Experimental Investigation on the Erosion Resistance Characteristics of Compressor Impeller Coatings to Water Droplet Impact

Abstract

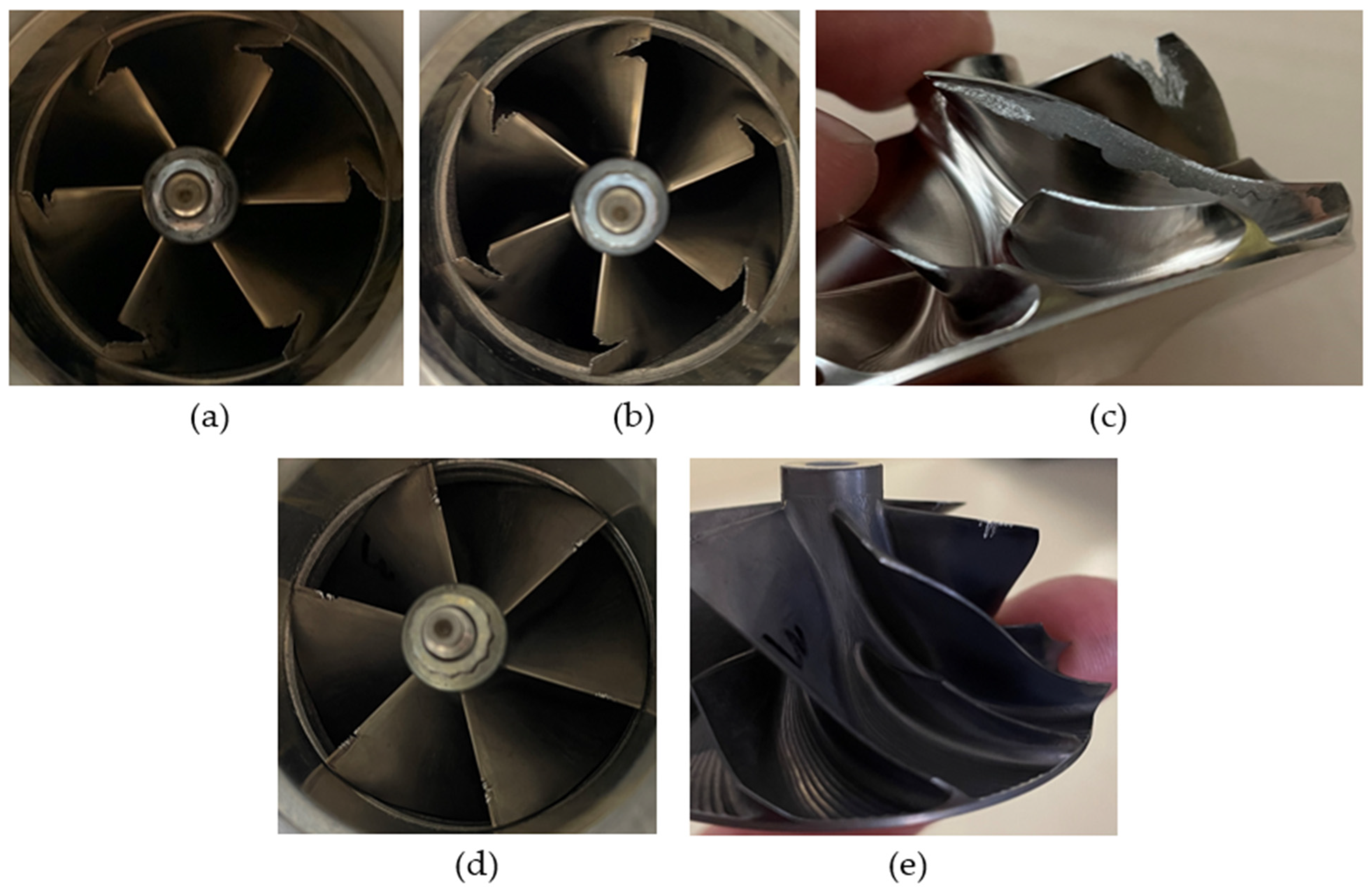

1. Introduction

2. Materials and Methods

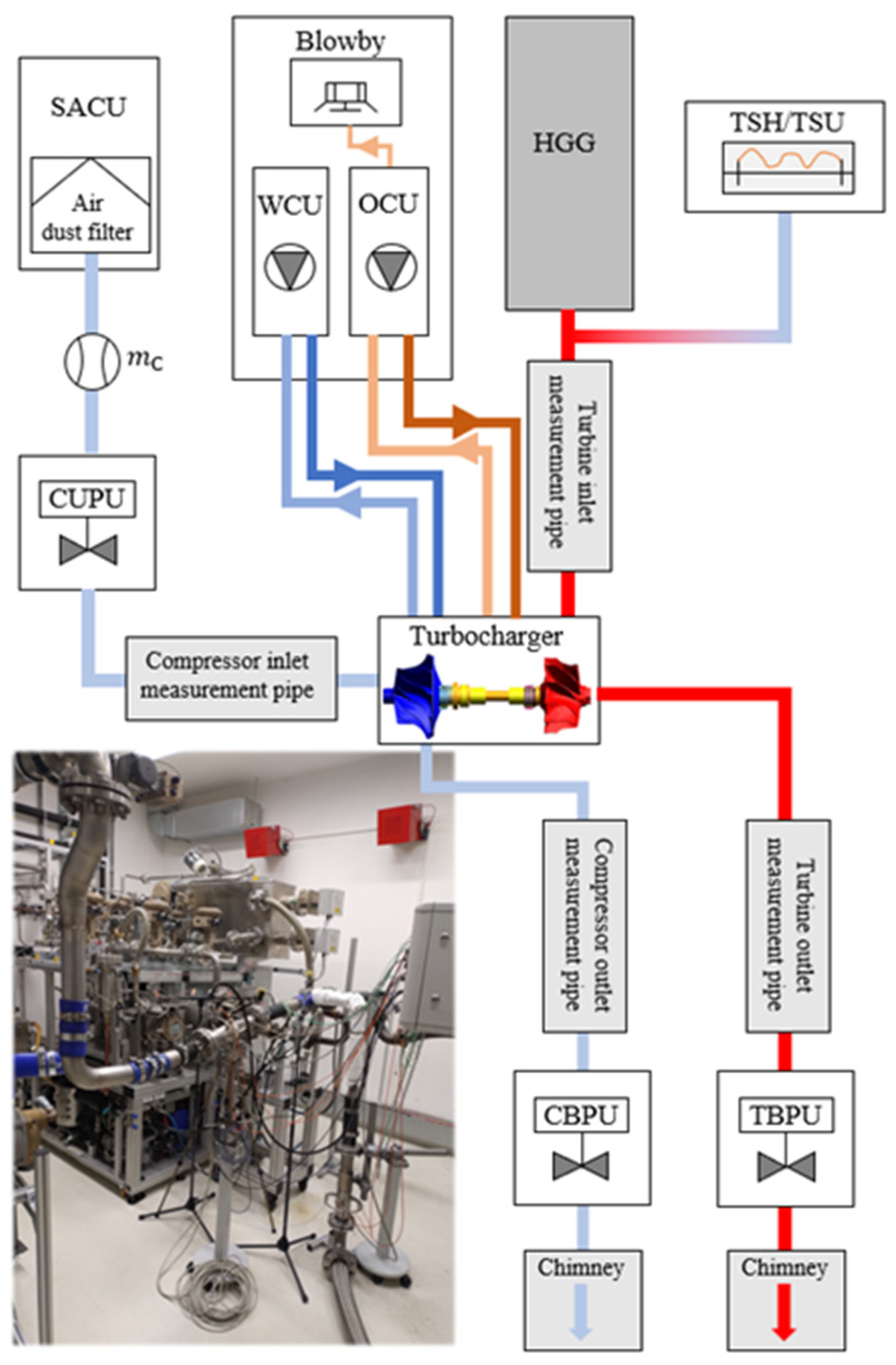

2.1. Test Apparatus

2.2. Samples

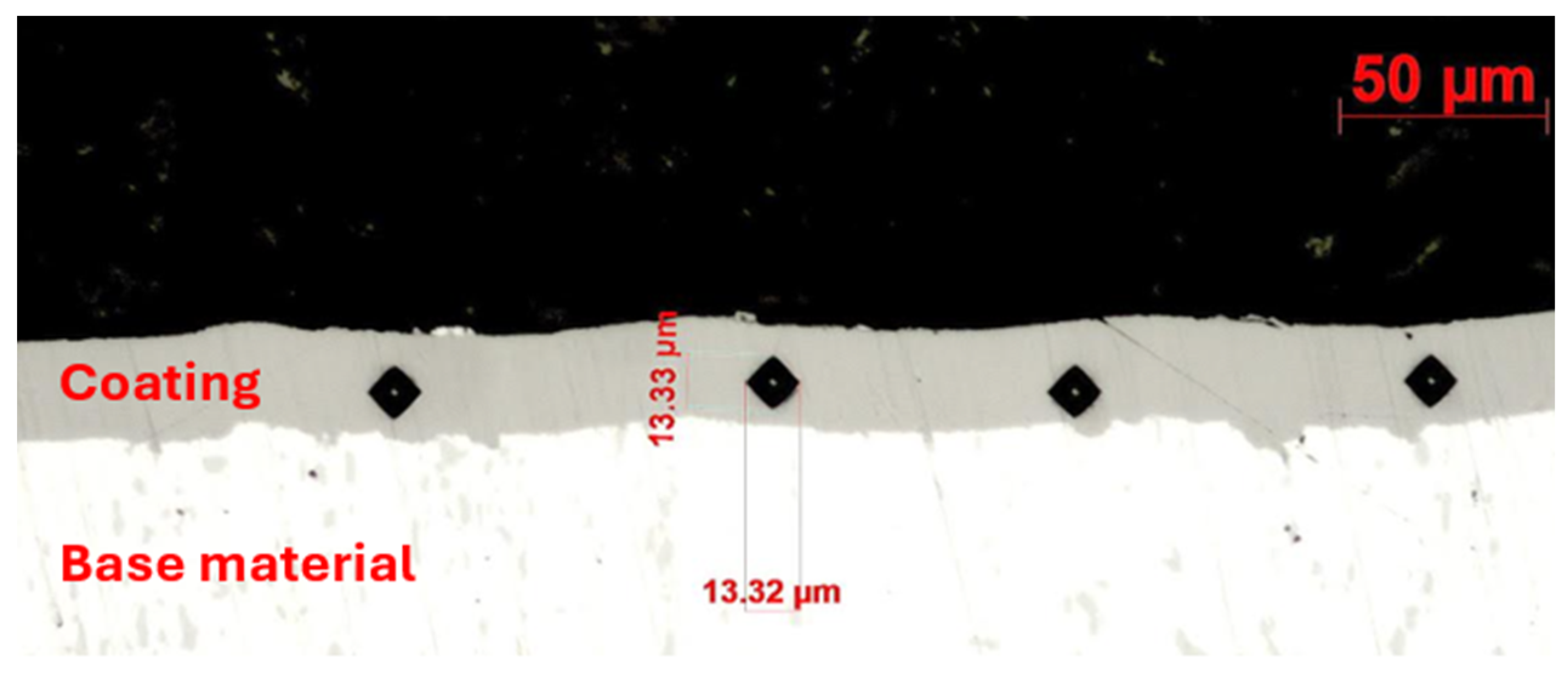

2.3. Hardness Measurement

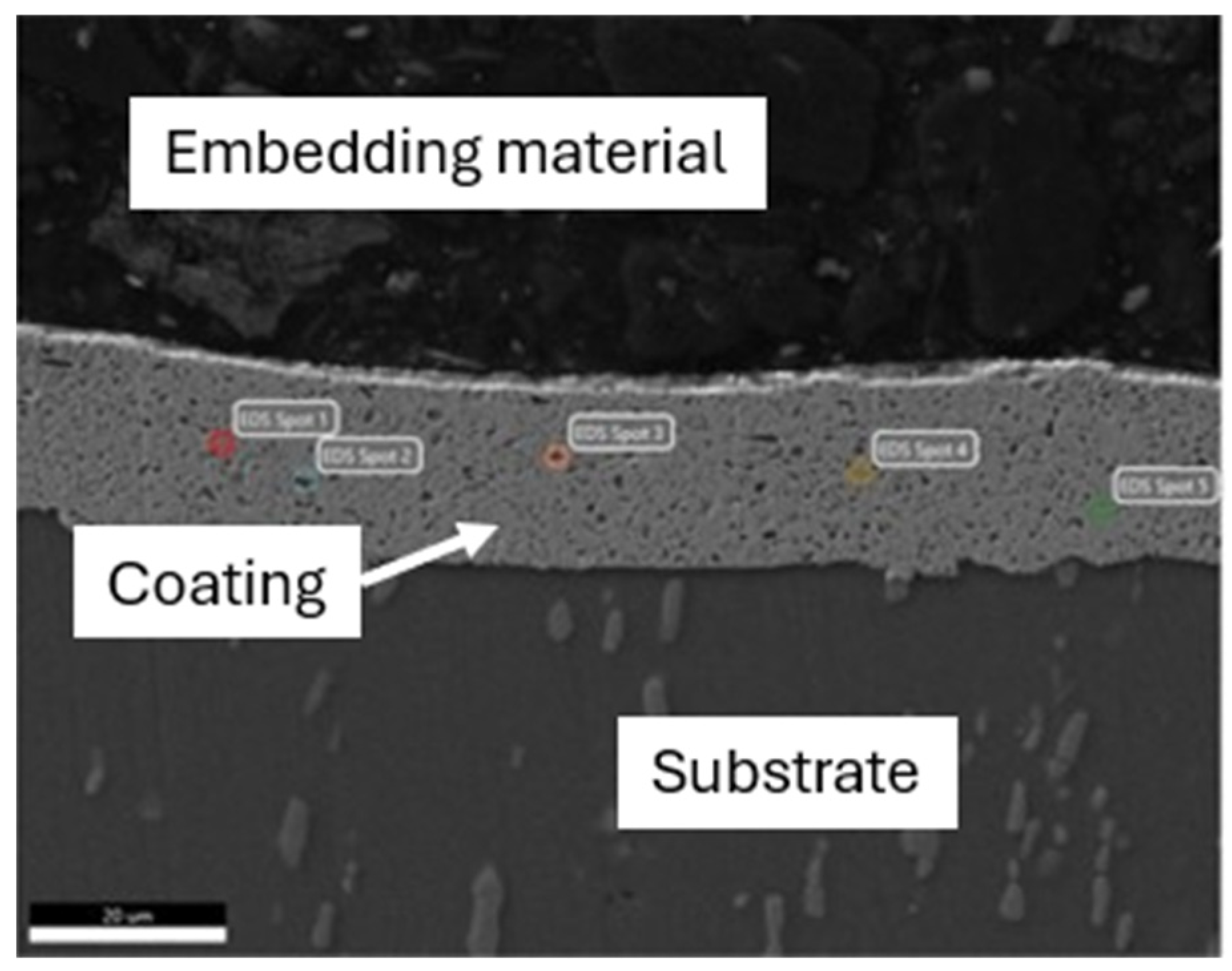

2.4. Chemical Composition Detection of the Coatings

2.5. Erosion Detection

2.6. Compressor Isentropic Efficiency Measurement

3. Results and Discussion

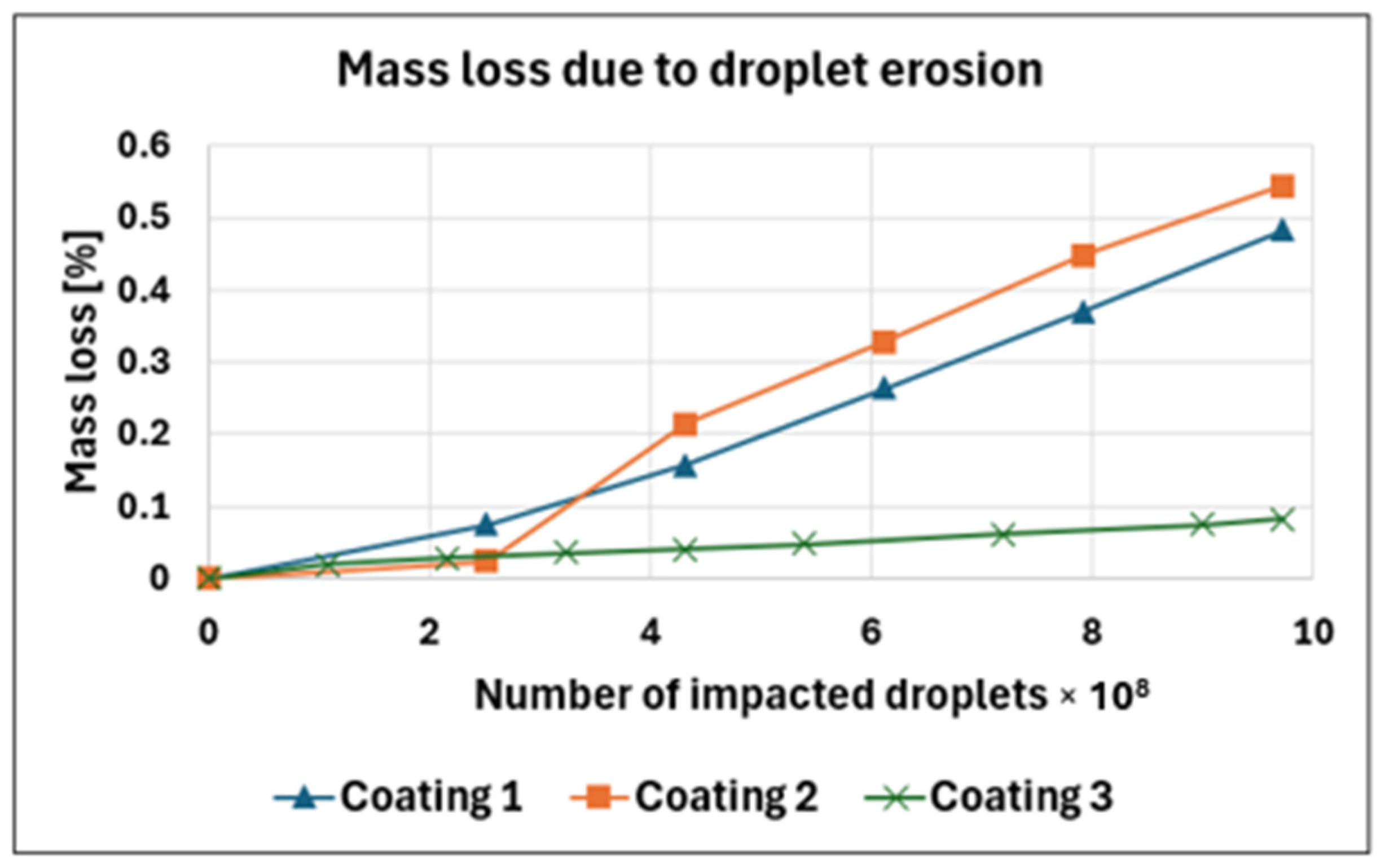

3.1. Mass Loss and Hardness

