4.1. Compressive Strength

Table 4 shows the average compressive strength of specimens from all mixtures at different ages. The early-age (up to seven days) results generally indicate that the compressive strength of the NFRM markedly improved with the addition of nano-silica, as all values were above 35 MPa even for binders containing 50% slag. For instance, compared to the control specimens without Ns (C-S and CG-BP) and irrespective of the type of fibers included, the compressive strength of the NFRM increased by up to 168% and 108% at three days for mixtures without and with slag, respectively. These results are consistent with the effect of nano-silica on cementitious systems, which effectively contributes to the strength development of cement-based materials through multiple mechanisms, including accelerated pozzolanic activity [

15,

16,

17,

18,

19,

20,

21,

22], filler effect [

20,

21], and water absorption into the high surface area of silica particles/agglomerates (

i.e., reduction of w/b in the paste) [

21]. In addition, the results of the NFRM at 28 and 56 days indicated that there was continuous and significant improvement in strength beyond seven days in comparison to the fiber reinforced mortars without nano-silica, especially for mixtures containing slag. The development of compressive strength for the NFRM containing slag and steel, basalt and hybrid fibers was significantly increased by 82%, 133%, and 140%, respectively between seven to 56 days. It is well-documented that the use of slag as a component of the binder delays the strength and microstructural development of mortar/concrete, especially at higher dosages [

14]. Hence, most building codes (e.g., Canadian Standards Association (CSA) A23.1 [

40]) stipulate that the properties of concrete comprising slag should be evaluated at 56 or 91 days. However, all the NFRM incorporating 50% slag had slightly higher compressive strength than that of corresponding NFRM without slag starting from 28 days (

Table 4). This trend of strength development can be ascribed to the synergistic effects of nano-silica and slag, which improved the kinetics of hydration of this ternary binder [

17].

As mentioned earlier, fibers are added to mortar/concrete mixtures mainly to improve flexural toughness, with an expected marginal contribution to compressive strength [

10]. In this study, the results generally indicated that the NFRM with steel fibers gained relatively higher compressive strength at early and later ages for mixtures without and with slag. For instance, the compressive strength for the NFRM specimens incorporating steel fibers CG-Ns-S at three days was 38% and 22%, respectively, greater than that of the corresponding specimens containing basalt (CG-Ns-B) and hybrid (CG-Ns-BP) fibers. This can be attributed to the higher stiffness (elastic modulus) of steel fibers compared to those of basalt and polypropylene fibers, resulting in better ability to delay formation and propagation of micro-cracks in the matrix and, thus, increasing the compressive strength of mortar. Moreover, the higher aspect ratio of steel fibers (

Table 2) led to improved bonding with the cementitious matrix, which also contributes to the strength development of mortar. On the other hand, by adding polypropylene fibers (29 mm in length) with basalt fibers (13 mm in length), the overall compressive strength of the NFRM containing hybrid fibers was increased by 26% and 13% at three days and 18% and 10% at seven days for mixtures without and with slag, respectively. The reason may be that the longer fibers (polypropylene) have a better bridging effect and pulling-out resistance, which contributed to the strength development of mortar. Additionally, hybrid fibers with different sizes and types offer variable restraint conditions to the lateral expansion of specimens and delay fracture, which can lead to improvement of compressive strength [

33].

Table 4.

Results of compressive strength at different ages.

Table 4.

Results of compressive strength at different ages.

| Mixture ID | Compressive Strength (50 mm Cubes, MPa) |

|---|

| Time (Days) |

|---|

| 3 | 7 | 14 | 28 | 56 |

|---|

| C-S | 19 | 45 | 70 | 70 | 88 |

| C-Ns-S | 51 | 64 | 78 | 89 | 101 |

| C-Ns-B | 34 | 57 | 75 | 84 | 85 |

| C-Ns-BP | 43 | 67 | 74 | 86 | 96 |

| CG-BP | 13 | 33 | 41 | 56 | 80 |

| CG-Ns-S | 33 | 60 | 69 | 91 | 109 |

| CG-Ns-B | 24 | 39 | 64 | 86 | 91 |

| CG-Ns-BP | 27 | 43 | 61 | 88 | 103 |

4.2. Flexural Behavior

Complying with the compressive strength results, all the NFRM exhibited marginally higher flexural strength than that of the control mixtures at 14 days (

