In-Line Nanostructuring of Glass Fibres Using Different Carbon Allotropes for Structural Health Monitoring Application

Abstract

:1. Introduction

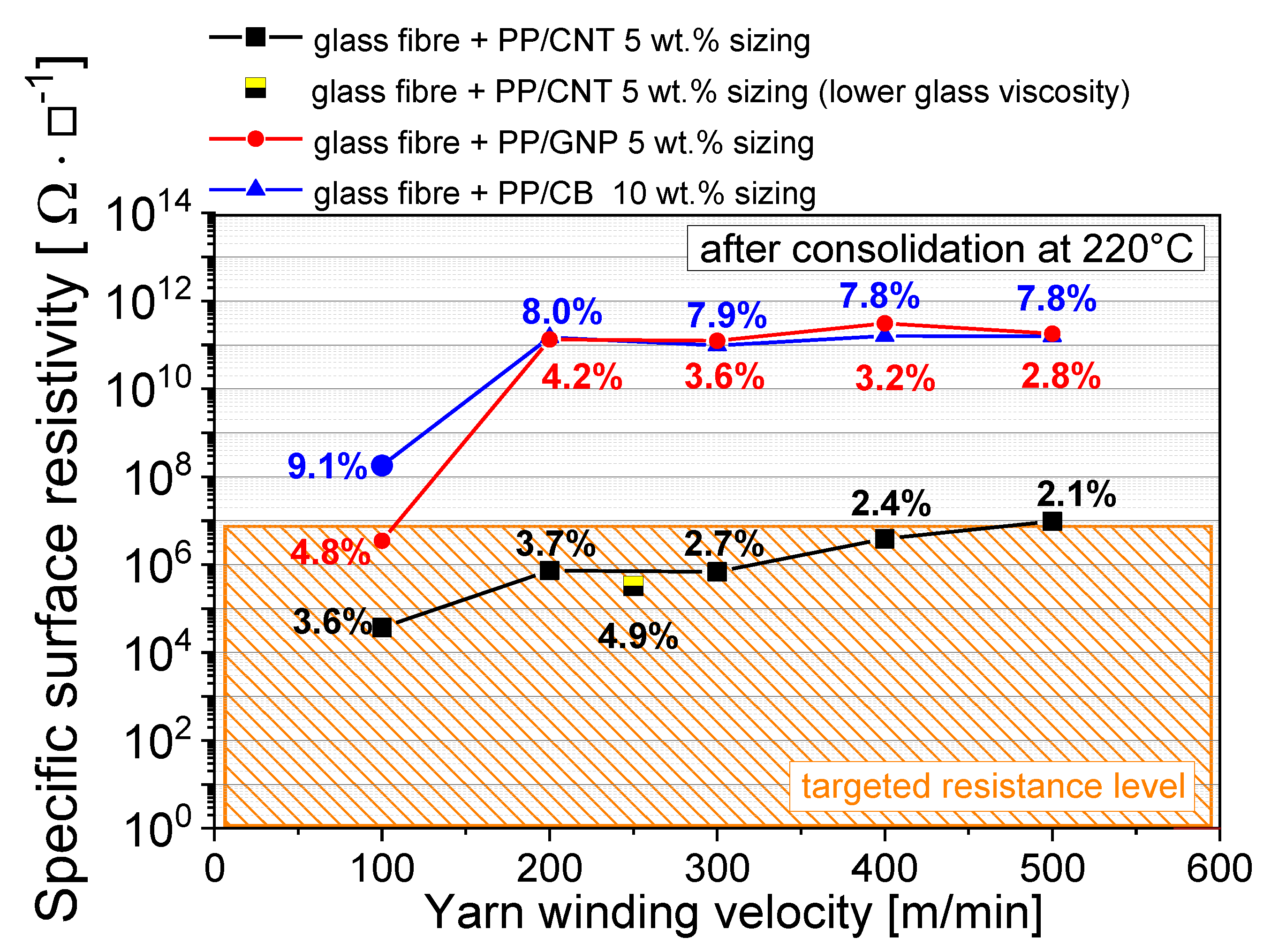

2. Experimental

2.1. Materials and Processing

