Influence of Carbonized Garbage Fly Ash on the Performance of Foam Concrete

Abstract

1. Introduction

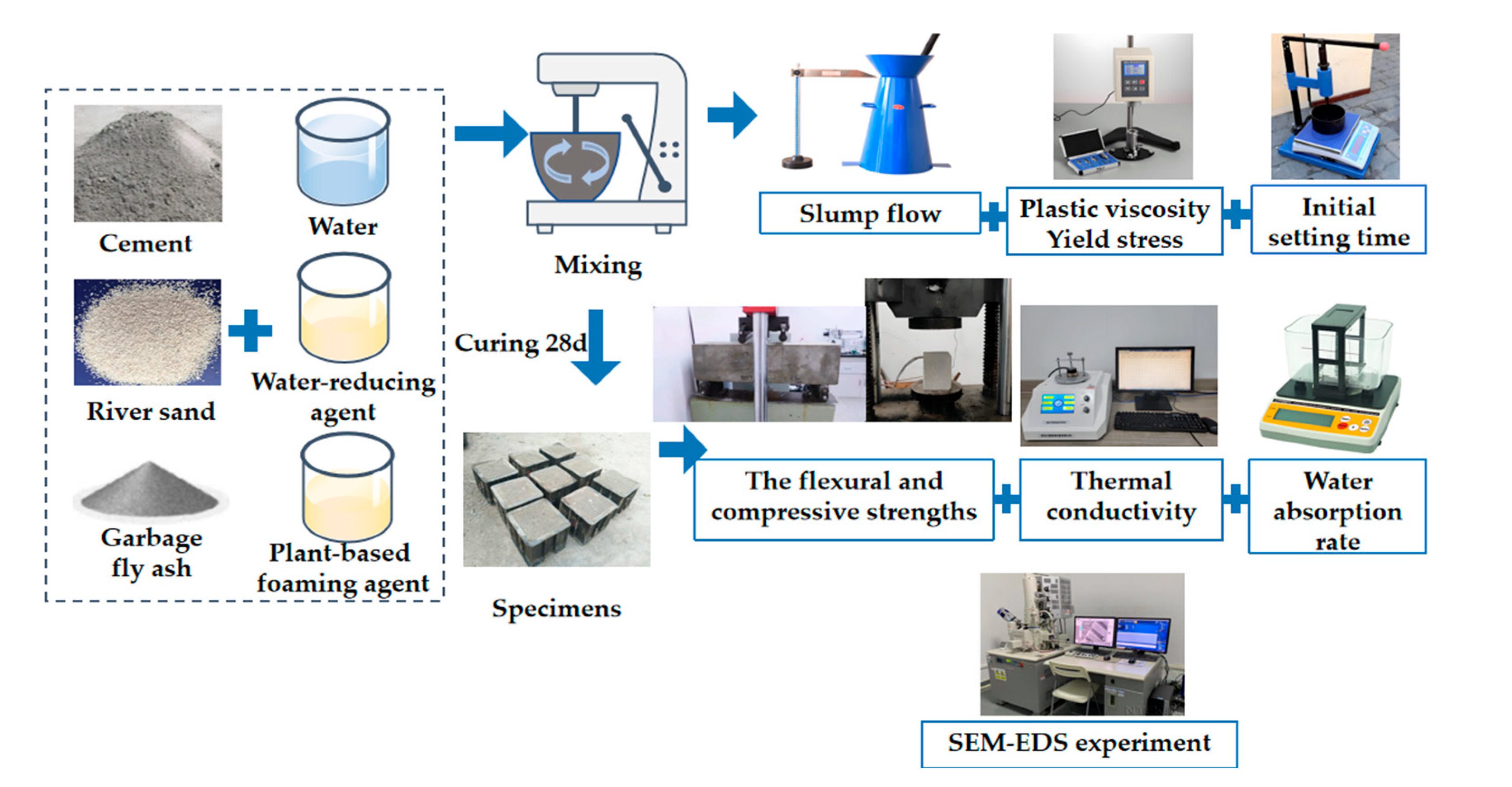

2. Experimental Sections

2.1. Raw Materials

2.2. Sample Preparation and Measurement

2.3. The Measurement of Workability

2.4. Determination of Thermal Conductivity and Water Resistance Coefficient

2.5. Measurement of Mechanical Properties

3. Results and Discussions

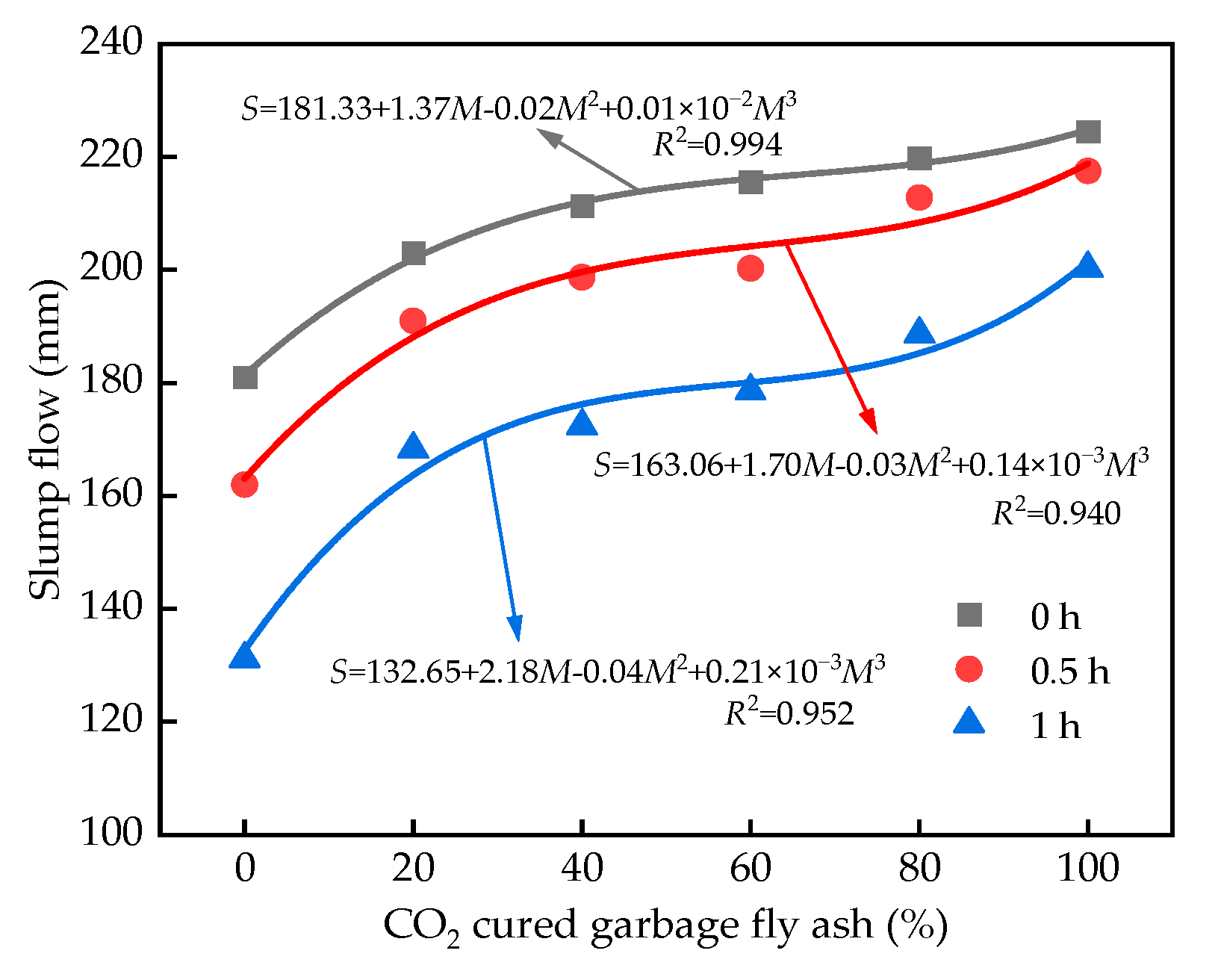