Table 5); the increase in flexural strength for the NFRM without and with slag, irrespective of the type of fibers, was up to 10% and 7%, respectively, compared to the control specimens (C-S and CG-BP). This behavior may be attributable to the higher degree of hydration and improved quality of the interfacial transition zone (ITZ) between the aggregate and/or fibers and cement paste as a result of the incorporation of nano-silica in the mixtures [

15,

16,

17], which led to higher tensile capacity at first-cracking (highest point in the

P-δ curve,

Figure 1). The marginally lower flextural strength for the NFRM containing slag relative to the corrsponding mixtures without slag at 14 days can be linked to the slower kinetics of hydrtion of slag [

14] and the significant reduction of the cment (clinker) factor to 50%. However, as discussed earlier in the compressive strength section, the difference in strength development between binders without and with slag diminished at 28 days owing to the effect of nano-silica on catalyzing the hydration of slag. A similar catlytic effect of nano-silica on the pozzolanic reactivity of Class F fly ash have been observed in other studies [

15,

16].

Fibers enhance the ductility of brittle materials such as mortar/concrete, and this improvement is strictly related to the process by which the load is transferred from the matrix to the fibers and the crack-bridging and arresting actions of fibers.

Table 5 provides the results of the toughness indices

I5,

I10, and

I30 for all the mixtures. The results generally indicate that the energy absorbed by the NFRM markedly improved with the addition of nano-silica, even for binders containing 50% slag. Compared to the control specimens without Ns (C-S and CG-BP), the

I5,

I10, and

I30 increased by 45%, 31%, and 49%, respectively, for C-Ns-S specimens and by 43%, 32%, and 53%, respectively for CG-Ns-BP specimens. This trend suggests that nano-silica not only contributes to the pre-cracking behavior by vigorously accelerating the kinetics of hydration and pozzolanic reactions, densifying the matrix, and refining the ITZ with aggregate, as explained earlier, but it also contributes to improving the post-cracking behavior (toughness), likely by enhancing the bond or refining the ITZ between the cementitious matrix and steel or non-metallic fibers.

Table 5.

Results of flexural strength and toughness indices.

Table 5.

Results of flexural strength and toughness indices.

| Mixture ID | Flexural Strength (MPa) | Toughness Indices |

|---|

| I5 | I10 | I30 |

|---|

| C-S | 7.0 | 7.1 | 9.8 | 21.4 |

| C-Ns-S | 7.7 | 10.3 | 12.8 | 31.8 |

| C-Ns-B | 9.1 | 8.1 | 14.7 | 22.5 |

| C-Ns-BP | 6.9 | 2.8 | 3.6 | 6.9 |

| CG-BP | 5.9 | 2.1 | 3.4 | 7.9 |

| CG-Ns-S | 7.3 | 3.7 | 6.5 | 15.9 |

| CG-Ns-B | 7.8 | 4.9 | 8.4 | 13.5 |

| CG-Ns-BP | 6.3 | 3.0 | 4.5 | 12.1 |

As shown in

Table 5, addition of basalt fibers to the NFRM led to a notable increase in the flexural strength. The flexural strength of the NFRM specimens incorporating basalt fibers C-Ns-B and CG-Ns-B was 18% and 20%, and 7% and 24%, respectively, greater than that of the corresponding specimens containing steel and hybrid fibers. This can be ascribed to the higher tensile strength of basalt fibers compared to those of steel and polypropylene fibers (

Table 2), resulting in a higher efficiency in controlling micro-cracking and strengthening the cementitious matrix at the critical location of the prisms (bottom face of the middle-third span), and consequently higher flexural strength. By adding polypropylene fibers with basalt fibers, the ultimate flexural strength of the NFRM containing hybrid fibers was reduced, as polypropylene fibers (0.4% by volume) have lower tensile strength and very low elastic modulus compared to basalt fibers; thus, the role of the hybrid fibers system was probably peculiar to bridging micro-cracks rather than strengthening the cementitious matrix [

8,

9,

33].

