Analysis of the Suitability of 3D-Printed Road Surface Replicas for Laboratory Testing of Rolling Resistance

Abstract

1. Introduction

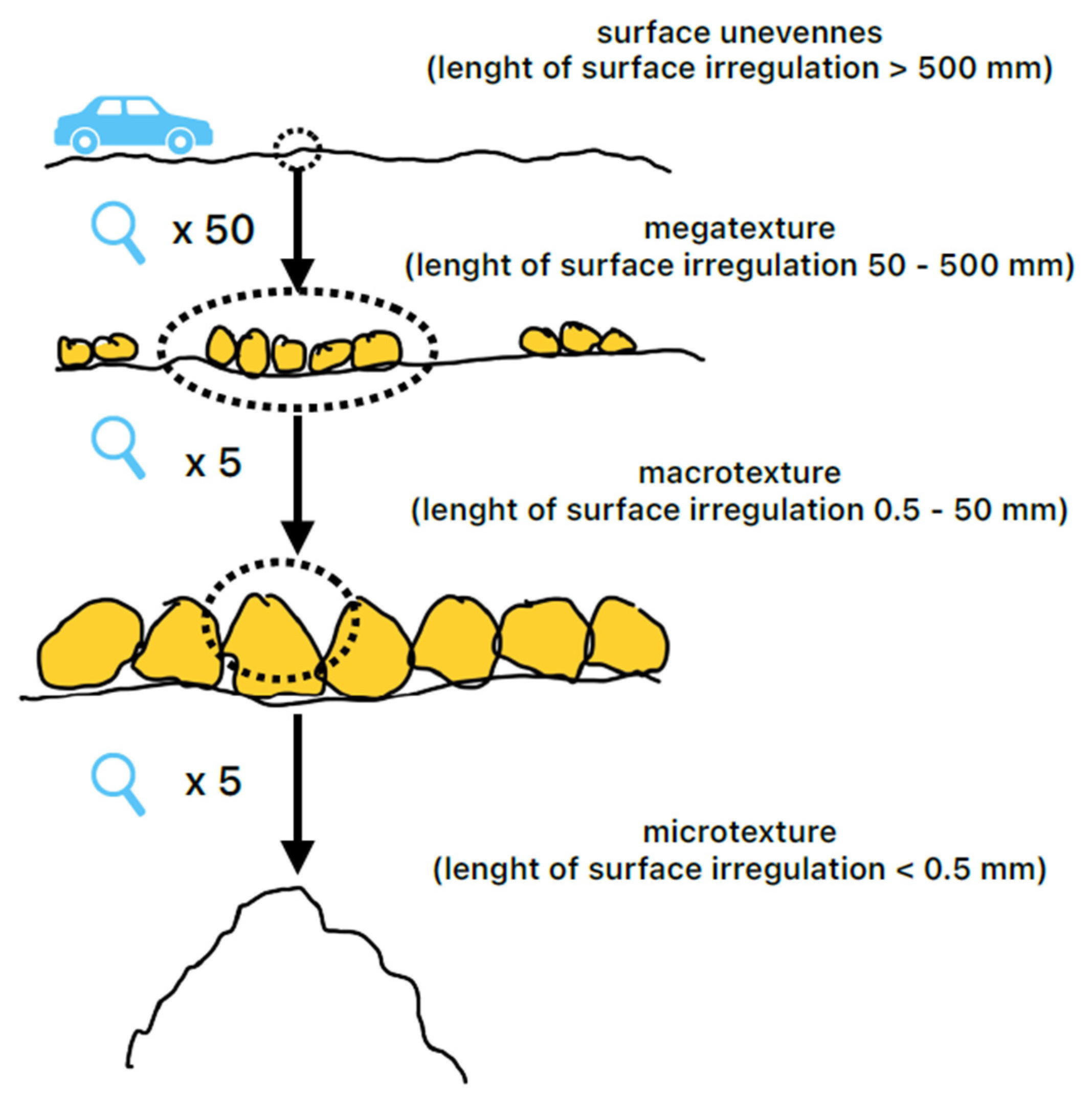

- Irregularities: Wavelengths greater than 500 mm.

- Megatexture: Wavelengths between 50 and 500 mm, with typical amplitudes ranging from 0.1 to 50 mm.

- Macrotexture: Wavelengths from 0.5 to 50 mm, with amplitudes between 0.1 and 20 mm.

- Microtexture: Wavelengths below 0.5 mm, with amplitudes from 0.001 to 0.5 mm.