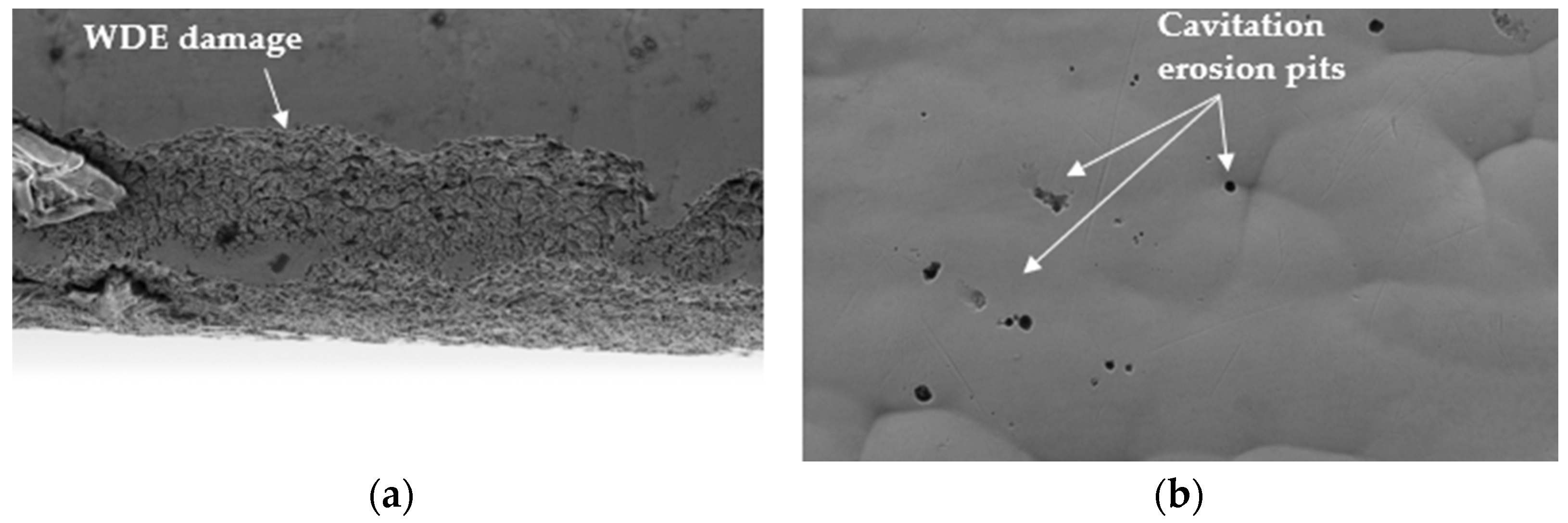

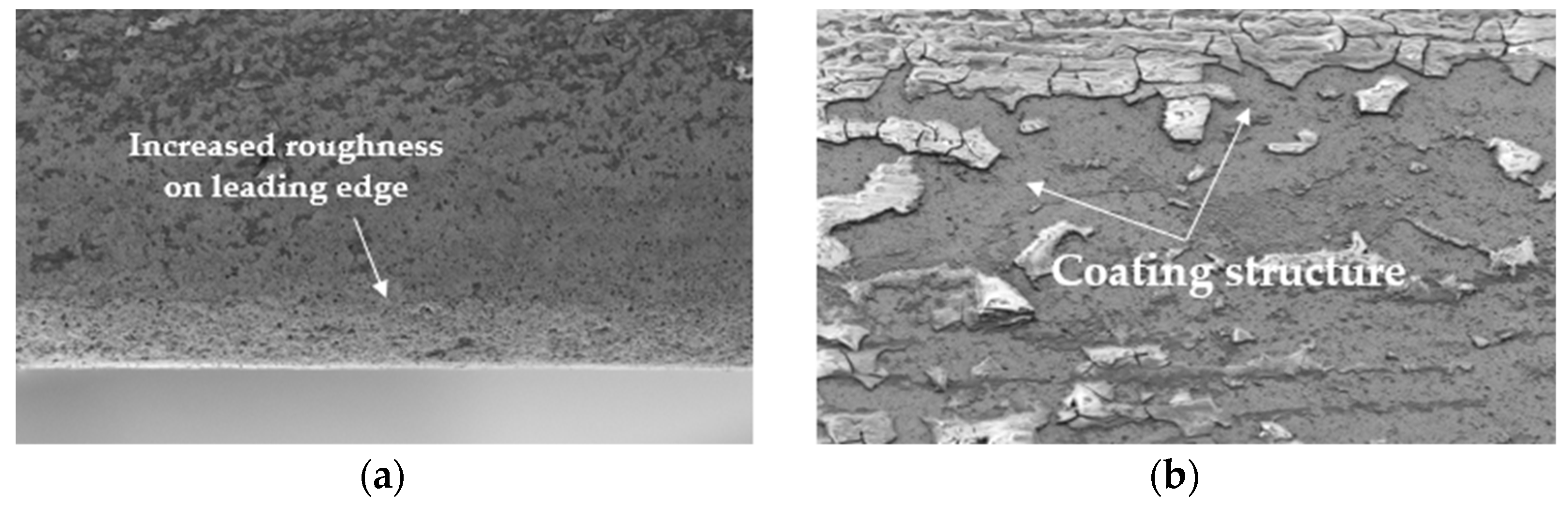

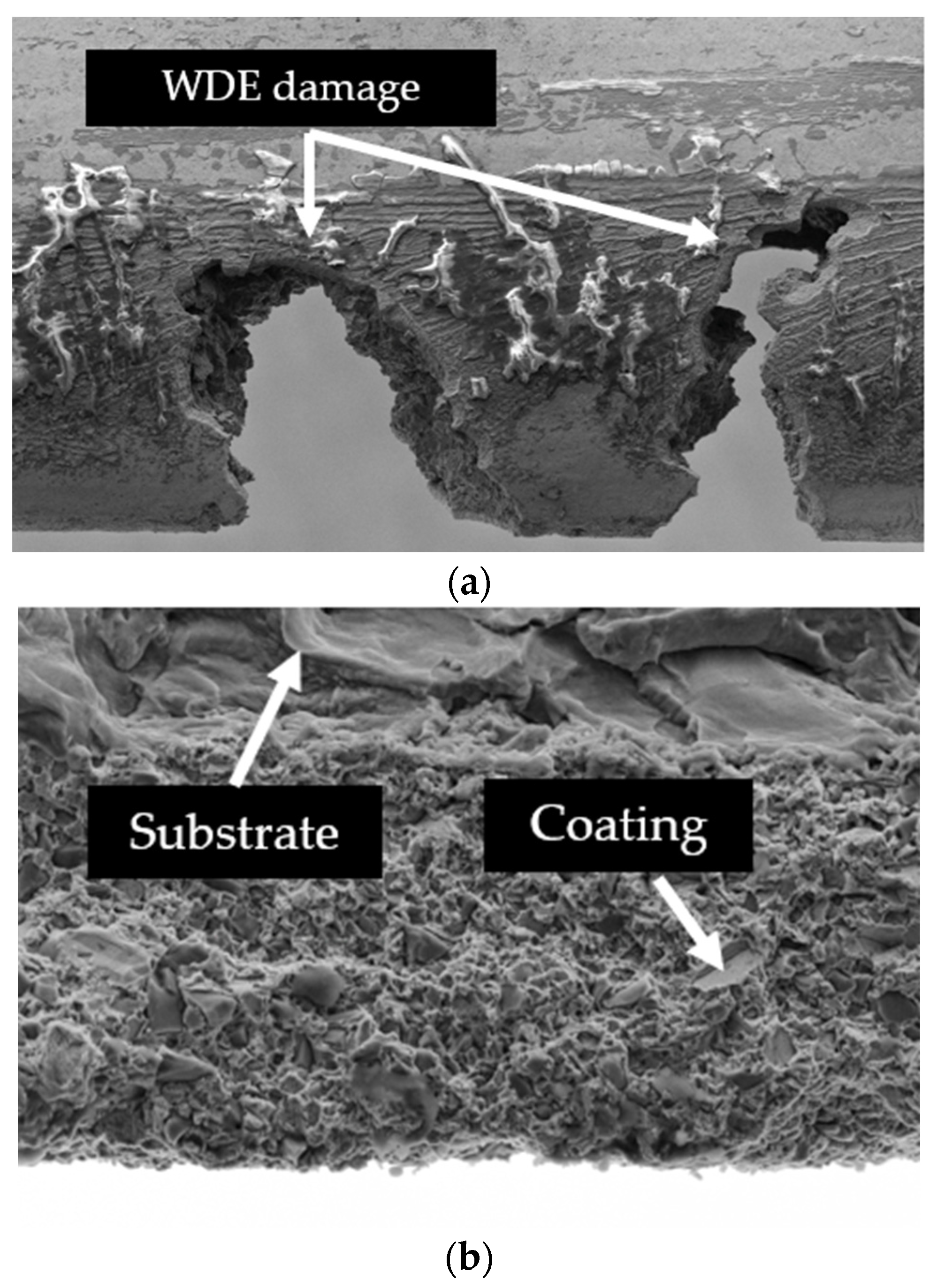

3.2. Wear Analysis with SEM

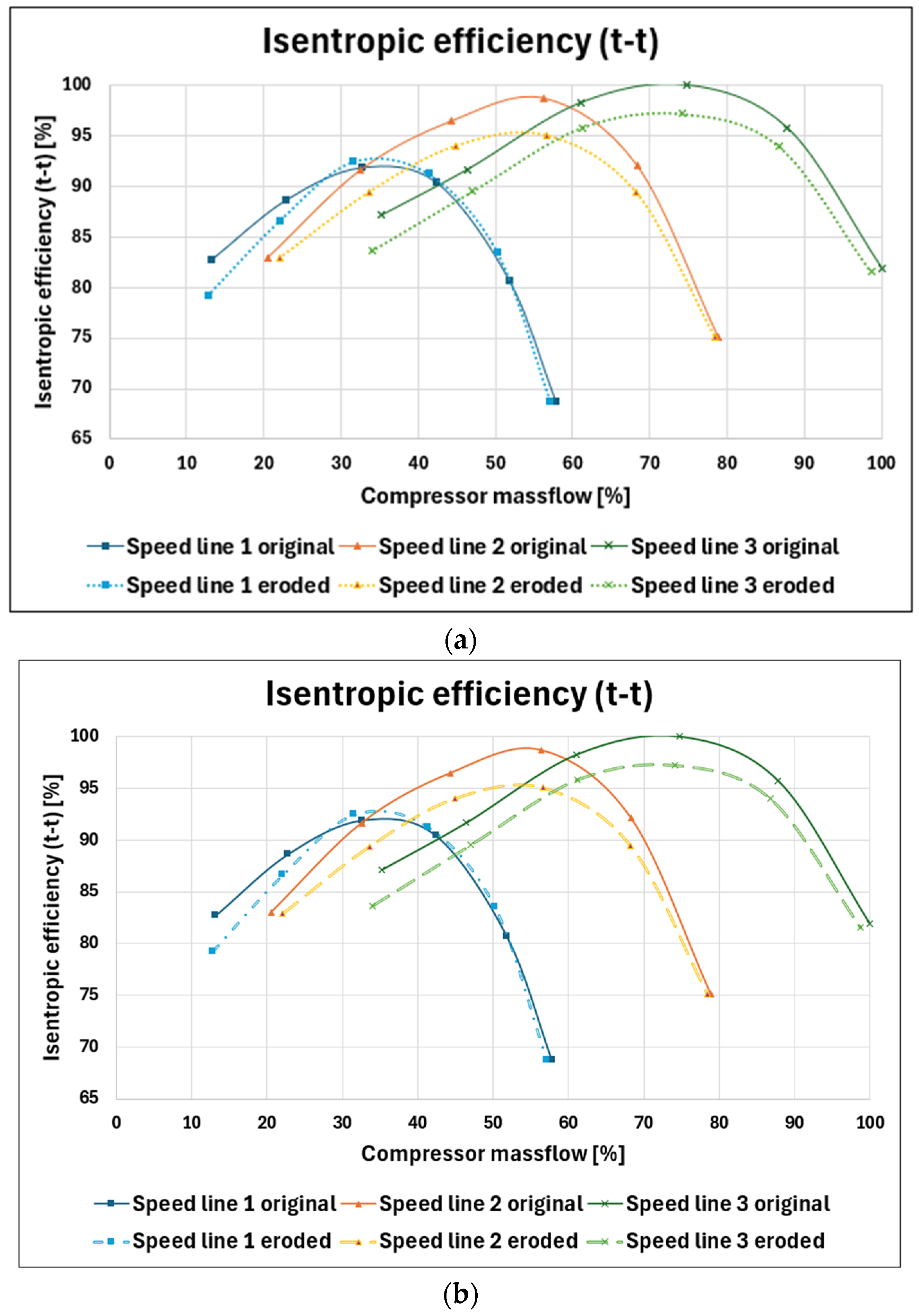

3.3. Compressor Isentropic Efficiency Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASP | Atmospheric Plasma Spray |

| CBPU | Compressor Backpressure Unit |

| CUPU | Compressor Under-pressure Unit |

| EDX | Energy-Dispersive X-ray Spectroscopy |

| Compressor isentropic efficiency | |

| HGG | Hot Gas Generator |

| HSC | High-speed Camera |

| HV | Vickers Hardness |

| HVOF | High-velocity Oxygen Fuel |

| κ | Adiabatic exponent |

