Highlights

What are the main findings?

- This study explores the potential of treated hybrid natural fibers as eco-friendly rein-forcements in concrete production. These fibers enhance mechanical strength and durability, control crack formation, shift the failure mode from brittle to ductile, and significantly improve energy absorption capacity compared to conventional concrete.

What are the implications of these findings?

- Uniquely treated hybrid natural fibers offer a breakthrough in concrete pavements, enabling an 11% reduction in thickness while maintaining performance, as validated by the AASHTO 1993 guidelines. This innovation paves the way for more sustainable and cost-effective infrastructure solutions.

Abstract

This research explores the use of treated hybrid natural fibers—wheat straw and bamboo—as reinforcements in concrete for pavement applications. Motivated by environmental and economic benefits, the study investigates how these fibers can enhance the mechanical and durability properties of concrete. Wheat straw fibers, abundant in Ethiopia due to extensive wheat farming, help control micro-cracks and increase the tensile strength of concrete, while bamboo fibers, also locally available, reduce macro-crack propagation and improve concrete toughness. To prepare these fibers, wheat straw was cut to 25 mm in length and bamboo fibers were treated with a 5% sodium hydroxide solution before being cut into lengths of 30, 45, and 60 mm. A concrete mix targeting a cube compressive strength of 30 MPa incorporated 0.1% wheat straw fibers, with varying bamboo fiber contents (0.5%, 1%, and 1.5%) by weight of cement. The results indicate that the uniquely treated hybrid natural fiber-reinforced concrete mix exhibits noticeable enhancements in mechanical properties, with approximate increases of 4.16%, 8.80%, and 8.93% at 7, 28, and 56 days, respectively. Furthermore, the split tensile strength, flexural strength, and durability properties of the concrete were significantly improved by the proposed fiber concentration and length compared to the control concrete mix design. This treatment also shifted the failure mode of the concrete from brittle to ductile and enhanced its energy absorption capacity up to 7.88% higher than that of the control concrete. Based on the AASHTO 1993 pavement design guidelines, this fiber-reinforced concrete reduces pavement thickness by 11% compared to the control concrete while improving post-cracking behavior. This hybrid natural fiber-reinforced concrete presents a promising, sustainable, and eco-friendly alternative for rigid pavement construction.

1. Introduction

Concrete stands as the most prevalent construction material worldwide, playing a pivotal role in a myriad of infrastructure projects, ranging from simple concrete pavement to intricate apartment complexes, dams, bridges, and underground tunnels. One prominent application of concrete in civil engineering is in rigid pavement construction, which highlights its superiority over flexible pavement alternatives due to its durability, capacity to withstand unexpected axial traffic loads, and extended design life with manageable maintenance costs, in addition to its adaptability to diverse environmental conditions. With its remarkable compressive strength, concrete can be molded into various shapes and is capable of withstanding sudden axial loads. However, plain concrete does have its limitations, including brittleness, particularly in areas subjected to tension, limited strain capacity, reduced toughness, and a modest resistance to early-age cracking. These deficiencies often become evident in the form of structural cracks prior to road usage or loading, primarily due to drying shrinkage or volume variation [1].

Presently, researchers are delving into enhancing the toughness of plain concrete by incorporating dispersed fibers during the production of composite concrete. This strategy has proven effective in controlling the formation, propagation, and coalescence of early-age cracks, thereby mitigating the material’s inherent brittleness. Consequently, the integration of fibers has long been recognized as a means to bolster energy-absorbing capacity, toughness, and resilience against early-age cracking, or as a solution for crack arrest [2,3,4].

The utilization of dispersed fibers in concrete serves as a mechanism for crack arrest, thwarting both the initiation and expansion of cracks within the concrete matrix [5]. Its primary application in concrete production, as a building material for various civil engineering projects, has yielded notable enhancements in the mechanical properties of concrete throughout its design life. Moreover, the exploration of natural fibers as an alternative reinforcement in plain concrete has garnered attention due to their environmental and economic advantages, leading to extensive studies by researchers worldwide [6,7,8,9,10,11].

The American Concrete Institute defines fiber-reinforced concrete as a composite material primarily comprising a blend of binder material (such as cement), coarse and fine aggregates, water, admixtures, and short, discrete, and discontinuous fibers. These fibers are added in varying proportions according to the specific mix design for concrete production, ensuring uniform dispersion throughout the mixture for its intended purpose [12].

Natural fibers offer a sustainable alternative to synthetic fibers due to their biodegradability, renewability, and lower carbon footprint. Unlike synthetic fibers such as polypropylene and steel, which are energy-intensive to produce and contribute to environmental pollution, natural fibers like jute, coir, flax, and sisal are derived from renewable plant sources and decompose naturally without causing microplastic pollution [13]. In terms of performance, natural fibers exhibit excellent tensile strength, flexibility, and thermal insulation, making them suitable for eco-friendly composites and soil stabilization [14]. However, they generally have lower durability and moisture resistance compared to synthetic counterparts, which may affect their long-term performance [15]. Nevertheless, advancements in fiber treatment and hybridization techniques have improved the mechanical properties and durability of natural fibers, making them a viable alternative to synthetic reinforcements in various engineering applications. Natural fibers have gained significant attention in material applications due to their sustainability, biodegradability, and cost-effectiveness compared to synthetic fibers. According to Jawaid and Abdul Khalil (2011) [16], natural fibers such as jute, hemp, and flax exhibit low densities and high specific strengths, making them suitable for lightweight applications. However, synthetic fibers like glass and carbon fibers generally possess superior mechanical properties, including higher tensile strengths and moduli [15]. While synthetic fibers offer better durability and moisture resistance, natural fibers tend to degrade over time due to their hydrophilic nature, leading to reduced long-term performance [13]. Despite this, the lower production cost and environmental benefits of natural fibers make them an attractive alternative, especially in applications where high-performance properties are not critical. Additionally, hybrid composites combining both fiber types can optimize mechanical performance while maintaining sustainability [17]. Thus, while synthetic fibers dominate high-strength applications, natural fibers remain a viable choice for cost-effective and eco-friendly materials.

The integration of natural fibers in concrete production offers a pathway towards alternative, eco-friendly materials, promoting sustainability in infrastructure construction. This approach proves economically advantageous due to several factors: the widespread availability of natural fibers, and their ease of handling, flexibility, and cost-effectiveness, factors that have been under scrutiny for several decades. Consequently, natural fibers present themselves as viable alternatives to synthetic fibers for dispersed reinforcement in cement composites, enhancing the mechanical properties of concrete [18,19,20]. Additionally, the overall cost of natural fibers is significantly lower compared to the total cost of cement composites during production, contributing to cost reduction [21,22].

Moreover, natural fibers continue to gain traction for various applications in cementitious compounds due to their sustainability and environmental friendliness, abundant availability, low initial processing costs, recyclability, non-toxicity to humans, low density and weight, and favorable mechanical properties during composite formation [23,24].

One of the primary types of natural fibers, derived from agricultural products such as vegetables and tree stems, is known as plant-based natural fibers. These fibers are categorized based on their origins within plants, namely the skin or bast surrounding the stem, referred to as bast natural fibers, and those obtained from leaves, known as leaf natural fibers. Other classifications include seed fibers from shells or seeds, grass fibers from grass plants, core fibers from plant stalks, root fibers from roots, and fruit fibers from fruit structures [12]. These plant fibers are also referred to as cellulose fibers or lignocellulose fibers, owing to their predominant composition of cellulose and lignin alongside hemicellulose and pectin.

Hemicellulose plays a key role in the thermal degradation and biodegradation of fibers via moisture absorption, while lignin governs the ultraviolet degradation of fibers. Plant-based natural fibers find extensive applications in construction materials, automotive and aerospace interior designs, and sports equipment manufacturing, primarily utilized to reduce self-weight during composite formation [1].

Furthermore, natural fibers demand less energy during production and processing compared to synthetic fibers, as evidenced by a notable comparison stating that the production of jute natural fibers requires only approximately 7% of the total energy needed to produce an equivalent weight of polypropylene synthetic fibers [12]. Additionally, while the production of one ton of polypropylene fibers emits approximately 3.7 tons of carbon dioxide, jute fibers serve as a carbon sink by absorbing CO2 from the environment. However, the hydrophobic nature of natural fibers poses a significant limitation in certain applications, particularly during composite formation [25].

The utilization of natural fibers in cementitious compounds has encountered a significant challenge stemming from their inherent variability, leading to inconsistencies in cementitious concrete materials. This discrepancy arises from several factors:

- Variability in Characteristics: Unlike synthetic fibers manufactured with precise standard specifications, natural fibers derived from plant sources exhibit inherent variations due to factors such as plant species, growth conditions, harvesting methods, and processing techniques. These variations manifest in differences in fiber length, diameter, orientation, and chemical composition, influencing mechanical behavior.

- Heterogeneous Structure: Natural fibers possess a heterogeneous structure comprising cellulose, hemicellulose, lignin, pectin, and extractives. The distribution and arrangement of these components within the fibers vary significantly, along with the presence of defects like knots, voids, and impurities, further contributing to inconsistency.

- Moisture Content Sensitivity: Natural fibers are hygroscopic, absorbing moisture from the environment, leading to fluctuations in weight, dimensions, strength, and stiffness. Variations in moisture content influence bonding between fibers and the matrix in cementitious concrete materials.

- Susceptibility to Degradation: Being biodegradable, natural fibers undergo chemical and biological degradation when exposed to environmental conditions such as temperature, humidity, UV radiation, and microbial activity. This degradation leads to a decline in mechanical properties, diminishing reinforcement effectiveness over time.

The inconsistent behavior of natural fibers poses significant implications for the performance of cementitious concrete materials, affecting properties like tensile strength, flexural strength, and impact resistance. This inconsistency complicates the prediction and control of fiber-reinforced concrete performance in practical applications. To address these challenges, a unique approach involving fiber extraction and surface treatment techniques has been adopted in this study to minimize the variability of natural fibers used as reinforcement in cementitious concrete materials.

1.1. Classification of Natural Fibers

Natural fibers can be categorized into three main groups according to their sources of origin: plant fibers, animal fibers, and mineral fibers, as depicted in Table 1. Among these, plant-based natural fibers hold particular significance. They primarily consist of cellulose, hemicellulose, lignin, and pectin.

Table 1.

Classification of natural fibers [1].

Chemical Composition of Natural Fibers

The primary chemical composition of natural fibers comprises cellulose microfibrils embedded within an amorphous matrix of lignin and hemicellulose. The lignocellulose cell wall can be conceptualized as a naturally occurring composite structure characterized by spirally oriented shapes and various chemical compounds. Plant fibers, in particular, are predominantly composed of lignocellulose, which encompasses cellulose, hemicellulose, and lignin, albeit in varying proportions depending on factors such as plant age, species type, and the specific part of the plant [26,27]. Moreover, geographical location and climatic conditions further influence the chemical composition of natural fibers, reflecting regional variations in plant growth environments. Table 2 outlines the average chemical composition of select plant fibers, with cotton fiber exhibiting the highest cellulose content and coir fiber containing the greatest proportion of lignin.

Table 2.

Chemical composition of some common natural fibers [1].

1.2. Surface Modifications of Natural Fibers

In recent years, researchers have been exploring the potential of natural fibers as replacements for synthetic fibers due to their numerous advantages. However, a significant limitation lies in the hydrophilic nature of natural fibers, which presents challenges such as weak moisture resistance. This inherent property can lead to compatibility issues with various components in composite matrices, as well as poor wettability with hydrophobic polymer composites. Consequently, the interaction and bonding at the fiber–matrix interface are diminished, highlighting the need for the surface modification of natural fibers to enhance their suitability for composite materials [1,12,25,28]. Surface modifications of natural fibers aim to eliminate chemicals and impurities such as lignin, hemicellulose, oil, and wax from the fiber surface. These contaminants can negatively impact fiber performance, affecting mechanical properties and the durability of cementitious composites during application [1]. Therefore, optimizing the surface morphology of natural fibers is crucial for maximizing their benefits in concrete production.

To achieve this, researchers have developed unique fiber preparation and treatment techniques aimed at removing chemicals and impurities prior to incorporating them into concrete, geopolymer concrete, and mortar production for various applications. Numerous studies have employed various treatment methods to enhance the performance of natural fibers in cementitious composite production [1,12,21,29,30]. A comparative investigation [31] was conducted on selected chemical treatments applied to prepared natural fibers, revealing notable mechanical improvements compared to untreated fibers. In the current landscape, various techniques have been adopted to mitigate the hydrophilic nature of natural fibers through surface modification, aimed at enhancing overall fiber performance during composite formation [12,32,33,34]. The microstructures and performances of natural fibers vary depending on the specific chemical treatments employed, including NaOH [35,36,37], HNO3–KClO3 [38], NaClO [39], and Benzoate [40].

Among these methods, alkali treatment stands out as one of the most popular and cost-effective approaches for obtaining high-performance natural fibers in composite production [41]. According to a literature review conducted by [12], sodium hydroxide (NaOH) is a cheap and readily available alkali solution capable of dissolving and removing non-cellulosic substances through a swelling reaction. This process does not entail the observable decomposition of cellulosic fibrils and concurrently increases the surface roughness of the fiber, thereby enhancing bonding between the cement matrix and fiber during composite formation. Furthermore, a comprehensive description of surface treatment techniques and their respective advantages and limitations is provided in Table 3, as elaborated in a detailed analysis [1].

Table 3.

Main advantages and limitations of each treatment technique [1].

1.3. Natural Fibers in Cementitious Composite Production

When considering the chemical properties of widely recognized natural fibers, it becomes apparent that plant-based fibers predominantly consist of cellulose, lignin, hemicellulose, and pectin, alongside smaller quantities of wax, ash, and sugars. These additional components must be removed from the fiber surface prior to their utilization in cementitious composite production. Cellulose stands out as the primary compound responsible for the fiber’s strength, while lignin and hemicellulose contribute to its lower durability. Therefore, it becomes imperative to undertake surface treatment techniques, often involving alkaline solutions, to enhance adhesion between the fiber and the matrix at the interface [42]. Natural fibers find application in various cementitious composite productions, including concrete, mortar, and geopolymers, owing to their numerous advantages, such as abundant availability, sustainability, eco-friendliness, low density, superior specific properties, and lower initial production costs. Leveraging these advantages, numerous studies have reported overall enhancements in concrete performance upon the addition of fibers in cementitious composite production. These improvements encompass enhancements in compressive strength, tensile strength, flexural strength, impact resistance, energy absorption capacity, ductility, and fracture toughness, and a reduction in crack propagation and size, as detailed in Table 4.

Table 4.

Performance enhancements due to addition of natural fibers in cementitious composites.

1.4. Hybrid Fiber-Reinforced Concrete

Fiber-reinforced concrete is commonly conceptualized as a composite material comprising two distinct phases: the concrete matrix phase and the fiber inclusion phase. While both phases play crucial roles in determining the performance of the composite material, the properties and characteristics of the fibers often hold greater significance. These include parameters such as fiber volume fraction, aspect ratio, and mechanical properties [56]. Depending on these factors, reinforcing concrete with a single type of fiber may only lead to limited improvements in the mechanical properties of the composite. Typically, the strengths of individual fibers are maximized while their weaknesses are minimized [57]. However, the concept of hybridization techniques, which involve combining two types of fibers without altering their identities within a single matrix formation, presents an opportunity to enhance the mechanical properties of composite materials by leveraging the potential synergies between different fibers in fiber-reinforced concrete. Numerous researchers have investigated the effects of fiber hybridization on the mechanical properties of concrete, and have concluded that utilizing a combination of fibers with diverse properties can result in a composite with superior mechanical characteristics [58,59,60,61]. According to Benthur and Mindess [62], the advantages of hybrid fiber systems can be summarized as follows:

- To establish a system wherein one type of fiber is smaller, thereby bridging micro-cracks and controlling their growth, consequently enhancing the tensile strength of the composite. Meanwhile, the second type of fiber, larger in size, acts to arrest propagating macro-cracks, significantly improving the toughness of the composite.

- To implement a system where one type of fiber, characterized by greater strength and stiffness, enhances the initial crack stress and ultimate strength. Concurrently, the second type of fiber, possessing increased flexibility and ductility, contributes to improved toughness and strain within the post-cracking zone.

- To establish a system with varying durability characteristics among fiber types. The presence of durable fibers can augment strength and/or toughness over time, while the other type ensures short-term performance during the transportation and installation of composite elements.

1.5. Durability Properties of Fiber-Reinforced Concrete

The durability of fiber-reinforced concrete refers to its capacity to withstand harsh environmental conditions without compromising its original physical and mechanical properties over its intended lifespan of functionality and serviceability. When subjected to severe environmental factors, such as extreme weather conditions, the penetrability of a concrete structure significantly influences its overall performance, particularly under these challenging circumstances [63]. Hence, within concrete technology, ensuring adequate protection for the reinforcements embedded in concrete is paramount. If the concrete lacks the ability to withstand these physical and chemical assaults, it may succumb to damage, leading to structural failure. Therefore, designing fiber-reinforced concrete to exhibit durability is crucial across various applications [64].

2. Experimental Program

2.1. Materials Required and Methods

In pursuit of the study objective, Non-Probability techniques were employed to gather samples from the study area. These samples included crushed coarse aggregate (CSA), sand (fine aggregate), cement (OPC), matured solid bamboo sticks, wheat straw fibers sourced from local farmers in proximity to their crop cultivation areas, and tap water utilized for drinking purposes, all of which were utilized in this investigation.

