Acoustic Characterization and Modeling of Silicone-Bonded Cocoa Crop Waste Using a Model Based on the Gaussian Support Vector Machine

Abstract

1. Introduction

2. Materials and Methods

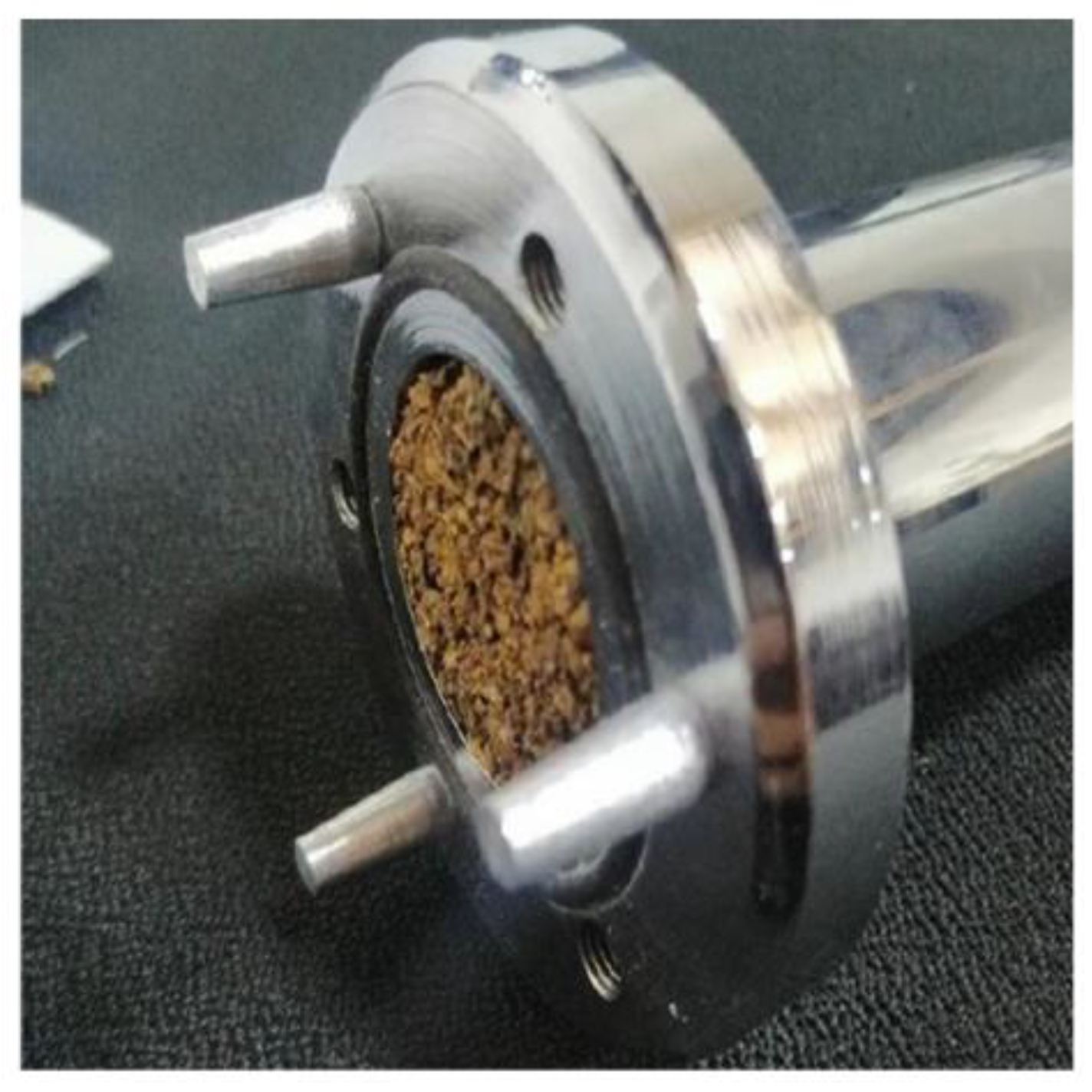

2.1. Characterization of the Cocoa Pod Husk Used in the Study

2.2. Acoustic Absorption Measurement Procedure

2.3. Support Vector Machine (SVM)-Based Method

- xn are the components of a d-dimensional vector containing the data attributes

- yn are the components of a one-dimensional vector containing the data classes

- d represents the number of classes

- T represents the set of data

- C represents the set of classes

- training phase in which the algorithm analyses a training data extracted from the entire set of available data, to build a model that approximates the mapping function.