2.1.1. Glass Fibre Spinning and Interface Modification

2.1.2. Preparation of the Nanostructured Fibre Sizing

2.1.3. Electrical Characterization

2.1.4. Mechanical Characterization

2.1.5. GF-Composite Preparation

2.1.6. Electro-Mechanical Response during a 3-Point Bending Test

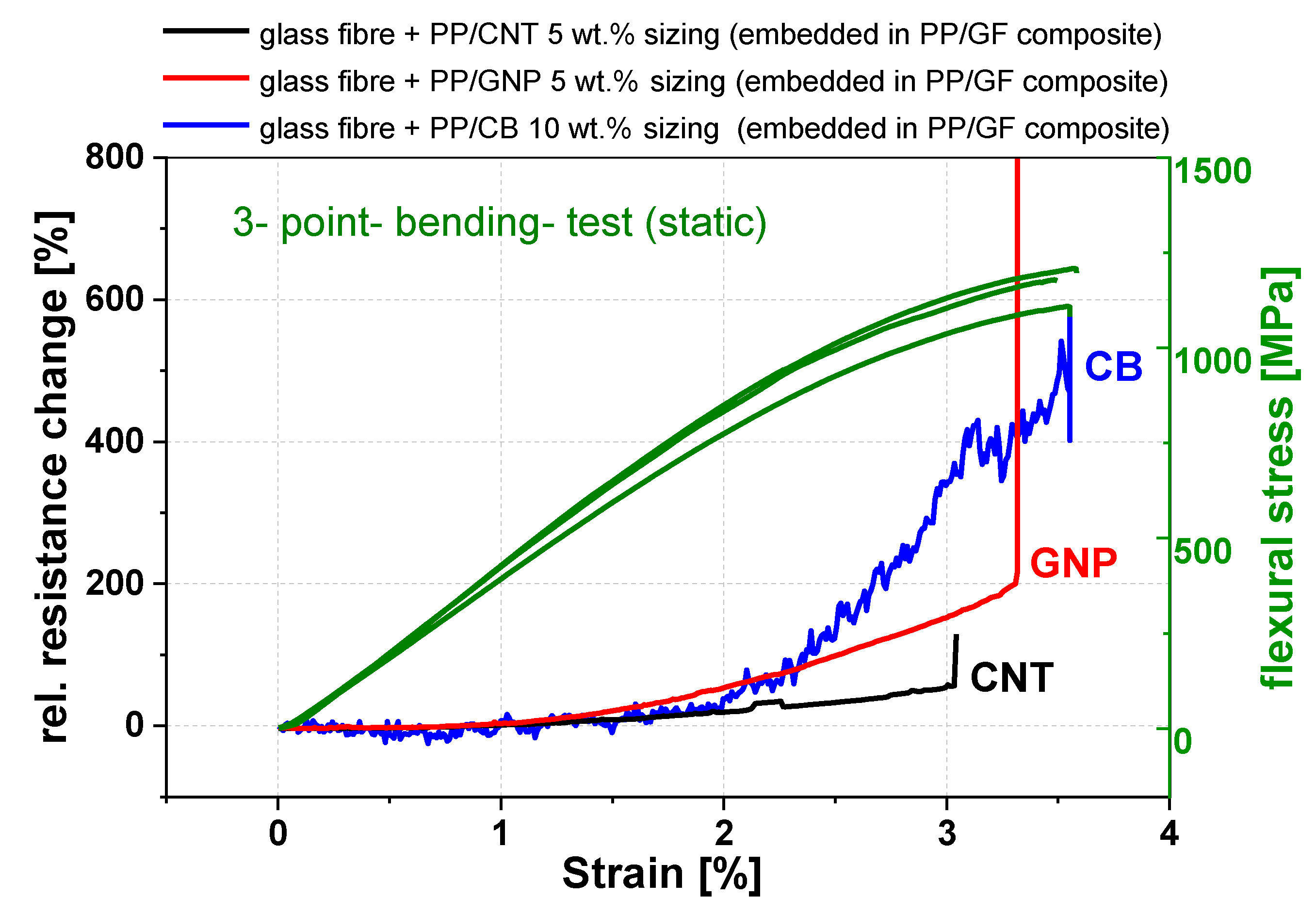

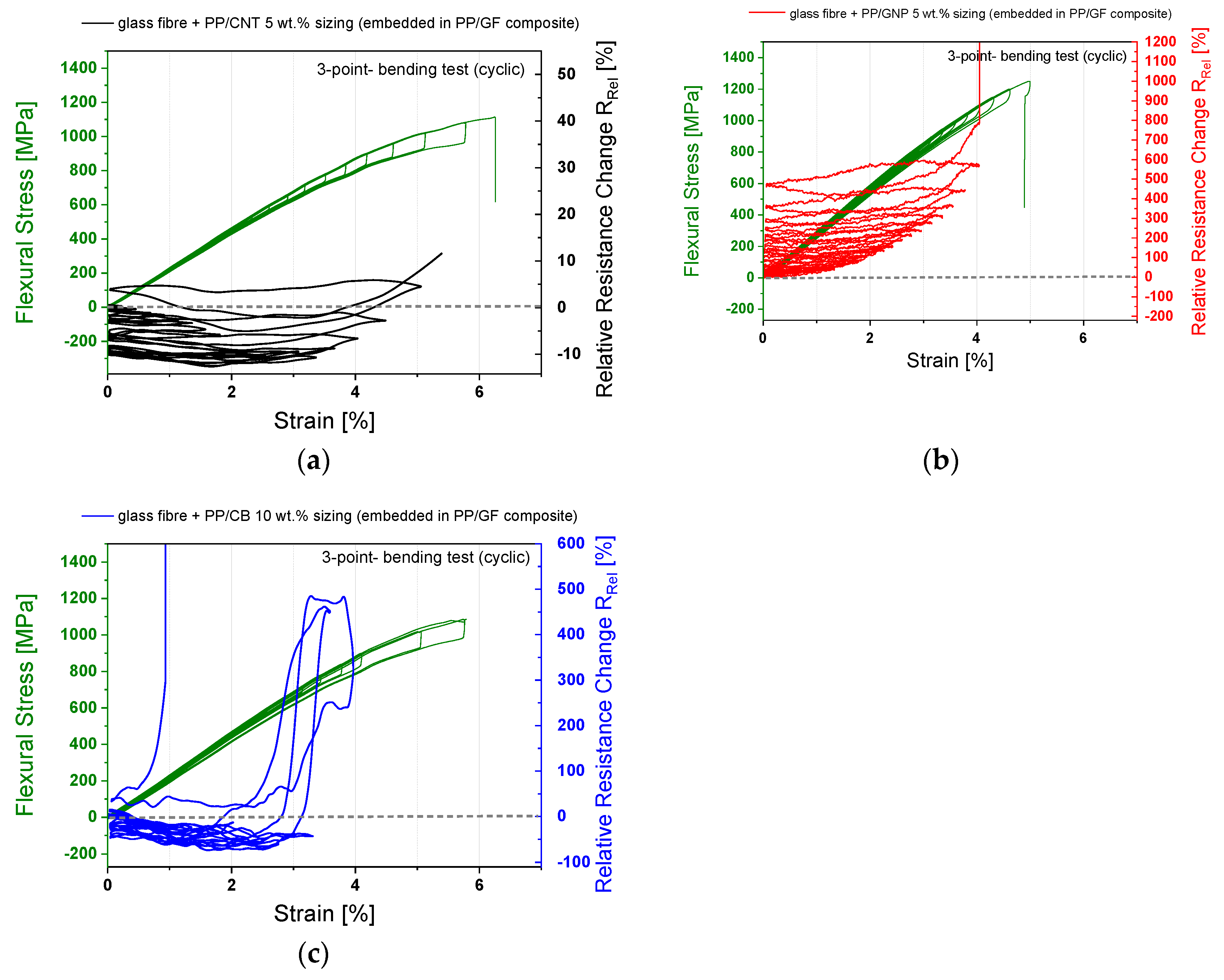

3. Results and Discussion

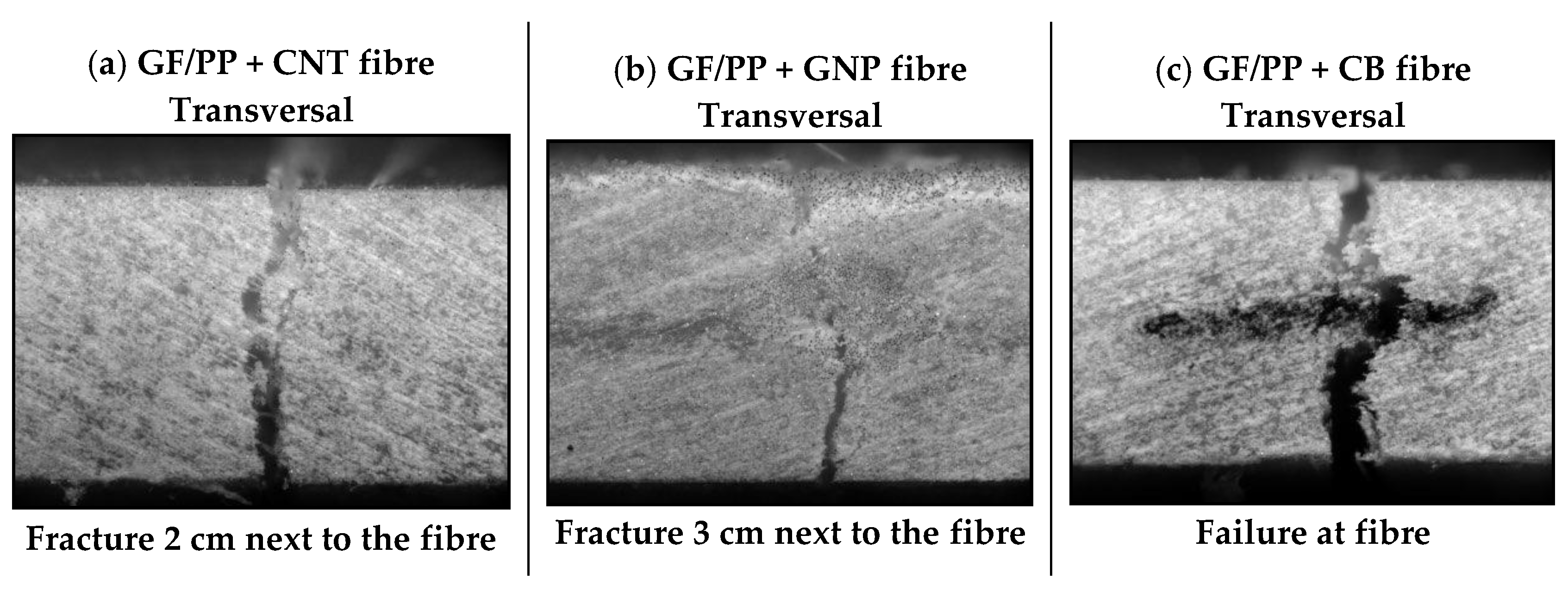

Mechanical Failure Behaviour

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Allwood, G.; Wild, G.; Hinckley, S. Optical Fiber Sensors in Physical Intrusion Detection Systems: A Review. IEEE Sens. J. 2016, 16, 5497–5509. [Google Scholar] [CrossRef] [Green Version]

