Utilization of Novel Basalt Fiber Pellets from Micro- to Macro-Scale, and from Basic to Applied Fields: A Review on Recent Contributions

Abstract

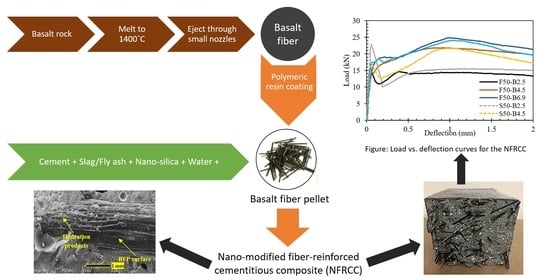

1. Introduction

2. Methodology

2.1. Overview

2.2. Materials

2.3. Test Parameters

3. Results and Discussions

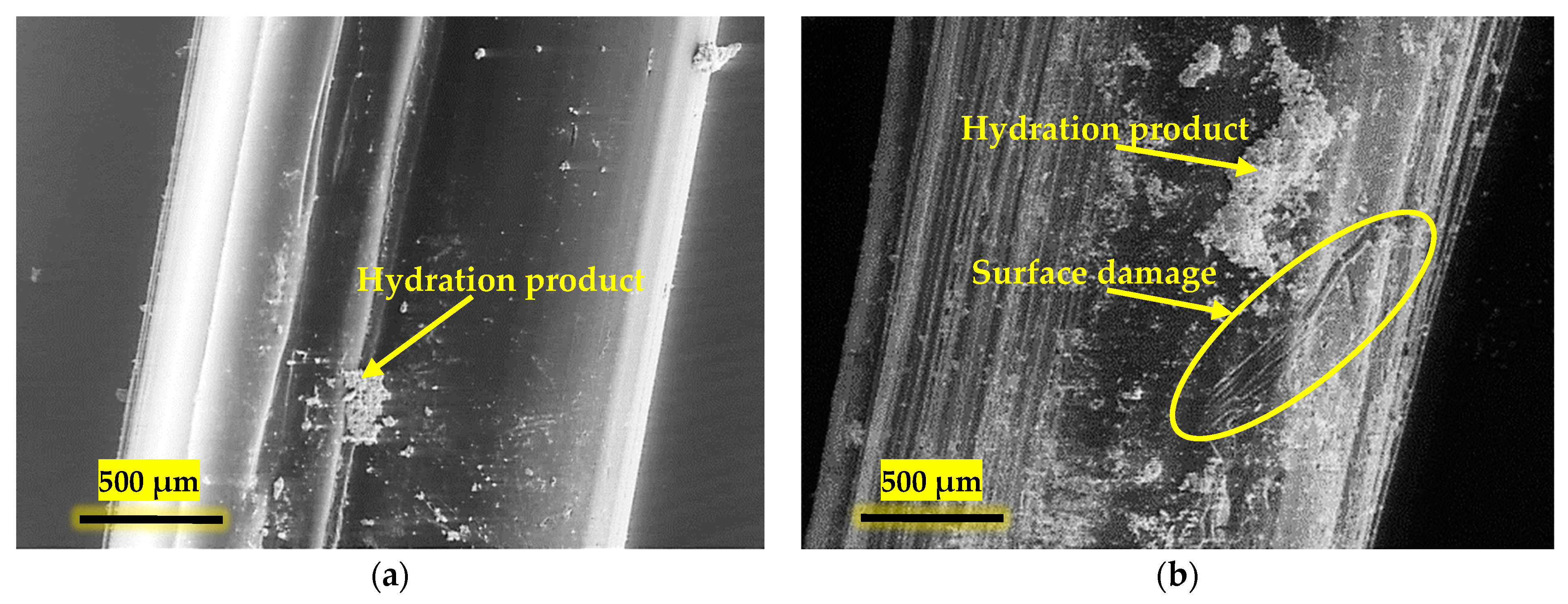

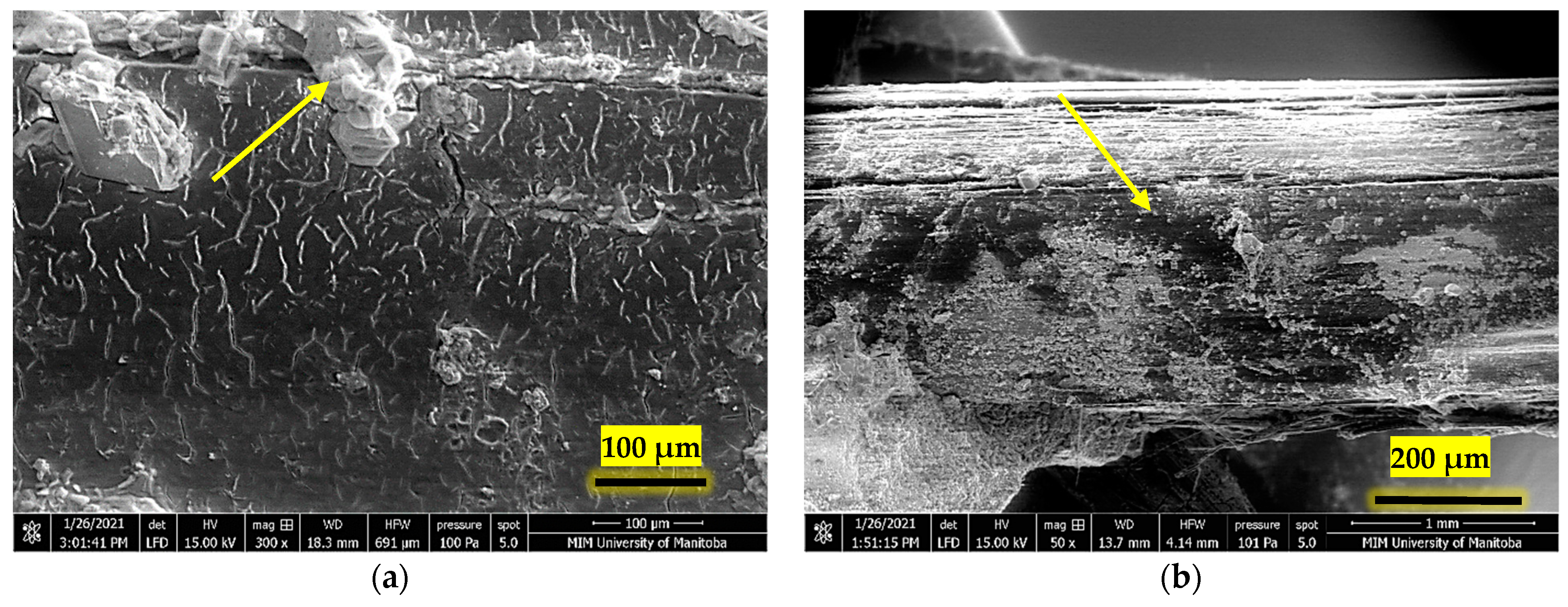

