1. Introduction

Separation of olefin/paraffin mixtures is one of the key tasks for the petrochemical industry, since olefins are used as precursors to produce numerous chemical compounds and materials, i.e., amines, aldehydes, alcohols, cycloalkenes, polyolefins (among which polyethylene, polypropylene, and poly methyl pentene are the most prominent), etc. [

1,

2,

3]. The conventional technology employed for this separation is a cryogenic distillation, but given the close boiling temperatures of the components, tall towers with high reflux ratios are needed [

4,

5]. Therefore, cryogenic distillation is viable only for separation of streams containing large quantities of olefins—e.g., for downstream from large-scale catalytic cracking plants [

6]. Other separation technologies such as extractive distillation and physical adsorption exist, but they are also expensive and energy-consuming [

7].

Currently, membrane technologies are widely used for olefin-paraffin separation. They possess a number of advantages and provide means for reducing operational costs on average by four times compared to distillation processes [

8]. One of the techniques employed for this purpose is membrane gas separation using nonporous membranes [

9,

10,

11]. The technique is based on the difference between the diffusion rates of olefins and paraffins in membrane materials. However, the industrial application of gas separation modules is limited because the sizes of the molecules of olefins and paraffins are very close [

9,

10]. In order to increase the separation selectivity and permeability of the target component, researchers were developing schemes employing liquid membranes, i.e., a solvent mixture immobilized in the pores of support membrane (facilitated olefin transport mechanism) [

12,

13,

14,

15,

16]. Nevertheless, despite numerous attempts to enhance the process design, the main disadvantage of such systems is poor stability over time, which leads to degradation of the solvent and drying-out of the membranes within several days [

17].

One of the most promising approaches to olefin/paraffin mixtures separation is gas-liquid membrane contactor. In this case, a membrane does not possess selective properties, it acts as an interface between the gas and liquid phases [

18,

19]. The main advantages of membrane contactors are the high specific surface area, the possibility of independent control of gas and liquid flows, and small equipment sizes [

20]. Olefin/paraffin separation in gas-liquid membrane contactor is performed employing liquid absorbent capable of reversible chemical interaction with only one component of the mixture (with olefin) [

17,

21,

22,

23]. These absorbents are usually solutions of transition metals salts, which interact reversibly with the double bond of olefin molecule (silver, copper; less commonly—platinum, palladium, and mercury) [

24]. The ability of a transition metal to act as facilitator strongly depends on the strength of π-complexation between metal and olefin, which is determined primarily by the electronegativity value of the respective metal [

25]. The most studied absorbent for olefin/paraffin separation is aqueous silver nitrate (AgNO

3) solution [

26,

27,

28,

29]. Copper (Cu (I)) solutions were also studied, but in copper-based systems, olefin desorption takes place at higher temperatures than in the case of silver [

30].

Recently, it has been proposed to use a novel type of absorbents—solutions of metal salts in ionic liquids. Ionic liquids are salts with melting temperature less than 100 °C. They are comprised of a bulky organic cation and an organic or inorganic anion. The high potential of ionic liquids in the separation process is accounted by zero vapor pressure which prevents sorbent evaporation in the membrane pores and their clogging by silver nitrate crystals. Other ionic liquids benefits are high chemical stability, a wide range of physical-chemical properties under varying ionic liquid cation or anion, and high olefins affinity [

7,

30,

31,

32,

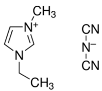

33]. For the purposes of olefin/paraffin separation, imidazolium liquids are widely used: 1-ethyl-3-methylimidazolium dicyanamide ([Emim][DCA]), 1-ethyl-3-methylimidazolium tetrafluoroborate ([Emim][BF

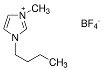

4]), and 1-butyl-3-methylimidazolium tetrafluoroborate ([Bmim][BF

4]) [

34,

35,

36,

37,

38]. These ionic liquids (ILs) are easy to obtain and therefore they are commonly used to solve various technological tasks, including different absorption-based separation processes [

38]. In [

7], one of the most widely used silver salt solutions—silver nitrate—was dissolved in 1-butyl-3-methylimidazolium nitrate ([Bmim][NO

3]); the concentration of AgNO

3 was up to 5 M, thus providing high ethylene absorption values.

In order to decrease mass transfer resistance, it is preferable to use porous hollow fiber membranes. However, such configuration of the process is connected with the problem of membrane wetting and penetration of liquid absorbent in the membrane pores, which in turn increases the membrane resistance and decreases its mass transfer properties [

39,

40,

41]. There are the following approaches to avoid this phenomenon:

Employment of hydrophobic membranes or surface hydrophobization of the membranes [

42,

43];

Employment of composite membranes with a thin nonporous layer facing the absorbent [

44,

45,

46];

Selection of liquid absorbents with surface tension enough to prevent pore wetting [

31,

47].