- Cherif, C.; Häntzsche, E.; Mueller, R.; Nocke, A.; Hübner, M.; Hasan, M. Carbon Fibre Sensors Embedded in Glass Fibre-Based Composites for Windmill Blades; Woodhead Publishing: Sawston, Cambridge, UK. 2016. [Google Scholar]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Häntzsche, E.; Onggar, T.; Nocke, A.; Hund, R.D.; Cherif, C. Multi-Layered Sensor Yarns for in Situ Monitoring of Textile Reinforced Composites; IOP Publishing: Bristol, UK, 2017; Volume 254, p. 042012. [Google Scholar]

- López-Higuera, J.M.; Rodriguez-Cobo, L.; Quintela Incera, A.; Cobo, A. Fiber Optic Sensors in Structural Health Monitoring. J. Light. Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Schueler, R.; Joshi, S.P.; Schulte, K. Damage detection in CFRP by electrical conductivity mapping. Compos. Sci. Technol. 2001, 61, 921–930. [Google Scholar] [CrossRef]

- Walter, S.E.G. Entwicklung Piezoelektrisch Wirksamer Sensorfasern Auf Basis Von Polyvinylidenfluorid; Shaker Verlag: Maastricht, The Netherlands, 2012. [Google Scholar]

- Zhou, G.; Sim, L.M. Damage detection and assessment in fibre-reinforced composite structures with embedded fibre optic sensors-review. Smart Mater. Struct. 2002, 11, 925. [Google Scholar] [CrossRef]

- Schubel, P.J.; Crossley, R.J.; Boateng, E.K.G.; Hutchinson, J.R. Review of structural health and cure monitoring techniques for large wind turbine blades. Renew. Energy 2013, 51, 113–123. [Google Scholar] [CrossRef]

- Abot, J.; Góngora-Rubio, M.; Anike, J.; Kiyono, C.; Mello, L.; Cardoso, V.; Rosa, R.; Kuebler, D.; Brodeur, G.; Alotaibi, A.; et al. Foil Strain Gauges Using Piezoresistive Carbon Nanotube Yarn: Fabrication and Calibration. Sensors 2018, 18, 464. [Google Scholar] [CrossRef]

- Augustin, T. Structural Health Monitoring of Carbon Fiber Reinforced Polymers and Carbon Nanotube Modified Adhesive Joints Via Electrical Resistance Measurement. Ph.D. Thesis, Technische Universität Hamburg, Hamburg, Germany, September 2018. [Google Scholar]

- Khan, T.A.; Nauman, S.; Asfar, Z.; Nasir, M.A.; Khan, Z.M. Screen-printed nanocomposite sensors for online in situ structural health monitoring. J. Thermoplast. Compos. Mater. 2018. [Google Scholar] [CrossRef]

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Zarrelli, M.; Russo, S.; Iannuzzo, G. Smart coatings of epoxy based CNTs designed to meet practical expectations in aeronautics. Compos. Part B Eng. 2018, 147, 42–46. [Google Scholar] [CrossRef]

- Augustin, T.; Karsten, J.; Kötter, B.; Fiedler, B. Health monitoring of scarfed CFRP joints under cyclic loading via electrical resistance measurements using carbon nanotube modified adhesive films. Compos. Part A Appl. Sci. Manuf. 2018, 105, 150–155. [Google Scholar] [CrossRef]

- Al-Sabagh, A.; Taha, E.; Kandil, U.; Nasr, G.-A.; Reda Taha, M. Monitoring Damage Propagation in Glass Fiber Composites Using Carbon Nanofibers. Nanomaterials 2016, 6, 169. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, Y.; Wan, B.; Han, B.; Cai, G.; Li, Z. Properties and mechanisms of self-sensing carbon nanofibers/epoxy composites for structural health monitoring. Compos. Struct. 2018, 200, 669–678. [Google Scholar] [CrossRef]