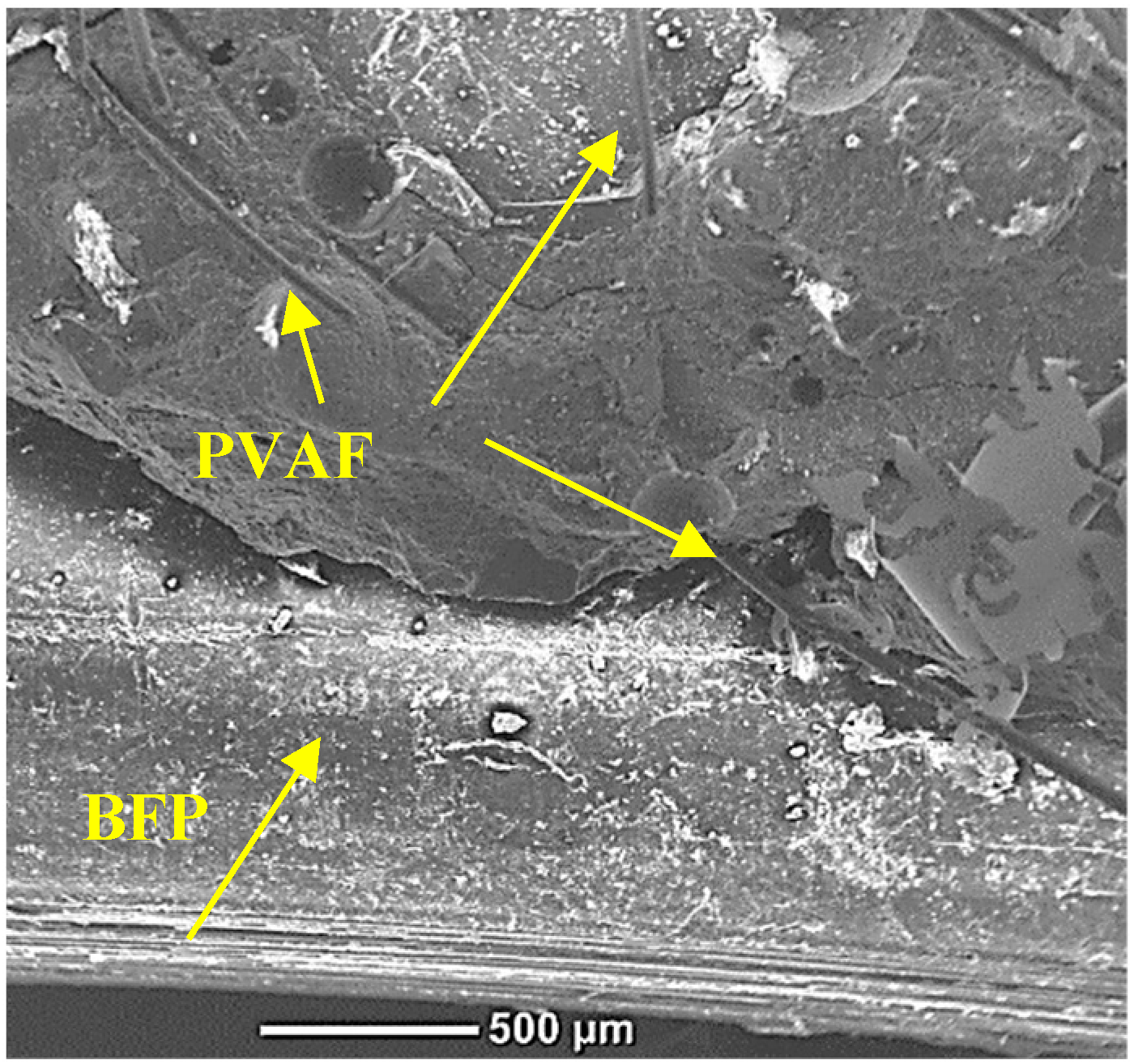

3.1. Phase I (Microstructural Analysis)

3.2. Phase II (Fresh, Mechanical, Impact, and Bond Properties)

3.2.1. Fresh Properties

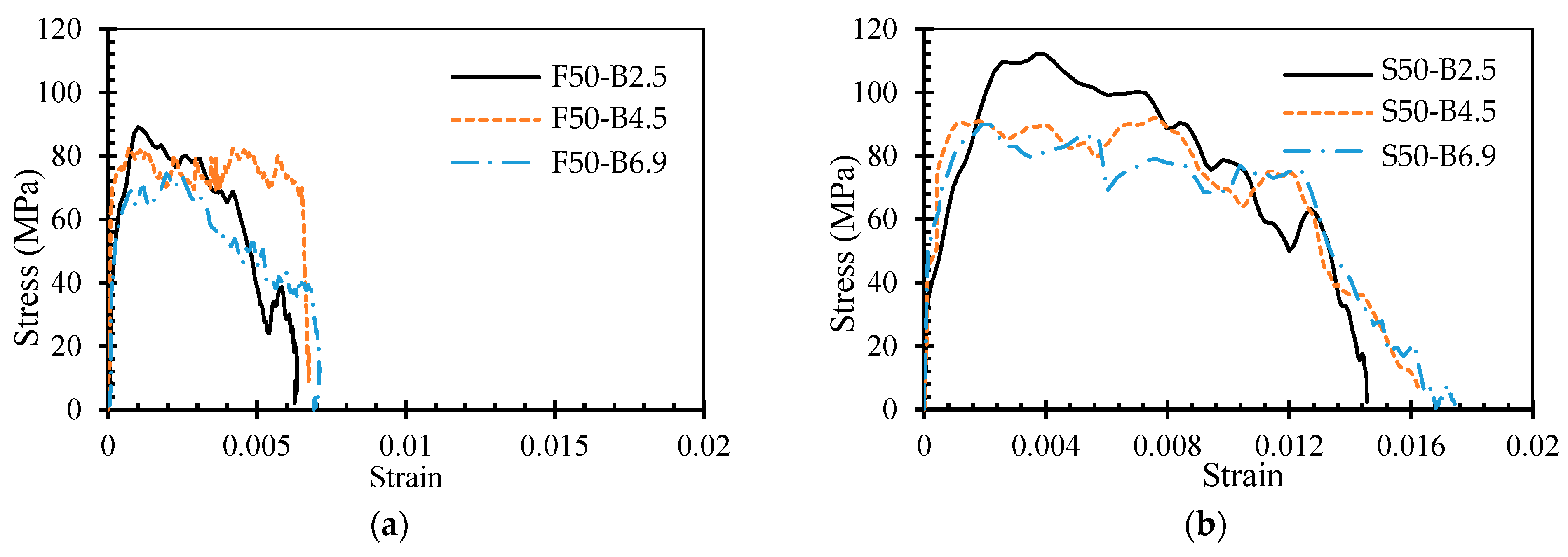

3.2.2. Compressive Strength

3.2.3. Flexural Strength

3.2.4. Impact Load

3.2.5. Single-Pellet Pullout Test

3.3. Phase III (Durability Properties)

3.3.1. Cyclic Freeze–Thaw and Wet–Dry Exposure