- testing phase, where the model created is tested on a different set of data to evaluate its performance.

3. Results and Discussion

3.1. Measurements Results

3.2. Gaussian Support Vector Machine Model

- is the true value.

- is the predicted value.

- N is the number of the observation.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ortiz-R, O.O.; Gallardo Villamizar, A.R.; Rangel, J.M. Applying Life Cycle Management of Colombian Cocoa Production. Food Sci. Technol. 2014, 34, 62–68. [Google Scholar] [CrossRef]

- Wirén-Lehr, S. Sustainability in Agriculture—An Evaluation of Principal Goal Oriented Concepts to Close the Gap between Theory and Practice. Agric. Ecosyst. Environ. 2001, 84, 115–129. [Google Scholar] [CrossRef]

- Mattsson, B.; Cederberg, C.; Blix, L. Agricultural Land Use in Life Cycle Assessment (LCA): Case Studies of Three Vegetable Oil Crops. J. Clean. Prod. 2000, 8, 283–292. [Google Scholar] [CrossRef]

- Carof, M.; Colomb, B.; Aveline, A. A Guide for Choosing the Most Appropriate Method for Multi-Criteria Assessment of Agricultural Systems According to Decision-Makers’ Expectations. Agric. Syst. 2013, 115, 51–62. [Google Scholar] [CrossRef]

- Ramírez Cando, L.J.; Spugnoli, P. A Review of Life Cycle Assessment: Agroproducts Modeling. Granja Rev. Cienc. Vida 2016, 24, 5–15. [Google Scholar] [CrossRef]

- Panak Balentic, J.; Ackar, Đ.; Jokic, S.; Jozinovic, A.; Babic, J.; Milicevic, B.; Subari, D.; Pavlovic, N. Cocoa Shell: A By-Product with Great Potential for Wide Application. Molecules 2018, 23, 1404. [Google Scholar] [CrossRef] [PubMed]

- Daud, Z.; Tun, U.; Onn, H.; Sari, A.; Kassim, M.; Tun, U.; Onn, H.; Aripin, A.M.; Tun, U.; Onn, H.; et al. Chemical Composition and Morphological of Cocoa Pod Husks and Cassava Peels for Pulp and Paper Production. Aust. J. Basic Appl. Sci. 2013, 7, 406–411. [Google Scholar]

- Graziani de Farinas, L.; Ortiz de Bertorelli, L.; Angulo, J.; Parra, P. Características Físicas Del Fruto de Cacaos Tipos Criollo, Forastero y Trinitario de La Localidad de Cumboto, Venezuela. Agron. Trop. 2002, 52, 343–362. [Google Scholar]

- Braudeau, J. El Cacao: Técnicas Agricolas y Producciones Tropicales; Técnicas Agrícolas y Producciones Tropicales; Blume: Madrid, Spain, 1970. [Google Scholar]

- Castillo, E.; Alvarez, C.; Contreras, Y. Physicochemical Characterization of the Fruit Shell of a Cocoa Clone (Theobroma cacao L.) Harvested in Caucagua, Miranda State. Venezuela. Rev. Investig. Pedagógica Exp. Libert. 2018, 45, 154–175. [Google Scholar]

- Voora, V.; Bermúdez, S.; Larrea, C. Global Market Report: Cocoa; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2019. [Google Scholar]

- Prabhakaran Nair, K.P. The Agronomy and Economy of Important Tree Crops of the Developing World; Elsevier: London, UK, 2010. [Google Scholar] [CrossRef]

- Ministerio de Cultura y Patrimonio de Ecuador. EC Ministerio de Cultura y Patrimonio. 2017; Acuerdo Ministerial No. DM-2017-063; Ministerio de Cultura y Patrimonio de Ecuador: Quito, Ecuador, 2017.