- Lu, S.; Tian, C.; Wang, X.; Zhang, L.; Du, K.; Ma, K.; Xu, T. Strain sensing behaviors of GnPs/epoxy sensor and health monitoring for composite materials under monotonic tensile and cyclic deformation. Compos. Sci. Technol. 2018, 158, 94–100. [Google Scholar] [CrossRef]

- Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Prolongo, S.G.; Ureña, A. Sensitivity, influence of the strain rate and reversibility of GNPs based multiscale composite materials for high sensitive strain sensors. Compos. Sci. Technol. 2018, 155, 100–107. [Google Scholar] [CrossRef]

- Ishida, H. A review of recent progress in the studies of molecular and microstructure of coupling agents and their functions in composites, coatings and adhesive joints. Polym. Compos. 1984, 5, 101–123. [Google Scholar] [CrossRef]

- Kim, J.-K.; Mai, Y.-w. High strength, high fracture toughness fibre composites with interface control—A review. Compos. Sci. Technol. 1991, 41, 333–378. [Google Scholar] [CrossRef]

- Pukánszky, B. Interfaces and interphases in multicomponent materials: Past, Present, Future. Eur. Polym. J. 2005, 41, 645–662. [Google Scholar] [CrossRef]

- Zhuang, R.C.; Burghardt, T.; Mäder, E. Study on interfacial adhesion strength of single glass fibre/polypropylene model composites by altering the nature of the surface of sized glass fibres. Compos. Sci. Technol. 2010, 70, 1523–1529. [Google Scholar] [CrossRef] [Green Version]

- Müller, M.; Pötzsch, H.; Gohs, U.; Heinrich, G. Online Structural-Health Monitoring of Glass Fiber-Reinforced Thermoplastics Using Different Carbon Allotropes in the Interphase. Materials 2018, 11, 1075. [Google Scholar] [CrossRef]

- Rausch, J.; Mäder, E. Health monitoring in continuous glass fibre reinforced thermoplastics: Tailored sensitivity and cyclic loading of CNT-based interphase sensors. Compos. Sci. Technol. 2010, 70, 2023–2030. [Google Scholar] [CrossRef] [Green Version]

- Rausch, J.; Mäder, E. Health monitoring in continuous glass fibre reinforced thermoplastics: Manufacturing and application of interphase sensors based on carbon nanotubes. Compos. Sci. Technol. 2010, 70, 1589–1596. [Google Scholar] [CrossRef] [Green Version]

- Rausch, J.; Mäder, E. Carbon nanotube coated glass fibres for interphase health monitoring in textile composites. Mater. Technol. 2011, 26, 153–158. [Google Scholar] [CrossRef]

- Wiegand, N.; Mäder, E. Multifunctional interphases for sensing applications in glass fiber polypropylene composites. In Proceedings of the CAMX, Orlando, FL, USA, 13–16 October 2014. [Google Scholar]

- Wiegand, N.; Mäder, E. Multifunctional Interphases: Percolation Behavior, Interphase Modification, and Electro-Mechanical Response of Carbon Nanotubes in Glass Fiber Polypropylene Composites. Adv. Eng. Mater. 2016, 18, 376–384. [Google Scholar] [CrossRef]

- Zhang, J.; Zhuang, R.; Liu, J.; Scheffler, C.; Mäder, E.; Heinrich, G.; Gao, S. A Single Glass Fiber with Ultrathin Layer of Carbon Nanotube Networks Beneficial to In-Situ Monitoring of Polymer Properties in Composite Interphases. Soft Mater. 2014, 12, S115–S120. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Zhuang, R.; Mäder, E.; Heinrich, G.; Gao, S. Single MWNT-Glass Fiber as Strain Sensor and Switch. Adv. Mater. 2011, 23, 3392–3397. [Google Scholar] [CrossRef]

