Flexural Behavior of High Strength Self-Compacted Concrete Slabs Containing Treated and Untreated Geogrid Reinforcement

Abstract

1. Introduction

2. Experimental Program

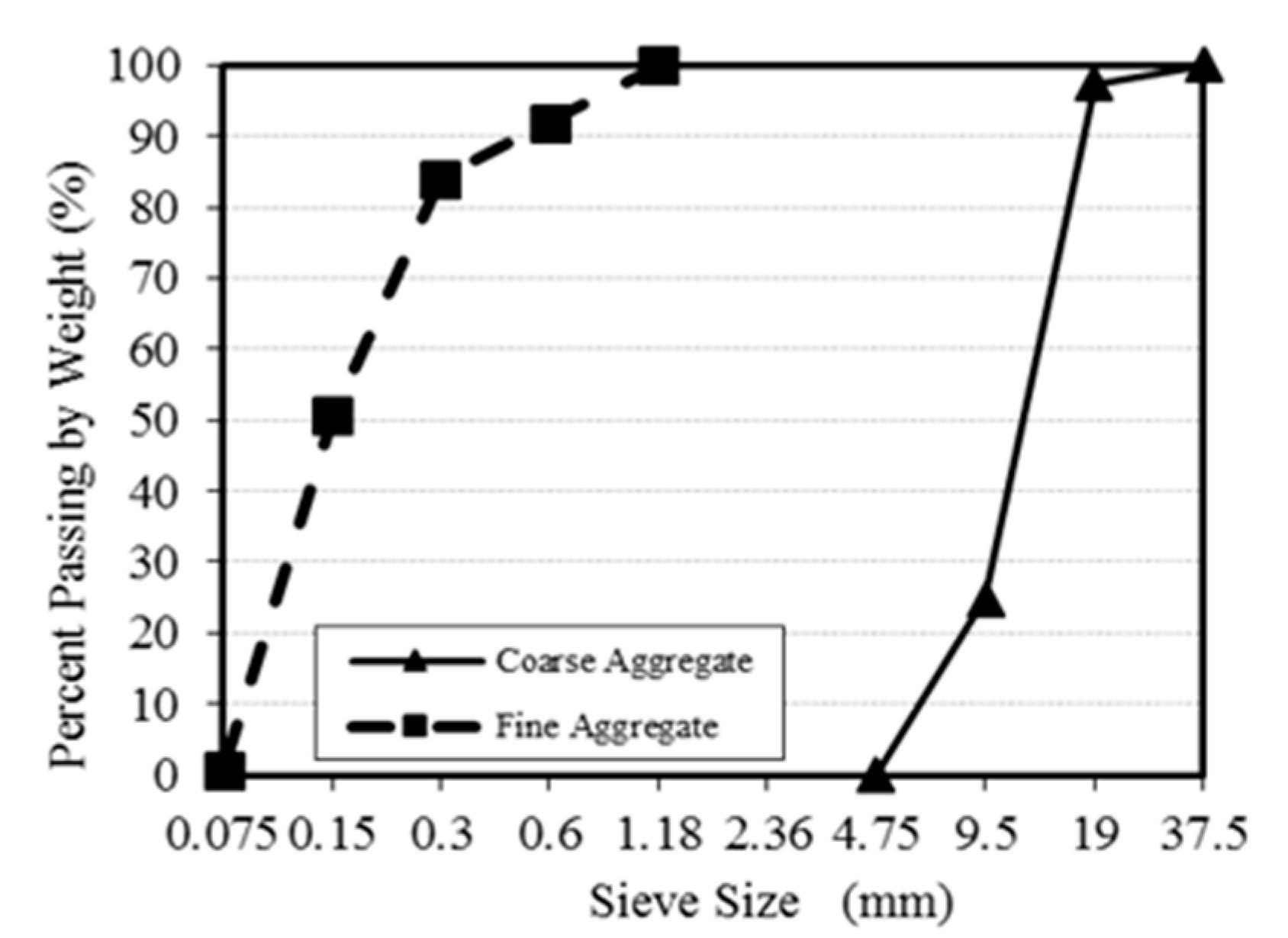

2.1. Materials

2.2. Mix Proportions and Properties

2.3. Specimen Casting and Curing

2.4. Nomenclature for Specimens

- The first part stands for slab thickness for 5 cm-slabs specimens.

- The second part contains of a letter and a number. The letter stands for the type of reinforcement as (P) refers to plain concrete control slab specimens, (U) refers to slabs specimens reinforced with uniaxial geogrids, (B) refers to slabs specimens reinforced with biaxial geogrids, (T) refers to slabs specimens reinforced with triaxial geogrids and (R) refers to slabs specimens containing steel reinforcement. The number stands for the number of geogrid layers used in the reinforcement of the slabs specimens as; (1) refers to one geogrid layer; (2) refers to two geogrid layers; and (3) refers to three geogrid layers. Also, it stands for the bar diameter of steel reinforcement meshes as; (6) refers to the slab specimens reinforced with 6 mm-steel bars; and (8) refers to the slab specimens reinforced with 8 mm-steel bars.

- The third part stands for the type of treatment method of geogrid layers as; (Ut) refers to untreated geogrid layers, (St) refers to geogrid layers glued with sand; and (Vt) refers to geogrid layers immersed in polycarboxylate.