In the present work, ethylene separation from a model mixture with ethane is implemented using silver salt solutions in ionic liquids as liquid absorbent. In order to avoid penetration of absorbent into the gas phase, we propose to use polysulfone hollow fiber membranes hydrophobized via impregnation by perfluorinated acrylic copolymer.

2. Materials and Methods

2.1. Materials

The main membrane polymer used was polysulfone (PSf) Ultrason® S 6010 purchased from BASF (Ludwigshafen, Germany); N-methylpyrrolidone (NMP) 99% extra pure (Acros Organics, Geel, Belgium) was used as a solvent, and polyethylene glycol (PEG) with average molecular weight 400 g/mole (Acros Organics, Geel, Belgium) was used as pore-forming additive.

Surface modification of membranes was performed using perfluorinated acrylic copolymer Protect Guard® (Guard Industrie, Montreuil, France).

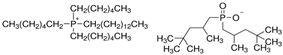

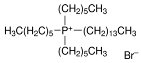

The ionic liquids studied were purchased from Sigma Aldrich Chemie GmbH (Saint Louis, MO, USA): 1-ethyl-3-methylimidazolium dicyanamide ([Emim][DCA], Aldrich #713384), 1-ethyl-3-methylimidazolium tetrafluoroborate ([Emim][BF4], Aldrich #711721), 1-butyl-3-methylimidazolium tetrafluoroborate ([Bmim][BF4], Aldrich #711748), trihexyltetradecylphosphonium bromide ([P66614][Br], Aldrich #96662), trihexyltetradecylphosphonium bis (2,4,4-trimethylpentyl)phosphinate ([P66614][Phos], Aldrich #28612).

Table 1 lists their chemical structures and physical/chemical properties [

48]. Also, the following silver salts were studied: silver nitrate (chemically pure, AgNO

3 content 99.9%, Chimmed, Moscow, Russia) and silver tetrafluoroborate (chemically pure, AgBF

4 content 99.9%, Sigma Aldrich Chemie GmbH, Saint Louis, MO, USA).

Ethylene (99.9%) and ethane (99.9%) were purchased from JSC “Moscow’s Gas Refinery Plant” (Moscow, Russia).

2.2. Fabrication of Hollow Fiber Membranes

Asymmetric porous hollow fiber PSf membranes were fabricated using lab-scale hollow fiber spinning setup via phase inversion technique described in details elsewhere [

49]. The spinning solution consisted of PSf, NMP, and PEG in ration 1.0:2.4:0.8, respectively, and was filtered and degassed prior to membrane fabrication. The bore liquid used was distilled water at 70 °С. The air gap length was 1 m; the spinneret ring sectional area was 1.77 mm

2. The membranes after spinning were washed consequently in distilled water, ethanol and n-hexane and then dried at ambient conditions for 24 h.

