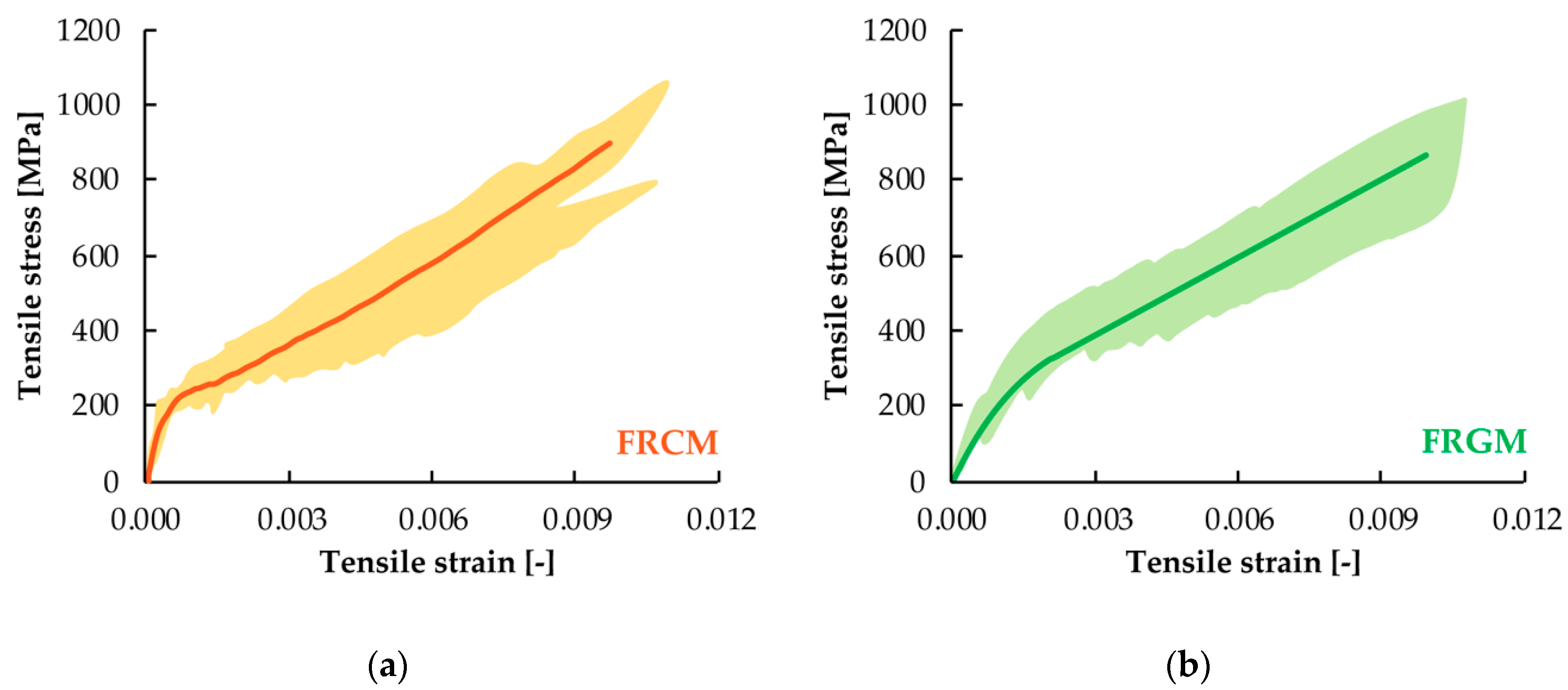

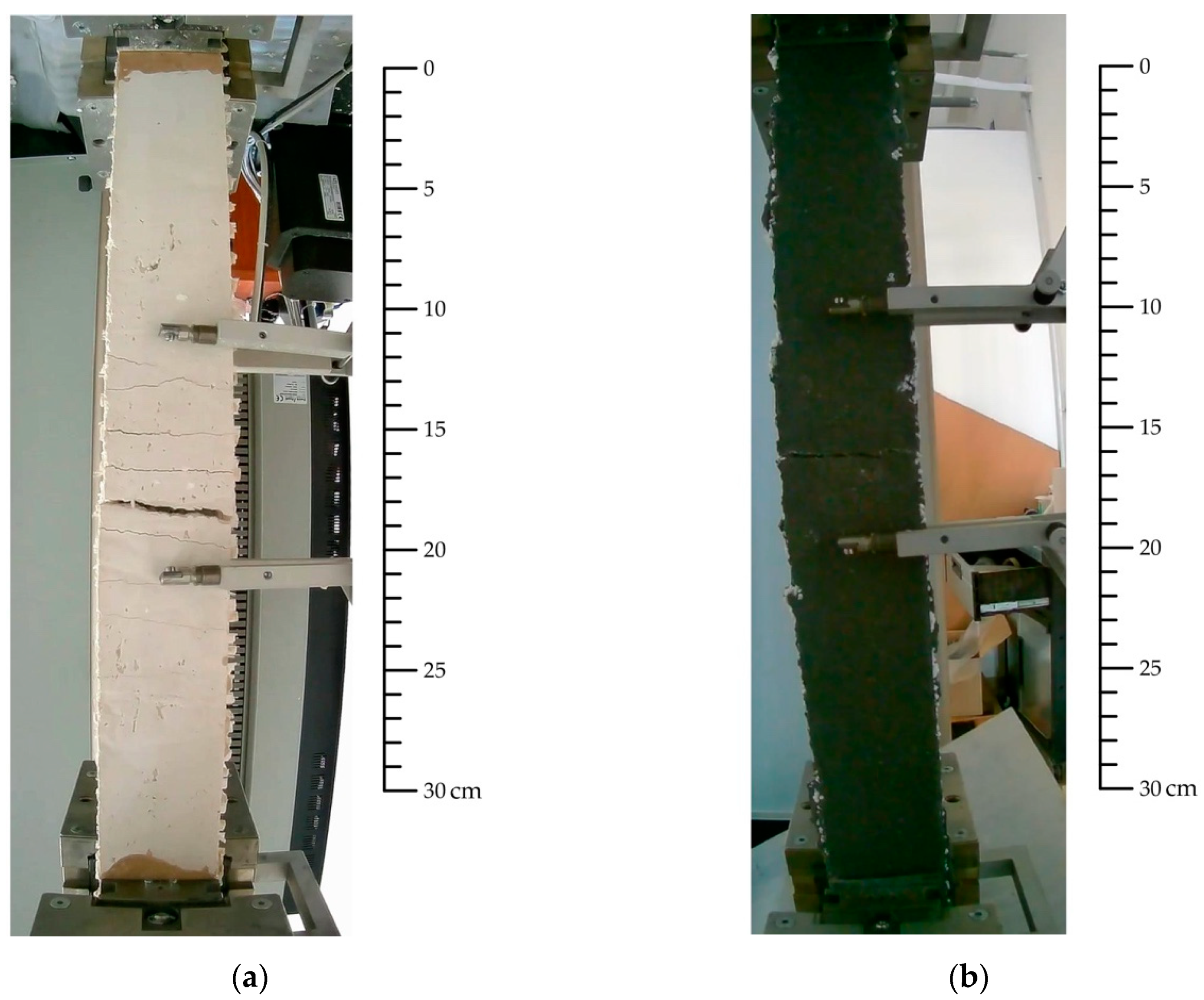

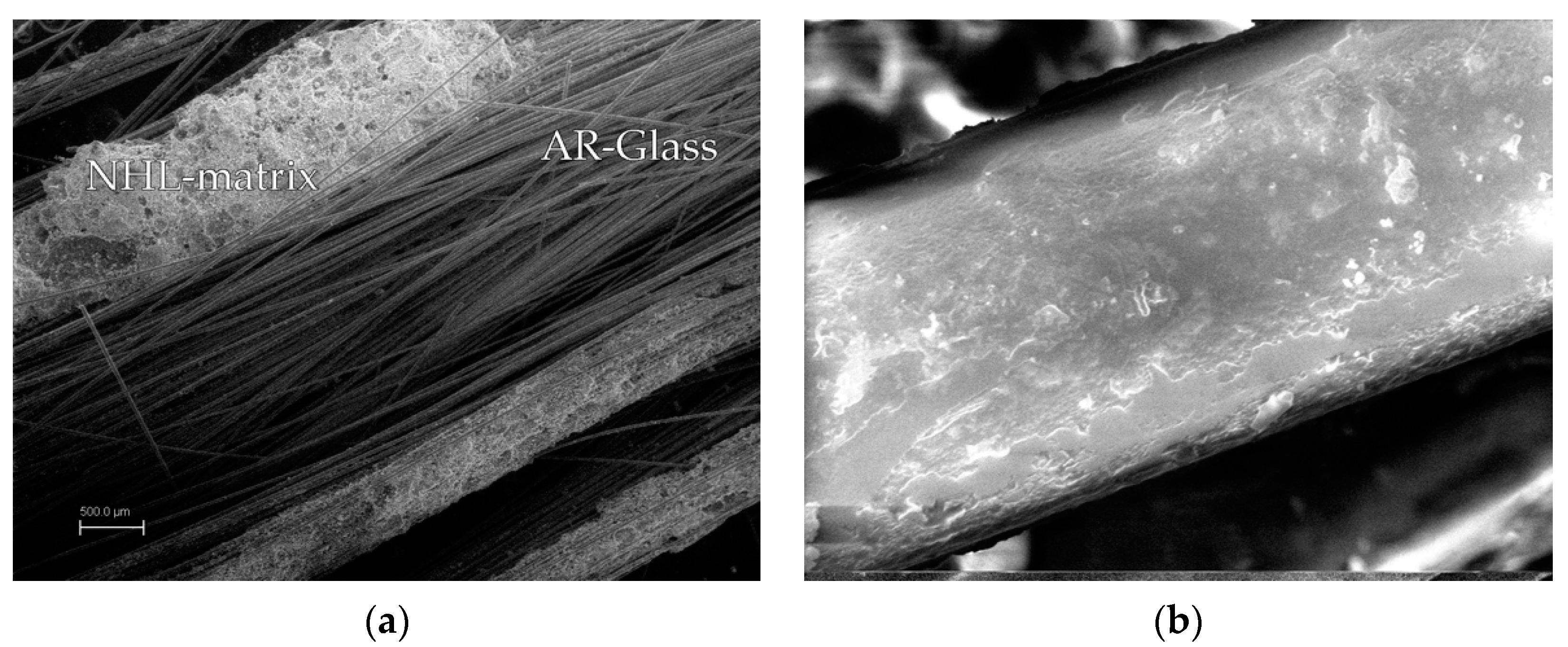

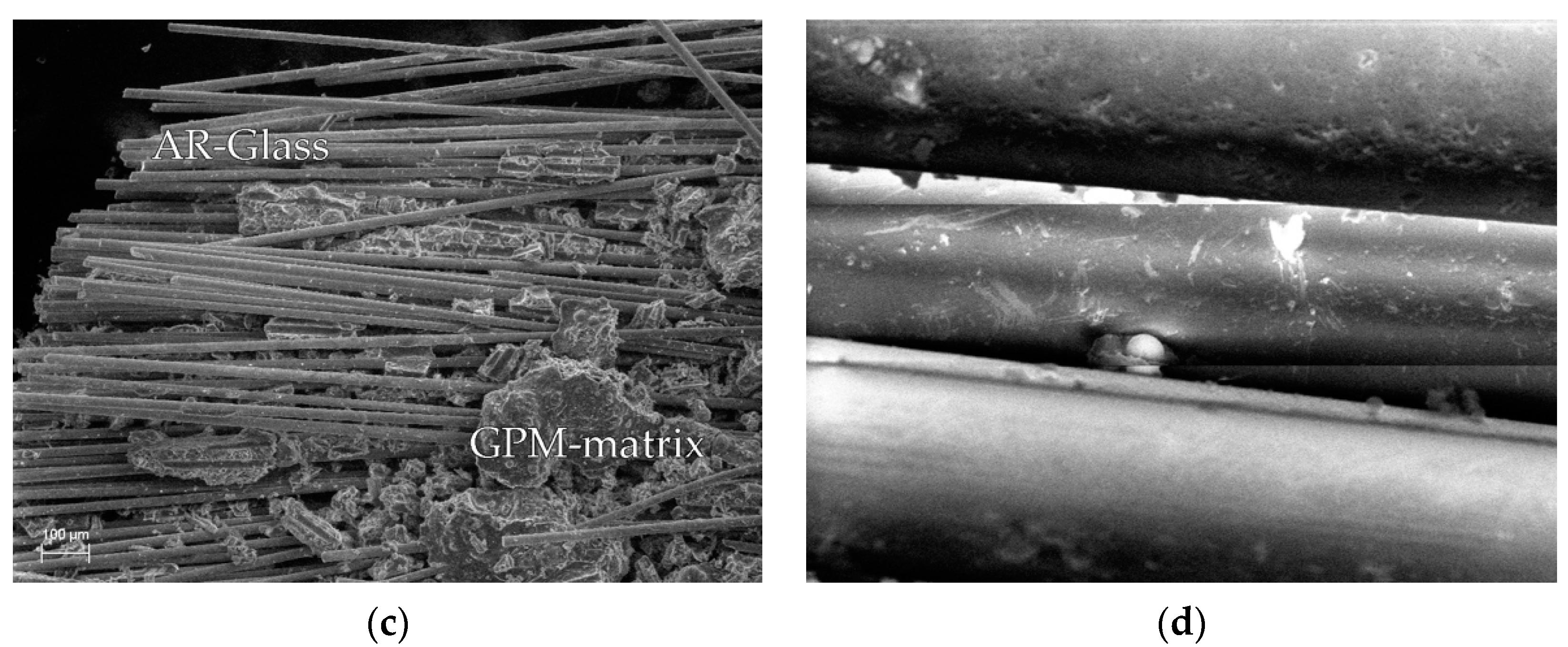

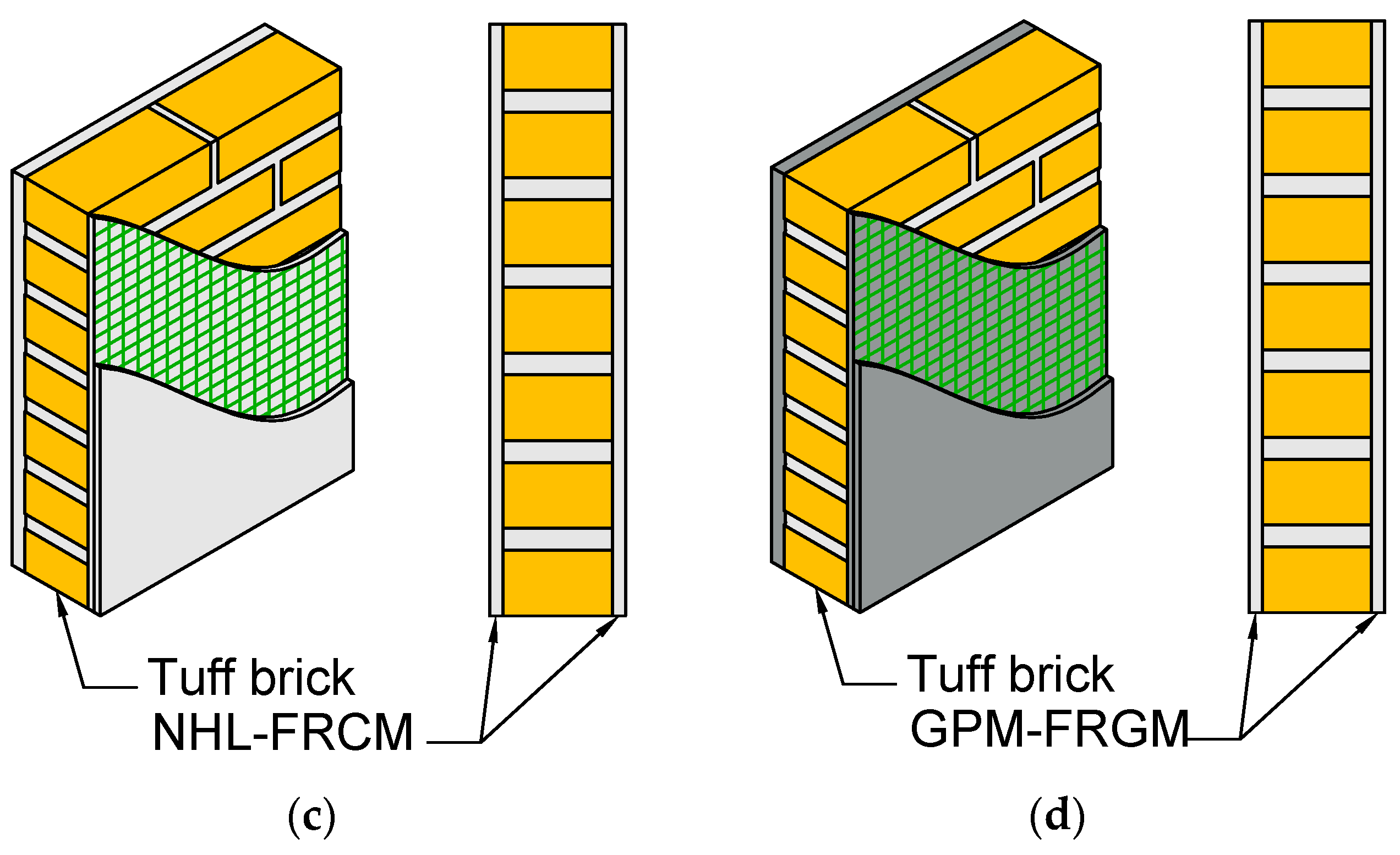

3.2. Mechanical Performance

4. Mechanical and Energetic Retrofitting: Applications

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gkournelos, D.P.; Bournas, D.A.; Triantafillou, T.C. Combined Seismic and Energy Upgrading of Existing Buildings Using Advanced Materials; EUR 29172 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-79-81824-0. [CrossRef]

- Ministerial Decree 17 January 2018, NTC 2018. Norme Tecniche per le Costruzioni, Ministero delle Infrastrutture. Available online: http//www.cslp.it (accessed on 30 July 2020). (In Italian).