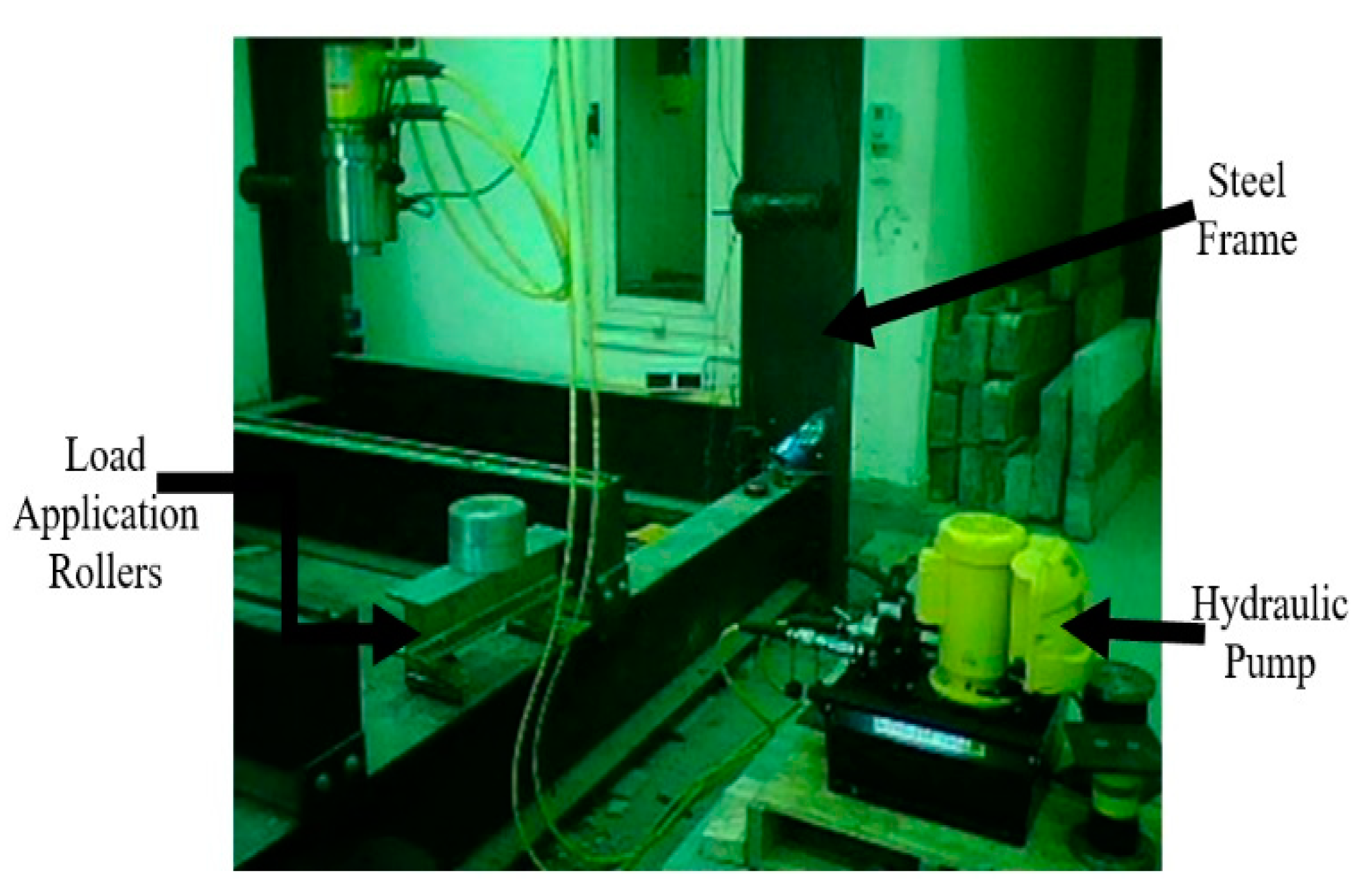

2.5. Three Points Flexural Loading Test

3. Results and Discussion

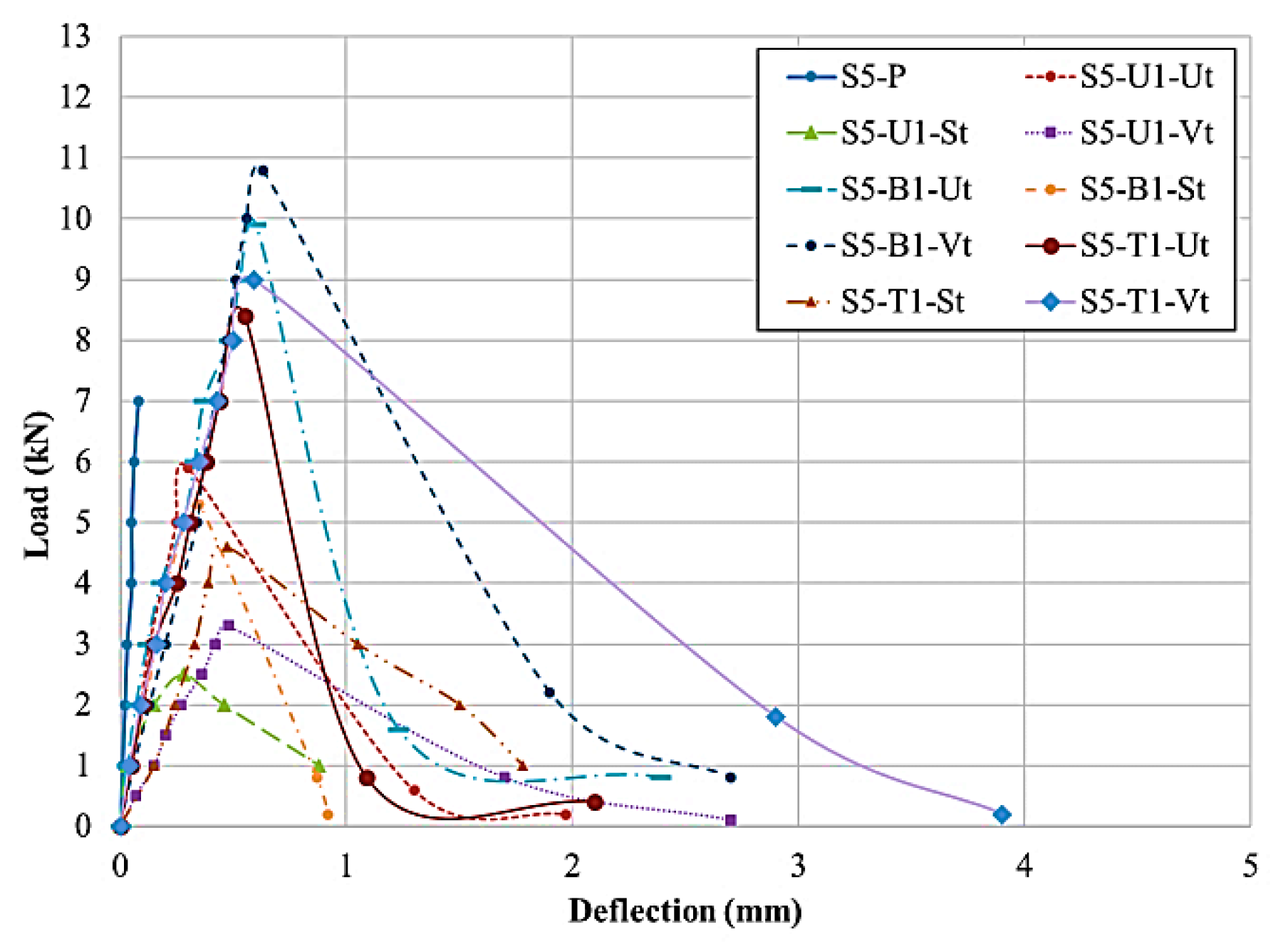

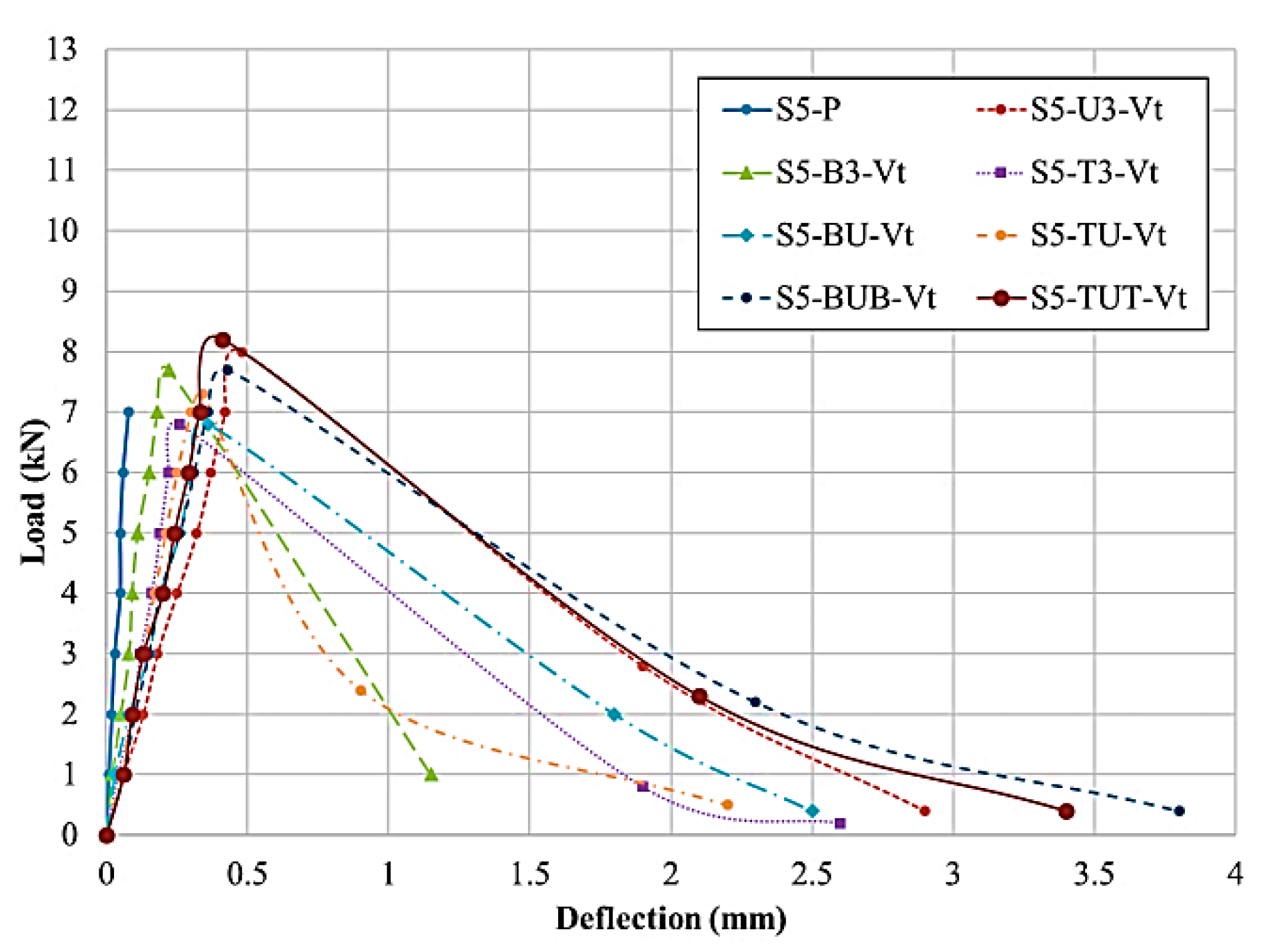

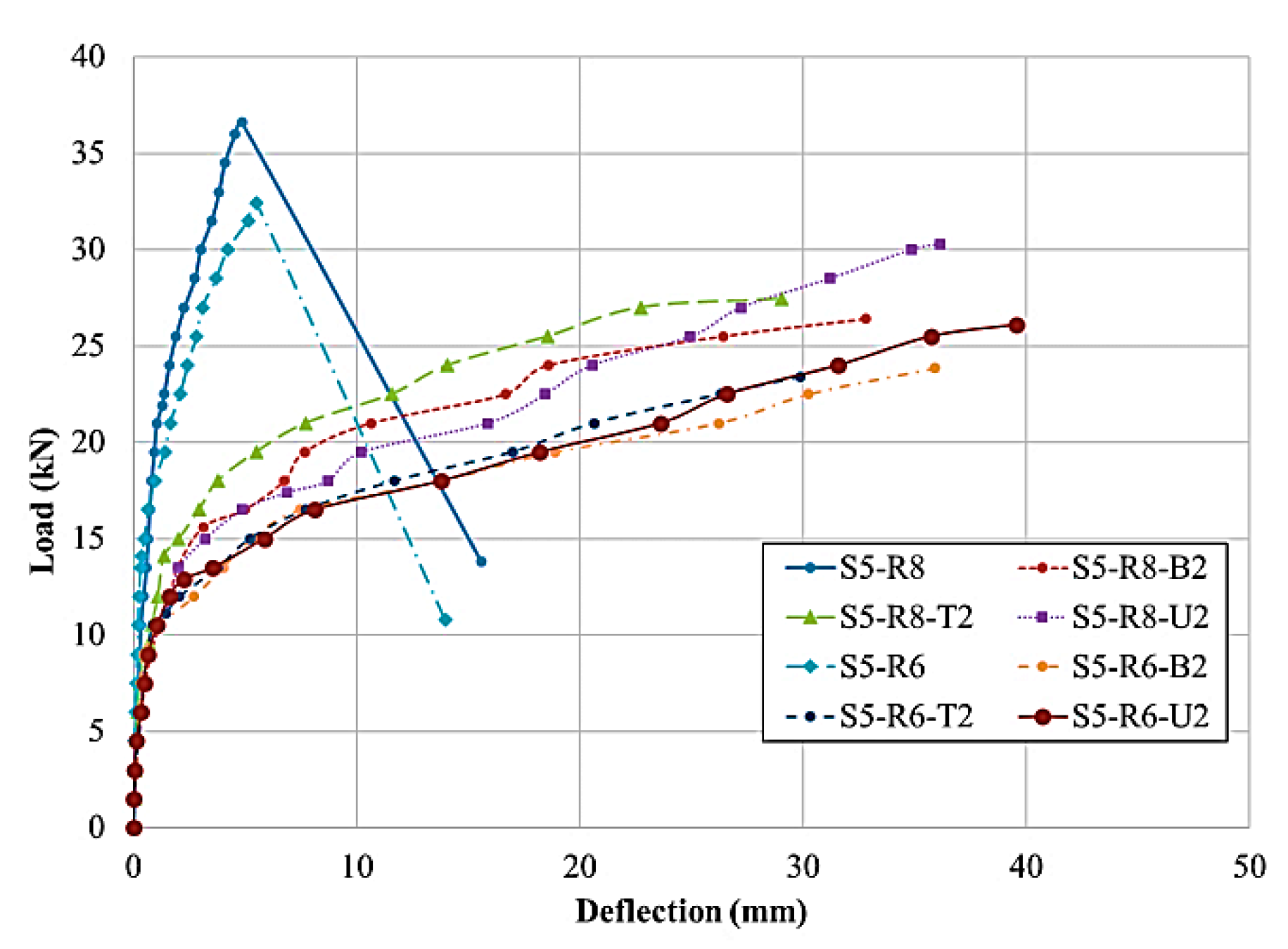

3.1. Load-Deflection Curves of the Tested Slabs

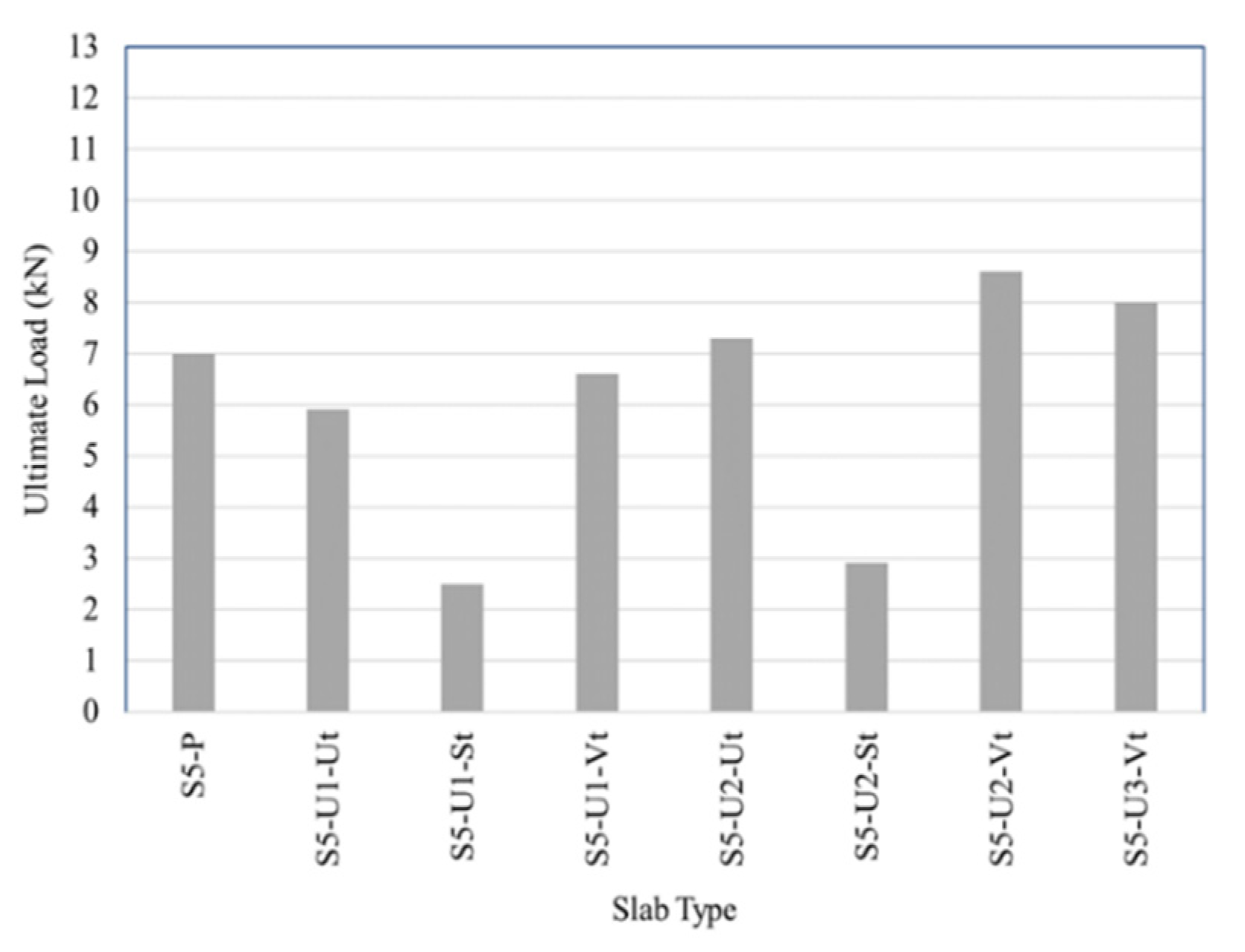

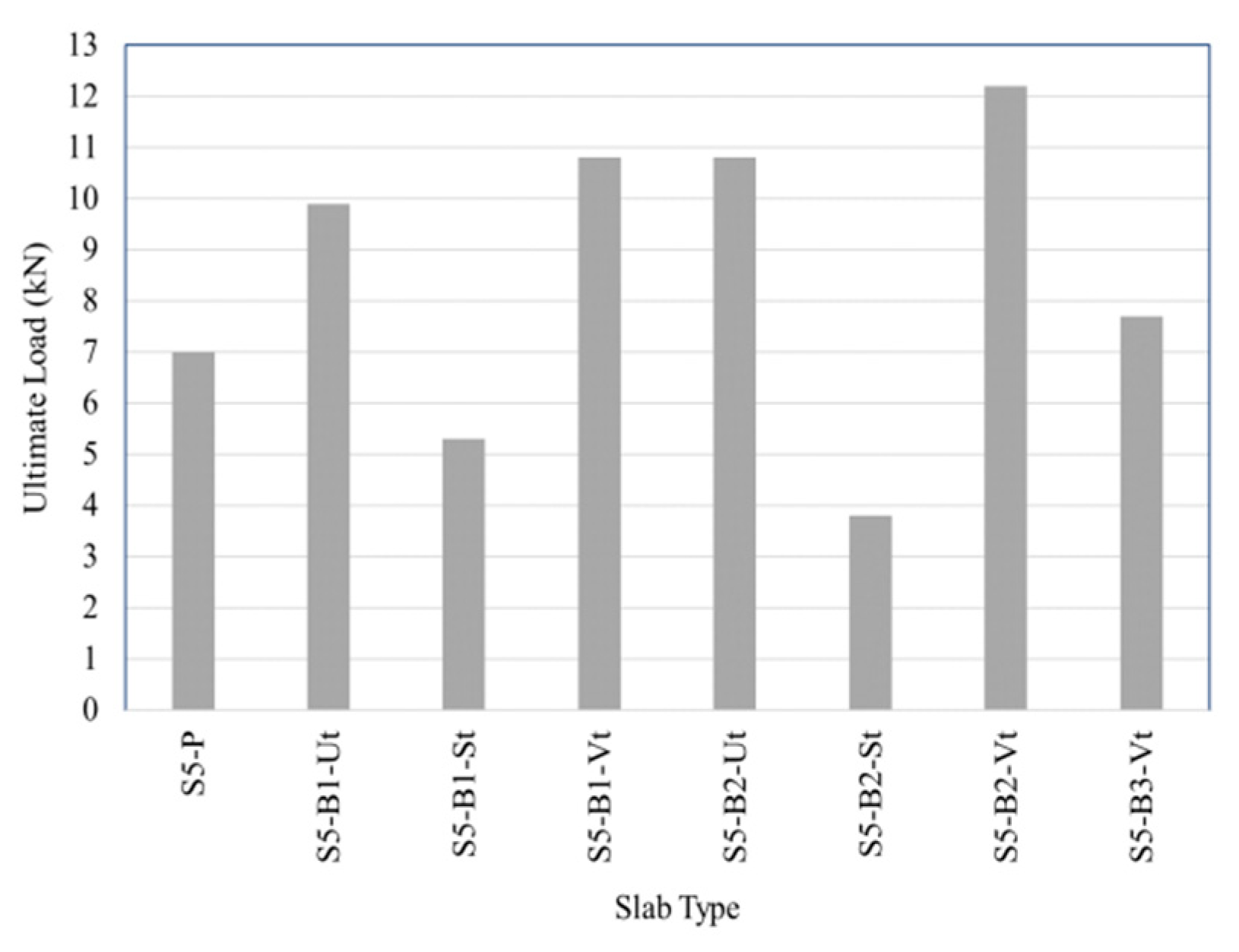

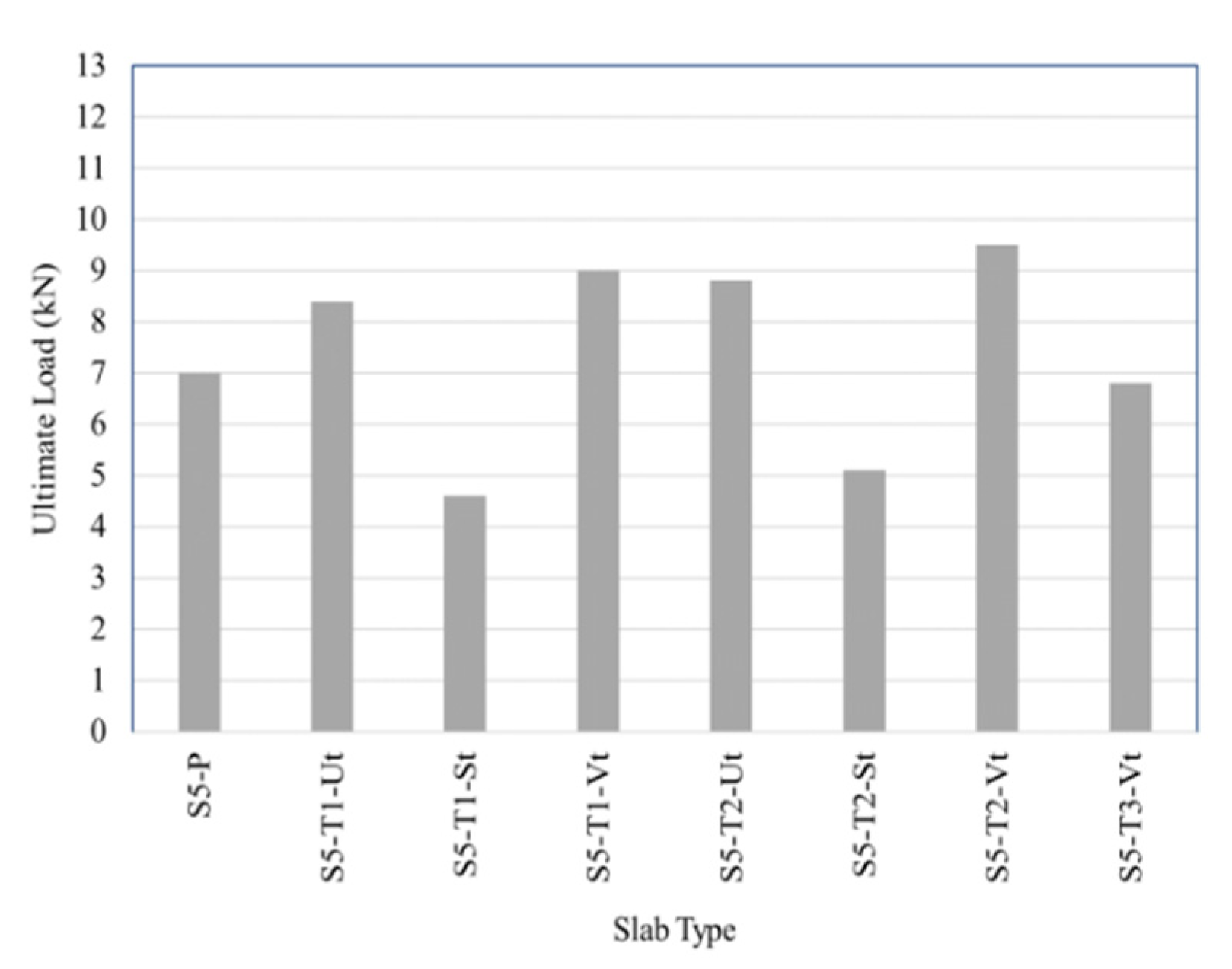

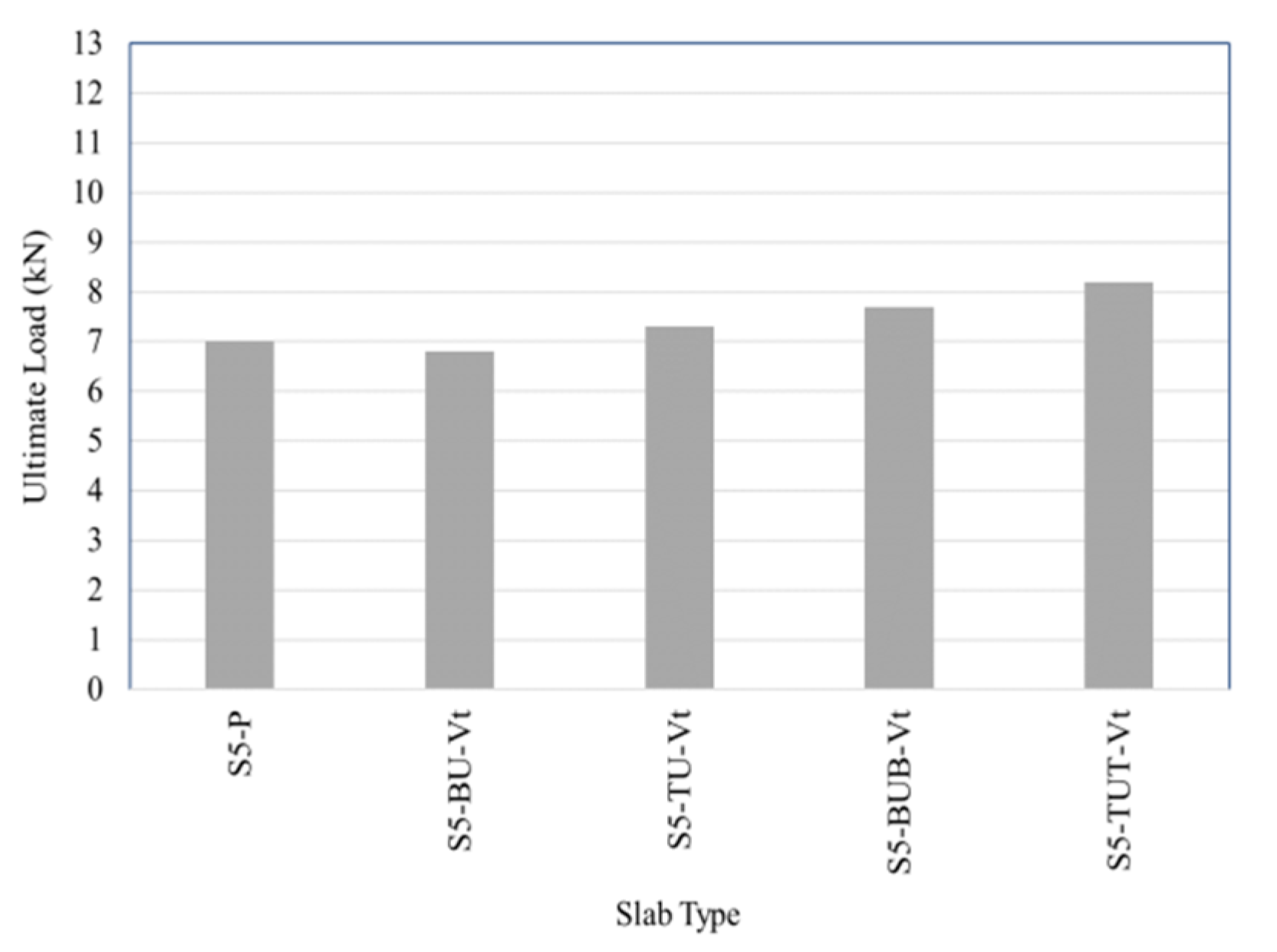

3.2. Ultimate and Cracking Loads of the Tested Slabs

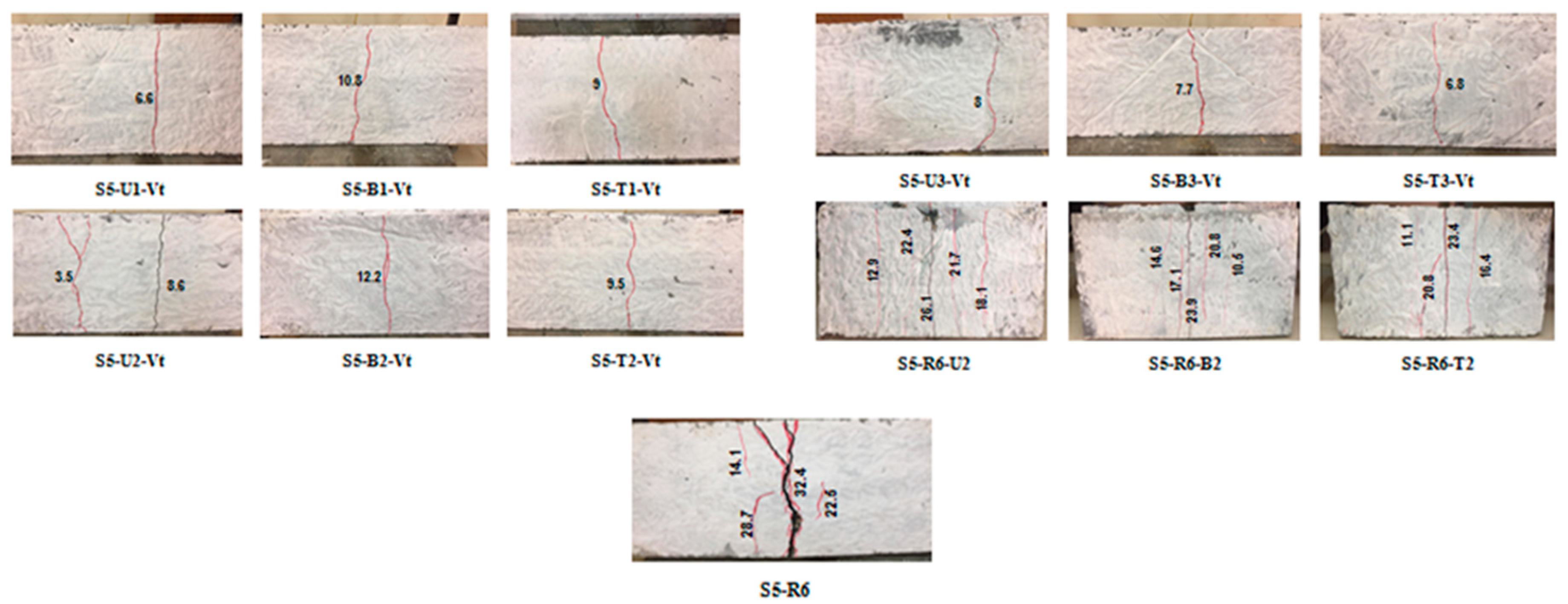

3.3. Crack Patterns of the Tested Slabs

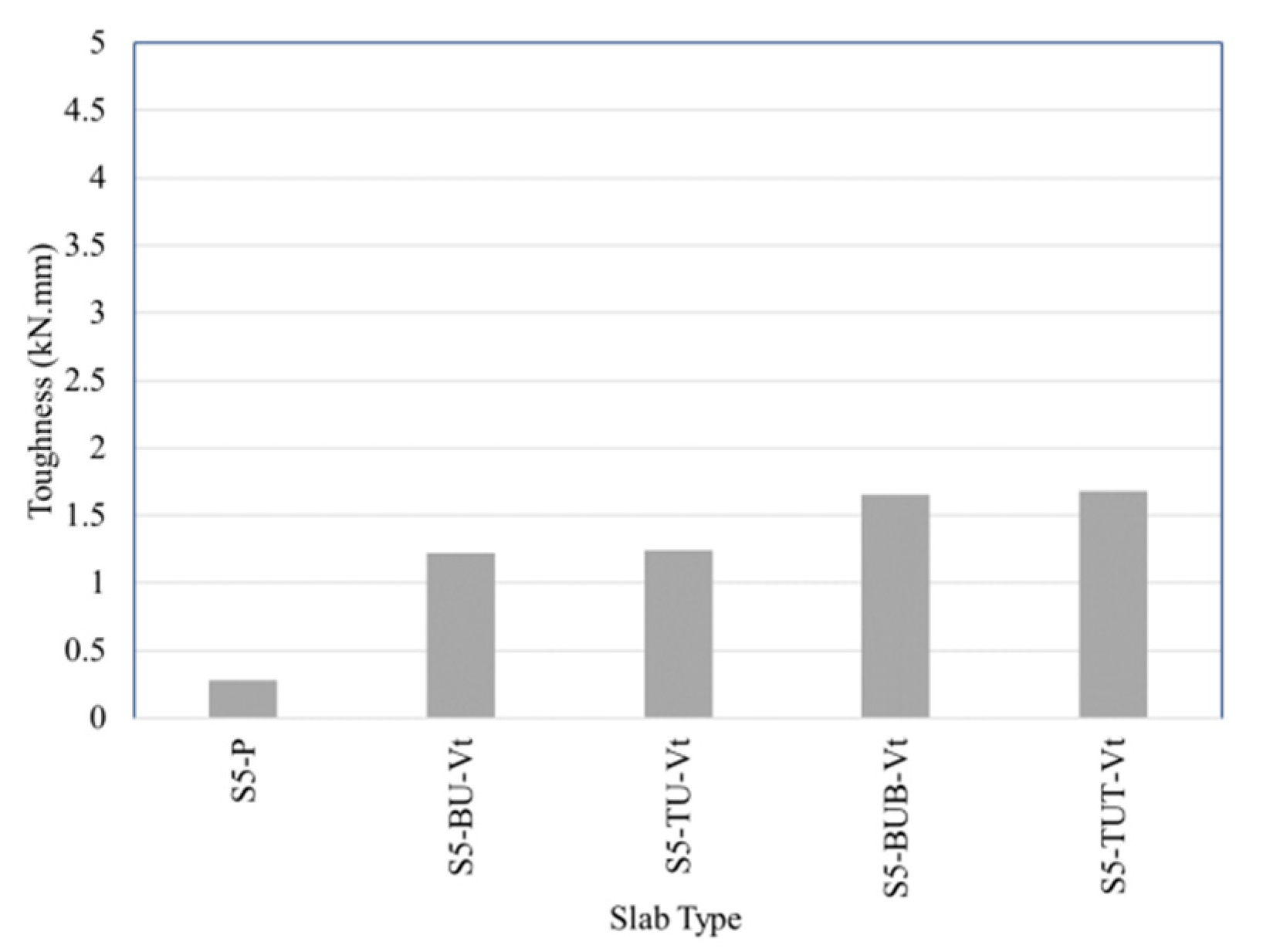

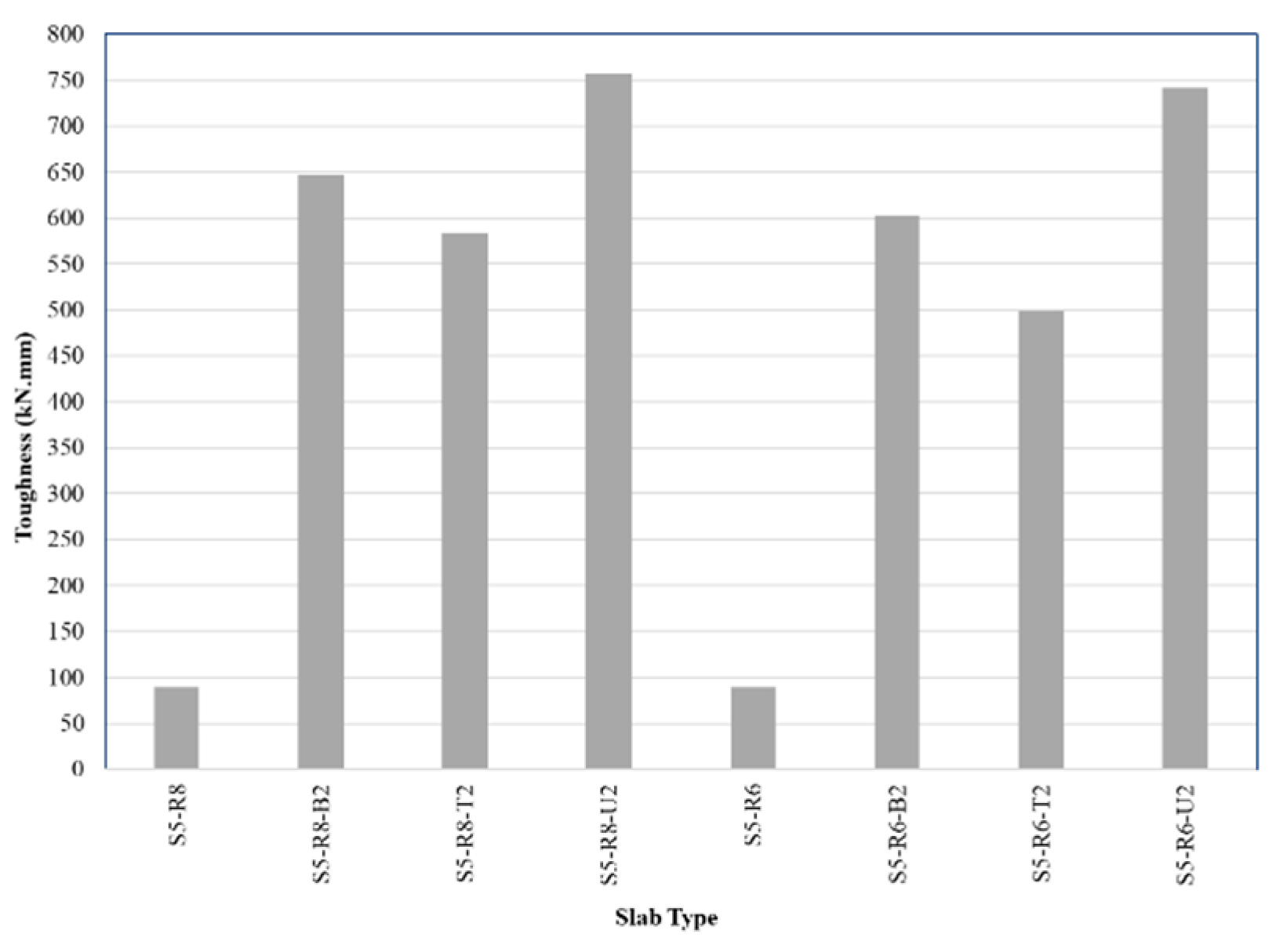

3.4. Absorbed Energy/Toughness of the Tested Slabs

4. Conclusions

- Using geogrids for the reinforcement of HSSCC plain concrete slabs has a good effect on the load-deflection behavior of slabs and improved their ductility.