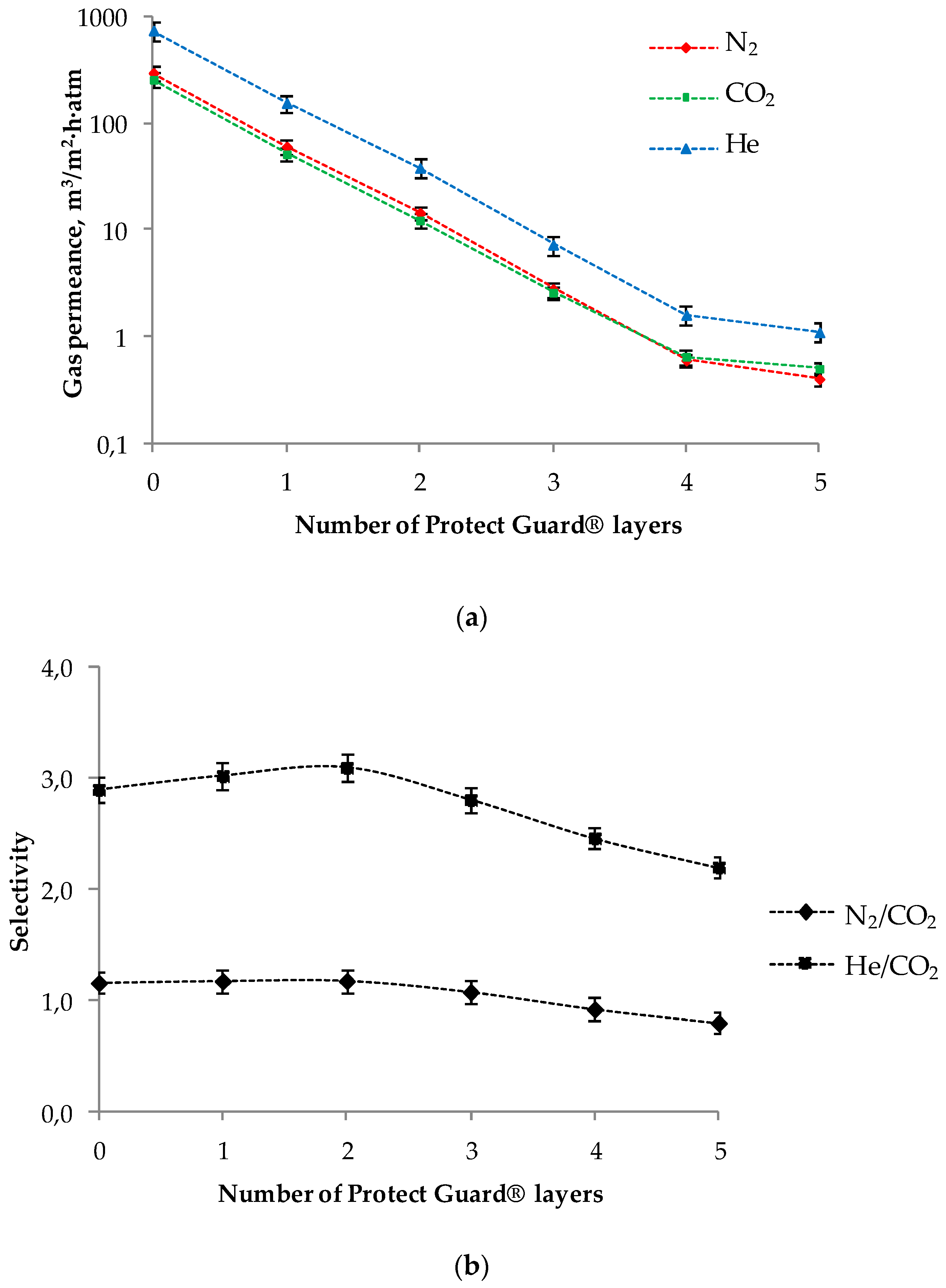

2.3. Membrane Modification

Surface modification of asymmetric porous hollow fiber PSf membranes was performed through deposition of perfluorinated acrylic copolymer Protect Guard® on the lumen surface of the fibers. A hollow fiber was fixed in a polypropylene housing, then the module was connected to the dosage device (syringe), and 10 mL of liquid Protect Guard® were pumped through the fiber. After the treatment, the module was dried for 24 h under a permanent stream of air flowing through the fiber lumen side (air flow rate—10 mL/min). According to the described procedure, the fibers were covered by 1 to 5 layers of modifying liquid.

2.4. Membrane Characterization

2.4.1. Gas Permeance of Hollow Fibers

Gas permeance of the membranes was measured for nitrogen, carbon dioxide and helium using the constant pressure/variable volume method, on a laboratory setup described in [

49]. The feed pressure was 0.5–2 bar, the permeate pressure was atmospheric. All experiments were carried out at room temperature (23 ± 2 °C). The molecular mass difference of these gases allows detecting the Knudsen flow regime based on ideal selectivity value (individual gases permeance coefficients ratio). Gas permeance of the membranes was calculated as follows:

where

Q is the volumetric flow rate of the gas passed through the membrane, m

3/h;

p is the transmembrane pressure, atm; and

S is the membrane area, m

2.

As a result, the value of P/l (m3/(m2∙h∙atm)) was obtained.

Ideal selectivity value

α was determined according to the equation:

where

Р1 and

Р2 are the permeance values for the respective gases.

2.4.2. Surface Properties of the Hollow Fibers

Contact angle values were measured via the conventional sessile drop technique using the LK-1 goniometer (RPC OpenScience Ltd, Moscow, Russia). To determine the surface properties of unmodified and modified membranes and to find their surface energy values, water and ethylene glycol (Chimmed, Moscow, Russia) were used as test liquids. Furthermore, the membrane contact angle values were determined for chosen ionic liquids and silver salt solutions in ILs. All measurements were performed at room temperature (23 ± 2 °C). The contact angle value was determined as an arithmetical mean for three measurements. For image capture and digital processing of the drop images, the DropShape

® software (Version 1.0, RPC OpenScience Ltd, Moscow, Russia) was used providing Laplace-Young contact angle calculation. Membrane surface energy value was determined according to the Owens-Wendt method [

50]. This technique allows calculating the surface energy value

γ as a sum of polar

γp and

γd dispersive components using two different liquids. The relation between surface energy and equilibrium contact angle of the liquid phase placed onto solid phase is derived from the Fowkes equation [

51]:

where

d and

p subscripts relate to the dispersive and polar components of the liquid surface energy (

γl) and the membrane surface (

γs).