2. Materials and Methods

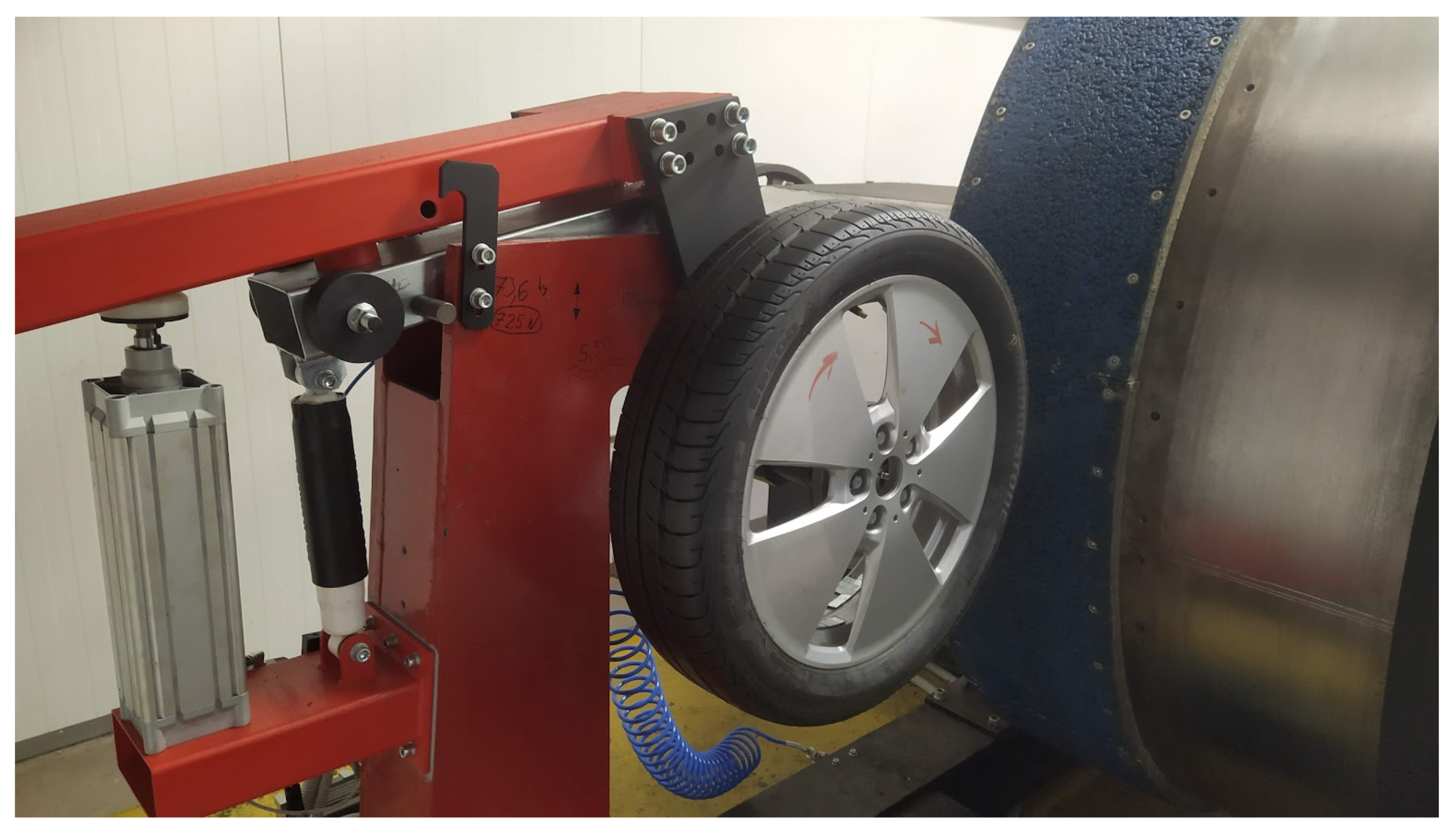

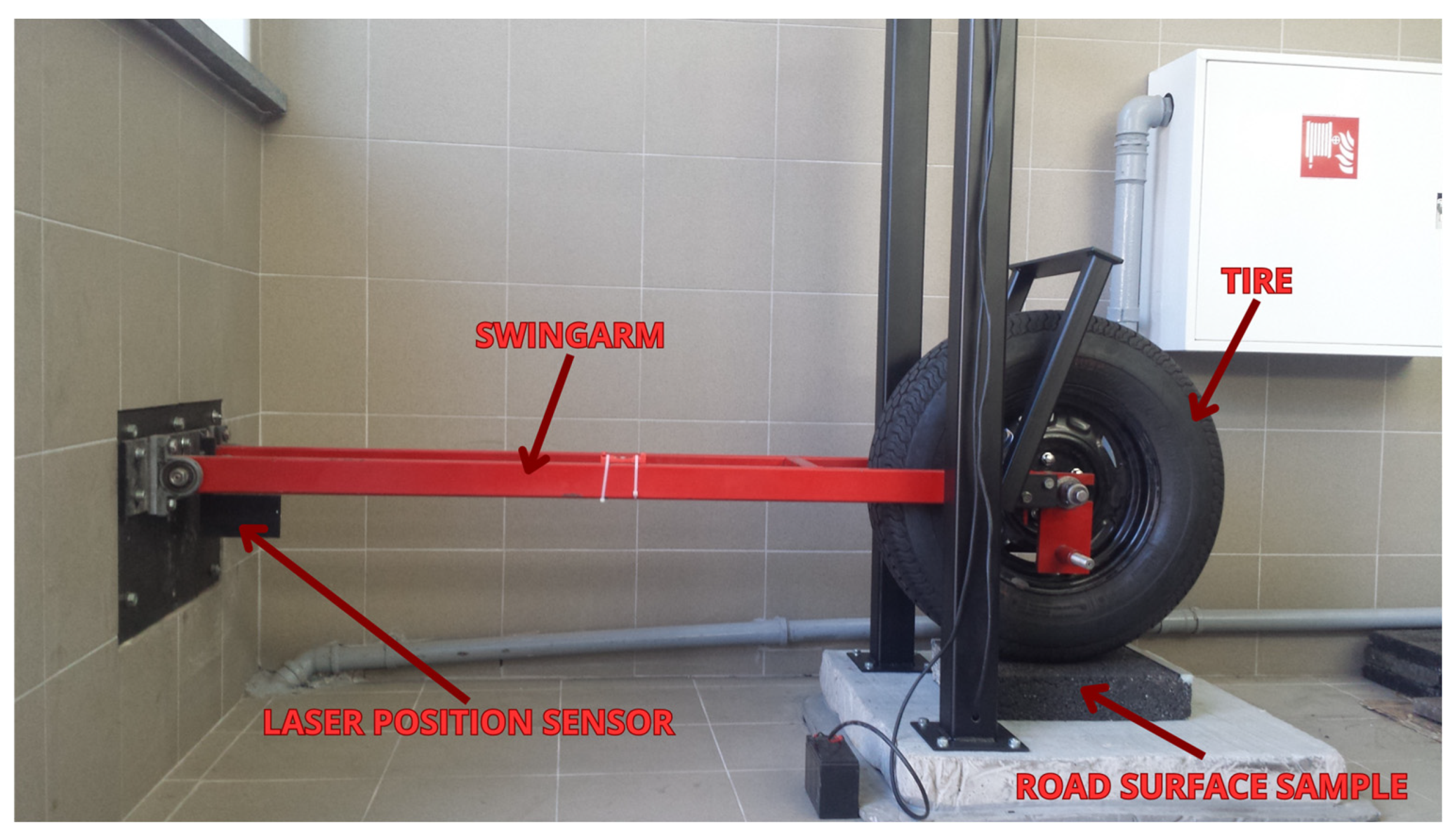

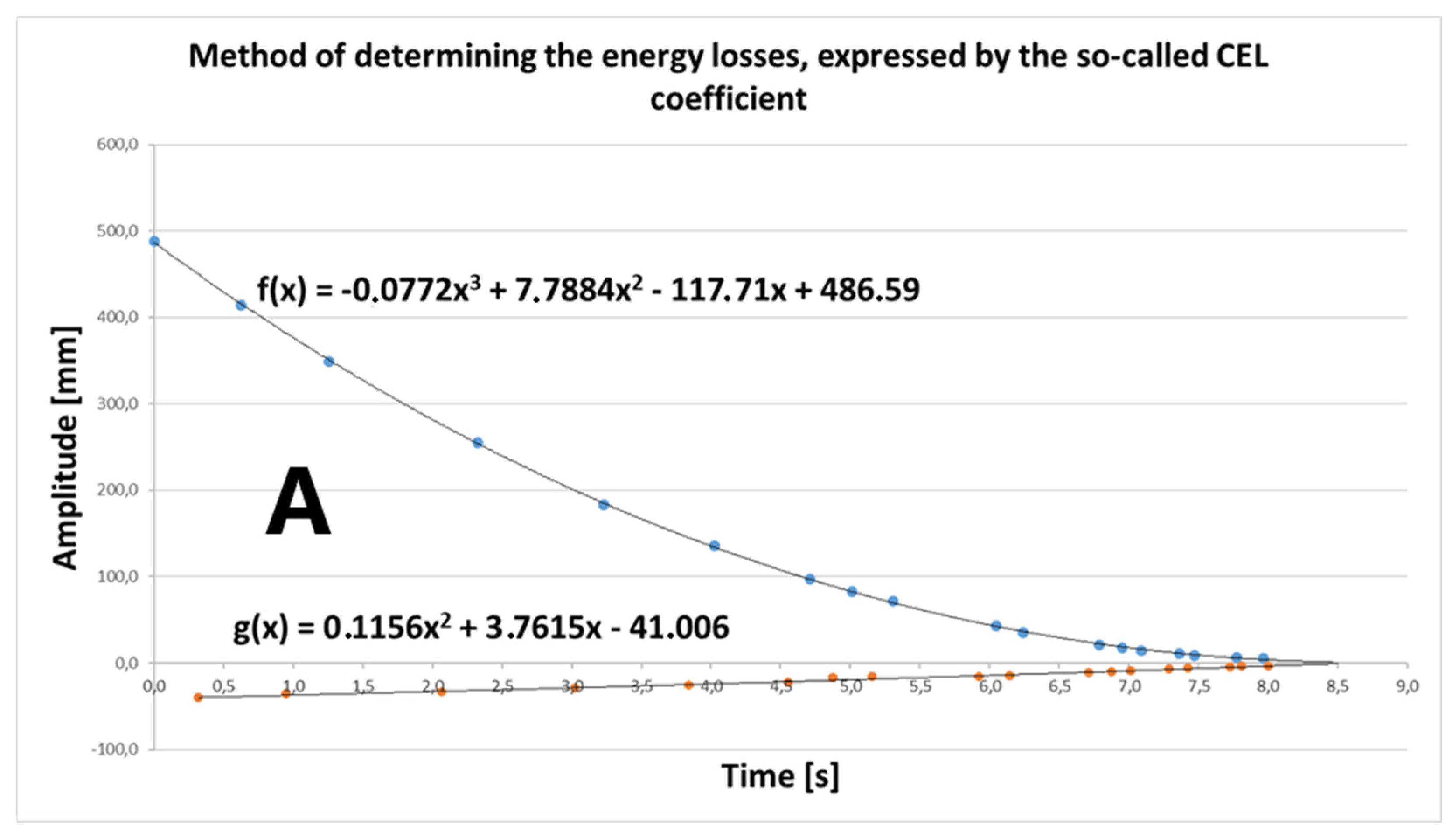

2.1. Oscillatory Method for Estimating Energy Losses During Tire–Road Surface Contact

2.2. The Road Surface Replicas Used During the Tests

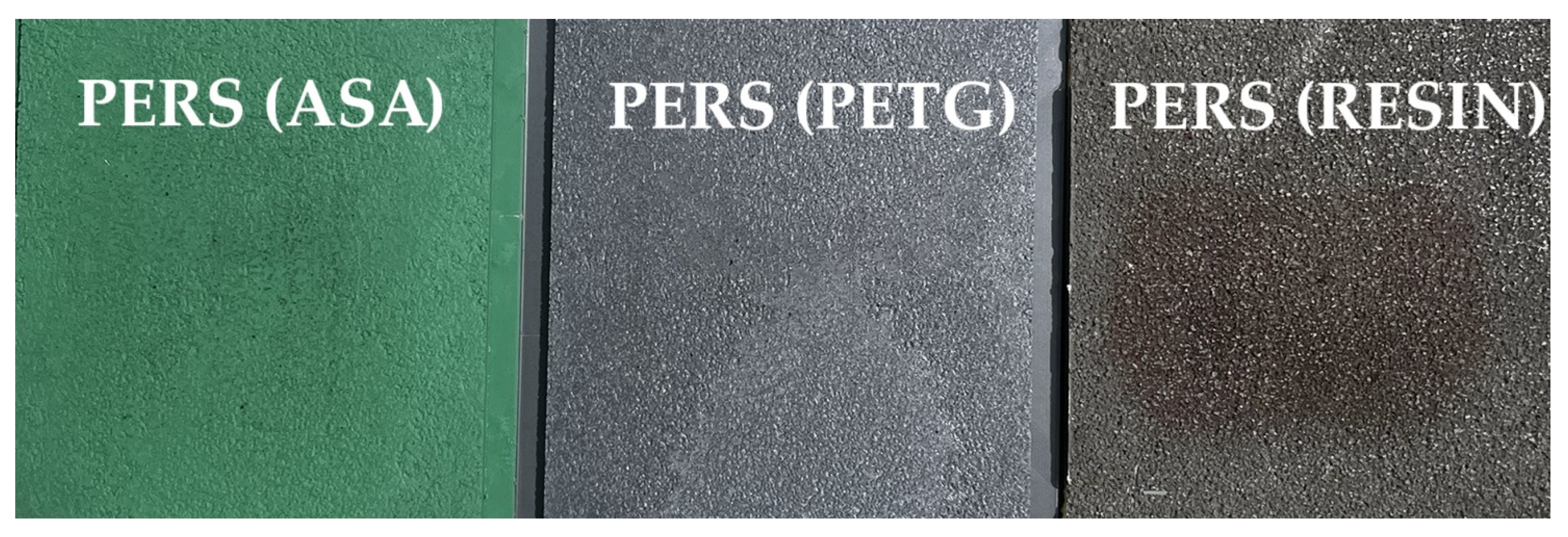

- PERS (Porous Elastic Road Surface) is a porous, elastic road surface designed to reduce noise generated by tire–road interaction. It is typically composed of a mixture of rubber granules (often recycled tire rubber) and a polyurethane binder. Due to its structure, PERS offers good elasticity, vibration damping capabilities, and anti-skid properties, while also allowing efficient water drainage, which enhances driving safety [32].