- Treating geogrid using chemical surface modification method (immersing in polycarboxylate) gives results higher than untreated layers and geogrid treated with physical surface modification method.

- Using physical surface modification method for geogrid surface by gluing sand with the used type of glue and the used grade of sand affected the ultimate loads behavior badly.

- Using two geogrid layers as reinforcement for plain concrete slab gives results higher than using one and three geogrid layers for the used geogrid types.

- Using biaxial geogrid as reinforcement for plain concrete slab gives higher results than uniaxial and triaxial geogrids, particularly when two layers of each type are used.

- The HSSCC 5-cm slab containing two biaxial geogrid layers treated with the used chemical surface modification method gives the highest values in ultimate load and absorbed energy. The slab’s ultimate load increased when compared to the untreated reinforced slab by about 13% and 74% when compared to the plain HSSCC slab.

- Using three layers of two geogrid types (one uniaxial layer between two triaxial layers) gives results better than using three triaxial geogrid only as the slab’s ultimate load, increased by about 20%, but still less than 2 layers of triaxial only.

- Using two geogrid layers treated with the used chemical surface modification method as additional reinforcement to the HSSCC 5-cm slabs, containing steel reinforcement bars decreased the ultimate loads by about 18% for uniaxial reinforced slabs, 27% for biaxial reinforced slabs and 26.5% for triaxial reinforced slabs when compared to steel reinforced slabs.

- Using two geogrid layers treated with the used chemical surface modification method as additional reinforcement to the HSSCC 5-cm slabs containing steel reinforcement bars increased the absorbed energy by about 496% for uniaxial reinforced