We used water and ethylene glycol as test liquids, as surface energy components of both these liquids are well known and widely described in the literature [

52,

53].

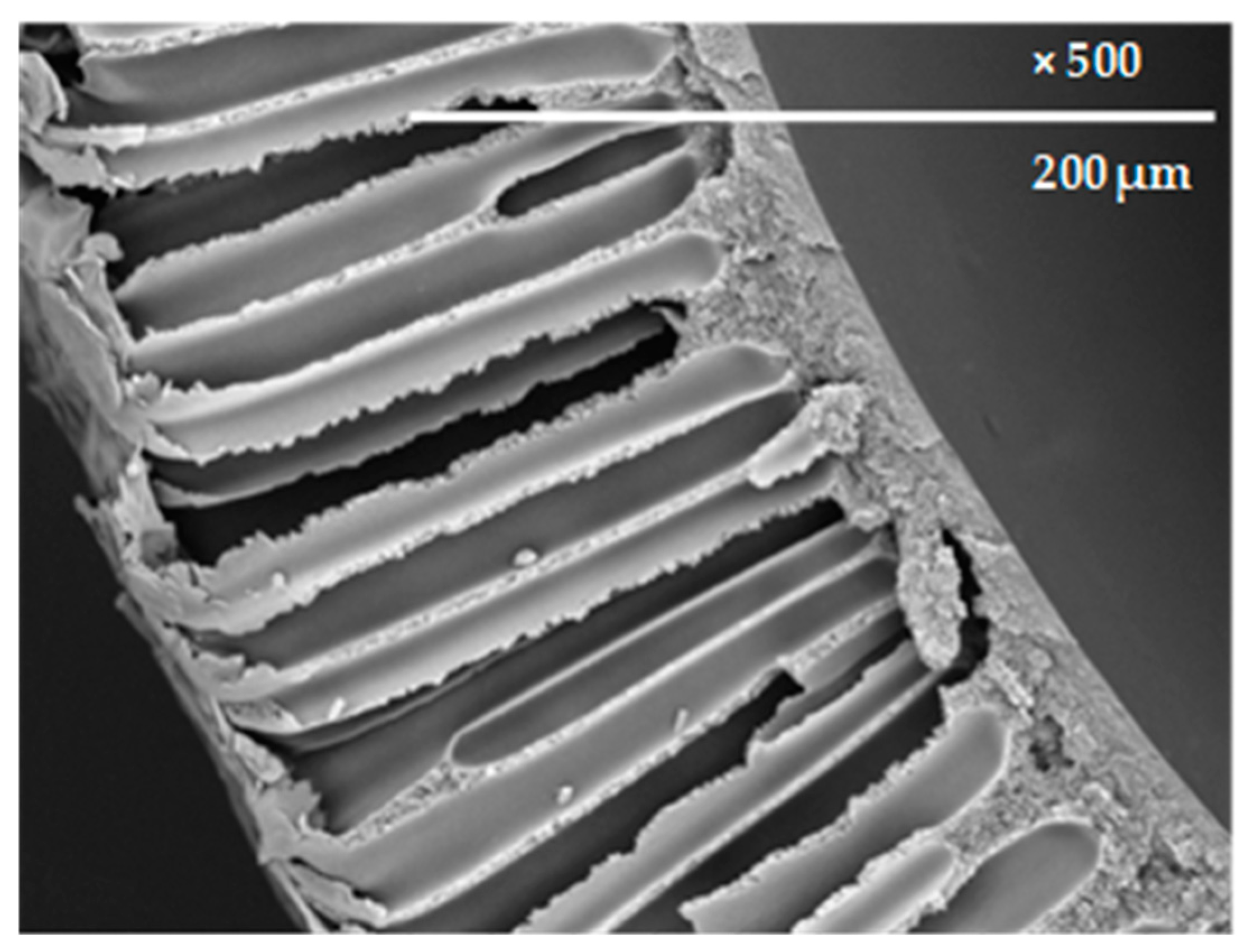

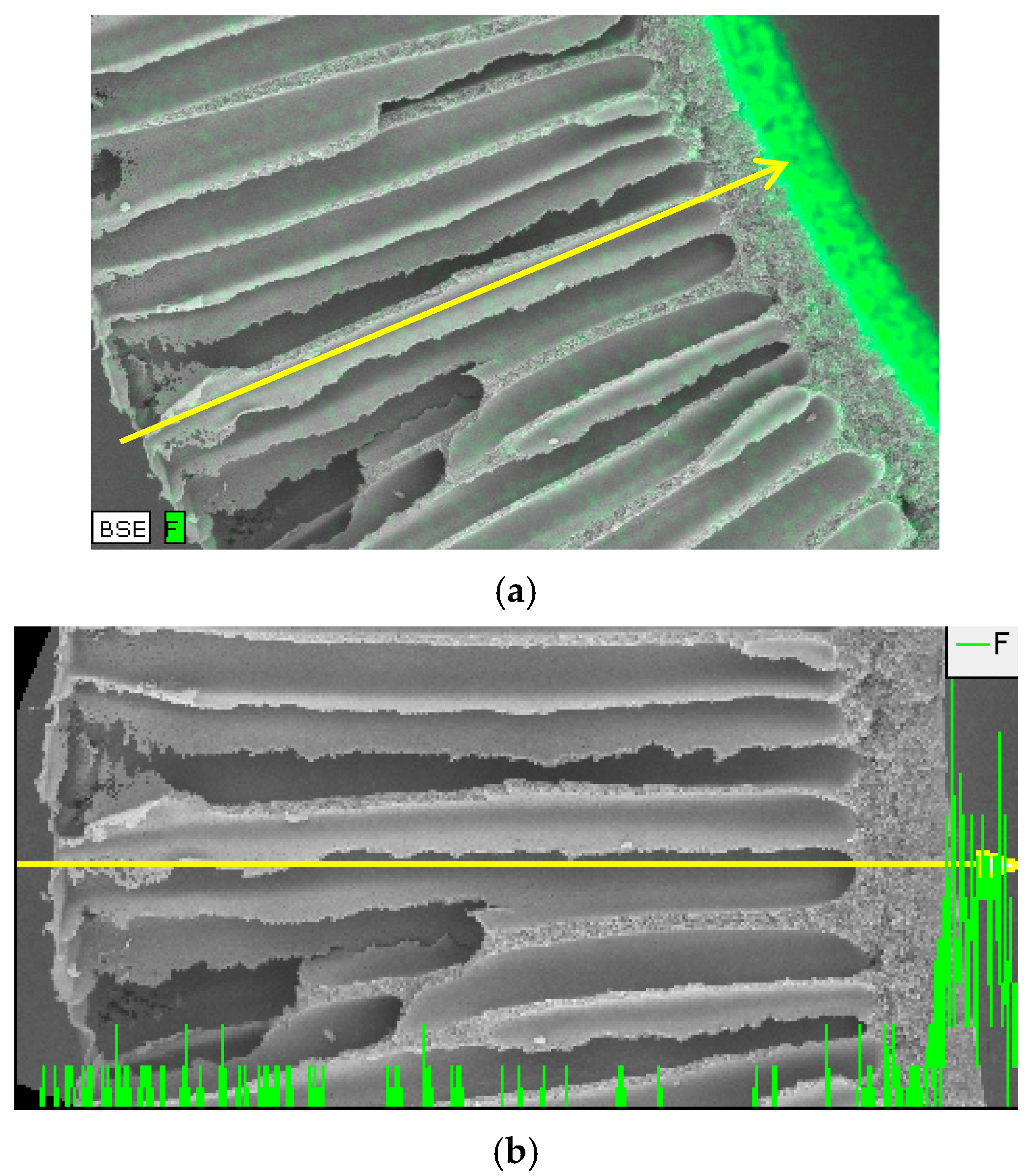

2.4.3. Scanning Electron Microscopy and EDXS Analysis

Cross sections and inner surface specimens of the hollow fiber membranes (both unmodified and modified) were studied via the scanning electron microscopy technique using Hitachi Table-top Microscope TM 3030 Plus with proprietary highly sensitive low-vacuum secondary electron detector (Hitachi High Technologies America Inc., Greenville, SC, USA), accelerating voltage was equal to 15 kV. For dispersive X-ray (EDXS) measurements, Bruker Quantax 70 EDXS system (Version ESPRIT 2, Bruker Ltd., Moscow, Russia) was used. Prior to image capture, the fibers were coated with gold (5 nm particles) by vacuum sputtering. The SEM images were processed with the Quantax 70 Microanalysis software (Version ESPRIT 2, Bruker Ltd., Moscow, Russia).