- SMA8 (Stone Mastic Asphalt 8) is a type of mastic asphalt featuring finer aggregate grading, with a maximum aggregate size of 8 mm. It is characterized by a high content of coarse aggregate, asphalt binder, and stabilizing additives such as cellulose fibers. SMA8 is commonly used as a wearing course in pavement structures, offering excellent rutting resistance, fatigue durability, and favorable acoustic properties. Its dense structure and high binder content ensure good impermeability and long-term performance. Testing on SMA8 replicas is especially relevant in light of findings by Zaumanis and Haritonovs (2015), who demonstrated that SMA mixtures provide superior durability and rutting resistance under long-term, real-world traffic loads. This supports the selection of SMA8 as a reference material in laboratory studies simulating wheel–pavement interaction [33].

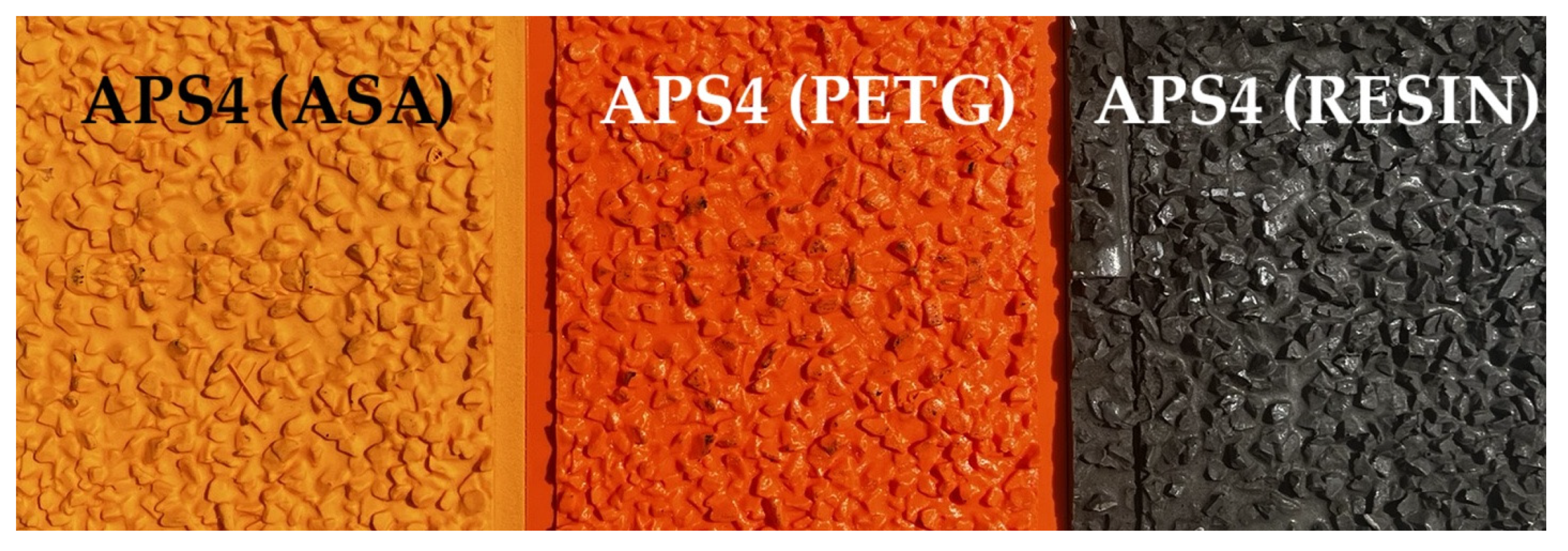

- APS4 is an imitation of a highly rough road surface, created as a surface treatment [34].

- The first and second series consisted of replicas fabricated via 3D printing. PETG (Polyethylene Terephthalate Glycol) and ASA (Acrylonitrile Styrene Acrylate) were selected due to their complementary mechanical and processing properties, which align well with the functional requirements of the test setup. The 3D printing parameters included a 5% infill density and a Tri-hexagon infill pattern. The choice of these filaments and the printing method were based on strength tests described in a previous publication by the researchers [35].

- The third series was produced using the conventional casting method with epoxy resin. This series served as the reference standard for comparison with the results obtained from the 3D-printed replicas.