- Barazarte, H.; Sangronis, E.; Unai, E. La cáscara de cacao (Theobroma cacao L.): Una posible fuente comercial de pectinas. Arch. Latinoam. Nutr. 2008, 58, 64–70. [Google Scholar]

- Gavilanes-Terán, I.; Paredes, C.; Pérez-Espinosa, A.; Ángeles Bustamante, M.; Gálvez-Sola, L.; Jara-Samaniego, J. Opportunities and Challenges of Organic Waste Management from the Agroindustrial Sector in South America: Chimborazo Province Case Study. Commun. Soil Sci. Plant Anal. 2015, 46 (Suppl. S1), 137–156. [Google Scholar] [CrossRef]

- Ramírez Gil, J. Pérdidas Económicas Asociadas a La Pudrición de La Mazorca Del Cacao Causada Por Phytophthora spp., y Moniliophthora Roreri (Cif y Par) Evans et Al., En La Hacienda Theobroma, Colombia. Rev. Protección Veg. 2016, 31, 42–49. [Google Scholar]

- Ouattara, L.Y.; Kouassi, E.K.A.; Soro, D.; Soro, Y.; Yao, K.B.; Adouby, K.; Drogui, A.P.; Tyagi, D.R.; Aina, P.M. Cocoa Pod Husks as Potential Sources of Renewable High-Value-Added Products: A Review of Current Valorizations and Future Prospects. BioResources 2021, 16, 1998. [Google Scholar] [CrossRef]

- Fidelis, C.; Rajashekhar Rao, B.K. Enriched Cocoa Pod Composts and Their Fertilizing Effects on Hybrid Cocoa Seedlings. Int. J. Recycl. Org. Waste Agric. 2017, 6, 99–106. [Google Scholar] [CrossRef]

- Campos Filho, P.C.; Carvalho Silva, R.; Ferreira de Sousa, D.; da Cunha e Silva, S.L.; da Conceicao, A.O.; Pungartnik, C.; Brendel, M. Use of Theobroma Cacao Pod Husk-Derived Biofertilizer Is Safe as It Poses Neither Ecological nor Human Health Risks. J. Fertil. Pestic. 2017, 8, 3. [Google Scholar] [CrossRef]

- Nortey, T.N.; Kpogo, D.V.; Kpogo, A.L.; Naazie, A.; Oddoye, E.O. Cocoa Pod Husk Is a Potential Feed Ingredient in Laying Hen Diets. Livest. Res. Rural Dev. 2015, 27. [Google Scholar]

- Oduro-Mensah, D.; Ocloo, A.; Nortey, T.; Antwi, S.; Okine, L.K.; Adamafio, N.A. Nutritional Value and Safety of Animal Feed Supplemented with Talaromyces Verruculosus-Treated Cocoa Pod Husks. Sci. Rep. 2020, 10, 13163. [Google Scholar] [CrossRef]

- Adeyeye, S.A.; Ayodele, S.O.; Oloruntola, O.D.; Agbede, J.O. Processed Cocoa Pod Husk Dietary Inclusion: Effects on the Performance, Carcass, Haematogram, Biochemical Indices, Antioxidant Enzyme and Histology of the Liver and Kidney in Broiler Chicken. Bull. Natl. Res. Cent. 2019, 43, 54. [Google Scholar] [CrossRef]

- Magistrelli, D.; Malagutti, L.; Galassi, G.; Rosi, F. Cocoa Husks in Diets of Italian Heavy Pigs. J. Anim. Sci. 2012, 90 (Suppl. S4), 230–232. [Google Scholar] [CrossRef][Green Version]