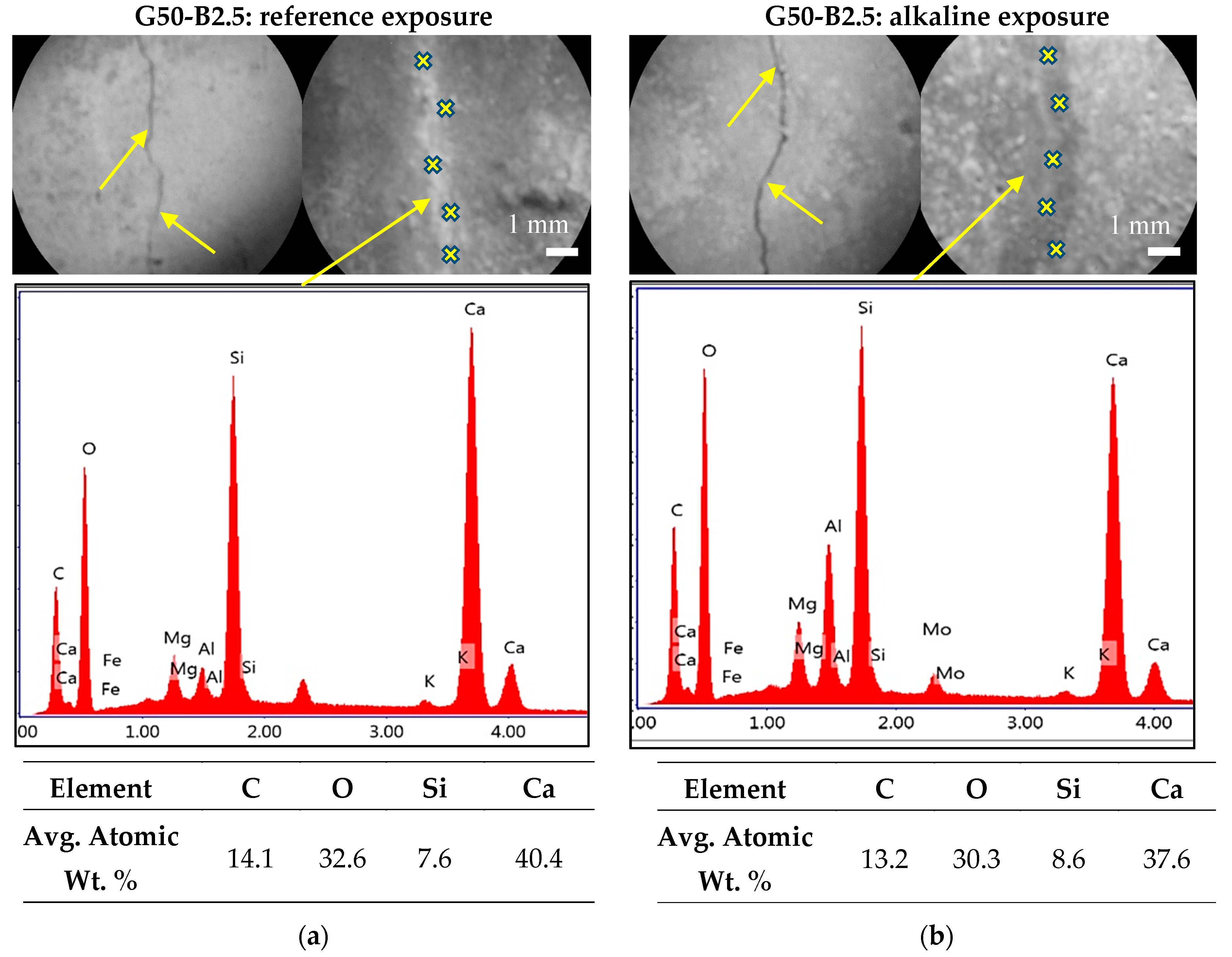

3.3.2. Alkaline Exposure

3.3.3. Salt–Frost Exposure

3.4. Phase IV (Repair and Structural Applications)

3.4.1. Bond Behavior

Bond between NFRCC Concrete and Regular Concrete

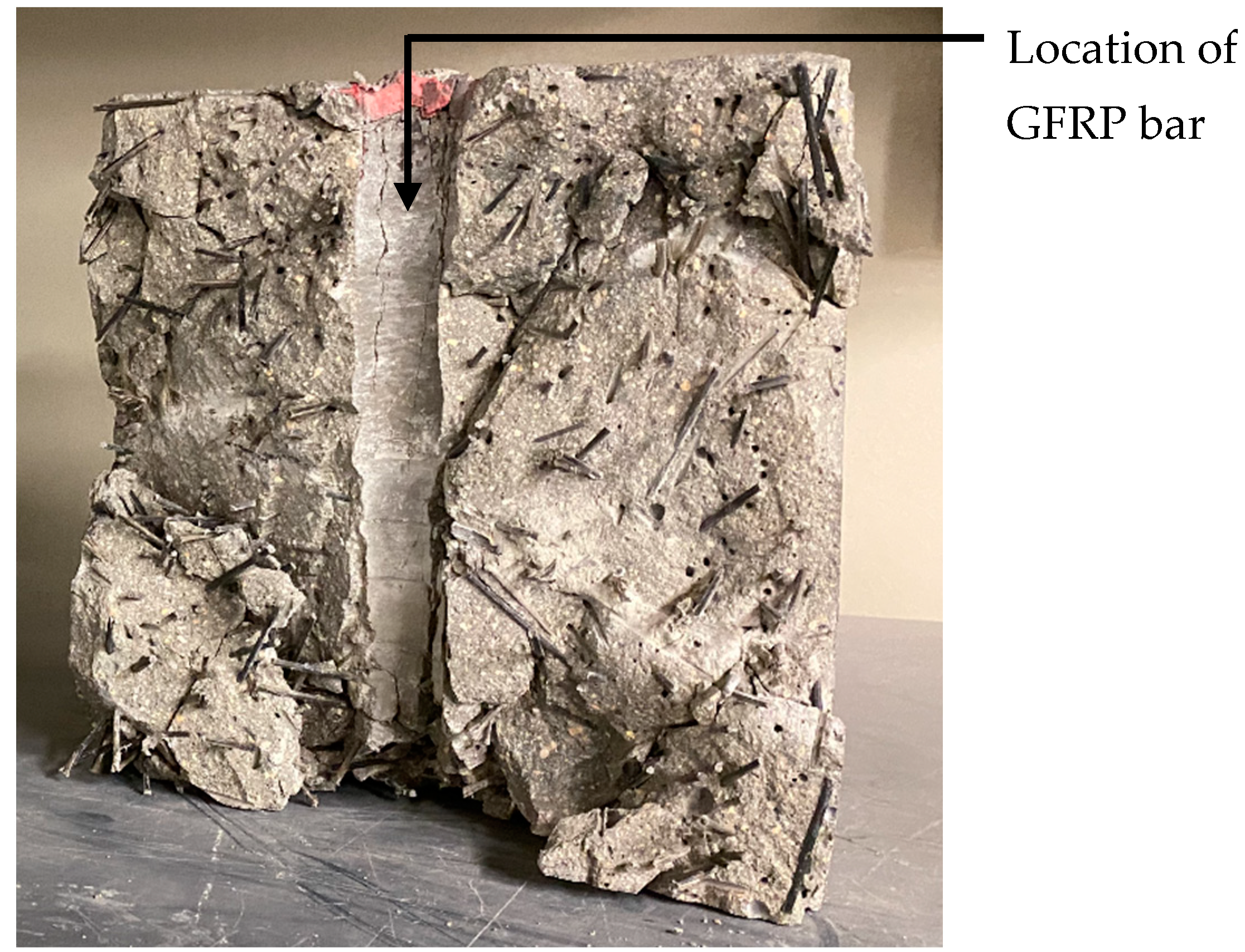

Bond between NFRCC Concrete and Reinforcing Bars

3.4.2. Full-Scale Structural Elements

3.5. Phase V (Hybrid Fibers)

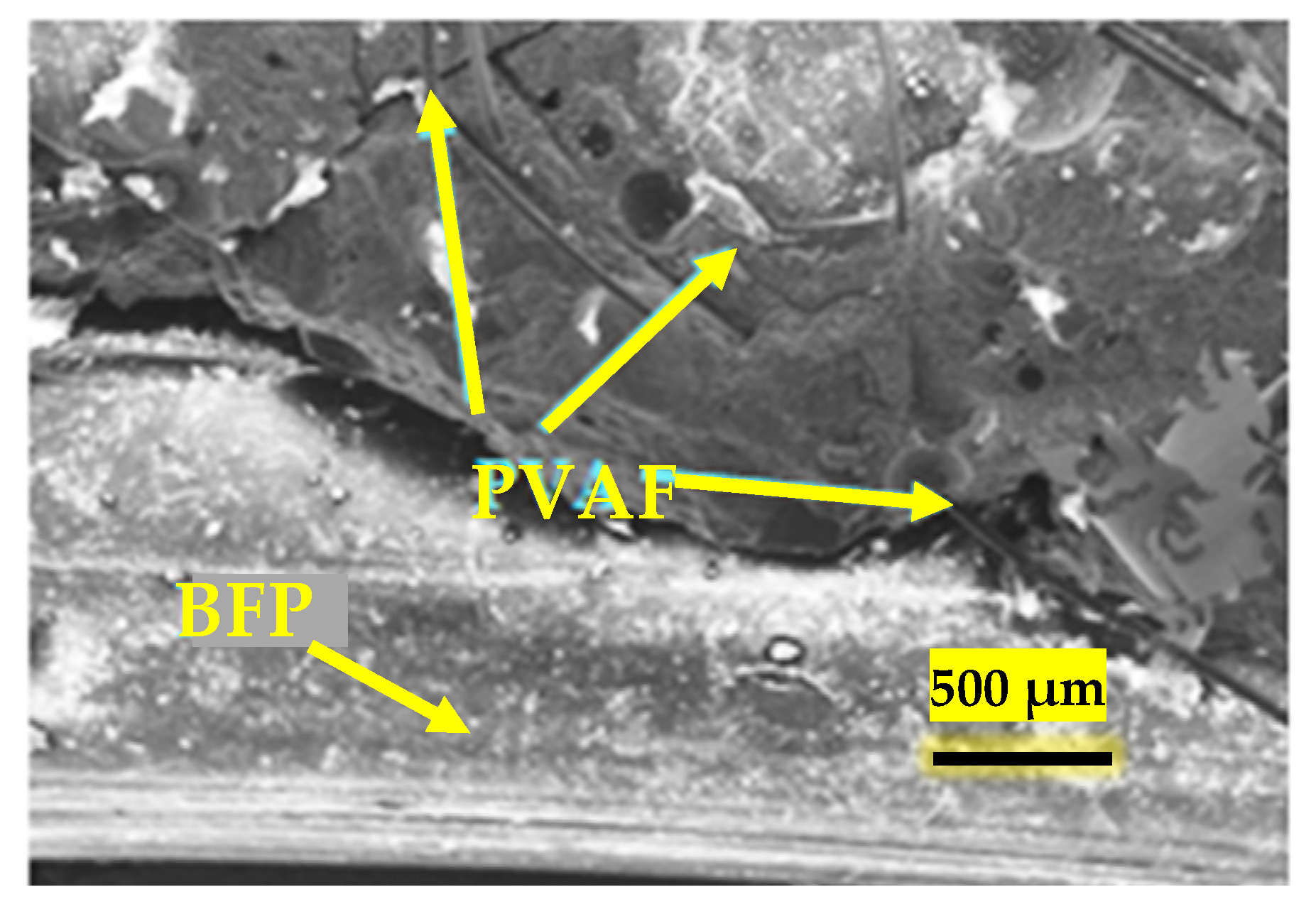