| LP-EGR | Low-pressure Exhaust Gas Recirculation |

| Compressor mass flow | |

| OCU | Oil Conditioning Unit |

| OP-S | Oxide-Polishing Silica |

| Compressor inlet pressure | |

| Compressor outlet pressure | |

| PID | Proportional-Integral-Derivative |

| SACU | Suction Air Conditioning Unit |

| SD | Standard Deviation |

| SDD | Silicon Drift Detector |

| SEM | Scanning Electron Microscope |

| Compressor inlet temperature | |

| Compressor outlet temperature | |

| TBPU | Turbine Backpressure Unit |

| TSH | Thermo-Shock Heater |

| TSU | Thermo-Schock Unit |

| Circumferential velocity of the compressor | |

| Circumferential velocity at the impact point | |

| Water droplet velocity | |

| Impact velocity of water droplet | |

| WCU | Water Conditioning Unit |

| WDG | Water Droplet Generator |

| wt | Weight ratio |

References

- Worthington, A.M. On the forms assumed by drops of liquids falling vertically on a horizontal plate. R. Soc. 1877, 25, 171–178. [Google Scholar] [CrossRef]

- Ahmad, M.; Schatz, M.; Casey, M. Experimental investigation of droplet size influence on low pressure steam turbine blade erosion. Wear 2013, 303, 83–86. [Google Scholar] [CrossRef]

- Mahdipoor, M.; Tarasi, F.; Moreau, C.; Dolatabadi, A.; Medraj, M. HVOF sprayed coatings of nano-agglomerated tungsten-carbide/cobalt