- Ministerial Decree 26 June 2015. In Applicazione Delle Metodologie di Calcolo Delle Prestazioni Energetiche e Definizione Delle Prescrizioni e dei Requisiti Minimi Degli Edifici; n. 162, 15-07-2015—Suppl. Ordinario n. 39; Gazzetta Ufficiale: Rome, Italy, 2015.

- Artino, A.; Evola, G.; Margani, G.; Marino, E.M. Seismic and Energy Retrofit of Apartment Buildings through Autoclaved Aerated Concrete (AAC) Blocks Infill Walls. Sustainability 2019, 11, 3939. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Maduta, C.; Bournas, D.A.; Kouris, L.A. Energy Performance of Existing Residential Buildings in Europe: A Novel Approach Combining Energy with Seismic Retrofitting. Energy Build. 2020, 223, 110024. [Google Scholar] [CrossRef]

- Ombres, L.; Iorfida, A.; Mazzuca, S.; Verre, S. Bond analysis of thermally conditioned FRCM-masonry joints. Measurement 2018, 125, 509–515. [Google Scholar] [CrossRef]

- Ombres, L.; Mancuso, N.; Mazzuca, S.; Verre, S. Bond between Carbon Fabric-Reinforced Cementitious Matrix and Masonry Substrate. J. Mater. Civ. Eng. 2018, 31, 4018356. [Google Scholar] [CrossRef]

- Pekmezci, B.Y.; Arabaci, E.; Ustundag, C. Freeze-Thaw Durability of Lime Based FRCM Systems for Strengthening Historical Masonry. Key Eng. Mater. 2019, 817, 174–181. [Google Scholar] [CrossRef]