3.5.1. Experimental Investigation

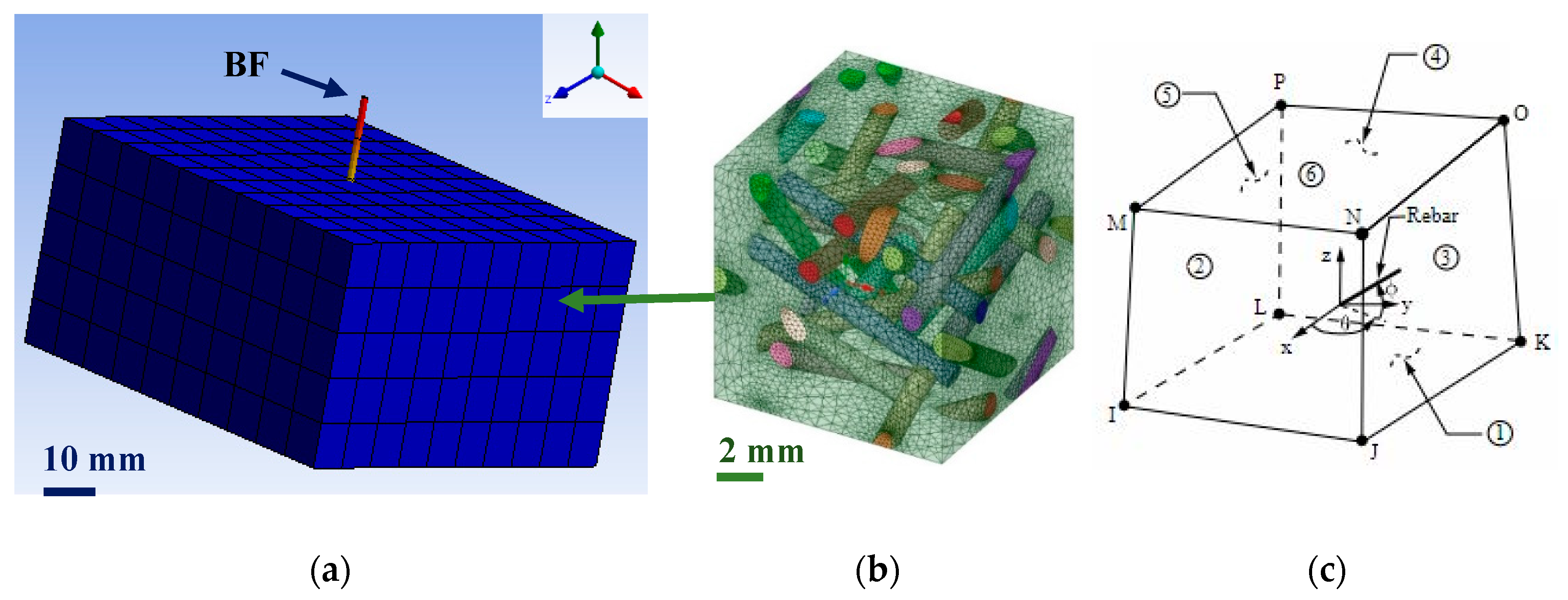

3.5.2. Modeling

4. Concluding Remarks

- The amalgamation of nano-silica particles with the high volume of SCM in the developed binders of NFRCC yielded adequate initial flow (180 ± 20 mm) as well as initial (3 to 5 h) and final setting times (4 to 6 h), which makes them practical for casting operations in the field;