slabs, 383% for biaxial reinforced slabs and 320% for triaxial reinforced slabs when compared to steel reinforced slabs as an indication for the great improvement of the slab’s ductility.

- The behavior of slabs containing two layers of chemically treated geogrid is the same for the two used steel reinforcement ratios.

Author Contributions

Funding

Conflicts of Interest

References

- Tang, X.; Chehab, G.R.; Palomino, A. Evaluation of geogrids for stabilising weak pavement subgrade. Int. J. Pavement Eng. 2008, 9, 413–429. [Google Scholar] [CrossRef]

- Abu-Farsakh, M.Y.; Akond, I.; Chen, Q. Evaluating the performance of geosynthetic-reinforced unpaved roads using plate load tests. Int. J. Pavement Eng. 2016, 17, 901–912. [Google Scholar] [CrossRef]

- Reddy, P.M.; Kumar, J.R. Study of geo-grid confined reinforced concrete beams. Int. J. Sci. Eng. Technol. Res. (IJSETR) 2018, 7, 278–286. [Google Scholar]

- El Meski, F.; Chehab, G. Flexural behavior of concrete beams reinforced with different types of geogrids. J. Mater. Civ. Eng. 2014, 26, 04014038. [Google Scholar] [CrossRef]

- Arulrajah, A.; Rahman, M.A.; Piratheepan, J.; Bo, M.; Imteaz, M. Evaluation of interface shear strength properties of geogrid-reinforced construction and demolition materials using a modified large-scale direct shear testing apparatus. J. Mater. Civ. Eng. 2014, 26, 974–982. [Google Scholar] [CrossRef]

- Abdesssemed, M.; Kenai, S.; Bali, A. Experimental and numerical analysis of the behavior of an airport pavement reinforced by geogrids. Constr. Build. Mater. 2015, 94, 547–554. [Google Scholar] [CrossRef]

- Chidambaram, R.S.; Agarwal, P. The confining effect of geo-grid on the mechanical properties of concrete specimens with steel fiber under compression and flexure. Constr. Build. Mater. 2014, 71, 628–637. [Google Scholar] [CrossRef]

- Chidambaram, R.S.; Agarwal, P. Flexural and shear behavior of geo-grid confined RC beams with steel fiber reinforced concrete. Constr. Build. Mater. 2015, 78, 271–280. [Google Scholar] [CrossRef]

- Siva Chidambaram, R.; Agarwal, P. Inelastic behaviour of RC beams with steel fibre and polymer grid confinement. Indian Concr. J. 2015, 89, 83–90. [Google Scholar]

- Wang, W.; Sheikh, M.N.; Hadi, M.N. Axial compressive behaviour of concrete confined with polymer grid. Mater. Struct. 2016, 49, 3893–3908. [Google Scholar] [CrossRef]

- Tang, X.; Higgins, I.; N Jlilati, M. Behavior of Geogrid-Reinforced Portland Cement Concrete under Static Flexural Loading. Infrastructures 2018, 3, 41. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Zapris, A.G.; Karayannis, C.G. U-Jacketing Applications of Fiber-Reinforced Polymers in Reinforced Concrete T-Beams against Shear—Tests and Design. Fibers 2020, 8, 13. [Google Scholar] [CrossRef]