- Tilocca, A.R.; Incerti, A.; Bellini, A.; Savoia, M. Influence of Matrix Properties on FRCM-CRM Strengthening Systems. Key Eng. Mater. 2019, 817, 478–485. [Google Scholar] [CrossRef]

- Castellano, A.; Fraddosio, A.; Scacco, J.; Milani, G.; Piccioni, M.D. Dynamic Response of FRCM Reinforced Masonry Arches. Key Eng. Mater. 2019, 817, 285–292. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Flexural Strengthening of RC Beams with Steel-Reinforced Grout: Experimental and Numerical Investigation. J. Compos. Constr. 2019, 23, 4019035. [Google Scholar] [CrossRef]

- Cascardi, A.; Micelli, F.; Aiello, M.A. FRCM-confined masonry columns: Experimental investigation on the effect of the inorganic matrix properties. Constr. Build. Mater. 2018, 186, 811–825. [Google Scholar] [CrossRef]

- Cascardi, A.; Micelli, F.; Aiello, M.A. Analytical model based on artificial neural network for masonry shear walls strengthened with FRM systems. Compos. Part B Eng. 2016, 95, 252–263. [Google Scholar] [CrossRef]

- Cascardi, A.; Longo, F.; Micelli, F.; Aiello, M.A. Compressive strength of confined column with Fiber Reinforced Mortar (FRM): New design-oriented-models. Constr. Build. Mater. 2017, 156, 387–401. [Google Scholar] [CrossRef]

- Cascardi, A.; Aiello, M.A.; Triantafillou, T. Analysis-oriented model for concrete and masonry confined with fiber reinforced mortar. Mater. Struct. 2017, 50, 202. [Google Scholar] [CrossRef]