powders for water droplet erosion application. Wear 2015, 330–331, 338–347. [Google Scholar] [CrossRef]

- Gerdes, C.; Karimi, A.; Bieler, H.W. Water droplet erosion and microstructure of laser-nitrided Ti-6Al-4V. Wear 1995, 186, 368–374. [Google Scholar] [CrossRef]

- Di, J.; Wang, S.; Yan, X.; Jiang, X.; Lian, J.; Zhang, Z.; Xie, Y. Experimental Research on Water Droplet Erosion Resistance Characteristics of Turbine Blade Substrate and Strengthened Layers Materials. Materials 2020, 13, 4286. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, D.; Xie, Y. Experimental study on water droplet erosion resistance of coatings (Ni60 and WC-17Co) sprayed by APS and HVOF. Wear 2019, 432, 202950. [Google Scholar] [CrossRef]

- Jones, L. Low angle scouring erosion behaviour of elastomeric materials. Wear 2011, 271, 1411–1417. [Google Scholar] [CrossRef]

- Dashtkar, A.; Hadavinia, H.; Sahinkaya, M.N.; Williams, N.A.; Vahid, S.; Ismail, F.; Turner, M. Rain erosion-resistant coatings for wind turbine blades: A review. Polym. Polym. Compos. 2019, 27, 443–475. [Google Scholar] [CrossRef]

- Slot, H.; Gelinck, E.; Rentrop, C.; van der Heide, E. Leading edge erosion of coated wind turbine blades: Review of coating life models. Renew. Energy 2015, 80, 837–848. [Google Scholar] [CrossRef]

