Effect of Silane Coupling Treatment on the Adhesion between Polyamide and Epoxy Based Composites Reinforced with Carbon Fibers

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Surface Pre-Treatment Process

2.3. PA12-CR Surface Treatment Methods

- Composition of the solution—90% v/v of ethanol, 5% v/v of distilled water, 5% v/v of silane,

- The obtained solution was magnetically stirred for 10 min at room temperature in a fume hood;

- Then, acetic acid was added to modify the pH of the solution from 11.4 to 4.2;

- Finally, the solution was left to rest in the fume hood in a stirrer for 24 h.

2.4. Analysis of the Treated Surfaces

2.5. Manufacturing Process of the Joints

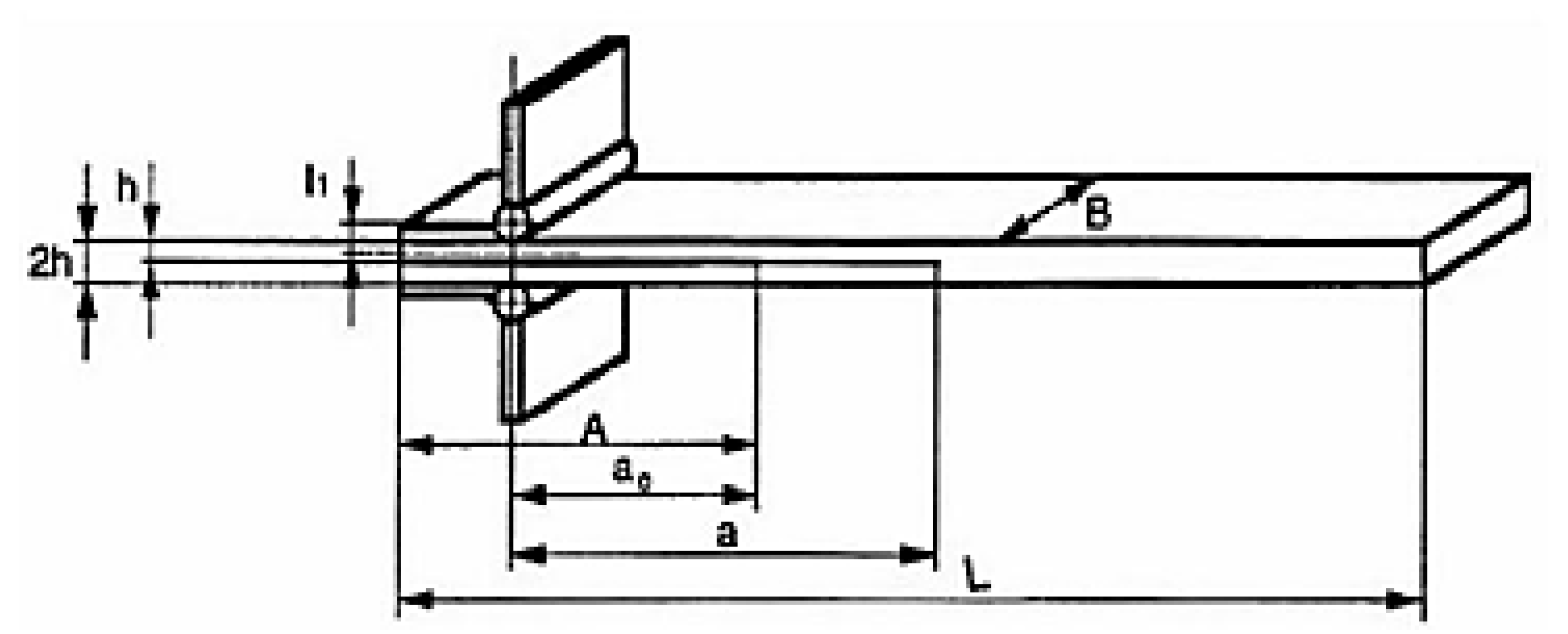