2.5. Dense PSf Membrane Preparation

The PSf pellets were exposed in a vacuum oven at 90 °C for 24 h in order to remove absorbed particles (e.g., water). After this procedure, the pellets were dissolved in chloroform under constant stirring by a magnetic stirrer for 4 h until the transparent solution with PSf content 1 wt. % was formed. The solution was filtered through filtering paper in nitrogen medium at 0.2 bar pressure. The transparent PSf films of ~70 µm width were fabricated by casting polymer solution onto the cellophane support with following slow evaporation of chloroform at room temperature for 7 days to constant weight.

2.6. Measurements of IL Sorption and Swelling in Dense PSf Membranes

The specimens of dense PSf membranes (films) with known size and weight were placed into pressurized vessels containing ILs studied and exposed under room temperature for 150 h. After the films were removed from the liquids, they were blotted with filtering paper in order to remove residual IL, and then the specimen weight and dimensions were determined. ILs sorption in PSf was calculated as

where

m is the weight after exposure in IL,

m0 is the initial weight of the specimen.

Polymer swelling degree (

SD) was calculated as:

where

d10,

d20 and

l0 are the dimensions and width of the initial sample;

d1,

d2 and

l are the dimensions and width of the sample after exposure in IL.

2.7. Preparation of Liquid Absorbents Based on ILs

Silver salts (AgBF

4 and AgNO

3) were dissolved in ionic liquids listed in

Table 1 to concentration 0.2; 0.5; 0.9 and 1 M. All solutions were stirred for 24 h. The presence of opaque precipitates was checked visually. The resulting solutions were used to determine contact angle values for unmodified and modified membranes.

2.8. Ethylene/Ethane Separation in Membrane Contactor

The parameters of membrane contactor module are given in

Table 2. The module was comprised by three hollow fibers placed into a stainless steel pipe with hot-melt end seals.