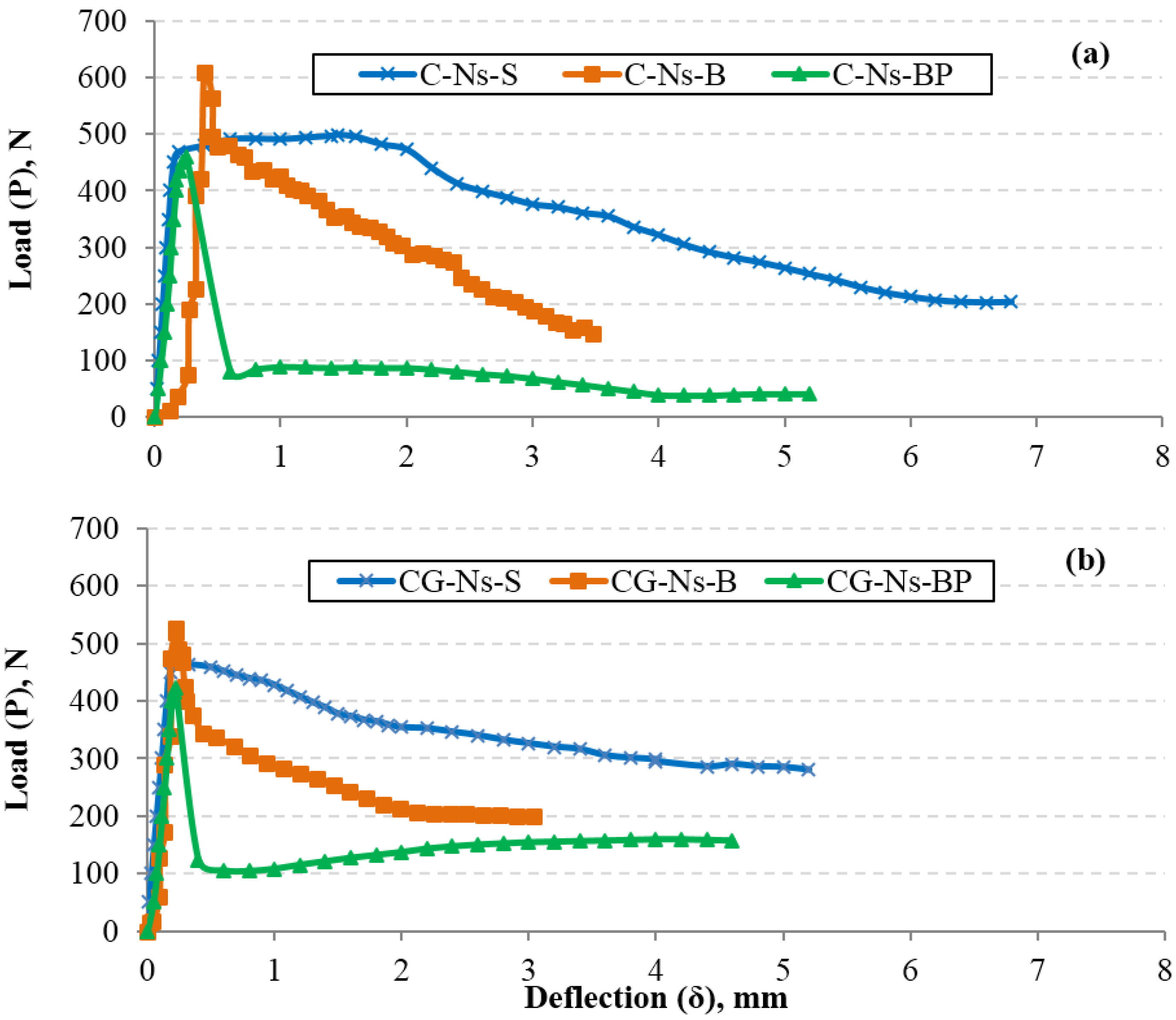

The

P-δ curves for the prisms reinforced with different types of fibers are shown in

Figure 1a,b. Except for the effect on ultimate flexural strength as explained earlier, the type of fibers had little influence on the behavior during the pre-cracking stage, as a comparable elastic portion before the first-cracking was obtained for all the mixtures. The type of fibers, however, had a key role in the post-cracking stage through deformation, fiber deboning and pull-out processes [

2,

33,

34,

41]. Due to the difference in aspect ratio, geometrical shape, material nature and surface property of fibers, the prisms reinforced with different fibers had distinctive post-cracking behavior. The prisms reinforced with steel fibers showed a ductile response after first-cracking (more pronounced in

Figure 1a). The load carrying capacity of the NFRM reinforced with steel fibers continued to increase beyond the limit of proportionality, exhibiting a deflection-hardening process, which is a characteristic of ductile fiber reinforced cementitious composites [

2,

42,

43]. This plateauing, especially for C-Ns-S, continued until reaching higher deflection values in the range of 0.5 to 2 mm. In addition, the NFRM with steel fibers yielded the highest

I30 values for mixtures with, and without, slag. Since steel fibers are much stiffer (much higher elastic modulus) than basalt and polypropylene fibers, they provide better restraint to the propagation of cracks, reduction of the extent of stress concentration at the tip of cracks, and efficiency in bridging macro-cracks and, thus, improving the behavior beyond first-cracking. Additionally, the higher aspect ratio of steel fibers (

Table 2) led to improved bonding with the cementitious matrix [

2,

5], which controlled the trend of load reduction at a slower rate until failure at large deflection values (5–7 mm), which increased flexural toughness.