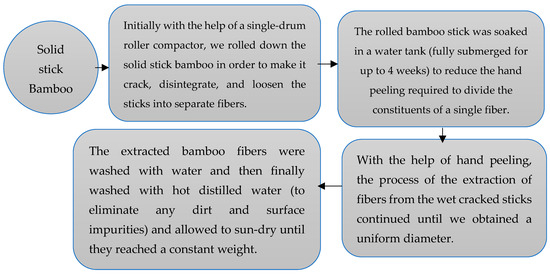

2.2. The Extraction Process of Bamboo Fibers from Solid Bamboo Sticks

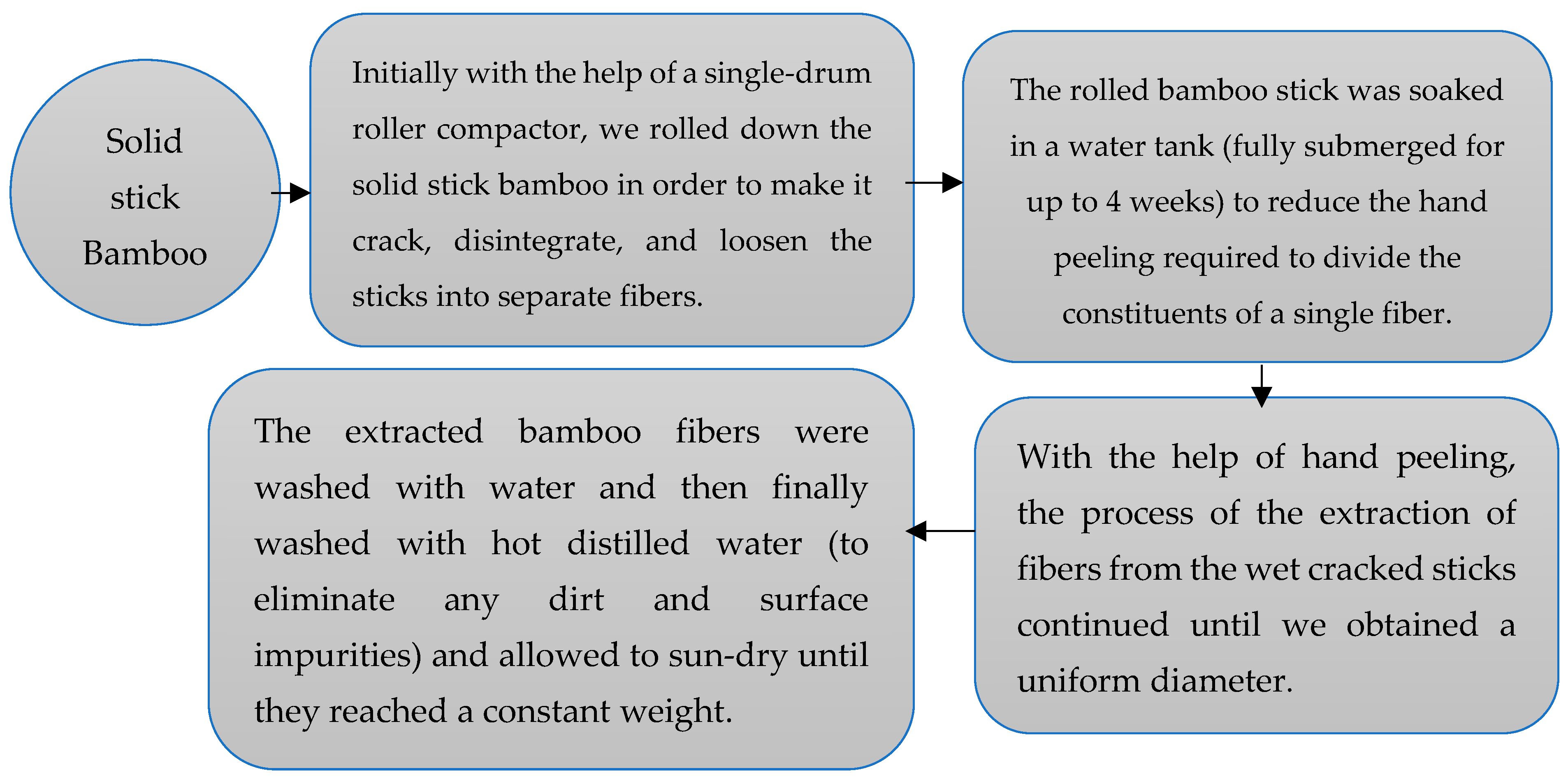

The detailed extraction process of obtaining a single bamboo fiber from a solid stick is illustrated in Figure 1, shown below.

Figure 1.

The extraction process of the bamboo fibers.

2.3. Alkali Treatment Process of Extracted Bamboo Fibers (BFs)

Initially, the extracted bamboo fibers were sun-dried and then cut into lengths of 30 mm, 45 mm, and 60 mm. Subsequently, a surface treatment (modification) was conducted by immersing the bamboo fibers in a 5 wt. % NaOH solution for 24 h at room temperature, due to this treatment’s ability to effectively remove impurities, enhance surface roughness, and improve fiber–matrix adhesion without causing excessive degradation. According to Li et al. (2007) [33] alkali treatment at this concentration efficiently eliminates hemicellulose and lignin, exposing cellulose microfibrils and increasing fiber crystallinity, which enhances mechanical properties. Similarly, Santhiarsa et al. (2024) [65] found that treating natural fibers with 5% NaOH for 24 h resulted in an optimal balance between fiber strength and flexibility, making them more suitable for composite applications. Moreover, Khalil et al. (2012) [66] demonstrated that prolonged exposure to higher NaOH concentrations (>5%) could lead to excessive fiber damage and reduced mechanical integrity. Thus, the selection of 5% NaOH for 24 h was based on experimental evidence showing its effectiveness in improving fiber properties while avoiding excessive weakening, ensuring an optimal balance between fiber strength, surface roughness, and interfacial bonding. The water absorptions of untreated bamboo fiber and 5% NaOH-treated bamboo fiber are 102.243% and 55.741%, respectively [67]. This decrease in water absorption after 5% NaOH treatment due to the introduction of certain functional groups during treatment may also make the fibers less hydrophilic, decreasing their affinity for water.

Following this, the alkali-treated fibers were thoroughly rinsed with distilled water multiple times to eliminate any residual alkali content from the fibers’ surfaces. Finally, the fibers were dried in sunlight until reaching a constant weight. The detailed treatment process is illustrated in Figure 2.

Figure 2.

Treatment process of extracted bamboo fibers.

2.4. Preparation of Naturally Treated Wheat Straw Fibers (NTWSFs)

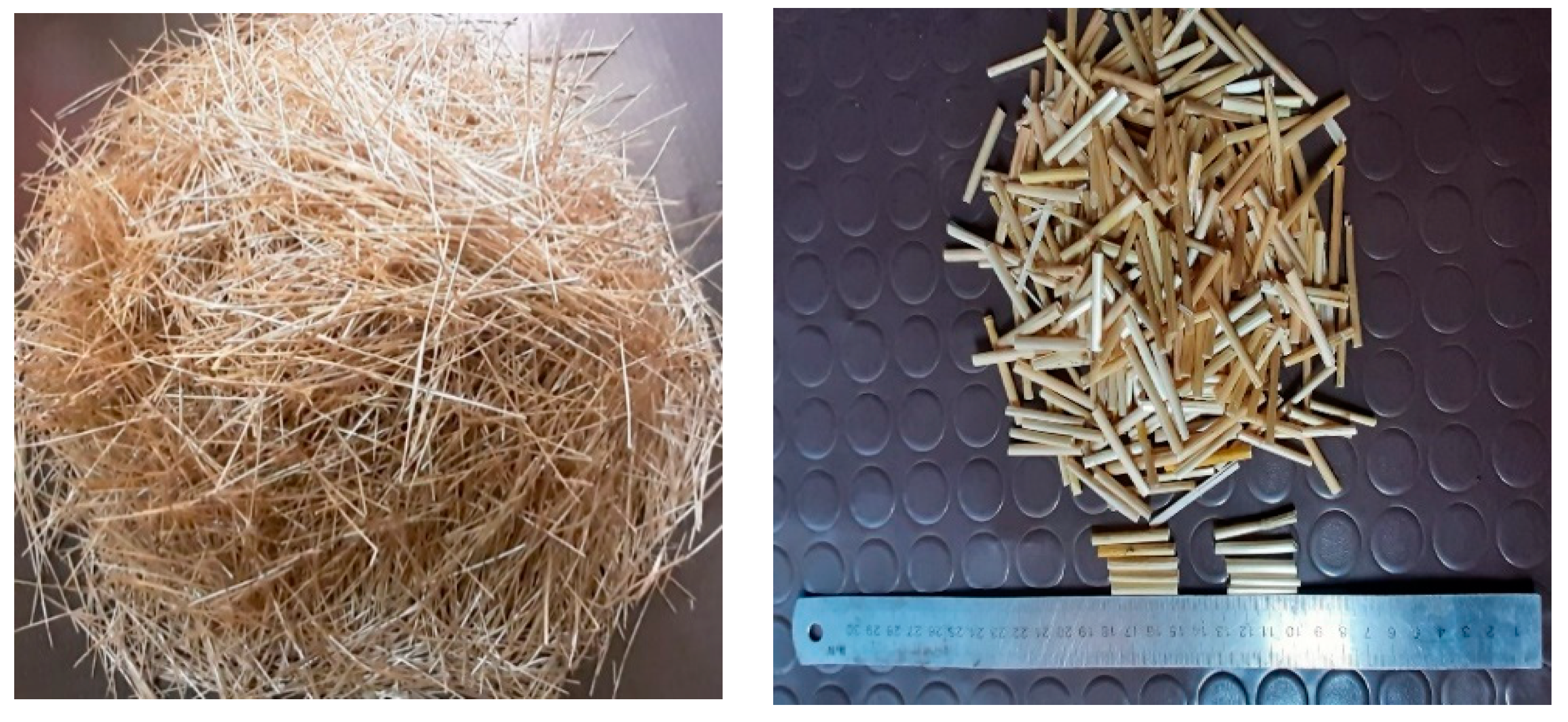

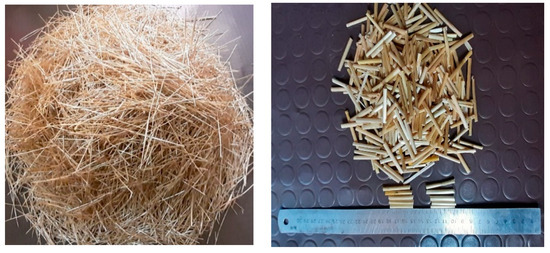

The locally sourced wheat straws were immersed in potable water for approximately 15 to 20 min. The primary objective of this process was to eliminate impurities or dust from the surface of the wheat straws until the water became clear. Subsequently, the wheat straws were left to air-dry. These processed wheat straws are referred to as naturally treated wheat straw fiber [68] and depicted in Figure 3. Finally, the naturally treated wheat straw fibers were cut to approximately 25 mm lengths.

Figure 3.

Naturally treated wheat straw fibers (NTWSFs).

The detailed physical and chemical compositions and the properties of the natural fibers used in this study are shown in Table 5.

Table 5.

Physical and chemical compositions of fibers.

2.5. Physical Property of Materials Used

2.5.1. Crushed Coarse Aggregate

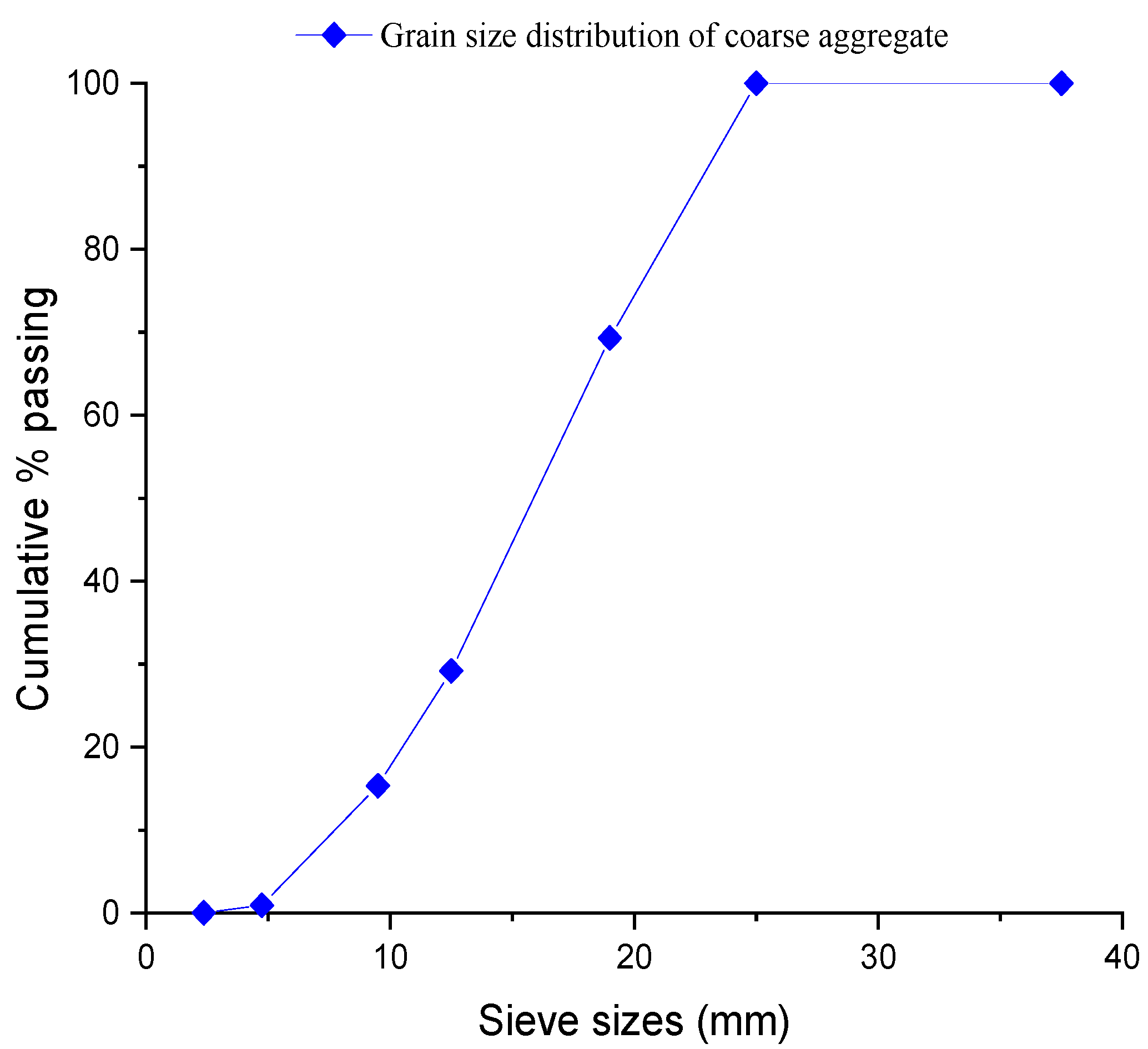

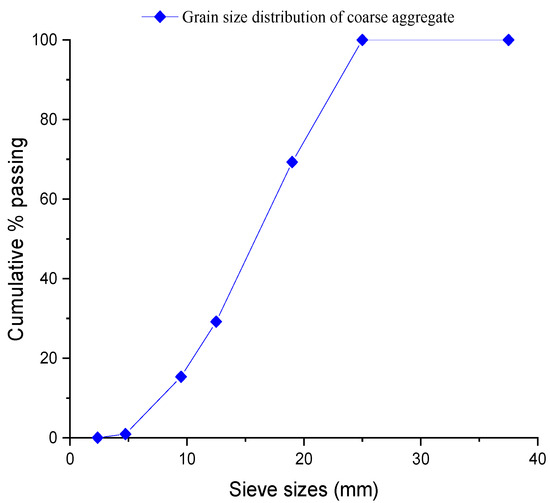

The primary objective of grain size analysis was to ascertain various physical properties, such as the fineness modulus and the relative distribution of particle sizes within the crushed aggregate utilized in this study. This was achieved through the utilization of a standard specified sieve size series, progressing from the largest to the smallest (top to bottom) during the analysis process. For this investigation, crushed stone gravel of basaltic origin was selected for the mix design analysis. This gravel passed through sieve sizes ranging from 37.5 mm to 4.75 mm, as indicated. The maximum nominal size of the coarse aggregate utilized was 20 mm, adhering to the ASTM C 136 standard specification. The grain size distribution curve of the coarse aggregate is presented in Figure 4. Additionally, a comprehensive analysis of the physical properties of the crushed aggregate was conducted in accordance with available standard specifications, ensuring compliance with the minimum requirements for concrete production, as detailed in Table 6.

Figure 4.

Gradation of coarse aggregate.

Table 6.

Physical properties of crushed coarse aggregate used.

2.5.2. Sand

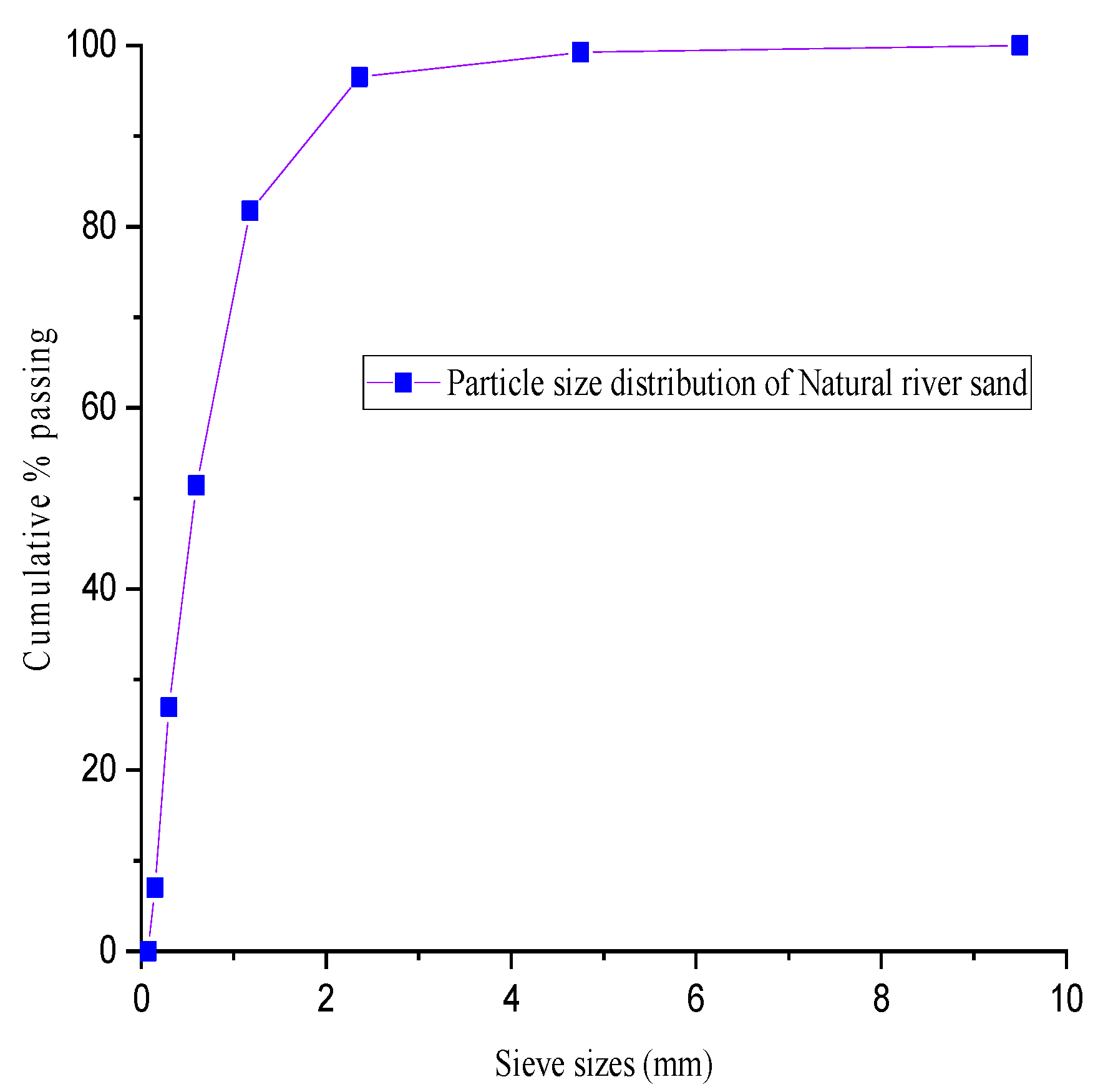

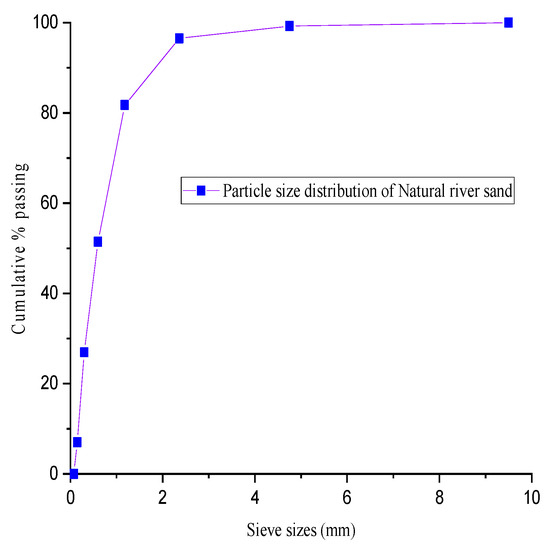

The fine aggregate for concrete production was sourced from the Gambella region in Ethiopia, comprising natural river sand. A detailed overview of the physical properties of this natural river sand from the Gambella region is presented in Table 4. Upon testing, the silt content of the natural river sand was determined to be 3.42%, exceeding the maximum allowable limit stipulated by the ASTM C 33-86 standard specification. Consequently, the river sand underwent a thorough washing process using clear pipe water until its silt content was reduced to 1.00%, thereby meeting the required standard specification for concrete production. The particle size distribution of this fine aggregate was analyzed in accordance with the ASTM C 33 standard specification, ensuring compliance with the specified requirements for concrete production, as delineated in Figure 5 and detailed in Table 7. With a fineness modulus value of 2.4, falling within the range of 2.3 to 3.1, the analysis confirmed the classification of the sand as fine sand.