- Jayeola, C.O.; Adebowale, B.A.; Yahaya, L.E.; Ogunwolu, S.O.; Olubamiwa, O. Production of Bioactive Compounds From Waste. Ther. Probiot. Unconv. Foods 2018, 317–340. [Google Scholar] [CrossRef]

- Vriesmann, L.C.; de Oliveira Petkowicz, C.L. Cacao Pod Husks as a Source of Low-Methoxyl, Highly Acetylated Pectins Able to Gel in Acidic Media. Int. J. Biol. Macromol. 2017, 101, 146–152. [Google Scholar] [CrossRef] [PubMed]

- Yusof, F.; Khanahmadi, S.; Amid, A.; Mahmod, S.S. Cocoa Pod Husk, a New Source of Hydrolase Enzymes for Preparation of Cross-Linked Enzyme Aggregate. Springerplus 2016, 5, 57. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.C.; Tsai, S.W. Enantioselective synthesis of (S)-ibuprofen ester prodrug in cyclohexane by Candida rugosa lipase immobilized on Accurel MP1000. Biotechnol. Prog. 2000, 16, 986–992. [Google Scholar] [CrossRef] [PubMed]

- Gotor-Fernández, V.; Brieva, R.; Gotor, V. Lipases: Useful biocatalysts for the preparation of pharmaceuticals. J. Mol. Catal. B Enzym. 2006, 40, 111–120. [Google Scholar] [CrossRef]

- Rajendran, A.; Palanisamy, A.; Thangavelu, V. Lipase applications in food industry. Indian J. Biotechnol. 2007, 6, 141–158. [Google Scholar]

- Mehta, A.; Guleria, S.; Sharma, R.; Gupta, R. The Lipases and Their Applications with Emphasis on Food Industry. In Microbial Biotechnology in Food and Health; Elsevier Inc.: Amsterdam, The Netherlands, 2021; pp. 143–164. [Google Scholar] [CrossRef]

- Holsinger, V.H.; Kligerman, A.E. Applications of lactase in dairy foods and other foods containing lactose. Food Technol. 1991, 45, 92–94. [Google Scholar]

- Emtenani, S.; Asoodeh, A.; Emtenani, S. Molecular Cloning of a Thermo-Alkaliphilic Lipase from Bacillus Subtilis DR8806: Expression and Biochemical Characterization. Process Biochem. 2013, 48, 1679–1685. [Google Scholar] [CrossRef]

- Hasan, F.; Shah, A.A.; Javed, S.; Hameed, A. Enzymes Used in Detergents: Lipases. Afr. J. Biotechnol. 2010, 9, 4836–4844. [Google Scholar] [CrossRef]

- Njoku, V.O.; Oguzie, E.E.; Duru, C.; Bello, O.S. Cocoa Pod Husk as a Low Cost Biosorbent for the Removal of Pb(II) and Cu(II) from Aqueous Solutions Cocoa Pod Husk as a Low Cost Biosorbent for the Removal of Pb(II) and Cu(II) from Aqueous Solutions. Aust. J. Basic Appl. Sci. 2011, 5, 101–110. [Google Scholar]

- Pua, F.L.; Sajab, M.S.; Chia, C.H.; Zakaria, S.; Rahman, I.A.; Salit, M.S. Alkaline-Treated Cocoa Pod Husk as Adsorbent for Removing Methylene Blue from Aqueous Solutions. J. Environ. Chem. Eng. 2013, 1, 460–465. [Google Scholar] [CrossRef]

- Tsai, W.; Hsu, C.; Lin, Y.; Tsai, C.; Chen, W.; Chang, Y. Enhancing the Pore Properties and Adsorption Performance of Cocoa Pod Husk (CPH)-Derived Biochars via Post-Acid Treatment. Processes 2020, 8, 144. [Google Scholar] [CrossRef]