The results in

Figure 1a,b show that the load-carrying capacity of the prisms incorporating basalt fibers (without or with polypropylene) reduces abruptly at the limit of proportionality. Afterwards, for the NFRM comprising basalt fibers only, there was a gradual decrease in the load until failure at a deflection value of about 3 mm, which is smaller than that of the NFRM incorporating steel and hybrid fibers. For the NFRM with basalt fibers, the decreasing trends were flatter (

Figure 1a,b), indicating that the addition of basalt fibers enhanced the toughness which yielded comparable or higher indices than that of steel fibers, especially for the

I5 and

I10. This may be attributed to the high ultimate tensile capacity for the basalt fibers, the moderate drop (average of 25%) in the peak load after first-cracking, and the moderate stiffness (73 GPa). The ultimate failure of specimens comprising basalt fibers alone at lower deflection values might be due to the small aspect ratio and short length of the fibers. In the case of hybrid fibers and irrespective of the type of binder, the average drop in the peak load was much more pronounced (about 76%), due to the existence of non-metallic (basalt and polypropylene) fibers of lower stiffness in the crack-opening location, which led to a notable increase in the deformation accompanying the drop in the peak load. The trend was magnified in the case of hybrid fibers due to the high opportunity of occurrence of polypropylene fibers (low specific gravity of 0.92) with very low modulus of elasticity (8 GPa) in the critical crack-opening location. However, the existence of polypropylene fibers in this critical location kept the crack-opening intact, as they better redistributed the stress to the right and left sides of the opening owing to the longer development (bonding) length compared to basalt fibers. This argument is substantiated by the notable deflection-hardening trend of the NFRM incorporating hybrid fibers, which is typical of polypropylene fibers [

2,

34,

35]. These specimens failed at higher deflection values (more than 4.5 mm) than that of the corresponding specimens with basalt fibers only. Nevertheless, this positive effect of the polypropylene fibers was mostly offset by the steeper drop in the P-δ curve that occurred after the peak-load and, thus, specimens containing basalt and polypropylene fibers yielded the lowest toughness indices.

Figure 1.

Load-deflation (P-δ) curves of the NFRM reinforced with different fibers: (a) OPC; and (b) OPC/GGBS.

Figure 1.

Load-deflation (P-δ) curves of the NFRM reinforced with different fibers: (a) OPC; and (b) OPC/GGBS.

4.3. Shrinkage

Volume instability (shrinkage) compromises the durability of cement-based materials by introducing direct pathways (cracks) for deleterious substances (e.g., sulfates, de-icing salts), thus impairing the integrity of the matrix. The length change (free shrinkage) can be used as an indicator for the volume instability of mortar/concrete and subsequent potential for cracking. Under dry environments, capillary stress, disjoining pressure, and surface tension are the mechanisms that cause drying shrinkage of hydrated cement paste. Indeed, shrinkage is linked to the features of pore structure in the cementitious matrix [

44,

45].

