Abstract

In the Direct Energy Deposition (DED) process, the deposited material experiences intricate thermo-mechanical processes. Subsequent thermal cycling can trigger Dynamic Recrystallization (DRX) under suitable conditions, with specific strain and temperature parameters facilitating grain refinement and homogenization. While prior research has examined the impact of thermal cycling in continuous wave (CW) lasers on DRX in 316 L stainless steel deposits, this study delves into the effects of pulsed wave (PW) laser thermal cycling on DRX. Here, the thermo-mechanical response to PW cyclic thermal loading is empirically assessed, and the evolution of microstructure, grain morphology, geometric dislocation density (GND), and misorientation map during PW DED of 316 L stainless steel is scrutinized. Findings reveal that DRX is activated between the 8th and 44th thermal cycles, with temperatures fluctuating in the range of 680 K–750 K–640 K and grains evolving within a 5.6%–6.2%–5.2% strain range. After 90 thermal cycles, the grain microstructure undergoes significant alteration. Throughout the thermal cycling, dynamic recovery (DRV) occurs, marked by sub-grain formation and low-angle grain boundaries (LAGBs). Continuous dynamic recrystallization (CDRX) accompanies discontinuous dynamic recrystallization (DDRX), with LAGBs progressively converting into high-angle grain boundaries (HAGBs). Elevated temperatures and accumulated strain drive dislocation movement and entanglement, augmenting GND. The study also probes the influence of frequency and duty cycle on grain microstructure, finding that low pulse frequency spurs CDRX, high pulse frequency favors DRV, and the duty cycle has minimal impact on grain microstructure under PW cyclic thermal load.

1. Introduction

Direct laser deposition (DED), takes high-energy-density laser beam as the heat source, and it forms a molten pool by laser acting on the substrate and powder material. It forms a single layer after the molten pool solidifies, and then forms a three-dimensional deposited through the “layer by layer” accumulation manufacturing method [1,2]. The characteristics of grain microstructure strongly depend on the solidification conditions of the molten pool during solidification [3,4,5] and the thermo-mechanical response during the subsequent thermal cycle deposition [6,7,8].

The 316 L stainless steel deposited samples under traditional CW deposition are mainly composed of large columnar grains that grow directionally from the substrate, oriented against the direction of the laser heat flow and extending upward. Their growth direction is inclined relative to the direction of the scanning speed [9,10]. However, the number of the grains would be “equiaxed” due to the introduction of dynamic recrystallization under suitable thermo-mechanical response caused by the subsequent thermal cycle, and the corresponding refined grain microstructure can be obtained [11]. Compared with traditional continuous-wave (CW) laser, PW laser additive manufacturing has its own characteristics, such as a lower heat accumulation and correspondingly less obvious thermo-mechanical response (temperature, thermal strain). Moreover, PW laser leads to periodic patterns of heat source variation [12]. A faster cooling rate of PW laser contributes to refined grain microstructure [13,14], and pulse parameters have a marked effect on the grain morphology [15]. The solidified grains of PW laser deposition samples experience the thermal load from the upper layer printing to the lower layer as the same as CW laser. However, its periodic laser characteristics produce various thermo-mechanical responses under cyclic thermal load, which have diverse abilities to initiate DRX. A detailed description is still not available. At present, there have been very few research works on in situ thermo-mechanical variations during the PW-DED process. How a PW laser’s thermo-mechanical response caused by cyclic thermal load acts on the initial solidification grain microstructure of fabricated parts remains unclear. The purpose of this paper is to (1) explore the thermo-mechanical response conditions (temperature and strain) to activate dynamic recrystallization; (2) investigate the evolution of the microstructure of the deposited samples, including grain morphology and dislocation configuration, after the activation of dynamic recrystallization. In this paper, the thermo-mechanical response (temperature and strain) of PW laser is experimentally measured, and compared with that of CW laser mode. The evolution of 316 L stainless steel microstructural grain, dislocation, and misorientation map was thoroughly investigated under different numbers of thermal cycles with the PW laser mode. On this basis, the influence of PW laser processing parameters (frequency, duty cycle) on the grain microstructure is explored.