Figure 5.

Particle size distribution of natural river sand (Gambella region).

Table 7.

Detailed physical properties of natural river sand (Gambella region).

2.5.3. Cement

In this study, Ordinary Portland Cement (OPC) from the National Cement factory—renowned for its quality cement, graded as 42.5 R Strength Class—was utilized. The physical properties of this cement, including setting time, specific gravity, and standard consistency, were determined in accordance with ASTM standard specifications, as detailed in Table 8. Additionally, the chemical composition of the National Cement OPC was analyzed by the Geochemical Laboratory of the Ethiopian Geological Survey, as depicted in Table 9.

Table 8.

Physical properties of National Cement Ordinary Portland Cement (OPC).

Table 9.

Chemical composition of National Cement Ordinary Portland Cement (OPC).

2.5.4. Water

One of the ingredients employed in concrete production was tap water, typically utilized for drinking purposes, which was also utilized in this laboratory work.

2.6. Preparation of Concrete Mix Design

The concrete mix design employed in this study followed the American Concrete Institute (ACI-211) method. A trial mix was conducted for a characteristic cube compressive strength of 30 MPa to formulate the concrete mix production. For this concrete grade, a water-to-cement ratio of 0.49 was selected, considering a maximum aggregate size of 20 mm. This ratio was chosen to ensure the workability of the concrete aligned with the maximum aggregate size, thereby achieving the intended compressive strength. The quantity of water required in the mix design was determined based on tables provided in the American Concrete Institute (ACI-211) mix design guidelines. Consequently, detailed information regarding the batch proportions of the constituent materials for the control concrete, measured per unit cubic meter, is presented in Table 10, reflecting the specifications outlined in the ACI mix design.

Table 10.

Batch proportion of control concrete constituents.

2.6.1. Methods Adopted for Preparation of Concrete Casting

The study encompassed the evaluation of specimens derived from hybrid natural fiber-reinforced concrete, comprising alkali-treated bamboo and naturally treated wheat straw fibers, in comparison to a control mix design of concrete. The total number of specimens included cubes, cylinders, and beams. Various lengths of alkali-treated bamboo fibers, namely 30 mm, 45 mm, and 60 mm, were utilized, each combined with varying percentages of alkali-treated bamboo fibers (0.5%, 1%, and 1.5% by weight of cement). Simultaneously, a constant percentage of approximately 0.1% by weight of cement of naturally treated wheat straw fibers, approximately 25 mm in length, was incorporated into the treated hybrid natural fiber-reinforced concrete mix design. The fibers were meticulously dispersed within the concrete mixture to prevent segregation or balling, ensuring uniform distribution and maintaining structural integrity by avoiding clumping or uneven settling.

To determine the minimum fiber length, it needed to exceed the maximum aggregate size used in this investigation, ensuring it sufficiently covered the aggregate. This following guide will help you start your trial and select fiber types, such as short fibers (e.g., NTWSFs) and long fibers (e.g., alkali-treated bamboo fibers). The primary criterion for determining the percentage of NTWSFs is their high water absorption capacity, despite their low degradation rate. In contrast, alkali-treated fibers require significantly less consideration due to their lower water absorption, though their proportions and lengths are still analyzed in this experiment. Additionally, the density of the fibers affects the mixing process and distribution within the composite material.

This should guide you to start your trial and select the types of the fibers, such as short fibers like NTWSFs and long fibers like the alkali-treated bamboo fibers. The main criteria used to fix the percentage of NTWSFs was its water absorption capacity, which is high, even if it has a low-degradation rate, while the alkali-treated fibers vary less as compared to NTWSFs when considering the various proportions and lengths considered in this experiment. Also, other parameters such as the density of the fibers affect the mixing process and its distribution.

To assess both the fresh and hardened concrete mechanical properties, tests were conducted on the 7th, 28th, and 56th days. Specifically, a hybrid mix comprising 5% alkali-treated bamboo fibers of varying lengths (30 mm, 45 mm, 60 mm) combined with 0.1% naturally treated wheat straw fibers of approximately 25 mm length was employed in the production of the hybrid fiber-reinforced concrete. Further details regarding the hybrid mix codes are outlined in Table 11.

Table 11.

Description of mix code proportion of treated hybrid natural fiber-reinforced concrete.

In accordance with the mix design outlined in Table 10, the preparation of the control concrete mix involved the simultaneous addition of aggregate, sand, and cement into a concrete mixer drum. The drum was then allowed to rotate for one minute to achieve uniform blending. Subsequently, the necessary amount of water was added to the homogeneously mixed materials, and rotation resumed for approximately four minutes. For the treated hybrid natural fiber-reinforced concrete, a precaution was taken to prevent the ’balling’ effect by dividing each ingredient equally into three parts. Initially, one-third of the aggregate, sand, cement, naturally treated wheat straw fibers (NTWSFs), and alkali-treated fibers were added, respectively, to the mixer drum. The same procedure was repeated for the remaining aggregate, sand, cement, NTWSFs, and alkali-treated fibers. Following this, two-thirds of the required water was added, and the drum was allowed to rotate for three minutes until a uniform mixture was observed. The remaining water was then added to the concrete mix drum, and rotation resumed for an additional four minutes until a uniform and homogeneous mixture was achieved. The prepared homogeneous mixture was poured into oil-lubricated molds for cubes, cylinders, and beams. Each layer was compacted with 25 blows from a steel tamping rod, freely lifted by approximately 100–150 mm followed by a free drop.

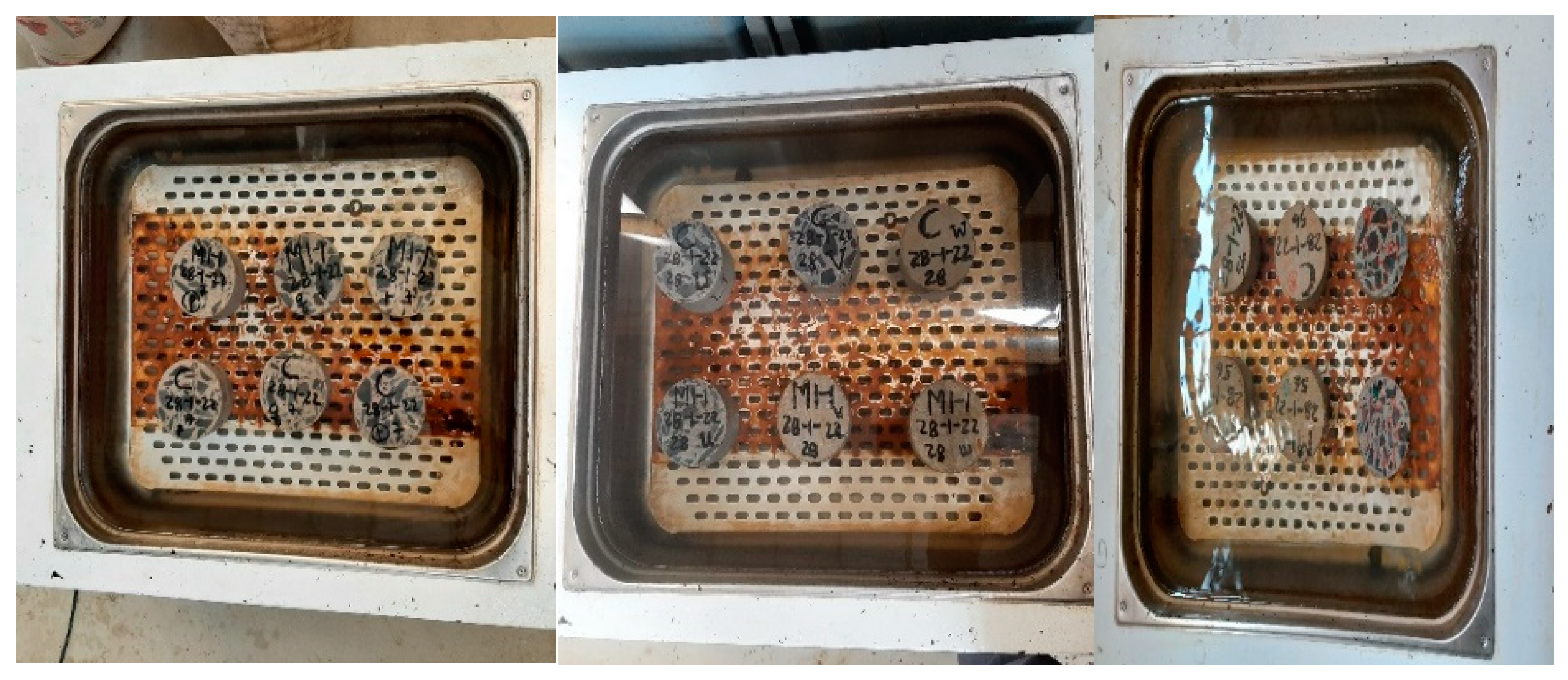

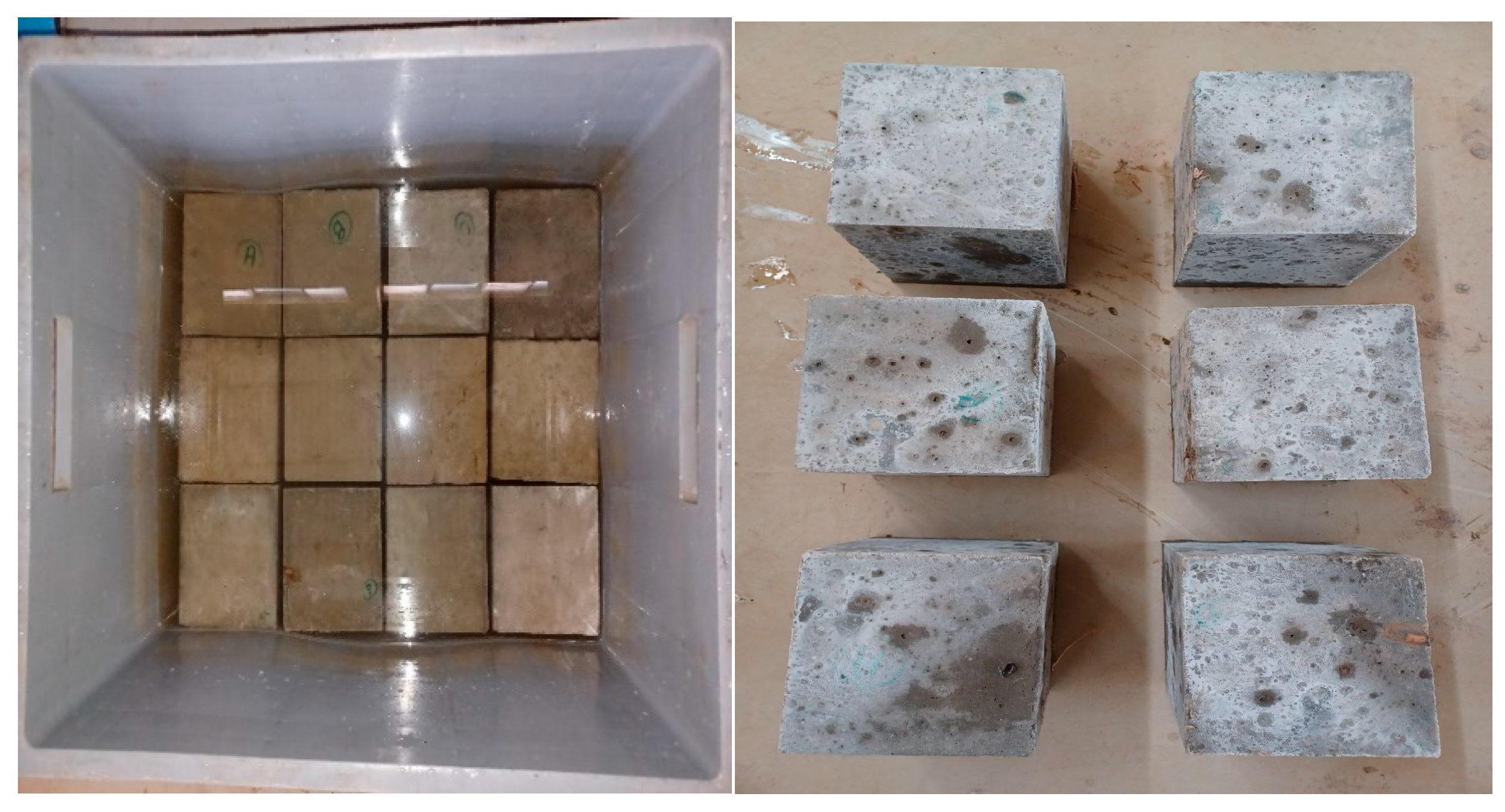

2.6.2. Curing

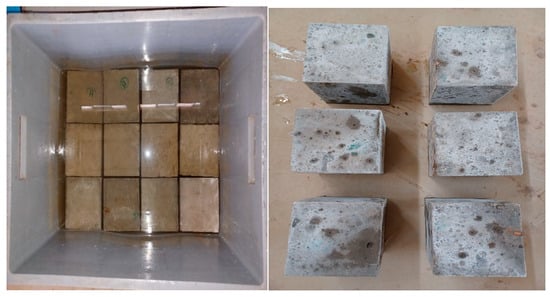

The cast specimens were demolded after 24 h of casting and subjected to curing using a water ponding method, as per ASTM C 192/C 192M standards, continuing until the respective testing dates, as depicted in Figure 6. The primary purpose of curing is to maintain concrete moisture, thus preventing moisture loss during the crucial period when it gains its required strength.

Figure 6.

Ponding method curing.

2.7. Tests on Hardened Concrete

2.7.1. Uniaxial Compression Strength Tests

In this study, the mechanical strength of the hardened concrete was evaluated through uniaxial compression strength tests conducted on standard cube specimens measuring 150 mm × 150 mm × 150 mm, in accordance with ASTM C 39/39M specifications. These tests aimed to examine the compressive behavior of the prepared concretes at different ages. Cube specimens were tested after curing for 7, 28, and 56 days, using an automatic uniaxial compression strength testing machine with a capacity of 2000 kN, as depicted in Figure 7. For each curing condition, three samples were tested, and an average was recorded for subsequent analysis in the study.

where = compressive stress;

- P = applied loading at failure stage;

- l =length;

- w = width.

Figure 7.

A uniaxial compression strength test.

Figure 7.

A uniaxial compression strength test.

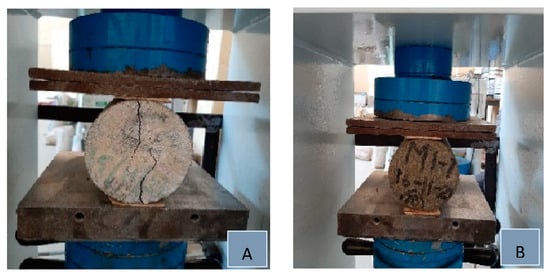

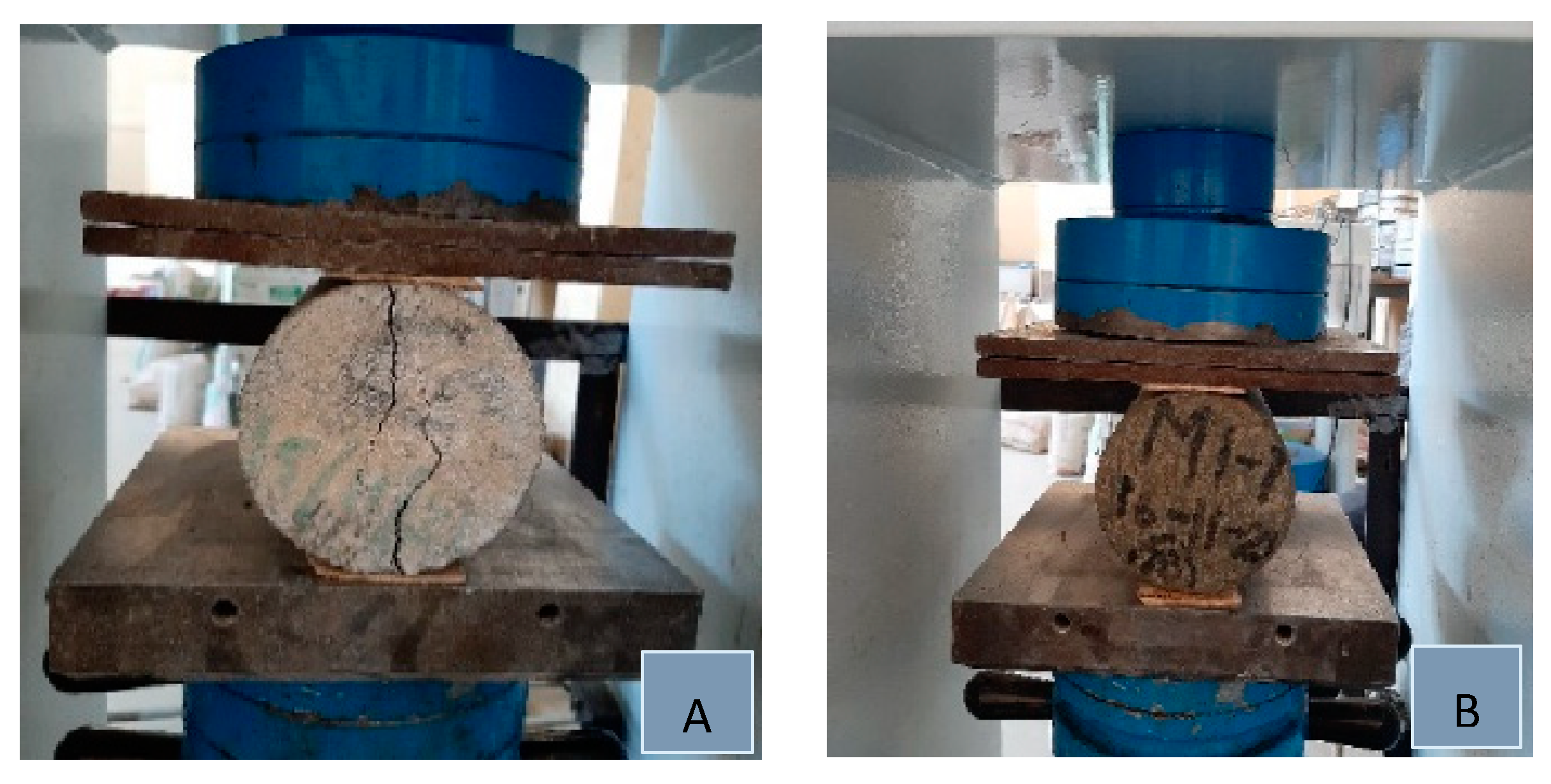

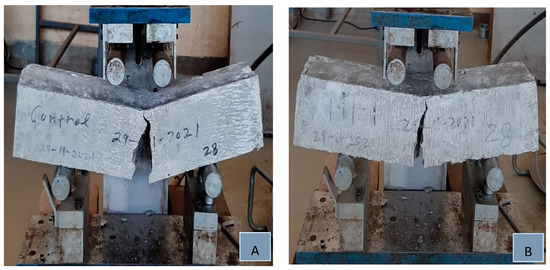

2.7.2. Splitting Tensile Test (Split-Cylinder Test)

The splitting tensile test was an indirect method to evaluate the tensile response of materials or the strength in concrete, as per ASTM C 496 standard specifications, as shown in Figure 8. The splitting tensile strength was calculated as follows:

where = tensile stress;

- P = applied loading at failure stage;

- D = diameter of cylinder;

- L = length of cylinder.