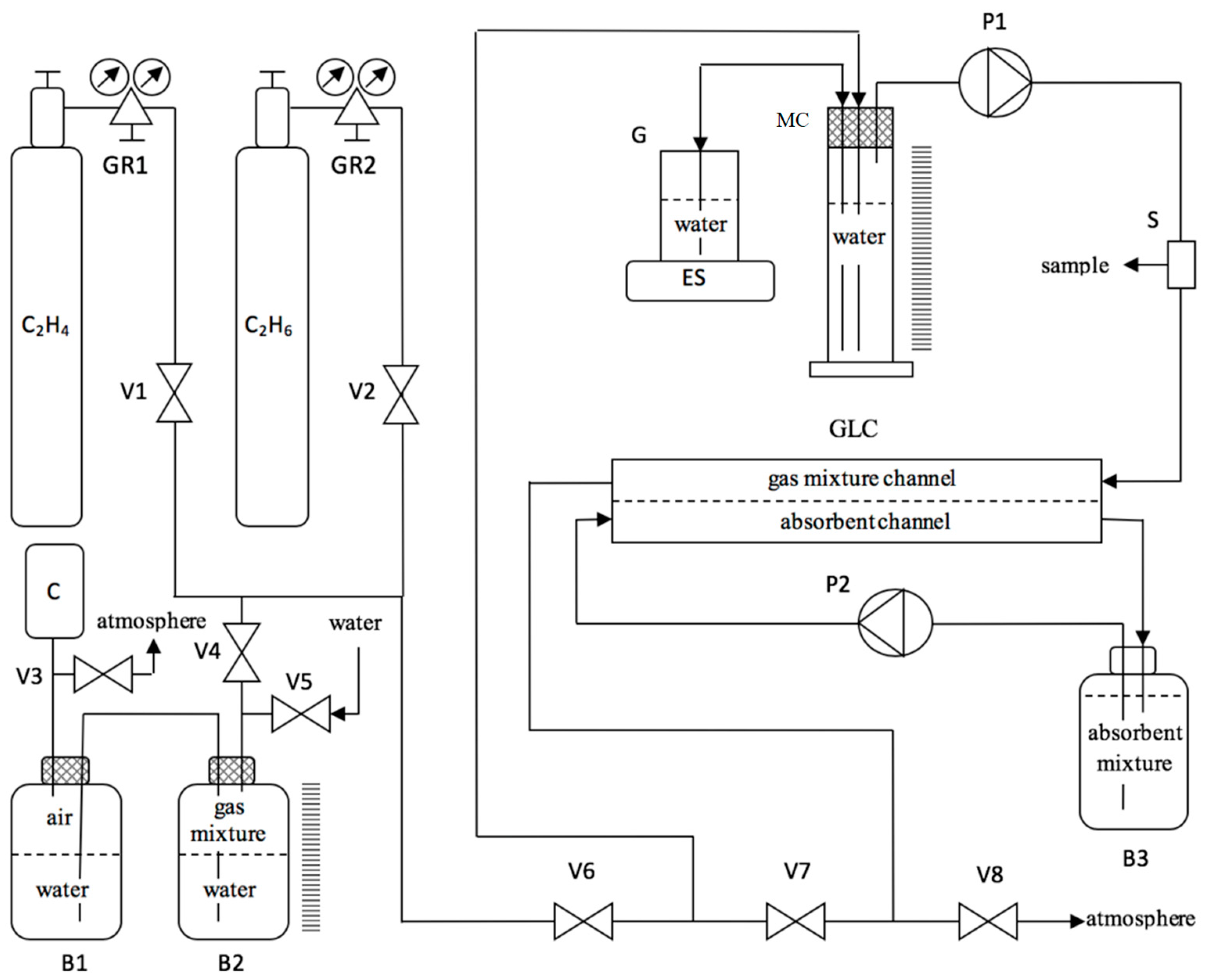

Gas-liquid membrane contactor experiments were carried out using the laboratory setup shown in

Figure 1. Initial gas mixture volume was 270 mL, ethylene to ethane ratio in the mixture was 4:1, respectively. Liquid absorbent (500 mL) was put into the fibers lumen using peristaltic pump LS-301 (JSC “LOIP”, St. Petersburg, Russia). The experiments were performed at room temperature.

The experiments were carried out as follows: reservoir B3 was filled with water through valve V5 until water appeared in reservoir B2. After that, the outlet pressure of gas reducers GR1 and GR2 (model RPA1, Hy-Lok Corporation, Busan, Korea) was preset to 0.5 bar. A calculated amount of ethylene was brought into reservoir B2 using valves V1 and V4, and the respective volume of water passed from reservoir B2 to reservoir B1. Then, peristaltic pump P1 was turned off and valve V8 was closed, followed by the opening of valves V4 and V6, in order to put the preset volume of the gas mixture into measuring cylinder MC, using compressor C Schego Optimal (Schego, Leipzig, Germany). After that, the compressor C was turned off and valves V4 and V6 were closed. To blow down the gas channel of the contactor (GLC) with the gas mixture from measuring cylinder MC, valve V8 was opened and the peristaltic pump was turned on. After several (3–4) repeating cycles of blow down, valves V6 and V8 were closed, valve V7 was opened, and peristaltic pumps P1 and P2 were turned on. During the whole time of experiments, chromatographic samples were regularly collected from sampler S with simultaneous measuring of decreasing weight of water in glass G, according to the readings of electronic scales ES (model LN420 2CE, Vibra, Moscow, Russia)—in other words, the decrease of gas mixture volume in gas channel of the contactor GLC was measured.

Gas mixture composition during the experiments was analyzed using gas chromatograph Crystallux-4000M with a TCD detector (SDB “Meta-Chrom”, Yoshkar-Ola, Russia). The GC parameters were as follows: injection port temperature was 230 °C, the column temperature was 60 °C, and the detector temperature was 230 °C. The mixtures were analyzed on a Porapak N packed column (Agilent Technologies Inc., Santa Clara, CA, USA). The sample volume was 0.2 mL.

4. Conclusions

In the present work, porous hollow fiber PSf membranes were obtained and their surface was modified by perfluorinated acrylic copolymer Protect Guard®. The membranes were analyzed through gas permeance measurement, SEM and EDXS, and contact angle measurement. Analysis of the data obtained showed that deposition of two layers of the modifying agent onto the lumen surface of asymmetric hollow fiber PSf membranes provides necessary hydrophobicity and the optimal trade-off between gas permeance and porous structure, the latter providing Knudsen gas flow regime. Furthermore, the modification significantly increases the contact angle value for both pure ILs and silver salts solutions in ILs, thus decreasing the probability of membrane wetting and absorbent penetration. The experiments on sorption and swelling confirmed that polysulfone is resistant towards the ionic liquids studied. According to the SEM data, the structure of modified membranes remains the same as in the case of the unmodified membranes, which means that the modifying agent does not affect the membrane morphology. EDXS analysis showed that the modifying agent does not penetrate into the membrane thus being present only on the lumen surface.