2. Experimental

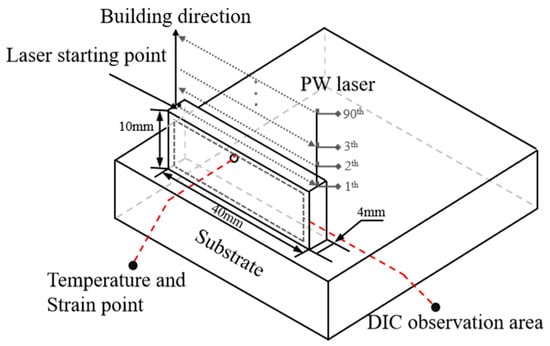

Commercially available 316 L stainless steel (45–125 μm) was used as feed stock. The detailed composition is shown in Table 1. Powder was processed in a vacuum drying chamber before the experiments were carried out. The chamber’s temperature had to be adjusted to 120° centigrade within 20 min in order to ensure the moisture in powder had been completely removed. The samples were directly fabricated by a YLS-4000-CL laser direct deposition system with a continuous 1070 nm wavelength fiber laser, which is provided by Dazu Laser Technology Co., Ltd. (Shenzhen, China). Laser power was set to 800 W, beam diameter to 1.2 mm, powder layer thickness to 0.2 mm, scanning speed to 8 mm/s, and powder feeding rate to 11.5 g/rad. Frequency varied from 20–80 Hz, and duty cycle was set to 50%–85%. Initially, four reference samples, each measuring 40 × 10 × 4 mm3, were fabricated in an argon atmosphere. Subsequently, a zig–zag deposition process was carried out along the build direction on three of these reference samples, resulting in layer counts of 25, 40, and 88, respectively (as depicted in Figure 1). For the purpose of investigating the in situ thermal cycling effects, four identical reference points situated at the mid-top positions of the four reference samples were chosen as the focal points for further analysis.

Table 1.

The detailed composition of 316 L.

Figure 1.

A schematic diagram of sample size, scanning path, temperature, and strain measurement locations.

To monitor the in situ temperature fluctuations at the reference points during thermal cycling, a thermocouple was embedded approximately 2 mm from the top, at the mid–top position of each reference sample. This strategic placement ensures the thermocouple’s integrity during subsequent depositions while allowing for precise temperature capture at the reference points. Additionally, an industrial camera equipped with the DIC method [16,17] was employed to capture in situ thermal strain data on the sample’s opposite side, with X-strain data near the reference point being specifically extracted. Four specimens were sectioned longitudinally parallel to the laser scanning direction and subsequently polished using progressively finer sandpaper grades (800#, 1200#, 2000#) before undergoing final polishing with a 1 μm paste. An electropolishing process was then conducted using a mixed electrolyte solution composed of 8% perchloric acid and 92% ethanol, applied at 20 V DC for a duration of 40 s. The metallographic specimens were chemically etched with a solution of mixture of concentrated hydrochloric acid (HCl) and concentrated nitric acid (HNO3) in a volume ratio of 3:1 for optical microscopy (OM) observation. The grain size, grain boundary characteristics, and geometric dislocation density (GND) at the reference points were analyzed using EBSD in conjunction with the Oxford Instruments MTEX 6.1. Beta3 open-source software. The step size for the analysis was set at 3 µm within a 750 µm × 750 µm area. Based on grain misorientation, low angle grain boundaries (LAGBs) and high angle grain boundaries (HAGBs) were identified, with LAGBs defined as having misorientation angles between 2°and 15°, and HAGBs characterized by misorientation angles greater than 15° [18].

Mechanical property tests were conducted using a universal testing machine (model Instron 5985, Instron Co., Ltd., Boston, MA, USA) to obtain the strain–stress curves of the specimens perpendicular to the component direction, as shown in Figure 1. During the testing process, the loading rate was set based on the material properties and testing standards, and high-precision load and displacement sensors were used to record the load and displacement data in real time. Stress was calculated based on the recorded load and the cross-sectional area of the specimen, while strain was derived from the displacement and the initial length of the specimen. Subsequently, the stress and strain data were plotted to form the strain–stress curves, which were analyzed to evaluate the mechanical properties of the material, such as tensile yield strength.

3. Results and Discussion

3.1. Thermo-Mechanical Response

3.1.1. In Situ Temperature

The temperature of the reference point would fluctuate regularly due to the heat conduction of the molten pool. Figure 2a shows the temperature history at the reference point during the DED process. At the initial stage of laser deposition (the first 50 s), the temperature rises rapidly from room temperature. At 100 s (about 20 thermal cycles), the temperature accumulates to the maximum point and stabilizes at 750 K. With the increased number of deposition layers, the distance between the heat source and the reference point becomes farther, and the temperature starts to drop slowly to about 640 K until the 90th thermal cycle is completed. Its temperature history trend is basically the same as that of CW laser processing [11] (Figure 2c). The temperature of the reference point is also maintained at a high level during the whole 90-layer thermal cycle deposition process even though the laser heat source has been far away from the reference point due to the increased number of deposition layers, except the maximum temperature value has a difference of 50 K.

Figure 2.

(a) Thermal history of 90-layer deposition (PW), (b) X-strain of 90-layer deposition (PW), (c) thermal history of 90-layer deposition (CW), (d) X-strain of 90-layer deposition (CW).