2.3. The Tires Used During the Tests

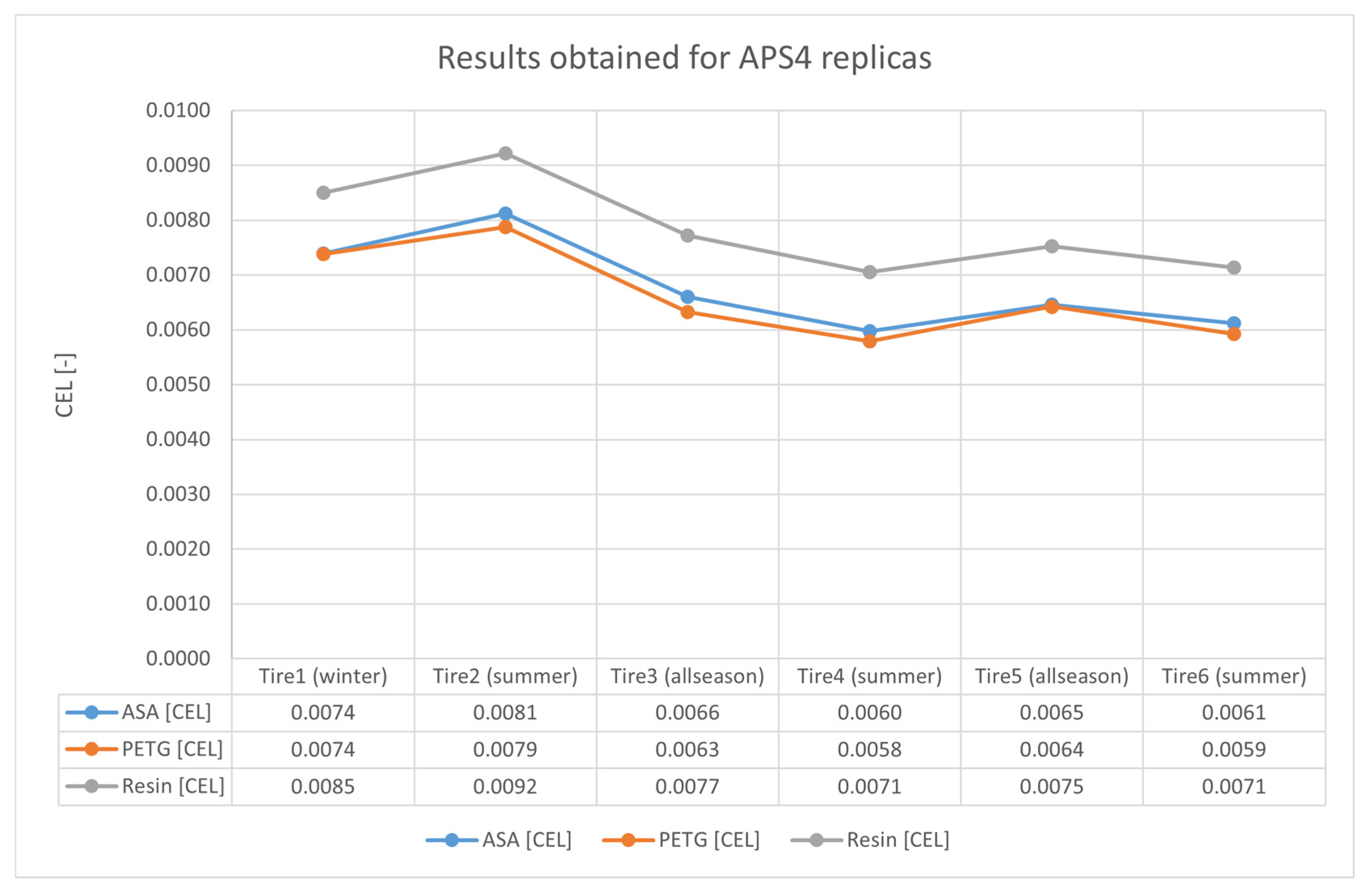

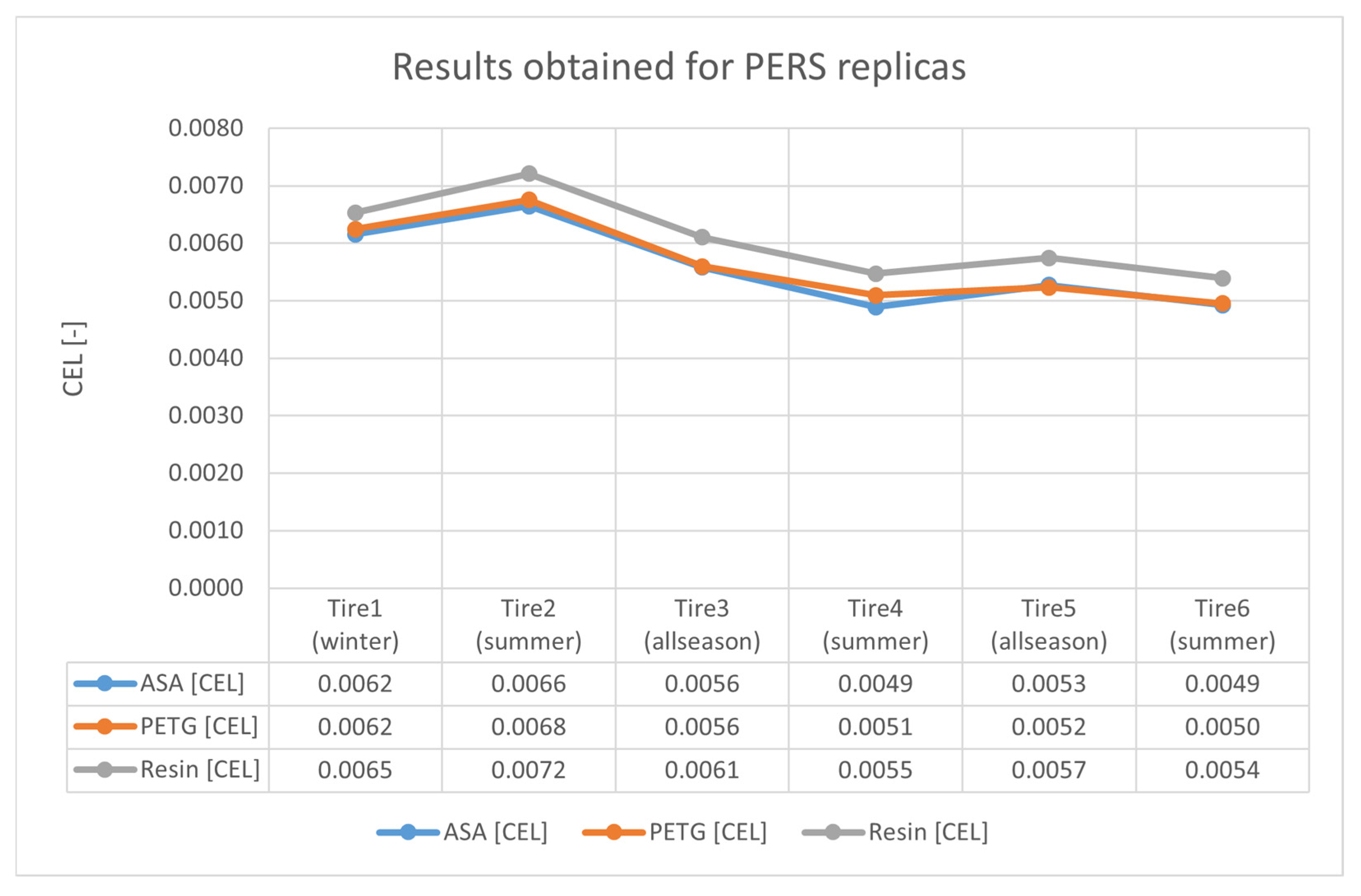

3. Results and Discussion

4. Conclusions

- Road surface replicas produced using 3D printing exhibited lower values of the CEL (coefficient of rolling resistance) compared to replicas made using the traditional epoxy resin casting method.

- The average reduction in CEL values was 11.23% for surfaces printed with ASA and 12.17% for those printed with PETG.

- The greatest differences between the methods were observed for the APS4 surface, followed