- The early-age and long-term compressive strengths of NFRCC comprising BFPs were significantly high due to the synergistic effects of nano-silica and fly ash or slag, where the nano-modified cementitious composites exceeded 30 MPa and 50 MPa at 1 and 56 days, respectively;

- BFPs were effective at improving the post-cracking behavior of NFRCC, where, for instance, the increase in BFPs in slag-based mixtures from 2.5% to 4.5% resulted in a 33% increase in toughness. This was alluded to the improved interfacial bond between the BFPs and matrix owing to the precipitation of hydration and pozzolanic products in the BFP-tailored surface grooves that enhanced the interlocking between the pellets and the matrix, which was positively reflected on the pull-out resistance of the pellets as verified through the single-pellet pull-out test;

- In general, slag-based mixtures exhibited high mechanical properties (compressive strength, tensile strength, impact resistance, etc.) relative to corresponding fly-ash-based ones, owing to the accelerated reactivity of the slag with nano-silica that was projected on the quality of the matrix as well as its interaction with the reinforcing pellets;

- Under severe alkaline exposure (1 N NaOH solution at 38 ± 2 °C), all composites experienced ductility losses of 17–25% “un-cracked specimens” and 29–46% “pre-cracked specimens” relative to the reference exposure owing to the degradation of the affected pellets by the exposure (near the surface or directly exposed). Furthermore, the extended exposure of the pellets to the alkaline medium led to a deleterious effect on the polyamide component and, in turn, access of the solution to the basalt component; thus, the pull-out toughening mechanism was compromised by the rupture of basalt strands. However, the exposure was favorable for the matrix, which was reflected in the stiffness and flexural capacity of the composites;

- Coupled chemical and environmental loading through salt–frost exposure negatively affected the different cementitious composites, where a coarsened microstructure was obtained for all matrices after the exposure (to different levels, though, according to the binder formulation). This was attributed to chemical and physical attacks, which led to the complete failure of most matrices (fly-ash-based and unmodified matrices) along with impairing the interfacial bond between the matrices and the pellets (although the pellets remained intact);

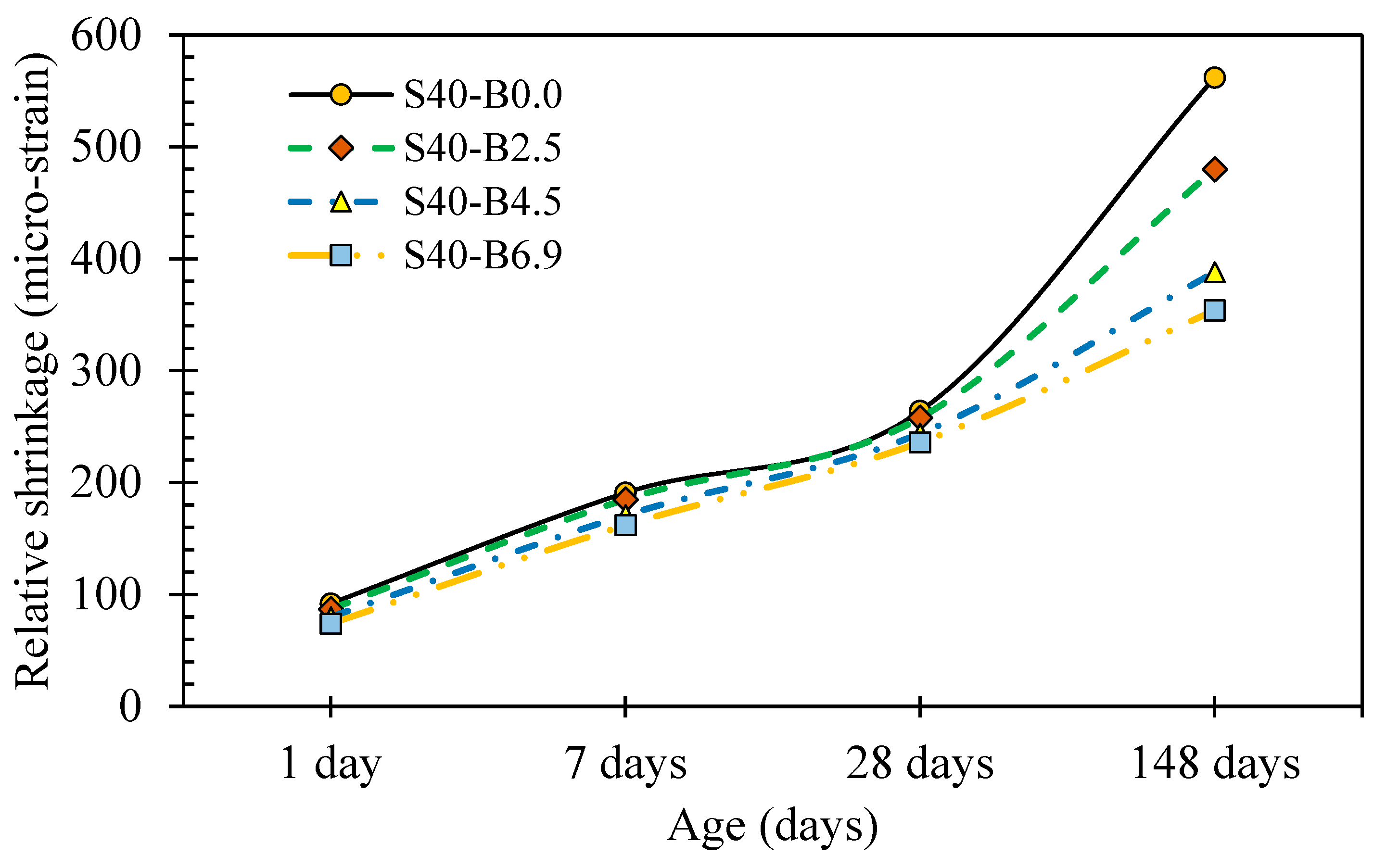

- The cementitious composites revealed adequate thermal compatibility as well as dimensional stability with the substrate concrete, which is attributed to the restraining role of the pellets. Hence, no surface cracks were spotted during the hot/arid exposure conditions, where the composites’ total restrained shrinkage strains remained low at 416 to 454 με. Accordingly, the cementitious composites had efficient integrity (bond strength) with the substrate concrete, with no bonding agents, where the dominant failure mode was in the substrate, guaranteeing the long service life of the repair/overlay assembly under field conditions;