Figure 8.

Splitting tensile strength test. (A) Control concrete, (B) uniquely treated hybrid natural fiber-reinforced concrete (M1-1).

Figure 8.

Splitting tensile strength test. (A) Control concrete, (B) uniquely treated hybrid natural fiber-reinforced concrete (M1-1).

2.7.3. Flexural Strength Test

The concrete beam specimens prepared in this study were subjected to loading in accordance with ASTM C 78 specifications. Flexural strength, also referred to as modulus of rupture or bending strength, is defined as the stress developed in a material just before it yields in a flexure test, as illustrated in Figure 9. For the flexural tests, specimens measuring 100 mm × 100 mm × 500 mm were cast using steel or wood molds. A two-point loaded flexural strength machine with a capacity of 2000 kN was employed for the analysis. Before conducting the flexural test, the prepared beam samples were marked at 10 cm from each end and at the mid-span. Standard loads were then applied at one-third of the distance from the support on both sides in the flexural strength setup. This two-point loading configuration was chosen to ensure stress concentration over a larger region, thereby preventing the premature failure of the specimens. This loading setup also allowed for the uniform distribution of the bending moment between the two loading noses.

Figure 9.

Two-point loading test arrangement.

The flexural stress ( was calculated using the following formula:

where P = the rupture load, in N;

- L = the length of the beam between the two supports (300 mm);

- b = the width of the beam cross-section (100 mm);

- d = the depth of the beam (100 mm).

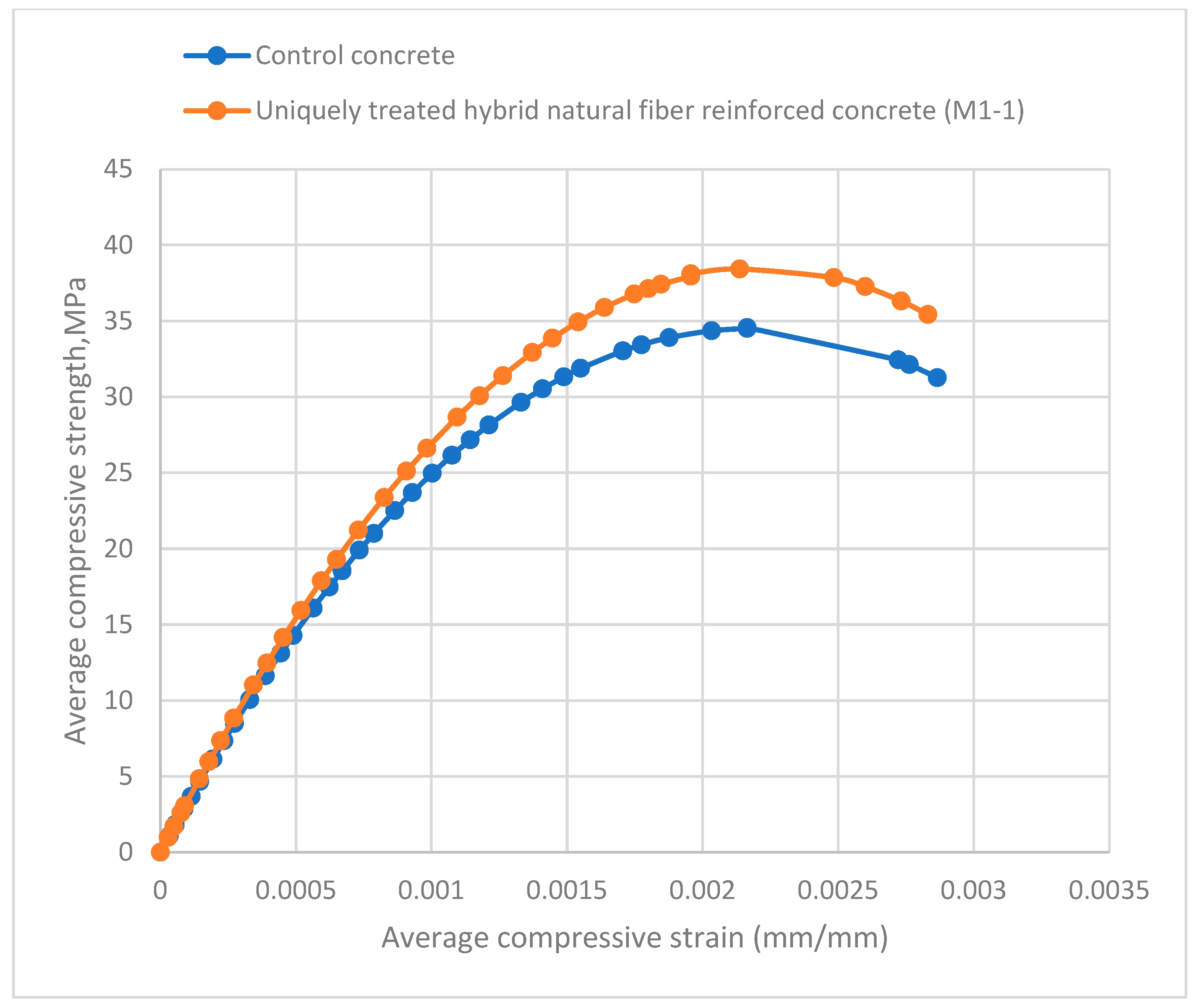

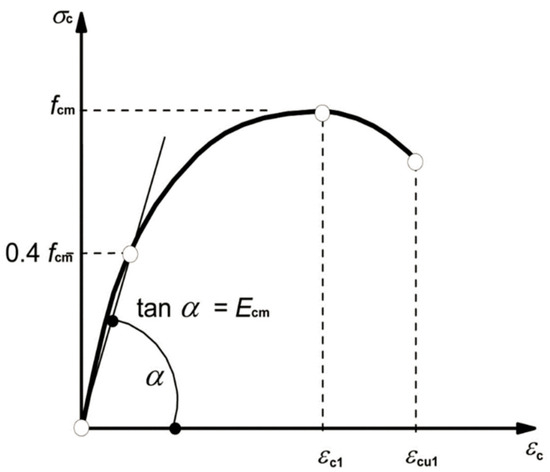

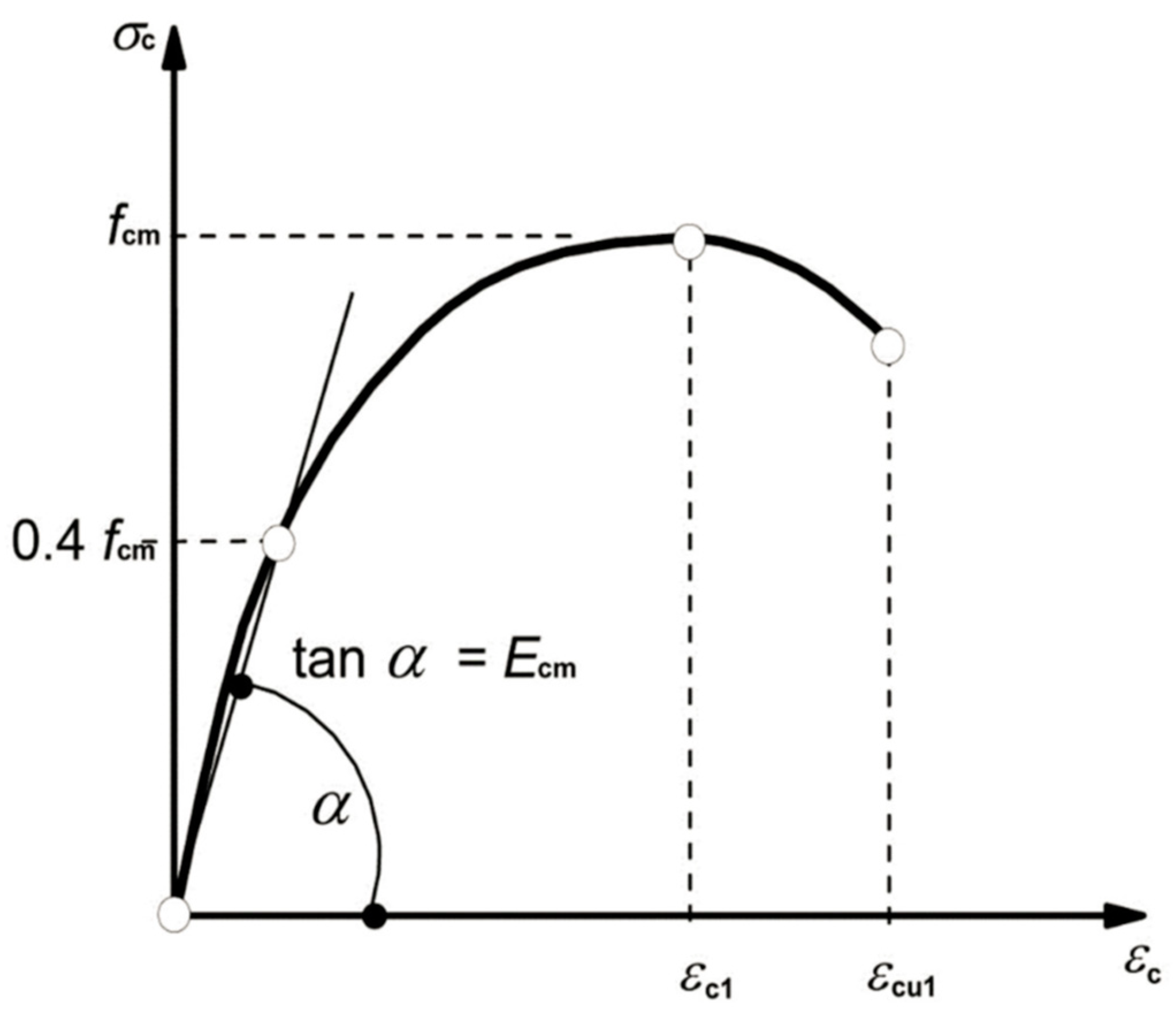

2.7.4. Stress–Strain Relationship for Compressive Strength

The stress–strain curve serves as a foundational tool in determining concrete mix designs for structural analysis and design in civil engineering projects. It provides essential insights into the mechanical strength of concrete, including parameters such as ultimate strain (elongation at break) and the modulus of elasticity, which significantly influence the behavior of the stress–strain curve, as per Ethiopian Standards based on European Norm ES EN 1992. The stress–strain curve typically exhibits an initial increase leading to a peak strength, followed by a descending segment, as illustrated in Figure 10. This curve’s behavior at various curing ages of concrete is crucial for analysis, capturing stress and strain relationships from loading initiation until failure stages. The strain at peak stress is particularly significant for establishing failure criteria in concrete, while the descending segment of the curve and its area represent the material’s plastic deformation ability and residual strength post-peak stress, respectively. The relation between and , as shown in Figure 10, for short-term uniaxial compressive loading is described by Equation (5).

where is the corresponding stress taken from readings during a compressive strength test.

- is the peak compressive stress of concrete.

- is the corresponding strain from stresses.

- is the peak stress corresponding to the peak stress of a cube sample during a compressive strength test.

Therefore, to determine the strain from the compressive stress scores of the compressive strength test results, we used Equation (5).

Figure 10.

Schematic representative of stress–strain relation for structural analysis (Ethiopian Standards—based on European Norm ES EN 1992).

Figure 10.

Schematic representative of stress–strain relation for structural analysis (Ethiopian Standards—based on European Norm ES EN 1992).

3. Experimental Results and Discussion

3.1. Workability (By Using Slump Test and Compaction Factor) Results

The workability tests of the control and treated hybrid natural fiber-reinforced concrete were conducted according to ASTM C-143 standard specifications and BS 1881: Part 103:1993. The results of the slump test, presented in Table 12, allow us to compare the control mix with the treated hybrid natural fiber-reinforced concrete mixes prepared as described in the concrete casting process. The slump test outcomes indicate that increasing the fiber content and length decreases the workability and consistency of the concrete. This decrease is attributed to the formation of balling during the mixing process, which creates voids even with proper compaction, while also enhancing stability and cohesion during concrete production.

Table 12.

Slump tests and compaction factor values.

In this study, it was observed that the M1-1 mix code exhibited a higher compaction factor and slump test results compared to the other mix codes of treated hybrid natural fiber-reinforced concrete. However, even with these improvements, the values still showed reductions of 7% and 41%, respectively, compared to the control concrete.

Notably, in mix codes M2-3 and M3-3, the slump test values were zero; however, their compaction factors of 0.771 and 0.791 had reductions of 13% and 11%, respectively, as compared to the control concrete. This phenomenon can be attributed to the natural fibers absorbing more water than other ingredients such as aggregates, sand, and cement. As a result, the concrete becomes stiffer, leading to reduced workability. Consequently, increasing the percentage of fiber content and its length results in diminished workability by reducing slump height, causing fiber clumping or clustering, making it harder to mix, place, and finish concrete and making these concretes challenging to pour and compact compared to control concrete.

3.2. Mechanical Properties of Concrete

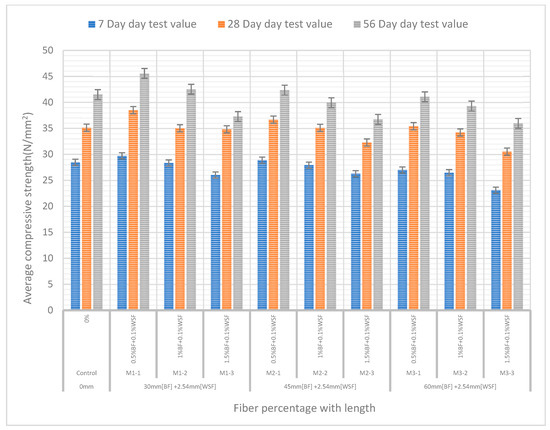

3.2.1. Compressive Strength

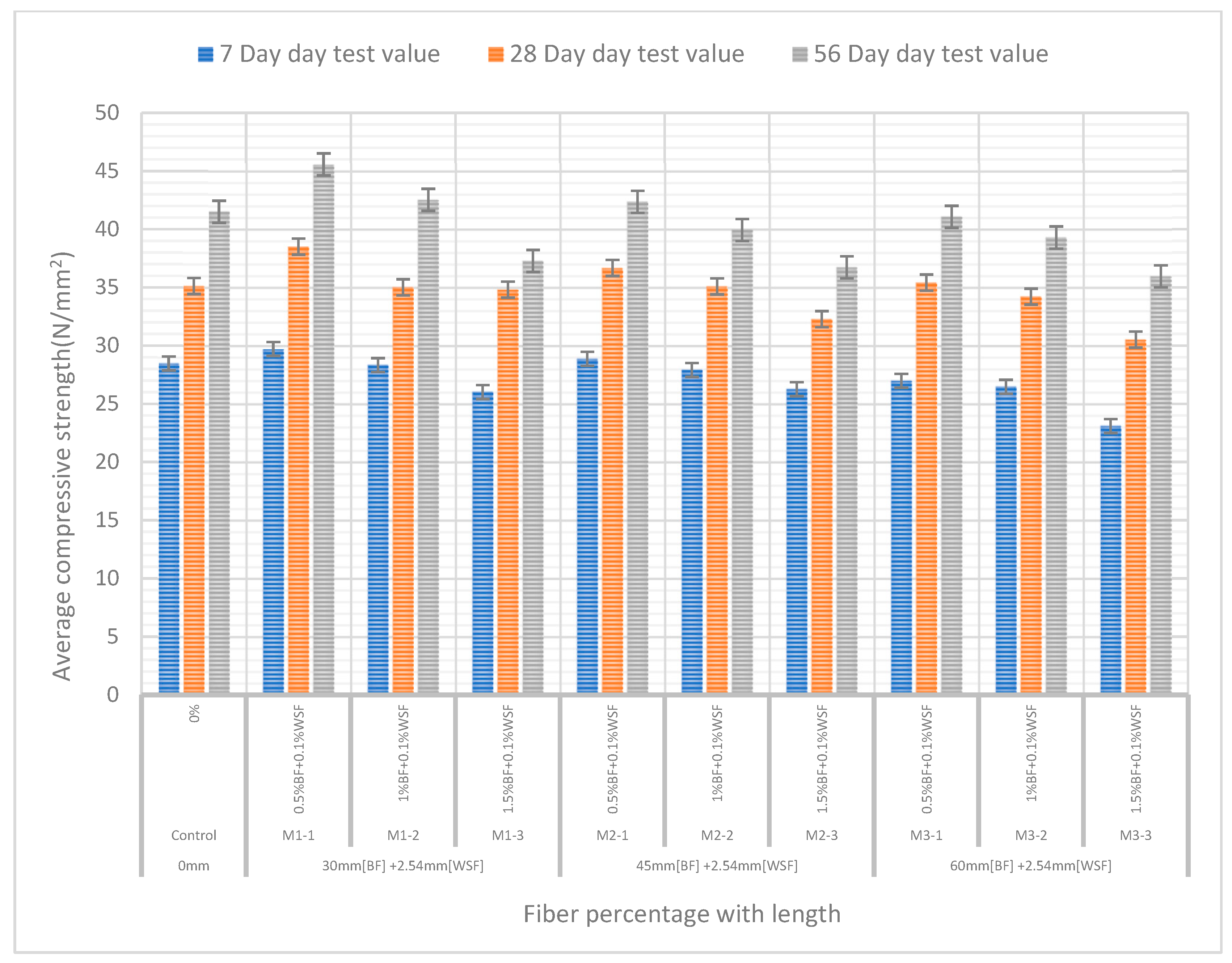

One of the pivotal metrics for evaluating the mechanical performance of hardened concrete is its compressive strength. The average uniaxial compressive strength test results from three specimens, shown in Figure 11, indicate that the addition of treated hybrid natural fibers enhances compressive strength to a certain degree. The maximum uniaxial compressive strength observed in this study is in the M1-1 mix code, with approximately 4.16%, 8.80%, and 8.93% increments at 7th, 28th, and 56th days, respectively, as compared to the control concrete. In this analysis, it observed that M1-1 and M2-1 have a higher compressive strength, while M1-3, M2-2, M2-3, M1-3, M3-2, and M1-3 have less compressive strength as compared to the control concrete strength at the 7th curing day, whereas M1-1, M2-1, and M3-1 have relatively higher compressive strengths of concrete attained at the 28th day of curing. But as curing age increases up to the 56th day, the maximum compressive strengths are found in mix codes M1-1, M1-2, and M2-1 as compared with the control. Similar studies show that various fibers are hybridized in concrete technology to enhance the overall mechanical properties of concrete [69]. Both positive and negative outcomes of the addition of natural fibers to the matrix have been reported [70,71,72]. Higher fiber contents in fiber-reinforced concrete often reduce compressive strength because they disrupt the integrity and density of the cement matrix. When too many fibers are added, the mix becomes less workable, prompting workers to add extra water to maintain a workable slump. This additional water increases the water-to-cement ratio, resulting in a weaker, more porous matrix. Moreover, excessive fibers tend to clump together rather than distribute uniformly, creating voids and stress concentration points that further hinder proper load transfer. These microstructural defects—poorer compaction, increased air pockets, and disrupted matrix continuity—collectively undermine the compressive capacity of the concrete, even as they may improve ductility and crack resistance in tension and flexure. Furthermore, as the percentage of fiber content and length increased, the compressive strength decreased by a considerable value; this was due to a decrease in adhesion between the prepared fibers and cement slurry, resulting in the need for more compacting energy to attain the required improved compressive strength [73,74]. The voids in treated hybrid natural fiber-reinforced concrete form due to poor compaction, weakening the matrix. Fiber balling occurs when fibers clump, hindering uniform distribution. Bonding issues arise from weak fiber–matrix interactions, affecting strength.