3.1.2. In Situ Strain

Figure 2b shows the X-strain of the reference point for single 90-layer PW laser additive manufacturing. At the beginning of deposition (0–50 s), the thermal strain increased significantly due to the rapid rise of temperature. A maximum thermal strain reached 6% at 75 s (about 15 thermal cycles). With the increased number of layers, the distance between the heat source and the reference point gradually increases. The heat transmitted by the heat source cannot compensate for the heat loss caused by heat conduction and heat radiation. The thermal strain gradually decreases until the end of laser deposition. About 4% of the thermal strain remained in the deposited sample. The accumulated increase in thermal strain is mainly due to the plastic deformation of the material left behind after laser deposition of each layer.

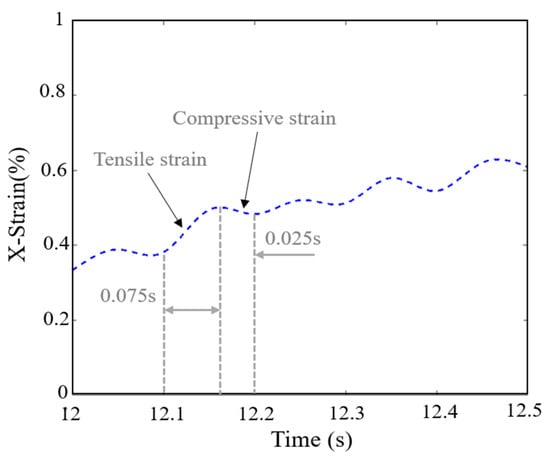

Compared with the X-strain of conventional CW laser (Figure 2d), the instantaneous thermal strain of PW laser has the following two characteristics: firstly, the maximum X-strain decreases by about 1% (7%–6%), which is caused by the introduction of compressive strain [19]. The thermal strain data in the 0.5 s time interval between 12 s and 12.5 s are extracted and fitted, as shown in Figure 3. It can be seen from the figure that the thermal strain in the PW laser presents a cyclic change trend of “tension–compression–tension–compression”. The pulse laser frequency is 10 Hz and the duty cycle is 75%. The laser switching cycle is 0.1 s, of which 0.075 s is on and 0.025 s is off. When the laser is turned on, the temperature rises, and the metal material begins to expand, resulting in tensile strain. When the laser is turned off, the temperature immediately drops and the material begins to shrink, resulting in compressive strain. However, due to the plastic deformation of the material, the compressive strain cannot completely offset the tensile strain, and the strain accumulated. When the next laser is turned on periodically, the material would be reheated and the expansion trend would be restored, and the tensile strain further improved. Within 0.5 s, the corresponding thermal strain has five periodic cyclic fluctuations, corresponding to five times of periodic laser switching on and off. Secondly, the time of the maximum X-strain is advanced to about 75 s (about 15 thermal cycles), it is earlier than that of CW laser, this is also due to the partial release of heat caused by the periodic cycle heating and cooling of PW laser and the thermal accumulation is smaller than that of CW laser. As the laser is far away from the reference point, the subsequent thermal cycle can no longer provide heat accumulation for this point, and the thermal strain gradually decreases.

Figure 3.

Thermal strain in the 0.5 s time interval.

3.1.3. Conditions for the Activation of Dynamic Recrystallization

The thermo-mechanical conditions during the deposition of 316 L stainless steel can be characterized by the Zener–Hollomon parameter via strain rate and temperature T as [20]

where Q = 460 kJ/mol [18] is the activation energy for triggering deformation and R = 8.314 J/mol K is the universal gas constant. The strain rate can be obtained by differentiating the measured transient strain by time:

The critical strain for dynamic recrystallization is [21]

DDRX can be activated when the thermal strain reaches the critical strain [22,23,24]. The initial grains would undergo dynamic recrystallization nucleation through the mechanism of strain-induced grain boundary bulging under appropriate temperature and strain conditions in the DED process. The fitted thermal strain and dynamic recrystallization critical strain at the measuring position during the deposition is shown in Figure 4a. The critical strain curve is calculated and fitted by the Formulas (1)–(3), and the transient thermal strain diagram is fitted by Figure 2b. The red solid line in the figure represents the instantaneous thermal strain , the blue dotted line represents the critical strain . The trend of critical strain in PW laser is the same as that of CW laser [11], showing a tendency of first falling and then rising. intersects with at the 8th thermal cycle. Conditions for DDRX are satisfied during the 8th to the 44th thermal cycles. After 44 thermal cycles, DDRX stopped, grain growth and DRV started at a high temperature. Corresponding to Figure 2a,b, the thermal strain range for promoting DDRX is about 5.5%–6%–5.5%, and the temperature range is 700 K–750 K–700 K. Compared with CW laser (8th to the 85th thermal cycles), the DDRX under the thermal cycles of PW laser occurs in a shorter time and requires a narrower range of thermal conditions [11] (Figure 4b). There are two main reasons: First, the relatively low temperature T generated under PW laser thermal cycling leads to a large Z bias and therefore a high . Second, the unique periodic switching optical cycling thermal characteristics of PW laser can generate opposite thermal strain (Figure 3), resulting in a decrease in the accumulated thermal strain.

Figure 4.