- The addition of 1% micro-PVA to macro-BFP (hybrid system) resulted in optimal performance of NFRCC in terms of modified pore structure, mechanical capacity, and ductility. While macro-BFP controlled the development of macro-cracks, micro-PVA prevented the nucleation of micro-cracks, accordingly, increasing the performance of the composites;

- The coexistence of 1% PVA micro-fibers with BFP macro-fibers (hybrid system) led to improvement in the bond strength with conventional concrete and ribs of steel rebar due to improving the adhesive capacity and friction at the interfacial zone with CC and efficient interlocking with BFP around steel reinforcement;

- Large-scale beams with an NFRCC layer demonstrated a deflection–softening behavior that was characterized by a gradual loss of load-carrying capability up to failure. Additionally, the brittle and rapid failure of deep beams with an NFRCC layer in the tie zone was replaced by a more ductile failure;

- The developed mesoscale RVEs homogenization models were capable of predicting the elastic properties of NFRCC. In addition, the FEM revealed that the hybrid PVA/BFP system improved the shear resistance force of box girders shear key system, meeting the AASHTO LRFD interface coefficient of friction and adhesion parameters for rough surfaces;

- The overall findings from this program indicate that the nano-modified composites comprising BFPs have superior performance, making them potentially an attractive alternative for a variety of infrastructure applications, including repair and strengthening. However, full-scale field studies are recommended for future research to compare the cost-performance attributes relative to other high-performance materials available in the building materials sector. Some of the fundamental properties are still not explored such as durability under different elevated temperatures, mechanical and environmental fatigue behavior, and their ability to resist cyclic load. These properties should be investigated in future to make BFP-reinforced nano-modified composites more acceptable for practical applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, I.H.; Joh, C.; Kim, B.-S. Structural behavior of ultra high performance concrete beams subjected to bending. Eng. Struct. 2010, 32, 3478–3487. [Google Scholar] [CrossRef]

- Bandelt, M.; Billington, S. Impact of Reinforcement Ratio and Loading Type on the Deformation Capacity of High-Performance Fiber-Reinforced Cementitious Composites Reinforced with Mild Steel. J. Struct. Eng. 2016, 142, 04016084. [Google Scholar] [CrossRef]

- Meng, D.; Huang, T.; Zhang, Y.X.; Lee, C.K. Mechanical behaviour of a polyvinyl alcohol fibre reinforced engineered cementitious composite (PVA-ECC) using local ingredients. Constr. Build. Mater. 2017, 141, 259–270. [Google Scholar] [CrossRef]

- Islam, M.J.; Islam, K.; Shahjalal, M.; Khatun, E.; Islam, S.; Razzaque, A.B. Influence of different types of fibers on the mechanical properties of recycled waste aggregate concrete. Constr. Build. Mater. 2022, 337, 127577. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Shahjalal, M.; Islam, K.; Rahman, J.; Ahmed, K.S.; Karim, M.R.; Billah, A.H.M.M. Flexural response of fiber reinforced concrete beams with waste tires rubber and recycled aggregate. J. Clean. Prod. 2021, 278, 123842. [Google Scholar] [CrossRef]

- Emon, M.A.B.; Manzur, T.; Yazdani, N. Improving performance of light weight concrete with brick chips using low cost steel wire fiber. Constr. Build. Mater. 2016, 106, 575–583. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Canbaz, M. Effect of different fibers on the mechanical properties of concrete containing fly ash. Constr. Build. Mater. 2007, 21, 1486–1491. [Google Scholar] [CrossRef]

- Hossain, F.M.Z.; Shahjalal, M.; Islam, K.; Tiznobaik, M.; Alam, M.S. Mechanical properties of recycled aggregate concrete containing crumb rubber and polypropylene fiber. Constr. Build. Mater. 2019, 225, 983–996. [Google Scholar] [CrossRef]

- ACI 544.1R-10; State-of-the Art Report on Fiber Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1991.

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Militký, J.; Mishra, R.; Jamshaid, H. 20—Basalt fibers. In Handbook of Properties of Textile and Technical Fibres, 2nd ed.; Bunsell, A.R., Ed.; Woodhead Publishing: Sawston, UK, 2018; pp. 805–840. [Google Scholar] [CrossRef]

- John, V.J.; Dharmar, B. Influence of basalt fibers on the mechanical behavior of concrete—A review. Struct. Concr. 2021, 22, 491–502. [Google Scholar] [CrossRef]

- Huang, T.; Zhang, Y.X. Chapter 11—Multiscale modeling of multiple-cracking fracture behavior of engineered cementitious composite (ECC). In Advances in Engineered Cementitious Composites; Zhang, Y.X., Yu, K., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 337–388. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Yıldırım, M.; Özhan, H.B. Durability properties of basalt fiber-reinforced mortars with different mineral admixtures exposed to high temperatures. Constr. Build. Mater. 2023, 400, 132574. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Xin, S. Performance Test and Thermal Insulation Effect Analysis of Basalt-Fiber Concrete. Materials 2022, 15, 8236. [Google Scholar] [CrossRef]

- Krassowska, J.; Lapko, A. The influence of steel and basalt fibers on the shear and flexural capacity of reinforced concrete beams. J. Civ. Eng. Archit. 2013, 7, 789. [Google Scholar] [CrossRef]

- Ludovico, M.D.; Prota, A.; Manfredi, G. Structural Upgrade Using Basalt Fibers for Concrete Confinement. J. Compos. Constr. 2010, 14, 541–552. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Zeng, G.; Chen, Z.; Guo, Y. Research progress on properties of basalt fiber-reinforced cement concrete. Mater. Today Commun. 2022, 33, 104824. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental Study on Basic Mechanical Properties of Basalt Fiber Reinforced Concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef] [PubMed]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Iyer, P.; Kenno, S.; Das, S. Mechanical Properties of Fiber-Reinforced Concrete Made with Basalt Filament Fibers. J. Mater. Civ. Eng. 2015, 27, 04015015. [Google Scholar] [CrossRef]

- Özkan, Ş.; Demir, F. The hybrid effects of PVA fiber and basalt fiber on mechanical performance of cost effective hybrid cementitious composites. Constr. Build. Mater. 2020, 263, 120564. [Google Scholar] [CrossRef]

- Shelote, K.M.; Gavali, H.R.; Bras, A.; Ralegaonkar, R.V. Utilization of Co-Fired Blended Ash and Chopped Basalt Fiber in the Development of Sustainable Mortar. Sustainability 2021, 13, 1247. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Wu, D. Mechanical and tribological enhancement of polyoxymethylene-based composites with long basalt fiber through melt pultrusion. Compos. Interfaces 2016, 23, 743–761. [Google Scholar] [CrossRef]

- Li, Y.; Sang, L.; Wei, Z.; Ding, C.; Chang, Y.; Chen, G.; Zhang, W.; Liang, J. Mechanical properties and crystallization behavior of poly(butylene succinate) composites reinforced with basalt fiber. J. Therm. Anal. Calorim. 2015, 122, 261–270. [Google Scholar] [CrossRef]