The optimal absorbent composition was found—silver salt solution in the ionic liquid, namely, 1 M solution of AgNO3 in [Emim][DCA], since it was possible to dissolve the highest amount of silver salt in this IL, and furthermore, this solution provides the highest contact angle values.

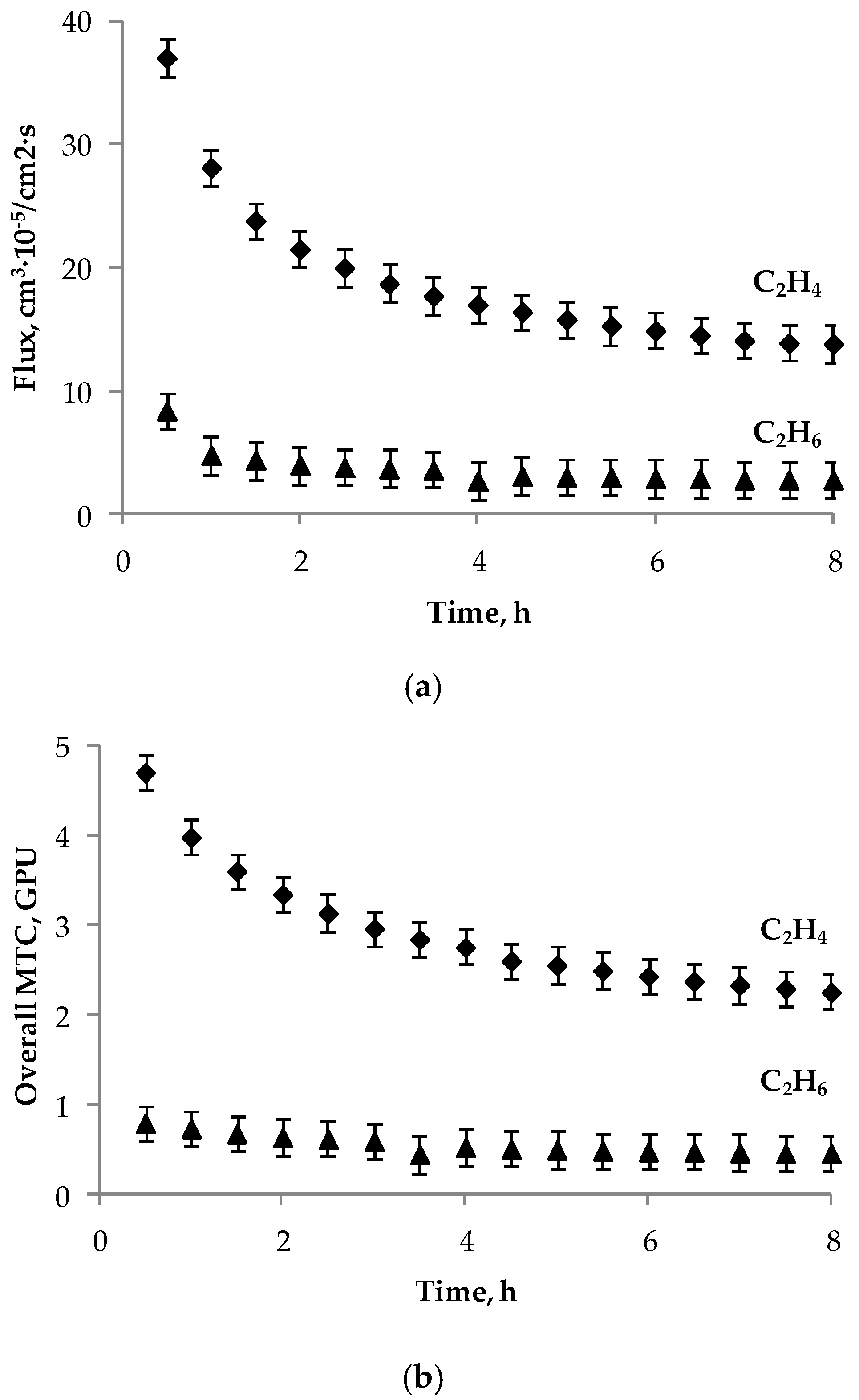

The membranes modified by deposition of two layers of the hydrophobizing agent were employed in ethylene/ethane separation in gas-liquid membrane contactor using 1 M solution of AgNO3 in [Emim][DCA] as liquid absorbent. It was shown that approximately 37% of the initial ethylene volume is absorbed during 8 h of the experiment, given the initial ethylene to ethane ratio 80:20. The mass transfer value differs from 2.2 to 4.7 GPU.