- Faella, C.; Napoli, A.; Realfonzo, R. Confinement of Concrete with FRCM Materials. In Proceedings of Italian Concrete Days 2018; Di Prisco, M., Menegotto, M., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Thermou, G.E.; Hajirasouliha, I. Compressive behaviour of concrete columns confined with steel-reinforced grout jackets. Compos. B Eng. 2018, 138, 222–231. [Google Scholar] [CrossRef]

- Minafò, G.; La Mendola, L. Experimental investigation on the effect of mortar grade on the compressive behaviour of FRCM confined masonry columns. Compos. Part B Eng. 2018, 146, 1–12. [Google Scholar] [CrossRef]

- CNR—Advisory Committee on Technical Recommendations for Construction. Guide for the Design and Construction of Externally Bonded Fibre Reinforced Inorganic Matrix Systems for Strengthening Existing Structures; CNR: Rome, Italy, 2019. [Google Scholar]

- Wang, X.; Lam, C.C.; Iu, V.P. Comparison of different types of TRM composites for strengthening masonry panels. Constr. Build. Mater. 2019, 219, 184–194. [Google Scholar] [CrossRef]

- Ombres, L. Analysis of the bond between fabric reinforced cementitious mortar (FRCM) strengthening systems and concrete. Compos. Part B Eng. 2015, 69, 418–426. [Google Scholar] [CrossRef]

- Nobili, A.; Signorini, C. On the effect of curing time and environmental exposure on impregnated Carbon Fabric Reinforced Cementitious Matrix (CFRCM) composite with design considerations. Compos. Part B Eng. 2017, 112, 300–313. [Google Scholar] [CrossRef]

- Wang, X.; Lam, C.C.; Sun, B.C.; Noguchi, T.; Iu, V.P. Effect of curing environment on the tensile behaviour of FRCM composites. Constr. Build. Mater. 2020, 238, 117729. [Google Scholar] [CrossRef]

- Butler, M.; Mechtcherine, V.; Hempel, S. Durability of textile reinforced concrete made with AR glass fibre: Effect of the matrix composition. Mater. Struct. 2010, 43, 1351–1368. [Google Scholar] [CrossRef]

- Ascione, L.; de Felice, G.; De Santis, S. A qualification method for externally bonded Fibre Reinforced Cementitious Matrix (FRCM) strengthening systems. Compos. Part B Eng. 2015, 78, 497–506. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical properties of FRCM using carbon fabrics with different coating treatments. Compos. Part B Eng. 2016, 88, 220–228. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V. Mechanical characterization of different FRCM systems for structural reinforcement. Compos. Part B Eng. 2017, 145, 565–575. [Google Scholar] [CrossRef]

- De Carvalho Bello, C.B.; Boem, I.; Cecchi, A.; Gattesco, N.; Oliveira, D.V. Experimental tests for the characterization of sisal fiber reinforced cementitious matrix for strengthening masonry structures. Constr. Build. Mater. 2019, 219, 44–55. [Google Scholar] [CrossRef]

- Romanazzi, A.; Oliveira, D.V.; Silva, R.A. Experimental Investigation on the Bond Behavior of a Compatible TRM-based Solution for Rammed Earth Heritage. Int. J. Archit. Herit. 2019, 13, 1042–1060. [Google Scholar] [CrossRef]

- John, S.K.; Nadir, Y.; Girija, K.; Giriprasad, S. Tensile behaviour of glass fibre textile reinforced mortar with fine aggregate partially replaced by fly ash. Mater. Today Proc. 2019. [Google Scholar] [CrossRef]

- Del Zoppo, M.; Di Ludovico, M.; Prota, A. Analysis of FRCM and CRM parameters for the in-plane shear strengthening of different URM types. Compos. Part B Eng. 2019, 171, 20–33. [Google Scholar] [CrossRef]

- Del Zoppo, M.; Di Ludovico, M.; Balsamo, A.; Prota, A. In-plane shear capacity of tuff masonry walls with traditional and innovative Composite Reinforced Mortars (CRM). Constr. Build. Mater. 2019, 210, 289–300. [Google Scholar] [CrossRef]

- Micelli, F.; Sciolti, M.S.; Leone, M.; Aiello, M.A.; Dudine, A. Shear behaviour of Fiber Reinforced Mortar strengthened masonry walls built with limestone blocks and hydraulic mortar. In Brick and Block Masonry—Trends, Innovations and Challenges; Modena, C., da Porto, F., Valluzzi, M.R., Eds.; Routledge: London, UK, 2016. [Google Scholar]