- Vásquez, Z.S.; De Carvalho, D.P.; Pereira, G.V.M.; Vandenberghe, L.P.S.; De Oliveira, P.Z.; Tiburcio, P.B.; Rogez, H.L.G.; Góes, A.; Soccol, C.R. Biotechnological Approaches for Cocoa Waste Management: A Review. Waste Manag. 2019, 90, 72–83. [Google Scholar] [CrossRef] [PubMed]

- Iannace, G.; Puyana-Romero, V.; Ciaburro, G. Corn plants as temporary acoustic barrier to limit the effects of noise pollution. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings; Institute of Noise Control Engineering: Washington, DC, USA, 2021; Volume 263, pp. 2164–2171. [Google Scholar]

- Rachmat, D.; Mawarani, L.J.; Risanti, D.D. Utilization of Cacao Pod Husk (Theobroma cacao L.) as Activated Carbon and Catalyst in Biodiesel Production Process from Waste Cooking Oil. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Syamsiro, M.; Saptoadi, H.; Tambunan, B.H. Experimental investigation on combustion of bio-pellets from Indonesian cocoa pod husk. Asian J. Appl. Sci. 2011, 4, 712–719. [Google Scholar] [CrossRef]

- Titiloye, J.O.; Abu, M.S.; Odetoye, T.E. Thermochemical Characterisation of Agricultural Wastes from West Africa. Ind. Crop. Prod. 2013, 47, 199–203. [Google Scholar] [CrossRef]

- Adamafio, N.A.; Afeke, I.K.; Wepeba, J.; Ali, E.K.; Quaye, F.O. Biochemical Composition and in Vitro Digestibility of Cocoa Pod Husk, Cassava Peel and Plantain Peel. Ghana J. Sci. 2004, 44, 29–38. [Google Scholar]

- Martínez-Ángel, J.D.; Villamizar-Gallardo, R.A.; Ortíz-Rodríguez, O.O. Characterization and Evaluation of Cocoa (Theobroma Cacao L.) Pod Husk as a Renewable Energy Source. Agrociencia 2015, 49, 329–345. [Google Scholar]

- Yao, F.; Liu, G.; Ji, Y.; Tong, W.; Du, X.; Li, K.; Martek, I. Evaluating the environmental impact of construction within the industrialized building process: A monetization and building information modelling approach. Int. J. Environ. Res. Public Health 2020, 17, 8396. [Google Scholar] [CrossRef]

- European Commission. Strategy for the Sustainable Competitiveness of the Construction Sector and Its Enterprises: Commision to the European Parliament and the Council; Publications Office of the European Union: Luxembourg, 2012. [Google Scholar]

- European Commission. of the R. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050: Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; Publications Office of the European Union: Luxembourg, 2011. [Google Scholar]

- MacDougall, C. Natural Building Materials in Mainstream Construction: Lessons from the U.K. J. Green Build. 2008, 3, 3–14. [Google Scholar] [CrossRef]

- Hebel, D.E.; Heisel, F. Cultivated Building Materials: Industrialized Natural Resources for Architecture and Construction; Birkhäuser: Berlin, Germany; Boston, MA, USA, 2017. [Google Scholar] [CrossRef]

- Sahat, S.; Ahmad, N.F.A.; Razali, S.N.A.M.; Kaamin, M.; Mokhtar, M.; Hamid, N.B.; Nyadiman, N. Effectiveness of Corn Cob as a Thermal Isolation Material. In AIP Conf. Proccedings; AIP Publishing LLC: Melville, NY, USA, 2018; p. 020127. [Google Scholar]

- Dewi, S.M.; Wijaya, M.N. The Use of Bamboo Fiber in Reinforced Concrete Beam to Reduce Crack. In AIP Conference Prceedigns: Green Construction and Engineering Education for Sustainable Future; AIP Publishing LLC: Melville, NY, USA, 2017; p. 020003. [Google Scholar] [CrossRef]