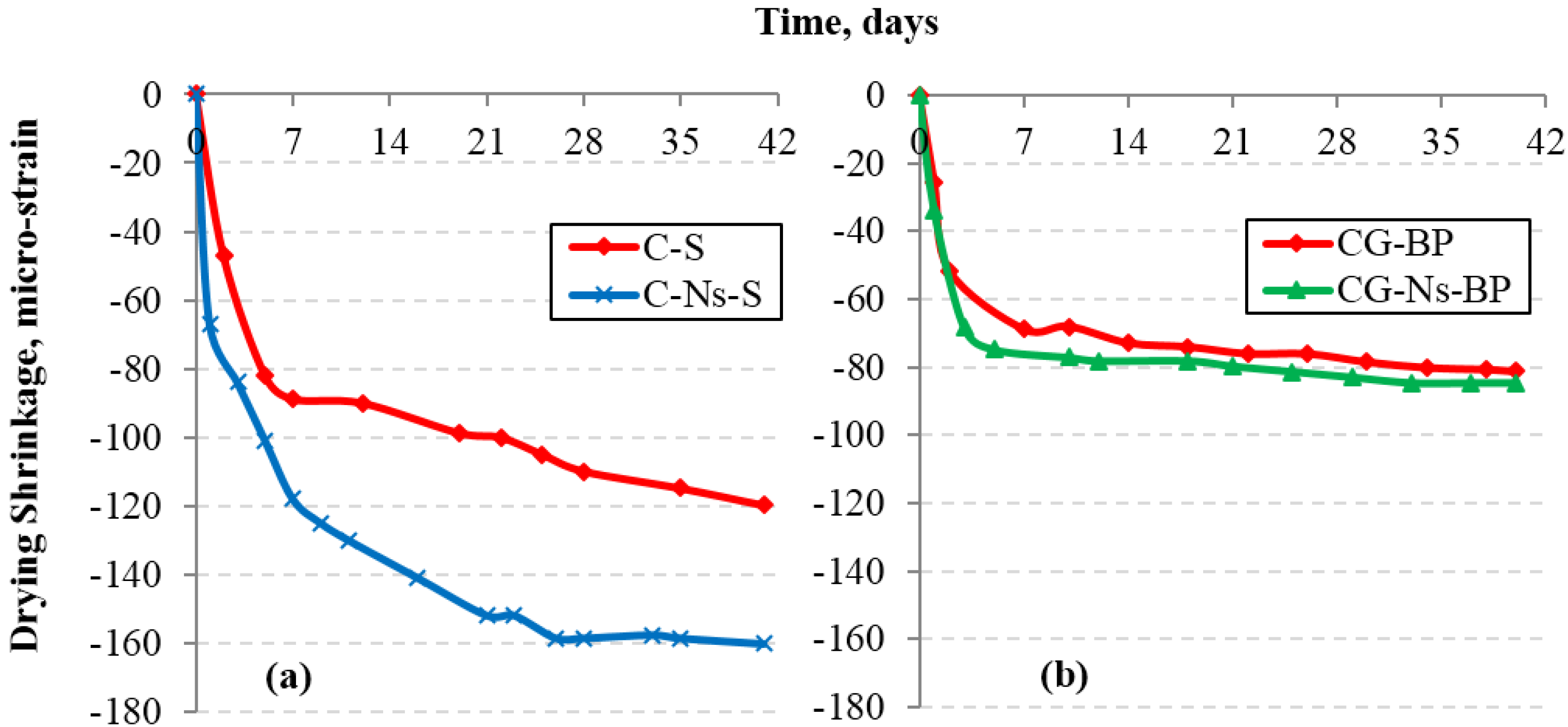

Figure 2 and

Figure 3 show the shrinkage behavior of the NFRM specimens stored at dry conditions for 40 days, which generally reflect small shrinkage values below 200 micro-strain, owing to the role of fibers. However, some distinctive trends among the mixtures were noted as described below.

For mixtures prepared with OPC and reinforced with different types of fibers (

Figure 2a and

Figure 3a), there was a higher rate of shrinkage for the mixtures incorporating nano-silica up to 10 days, which subsequently decreased up to the end of exposure. For instance, at 40 days, the NFRM with steel fibers (C-Ns-S) yielded a higher cumulative shrinkage (an increase of 34%) than that of the control specimens without Ns (C-S). The increase in the drying shrinkage of NFRM might be primarily due to the densification of the matrix as a result of incorporating nano-silica, resulting in increasing the volume of fine pores in the matrix (e.g., [

16,

17,

18]). For instance, Said

et al. [

16] reported that the total porosity and the proportion of micro-pores (less than 0.1 µm) were reduced when up to 6% nano-silica was added to concrete mixtures, due to the pozzolanic and filling effects of nano-silica. It was reported that smaller pores induce higher capillary stress in the matrix upon drying, resulting in higher shrinkage [

44,

45]. Mortars (with and without nano-silica) containing 50% slag and reinforced with different fibers had lower rate of shrinkage, as shown in

Figure 2b and

Figure 3b. For example, the cumulative shrinkage of the NFRM containing slag and steel, basalt, and hybrid fibers was significantly reduced by 23%, 25%, and 26%, respectively relative to that of the corresponding mortar mixtures made with OPC. Previous studies indicated that the amount of drying shrinkage in cementitious systems containing slag is associated with the amount of calcium silicate hydrate produced, and, thus, it may vary with the degree of cement hydration and densification of the matrix [

45,

46,

47]. Thereby, this trend may be linked to the reactivity of slag and the significant reduction of the cement (clinker) factor in these mixtures, which led to discontinuity of the pore structure without excessive refinement, as reported by Zhang

et al. [

18]. This might have reduced the driving force in the capillaries, and consequently lower tensile stress was exerted on the walls of pores [

45].