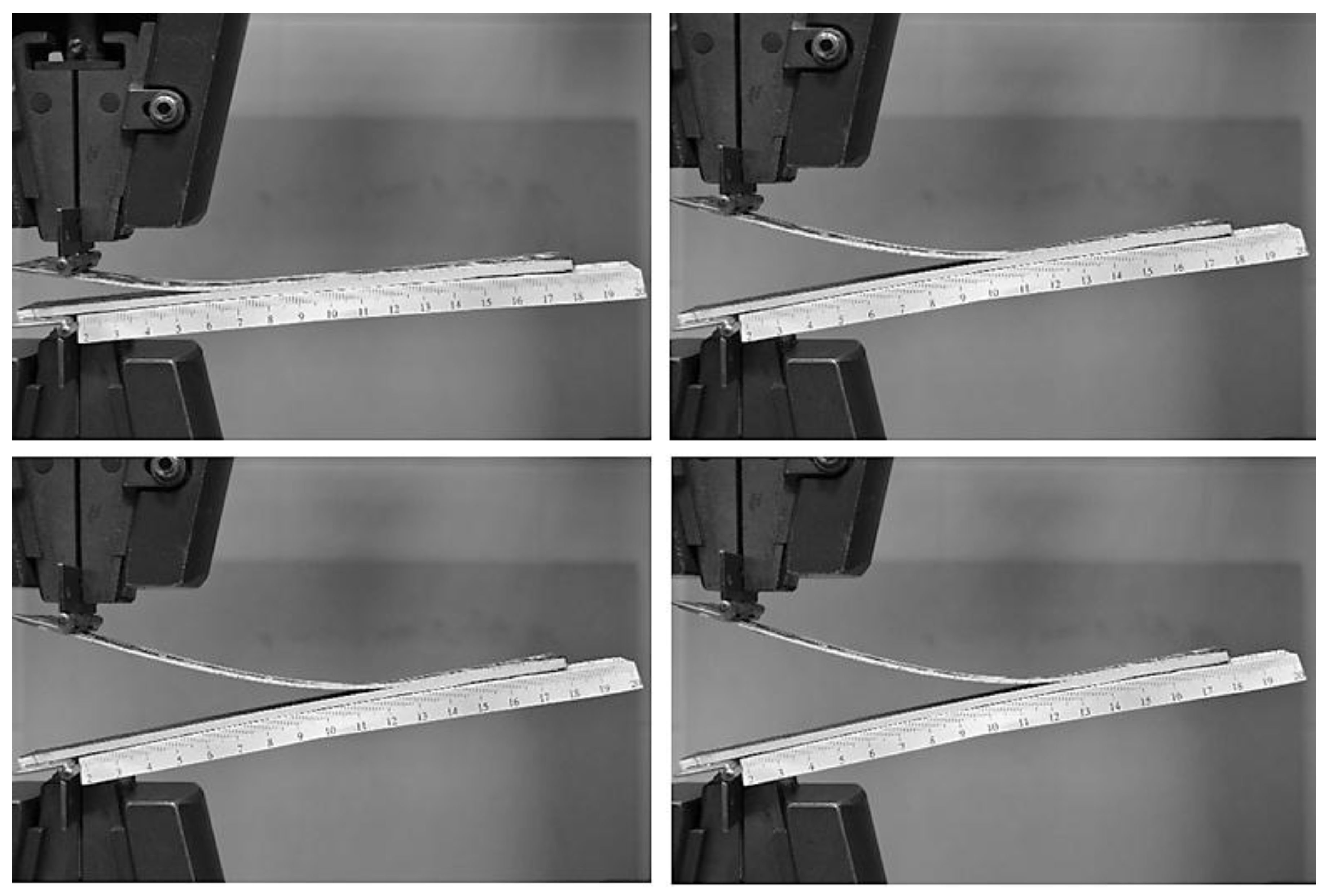

2.6. Samples Preparation for the Double Cantilever Beam Test

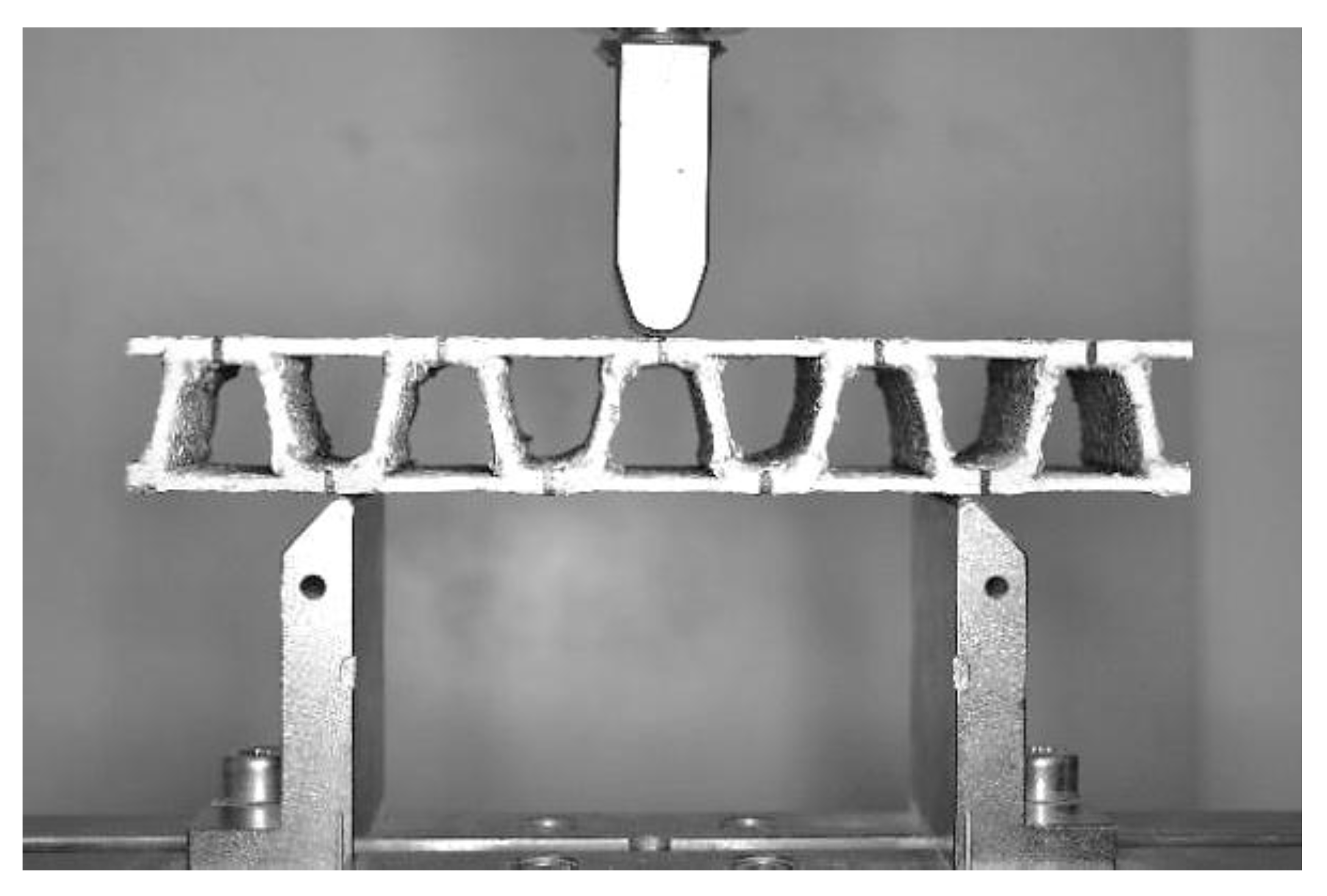

2.7. Mechanical Analysis of Sandwich Structures

3. Results and Discussion

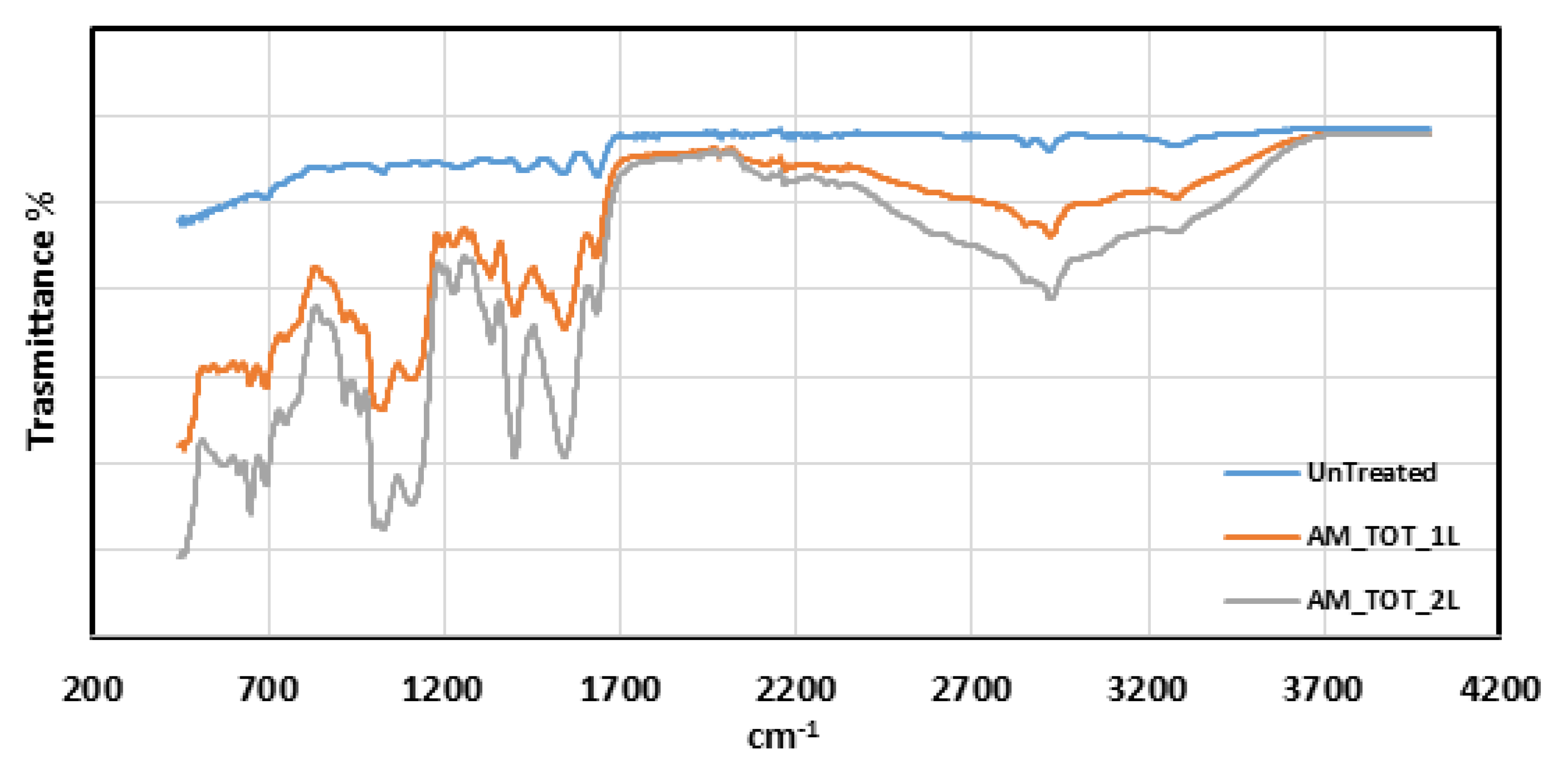

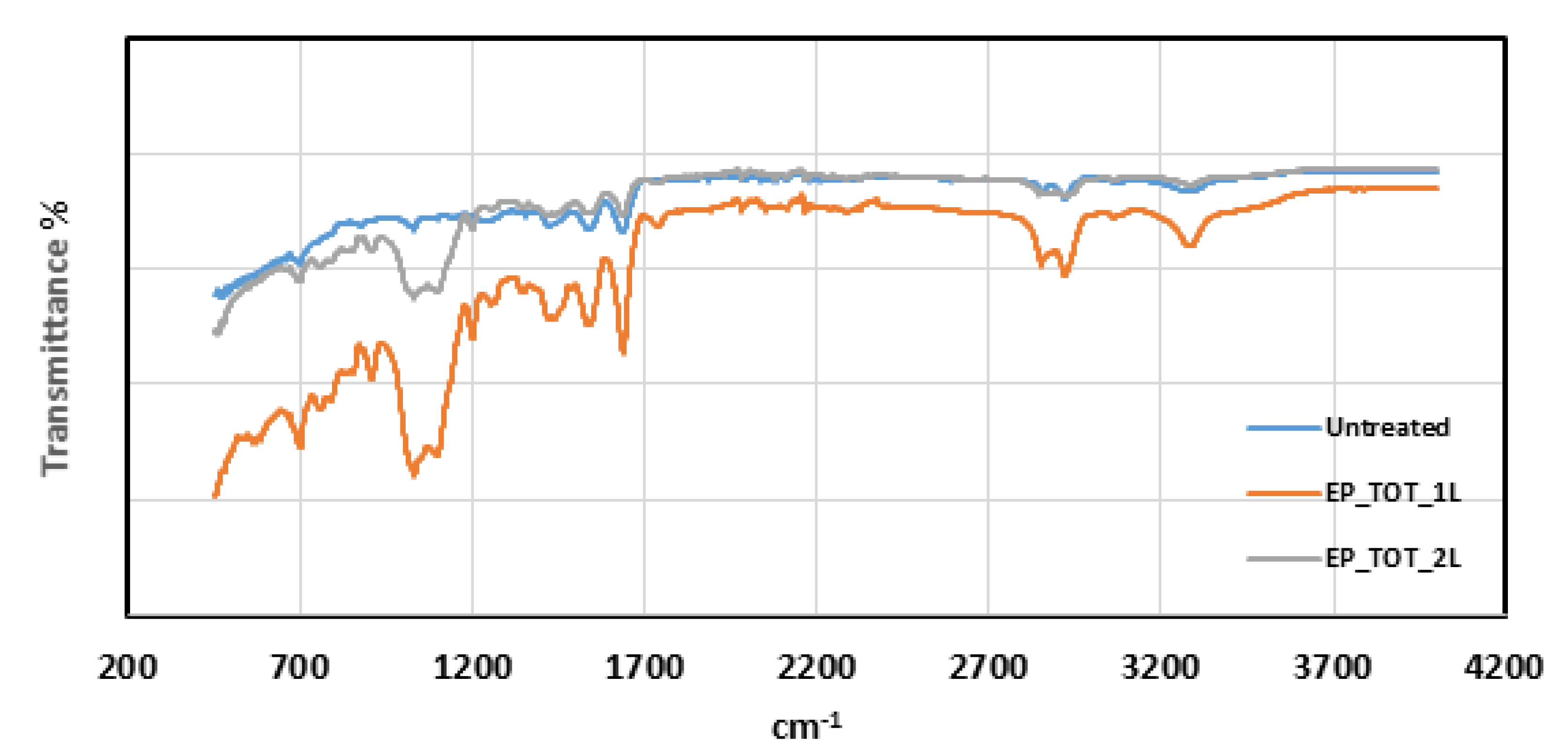

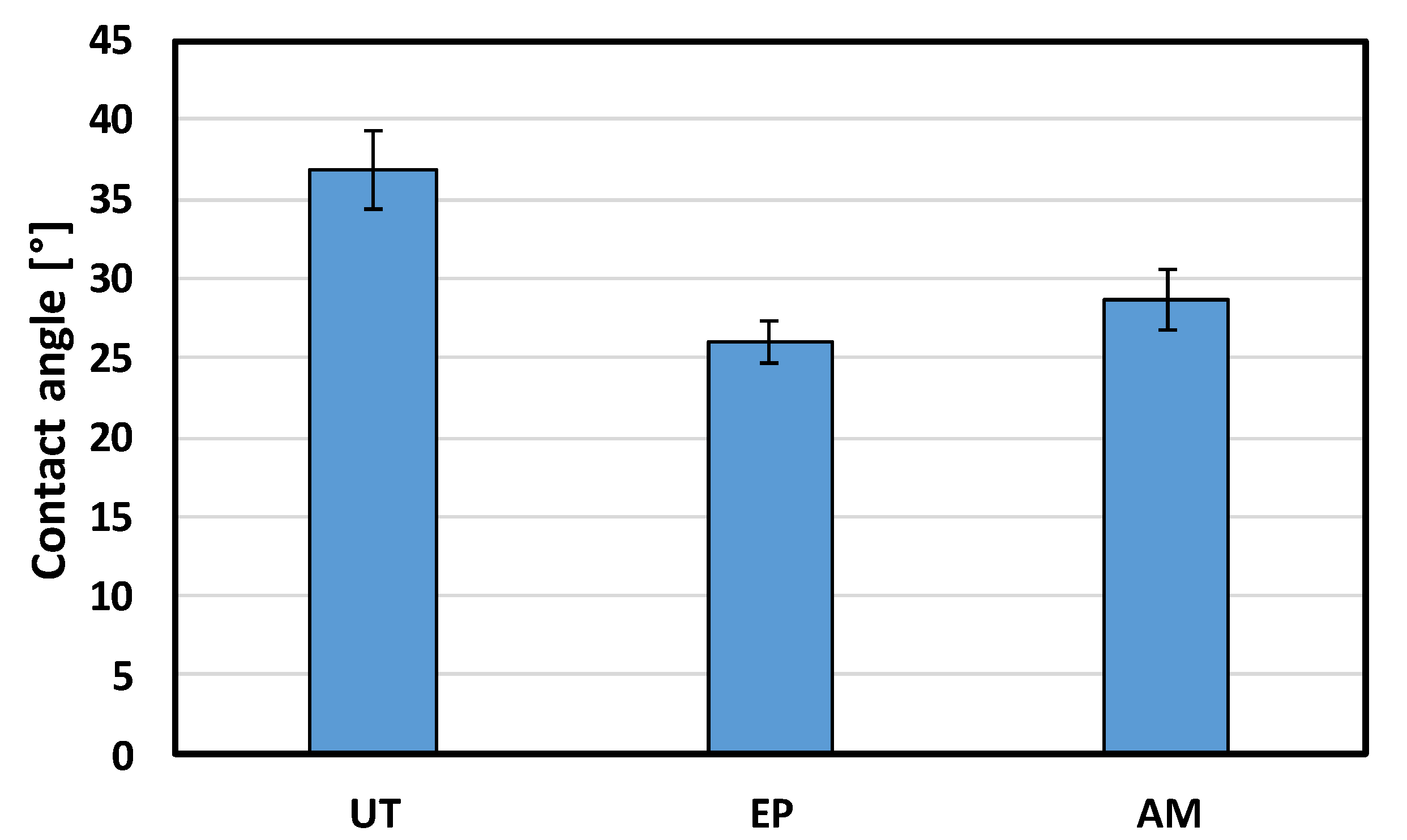

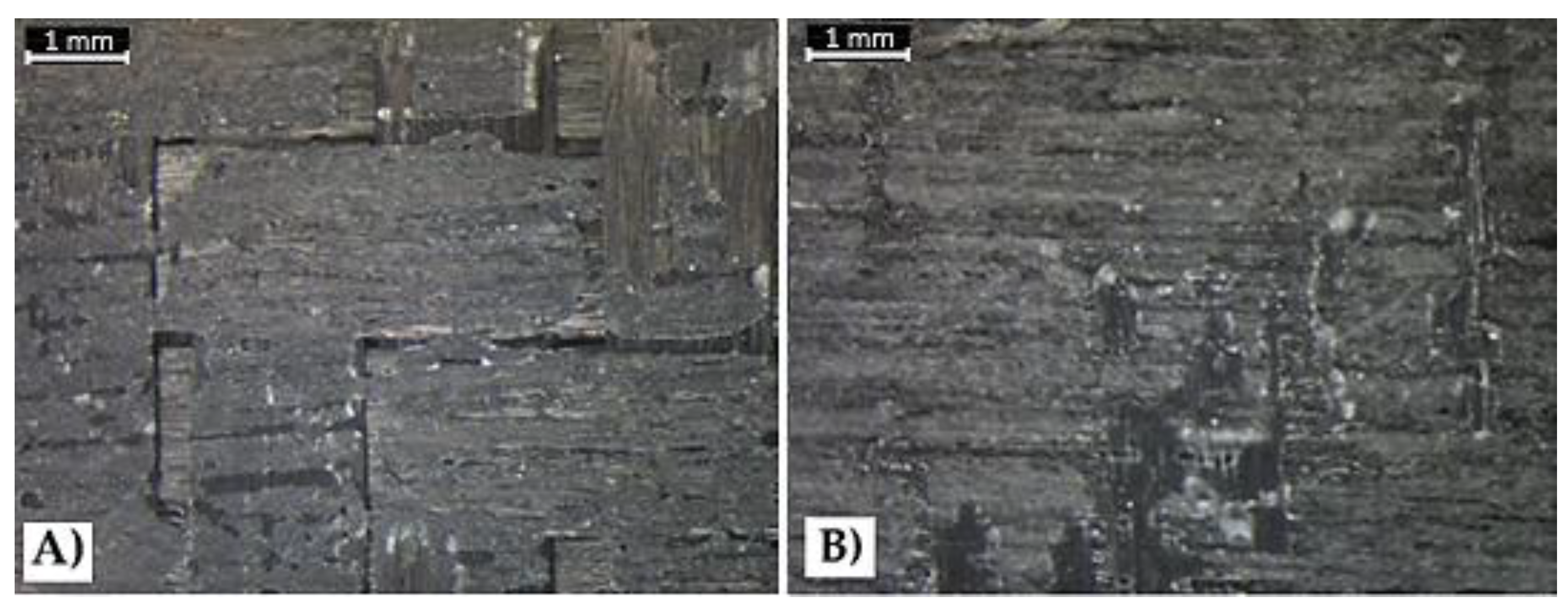