- High, C.; Seliem, H.M.; El-Safty, A.; Rizkalla, S.H. Use of basalt fibers for concrete structures. Constr. Build. Mater. 2015, 96, 37–46. [Google Scholar] [CrossRef]

- Li, W.; Xu, J. Mechanical properties of basalt fiber reinforced geopolymeric concrete under impact loading. Mater. Sci. Eng.A 2009, 505, 178–186. [Google Scholar] [CrossRef]

- Xu, M.; Song, S.; Feng, L.; Zhou, J.; Li, H.; Li, V.C. Development of basalt fiber engineered cementitious composites and its mechanical properties. Constr. Build. Mater. 2021, 266, 121173. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; Xie, H.; Wei, P.; Li, D.; Xu, Y.; Zhang, F. Research on impact toughness and crack propagation of basalt fiber reinforced concrete under SHPB splitting test. J. Build. Eng. 2023, 77, 107445. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Kutz, M. Handbook of Environmental Degradation of Materials; William Andrew: New York, NY, USA, 2018. [Google Scholar]

- Arslan, M.E. Effects of basalt and glass chopped fibers addition on fracture energy and mechanical properties of ordinary concrete: CMOD measurement. Constr. Build. Mater. 2016, 114, 383–391. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Khan, S. Compressive Stress-Strain Behavior of HSFRC Reinforced with Basalt Fibers. J. Mater. Civ. Eng. 2015, 28, 06015014. [Google Scholar] [CrossRef]

- Liu, J.; Chen, M.; Yang, J.; Wu, Z. Study on Mechanical Properties of Basalt Fibers Superior to E-glass Fibers. J. Nat. Fibers 2022, 19, 882–894. [Google Scholar] [CrossRef]

- Tang, C.; Xu, F.; Li, G. Combustion Performance and Thermal Stability of Basalt Fiber-Reinforced Polypropylene Composites. Polymers 2019, 11, 1826. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.; Qi, Y. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Bediwy, A.; Bassuoni, M.; El-Salakawy, E. Residual Mechanical Properties of BPRCC under Cyclic Environmental Conditions. ASCE J. Mater. Civ. Eng. 2021, 33, 04021290. [Google Scholar] [CrossRef]

- Neville, A. Properties of Concrete, 5th ed.; Prentice Hall: Harlow, UK, 2011. [Google Scholar]

- CSA A3001-18; Cementitious Materials for Use in Concrete. Canadian Standards Association: Mississauga, ON, Canada, 2018.

- Kong, D.; Du, X.; Wei, S.; Zhang, H.; Yang, Y.; Shah, S. Influence of nano-silica agglomeration on microstructure and properties of the hardened cement-based materials. Constr. Build. Mater. 2012, 37, 707–715. [Google Scholar] [CrossRef]

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2019.

- Madani, H.; Bagheri, A.; Parhizkar, T. The pozzolanic reactivity of monodispersed nanosilica hydrosols and their influence on the hydration characteristics of Portland cement. Cem. Concr. Res. 2012, 42, 1563–1570. [Google Scholar] [CrossRef]

- Azzam, A.; Bassuoni, M.; Shalaby, A. Properties of High-Volume Fly Ash and Slag Cementitious Composites Incorporating Nanosilica and Basalt Fiber Pellets. Adv. Civ. Eng. Mater. 2019, 8, 20190018. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Bhatty, J.I.; Battacharja, S. Supplementary Cementing Materials for Use in Blended Cements; The National Academies of Sciences: Washington, DC, USA, 1996. [Google Scholar]

- Azzam, A. Nano-Modified Cementitious Composites Reinforced with Basalt Fiber Pellets and Their Potential for Repair/Overlay Applications. Ph.D. Thesis, University of Manitoba , Winnipeg, MB, Canada, 2021. [Google Scholar]

- Elhadary, R.; Bassuoni, M.T. Nano-modified slag-based cementitious composites reinforced with basalt pellets and polyvinyl alcohol fibers. J. Sustain. Cem. -Based Mater. 2023, 12, 305–316. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Puertas, F.; Amat, T.; Fernández-Jiménez, A.; Vázquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- MacGregor, J.G.; Wight, J.K.; Teng, S.; Irawan, P. Reinforced Concrete: Mechanics and Design; Prentice Hall: Upper Saddle River, NJ, USA, 1997; Volume 3. [Google Scholar]

- Azzam, A.; Bassuoni, M.; Shalaby, A. Nanomodified cementitious composites incorporating basalt fiber pellets under tensile and impact loads. ASCE J. Mater. Civ. Eng. 2021, 33, 04021260. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Zheng, K.; Bakura, T.J.; Totakhil, P.G. Research on compressive impact dynamic behavior and constitutive model of polypropylene fiber reinforced concrete. Constr. Build. Mater. 2018, 187, 584–595. [Google Scholar] [CrossRef]

- Azzam, A.; Bassuoni, M.T.; Shalaby, A. Performance of nano silica-modified cementitious composites reinforced with basalt fiber pellets under alkaline and salt-frost exposures. Cem. Concr. Compos. 2022, 134, 104761. [Google Scholar] [CrossRef]

- Azzam, A.; Bassuoni, M.; Shalaby, A. Flexural Performance of Nanomodified Cementitious Composites Reinforced with BFP in Bonded Overlays. J. Mater. Civ. Eng. 2022, 34, 04022169. [Google Scholar] [CrossRef]

- ASTM C1609; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2019.

- Bediwy, A.; El-Salakawy, E. Bond Behavior of Straight and Headed GFRP Bars Embedded in a Cementitious Composite Reinforced with Basalt Fiber Pellets. ASCE J. Compos. Constr. 2021, 25, 04021038. [Google Scholar] [CrossRef]

- Bediwy, A. Nano-Modified Basalt Fiber-Reinforced Cementitious Composites for Structural Applications. Ph.D. Thesis, University of Manitoba, Winnipeg, MB, Canada, 2021. [Google Scholar]

- Bediwy, A.; Mahmoud, K.; El-Salakawy, E. Structural behavior of FRCC layered deep beams reinforced with GFRP headed-end bars. Eng. Struct. 2021, 243, 112648. [Google Scholar] [CrossRef]

- Bediwy, A.; El-Salakawy, E. Ductility and Performance Assessment of Glass Fiber-Reinforced Polymer-Reinforced Concrete Deep Beams Incorporating Cementitious Composites Reinforced with Basalt Fiber Pellets. ACI Struct. J. 2021, 118, 83–95. [Google Scholar] [CrossRef]

- Dawood, E.T.; Ramli, M. High strength characteristics of cement mortar reinforced with hybrid fibres. Constr. Build. Mater. 2011, 25, 2240–2247. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, M. Fiber synergy in multi-scale fiber-reinforced cementitious composites. J. Reinf. Plast. Compos. 2014, 33, 862–874. [Google Scholar] [CrossRef]

- Sindu, B.S.; Sasmal, S. On the development and studies of nano- and micro-fiber hybridized strain hardened cementitious composite. Arch. Civ. Mech. Eng. 2019, 19, 348–359. [Google Scholar] [CrossRef]