- Eisenreich, N.; Eyerer, P. Arboform®—A Thermoplastic, Processable Material from Lignin and Natural Fibers. In Chemical Modification, Properties, and Usage of Lignin; Springer: Boston, MA, USA, 2002. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A review of sustainable materials for acoustic applications. Build. Acoust. 2012, 19, 283–311. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G.; Trematerra, A. Modelling Sound Absorption Properties of Broom Fibers Using Artificial Neural Networks. Appl. Acoust. 2020, 163, 107239. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Predicting the Sound Absorption of Natural Materials: Best-Fit Inverse Laws for the Acoustic Impedance and the Propagation Constant. Appl. Acoust. 2017, 115, 131–138. [Google Scholar] [CrossRef]

- Glé, P.; Gourdon, E.; Arnaud, L. Modelling of the Acoustical Properties of Hemp Particles. Constr. Build. Mater. 2012, 37, 801–811. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petr, M.; Noman, M.T.; Mishra, R.; Militky, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, X.; Zhang, H.; Zhuang, X.; Yan, X. Corn Husk for Noise Reduction: Robust Acoustic Absorption and Reduced Thickness. Appl. Acoust. 2018, 134, 60–68. [Google Scholar] [CrossRef]

- Oldham, D.J.; Egan, C.A.; Cookson, R.D. Sustainable Acoustic Absorbers from the Biomass. Appl. Acoust. 2011, 72, 350–363. [Google Scholar] [CrossRef]

- Putra, A.; Or, K.H.; Selamat, M.Z.; Nor, M.J.M.; Hassan, M.H.; Prasetiyo, I. Sound absorption of extracted pineapple-leaf fibres. Appl. Acoust. 2018, 136, 9–15. [Google Scholar] [CrossRef]

- Yahya, K.; Haron, Z.; Shaikh Abdul Hamid, S.N.; Mohd Fasli, N.; Taiwo, E.M. The Potential of Pinepple Leaf Fibre as an Acoustic Absorber. In Proceedings of the AICCE’19, Penang, Malaysia, 21–22 August 2019; pp. 919–932. [Google Scholar]

- Iannace, G.; Umberto, B.; Bravo-Moncayo, L.; Ciaburro, G.; Puyana-Romero, V. Organic Waste as Absorbent Materials. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings, InterNoise20; Institute of Noise Control Engineering: Washington, DC, USA, 2020. [Google Scholar]

- Ciaburro, G.; Puyana-romero, V.; Iannace, G.; Andres, W.; Iannace, G. Characterization and Modeling of Corn Stalk Fibers Tied with Clay Using Support Vector Regression Algorithms Characterization and Modeling of Corn Stalk Fibers Tied with Clay Using Support Vector Regression Algorithms. J. Nat. Fibers 2021, 1–16. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G.; Ali, M.; Alabdulkarem, A.; Nuhait, A. An Artificial Neural Network Approach to Modelling Absorbent Asphalts Acoustic Properties. J. King Saud Univ.-Eng. Sci. 2021, 33, 213–220. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G.; Puyana-Romero, V.; Trematerra, A. A Comparison between Numerical Simulation Models for the Prediction of Acoustic Behavior of Giant Reeds Shredded. Appl. Sci. 2020, 10, 6881. [Google Scholar] [CrossRef]

- Chávez Cruz, G.; Olaya Cum, R.L.; Maza Iñiguez, J.V. Cost of Production of Clonal Cacao CCN-51 in the Parish Bella-Maria, Ecuador. Univ. Soc. 2018, 10, 179–185. [Google Scholar]

- Alvarado Valarezo, J.; Castro Bravo, J.; Guerrero Martínez, Á.; Nolivos Álvarez, I. Sistema Experto Para Decisiones de Riego En Cultivos de Cacao CCN51. Artículos Tesis Grado-FIEC 2012. Available online: http://www.dspace.espol.edu.ec/xmlui/handle/123456789/20806?show=full (accessed on 4 March 2022).