3.1. PA12-CR Surface Treatments

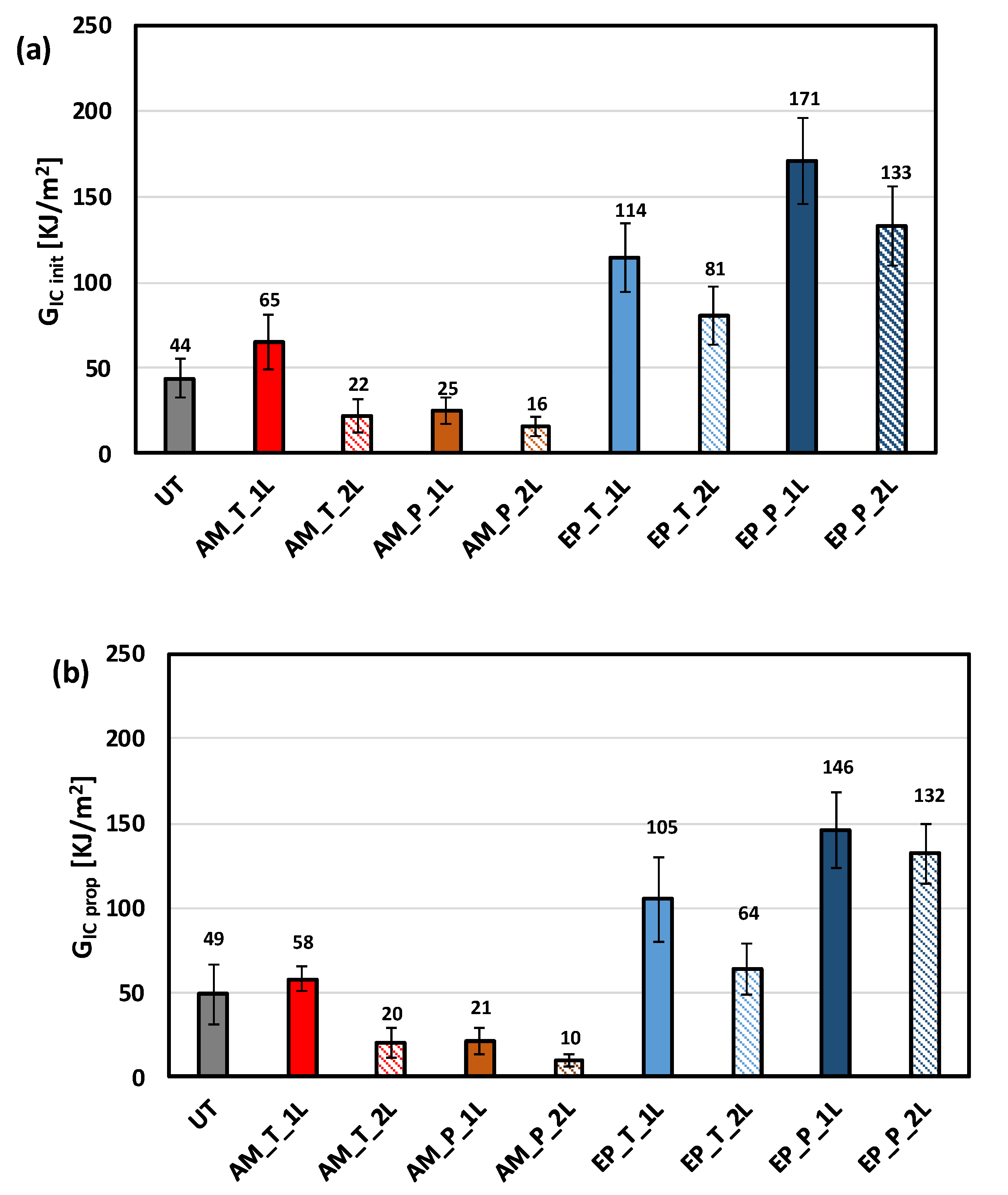

3.2. Analysis of the Double Cantilever Beam Test

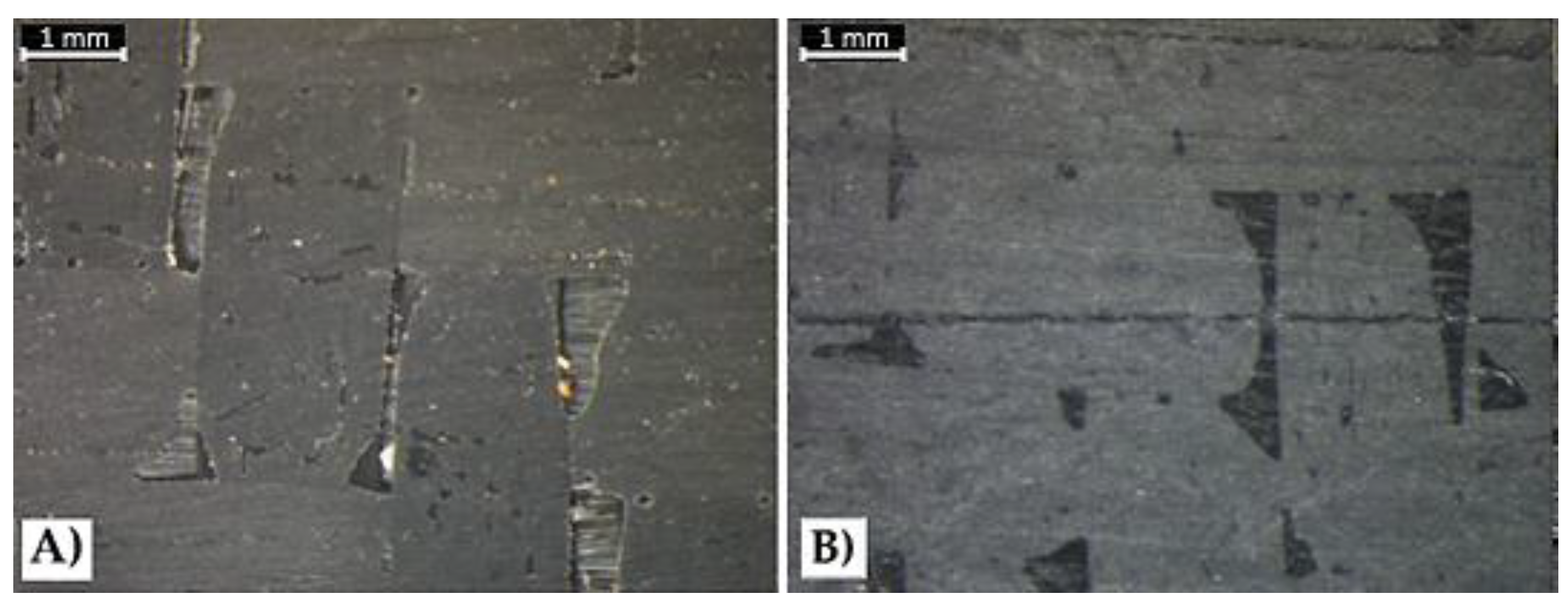

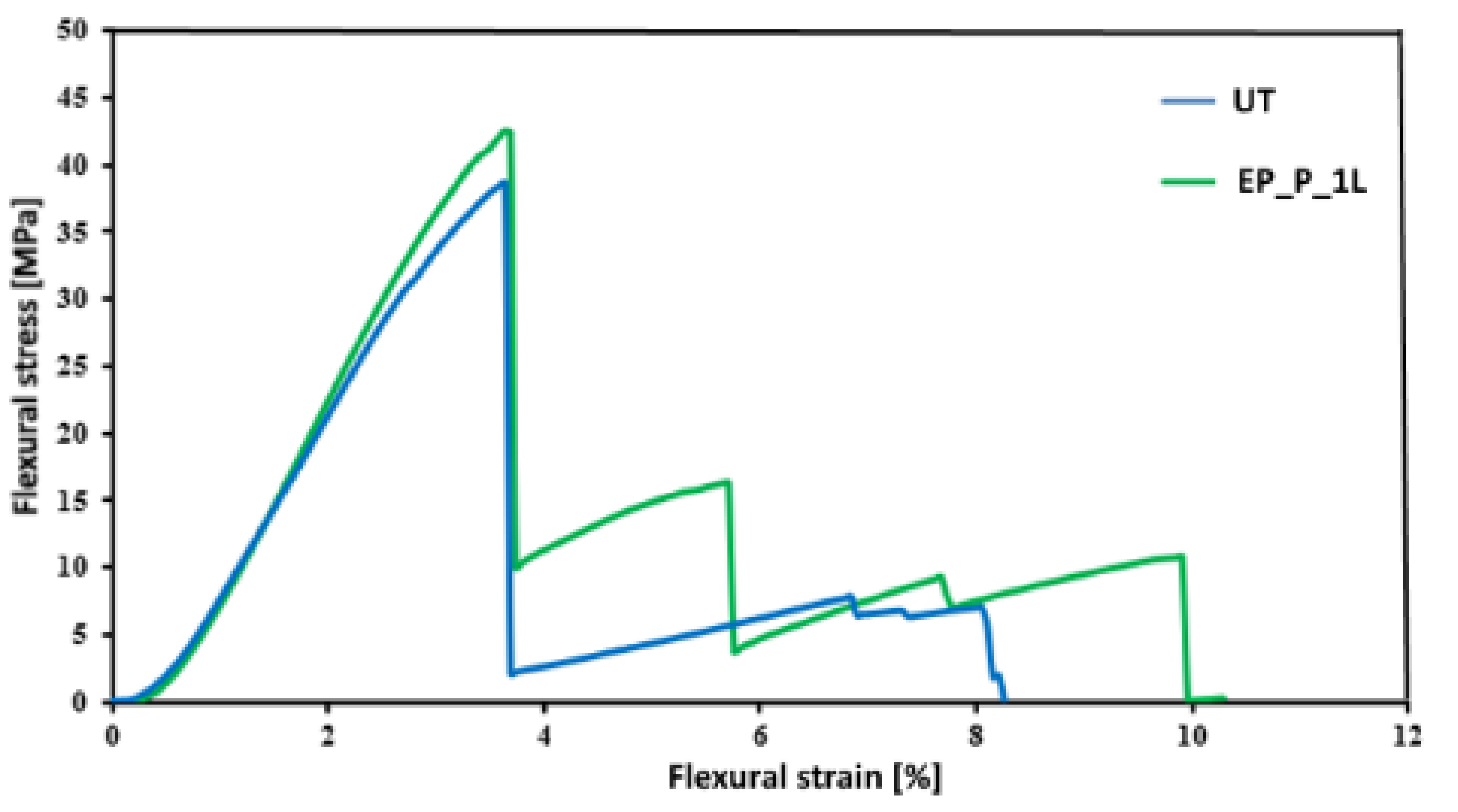

3.3. Mechanical Analysis of the Sandwich Structure

4. Conclusions

- The epoxy-based silane (EP) allows to obtain better adhesion improvement in comparison to amine-based silane (AM). In particular, (3-Glycidyloxypropyl)trimethoxysilane (EP) leads to improvements, in comparison to the reference sample, of about 288% and 197% for the GIC init and GIC prop, respectively;

- The application of the second layer of silane coupling agent is not effective for improving the adhesion. The deposition of a single layer allows to create a homogeneous coating layer;

- The Partial Cure has beneficial effect on the adhesion only in the case of epoxy-based silane, whereas it is not useful for amine-based silane, due to the insufficient conditions for reaction between AM silane and epoxy in this curing conditions (i.e., 80 °C for 10 min before the hand lay-up phase of CFRP substrate);