by SMA8, with the smallest differences noted for PERS. This suggests that rougher and more complex textures are more difficult to reproduce accurately using 3D printing.

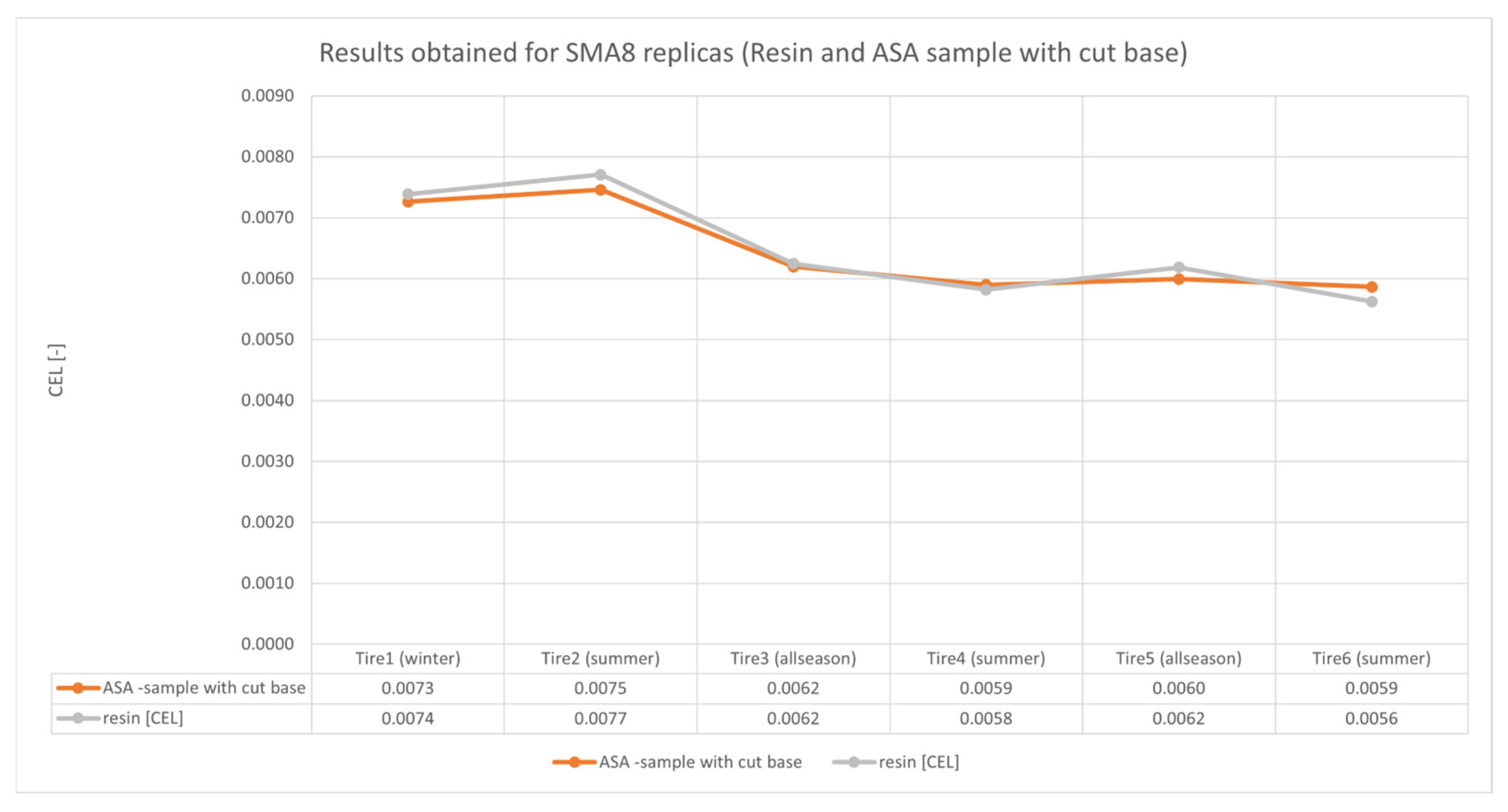

- Modifying the replica design—by removing the low-infill base and retaining only a thin textured layer—improved the consistency of results, reducing the average discrepancy to 2.43%.

- Despite the absolute value differences, a high correlation was maintained between the results from 3D-printed and cast replicas, along with consistent surface and tire ranking.