- Herring, R.; Dyer, K.; Martin, F.; Ward, C. The increasing importance of leading-edge erosion and a review of existing protection solutions. Renew. Sustain. Energy Rev. 2019, 115, 109367. [Google Scholar] [CrossRef]

- Engel, O.G. Waterdrop collision with solid surfaces. J. Res. Natl. Bur. Stand. 1955, 54, 281–298. [Google Scholar] [CrossRef]

- Tobin, E.; Young, T.; Raps, D.; Rohr, O. Comparison of liquid impingement results from whirling arm and water-jet rain erosion test facilities. Wear 2011, 271, 2625–2631. [Google Scholar] [CrossRef]

- Bonu, V.; Barshilia, H.C. High-Temperature Solid Particle Erosion of Aerospace Components: Its Mitigation Using Advanced Nanostructured Coating Technologies. Coatings 2022, 12, 1979. [Google Scholar] [CrossRef]

- Debasish, D.; Panigrahi, A.; Sengupta, P.; Bajpai, S. Erosive wear characteristic of Mo-TiN composite coatings on turbocharger compressor wheel using Taguchi experimental design. Mater. Today Proc. 2022, 66, 534–539. [Google Scholar] [CrossRef]

- Xie, X.-M.; Liu, X.-B.; He, B.-M.; Zhang, F.-Z.; Liang, J.-X.; Liu, X.-Y.; Zheng, J. Laser cladding Ni60-SiC/Ti3SiC2 self-lubricating composite coatings on IN718 alloy: Wear mechanisms and oxidation behaviors. Wear 2024, 560, 205611. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Lv, Z.; Cao, J.; Tong, Y.; Sun, M.; Cui, C.; Wang, X. Effect of SiC and TiC content on microstructure and wear behavior of Ni-based composite coating manufactured by laser cladding on Ti–6Al–4V. Wear 2024, 552, 205431. [Google Scholar] [CrossRef]

- Natarajan, P.; Sakthivel, P.; Vijayan, V.; Chellamuthu, K. Characterization of Pulse Electrodeposited Ni-SiC Nanocomposite Coating on Four Stroke Internal Combustion Engine Cast Iron Cylinder Liner. Silicon 2024, 16, 6193–6208. [Google Scholar] [CrossRef]

- Lapuerta, M.; Ramos, Á.; Fernández-Rodríguez, D.; González-García, I. High-pressure versus low-pressure exhaust gas recirculation in a Euro 6 diesel engine with lean-NOx trap: Effectiveness to reduce NOx emissions. Int. J. Engine Res. 2018, 20, 155–163. [Google Scholar] [CrossRef]

- Serrano, J.P.; Piqueras, P.; Navarro, R.; Tarí, D.; Meano, C.M. Development and verification of an in-flow water condensation model for 3D-CFD simulations of humid air streams mixing. Comput. Fluids 2018, 167, 158–165. [Google Scholar] [CrossRef]

- Desantes, J.M.; Luján, J.M.; Pla, B.; Soler, J.A. On the combination of high-pressure and low-pressure exhaust gas recirculation loops for improved fuel economy and reduced emissions in high-speed direct-injection engines. Int. J. Engine Res. 2012, 14, 3–11. [Google Scholar] [CrossRef]

- Siokos, K.; Koli, R.; Prucka, R.; Schwanke, J.; Miersch, J. Assessment of cooled low pressure EGR in a turbocharged direct injection gasoline engine. SAE Int. J. Engines 2015, 8, 1535–1543. [Google Scholar] [CrossRef]

- Venu, H.; Subramani, L.; Raju, V.D. Emission reduction in a DI diesel engine using exhaust gas recirculation (EGR) of palm biodiesel blended with TiO2 nano additives. Renew. Energy 2019, 140, 245–263. [Google Scholar] [CrossRef]

- Moroz, S.; Bourgoin, G.; Luján, J.M.; Pla, B. Acidic condensation in low pressure EGR systems using diesel and biodiesel fuels. SAE Int. J. Fuels Lubr. 2009, 2, 305–312. [Google Scholar] [CrossRef]

- D’ambrosio, S.; Mancarella, A.; Manelli, A. Utilization of Hydrotreated Vegetable Oil (HVO) in a Euro 6 Dual-Loop EGR Diesel Engine: Behavior as a Drop-In Fuel and Potentialities along Calibration Parameter Sweeps. Energies 2022, 15, 7202. [Google Scholar] [CrossRef]

- Szwaja, S.; Piotrowski, A.; Szwaja, M.; Musial, D. Thermodynamic Analysis of the Combustion Process in Hydrogen-Fueled Engines with EGR. Energies 2024, 17, 2833. [Google Scholar] [CrossRef]

- Johar, T.; Hsieh, C.-F. Design Challenges in Hydrogen-Fueled Rotary Engine—A Review. Energies 2023, 16, 607. [Google Scholar] [CrossRef]

- Karstadt, S.; Werner, J.; Münz, S.; Aymanns, R. Effect of water droplets caused by low pressure EGR on spinning compressor wheels. In Proceedings of the 19th Supercharging Conference Dresden, Aachen, Germany, 17–18 September 2014. [Google Scholar]

- Wittmann, T.; Lück, S.; Bode, C.; Friedrichs, J. On the Impact of Condensation and Liquid Water on the Radial Turbine of a Fuel Cell Turbocharger. Machines 2022, 10, 1053. [Google Scholar] [CrossRef]

- ASTM G73-10; Standard Practice for Liquid Impingement Erosion Testing. ASTM International: West Conshohocken, PA, USA, 2010.

- Hattori, S.; Kakuichi, M. Effect of impact angle on liquid droplet impingement erosion. Wear 2013, 298–299, 1–7. [Google Scholar] [CrossRef]

- Rayleigh, L. On the instability of jets. Proc. Lond. Math. Soc. 1878, 1, 4–13. [Google Scholar] [CrossRef]

- EN 573-3:2019+A2:2023; Aluminum and Aluminum Alloys—Chemical Composition and Form of Wrought Products—Part 3: Chemical Composition and Form of Products (EN 573-3:2019). European Committee for Standardization: Brussels, Belgium, 2019.