- Abdulhameed, A.A.; Said, A.I. CFRP Laminates Reinforcing Performance of Short-Span Wedge-Blocks Segmental Beams. Fibers 2020, 8, 6. [Google Scholar] [CrossRef]

- Jaafer, A.A.; AL-Shadidi, R.; Kareem, S.L. Enhancing the Punching Load Capacity of Reinforced Concrete Slabs Using an External Epoxy-Steel Wire Mesh Composite. Fibers 2019, 7, 68. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kosmidou, P.-M.K.; Papadopoulos, N.A. Investigation of a new strengthening technique for RC deep beams using carbon FRP ropes as transverse reinforcements. Fibers 2018, 6, 52. [Google Scholar] [CrossRef]

- Itani, H.; Saad, G.; Chehab, G. The use of geogrid reinforcement for enhancing the performance of concrete overlays: An experimental and numerical assessment. Constr. Build. Mater. 2016, 124, 826–837. [Google Scholar] [CrossRef]

- Al-Hedad, A.S.; Bambridge, E.; Hadi, M.N. Influence of geogrid on the drying shrinkage performance of concrete pavements. Constr. Build. Mater. 2017, 146, 165–174. [Google Scholar] [CrossRef]

- Kim, S.; Tang, X.; Chehab, G.R. Laboratory study of geogrid reinforcement in portland cement concrete. In Pavement Cracking: Mechanisms, Modeling, Detection, Testing and Case Histories; CRC Press: Boca Raton, FL, USA, 2008; pp. 769–778. [Google Scholar]

- Al-Hadithi, A.I.; Hilal, N.N. The possibility of enhancing some properties of self-compacting concrete by adding waste plastic fibers. J. Build. Eng. 2016, 8, 20–28. [Google Scholar] [CrossRef]

- Khaloo, A.; Raisi, E.M.; Hosseini, P.; Tahsiri, H. Mechanical performance of self-compacting concrete reinforced with steel fibers. Constr. Build. Mater. 2014, 51, 179–186. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Pourzitidis, C.N. Rehabilitation of shear-damaged reinforced concrete beams using self-compacting concrete jacketing. ISRN Civ. Eng. 2012, 2012. [Google Scholar] [CrossRef]

- Mahoutian, M.; Shekarchi, M. Effect of inert and pozzolanic materials on flow and mechanical properties of self-compacting concrete. J. Mater. 2015, 2015. [Google Scholar] [CrossRef][Green Version]

- Hassan, H.M.; Arab, M.A.E.S.; Ismail el-kassas, A. Behavior of high strength self compacted concrete deep beams with web openings. Heliyon 2019, 5, e01524. [Google Scholar] [CrossRef] [PubMed]

- ASTM. ASTM C494: Chemical Admixtures; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Egyptian Organization for Standards & Quality. E.S.S. 4756-1/2009: Egyptian Standard Specification for Ordinary Portland Cement; Egyptian Organization for Standards & Quality: Cairo, Egypt, 2009. [Google Scholar]

- ASTM. ASTM C1240-05: Standard Specification for Silica Fume Used in Cementitious Mixtures; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- EN, B. 206-9 2010 Concrete, Part 9: Additional Rules for Selfcompacting Concrete (SCC); British Standards Institution: London, UK, 2010. [Google Scholar]

- Committee, E.-P. Egyptian Code of Practice for Design and Construction of Concrete Structures; Ministry of Housing Cairo: Cairo, Egypt, 2018.

- Buyukozturk, O. Mechanics and Design of Concrete Structures; Massachusetts Institute of Technology, Cambridge: Cambridge, MA, USA, 2004. [Google Scholar]

- Mohammadhassani, M.; Jumaat, M.Z.; Jameel, M.; Badiee, H.; Arumugam, A.M. Ductility and performance assessment of high strength self compacting concrete (HSSCC) deep beams: An experimental investigation. Nucl. Eng. Des. 2012, 250, 116–124. [Google Scholar] [CrossRef]

- Ismail el-kassas, A.; Hassan, H.M.; Arab, M.A.E.S. Effect of Longitudinal Opening on The Structural Behavior of Reinforced High-Strength Self-Compacted Concrete Deep Beams. Case Stud. Constr. Mater. 2020, 12, e00348. [Google Scholar]

| Performance Related to Physical Properties of the Product | Product Characteristic | Unit | Declared Value | Tolerance |

| Radial Secant Stiffness at 0.5% strain | kN/m | 390 | −75 | |

| Radial Secant Stiffness Ratio | - | 0.80 | −0.15 | |

| Junction Efficiency | % | 100 | −10 | |

| Properties for Identification of the Product | Radial Secant Stiffness at 2% strain | kN/m | 290 | −65 |

| Hexagon Pitch | mm | 80 | ±4 | |

| Weight of the product | kg/m2 | 0.220 | −0.035 |

| Component | Description | Unit | |

|---|---|---|---|

| Uniaxial | Biaxial | ||

| Tensile Strength at 2% strain | 17 | 14 | kN/m |

| Tensile Strength at 5% strain | 32 | 28 | kN/m |

| Peak tensile strength | 60 | 40 | kN/m |

| Yield point elongation | 13 | 11 | % |

| Junction strength | 95 | 95 | % |

| Steel Type | Diameter | Yield Stress | Tensile Strength | Elongation |

|---|---|---|---|---|

| (mm) | (Kg/cm2) | (Kg/cm2) | (%) | |

| Mild St. | 8 | 2950 | 3990 | 24.2 |

| 6 | 2520 | 3860 | 27.5 |

| Cement | Silica Fume | Water | Fine Aggregate | Coarse Aggregate | Super- Plasticizer |

|---|---|---|---|---|---|

| 500 | 25 | 168 | 810 | 810 | 6.825 |

| Property | Compressive Strength (MPa) | Indirect Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|

| Value | 64.5 | 7.2 | 9.2 |

| Part 1 | Part 2 | Part 3 | |||||

|---|---|---|---|---|---|---|---|

| Letter | Mean | No. | Mean | ||||

| S5 | 5 cm slab thickness | P | control | 1 | One layer | Ut | Untreated |

| U | Uniaxial | 2 | Two layers | St | Sand treating | ||

| B | Biaxial | 3 | Three layers | Vt | Polycarboxylate treating | ||

| T | Triaxial | ||||||

| BUB | Biaxial + Uniaxial + Biaxial | ||||||

| TUT | Triaxial + Uniaxial + Triaxial | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fares, A.E.-R.; Hassan, H.; Arab, M. Flexural Behavior of High Strength Self-Compacted Concrete Slabs Containing Treated and Untreated Geogrid Reinforcement. Fibers 2020, 8, 23. https://doi.org/10.3390/fib8040023

Fares AE-R, Hassan H, Arab M. Flexural Behavior of High Strength Self-Compacted Concrete Slabs Containing Treated and Untreated Geogrid Reinforcement. Fibers. 2020; 8(4):23. https://doi.org/10.3390/fib8040023

Chicago/Turabian StyleFares, Abd El-Rahman, Hassan Hassan, and Mohammed Arab. 2020. "Flexural Behavior of High Strength Self-Compacted Concrete Slabs Containing Treated and Untreated Geogrid Reinforcement" Fibers 8, no. 4: 23. https://doi.org/10.3390/fib8040023

APA StyleFares, A. E.-R., Hassan, H., & Arab, M. (2020). Flexural Behavior of High Strength Self-Compacted Concrete Slabs Containing Treated and Untreated Geogrid Reinforcement. Fibers, 8(4), 23. https://doi.org/10.3390/fib8040023