- 3D-printed replicas can be effectively used for comparative rolling resistance testing, provided that printing parameters and sample construction are optimized.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reimpell, J.; Betzler, J. Podwozia Samochodów Podstawy Konstrukcji; WKŁ: Warszawa, Poland, 2001; pp. 151–154. [Google Scholar]

- Taryma, S. Opór Toczenia Opon Samochodowych; Wydawnictwo PG: Gdańsk, Poland, 2007. [Google Scholar]

- Clark, S.K. A brief history of tire rolling resistance. In Proceedings of the Symposium on Tire Rolling Resistance at 122nd Meeting of Rubber Division, American Chemical Society, Chicago, IL, USA, 5–7 October 1982. [Google Scholar]

- Clark, S.K.; Dodge, R.N. A Handbook for the Rolling Resistance of Pneumatic Tires; Institute of Science and Technology, The University of Michigen: Ann Arbor, MI, USA, 1979. [Google Scholar]

- Andersen, L.G.; Larsen, J.K.; Fraser, E.S.; Schmidt, B.; Dyre, J.C. Rolling resistance measurement and model development. J. Transp. Eng. 2015, 141, 04014075. [Google Scholar] [CrossRef]

- 6. Ejsmont, J.; Ronowski, G.; Berge, T.; Sommer, S.; Owczarzak, W.; Szerszyńska, A. At what temperature should the tire rolling resistance be measured? Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024. [Google Scholar] [CrossRef]

- Sun, Z.; Premarathna, W.; Anupam, K.; Kasbergen, C.; Erkens, S.M. A state-of-the-art review on rolling resistance of asphalt pavements and its environmental impact. Constr. Build. Mater. 2024, 411, 133589. [Google Scholar] [CrossRef]

- ISO 13473-5:2009(en); Characterization of Pavement Texture by Use of Surface Profiles—Part 5: Determination of Megatexture. International Organization for Standardization: Geneva, Switzerland, 2009.

- Sandberg, U. Influence of Road Surface Texture on Traffic Characteristics Related to Environment, Economy and Safety; VTI Notat 53A-1997; Swedish National Road and Transport Research Institute: Linkoeping, Sweden, 1997.

- Fathi, H.; El-Sayegh, Z.; Ren, J.; El-Gindy, M. Analysis of Tire-Road Interaction: A Literature Review. Machines 2024, 12, 812. [Google Scholar] [CrossRef]

- Von Meier, A.; Van Blokland, G.J.; Descornet, G. The influence of texture and sound absorption on the noise of porous road surfaces. In Proceedings of the 2nd International Symposium on Road Surface Characteristics, Berlin, Germany, 23–26 June 1992. [Google Scholar]

- Lak, M.A.; Degrande, G.; Lombaert, G. Influence of poroelastic road surfaces on ground borne vibration due to traffic. In Deliverable D6.8; 7FP Persuade; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- Hoever, C.; Kropp, W. A model for investigating the influence of road surface texture and tyre tread pattern on rolling resistance. J. Sound Vib. 2015, 351, 161–176. [Google Scholar] [CrossRef]

- Ejsmont, J.; Ronowski, G.; Ydrefors, L.; Owczarzak, W.; Sommer, S.; Świeczko-Żurek, B. Comparison of Tire Rolling Resistance Measuring Methods for Different Surfaces. Int. J. Automot. Technol. 2024, 25, 965–976. [Google Scholar] [CrossRef]

- ISO28580; Passenger Car, Truck and Bus Tyres—Methods of Measuring Rolling Resistance—Single Point Test and Correlation of Measurement Results, 2nd ed. International Organization for Standardization: Genève, Switzerland, 2018.

- J2452_201707; Society of Automotive Engineers. Stepwise Coastdown Methodology for Measuring Tire Rolling Resistance. Society of Automotive Engineers: Warrendale, PA, USA, 2017.

- ISO18164; Passenger Car, Truck, Bus and Motorcycle Tyres—Methods of Measuring Rolling Resistance, 2nd ed. International Organization for Standardization: Genève, Switzerland, 2005.

- J1269_201912; Rolling Resistance Measurement Procedure for Passenger Car, Light Truck, and Highway Truck and Bus Tires. Society of Automotive Engineers: Warrendale, PA, USA, 2019.

- Ejsmont, J.; Ronowski, G.; Sommer, S.; Owczarzak, W.; Berge, T. Replica road pavements for rolling resistance measurements. Road Mater. Pavement Des. 2025, 1–11. [Google Scholar] [CrossRef]

- Gong, Z.; Miao, Y.; Lantieri, C. Review of Research on Tire–Pavement Contact Behavior. Coatings 2024, 14, 157. [Google Scholar] [CrossRef]

- Chen, B.; Ding, P.; Wei, G.; Xiong, C.; Wang, F.; Yu, J.; Yu, H.; Zou, Y. A Study on the Contact Characteristics of Tires–Roads Based on Pressure-Sensitive Film Technology. Materials 2023, 16, 6323. [Google Scholar] [CrossRef]

- Chen, X.; Sathyanarayan, H.; Gong, Y.; Yi, J.; Wang, H. Dynamic Tire/Road Friction Estimation With Embedded Flexible Force Sensors. IEEE Sens. J. 2023, 23, 26608–26619. [Google Scholar] [CrossRef]

- Yang, S.; Chen, Y.; Shi, R.; Wang, R.; Cao, Y.; Lu, J. A Survey of Intelligent Tires for Tire-Road Interaction Recognition Toward Autonomous Vehicles. IEEE Trans. Intell. Veh. 2022, 7, 520–532. [Google Scholar] [CrossRef]

- Guan, J.; Zhou, X.; Liu, L.; Ran, M. Measurement of Tire-Pavement Contact Tri-Axial Stress Distribution Based on Sensor Array. Coatings 2023, 13, 416. [Google Scholar] [CrossRef]

- Ge, H.; Quezada, J.C.; Le Houerou, V.; Chazallon, C. Multiscale analysis of tire and asphalt pavement interaction via coupling FEM–DEM 547 simulation. Eng. Struct. 2022, 256, 113925. [Google Scholar] [CrossRef]

- Liu, X.; Jayme, A.; Al-Qadi, I.L. ContactGAN development–prediction of tire-pavement contact stresses using a generative and 549 transfer learning model. Int. J. Pavement Eng. 2023, 24, 2138876. [Google Scholar] [CrossRef]

- Gao, X.; Zhuang, Y.; Liu, S. High-speed 3D digital image correlation for measuring tire rolling resistance coefficient. Measurement 2020, 171, 108830. [Google Scholar] [CrossRef]