- ISO 6507-1:2024; Metallic Materials—Vickers Hardness Test—Part 1: Test Method (1 kgf to 100 kgf Load). International Organization for Standardization: Geneva, Switzerland, 2024.

- Rácz, B.; Pesthy, M.; Sass, P.; Rohde-Brandenburger, J. Experimental investigation of vibroacoustic behavior of an automotive turbocharger with semi-floating bearing. In Vehicle and Automotive Engineering; Springer: Singapore, 2020; pp. 245–255. [Google Scholar]

- DIN EN 60751:2023-06; Industrial Platinum Resistance Thermometers (EN 60751:2008). Deutsches Institut für Normung/Beuth Verlag: Berlin, Germany, 2009.

- Kirols, H.; Kevorkov, D.; Uihlein, A.; Medraj, M. The effect of initial surface roughness on water droplet erosion behaviour. Wear 2015, 342, 198–209. [Google Scholar] [CrossRef]

- Luiset, B.; Sanchette, F.; Billard, A.; Schuster, D. Mechanisms of stainless steels erosion by water droplets. Wear 2013, 303, 459–464. [Google Scholar] [CrossRef]

- Shaik, R.A.; Ibrahim, M.E.; Gujba, A.K.; Pugh, M.D.; Medraj, M. On the role of strain hardening and mechanical properties in water droplet erosion of metals. Tribol. Int. 2022, 173, 107649. [Google Scholar] [CrossRef]

- Ibrahim, M.E.; Marzbali, M.; Gujba, A.K.; Medraj, M. The role of hardening and roughening during the incubation period in water droplet impingement erosion of Ti–6Al–4V. Wear 2023, 520, 204658. [Google Scholar] [CrossRef]

- Ahmad, M.; Casey, M.; Sürken, N. Experimental assessment of droplet impact erosion resistance of steam turbine blade materials. Wear 2009, 267, 1605–1618. [Google Scholar] [CrossRef]

- Mann, B.S. Water Droplet and Cavitation Erosion Behavior of Laser-Treated Stainless Steel and Titanium Alloy: Their Similarities. J. Mater. Eng. Perform. 2013, 22, 3647–3656. [Google Scholar] [CrossRef]

| Coating Thickness [µm] (Mean (±SD)) | |

|---|---|

| Sample 1 | 22.4 (±1.1) |

| Sample 2 | 21.9 (±0.9) |

| Sample 3 | 23.6 (±1.3) |

| Sample 1 | Sample 2 | Sample 3 | |

|---|---|---|---|

| Hardness of base material [HV10] (mean (±SD)) | 145 (±0.71) | 146 (±0.71) | 133.6 (±0.55) |

| Hardness of coating [HV0.05] (mean (±SD)) | 521 (±2.24) | 517.2 (±0.45) | 616.2 (±0.45) |

| Chemical Composition of the Coating | Sample 1 [wt%] | Sample 2 [wt%] | Sample 3 [wt%] |

|---|---|---|---|

| Ni | 77.1 | 83.92 | 82.6 |

| P | 17.9 | 11.08 | 7.41 |

| S | 0 | 0 | 4.98 |

| Quantity | Sensor type | Measurement Range | Measurement Accuracy |

|---|---|---|---|

| Turbocharger speed | Speed sensor (Jaquet HMS-5 DSE 0805) | 5000–400,000 rpm | ±1.5%, class 1, DIN EN 60584 |

| Compressor inlet temperature | Thermocouple (Pt100) | −200–650 °C | ±0.35 °C for −200–100 °C or ±0.55 °C for 100–650 °C, class 1, DIN EN 60751 [35] |

| Compressor outlet temperature | Thermocouple (Pt100) | −200–650 °C | ±0.35 °C for −200–100 °C or ±0.55 °C for 100–650 °C, class 1, DIN EN 60751 [35] |

| Compressor inlet pressure | Piezoresistive | 0.1–1000 bar | ±0.75 µm for 0.1–0.3 bar or ±0.25 µm for 0.3–1000 bar |

| Compressor outlet pressure | Piezoresistive | 0.1–1000 bar | ±0.75 µm for 0.1–0.3 bar or ±0.25 µm for 0.3–1000 bar |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takács, R.; Zsoldos, I.; Kiss, N.; Popa-Müller, I.; Barabás, I.; Dobos, B.; Tabakov, M.Z.; Tóth-Nagy, C.; Novotny, P. Experimental Investigation on the Erosion Resistance Characteristics of Compressor Impeller Coatings to Water Droplet Impact. Coatings 2025, 15, 767. https://doi.org/10.3390/coatings15070767

Takács R, Zsoldos I, Kiss N, Popa-Müller I, Barabás I, Dobos B, Tabakov MZ, Tóth-Nagy C, Novotny P. Experimental Investigation on the Erosion Resistance Characteristics of Compressor Impeller Coatings to Water Droplet Impact. Coatings. 2025; 15(7):767. https://doi.org/10.3390/coatings15070767

Chicago/Turabian StyleTakács, Richárd, Ibolya Zsoldos, Norbert Kiss, Izolda Popa-Müller, István Barabás, Balázs Dobos, Miklós Zsolt Tabakov, Csaba Tóth-Nagy, and Pavel Novotny. 2025. "Experimental Investigation on the Erosion Resistance Characteristics of Compressor Impeller Coatings to Water Droplet Impact" Coatings 15, no. 7: 767. https://doi.org/10.3390/coatings15070767

APA StyleTakács, R., Zsoldos, I., Kiss, N., Popa-Müller, I., Barabás, I., Dobos, B., Tabakov, M. Z., Tóth-Nagy, C., & Novotny, P. (2025). Experimental Investigation on the Erosion Resistance Characteristics of Compressor Impeller Coatings to Water Droplet Impact. Coatings, 15(7), 767. https://doi.org/10.3390/coatings15070767