Fitted thermal strain and critical strain during the deposition of 90 layers, (a) CW, (b) PW.

3.2. Evolution of Microstructure and Mechanical Property

3.2.1. Grain Morphology and Size

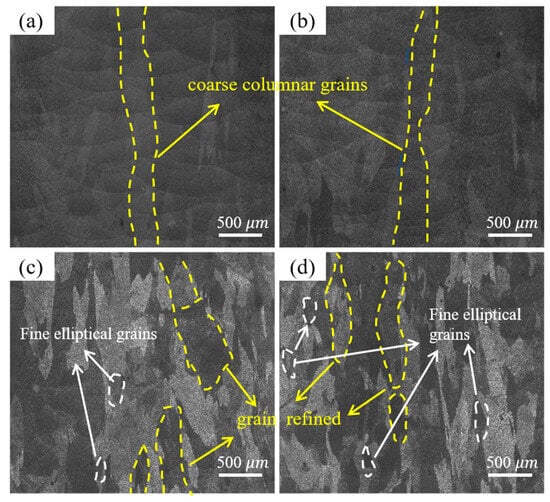

According to Figure 4, DDRX activated during the 8th to 44th thermal cycles. Therefore, the longitudinal-section microstructures under scanning electron microscope after 25, 40, and 88 thermal cycles (Figure 5b–d) are compared with that without experiencing any thermal cycles (Figure 5a). There they exhibit coarse columnar grains under no thermal cycling load and penetrate the multilayer deposition layers (Figure 5a). The grain morphology under 25 thermal cycles does not change significantly (Figure 5b). Under 40 thermal cycles, the grain is obviously refined. Although there are also coarse columnar grains through the multilayer deposition layers, many relatively fine elliptical grains are formed around them, and their length width ratio is more uniform (Figure 5c). After 88 thermal cycles, the grains of the deposited sample gradually become uniform and refined, showing irregular dispersion distribution of elliptical grains (Figure 5d). This indicates that under the thermal cycling load, the generated temperature and strain reached the conditions for dynamic recrystallization to occur, and the activation of dynamic recrystallization led to grain refinement [11].

Figure 5.

The evolution of longitudinal-section microstructure. (a) As-deposited sample, (b) 25-layer thermal cycle sample, (c) 40-layer thermal cycle sample, (d) 88-layer thermal cycles sample.

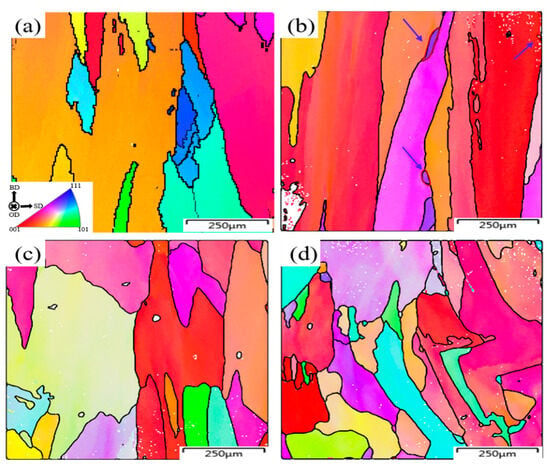

In order to obtain the characteristics of DDRX grains under PW laser thermal cycle load more clearly and accurately, electron backscatter diffraction analysis was carried out on the samples deposited under different thermal cycles. Figure 6a–d show the grain size and morphology after 0, 25, 40, and 88 thermal cycles. Compared with CW laser, the PW laser shows the same grain refinement trend under the thermo-mechanical conditions of the thermal cycle [11], and the initially solidified grains are columnar, as shown in Figure 6a. The growth direction is opposite to the direction of heat flow, and the average grain size is 74 ± 10 . After 25 thermal cycles, the average grain size is reduced to 71 ± 10 . There is little change in grain morphology except for a few small protrusions along the original grain boundaries, which is marked by blue arrows in Figure 6b. However, the number of these protrusions is relatively small compared with the CW laser. This is because the thermal strain in the PW mode is relatively small (Figure 2), which cannot provide more energy for DDRX nucleation [6]. After the 40 thermal cycles, the grain morphology changes slightly, some irregular equiaxed grains are mixed in the coarse columnar grains, and the average grain size is 72 ± 10 . At this time, DDRX is nearing its end, and the grains keep growing through grain boundary migration after passing through strain-induced nucleation, as shown in Figure 6c. The grain morphology after 88 thermal cycles is shown in Figure 6d. After DDRX nucleation, the grain growth is complete, a large number of irregular equiaxed grains coexist with more uniform aspect ratio columnar grains. A new grain morphology is formed with an average grain size of 53 ± 10 , which is 28% less compared to the grain morphology without experiencing any thermal cycling. Compared to CW laser, there is no significant difference in grain morphology and size [11]. It proves that the initial grains have almost no effect on DDRX under thermal cyclic loading. This is also identical to the description in the literature [22].