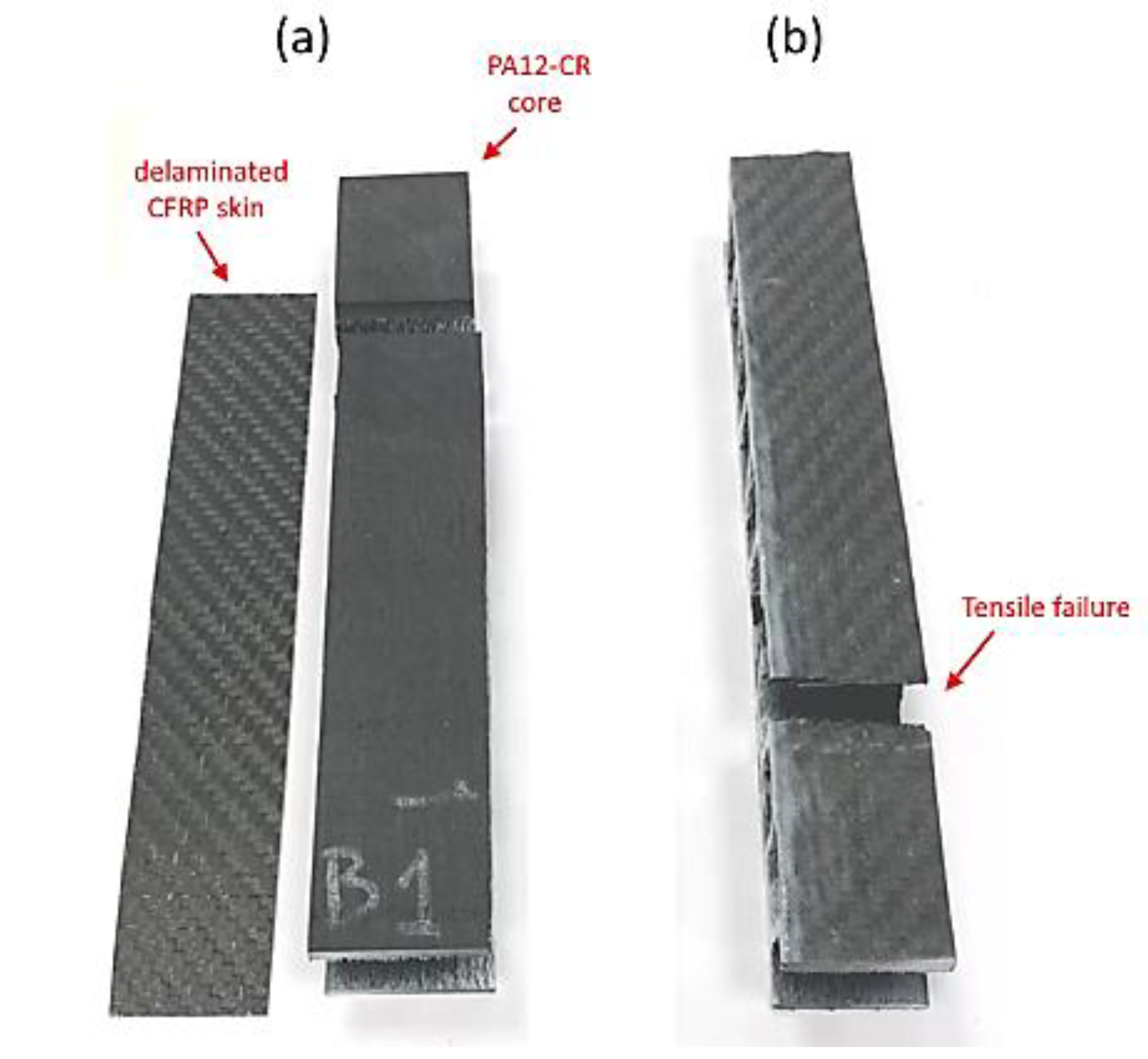

- The application of the epoxy-based silane treatment led to an improvement of the adhesion between CFRP skin and printed PA12-CR core, thus leading to the improvement of the overall flexural response of the sandwich structures (i.e., +5% and +20% in the flexural strength and in the equivalent flexural modulus, respectively);

- The enhanced adhesive properties lead to an improvement of the skin-core adhesion, thus resulting in the change of the failure mode from delamination between PA12-CR substrate and CFRP to tensile failure of the CFRP skin.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dau, J.; Lauter, C.; Damerow, U.; Homberg, W.; Tröster, T. Multi-material systems for tailored automotive structural components. In ICCM International Conferences on Composite Materials, 2011. Available online: https://www.iccm-central.org/Proceedings/ICCM18proceedings/data/2.%20Oral%20Presentation/Aug24(Wednesday)/W23%20Processing%20and%20Manufacturing%20Technologies/W23-3-IF1880.pdf (accessed on 27 May 2020).

- Zhang, J.; de Souza, M.; Creighton, C.; Varley, R.J. New approaches to bonding thermoplastic and thermoset polymer composites. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105870. [Google Scholar] [CrossRef]

- Abbas, M.K.G.; Sakundarini, N.; Kong, I. Optimal Selection for Dissimilar Materials using Adhesive Bonding and Mechanical Joining. In Proceeding of the 1st International Postgraduate Conference on Mechanical Engineering (IPCME2018); IOP Publishing Ltd.: Pahang, Malaysia, 2018. [Google Scholar]

- Lee, S.W.; Chang, S.H. Experimental investigation of pull-through force of wing-type fastening inserts co-cured in long fiber prepreg sheet (LFPS). Compos. Struct. 2018, 206, 978–986. [Google Scholar] [CrossRef]

- Abouhamzeh, M.; Sinke, J. Effects of fusion bonding on the thermoset composite. Compos. Part A Appl. Sci. Manuf. 2019, 118, 142–149. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L.; Hou, M. Advances in fusion bonding techniques for joining thermoplastic matrix composites: A review. Compos. Part A Appl. Sci. Manuf. 2001, 32, 839–857. [Google Scholar] [CrossRef]

- Encinas, N. Surface modification of aircraft used composites for adhesive bonding. Int. J. Adhes. Adhes. 2014, 50, 157–163. [Google Scholar] [CrossRef]

- Alamir, M.; Alonayni, A.; Asmatulu, E.; Paranjpe, N.; Rahman, M.M.; Asmatulu, R. Strength and failure analysis of composite-to-composite adhesive bonds with different surface treatments. Proc. SPIE 2018, 10596, 105961K. [Google Scholar]

- Tornow, C. Quality assurance concepts for adhesive bonding of composite aircraft structures-characterisation of adherent surfaces by extended NDT. J. Adhes. Sci. Technol. 2014, 29, 2281–2294. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. IMechE art L J. Mat. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Baldan, A. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Don, R.C.; Gillespie, J.W., Jr.; McKnight, S.H. Bonding techniques for high performance thermoplastic compositions. 1997. Available online: https://patents.google.com/patent/US5643390A/en (accessed on 27 May 2020).

- Williams, T.S.; Yu, H.; Hicks, R.F. Atmospheric pressure plasma activation of polymers and composites for adhesive bonding: A critical review. Rev. Adhes. Adhes. 2013, 1, 46–87. [Google Scholar] [CrossRef]

- Urbaniak-Domagala, W. Pretreatment of polypropylene films for the creation of thin polymer layers, part 1: The use of chemical, electrochemical, and UV methods. J. Appl. Polym. Sci. 2011, 122, 2071–2080. [Google Scholar] [CrossRef]

- Williams, D.F.; Abel, M.L.; Grant, E.; Hrachova, J.; Watts, J.F. Flame treatment of polypropylene: A study by electron and ion spectroscopies. Int. J. Adhes. Adhes. 2015, 63, 26–33. [Google Scholar] [CrossRef]

- Rider, A.N.; Arnott, D.R. Boiling water and silane pre-treatment of aluminum alloys for durable adhesive bonding. Int. J. Adhes. Adhes. 2000, 20, 209–220. [Google Scholar] [CrossRef]

- Wu, H.F.; Dwight, D.W.; Huff, N.T. Effects of silane coupling agents on the interphase and performance of glass-fiber-reinforced polymer composites. Compos. Sci. Technol. 1997, 57, 975–983. [Google Scholar] [CrossRef]

- Park, J.M.; Subramanian, R.V.; Bayoumi, A.E. Interfacial shear strength and durability improvement by silanes in single-filament composite specimens of basalt fiber in brittle phenolic and isocyanate resins. J. Adhes. Sci. Technol. 1994. [Google Scholar] [CrossRef]

- Plueddemann, E.P. Silane Coupling Agents, 2nd ed.; Springer Nature: London, UK, 1991; pp. 1–29. [Google Scholar]

- Zhu, L. Effect of absorbed moisture on the atmospheric plasma etching of polyamide fibers. Surf. Coatings Technol. 2008, 202, 1966–1974. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Calabrese, L.; Bonaccorsi, L.; Caprì, A.; Proverbio, E. Effect of silane matrix composition on performances of zeolite composite coatings. Prog. Org. Coatings 2016, 101, 100–110. [Google Scholar] [CrossRef]

- Scalici, T.; Pitarresi, G.; Badagliacco, D.; Fiore, V.; Valenza, A. Mechanical properties of basalt fiber reinforced composites manufactured with different vacuum assisted impregnation techniques. Compos. Part B Eng. 2016, 104, 35–43. [Google Scholar] [CrossRef]

- ASTM D5528-01. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites. Am. Stand. Test. Methods 2014, 3, 1–12. [Google Scholar]

- Standard Test Method for Flexural Properties of Sandwich Constructions: ASTM C 393; ASTM International: West Conshohocken, PA, USA, 2000.