- Liu, S.G.; He, C.; Yan, C.W.; Zhao, X.M. Water Permeability of Polyvinyl Alcohol (PVA) Fiber Reinforced Cementitious Composites. Adv. Mater. Res. 2011, 150–151, 1009–1012. [Google Scholar] [CrossRef]

- Toutanji, H.A.; Lavin, T. Fracture Toughness Model for Poly (vinyl alcohol) Fiber Reinforced High-Performance Cementitious Material. In Proceedings of the 8th International Symposium on Utilization of High-Strength and High-Performance Concrete, Tokyo, Japan, 27–29 October 2008. [Google Scholar]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Elhadary, R. Characteristics of Nano-Modified Cementitious Composites Incorporating Basalt Fiber Pellets and Polyvinyl Alcohol Fibers and Their Suitability for Shear Key Joints. Ph.D. Thesis, University of Manitoba, Winnipeg, MB, Canada, 2023. [Google Scholar]

- Thong, C.C.; Teo, D.C.L.; Ng, C.K. Application of polyvinyl alcohol (PVA) in cement-based composite materials: A review of its engineering properties and microstructure behavior. Constr. Build. Mater. 2016, 107, 172–180. [Google Scholar] [CrossRef]

- Elhadary, R.; Bassuoni, M.T. Bonding Evaluation of Nano-Silica Modified Slag-Based Composites Comprising Basalt Pellets and Polyvinyl Alcohol Fibers for Shear Joints. J. Mater. Civ. Eng. ASCE 2024, 36, 04023560. [Google Scholar] [CrossRef]

- Elhadary, R.; Bassuoni, M.T. Interfacial Bonding between Basalt Fiber/Polymer Pellets and Various Nano-Modified Cementitious Matrices. J. Mater. Civ. Eng. 2023, 35, 04022471. [Google Scholar] [CrossRef]

- Ansys Workbench 19 R2; ANSYS Inc.: Canonsburg, PA, USA, 2020.

| GU Cement | Slag | Fly Ash | |

|---|---|---|---|

| Chemical analysis | |||

| SiO2 (%) | 19.22 | 33.40 | 55.20 |

| CaO (%) | 63.22 | 42.70 | 10.81 |

| Al2O3 (%) | 5.01 | 13.40 | 23.13 |

| Fe2O3 (%) | 2.33 | 0.76 | 3.62 |

| MgO (%) | 3.31 | 5.30 | 1.11 |

| SO3 (%) | 3.01 | 2.40 | 0.22 |

| Na2Oeq. (%) | 0.12 | 0.30 | 3.21 |

| Physical properties | |||

| Specific gravity | 3.15 | 2.87 | 2.12 |

| Fineness (m2/kg) | 390 | 492 | 290 |

| Designation | Nano Silica (%) | Slag (%) | Fly Ash (%) | BFP (%) |

|---|---|---|---|---|

| S40-B0.0 | 6 | 40 | - | 0.0 |

| S40-B2.5 | 6 | 40 | - | 2.5 |

| S40-B4.5 | 6 | 40 | - | 4.5 |

| S40-B6.9 | 6 | 40 | - | 6.9 |

| S50-B0.0 | 6 | 50 | - | 0.0 |

| S50-B2.5 | 6 | 50 | - | 2.5 |

| S50-B4.5 | 6 | 50 | - | 4.5 |

| S50-B6.9 | 6 | 50 | - | 6.9 |

| F50-B2.5 | 6 | - | 50 | 2.5 |

| F50-B4.5 | 6 | - | 50 | 4.5 |

| F50-B6.9 | 6 | - | 50 | 6.9 |

| Mixture ID | Test Time (min) | Setting Time (min) | |||||

|---|---|---|---|---|---|---|---|

| 0 | 15 | 30 | 45 | 60 | Initial | Final | |

| F50-B2.5 | 180 | 154 | 138 | 129 | 112 | 250 | 360 |

| F50-B4.5 | 186 | 154 | 134 | 127 | 108 | 270 | 370 |

| F50-B6.9 | 220 | 202 | 177 | 154 | 133 | 285 | 380 |

| S50-B2.5 | 205 | 190 | 154 | 142 | 130 | 180 | 285 |

| S50-B4.5 | 212 | 196 | 173 | 148 | 134 | 195 | 300 |

| S50-B6.9 | 217 | 187 | 165 | 139 | 118 | 230 | 325 |

| Calcium Hydroxide Content (%) | Exposure | ||

|---|---|---|---|

| Reference | Alkaline | Salt-Frost | |

| Fly-ash-based NFRCC | 1.2 | 1.8 | 2.5 |

| Slag-based NFRCC | 1.3 | 1.4 | 2.1 |

| Specimen | Reinf. Ratio | First Crack Load (kN) | Shear Crack Load (kN) | Ultimate Load (kN) | Deflection at Ultimate Load (mm) | Energy Absorption Capacity (kN-mm) |

|---|---|---|---|---|---|---|

| X-0.6 | 0.6 | 133 | 310 | 716 | 10.5 | 4968 |

| X-1.0 | 1.0 | 140 | 340 | 800 | 10.1 | 4679 |

| BFP-0.6 | 0.6 | 160 | 320 | 851 | 25.2 | 9125 |

| BFP-1.0 | 1.0 | 200 | 310 | 900 | 19.9 | 8245 |

| Mixture ID | Bond Strength (MPa) | Error (%) | De-Bonding Energy Up to 4 mm Slip (J) | Error (%) | ||

|---|---|---|---|---|---|---|

| Experimental | Numerical | Experimental | Numerical | |||

| S50-P0 | 5.68 | 5.34 | 6 | 1.78 | 1.87 | 5 |

| S50-P1 | 7.1 | 6.87 | 3 | 2.59 | 2.35 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, T.; Bediwy, A.; Azzam, A.; Elhadary, R.; El-Salakawy, E.; Bassuoni, M.T. Utilization of Novel Basalt Fiber Pellets from Micro- to Macro-Scale, and from Basic to Applied Fields: A Review on Recent Contributions. Fibers 2024, 12, 17. https://doi.org/10.3390/fib12020017

Ahmed T, Bediwy A, Azzam A, Elhadary R, El-Salakawy E, Bassuoni MT. Utilization of Novel Basalt Fiber Pellets from Micro- to Macro-Scale, and from Basic to Applied Fields: A Review on Recent Contributions. Fibers. 2024; 12(2):17. https://doi.org/10.3390/fib12020017

Chicago/Turabian StyleAhmed, Tasnia, Ahmed Bediwy, Ahmed Azzam, Riham Elhadary, Ehab El-Salakawy, and Mohamed T. Bassuoni. 2024. "Utilization of Novel Basalt Fiber Pellets from Micro- to Macro-Scale, and from Basic to Applied Fields: A Review on Recent Contributions" Fibers 12, no. 2: 17. https://doi.org/10.3390/fib12020017

APA StyleAhmed, T., Bediwy, A., Azzam, A., Elhadary, R., El-Salakawy, E., & Bassuoni, M. T. (2024). Utilization of Novel Basalt Fiber Pellets from Micro- to Macro-Scale, and from Basic to Applied Fields: A Review on Recent Contributions. Fibers, 12(2), 17. https://doi.org/10.3390/fib12020017