Figure 6.

The evolution of grain morphology at the reference point. (a) As-deposited sample, (b) 25-layer thermal cycle sample, (c) 40-layers thermal cycle sample, (d) 88-layer thermal cycle sample.

3.2.2. GND and Grain Misorientations

Figure 7a–d show the GND at the reference point after 0, 25, 40, and 88 thermal cycles. The value reaches about 1015 m−2 at the grain boundaries (white line) while it lowers at 1011 m−2 in the grain interior (dark red region). Sub-grain structure appears (yellow winding curve) with a magnitude of 1014 m−2. The average value of GND increases steadily from 2.3 × 1012 m−2 to 5.3 × 1012 m−2 with thermal cycling. It is worth noting that the yellow winding line in the figure increases substantially with increasing number of thermal cycles, a phenomenon that mirrors the variation of GND of the deposited samples under thermal cycling load in CW laser. This is the result of the movement of dislocations in thermo-mechanical conditions being impeded by the precipitates to peg, or their own intertwining and plugging to form sub-grain structures.

Figure 7.

The evolution of GND at the reference point under thermal cycles. (a) As-deposited sample, (b) 25-layer thermal cycle sample, (c) 40-layer thermal cycle sample; (d) 88-layer thermal cycle sample.

Figure 8 gives the variation of recrystallization map combined with the grain boundary misorientations at the reference point under different thermal cycles. Grain angles < 2° are blue areas, which can be regarded as recrystallized grains; grain angles 2°~15° are yellow areas, called sub-grain structures; grains angles > 15° are deformed grains. The green line pointed by the black arrow is the low-angle grain boundaries (LAGBs) from 2° to 15°, and the black line is the large-angle grain boundaries (HAGBs) > 15°. As can be seen from the figure, compared with the CW laser, the deposited samples in the PW laser have almost no deformed grains, and the sub-grain structures and recrystallized grains account for a larger proportion. This may be due to two reasons [19]: (1) the temperature gradient in the heat-affected zone in the PW laser is relatively small, leading to less thermal strain; (2) the unique periodic switching optical process characteristic of PW laser is the key to the “ tension–compression” cycle of thermal stresses to offset each other. This energy “internal consumption” and relatively low thermal strains cannot provide sufficient driving force for the rotation of the grains [25], which also cannot lead to large misorientations between the grains.

Figure 8.

Recrystallization map combined with the grain boundary misorientations. (a) As-deposited sample, (b) 25-layer thermal cycle sample, (c) 40-layer thermal cycle sample, (d) 88-layer thermal cycle sample.

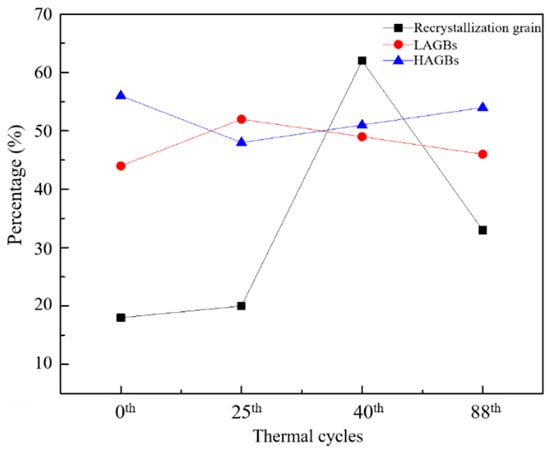

Figure 9 shows the changes of recrystallization fraction and grain boundary misorientations of the deposited sample under different thermal cycles. The grain recrystallization fraction shows a first increasing and then decreasing (18%–20%–63%–33%) trend with the increase in thermal cycles. LAGBs show a trend of first increasing and then decreasing (44.2%–52.6%–49.7%–46.4%), and HAGBs exhibit the opposite trend (55.8%–47.4%–50.3%–53.6%). This further indicates that the initial solidified grains undergo DRV as well as DDRX during the first 40 layers of thermal cycling load, and DRV can make a large number of sub-grain structures to prepare for the subsequent occurrence of CDRX [22], which is also the main reason for the increase in the percentage of LAGBs in the early stage. In fact, DRV occurs before DDRX, when DDRX is activated, DRV does not stop, but acts on the grains simultaneously with DDRX. The occurrence of DDRX leads to a sharp increase in recrystallized grains. In the latter 50 layers of thermal cycling load, after DDRX stops, the accumulated thermal strains still provide energy for the gradual increase in grain misorientations, which directly leads to the decrease in grain recrystallization. The occurrence of CDRX makes LAGBs rotate and merge into HAGBs gradually [26], which is the main reason for the decrease in LAGBs and the increase in HAGBs in the late stage of thermal cycling.

Figure 9.

Recrystallization fraction and grain boundary misorientations under thermal cycles.