- Kawakami, A.; Ishigaki, T.; Shirai, Y.; Terada, M.; Kubo, K. Evaluation method of pavement surface characteristics for rolling resistance. Road Mater. Pavement Des. 2017, 18 (Suppl. S2), 2–11. [Google Scholar] [CrossRef]

- Cho, J.R.; Lee, H.W.; Jeong, W.B.; Jeong, K.M.; Kim, K.W. Numerical estimation of rolling resistance and temperature distribution of 3-D periodic patterned tire. Int. J. Solids Struct. 2013, 50, 86–96. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, H.; Qian, J.; Zhou, H. Evaluation of tire rolling resistance from tire-deformable pavement interaction modeling. J. Transp. Eng. Part B Pavements 2021, 147, 04021041. [Google Scholar] [CrossRef]

- Ejsmont, J.; Owczarzak, W. Engineering method of tire rolling resistance evaluation. Measurement 2019, 145, 144–149. [Google Scholar] [CrossRef]

- Ejsmont, J.; Sandberg, U.; Świeczko-Zurek, B.; Mioduszewski, P. Tyre/Road Noise Reduction by a Poroelastic Road Surface. Presented at the 43rd International Congress on Noise Control Engineering: Improving the World Through Noise Control, INTERNOISE 2014, Melbourne, Australia, 16–19 November 2014. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:vti:diva-9349 (accessed on 30 May 2025).

- Zaumanis, M.; Haritonovs, V. Long term monitoring of full scale pavement test section with eight different asphalt wearing courses. Mater. Struct. 2016, 49, 1817–1828. [Google Scholar] [CrossRef]

- Taryma, S.; Woźniak, R. Wpływ zużycia opony samochodowej na jej opór toczenia. Autobusy Tech. Eksploat. Syst. Transp. 2014, 15, 272–275. [Google Scholar]

- Owczarzak, W.; Sommer, S.; Ronowski, G. Method of Forming Road Surface Replicas Using 3D Printing Technology. Coatings 2024, 14, 1455. [Google Scholar] [CrossRef]

| Tire | ASA [CEL] | PETG [CEL] | Resin [CEL] | ASA- Resin[%] | PETG- Resin[%] |

|---|---|---|---|---|---|

| Tire1 (winter) | 0.0065 | 0.0064 | 0.0074 | 12.3 | 13.4 |

| Tire2 (summer) | 0.0072 | 0.0068 | 0.0077 | 7.0 | 11.4 |

| Tire3 (allseason) | 0.0058 | 0.0053 | 0.0062 | 6.6 | 14.5 |

| Tire4 (summer) | 0.0050 | 0.0049 | 0.0058 | 14.2 | 16.4 |

| Tire5 (allseason) | 0.0053 | 0.0054 | 0.0062 | 14.5 | 13.0 |

| Tire6 (summer) | 0.0048 | 0.0050 | 0.0056 | 14.3 | 11.4 |

| Tire | ASA [CEL] | PETG [CEL] | Resin [CEL] | ASA- Resin[%] | PETG- Resin[%] |

|---|---|---|---|---|---|

| Tire1 (winter) | 0.0065 | 0.0064 | 0.0074 | 12.3 | 13.4 |

| Tire2 (summer) | 0.0072 | 0.0068 | 0.0077 | 7.0 | 11.4 |

| Tire3 (allseason) | 0.0058 | 0.0053 | 0.0062 | 6.6 | 14.5 |

| Tire4 (summer) | 0.0050 | 0.0049 | 0.0058 | 14.2 | 16.4 |

| Tire5 (allseason) | 0.0053 | 0.0054 | 0.0062 | 14.5 | 13.0 |

| Tire6 (summer) | 0.0048 | 0.0050 | 0.0056 | 14.3 | 11.4 |

| Tire | ASA [CEL] | PETG [CEL] | Resin [CEL] | ASA- Resin[%] | PETG- Resin[%] |

|---|---|---|---|---|---|

| Tire1 (winter) | 0.0062 | 0.0062 | 0.0065 | 5.7 | 4.4 |

| Tire2 (summer) | 0.0066 | 0.0068 | 0.0072 | 7.8 | 6.4 |

| Tire3 (allseason) | 0.0056 | 0.0056 | 0.0061 | 8.6 | 8.3 |

| Tire4 (summer) | 0.0049 | 0.0051 | 0.0055 | 10.6 | 6.9 |

| Tire5 (allseason) | 0.0053 | 0.0052 | 0.0057 | 8.2 | 8.9 |

| Tire6 (summer) | 0.0049 | 0.0050 | 0.0054 | 8.8 | 8.1 |

| Tire | ASA Sample with Cut Base [CEL] | Resin [CEL] |

|---|---|---|

| Tire1 (winter) | 0.0073 | 0.0074 |

| Tire2 (summer) | 0.0075 | 0.0077 |

| Tire3 (allseason) | 0.0062 | 0.0062 |

| Tire4 (summer) | 0.0059 | 0.0058 |

| Tire5 (allseason) | 0.0060 | 0.0062 |

| Tire6 (summer) | 0.0059 | 0.0056 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Owczarzak, W.; Sommer, S.; Ronowski, G. Analysis of the Suitability of 3D-Printed Road Surface Replicas for Laboratory Testing of Rolling Resistance. Coatings 2025, 15, 766. https://doi.org/10.3390/coatings15070766

Owczarzak W, Sommer S, Ronowski G. Analysis of the Suitability of 3D-Printed Road Surface Replicas for Laboratory Testing of Rolling Resistance. Coatings. 2025; 15(7):766. https://doi.org/10.3390/coatings15070766

Chicago/Turabian StyleOwczarzak, Wojciech, Sławomir Sommer, and Grzegorz Ronowski. 2025. "Analysis of the Suitability of 3D-Printed Road Surface Replicas for Laboratory Testing of Rolling Resistance" Coatings 15, no. 7: 766. https://doi.org/10.3390/coatings15070766

APA StyleOwczarzak, W., Sommer, S., & Ronowski, G. (2025). Analysis of the Suitability of 3D-Printed Road Surface Replicas for Laboratory Testing of Rolling Resistance. Coatings, 15(7), 766. https://doi.org/10.3390/coatings15070766