- di Bella, G.; Calabrese, L.; Borsellino, C. Mechanical characterisation of a glass/polyester sandwich structure for marine applications. Mater. Des. 2012, 42, 486–494. [Google Scholar] [CrossRef]

- España, J.M.; Samper, M.D.; Fages, E.; Sanchez-Nacher, L.; Balart, R. Investigation of the Effect of Different Silane Coupling Agents on Mechanical Performance of Basalt Fiber Composite Laminates with Biobased Epoxy Matrices J.M. Polym. Compos. 2013, 34, 376–381. [Google Scholar] [CrossRef]

- Hoikkanen, M.; Honkanen, M.; Vippola, M.; Lepistö, T.; Vuorinen, J. Effect of silane treatment parameters on the silane layer formation and bonding to thermoplastic urethane. Prog. Org. Coatings 2011, 72, 716–723. [Google Scholar] [CrossRef]

| Mechanical Properties at 23 °C/50% RH | Normative | Value |

|---|---|---|

| Tensile Strength | ISO 527 | 170 MPa |

| Elongation at break | ISO 527 | 2% |

| Modulus of Elasticity | ISO 527 | 15 GPa |

| Charpy Impact Strength | ISO 179 | 47 KJ/m2 |

| (3-Aminopropyl)trimethoxysilane (AM) | (3-Glycidyloxypropyl)trimethoxysilane (EP) | |

|---|---|---|

| Empirical Formula | C9H23NO3SI | C9H20O5Si |

| Molecular Weight | 179.29 | 236.34 |

| Assay | 97% | ≥98% |

| Reactive Groups | Amine/Methoxy | Epoxy/Methoxy |

| Density | 1.027 g/mL at 25 °C | 1.07 g/mL at 25 °C |

| Refractive Index | 1.424 | 1.429 |

| Type of Pre-Treatment | Description of Pre-Treatment |

|---|---|

| Roughing | Performed by a belt sander equipped with 40, 80 and 120 grit |

| Finishing | Performed by a vibrating sander equipped with 150 grit |

| Cleaning and removing dust | Performed by a compressed air jet and absorbent paper |

| Type of Cure | Type of Deposition | Pa12-Cr Treatment Description |

|---|---|---|

| Total Cure | 1. Layer | (1)Spray deposition of the layer |

| (2)Cure for 3 h in oven at 80 °C | ||

| (3)Hand lay-up lamination | ||

| (4)Cure for 24 h in vacuum at room temperature | ||

| 2 Layers | (1)Spray deposition of the 1st layer | |

| (2)Cure for 10 min in oven at 80 °C | ||

| (3)Spray deposition of the 2nd layer | ||

| (4)Cure for 3 h in oven at 80 °C | ||

| (5)Hand lay-up lamination | ||

| (6)Cure for 24 h in vacuum at room temperature | ||

| Partial Cure | 1 Layer | (1)Spray deposition of the layer |

| (2)Cure for 10 min in oven at 80 °C | ||

| (3)Hand lay-up lamination | ||

| (4)Cure for 24 h in vacuum at room temperature | ||

| (5)Post-cure for 3 h in oven at 80 °C | ||

| 2 Layers | (1)Spray deposition of the 1st layer | |

| (2)Cure for 10 min in oven at 80 °C | ||

| (3)Spray deposition of the 2nd layer | ||

| (4)Cure for 10 min in oven at 80 °C | ||

| (5)Hand lay-up lamination | ||

| (6)Cure for 24 h in vacuum at room temperature | ||

| (7)Post-cure for 3 h in oven at 80 °C |

| Code | Description |

|---|---|

| UT | Untreated |

| AM_T_1L | Amino-based silane—Total Cure—1 Layer |

| AM_T_2L | Amino-based silane—Total Cure—2 Layers |

| AM_P_1L | Amino-based silane—Partial Cure—1 Layer |

| AM_P_2L | Amino-based silane—Partial Cure—2 Layers |

| EP_T_1L | Epoxy-based silane—Total Cure—1 Layer |

| EP_T_2L | Epoxy-based silane—Total Cure—2 Layers |

| EP_P_1L | Epoxy-based silane—Partial Cure—1 Layer |

| EP_P_2L | Epoxy-based silane—Partial Cure—2 Layers |

| σmax [MPa] | Ef [MPa] | |||

|---|---|---|---|---|

| Average | Dev.St. | Average | Dev.St. | |

| UT | 39.8 | 3.7 | 1198 | 222.8 |

| EP_P_1L | 41.8 | 2.3 | 1428 | 146.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiore, V.; Orlando, V.; Sanfilippo, C.; Badagliacco, D.; Valenza, A. Effect of Silane Coupling Treatment on the Adhesion between Polyamide and Epoxy Based Composites Reinforced with Carbon Fibers. Fibers 2020, 8, 48. https://doi.org/10.3390/fib8080048

Fiore V, Orlando V, Sanfilippo C, Badagliacco D, Valenza A. Effect of Silane Coupling Treatment on the Adhesion between Polyamide and Epoxy Based Composites Reinforced with Carbon Fibers. Fibers. 2020; 8(8):48. https://doi.org/10.3390/fib8080048

Chicago/Turabian StyleFiore, Vincenzo, Vincenzo Orlando, Carmelo Sanfilippo, Dionisio Badagliacco, and Antonino Valenza. 2020. "Effect of Silane Coupling Treatment on the Adhesion between Polyamide and Epoxy Based Composites Reinforced with Carbon Fibers" Fibers 8, no. 8: 48. https://doi.org/10.3390/fib8080048

APA StyleFiore, V., Orlando, V., Sanfilippo, C., Badagliacco, D., & Valenza, A. (2020). Effect of Silane Coupling Treatment on the Adhesion between Polyamide and Epoxy Based Composites Reinforced with Carbon Fibers. Fibers, 8(8), 48. https://doi.org/10.3390/fib8080048