- Gattesco, N.; Boem, I.; Andretta, V. Experimental behaviour of non-structural masonry vaults reinforced through fibre-reinforced mortar coating and subjected to cyclic horizontal loads. Eng. Struct. 2018, 172, 419–431. [Google Scholar] [CrossRef]

- De Santis, S.; de Felice, G.; Di Noia, G.L.; Meriggi, P.; Volpe, M. Shake Table Tests on a Masonry Structure Retrofitted with Composite Reinforced Mortar. Key Eng. Mater. 2019, 817, 342–349. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Sannino, A.; Aiello, M.A. Mechanical and Thermal Characterization of FRCM-Matrices. Key Eng. Mater. 2019, 817, 189–194. [Google Scholar] [CrossRef]

- Haq, E.U.; Padmanabhan, S.K.; Licciulli, A. In-situ carbonation of alkali activated fly ash geopolymer. Constr. Build. Mater. 2014, 66, 781–786. [Google Scholar] [CrossRef]

- Provis, J.L.; Van Deventer, J.S.J. (Eds.) Geopolymers: Structures, Processing, Properties and Industrial Applications; Elsevier: New York, NY, USA, 2009. [Google Scholar]

- Alanazi, H.; Hu, J.; Kim, Y.R. Effect of slag, silica fume, and metakaolin on properties and performance of alkali-activated fly ash cured at ambient temperature. Constr. Build. Mater. 2019, 197, 747–756. [Google Scholar] [CrossRef]

- Longo, F.; Lassandro, P.; Moshiri, A.; Phatak, T.; Aiello, M.A.; Krakowiak, K.J. Lightweight geopolymer-based mortars for the structural and energy retrofit of buildings. Energy Build. 2020, in press. [Google Scholar] [CrossRef]

- Consiglio Superiore dei Lavori Pubblici. Linea Guida per la Identificazione, la Qualificazione ed il Controllo di Accettazione di Compositi Fibrorinforzati a Matrice Inorganica (FRCM) da Utilizzarsi per il Consolidamento Strutturale di Costruzioni Esistenti. In Italian Standard for the Qualification of FRP Composites for the Externally Bonded Reinforcement of Existing Structures; Consiglio Superiore dei Lavori Pubblici: Ravenna, Italy, 2015. [Google Scholar]

- ASTM D7984-16. Standard Test Method for Measurement of Thermal Effusivity of Fabrics Using a Modified Transient Plane Source (MTPS) Instrument; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 30 July 2020).

- UNI—Italian Organization for Standardization. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; EN 1015-11; UNI—Italian Organization for Standardization: Milano, Italy, 2007. [Google Scholar]

- Scanning Electron Microscopy Specifications. Available online: https://www.zeiss.com/corporate/int/home.html?vaURL=www.zeiss.de/en (accessed on 30 June 2020).

- Cheng, C.; He, J.; Zhang, J.; Yang, Y. Study on the time-dependent mechanical properties of glass fiber reinforced cement (GRC) with fly ash or slag. Constr. Build. Mater. 2019, 217, 128–136. [Google Scholar] [CrossRef]

- Ministero delle Infrastrutture e dei Trasporti. CNTC19-Circolare Applicativa delle Norme Tecniche delle Costruzioni di cui al DM 17 January 2018. (NTC 2018); Ministero delle Infrastrutture e dei Trasporti: Rome, Italy, 2019.

- UNI—Italian Organization for Standardization. Thermal Performance of Building Components—Dynamic Thermal Characteristics-Calculation Methods; EN ISO 13786:2008; UNI—Italian Organization for Standardization: Milano, Italy, 2008. [Google Scholar]

- UNI—Italian Organization for Standardization. Masonry and Masonry Products—Methods for Determining Thermal Properties; EN 1745:2012; UNI—Italian Organization for Standardization: Milano, Italy, 2012. [Google Scholar]

- Ozkahraman, H.T.; Bolatturk, A. The use of tuff stone cladding in buildings for energy conservation. Constr. Build. Mater. 2006, 20, 435–440. [Google Scholar] [CrossRef]

- Xie, C. Interactive Heat Transfer Simulations for Everyone. Phys. Teach. 2012, 50, 237–240. [Google Scholar] [CrossRef]