- Teas, Cocoa and Coffee: Plant Secondary Metabolites and Health; Crozier, A., Ashihara, H., Tomás-Barbéran, F., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Cajas Camacho, L.G. La Cáscara de Cacao Como Material Acústico: Evaluación de las Propiedades Absorbentes de Muestras con Distinta Densidad y Espesor. Bachelor’s Thesis, Universidad de las Américas, Quito, Ecuador, 2019. [Google Scholar]

- Ray, D.; Sarkar, B.K.; Rana, A.K.; Bose, N.R. Effect of alkali treated jute fibres on composite properties. Bull. Mater. Sci. 2001, 24, 129–135. [Google Scholar] [CrossRef]

- Kilama, G.; Lating, P.O.; Byaruhanga, J.; Biira, S. Quantification and Characterization of Cocoa Pod Husks for Electricity Generation in Uganda. Sustain. Soc. 2019, 9, 2–11. [Google Scholar] [CrossRef]

- Velazquez-Araque, L.; Cárdenas, J. A Preliminary Study of Pelletized Ecuadorian Cocoa Pod Husk for Its Use as a Source of Renewable Energy. In Proceedings of the 20th World Mult-Conference on Systems, Cybernetics and Informatics (WMSCI 2016), Orlando, FL, USA, 5–8 July 2016; pp. 29–33. [Google Scholar]

- Barreiro, A.; Sandoval, A.J. Kinetics of Moisture Adsorption during Simulated Storage of Whole Dry Cocoa Beans at Various Relative Humidities. J. Food Eng. 2020, 273, 109869. [Google Scholar] [CrossRef]

- ISO 354:2003(En); Acoustics—Measurement of Sound Absorption in a Reverberation Room. International Organization for Standardization: Geneva, Switzerland, 2003.

- ISO 10534-2; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes-Part 2: Transfer-Function Method. International Organization for Standardization: Geneva, Switzerland, 1998.

- ASTM E1050-98; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones, and a Digital Frequency Analysis System. ASTM International: West Conshohocken, PA, USA, 1998. [CrossRef]

- Vapnik, V. The Nature of Statistical Learning Theory; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Mangasarian, O.L.; Musicant, D.R. Lagrangian support vector machines. J. Mach. Learn. Res. 2001, 1, 161–177. [Google Scholar]

- Amari, S.I.; Wu, S. Improving support vector machine classifiers by modifying kernel functions. Neural. Netw. 1999, 12, 783–789. [Google Scholar] [CrossRef]

- Platt, J. Sequential Minimal Optimization: A Fast Algorithm for Training Support Vector Machines; Technical Report MSR-TR-98–14; Microsoft Research: Redmond, WA, USA, 1999. [Google Scholar]

- Fan, R.E.; Chen, H.P.; Li, J.C. Working Set Selection Using Second Order Information for Training Support Vector Machines. J. Mach. Learn. Res. 2005, 6, 1871–1918. [Google Scholar]

- Huang, T.M.; Kecman, V.; Kopriva, I. Kernel Based Algorithms for Mining Huge Data Sets: Supervised, Semi-Supervised, and Unsupervised Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

- Fan, R.E.; Chen, H.P.; Li, J.C. A Study on SMO-Type Decomposition Methods for Support Vector Machines. IEEE Trans. Neural Netw. Learn. Syst. 2006, 17, 893–908. [Google Scholar]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Bengio, Y.; Grandvalet, Y. No unbiased estimator of the variance of k-fold cross-validation. J. Mach. Learn. Res. 2004, 5, 1089–1105. [Google Scholar]

- Weidong, Y.; Yan, L.I. Sound Absorption Performance of Natural Fibers and Their Composites. Sci. China Technol. Sci. 2015, 55, 2278–2283. [Google Scholar] [CrossRef]

- Köksoy, O. Multiresponse robust design: Mean square error (MSE) criterion. Appl. Math. Comput. 2006, 175, 1716–1729. [Google Scholar] [CrossRef]

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef]

- Willmott, C.J.; Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 2005, 30, 79–82. [Google Scholar] [CrossRef]