- Can-Ortiz, A.; Abot, J.L.; Avilés, F. Electrical characterization of carbon-based fibers and their application for sensing relaxation-induced piezoresistivity in polymer composites. Carbon 2019, 145, 119–130. [Google Scholar] [CrossRef]

- Liu, L.; Ma, P.-C.; Xu, M.; Khan, S.U.; Kim, J.-K. Strain-sensitive Raman spectroscopy and electrical resistance of carbon nanotube-coated glass fibre sensors. Compos. Sci. Technol. 2012, 72, 1548–1555. [Google Scholar] [CrossRef]

- Boehle, M.; Jiang, Q.; Li, L.; Lagounov, A.; Lafdi, K. Carbon nanotubes grown on glass fiber as a strain sensor for real time structural health monitoring. Int. J. Smart Nano Mater. 2012, 3, 162–168. [Google Scholar] [CrossRef] [Green Version]

- Sebastian, J.; Schehl, N.; Bouchard, M.; Boehle, M.; Li, L.; Lagounov, A.; Lafdi, K. Health monitoring of structural composites with embedded carbon nanotube coated glass fiber sensors. Carbon 2014, 66, 191–200. [Google Scholar] [CrossRef]

- Boehle, M.C. Synthesis and Characterization of a Carbon Nanotube Based Composite Strain Sensor. Master’s Thesis, University of Dayton, Dayton, OH, USA, May 2016. [Google Scholar]

- Rausch, J.; Zhuang, R.C.; Maeder, E. Systematically varied interfaces of continuously reinforced glass fibre/polypropylene. Express Polym. Lett. 2010, 4, 576–588. [Google Scholar] [CrossRef]

- Mäder, E.; Rausch, J.; Schmidt, N. Commingled yarns—Processing aspects and tailored surfaces of polypropylene/glass composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 612–623. [Google Scholar] [CrossRef]

- Krause, B.; Mende, M.; Pötschke, P.; Petzold, G. Dispersability and particle size distribution of CNTs in an aqueous surfactant dispersion as a function of ultrasonic treatment time. Carbon 2010, 48, 2746–2754. [Google Scholar] [CrossRef]

- Nanocyl, NC7000 Series—Product Datasheet—Thin Multi-Wall Carbon Nanotubes; Nanocyl SA: Sambreville, Belgium, 2010.

- Müller, M.; Hilarius, K.; Liebscher, M.; Lellinger, D.; Alig, I.; Pötschke, P. Effect of Graphite Nanoplate Morphology on the Dispersion and Physical Properties of Polycarbonate Based Composites. Materials 2017, 10, 545. [Google Scholar] [CrossRef] [PubMed]

- Graphit-Kropfmühl, Datasheet—Multilayer graphene EXG 98 300; Graphit Kropfmühl GmbH: Hauzenberg, Germany, 2013.

- Carbons, O.E. Datasheet—Printex XE2B; Orion Engineered Carbons GmbH: Frankfurt am Main, Germany, 2010. [Google Scholar]

- ASTM-D257. Standard Test Methods for DC Resistance or Conductance of Insulating Materials; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- DIN EN ISO 14125. Faserverstärkte Kunststoffe-Bestimmung der Biegeeigenschaften, 5th ed.; DIN Deutsches Institut für Normung e. V.: Berlin Germany, 2011. [Google Scholar]

- DIN EN ISO 527. Kunststoffe-Bestimmung der Zugeigenschaften-Teil 1: Allgemeine Grundsätze, 6th ed.; DIN Deutsches Institut für Normung e. V.: Berlin Germany, 2012. [Google Scholar]

- ISO 9291. Textile-Glass-Reinforced Plastics-Rovings-Preparation of Unidirectional Plates by Winding, 10th ed.; DIN Deutsches Institut für Normung e. V.: Berlin Germany, 1996. [Google Scholar]