- De Santis, S.; de Felice, G.; Roscini, F. Retrofitting of Masonry Vaults by Basalt Textile-Reinforced Mortar Overlays. Int. J. Archit. Herit. 2019, 13, 1061–1077. [Google Scholar] [CrossRef]

| Component | Oxide Concentration % | Particle Density g/cm3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | Na2O | Al2O3 | Fe2O3 | K2O | TiO2 | SO3 | ||

| Fly ash | 37.33 | 6.13 | - | 16.14 | 30.79 | 5.28 | 3.65 | 0.68 | 2.30 |

| Metakaolin | 55.00 | 0.30 | - | 40.00 | 1.40 | 0.80 | 1.50 | - | 2.40 |

| LWA | 72.50 | 9.00 | 13.00 | 3.25 | - | 2.25 | - | - | 0.57 |

| Label | Dry Mass Density (ρ) | Thermal Conductivity (λ) | ||||

|---|---|---|---|---|---|---|

| Mean kg/m3 | CoV 1 % | ρ GPM/ρ NHL % | Mean W m–1 K–1 | CoV 1 % | λGPM/λNHL % | |

| NHL | 1540 | 0.5 | 66.95 | 0.830 | 1.5 | 26.75 |

| GPM | 1031 | 1.8 | 0.222 | 2.7 | ||

| Label | Flexural Strength (fb) | Compressive Strength (fc) | Young’s Modulus (E) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean MPa | CoV 1 % | fb,GPM/fb,NHL % | Mean MPa | CoV 1 % | fc,GPM/fc,NHL % | Mean GPa | CoV 1 % | EGPM/ENHL % | |

| NHL | 3.10 | 7.4 | 66.45 | 9.13 | 3.3 | 64.95 | 8.58 | 8.9 | 37.64 |

| GPM | 2.06 | 6.3 | 5.93 | 5.0 | 3.23 | 10.2 | |||

| Label | Tensile Strength (σu) | Ultimate Strain (εu) | ||||

|---|---|---|---|---|---|---|

| Mean MPa | CoV 1 % | σu,GPM/σu,NHL % | Mean % | CoV 1 % | εu,GPM/εu,NHL % | |

| NHL | 890.75 | 15.7 | 97.41 | 0.87 | 19.0 | 100.00 |

| GPM | 867.69 | 10.7 | 0.87 | 19.4 | ||

| Label | Un-Cracked Slope 2 (EI) | Un-Cracked Slope 3 (E*I) | Cracked Slope (EII) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean GPa | CoV 1 % | EI,GPM/EI,NHL % | Mean GPa | CoV 1 % | E*I,GPM/E*I,NHL % | Mean GPa | CoV 1 % | EII,GPM/EII,NHL % | |

| NHL | 514.47 | 8.5 | 44.59 | 2.52 | 8.3 | 44.59 | 77.45 | 5.1 | 89.26 |

| GPM | 229.33 | 9.8 | 1.12 | 9.8 | 69.13 | 5.4 | |||

| Label | Shear Strength | Thermal Transmittance | ||

|---|---|---|---|---|

| Unreinforced MPa | Reinforced MPa | Unreinforced W m–2 K–1 | Reinforced W m–2 K–1 | |

| SCB – FRCM | 0.85 | 1.07 | 1.471 | 1.330 |

| SCB – FRGM | 0.85 | 1.05 | 1.471 | 1.053 |

| TBM – FRCM | 0.67 | 0.90 | 1.258 | 1.153 |

| TBM – FRGM | 0.67 | 0.88 | 1.258 | 0.939 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M.A. A New Fabric Reinforced Geopolymer Mortar (FRGM) with Mechanical and Energy Benefits. Fibers 2020, 8, 49. https://doi.org/10.3390/fib8080049

Longo F, Cascardi A, Lassandro P, Aiello MA. A New Fabric Reinforced Geopolymer Mortar (FRGM) with Mechanical and Energy Benefits. Fibers. 2020; 8(8):49. https://doi.org/10.3390/fib8080049

Chicago/Turabian StyleLongo, Fabio, Alessio Cascardi, Paola Lassandro, and Maria Antonietta Aiello. 2020. "A New Fabric Reinforced Geopolymer Mortar (FRGM) with Mechanical and Energy Benefits" Fibers 8, no. 8: 49. https://doi.org/10.3390/fib8080049

APA StyleLongo, F., Cascardi, A., Lassandro, P., & Aiello, M. A. (2020). A New Fabric Reinforced Geopolymer Mortar (FRGM) with Mechanical and Energy Benefits. Fibers, 8(8), 49. https://doi.org/10.3390/fib8080049