Figure 11.

Uniaxial compression strength results.

Failure Modes Observed During Compressive Strength Tests

The common failure modes observed in hard concrete during the testing of the cube-shaped specimens of control mix concrete compared with those of the treated hybrid fiber-reinforced concrete for the 7th, 28th, and 56th days, respectively, are illustrated in Table 13. This treated hybrid natural fiber-reinforced concrete increased in compressive strength at different lengths as well as with the different percentages of fiber, to a certain fiber content; this aligns with a similar study conducted [75], as, during the test, the control concrete specimens show less ductility as compared to the specimens with the addition of hybrid natural fibers in their concrete. The failure mode of the fiber-reinforced concrete with various proportions and lengths is quite different from the control concrete, as observed in Table 13. Moreover, in the individual failure modes observed for the hybrid natural fiber-reinforced concrete, failure becomes reduced as the proportions and lengths of fibers incorporated increased during the compressive strength test. This was due to the fibers’ absorbing energy capacity and resisting the total collapse of structure.

Table 13.

Failure modes observed for 7th, 28th, and 56th day concrete cubes.

3.2.2. Splitting Tensile Strength (Indirect Tensile Strength)

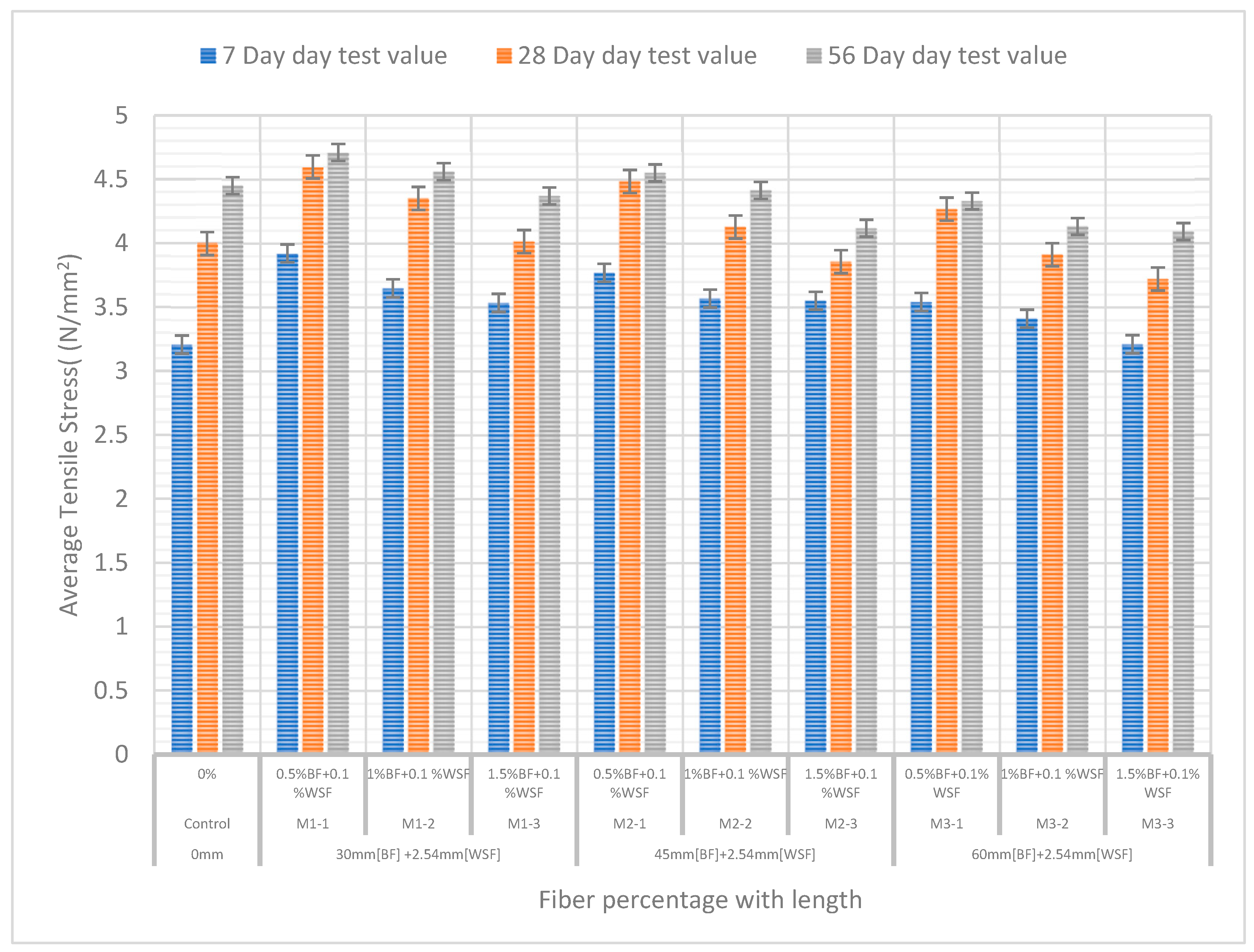

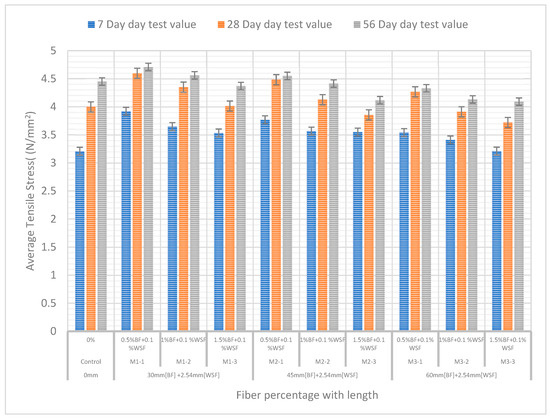

The main purpose of adding these treated hybrid natural fibers to concrete is to increase the split tensile strength and to reduce the brittle nature of the fiber-reinforced concrete. Plain concrete is naturally characterized by its brittle failure behavior, observed specifically in the tension vicinity. In this investigation, it is observed that a conventional concrete specimen can easily split into two halves after achieving its peak fracture load. This is due to the influence of hybrid fiber materials; its internal interfacial bonding strength tends to hold tightly when the fracture load causes failure [51,52]. Therefore, the effect of adding this treated hybrid natural fiber content is an increase in the concrete’s split tensile stress, a certain improvement as compared to the control concrete, as observed in Figure 12. The average splitting tensile strength test results from three specimens were considered for analysis, following ASTM C 496 standard specifications for both the control concrete and treated hybrid natural fiber-reinforced concrete, respectively. The split tensile strength of the treated hybrid natural fiber-reinforced concrete improved totally as compared to the control concrete; as the percentage and length of fibers and age of curing increases, the split tensile strength increases due to the strong internal bonding.

Figure 12.

Splitting tensile strength results.

3.2.3. Flexural Strength

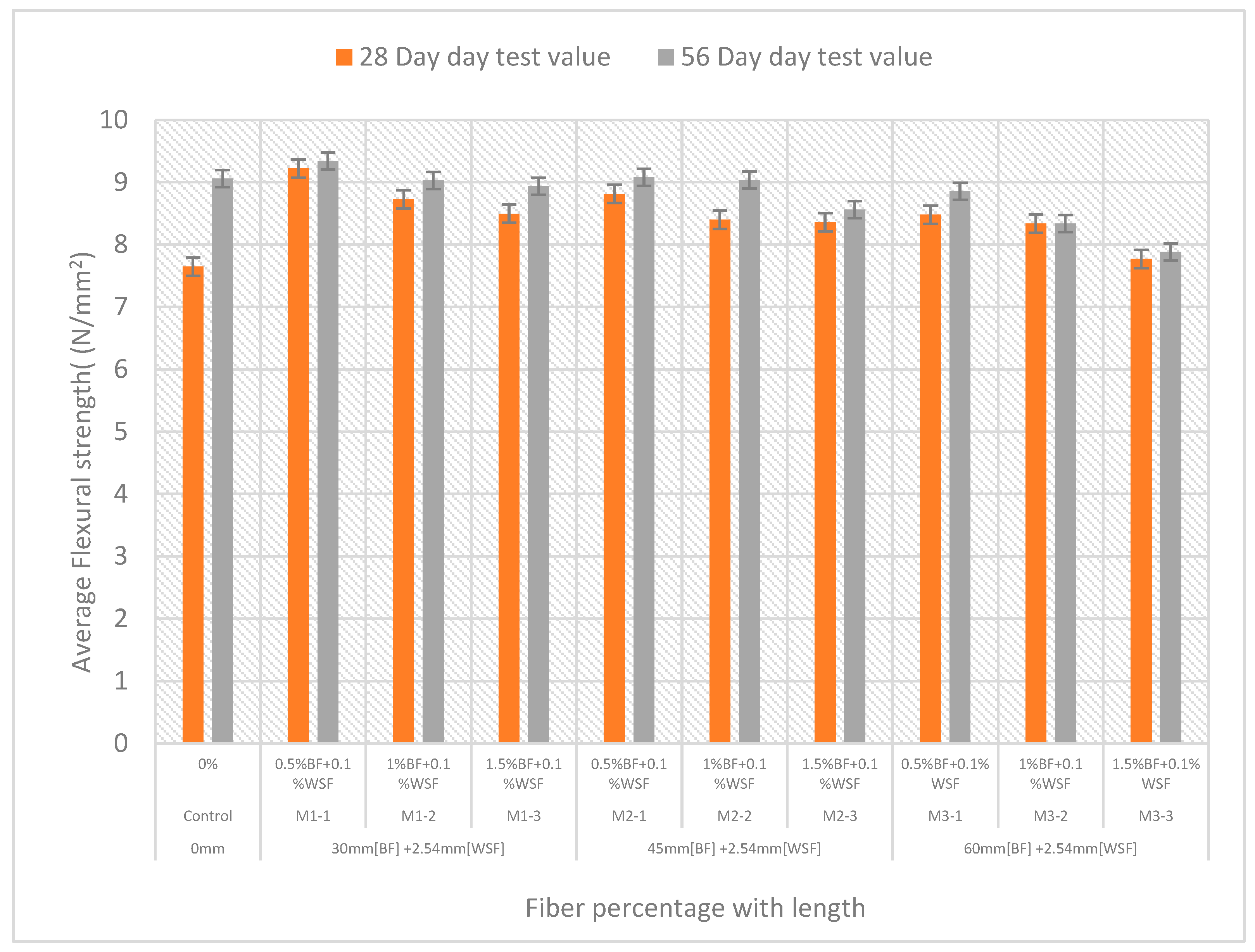

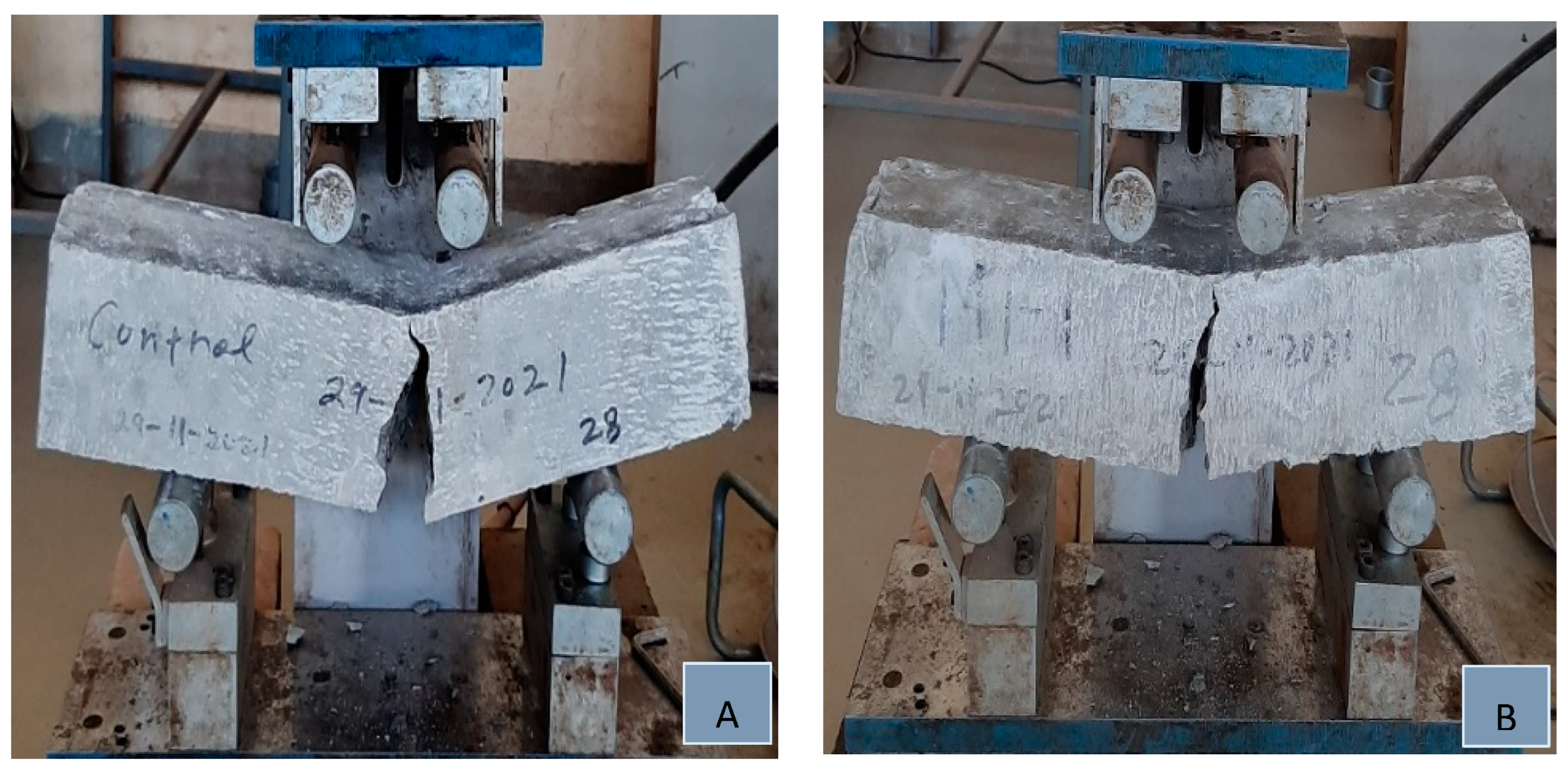

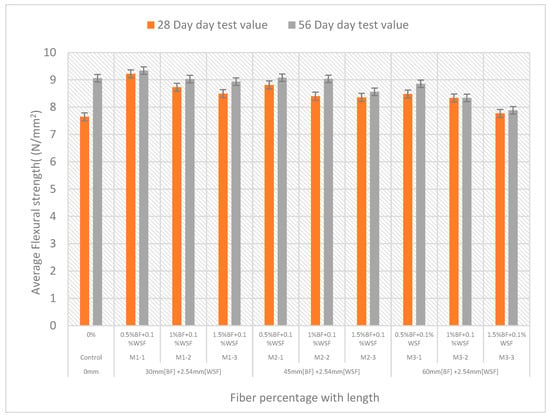

As shown in Figure 13, the maximum value for the flexural strength capacity attained in the hybrid fiber-reinforced concrete is in M1-1 mix design, increasing by 20.6% and 3.09% at the 28th and 56th days of aging, respectively, in comparison to the plain concrete or control concrete. In addition to this, the hybrid natural fiber-reinforced concrete seems to change in failure mode from brittle to ductile, as observed during this test; it improves in post-cracking load and also increases energy absorption capacity in comparison to plain concrete. Also, it helps bridge the cracks, transmitting the force and controlling crack propagation during the flexural strength tests [2,3,4]. This investigation shows that hybrid natural fiber-reinforced concretes have increased flexural strength at different lengths as well as at different percentages of fibers added in concrete production. This is due to the effectiveness of hybrid natural fibers in delaying the development of micro-cracks in concrete. This shows a drastically different failure mode, observed in this investigation; in plain concrete, the failure mode is an immediate collapse which occurred at the onset of cracking within the tension zone, as observed in Figure 14. To summarize, all the prepared mix designs in this study had more flexural strength as compared to the control concrete due to the incorporation of fibers in the concrete production.

Figure 13.

Flexural strength results.

Figure 14.

Cracked beam after loading (failure mode of beam): (A) control concrete, (B) uniquely treated hybrid natural fiber-reinforced concrete (M1-1).