3.2.3. Hardness and Mechanical Properties

The hardness tests were conducted for the as-deposited and after 88 thermal cycles sample; three points (S1, S2, S3) of each sample were randomly measured and averaged. The results are shown in Table 2. The average hardness of the as-deposited and after 88 thermal cycles sample is 172.3 HV and 188.1 HV, respectively. The convention tensile test was measured and the stress-strain curve is given in Figure 10. It can be seen that the tensile yield strength of the as-deposited sample is about 400 MPa and that of the after 88 thermal cycle sample is about 450 MPa. Grain refinement and dislocation enhancement effect under thermal cyclic loading [27] are important reasons for the hardness and strength enhancement of the thermal cyclic sample.

Table 2.

Vickers hardness (HV) of as-deposited and after 88 thermal cycle sample.

Figure 10.

Stress–strain curve of as-deposited and after 88 thermal cycles sample.

3.3. Effect of Pulsed Laser Parameters on Microstructure and Hardness of Thermal Cycle Samples

3.3.1. Frequency

Figure 11a–c show the grain characteristics of 20 Hz, 40 Hz, and 80 Hz (75% duty cycle) thermal cyclic samples. As can be seen from the figure, the grain morphology varies little under low-frequency and high-frequency laser thermal cycling loads. They all reflect columnar grains with uniform aspect ratios and irregular equiaxed grains, with average grain sizes of 52 ± 5 , 55 ± 5 and 59 ± 5 . This indicates that the initially solidified grains are activated for DDRX under suitable thermo-mechanical conditions, despite high-frequency and low-frequency thermal cycling loads. The recrystallization map combined with the grain boundary misorientations are further demonstrated, as shown in Figure 11d–f. The results show that the sub-grain structure shows an increasing trend with increasing frequency (48%–57%–71%). LABGs gradually increase (46.2%–47.1%–49.2%), and correspondingly, HAGBs decrease (53.8%–52.9%–50.8%); this implies that high pulse frequency is more favorable for DRV, resulting in more sub-grain structures; lower pulse frequencies can effectively promote the occurrence of CDRX. Compared with high-frequency pulses, the melt pool under low-frequency pulses has a faster solidification rate and cooling rate, leading to finer initial solidified grains, and correspondingly accelerates the grain refinement kinetics, which is more favorable to the occurrence of CDRX [28].

Figure 11.

Grain characteristics of thermal cyclic samples at different frequencies: (a) 20 Hz, (b) 40 Hz, (c) 80 Hz; grain boundary misorientation and proportion of sub-grain structure of (d) 20 Hz, (e) 40 Hz, (f) 80 Hz.

3.3.2. Duty Cycle

Figure 12a–c show the grain characteristics of 50%, 75%, and 85% duty cycle (10 Hz) thermal cyclic samples. It can be seen from the figure that duty cycle has little effect on the average grain size, with 65 ± 5 , 53 ± 5 , and 60 ± 5 respectively. Figure 12d–f show that the sub-grain structure increases slightly with the increasing duty cycle (57%–67%–64%). However, duty cycle has little effect on LAGBs and HAGBs of the thermal cyclic samples, which are stable at 49% and 51%, respectively.

Figure 12.

Grain characteristics of thermal cyclic samples at different duty cycles. (a) 50%, (b) 75%, (c) 85%; grain boundary misorientation and proportion of substructure of (d) 50%, (e) 75%, (f) 85%.

Duty cycle affects the average power and duration of the laser’s action on the deposited sample. A larger duty cycle means that the laser’s power acting on the sample is greater, the duration of action is longer, the temperature generated is higher, and the strain is larger. However, under the three duty cycle parameters set in this paper, the differences in grain morphology, size, low-angle grain boundaries (LAGBs), and high-angle grain boundaries (HAGBs) are not significant. This indicates that regardless of whether under low or high duty cycle thermal cycling loads, the actual strain generated exceeds the critical strain threshold. The initial solidification grains are activated for dynamic recrystallization under appropriate thermo-mechanical conditions, and the grain morphology transforms from the original columnar grains to more equiaxed grains with a more uniform aspect ratio and irregular equiaxed grains.

3.3.3. Hardness

Table 3 shows the effect of pulse frequency (10 Hz–80 Hz) and duty cycle (50%–85%) on the hardness of thermal cyclic samples.

Table 3.

Effect of pulse laser frequency and duty ratio on hardness of thermal cycle samples.

It can be seen from the table that with the increase in pulse frequency, the hardness of the samples slightly increases (188 HV–192 HV), which may be related to the increase in LAGBs and sub-grain structure under the high-frequency; duty cycle varies little on the hardness of the thermal cyclic samples, its values are basically stable in the range of 186 HV–188 HV.