Figure 2.

Effect of nano-silica on the drying shrinkage of NFRM: (a) OPC; and (b) OPC/GGBS binders.

Figure 2.

Effect of nano-silica on the drying shrinkage of NFRM: (a) OPC; and (b) OPC/GGBS binders.

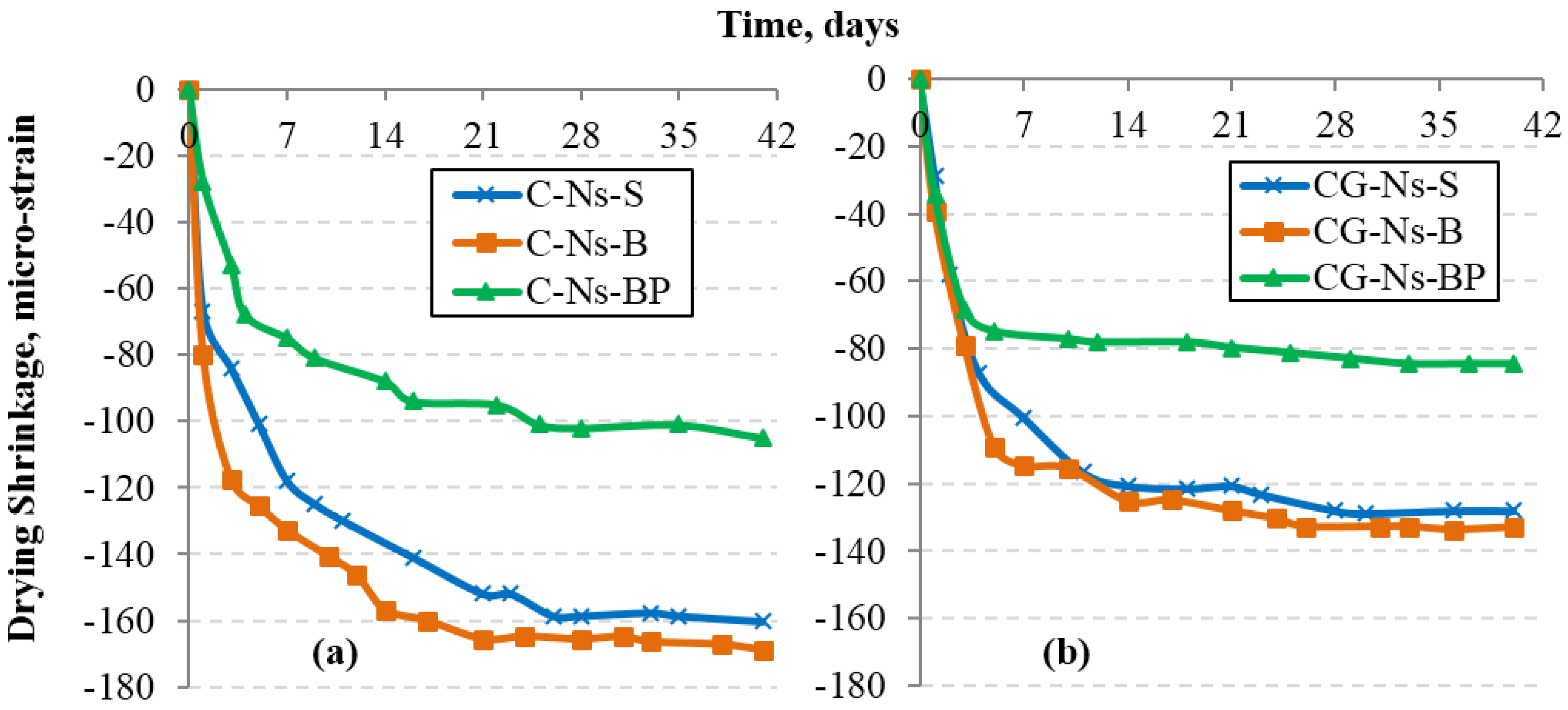

Figure 3.

Drying shrinkage of the NFRM with different types of fibers: (a) OPC; and (b) OPC/GGBS binders.

Figure 3.