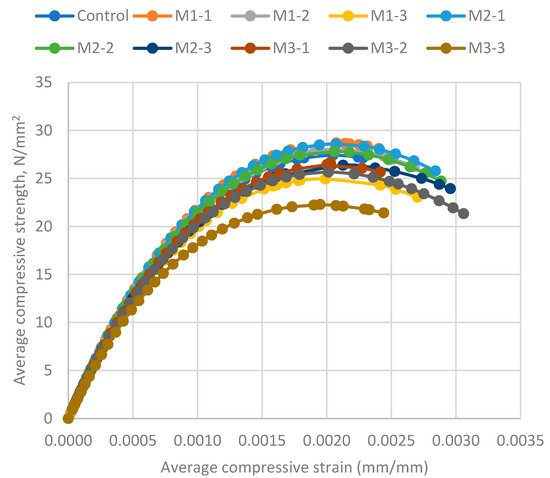

3.2.4. The Compressive Stress–Strain Behavior of the Hybrid Fiber-Reinforced Concrete as Compared with the Control Concrete

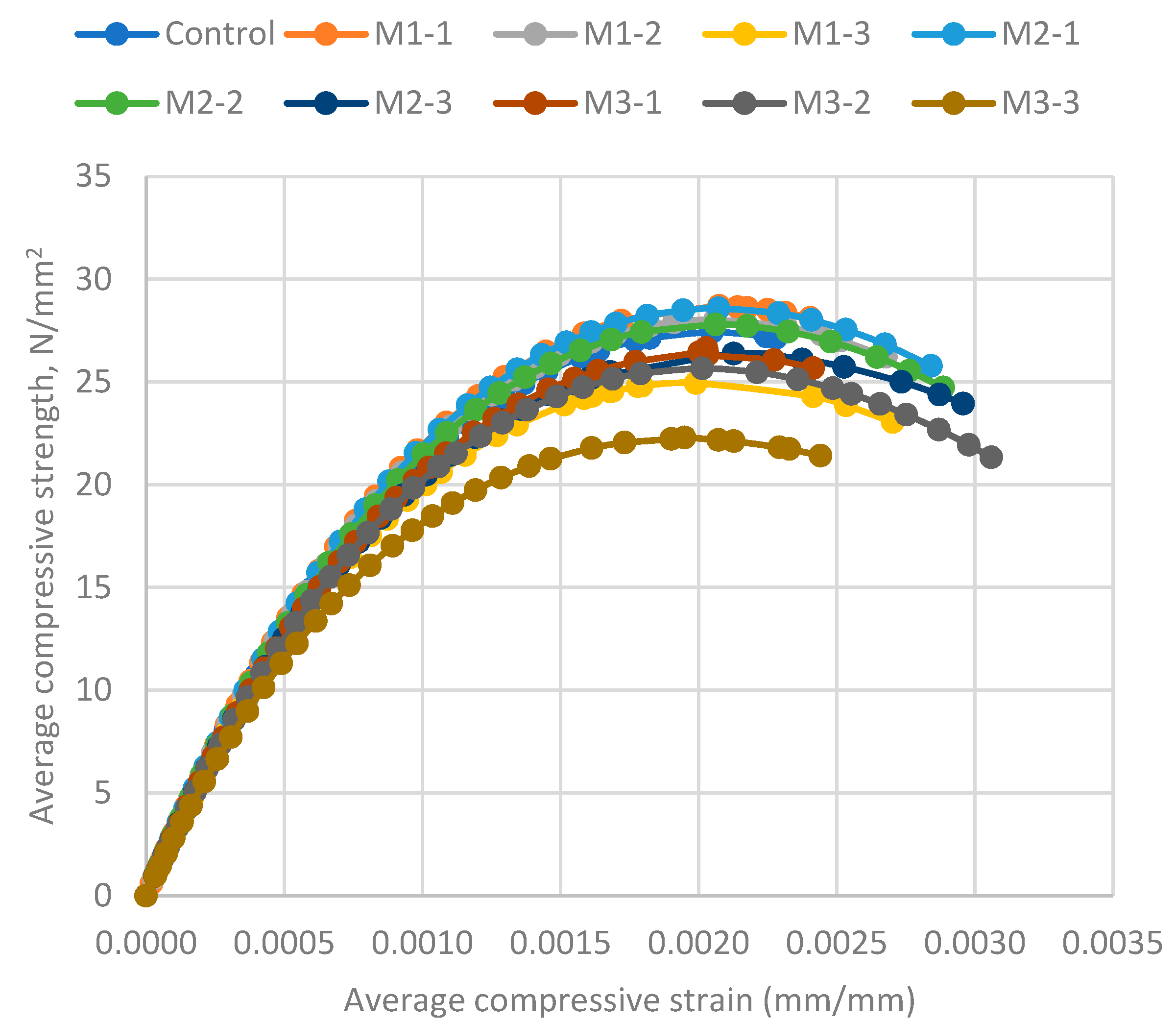

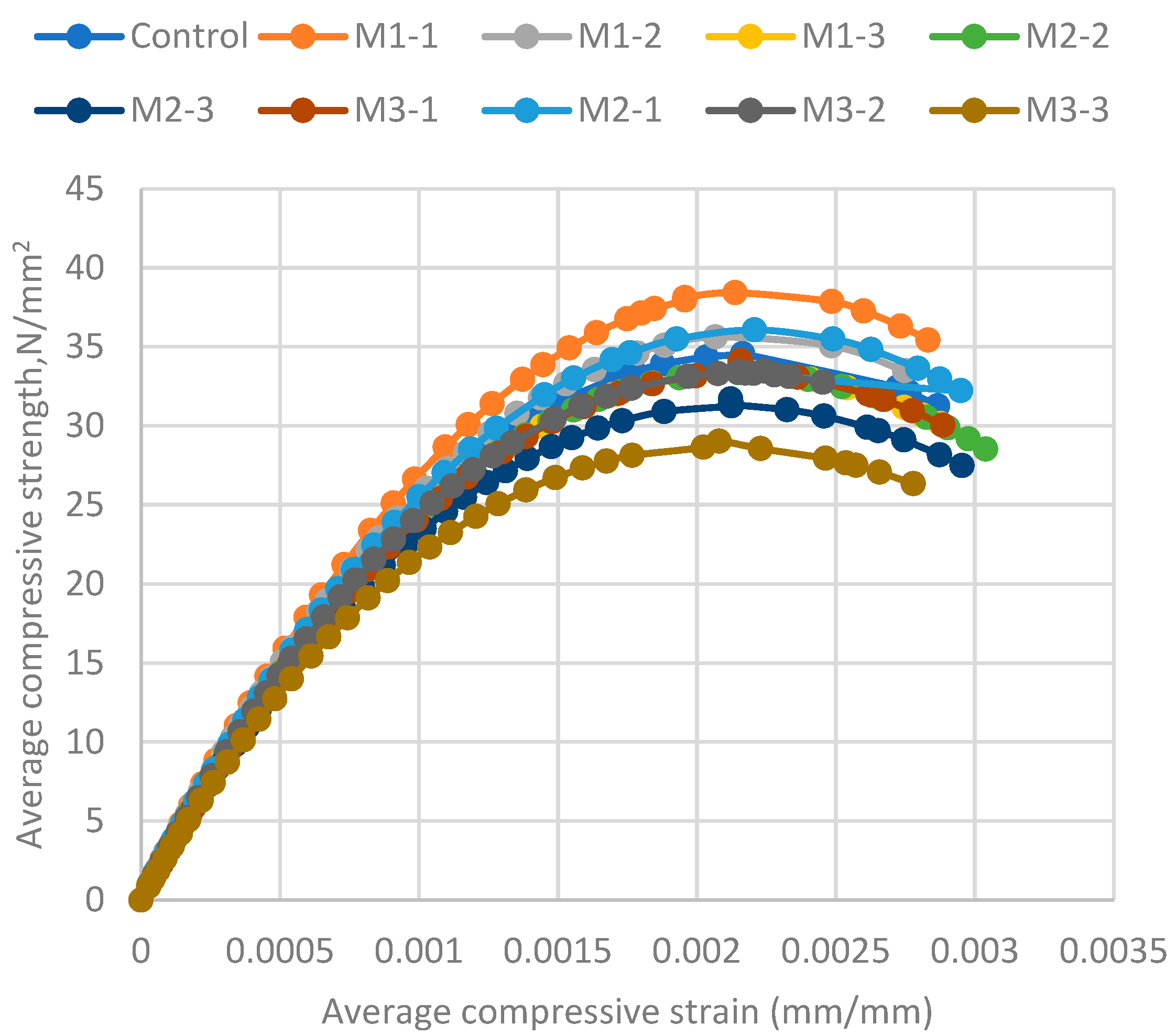

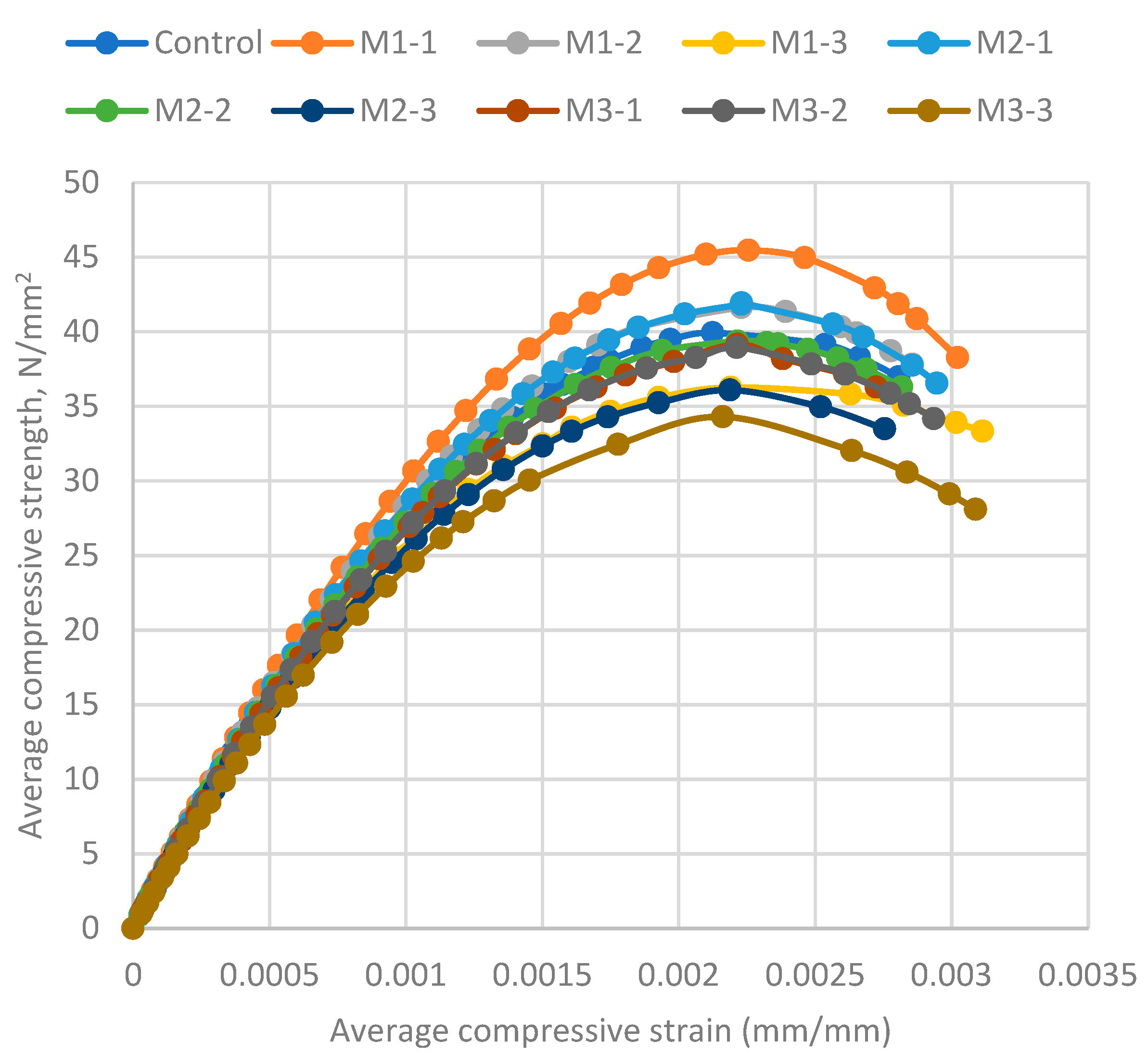

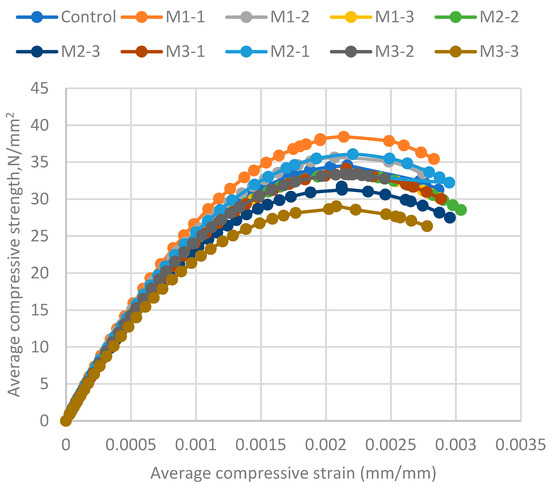

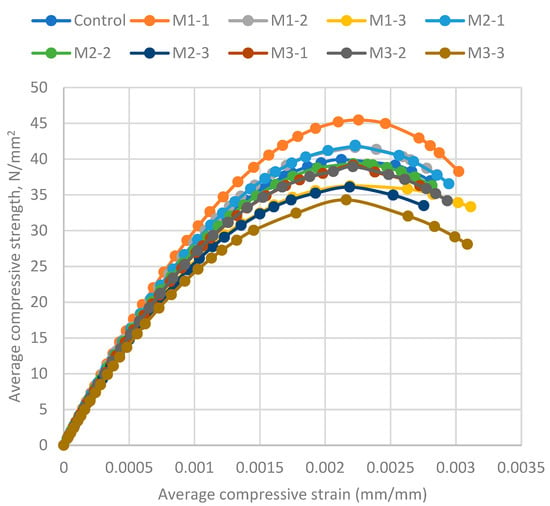

The technique used for strain measurement in this investigation was strain gauges attached to the middle height of the concrete cubes to measure the strain change while, simultaneously, a corresponding compressive applied load was recorded during this test procedure from beginning to end. Figure 15, Figure 16 and Figure 17 show the stress–strain curves for the treated hybrid fiber-reinforced concrete as compared with the control mix for the 7th, 28th, and 56th day test results, respectively. The slope of the stress–strain curves slightly decreases as the percentage of treated hybrid fiber content replacement increases, except for the optimum value (M1-1). Moreover, once the peak load is reached, the load-carrying capacity from the yield strain up to the point of rupture for the treated hybrid fiber-reinforced concrete was more than that of the control mix concrete. This shows that as the percentage of treated hybrid natural fiber content increases in concrete production, the concrete’s ductility increases due to the addition of treated hybrid fibers [49]. As the slope of the stress–strain curve becomes steep, the elastic modulus acquires a maximum value; while the treated concrete had high elongations or strains at ultimate failure, this shows that it was more ductile than the control concrete, with a low strain value. Once the ultimate load is reached, the load-carrying capacity (ductile properties of concrete) changes for each mix type based on the percentage variation in treated hybrid natural fiber content, as observed in the compressive strength tests.

Figure 15.

The compressive stress–strain responses at an age of 7 days.

Figure 16.

The compressive stress–strain responses at an age of 28 days.

Figure 17.

The compressive stress–strain responses at an age of 56 days.

3.3. Durability Property Test

The various test methods adopted in this study to evaluate the durability properties of the control concrete compared with that of the maximum compressive strength of the treated hybrid natural fiber-reinforced concrete are clarified in detail as follows.

3.3.1. Water Absorption and Voids in Hardened Concrete

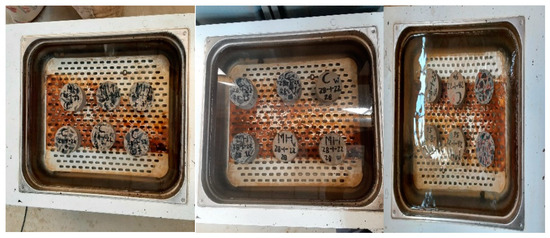

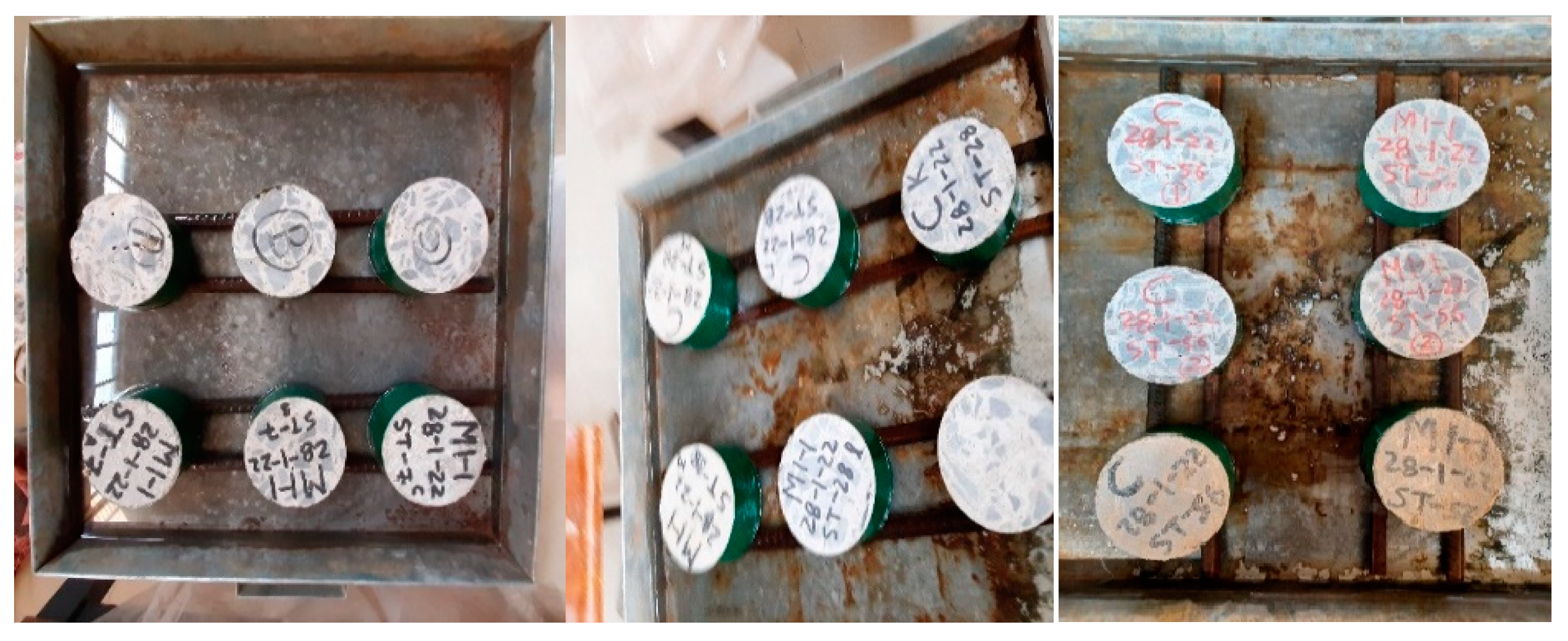

The voids in hardened concrete are an important property of any concrete during its design life structure. This property is responsible for allowing moisture and air to enter into hardened concrete during its service life [63]. Based on this, an oven-drying method recommended by ASTM C 642-97 was used to determine the water absorption and the voids in the hardened concrete. This standard suggested we use three cylindrical specimens of size 100 mm diameter and 100 mm height, as shown in Figure 18, cut from the center core of a cylinder of size 100 mm diameter and 200 mm height; the average values of the control concrete and uniquely treated hybrid natural fiber-reinforced concretes were considered in the analysis. This test was carried out at the 7th, 28th, and 56th days of curing, and then the specimens were allowed to air-dry to remove the surface moisture.