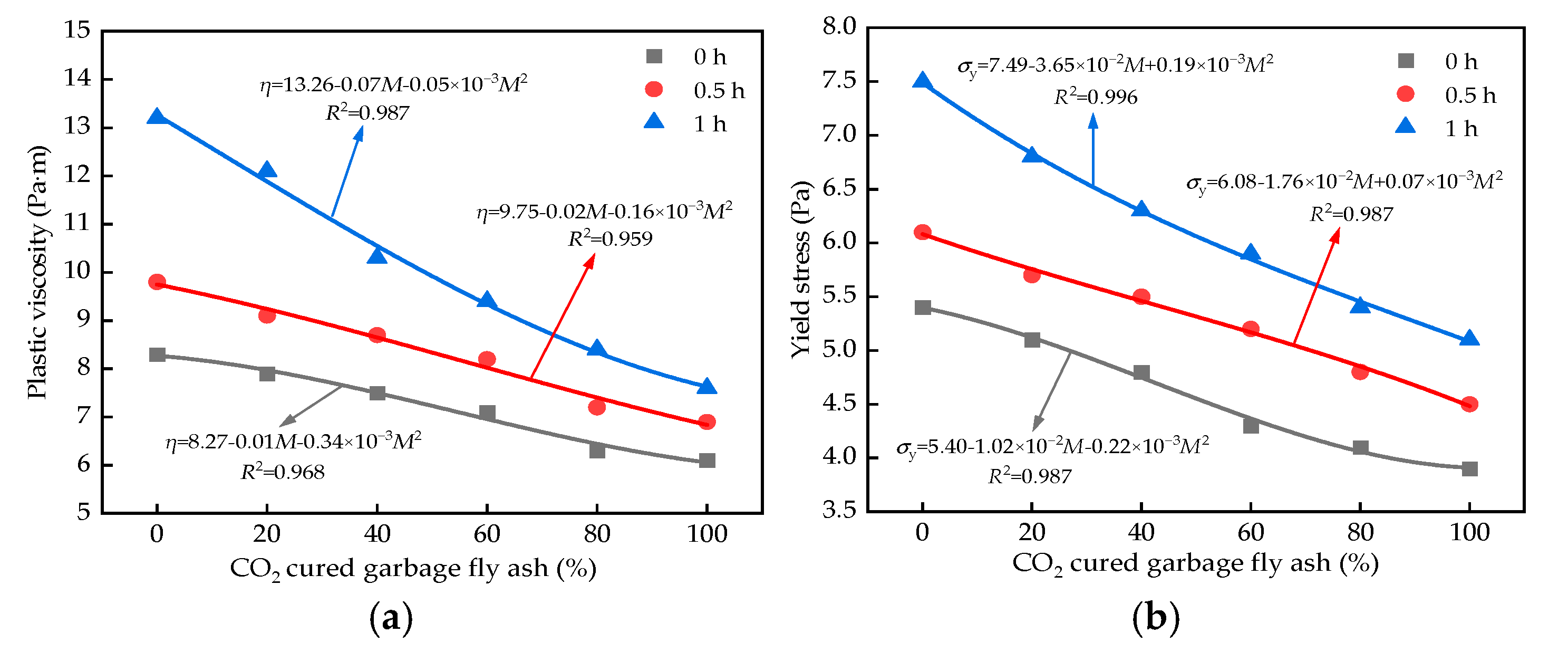

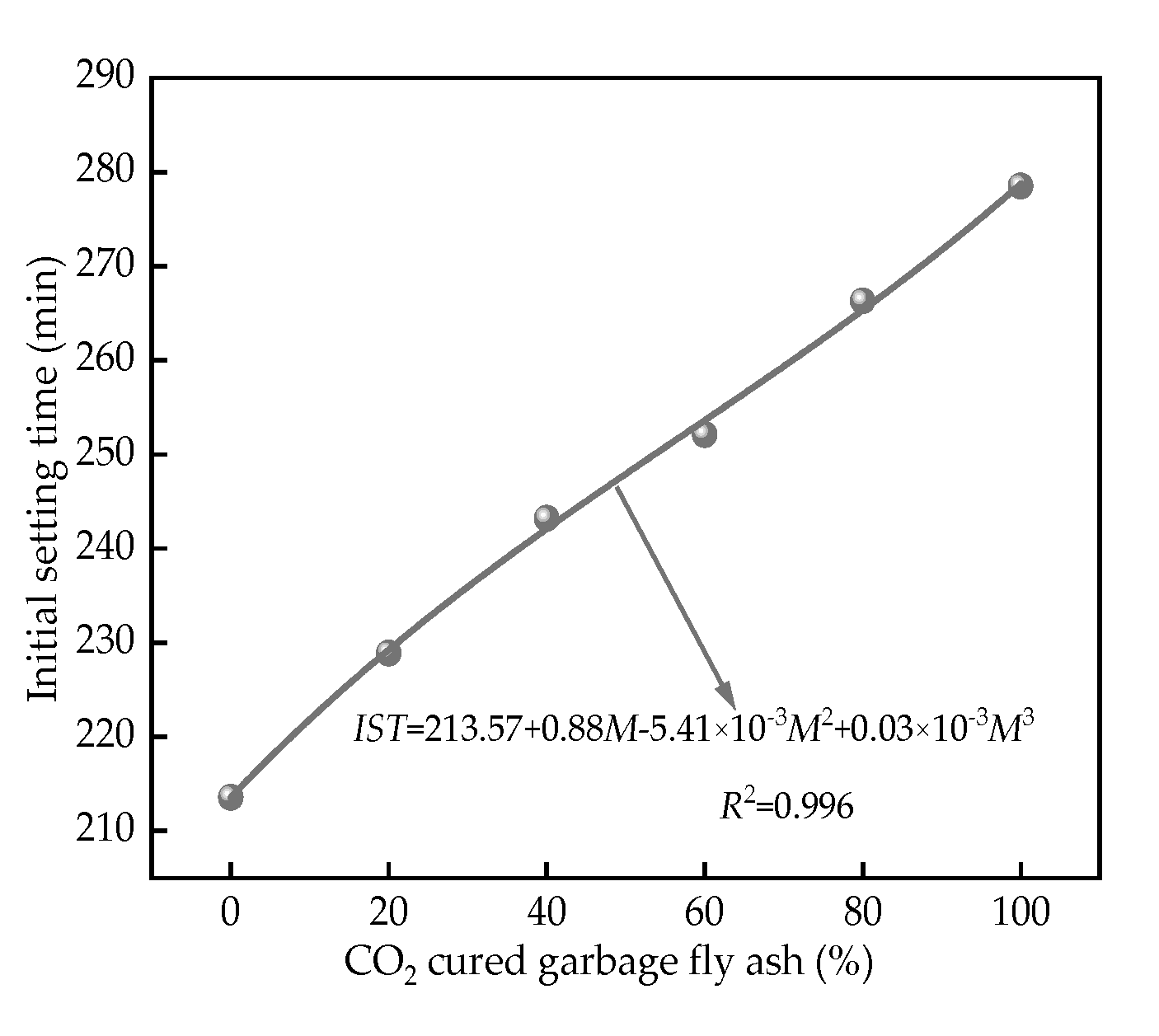

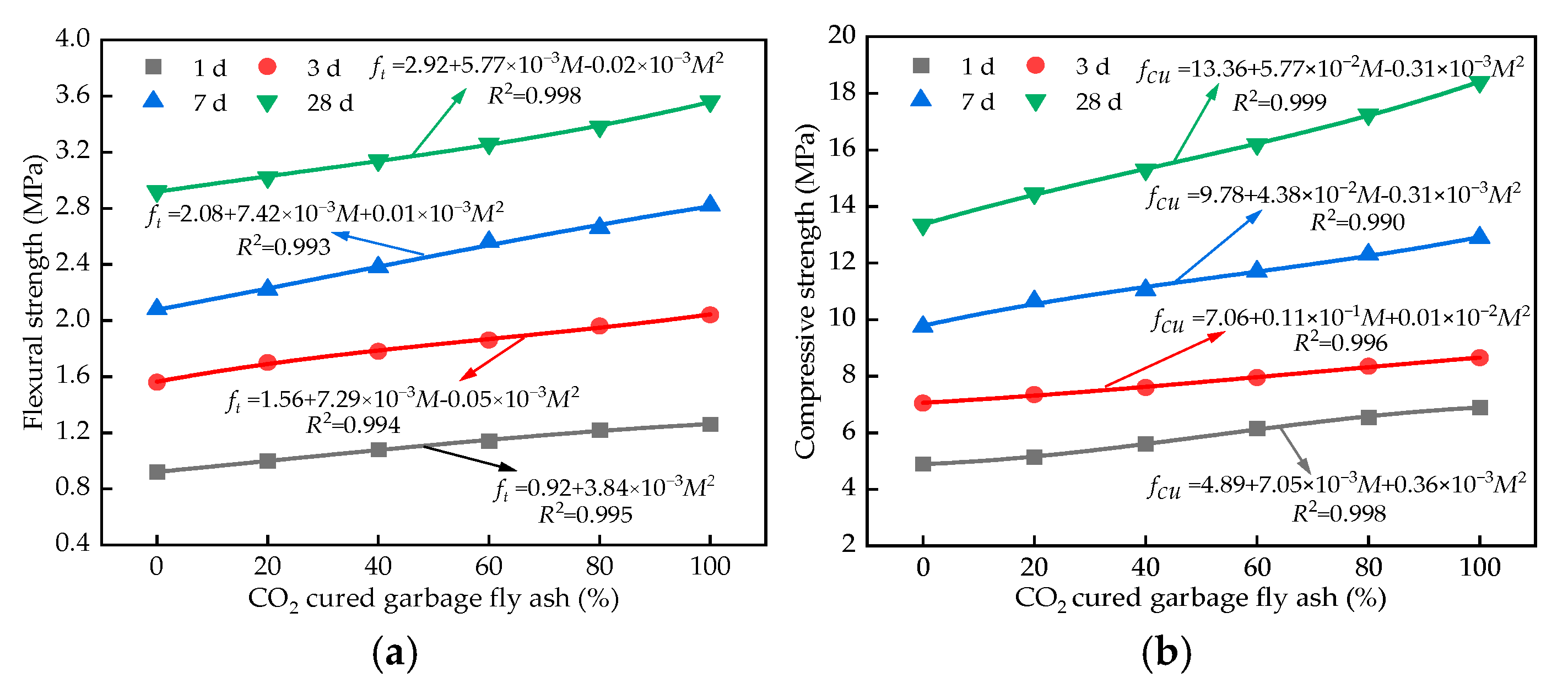

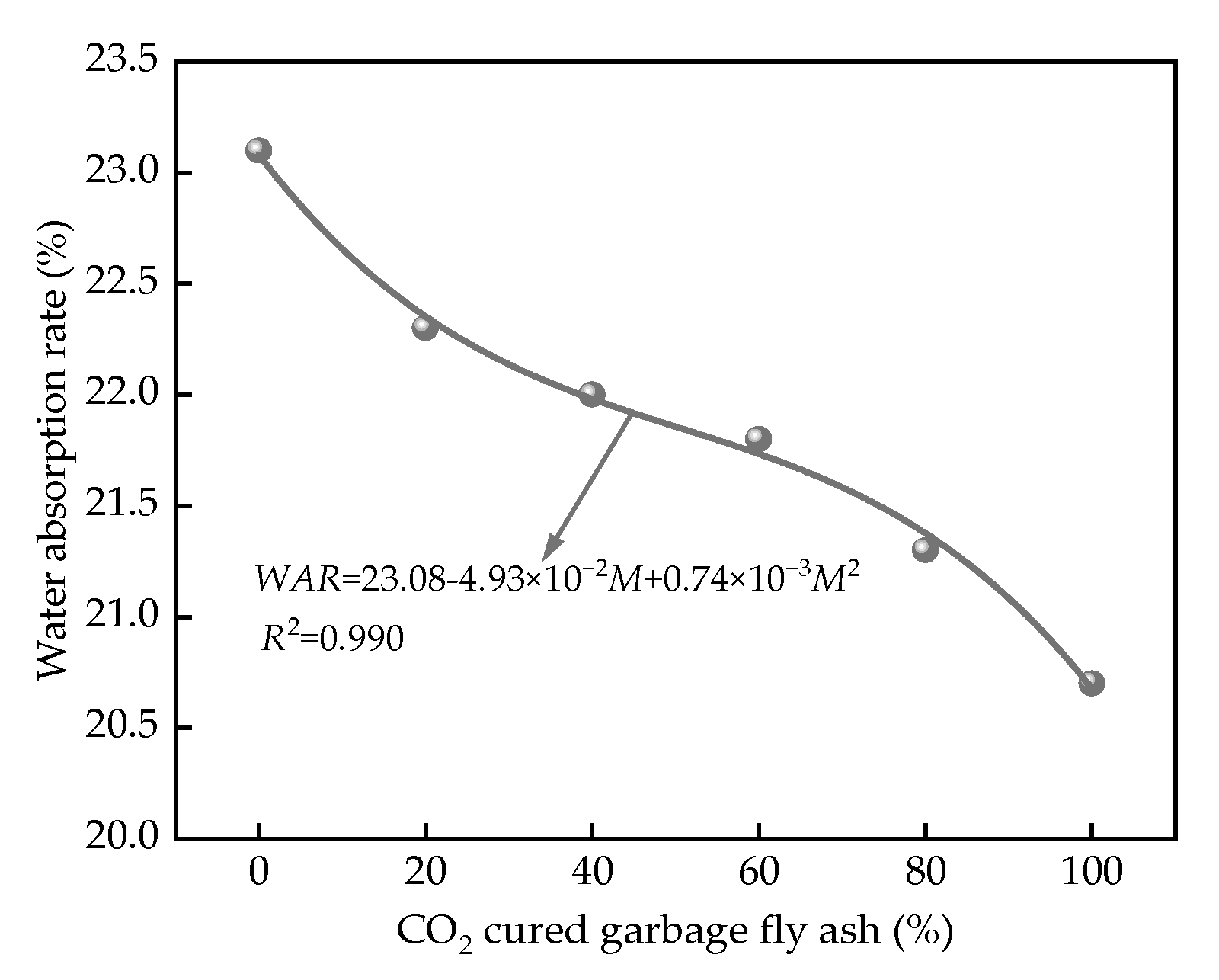

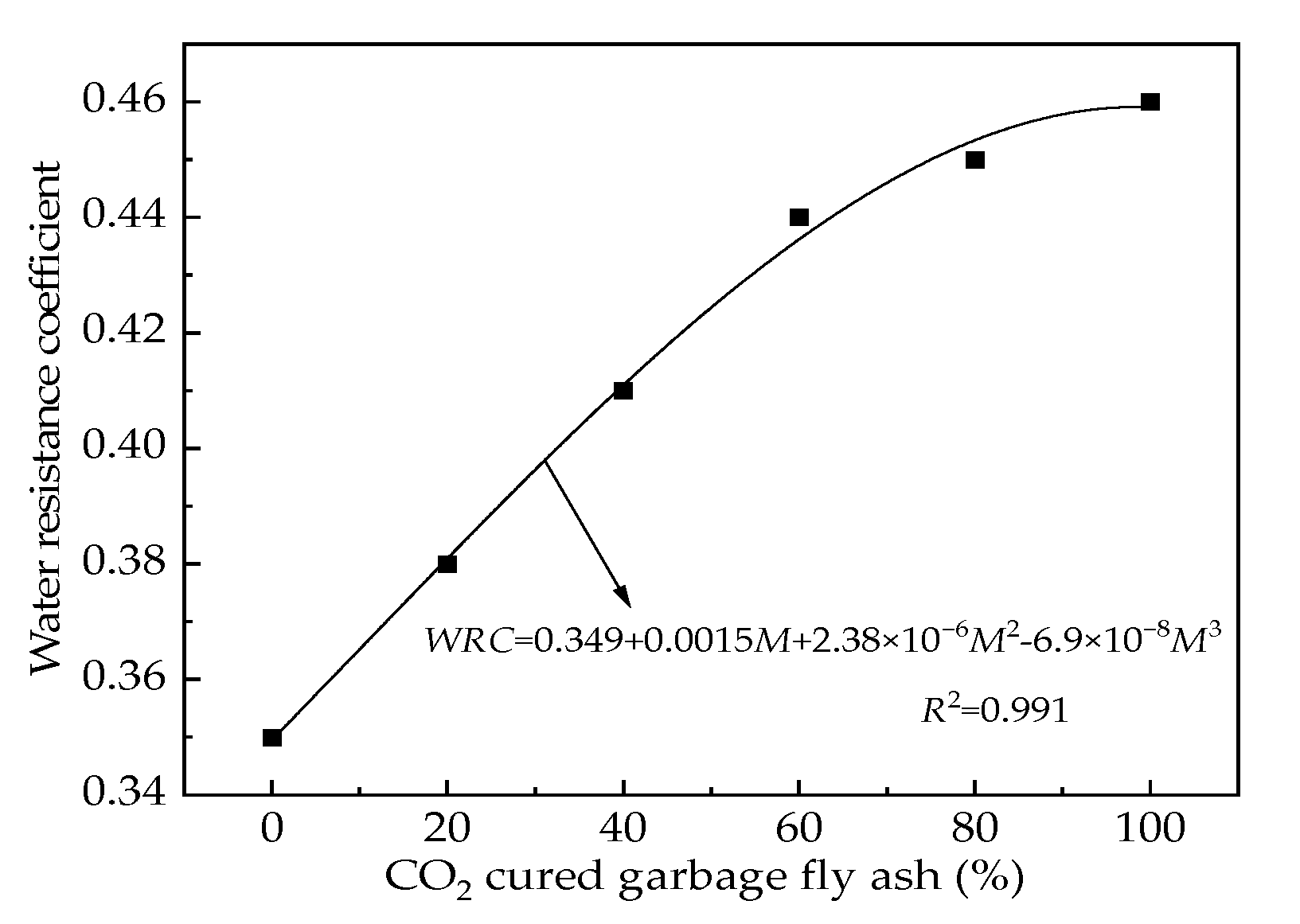

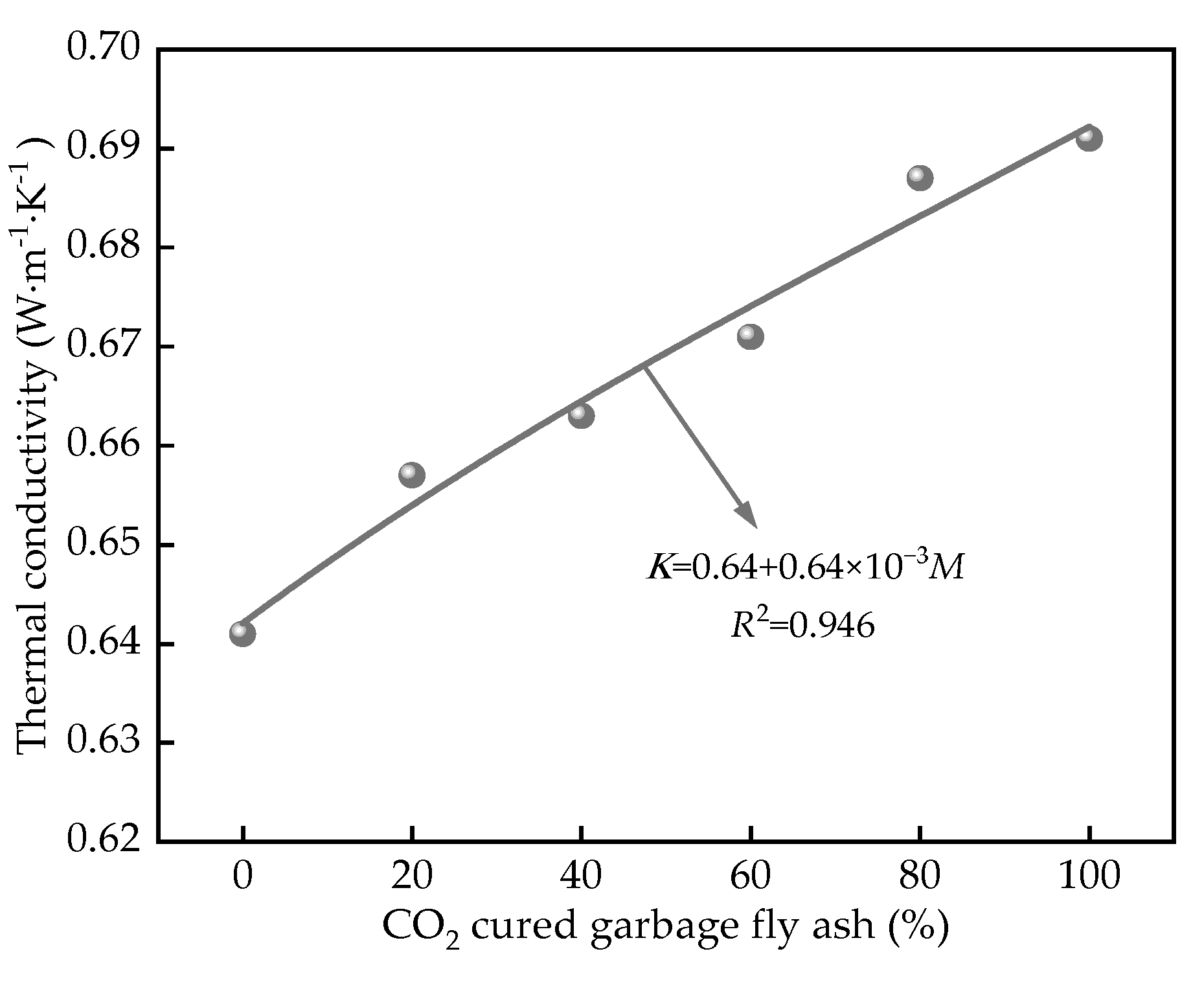

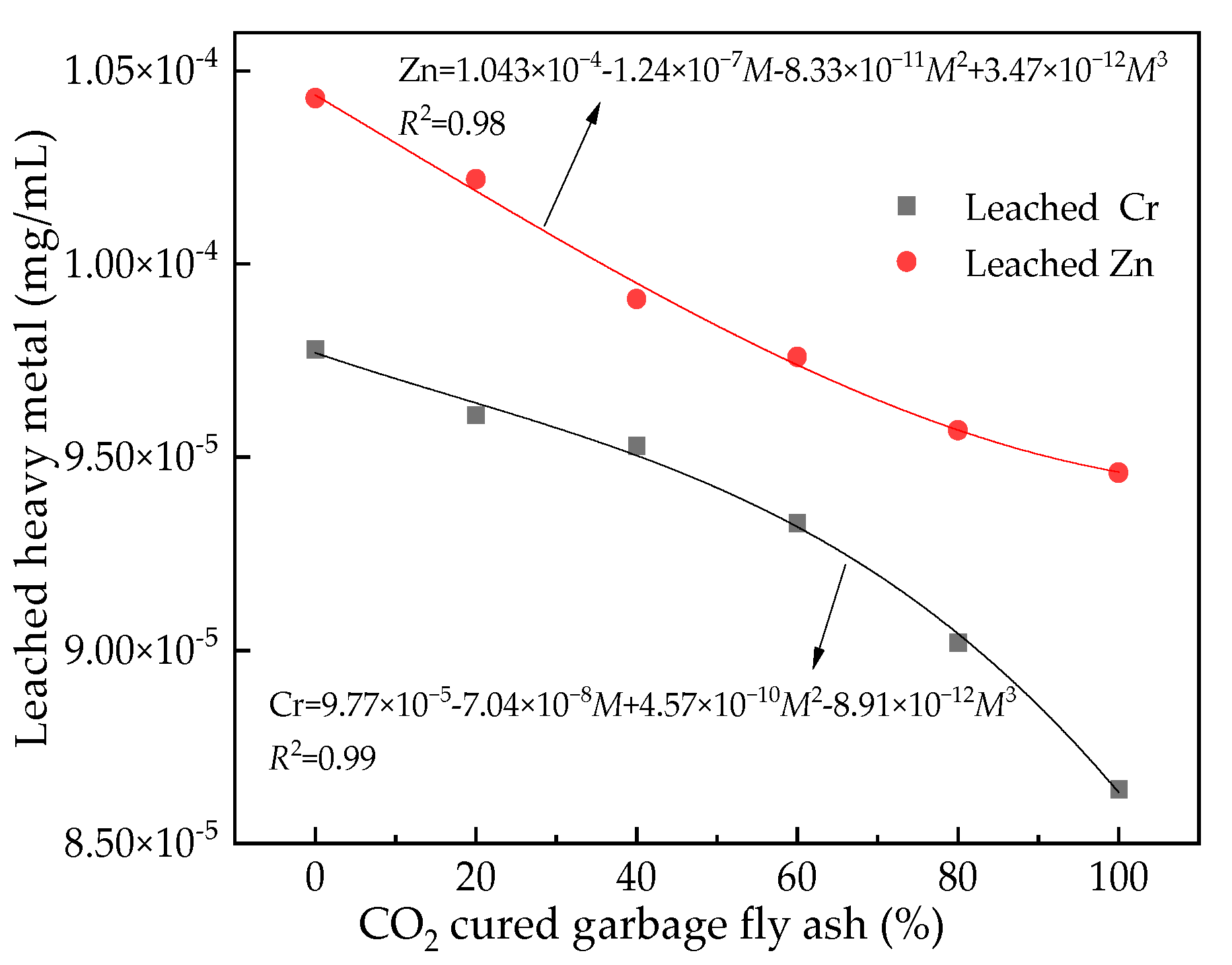

3.1. The Influence of CO2-Cured Garbage Fly Ash

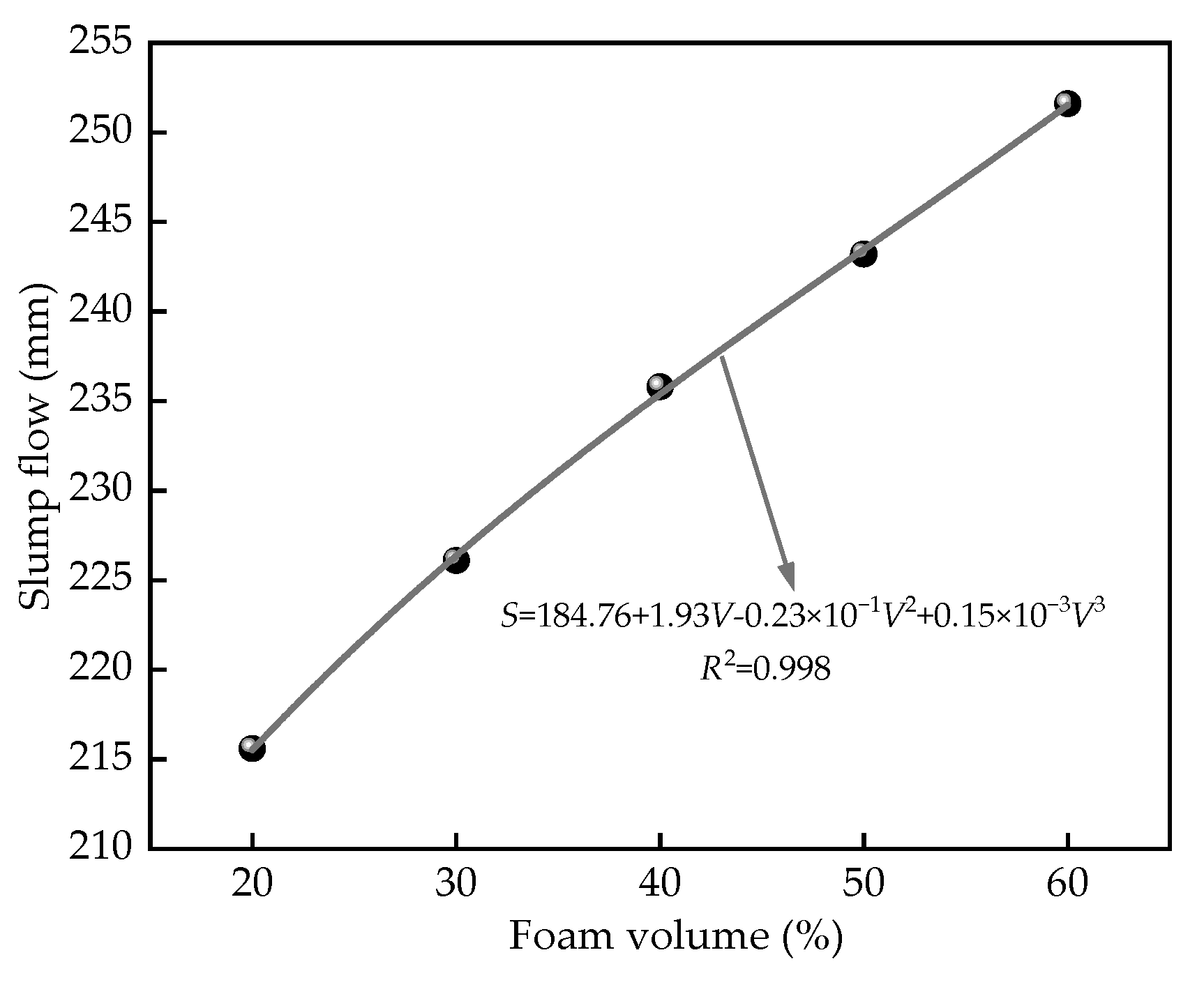

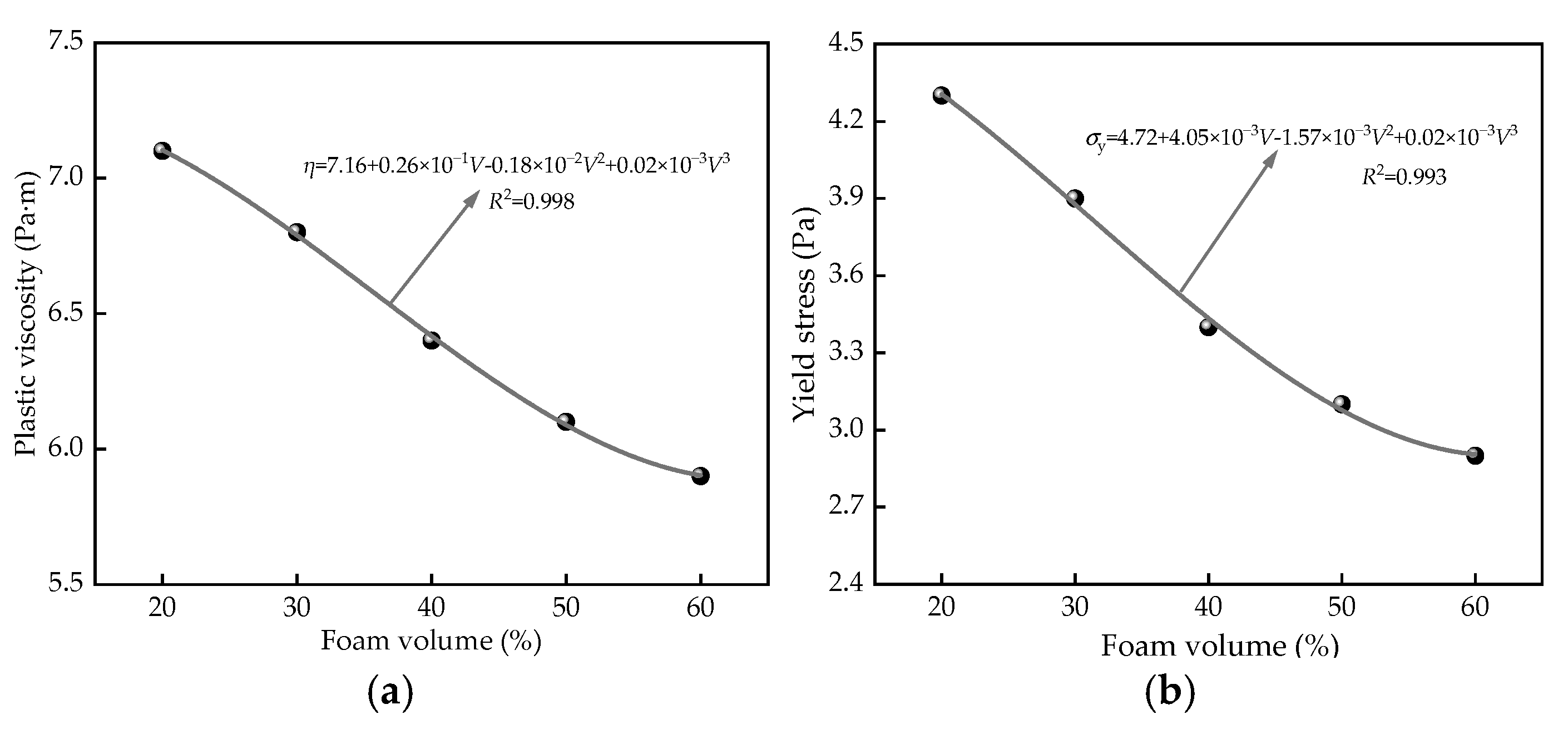

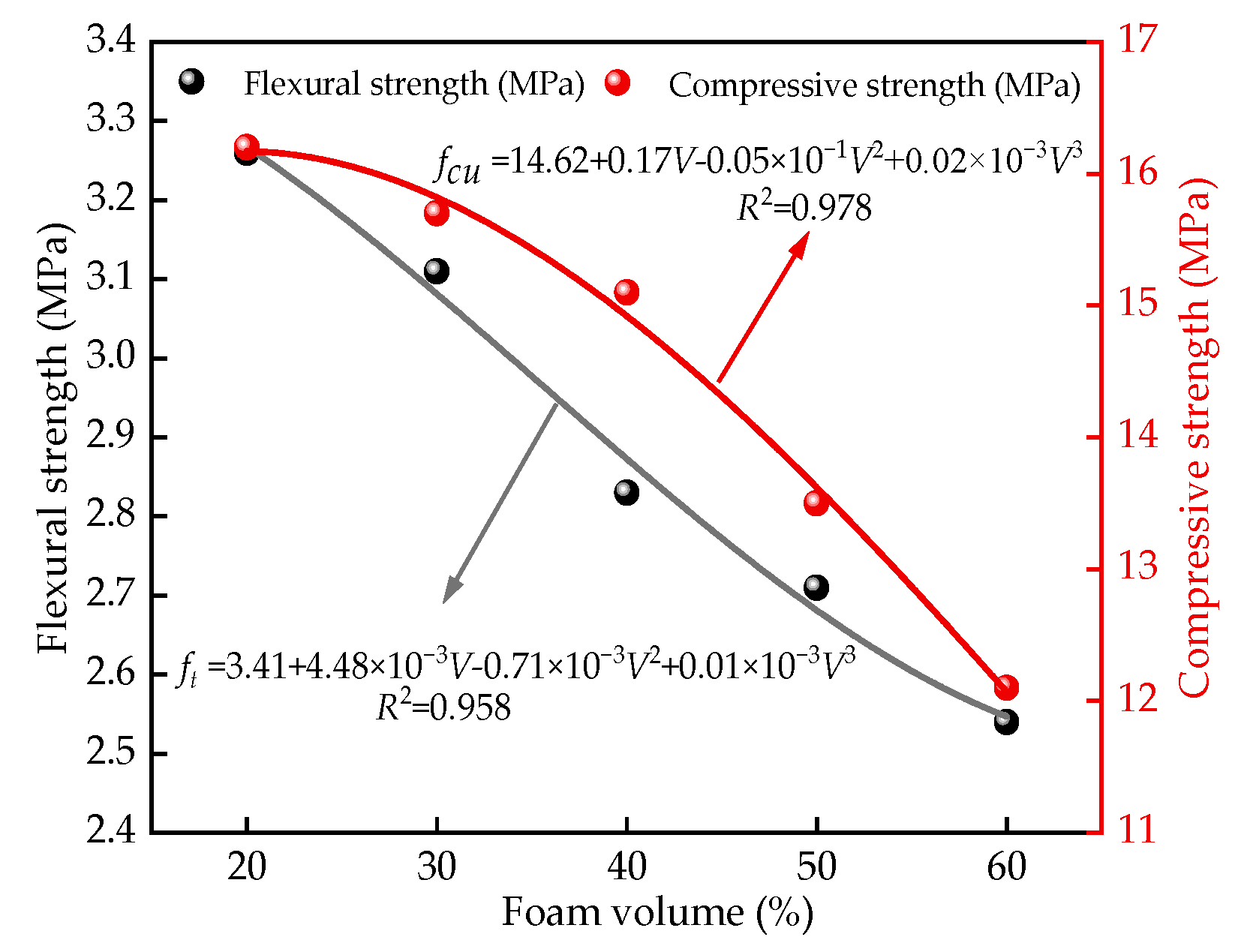

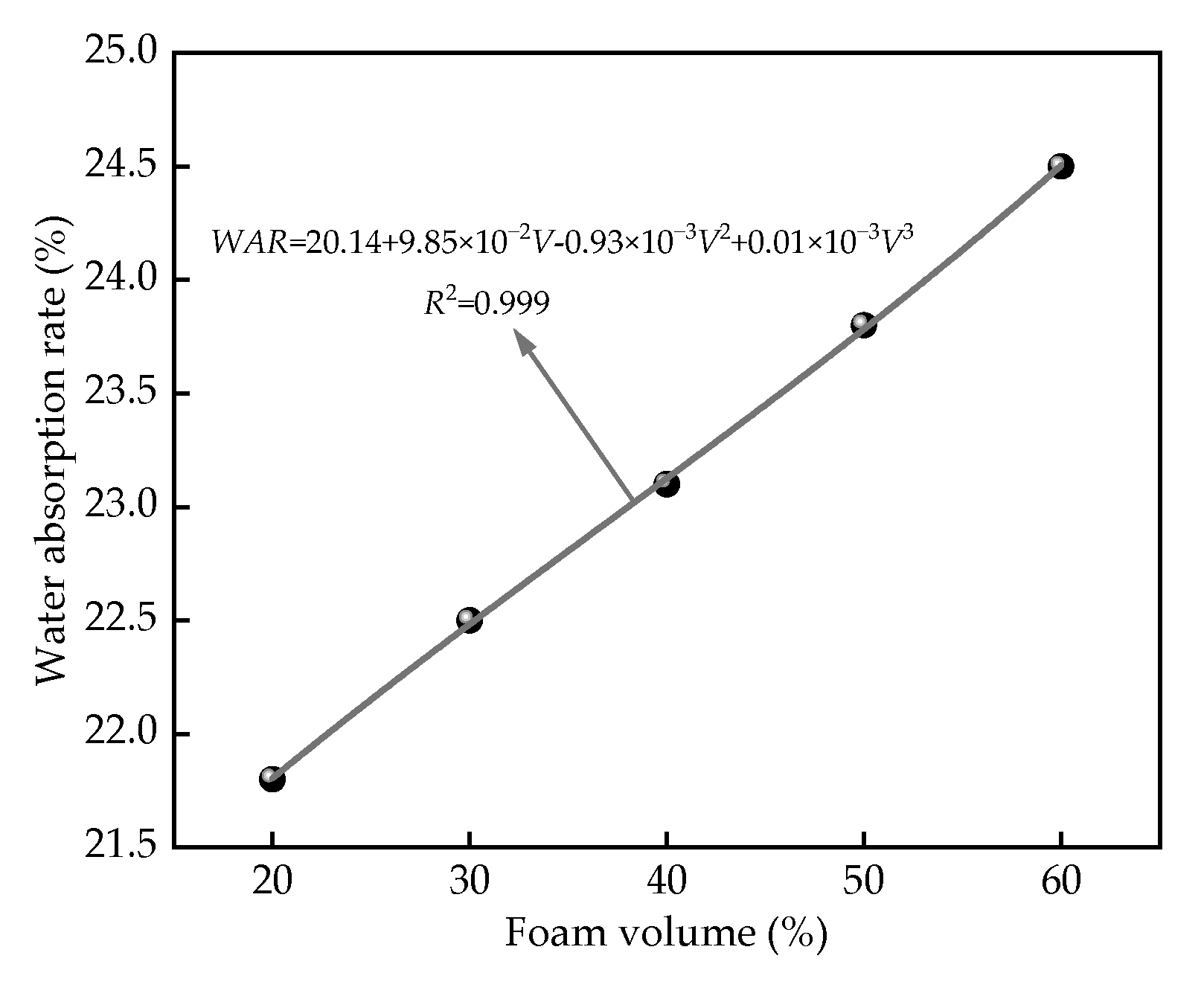