Drying shrinkage of the NFRM with different types of fibers: (a) OPC; and (b) OPC/GGBS binders.

The effect of the type of fibers on the shrinkage behavior of the mortar composites is shown in

Figure 3a,b. It was reported that the shrinkage behavior of mortar/concrete is affected by the stiffness (elastic modulus) of the fibers, as well as their size and quantity in the matrix [

48].

Figure 3a,b shows that the NFRM with basalt and steel fibers had the highest cumulative shrinkage of 168 and 161 micro-strain, respectively for mixtures with OPC and 132 and 128 micro-strain, respectively for mixtures containing slag. Comparatively, the NFRM mixtures containing hybrid fibers (0.6% basalt and 0.4% polypropylene) had the lowest shrinkage values of 107 and 87 micro-strain, respectively, for mixtures without and with slag. Perhaps, due to the relatively small specific gravity of polypropylene fibers, they were abundant in the matrix with decreased spacing (

i.e., increased fibers availability), which helped to control stresses and micro-cracks resulting from shrinkage. This observation is in agreement with previous studies [

49,

50], which reported that the use of polypropylene fibers restrained movements at the micro-level in mortar by bridging and stitching micro-cracks. However, this trend diminished in the case of large deformations/strains, such as the post-peak behavior after first-cracking in flexural tests (

Table 5,

Figure 1), which was primarily controlled by the fiber stiffness as discussed earlier.

4.4. Penetrability

A major factor that affects the durability/longevity of cementitious composites is their resistance to the ingress of moisture and aggressive substances. The results of passing charges from the PERMIT test and the corresponding penetrability class according to ASTM C1202 [

38] are listed in

Table 6. According to this classification, all the NFRM, except C-Ns-S, had “very low” penetrability as their passing charges were below 1000 coulombs. Additionally, the results generally indicate that the penetrability of the NFRM markedly reduced for binders containing 50% slag. Compared to the control specimens without Ns (C-S and CG-BP) and irrespective of the type of fibers included, the passing charges of NFRM decreased by up to 45% and 77% for mixtures with, and without, slag, respectively. These results are consistent with the effect of nano-silica on densifying cementitious systems, which effectively contributed to reducing the penetrability of the mixtures through multiple mechanisms (high pozzolanic activity [

15,

16,

17,

18,

19,

20,

21], filler effect [

19,

20,

22], and water absorption [

20,

23]). In addition, the further reduction of passing charges in mixtures CG-Ns-S, CG-Ns-B, and CG-Ns-BP can be ascribed to the synergistic effects of nano-silica and slag, which improved the kinetics of hydration of the binder, even after 14 days of curing, resulting in densification of microstructure and dilution of the pore solution concentration by binding ionic species [

17,

18].

Even though addition of fibers to mortar/concrete has a number of advantages, it was also reported that fibers can increase the intensity of the transition zone in the matrix resulting in increasing its permeability [

7,

8,

9,

10]. From

Table 6, it can be noted that the NFRM specimens containing steel had higher passing charges than that of corresponding specimens comprising basalt or hybrid fibers. The increase in the passing charges in the NFRM with steel fibers may be attributed to the high electrical conductivity of steel fibers. Since the PERMIT is an electro-migration test, conductive steel fibers influenced the bulk resistivity of the specimens, which might give misleading conclusions about the penetrability of specimens. However, this was not the case in the present study as the mixtures containing steel fibers and nano-silica without or with slag had “low” and “very low” penetrability classes, respectively. From the results in

Table 6, it can be noted that significant reduction of penetrability obtained by reinforcing the mixtures with hybrid and non-metallic fibers. For instance, the passing charges of the NFRM specimens incorporating hybrid fibers C-Ns-BP and CG-Ns-BP was 78% and 27%, and 56% and 16%, respectively, lower than that of the corresponding mixtures containing steel and basalt fibers. This significant decrease in the penetrability of the NFRM with hybrid fibers may be attributed to a considerable reduction in the occurrence of plastic shrinkage cracks with addition of polypropylene fibers mixed with basalt fibers, as discussed in the shrinkage section. Furthermore, addition of hybrid fibers with different lengths can aid in disrupting/breaking the continuity or interconnectivity of porous channels existing in the system [

8,

9,

50], thus resulting in lower penetrability.

Table 6.

The PERMIT ion migration test results.

Table 6.