Figure 18.

Prepared center core cut specimens for water absorption and volume of permeable pore voids tests.

Procedures were adopted from ASTM C 642-97 as follows in order to calculate the water absorption and voids in the hardened concrete:

- The first step was determining the mass of each of three samples and drying them in an oven at a temperature of 100 °C–110 °C for not less than 24 h. After removing each specimen from the oven, we allowed it to cool in dry air (preferably in desiccators) at room temperature, and then the weights were measured frequently until the weights became constant. This value was considered as the mass of the specimen, and noted as A.

- The second step was to immerse the samples in water at approximately 21 °C for not less than 48 h, and then surface dry the specimens by removing surface moisture with a clean towel properly. The weights were taken in the surface-dried condition, and noted as B.

- Third step was to keep the specimens in boiling water for 5 h at 100 °C, as shown in Figure 19, and allowing them to cool at room temperature for not less than 14 h. The masses of the specimens were determined, and noted as C.

Figure 19. Specimens under boiling process.

Figure 19. Specimens under boiling process. - The final step was to tie the samples with thin copper wire and immerse them in water with a spring gauge. In this immersed condition, the weights of the specimens were taken and noted as D. The water absorption and volume of permeable pore voids were calculated as follows:

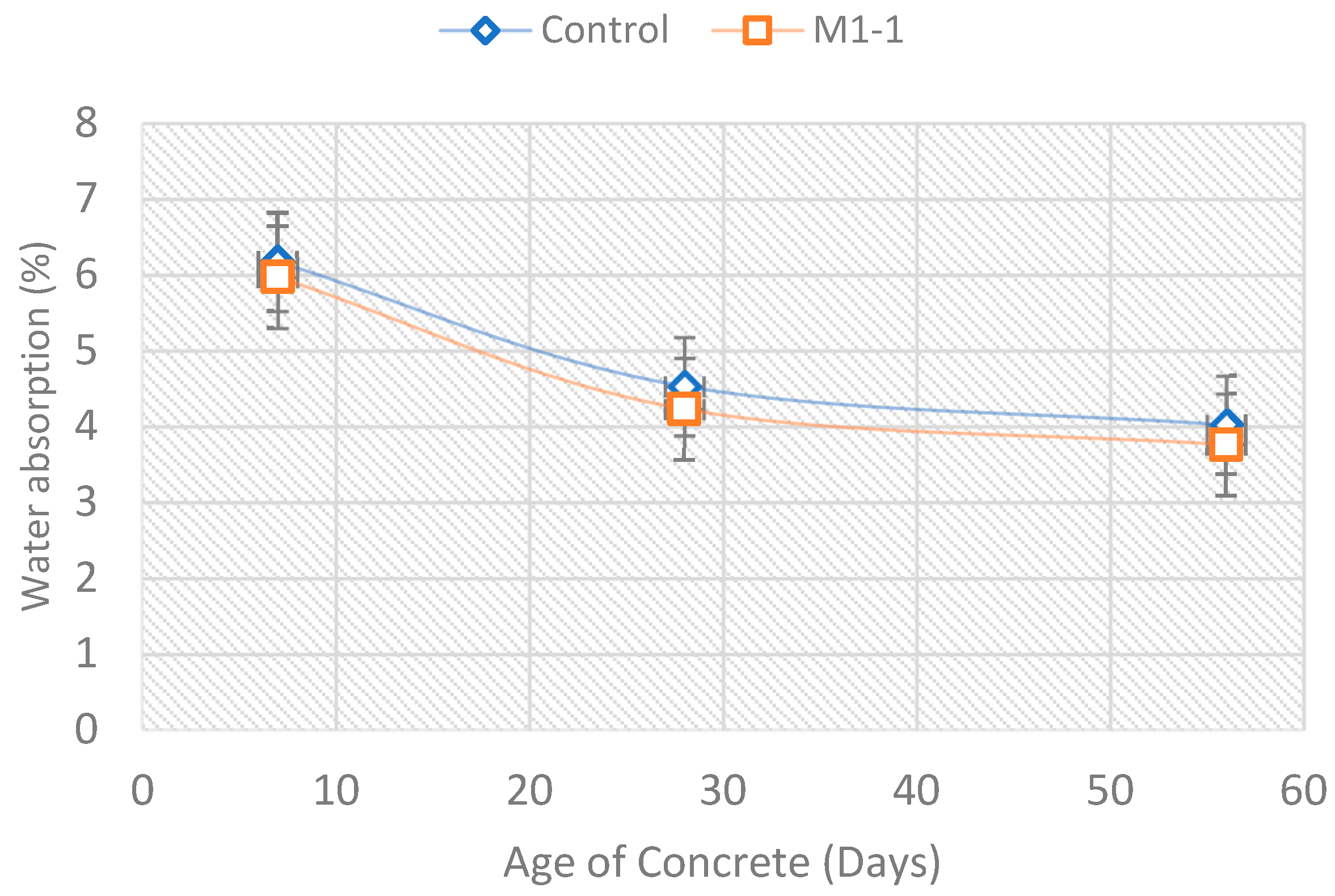

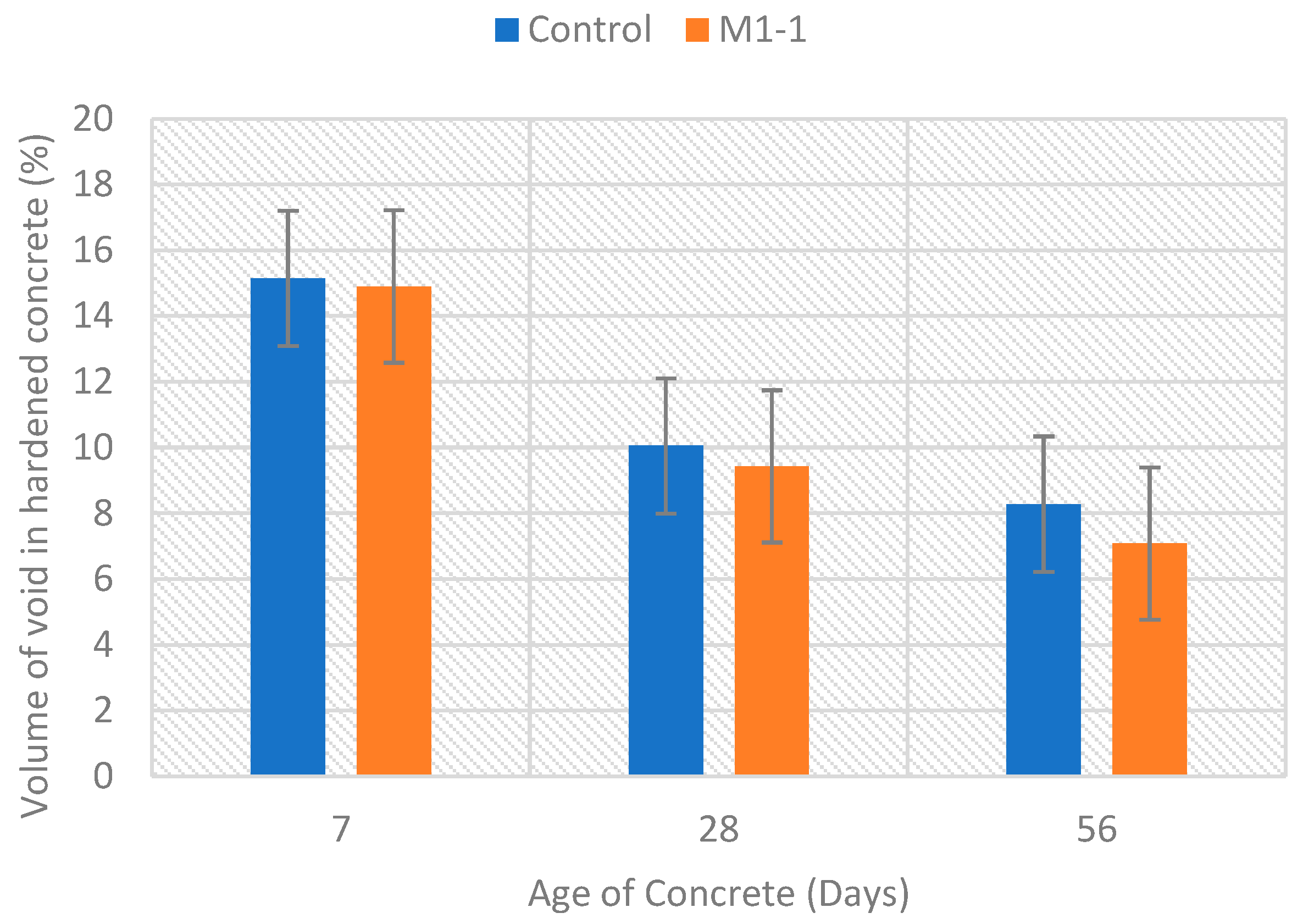

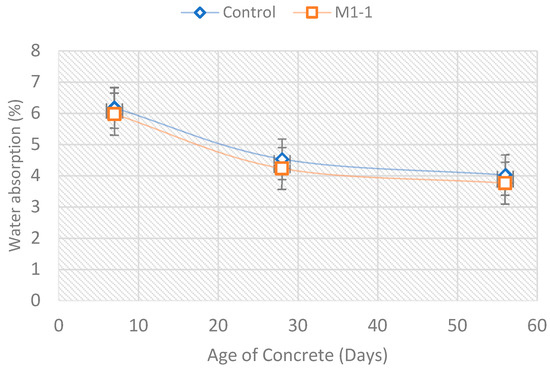

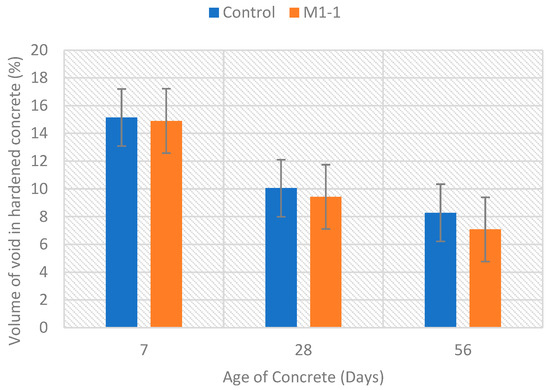

Based on this, Figure 20 shows the water absorption of the control mix design compared with the optimum value of the treated hybrid natural fiber-reinforced concrete. For the control specimen, the average values of water absorption at the 7th, 28th, and 56th days were 6.17%, 4.53%, and 4.17%, respectively. However, in the optimum value of the treated hybrid natural fiber-reinforced concrete, the water absorptions at the 7th, 28th, and 56th days were 5.97%, 4.23%, and 3.02%, respectively, for its curing condition. This indicates that as the age of curing increases, water absorption decreases; however, the water absorption in both cases is in limited values below 5%, based on the standards stated in ASTM C 1585, except at the curing age of 7 days. The volume of void in hardened concrete, as shown in Figure 21, shows that as the age of curing increases, the volume of void in hardened concrete decreases.

Figure 20.

Results of water absorption tests.

Figure 21.

Results of volume of void in hardened concrete tests.

3.3.2. Sorptivity Test

Sorptivity is defined as the quantity that measures the unsaturated flow of water within a concrete member during its design period, or as a means to measure the capillary forces exerted by the pore structure of concrete causing water to be drawn into the concrete structure. To perform this test, the prepared concrete samples should be dried consistently, and their flow conditions should be well defined. By using a least-squares regression method, it is relatively easy to achieve a good fit while plotting a graph between cumulative water absorption per unit area of concrete surface (i) and the square root of time (). One simple technique is suggested by ASTM C1585 for the measurement of the rate of absorption of water by concretes. The apparatus required for this test were a scale, a stopwatch, and a shallow pan of water. The test required the use of triplicate specimens of size 100 mm diameter and 50 mm thickness cut from the center core of a cylinder of size 100 mm diameter and 200 mm height, as shown in Figure 22. Initially, the prepared specimens were covered with electrical insulation tape and their initial masses were recorded. The specimens were then placed in a tray filled with a 5–10 mm depth of water in such a way that the water should have access only from the bottom side of the specimen, and they were checked at intervals of 0 min, 1 min, 2 min, 5 min, 10 min, 20 min, 30 min, 60 min, 2 h, 3 h, 4 h, and 6 h, as shown in Figure 23. Finally, after the stated interval of time, the prepared specimens were taken out of the water and their masses were immediately recorded after the surface water present was wiped off. The mass gained per unit area over water density was graphed to the square root of time elapsed, and the slope for the best-fit line was taken as sorptivity.

where i is the cumulative water absorption per unit area of a concrete surface,

- S is the sorptivity coefficient, and

- t is the time at which the weight was determined.

Figure 22.

Prepared center core cut specimens for sorptivity test.

Figure 22.

Prepared center core cut specimens for sorptivity test.

Figure 23.

Specimens under sorptivity testing.

Figure 23.

Specimens under sorptivity testing.

The prepared concrete samples that underwent a sorptivity test revealed details about the pore structure of the material. The lower sorptivity results show a higher quality of concrete in terms of resistance to water absorption. Based on [76], if the quality of concrete is to be high, its sorptivity value should be less than 0.1 mm/mim0.5. Based on the procedure stated above, in order to determine a comparative investigation, the sorptivity tests were carried out between a control concrete and a concrete with the optimum value of treated hybrid natural fibers. Therefore, for the optimum value of treated hybrid natural fiber-reinforced concrete, its average sorptivity values at the 7th, 28th, and 56th days were 5.2%, 3.99%, and 2.89% lower than that of the control concrete, respectively. This test indicates that as concrete increases in curing age, its sorptivity decreases, due to the rate of change in mass decreasing.

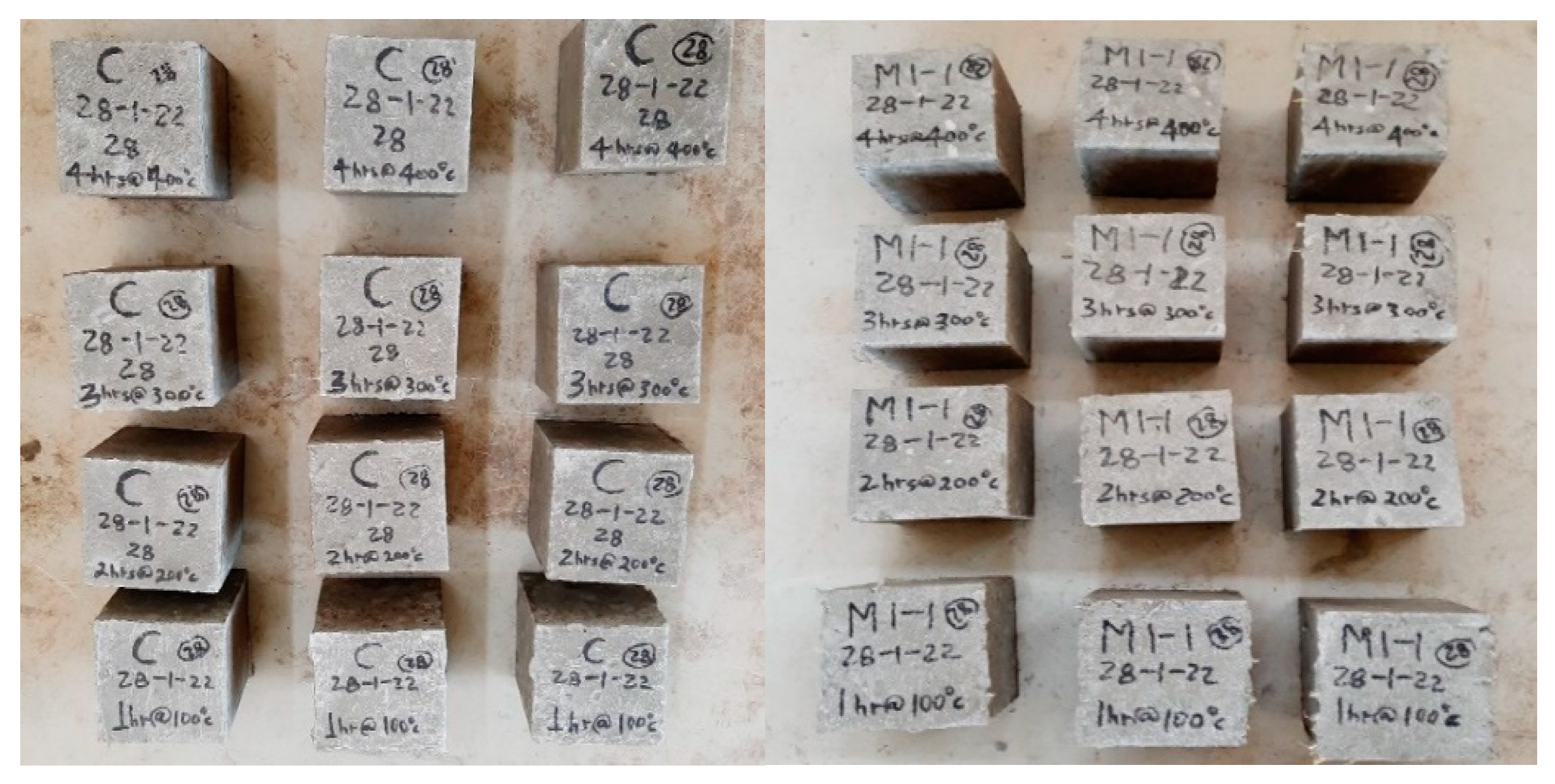

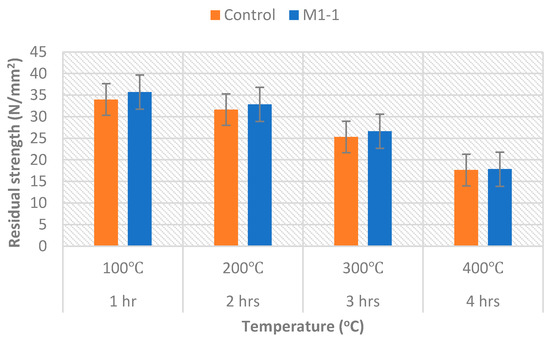

3.3.3. Resistance Strength at Elevated Temperatures

In order to investigate the performance of concrete in resistance to elevated temperatures, the results of the optimum mix of the treated hybrid natural fiber-reinforced concrete compared with those of the control were studied. Figure 24 shows the specimens that were prepared for resistance to elevated temperatures testing before curing. After 28 days of curing, the prepared concrete specimens used for this test analysis were placed in an electric oven at 100 °C, 200 °C, 300 °C, and 400 °C for 1, 2, 3, and 4 h, respectively, and comparisons were drawn between the optimum hybrid fiber-reinforced concrete cube and the control concrete specimens. Also, the specimens were then allowed to cool at room temperature before being tested in a compression strength test. The results of the temperature tests are reported and analyzed as averages of triplicate specimens of the treated hybrid natural fiber-reinforced concrete and control concrete.

Figure 24.

Specimens prepared for resistance to elevated temperatures testing before curing.