- Cameron, A.C.; Windmeijer, F.A. An R-squared measure of goodness of fit for some common nonlinear regression models. J. Econom. 1997, 77, 329–342. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G. Modelling sound absorption properties for recycled polyethylene terephthalate-based material using Gaussian regression. Build. Acoust. 2021, 28, 185–196. [Google Scholar] [CrossRef]

- Copas, J.B. Using regression models for prediction: Shrinkage and regression to the mean. Stat. Methods Med. Res. 1997, 6, 167–183. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Numerical simulation for the sound absorption properties of ceramic resonators. Fibers 2020, 8, 77. [Google Scholar] [CrossRef]

- Poldrack, R.A.; Huckins, G.; Varoquaux, G. Establishment of best practices for evidence for prediction: A review. JAMA Psychiatry 2020, 77, 534–540. [Google Scholar] [CrossRef]

| Fiber | Thickness (mm) | Frequency (Hz) | ||||

|---|---|---|---|---|---|---|

| 125 | 250 | 500 | 1000 | 2000 | ||

| Cocoa | 25 | 0.13 | 0.14 | 0.20 | 0.65 | 0.30 |

| Wood | 30 | 0.05 | 0.10 | 0.10 | 0.20 | 0.40 |

| Hemp | 30 | 0.01 | 0.15 | 0.25 | 0.51 | 0.70 |

| Kenaf | 40 | 0.08 | 0.18 | 0.32 | 0.70 | 0.94 |

| Sheep Wool | 40 | 0.10 | 0.14 | 0.36 | 0.73 | 0.94 |

| Coconut | 50 | 0.10 | 0.20 | 0.34 | 0.67 | 0.79 |

| Fiberglass | 25 | 0.18 | 0.20 | 0.36 | 0.70 | 0.84 |

| Model Type | Fine Gaussian SVM |

|---|---|

| Kernel function | Gaussian |

| Kernel scale | 0.56 |

| Box constraint | 0.1445 |

| Epsilon | 0.0144 |

| Number of iterations | 2524 |

| Bias | 0.2779 |

| Gap | 6.832 × 10−4 |

| DeltaGradient | 0.0021 |

| Model | MSE | RMSE | MAE | R-Squared |

|---|---|---|---|---|

| Linear regression | 0.032 | 0.178 | 0.129 | 0.15 |

| Fine Gaussian SVM | 0.0002 | 0.017 | 0.012 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puyana-Romero, V.; Iannace, G.; Cajas-Camacho, L.G.; Garzón-Pico, C.; Ciaburro, G. Acoustic Characterization and Modeling of Silicone-Bonded Cocoa Crop Waste Using a Model Based on the Gaussian Support Vector Machine. Fibers 2022, 10, 25. https://doi.org/10.3390/fib10030025

Puyana-Romero V, Iannace G, Cajas-Camacho LG, Garzón-Pico C, Ciaburro G. Acoustic Characterization and Modeling of Silicone-Bonded Cocoa Crop Waste Using a Model Based on the Gaussian Support Vector Machine. Fibers. 2022; 10(3):25. https://doi.org/10.3390/fib10030025

Chicago/Turabian StylePuyana-Romero, Virginia, Gino Iannace, Lilian Gisselle Cajas-Camacho, Christiam Garzón-Pico, and Giuseppe Ciaburro. 2022. "Acoustic Characterization and Modeling of Silicone-Bonded Cocoa Crop Waste Using a Model Based on the Gaussian Support Vector Machine" Fibers 10, no. 3: 25. https://doi.org/10.3390/fib10030025

APA StylePuyana-Romero, V., Iannace, G., Cajas-Camacho, L. G., Garzón-Pico, C., & Ciaburro, G. (2022). Acoustic Characterization and Modeling of Silicone-Bonded Cocoa Crop Waste Using a Model Based on the Gaussian Support Vector Machine. Fibers, 10(3), 25. https://doi.org/10.3390/fib10030025