4. Conclusions

The present study investigated thermo-mechanical response (thermal strain and temperature) to promote DDRX under PW cyclic thermal load, and the corresponding evolution of grain morphology, GND, and misorientation map were studied. The hardness and mechanical properties of the as-deposited sample and thermal cyclic sample were compared. On this basis, the influence of PW laser parameters (frequency and duty cycle) on the microstructure and hardness was explored. The following conclusions can be drawn from the findings of the study:

- (1)

- DDRX is activated from the 8th to 44th thermal cycles of PW laser with temperature evolving in the range of 680 K–750 K–640 K and the corresponding thermal strain evolving in the range of 5.6%–6.2%–5.2%. Compared with CW laser, the improvement of and the decline in makes the DDRX conditions more rigorous and the duration shorter.

- (2)

- During the process of PW laser thermal cycling, the original solidified grains undergo DRV, DDRX, and CDRX successively. DRV can make a large number of sub-grain structures inside the grains to prepare for the subsequent occurrence of CDRX. When DDRX is activated, DRV does not stop, but occurs simultaneously with DDRX. Meanwhile, the occurrence of CDRX makes the LAGBs gradually rotate and merge into HAGBs.

- (3)

- The grain morphology of the thermal cyclic sample exhibits a large number of irregular equiaxed grains coexisting with uniform aspect ratio columnar grains with an average grain size of 53 ± 10 , which is 28% less than that of the as-deposited sample. The average value of GND increases steadily from 2.3 × 1012 m−2 to 5.3 × 1012 m−2 with thermal cycling. The hardness and tensile yield strength are improved to a certain extent.

- (4)

- There exist few various on the grain morphology of PW laser cyclic samples with different frequency and duty cycle. Under high frequency, it is more favorable to obtain LAGBs and sub-grain structures, which is beneficial to the hardness of the PW laser thermal cyclic sample.

Author Contributions

Conceptualization, M.C. and X.Z.; methodology, M.C., X.Z., Y.Z., J.N. and T.C.; validation, M.C., Y.Z. and Q.C.; formal analysis, X.Z., H.J., Q.C., Y.D. and L.Q.; investigation, M.C., Y.Z., J.N. and T.C.; resources, M.C., Y.Z., Y.D. and L.Q.; writing—original draft preparation, M.C. and X.Z.; writing—review and editing, M.C., Y.Z., X.Z. and H.J.; supervision, M.C., X.Z., Y.Z. and T.C.; funding acquisition, M.C. and X.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Scientific Research Projects of Hunan Provincial Education Department (grant number 24C0219 and 23B0833) and the Scientific Research Project of Hunan Institute of Technology (grant number HQ23011). the College Student Innovation and Entrepreneurship Program Project (grant number CX2025450, S202511528092 and S202511528088).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Yuan Zhu was employed by the company EVE Energy Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Blinn, B.; Lion, P.; Jordan, O.; Meiniger, S.; Mischliwski, S.; Tepper, C.; Gläßner, C.; Aurich, J.C.; Weigold, M.; Beck, T. Process-influenced fatigue behavior of AISI 316L manufactured by powder- and wire-based Laser Direct Energy Deposition. Mater. Sci. Eng. A 2021, 818, 141383. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Jenn, M. Selective laser melting of TiC reinforced 316L stainless steel matrix nanocomposites: Influence of starting TiC particle size and volume content. Mater. Des. 2016, 104, 141–151. [Google Scholar] [CrossRef]

- Ma, K.; Zhao, Y.; Xu, X.; Hou, H. The effect of undercooling on growth velocity and microstructure of Ni95Cu5 alloys. J. Cryst. Growth 2019, 513, 30–37. [Google Scholar] [CrossRef]

- An, Y.; Xu, X.; Liang, L.; Zhao, Y.; Hou, H. Microstructure transformation and grain refinement during non-equilibrium solidification of a highly undercooled alloy system. J. Alloys Compd. 2021, 864, 158821. [Google Scholar] [CrossRef]

- Sabzi, H.E.; Aboulkhair, N.T.; Liang, X.; Li, X.-H.; Simonelli, M.; Fu, H.; Rivera-Díaz-del-Castillo, P.E.J. Grain refinement in laser powder bed fusion: The influence of dynamic recrystallization and recovery. Mater. Des. 2020, 196, 109181. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Bayat, M.; Tan, Q.; Yin, Y.; Fan, Z.; Liu, S.; Hattel, J.H.; Dargusch, M.; Zhang, M.-X. Achieving high ductility in a selectively laser melted commercial pure-titanium via in-situ grain refinement. Scr. Mater. 2021, 191, 155–160. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Z.G.; Chen, H.; Wang, A.G.; Liu, J.Q.; Liu, H.W.; Zheng, R.K.; Nai, S.M.L.; Primig, S.; Babu, S.S.; et al. Effect of cyclic rapid thermal loadings on the microstructural evolution of a CrMnFeCoNi high-entropy alloy manufactured by selective laser melting. Acta Mater. 2020, 196, 609–625. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; He, Y.; Song, G.; Liu, L. The effect of low-power laser on micro-forming of 316 stainless steel additive manufacturing part. J. Manuf. Process. 2021, 68, 583–601. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; Marchi, C.S.; Schoenung, J.M. Microstructural development in DED stainless steels: Applying welding models to elucidate the impact of processing and alloy composition. J. Mater. Sci. 2020, 56, 762–780. [Google Scholar] [CrossRef]