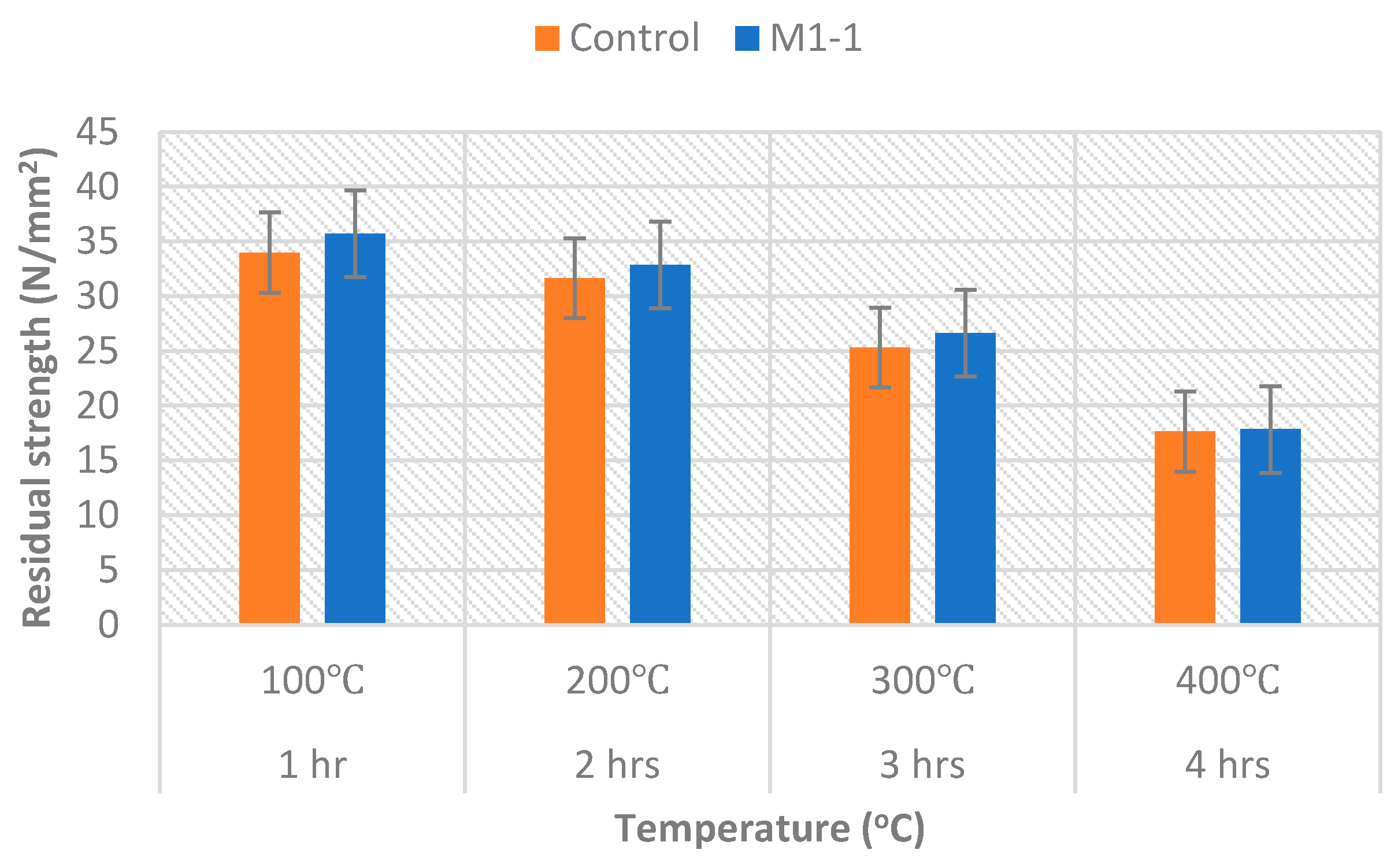

The compressive strengths of the control concrete and the optimum mix of the treated hybrid natural fiber-reinforced concrete cubes (M1-1) that were not subjected to the temperature at a 28-day curing age were 35.12 N/mm2 and 38.51 N/mm2, respectively. This test was conducted at a specific temperature for a specific time duration to determine the residual strength of concrete, comparing the control concrete with the optimum treated hybrid natural fiber-reinforced concrete (M1-1). As per ASTM C 330-09, the minimum strength should be 17 N/mm2 to satisfy the requirements for structural concrete. From the test results shown in Figure 25, it can be concluded that the residual strengths of the control concrete mix and the optimum mix of the treated hybrid natural fiber-reinforced concrete (M1-1), at 100 °C, 200 °C, 300 °C, and 400 °C for 1, 2, 3, and 4 h, respectively, were more than 17 N/mm2. Therefore, at a minimum, these concretes offer safe resistance against a higher temperature for 2 h, which is 90% of the original un-subjected temperature of its compressive strength.

Figure 25.

Temperature versus residual strength of 28-days curing age concretes.

3.3.4. Water Permeability Test (WPT) of Concrete

This test was conducted according to procedures described in BS EN 12390-8 [77] and the German code DIN 1048 Part 5. Typically, three specimens are prepared for the control concrete and uniquely treated hybrid natural fiber-reinforced concrete, and their average values are reported for analysis. To determine the water permeability of concrete, the optimum mix of the treated hybrid natural fiber-reinforced concrete (M1-1) and control concrete specimens of cubes 150 mm × 150 mm × 150 mm in size were cast and cured for 28 days to compare the results of a water permeability test. The cubes were placed in the permeability test apparatus at a hydrostatic pressure of 5 bars for 72 h, as shown in Figure 26. The cubes were removed from the setup and placed one by one in the compressive strength test machine while also placing a smooth steel rod in the center at the top of the cubes to split or divide the cube specimens in order to visualize the maximum depth penetration by the water. Based on this average depth for the water permeability test, the results for the optimum mix of treated hybrid natural fiber-reinforced concrete (M1-1) and the control concrete at ages of 28 days were 13.45 mm and 12.79 mm, respectively. This shows that a smaller depth of penetration results in higher resistance to water pressure due to the treatment of fibers in concrete.

Figure 26.

Procedures for water permeability tests of concrete.

3.3.5. Rapid Chloride Permeability Test (RCPT)

One of the main environmental attacks that initiates the deterioration of reinforced concrete members is chloride infiltration, which, in turn, starts the corrosion of embedded steel bars in composite materials. This degrades or reduces concrete’s structural performance during its design life. The strategy implemented to avoid this is the prevention of chloride infiltration into the steel bars by means of preparing impermeable concrete to the greatest degree possible [78]. In order to control the quality of concrete for its design purpose, it is important to understand the ability of chloride ions to penetrate the concrete members. But this process takes a long period, and it is difficult to determine in a short time [79]. Therefore, instead of this technique, an accelerating process was applied that clearly stated its detailed procedures in the ASTM C 1202 standard specification. Based on this, Table 14 shows the results of the RCPT as per ASTM C1202 with respect to the charge passed in Coulombs versus chloride ion penetrability.

Table 14.

Rating of RCPT as per ASTM C1202.

There was a simple method demonstrated to determine the chloride penetration of concrete, as follows:

- Prepare cylindrical specimens of 100 mm in diameter and 200 mm in height, set based on mix design.

- With the help of a concrete cutter, cut a cylindrical sample into 50 mm heights from the core of the initial cylinder specimen, as shown in Figure 27.

Figure 27. Prepared specimens for RCPTs.

Figure 27. Prepared specimens for RCPTs. - To determine the chloride penetration test of a concrete sample requires, subject triplicate specimens to 60 V applied through direct current for a duration of 6 h by using the apparatus and the cells arranged. One of the chambers should contain 3.0% NaCl solution and the other chamber should contain the 0.3 M NaOH solution used in the analysis.

- Determine the total charge passed by an average of the three specimens, reported in Coulombs.

Comparing RCPT values, the charges that passed through the optimum mix of the treated hybrid natural fiber-reinforced concrete (M1-1) as compared to the control concrete at 28th days, as per ASTM C1202, were 2653 C and 2493 C, respectively, which shows a significant resistance towards chloride ion penetration during this curing time, around 21.84% lower than control concrete. The treated hybrid natural fiber-reinforced concrete reduces chloride penetration by enhancing fiber–matrix bonding, minimizing micro-cracks, and refining pore structure. These improvements limit chloride ingress pathways. Studies, such as [80,81], confirm that fiber treatment boosts durability and chloride resistance in concrete. Therefore, from this test result, the control mix and optimum mix of treated hybrid natural fiber-reinforced concrete are both in the range of moderate chloride ion penetrability.

3.3.6. Sulfate Resistance of Concrete

The ubiquitous sodium sulfate (Na2SO4), which is available environmentally, has an adversary consequence. Existing in soil, industrial wastes, and groundwater, it promotes deterioration and has a detrimental impact on the long-term performance of the durability of concrete. However, the chemical reaction between sodium sulfate and cementitious forming materials usually produces gypsum and ettringite, with excessive expansion in the form of cracking, spalling, and it reduces concrete strength and mass variation [82]. The sulfate resistance tests were conducted based on ASTM C1012; the durability performance of the prepared concrete samples of the control concrete were compared with the optimum mix of the hybrid fiber-reinforced concrete. In this investigation, initially, three concrete cube samples were prepared with dimensions 150 mm × 150 mm × 150 mm, cured with the prepared water ponding method for 28 days for the control concrete and the uniquely treated hybrid natural fiber-reinforced concrete, and their average values were considered. At the end of the curing stage, the prepared specimens were removed from the water ponding, the excess film of water on the surface of the specimens was cleaned by using a usual preliminary surface cleaning processing method, and the samples’ mass immediately measured as their initial mass. Thus, sulfate attacks were assessed by the immersion of the 28-day cured prepared concrete specimens in 5% Na2SO4 solution for 28 days, and the weight variation and loss in mechanical strength of the specimen were considered for analysis. As observed in Figure 28, the visual appearance of the prepared specimens changed after their immersion in Na2SO4 solution, showing a white salt deposit that can be observed on the cubes’ surfaces. In Table 15, it can be seen that after the immersion of the prepared specimens in Na2SO4 solution, as in the chloride resistance test, the control mix possessed a minimum loss of compressive strength of 3.6% and loss of weight of 2.81%, whereas the optimum mix of the treated hybrid natural fiber-reinforced concrete (M1-1) had a minimum loss in compressive strength of 5.11% and a loss of weight of 2.69%.

Figure 28.

The visual appearance of the prepared specimens after their immersion in a Na2SO4 solution.

Table 15.

Loss in weight and strength due to Na2SO4 solution.

3.4. Overview of Comparison of Thickness Design of Control Concrete and Uniquely Treated Hybrid Natural Fiber-Reinforced Concrete as per AASHTO 1993

The application of fiber-reinforced concrete has significantly advanced over the past few decades for various purposes. The concept dates back to the early 1900s, when a cement-based paste reinforced with asbestos fibers was first introduced in concrete production for use in roofing plates and pipes [62,83]. In modern times, the use of fibers in concrete has become more prevalent due to their ability to enhance several key properties. These fibers improve flexural strength, abrasion resistance, and fatigue resistance, while also reducing early-age thermal cracking and drying shrinkage compared to conventional concrete. Because of these benefits, fibers are now incorporated into concrete in various forms—either chopped, depending on their aspect ratio, or in long forms for structural applications. Fiber-reinforced concrete is widely used in the production of floor slabs, beams, canal linings, and pavements [84]. The Federal Republic of Ethiopia’s road design manual primarily emphasizes flexible and rigid pavement types, designed to sustain traffic loads throughout their service life based on the axle load distribution mechanism. In flexible pavements, the axial load diminishes over large areas as it is transferred to the compacted subgrade soil through a grain-to-grain mechanism, passing through the wearing, base, and sub-base courses. In contrast, rigid pavements, which are constructed with high-strength concrete slabs, rely on the mechanical properties of rigidity, durability, and a high elastic modulus to transfer and distribute wheels’ axial loads to the compacted subgrade soil through slab action. This type of pavement is preferable in situations involving heavy mixed traffic volumes and low California Bearing Ratio (CBR) values of compacted subgrade soil layers, as it provides a road network with long-term structural capability and greater durability compared to flexible pavement. Consequently, rigid pavements require less maintenance and rehabilitation and consume less energy over their lifespan, making them a more sustainable option in various ways [85].

However, the concrete application industry faces significant challenges, such as high costs due to the expensive constituents of concrete materials and discrepancies between experimental procedures, including casting standards and appropriate mix design preparations, based on material properties. These issues can lead to premature distress, resulting in early-age micro-cracking, which continues to worsen throughout the pavement’s design life, ultimately affecting the overall serviceability of concrete pavements. These problems can be mitigated by incorporating natural fibers into fiber-reinforced concrete production. The use of fibers in concrete enhances the fundamental properties of composite materials and provides a bridging effect across cracks, improving the post-cracking toughness and residual strength of composites throughout their intended design life [86]. Research indicates that adding up to 1% fiber content by weight of cement improves the properties of fiber-reinforced concretes, including flexural strength and abrasion resistance [87].

As a civil engineer, it is essential not only to design rigid pavements effectively but also to understand and address the primary defects observed, such as poor construction practices, a lack of proper supervision, and other contributing factors. By adopting environmentally friendly, sustainable materials and innovative techniques, the mechanical properties of fiber-reinforced concrete can be improved, thereby enhancing its capacity to resist early-age cracking. Recent studies highlight the potential of natural fibers as construction materials, with research over the past few decades demonstrating their physical properties. Commonly used natural fibers in civil engineering include coir, sisal, sugarcane, bamboo, jute, palm, hemp, pineapple leaf, hair, and wheat straw [2,88,89,90,91]. Utilizing these naturally available fibers in construction leads to sustainable development from various perspectives. Combining different types of materials in a single matrix without altering their identities is a growing area of research, with the goal of producing durable green concrete at a lower cost while reducing carbon emissions and minimizing environmental pollutants during processing. To the best of the authors’ knowledge, treated hybrid natural fibers (such as alkali-treated bamboo fibers and naturally treated wheat straw fibers) have not yet been applied to concrete pavement applications, presenting a unique opportunity for further research and innovation.

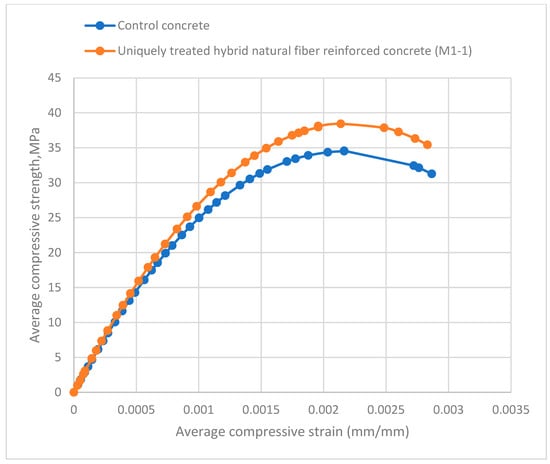

3.5. Compressive Design Parameters

The total absorbed energy was calculated using Origin Lab 2019b by determining the area under the stress–strain curve. In some studies, this value is considered as compressive toughness [92,93], which is the sum of the energy absorbed up to the maximum stress and the energy absorbed after reaching maximum stress. Table 16 presents a comparison of compressive toughness between the control concrete and the uniquely treated hybrid natural fiber-reinforced concrete (M1-1) as determined from the compressive stress–strain curves depicted in Figure 29.

Table 16.

Total absorbed energy and compressive toughness index of control concrete and uniquely treated hybrid natural fiber-reinforced concrete (M1-1).

Figure 29.

Compressive stress–strain response of 28-day aged control concrete and uniquely treated hybrid natural fiber-reinforced concrete (M1-1).

The energy absorbed up to maximum stress is represented by the area under the stress–strain curve up to the point of maximum stress. Conversely, the energy absorbed after maximum stress is represented by the area under the curve from the point of maximum stress to the maximum strain. The compressive toughness index is defined as the ratio of the total absorbed energy to the energy absorbed up to maximum stress. According to Table 16, the total energy absorbed by the uniquely treated hybrid natural fiber-reinforced concrete (M1-1) is 7.88% higher than that of the control concrete. Additionally, the compressive toughness index of the M1-1 mix is 1.4% greater than that of the control concrete, attributed to the improved interlocking behavior of the fibers.

3.6. Rigid Pavement Design Parameters and Performance

The design thickness of rigid pavement can be reduced by increasing the modulus of rupture and the modulus of elasticity, as outlined in the AASHTO Guide from 1993 [94], while keeping other parameters constant. As similarly reported by [91], the modulus of rupture (MoR) and modulus of elasticity (Ec) are the two primary factors influencing concrete pavement thickness design. Consequently, the thickness of rigid pavement is inversely proportional to the MoR and Ec of the concrete, as demonstrated by the AASHTO equation. By adopting techniques that enhance the mechanical properties of concrete, the required thickness of the concrete slab can be reduced. Huang [95] noted that the fundamental equation for rigid pavement design, as provided by the American Association of State Highway and Transportation Officials (AASHTO) in 1993 (II-45), is utilized for this purpose. The equation is described as follows:

where = traffic load in equivalent standard axle loads;

- = standard normal deviation for desired reliability;

- = overall standard deviation;

- = slab thickness (in);

- = serviceability index =

- initial serviceability index

- terminal serviceability index

- = flexural strength of concrete (psi);

- = drainage coefficient;

- = load transfer coefficient;

- = elastic modulus of concrete (psi); and

- = subgrade reaction modulus (psi/in).

In this study, the design thickness of the control concrete and uniquely treated hybrid natural fiber-reinforced concrete (naturally treated wheat straw fibers and alkali-treated bamboo fibers) were compared based on the design input parameters described in Table 17 being kept constant, as considered in the example performed in AASHTO 1993: II-45, except for the concrete material properties, i.e., flexural strength () and modulus of elasticity ().

Table 17.

Design parameters for 1993 AASHTO rigid pavement design.

The comparison of the variation in concrete pavement slab thickness of the control concrete and uniquely treated hybrid natural fiber-reinforced concrete (alkali-treated bamboo fibers and naturally treated wheat straw fibers) specimens is given in Table 18.

Table 18.

Comparison of plain concrete pavement thicknesses against flexural strength and modulus of elasticity for control concrete and uniquely treated hybrid natural fiber (alkali-treated bamboo fibers and naturally treated wheat straw fibers)-reinforced concrete.

Therefore, based on Table 18, the uniquely treated hybrid natural fibers (alkali-treated bamboo fibers and naturally treated wheat straw fibers)-reinforced concrete pavement thickness is reduced by approximately 11% as compared to the control concrete. This is due to the addition of uniquely treated hybrid natural fibers in the concrete production and the bridging mechanism that occurs, which enhances the energy absorption of the treated hybrid natural fibers (alkali-treated bamboo fibers and naturally treated wheat straw fibers)-reinforced concrete by resisting crack formation due to better bonding between the uniquely treated natural fibers and the surrounding concrete matrix because of the pretreatment techniques adopted. Also, once the cracks are formed, the crack width and its propagation under axial traffic loading are restricted and delayed, respectively; this is due to the crack-arresting mechanism which occurs with the incorporation of treated hybrid natural fibers in concrete production. Therefore, the addition of treated hybrid natural fibers (alkali-treated bamboo fibers and naturally treated wheat straw fibers) may result in improved structural capacity which can lead to the better performance of concrete roads in terms of longer lives with less deterioration.

4. Summary and Conclusions