The PERMIT ion migration test results.

| Mixture ID | Passing Charges, Coulombs | Chloride Ions Penetrability Class (ASTM C1202) |

|---|

| C-S | 2138 | Moderate |

| C-Ns-S | 1235 | Low |

| C-Ns-B | 880 | Very Low |

| C-Ns-BP | 692 | Very Low |

| CG-BP | 1980 | Low |

| CG-Ns-S | 725 | Very Low |

| CG-Ns-B | 537 | Very Low |

| CG-Ns-BP | 464 | Very Low |

4.5. Surface Scaling

The results of surface scaling due to the combined action of de-icing salt and F/T cycles are listed in

Table 7. The RILEM TC 117-FDC test stipulates that the failure limit of salt-frost scaling is 1500 g/m

2. The results generally indicate that the resistance to salt-frost scaling of the NFRM with different types of fibers markedly improved with the addition of nano-silica, as all the values were in the range of 299 to 715 g/m

2, which is well below the failure limit, even for binders containing 50% slag and in the absence of air entrainment (by adding an air entraining agent to the fresh mortar). It is well-established that air entrainment can significantly enhance the frost resistance of concrete; however, some studies argue that the need for air entrainment in high-strength high-performance concrete is unnecessary owing to the very low porosity and amount of freezable water in the matrix [

51]. For instance, compared to the control specimens without Ns (C-S and CG-BP) and irrespective of the type of fibers included, the reduction in surface scaling of the NFRM was up to 60% and 81% for mixtures without and with slag, respectively. Cementitious systems containing high volumes of SCMs such as slag are vulnerable to surface scaling due to the slow reactivity of hydration and binding of SCMs [

14,

52] (e.g., the control specimens CG-BP had a mass loss of 1576 g/m

2). However, the significantly limited surface scaling of the NFRM containing slag can be attributed to the incorporation of nano-silica in these mixtures, which enhanced the reactivity and binding of slag, as indicated for example by the evolution of compressive strength and reduction of penetrability of these mixtures. According to the glue-spall theory [

53], which employs fracture mechanics to explain the process of salt-frost scaling by the ease of crack propagation into the surface of concrete, the strength and quality of cementitious matrix, especially at the exposed surface, substantially control its resistance to scaling. Results from the PERMIT and surface scaling tests suggest that incorporation of nano-silica in the mixtures led to a dense matrix, further densifying with time as reflected by the evolution of compressive strength (

Table 4) especially for the mixtures containing slag [

17,

18]. This might have discounted the process of crack propagation (especially with the incorporation of fibers) in the surface of samples and, thus, improving their resistance to salt-frost scaling as per the glue-spall theory.

The resistance of cementitious composites to freeze-thaw cycles depends on mixture components and proportions. Fibers have the ability to entrain air and to improve the tensile strength of the composite, resulting in improvement in freeze-thaw durability [

2,

9]. The marginally high surface scaling for the NFRM with steel fibers (

Table 7) relative to the corresponding mixtures with basalt and hybrid fibers can be linked to the balling effect during mixing, which impaired the workability and the finishability of the surface [

35] (e.g., the control specimens C-S had a mass loss of 1248 g/m

2). Nevertheless, this trend diminished in the NFRM specimens owing to the effects of nano-silica without or with slag as explained earlier. Compared to steel fibers, addition of basalt fibers alone to the NFRM led to a notable resistance to surface scaling. This can be ascribed to the higher tensile strength of basalt fibers compared to those of steel and polypropylene fibers (

Table 2), resulting in higher tensile strength for the system (including the surface of specimens), as shown earlier. In addition, the NFRM specimens with hybrid fibers had the lowest mass loss values of 502 and 299 g/m

2, respectively, for mixtures with, and without, slag. This may be attributed to the abundance of polypropylene fibers in the system and the variable length of fibers, which might have helped breaking the continuity of pores and better arrested/controlled crack propagation into the surface of specimens, thus improving the resistance of the NFRM to salt-frost scaling. The latter arguments concerning basalt and hybrid fibers emphasize the significance of the quality of the surface vulnerable to salt-frost scaling, which is in agreement with the glue-spall theory [

53].

Table 7.

The mass loss results after 28 freezing-thawing cycles.

Table 7.

The mass loss results after 28 freezing-thawing cycles.

| Mixture ID | Mass Loss (g/m2) |

|---|

| C-S | 1248 |

| C-Ns-S | 715 |

| C-Ns-B | 636 |

| C-Ns-BP | 502 |

| CG-BP | 1576 |

| CG-Ns-S | 522 |

| CG-Ns-B | 413 |

| CG-Ns-BP | 299 |