- Zou, X.; Yan, Z.; Zou, K.; Liu, W.; Song, L.; Li, S.; Cha, L. Grain refinement by dynamic recrystallization during laser direct energy deposition of 316L stainless steel under thermal cycles. J. Manuf. Process. 2022, 76, 646–655. [Google Scholar] [CrossRef]

- Li, S.; Xiao, H.; Liu, K.; Xiao, W.; Li, Y.; Han, X.; Mazumder, J.; Song, L. Melt-pool motion, temperature variation and dendritic morphology of Inconel 718 during pulsed- and continuous-wave laser additive manufacturing: A comparative study. Mater. Des. 2017, 119, 351–360. [Google Scholar] [CrossRef]

- Xiao, H.; Li, S.M.; Xiao, W.J.; Li, Y.Q.; Cha, L.M.; Mazumder, J.; Song, L.J. Effects of laser modes on Nb segregation and Laves phase formation during laser additive manufacturing of nickel-based superalloy. Mater. Lett. 2017, 188, 260–262. [Google Scholar] [CrossRef]

- Xiao, H.; Li, S.; Han, X.; Mazumder, J.; Song, L. Laves phase control of Inconel 718 alloy using quasi-continuous-wave laser additive manufacturing. Mater. Des. 2017, 122, 330–339. [Google Scholar] [CrossRef]

- Cheng, M.; Xiao, X.; Luo, G.; Song, L. Integrated control of molten pool morphology and solidification texture by adjusting pulse duration in laser additive manufacturing of Inconel 718. Opt. Laser Technol. 2021, 142, 107137. [Google Scholar] [CrossRef]

- Biegler, M.; Graf, B.; Rethmeier, M. In-situ distortions in LMD additive manufacturing walls can be measured with digital image correlation and predicted using numerical simulations. Addit. Manuf. 2018, 20, 101–110. [Google Scholar] [CrossRef]

- Xie, R.; Chen, G.; Zhao, Y.; Zhang, S.; Yan, W.; Lin, X.; Shi, Q. In-situ observation and numerical simulation on the transient strain and distortion prediction during additive manufacturing. J. Manuf. Process. 2019, 38, 494–501. [Google Scholar] [CrossRef]

- Puli, R.; Ram, G.D.J. Dynamic recrystallization in friction surfaced austenitic stainless steel coatings. Mater. Charact. 2012, 74, 49–54. [Google Scholar] [CrossRef]

- Zou, X.; Yan, Z.; Zou, K.; Zhang, S.G.; Liu, W.; Song, L. Residual stress control of 316 L stainless steel using pulsed-wave laser additive manufacturing. Opt. Laser Technol. 2022, 150, 107910. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of Strain Rate Upon Plastic Flow of Steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Liu, X.G.; Zhang, L.G.; Qi, R.S.; Chen, L.; Jin, M.; Guo, B.F. Prediction of critical conditions for dynamic recrystallization in 316LN austenitic steel. J. Iron Steel Res. Int. 2016, 23, 238–243. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Dong, D.; Chen, F.; Cui, Z. Investigation on metadynamic recrystallization behavior in SA508-III steel during hot deformation. J. Manuf. Process. 2017, 29, 18–28. [Google Scholar] [CrossRef]

- Mozumder, Y.H.; Babu, K.A.; Saha, R.; Sarma, V.S.; Mandal, S. Dynamic microstructural evolution and recrystallization mechanism during hot deformation of intermetallic-hardened duplex lightweight steel. Mater. Sci. Eng. A 2020, 788, 139613. [Google Scholar] [CrossRef]

- Yu, S.; Liu, C.; Gao, Y.; Jiang, S.; Bao, Z. Dynamic recrystallization mechanism of Mg-8.5Gd-2.5Y-0.4Zr alloy during hot ring rolling. Mater. Charact. 2017, 131, 135–139. [Google Scholar] [CrossRef]

- Sabzi, H.E.; Hernandez-Nava, E.; Li, X.-H.; Fu, H.; San-Martín, D.; Rivera-Díaz-del-Castillo, P.E.J. Strengthening control in laser powder bed fusion of austenitic stainless steels via grain boundary engineering. Mater. Des. 2021, 212, 110246. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; Marchi, C.S.; Schoenung, J.M. Strengthening mechanisms in directed energy deposited austenitic stainless steel. Acta Mater. 2019, 164, 728–740. [Google Scholar] [CrossRef]

- Dehghan-Manshadi, A.; Hodgson, P.D. Dependency of Recrystallization Mechanism to the Initial Grain Size. Metall. Mater. Trans. A 2008, 39, 2830–2840. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).