- Wiegand, N.; Mäder, E. Commingled Yarn Spinning for Thermoplastic/Glass Fiber Composites. Fibers 2017, 5, 26. [Google Scholar] [CrossRef]

- DIN EN 2563. Aerospace series-Carbon Fibre Reinforced Plastics-Unidirectional Laminates; Determination of Apparent Interlaminar Shear Strength; DIN Deutsches Institut für Normung e. V.: Berlin Germany, 1997. [Google Scholar]

| Material as Named by the Producer/Producer | Morphology | Average Particle Size d50 [µm] | Thickness/Diameter | Electrical Conductivity [S∙cm−1] | Specific Surface [m2∙g−1] | Bulk Density [kg∙m−3] |

|---|---|---|---|---|---|---|

| Nanocyl™ NC7000 (CNT) Nanocyl S.A. | Fibre | >675 [38] | Ø 9.5 nm [39] | 15 [40] *2 | 250–300 [39] | 66 [38] |

| EXG 98 300 (GNP) Graphit Kropfmühl | Lamellar | 305 *3 | - | 3 [40] *2 | >300 [41] | 1 *1 |

| Printex XE2B (CB) Orion Engineered Carbons | Spherical | 60 *3 | Ø 30–35 nm [42] | 20 [40] *2 | 1000 [42] | 100–400 [42] |

| Sample | Gauge Factor (Neutral Plane Zone) |

|---|---|

| CNT (5 wt.%) | 650 |

| GNP (5 wt.%) | 670 |

| CB (10 wt.%) | 390 |

| Sample | Et [MPa] | σB [MPa] | εB [%] |

|---|---|---|---|

| GF/PP, transversal | 4399 ± 74 | 24.7 ± 0.6 | 1.2 ± 0.1 |

| GF/PP + CNT fibre, transversal | 4176 ± 54 | 24.3 ± 0.7 | 1.1 ± 0.1 |

| GF/PP + GNP fibre, transversal | 4291 ± 66 | 24.4 ± 0.6 | 1.0 ± 0.1 |

| GF/PP + CB fibre, transversal | 4172 ± 119 | 24.5 ± 0.8 | 1.1 ± 0.1 |

| GF/PP, longitudinal | 36,923 ± 1279 | 1201 ± 51 | 5.4 ± 0.4 |

| GF/PP + CNT fibre, longitudinal | 38,251 ± 1622 | 1164 ± 80 | 5.3 ± 0.4 |

| GF/PP + GNP fibre, longitudinal | 40,283 ± 683 | 1188 ± 79 | 4.9 ± 0.5 |

| GF/PP + CB fibre, longitudinal | 41,676 ± 562 | 1250 ± 26 | 5.0 ± 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Müller, M.T.; Eichhorn, K.; Gohs, U.; Heinrich, G. In-Line Nanostructuring of Glass Fibres Using Different Carbon Allotropes for Structural Health Monitoring Application. Fibers 2019, 7, 61. https://doi.org/10.3390/fib7070061

Müller MT, Eichhorn K, Gohs U, Heinrich G. In-Line Nanostructuring of Glass Fibres Using Different Carbon Allotropes for Structural Health Monitoring Application. Fibers. 2019; 7(7):61. https://doi.org/10.3390/fib7070061

Chicago/Turabian StyleMüller, Michael Thomas, Kristina Eichhorn, Uwe Gohs, and Gert Heinrich. 2019. "In-Line Nanostructuring of Glass Fibres Using Different Carbon Allotropes for Structural Health Monitoring Application" Fibers 7, no. 7: 61. https://doi.org/10.3390/fib7070061

APA StyleMüller, M. T., Eichhorn, K., Gohs, U., & Heinrich, G. (2019). In-Line Nanostructuring of Glass Fibres Using Different Carbon Allotropes for Structural Health Monitoring Application. Fibers, 7(7), 61. https://doi.org/10.3390/fib7070061