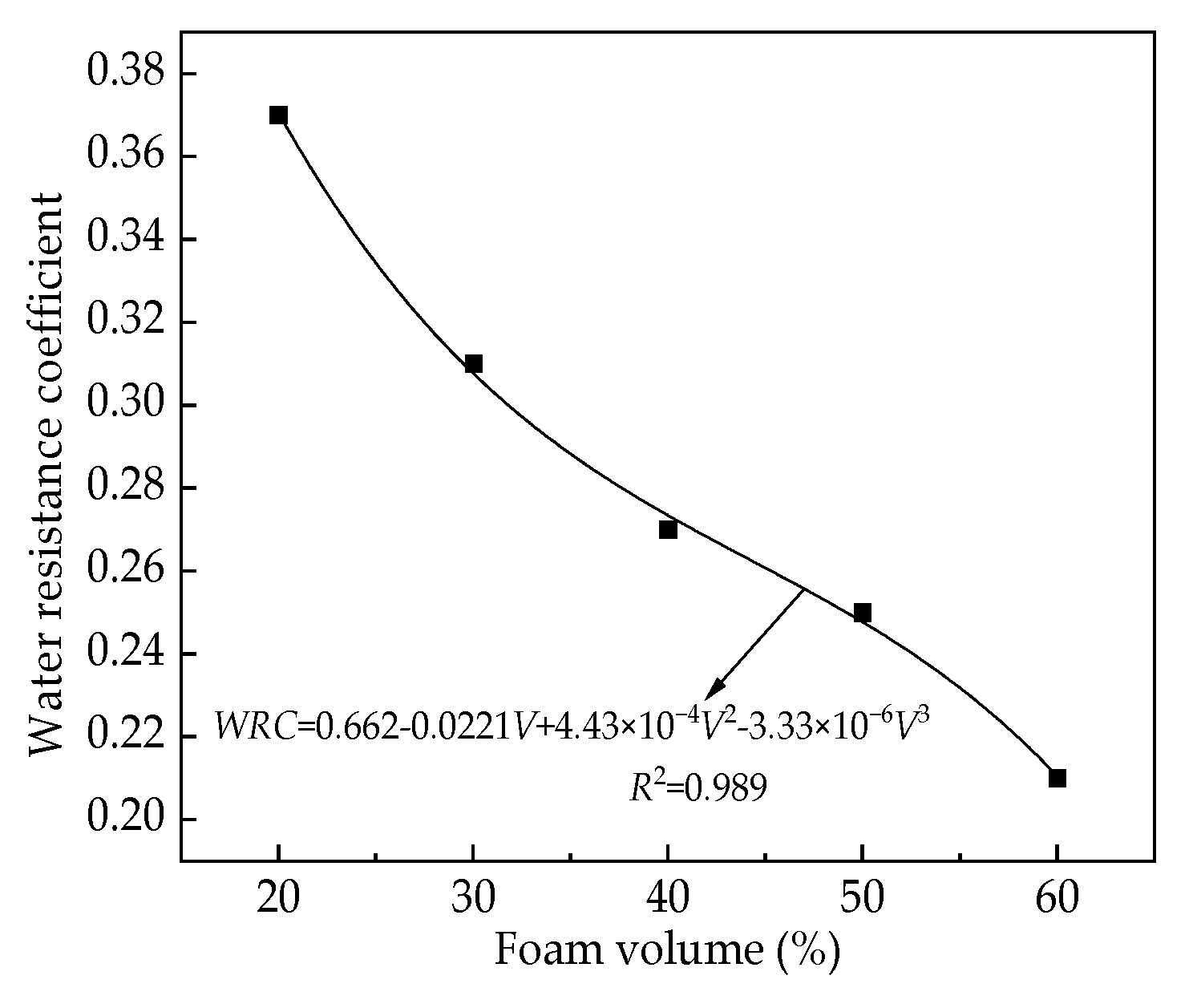

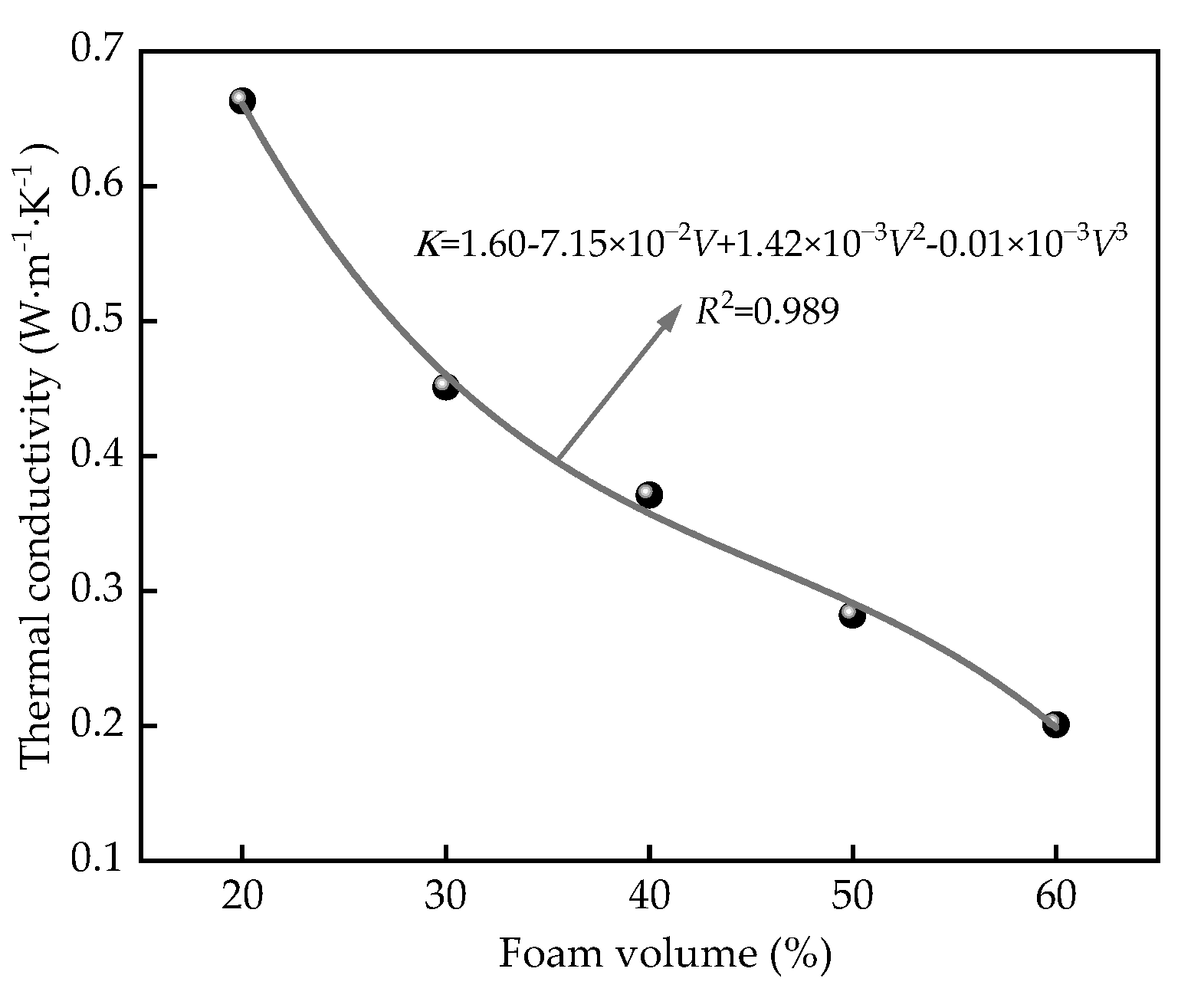

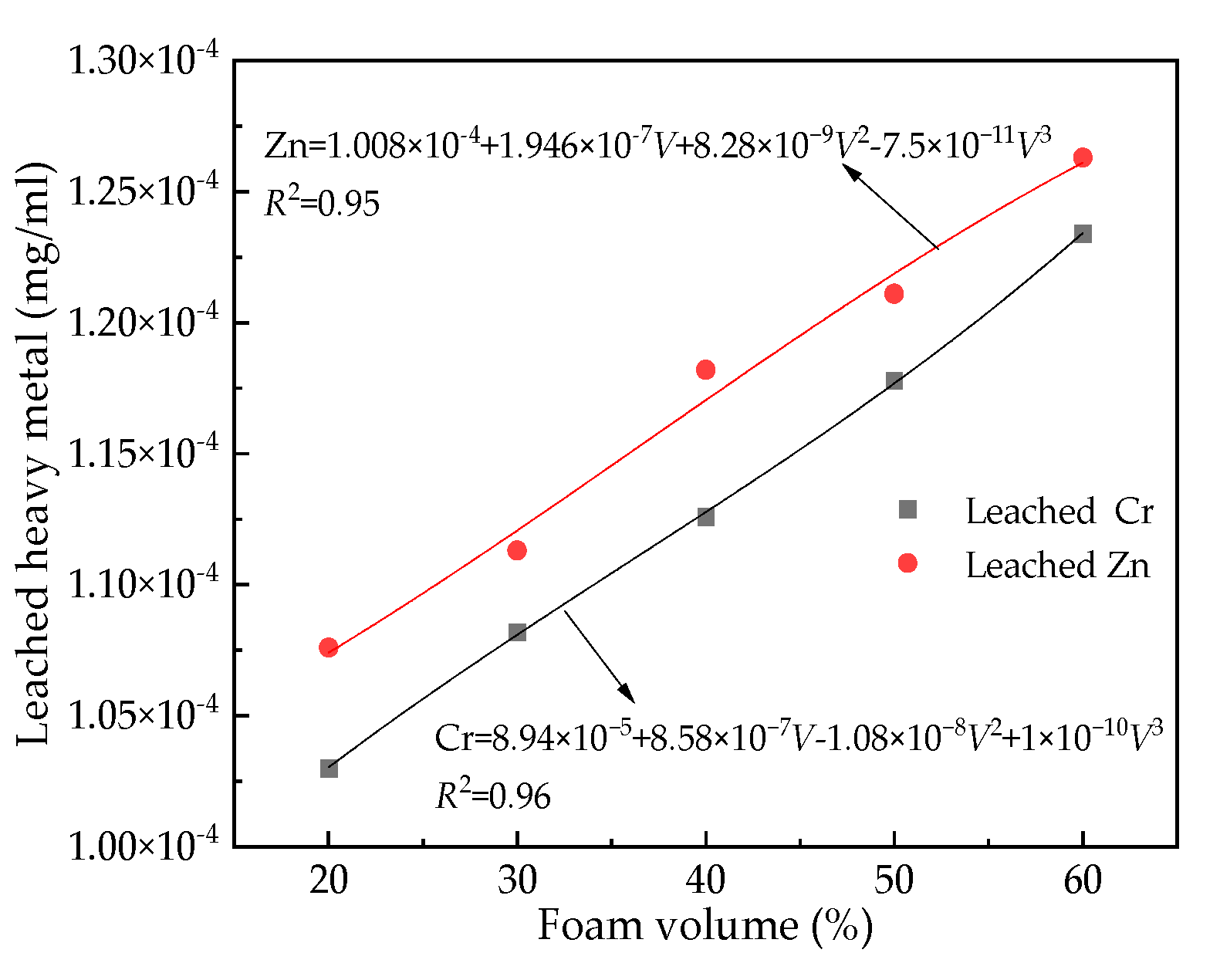

3.2. The Influence of Foam Volume

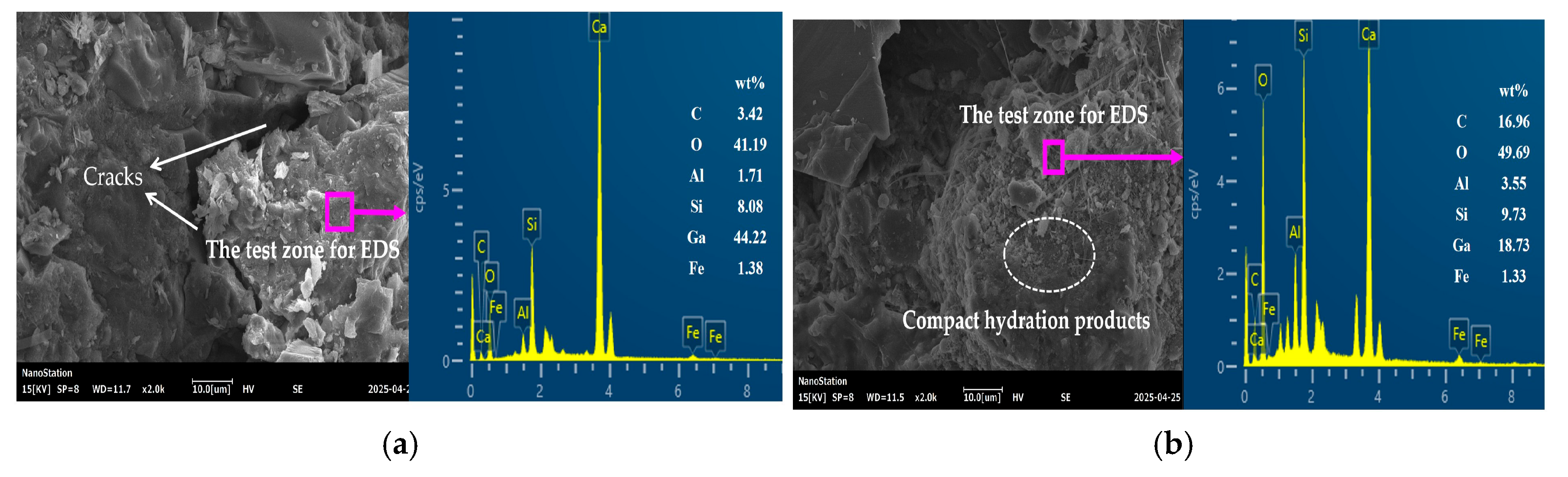

3.3. Microscopic Research Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Wu, Z.; Long, Q.; Feng, W.; Liu, S.; Yuan, X. Preparation of municipal waste incineration fly ash artificial aggregate using CO2 curing and its properties. J. CO2 Util. 2025, 93, 103042. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Silva, R.V.; Bravo, M.; Jiménez, J.R.; Fernández-Rodríguez, J.M.; Brito, J. Effect of incorporating municipal solid waste incinerated bottom ash in alkali-activated fly ash concrete subjected to accelerated CO2 curing. J. Clean. Prod. 2022, 370, 133533. [Google Scholar] [CrossRef]

- Alamri, M.; Ali, T.; Ahmed, H.; Qureshi, M.Z.; Elmagarhe, A.; Khan, M.A.; Ajwad, A.; Mahmood, M.S. Enhancing the engineering characteristics of sustainable recycled aggregate concrete using fly ash, metakaolin and silica fume. Heliyon 2024, 10, e29014. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Jeon, D.; Kim, S.; Lim, A.; Moon, J. Enhancement of fly ash reactivity through triethanolamine addition and CO2 curing. Cem. Concr. Compos. 2025, 157, 105874. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, Y.; Liu, Z.; Liu, C.; She, W.; Wu, Z. Experimental study on eco-friendly one-part alkali-activated slag-fly ash-lime composites under CO2 environment: Reaction mechanism and carbon capture capacity. Constr. Build. Mater. 2024, 421, 135779. [Google Scholar] [CrossRef]

- Song, B.; Shi, C.; Hu, X.; Ouyang, K.; Ding, Y.; Ke, G. Effect of early CO2 curing on the chloride transport and binding behaviors of fly ash-blended Portland cement. Constr. Build. Mater. 2021, 288, 123113. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Z.; Shen, Y.; Li, H.; Lin, X.; Li, X.; Yan, J. A novel insight into CO2-cured cement modified by ultrasonic carbonated waste incineration fly ash: Mechanical properties, carbon sequestration, and heavy metals immobilization. Carbon Capture Sci. Technol. 2025, 14, 100368. [Google Scholar] [CrossRef]

- Wi, K.; Sahin, O.; Wang, K.; Lee, Y. Characterization and evaluation of cement-based systems containing solution-treated municipal solid-waste incineration fly ash. Constr. Build. Mater. 2024, 416, 135230. [Google Scholar] [CrossRef]

- Gao, S.; Chu, H.; Shi, W.; Wang, F.; Jiang, J. Utilization of municipal solid waste incineration fly ash in ecological concrete and pavement bricks: Mechanical properties and environmental impact. Case Stud. Constr. Mater. 2024, 21, e03999. [Google Scholar] [CrossRef]

- Fan, D.; Lu, J.; Lv, X.; Noguchi, T.; Yu, R.; Sun, C. Carbon capture and storage CO2 foam concrete towards higher performance: Design, preparation and characteristics. Cem. Concr. Compos. 2025, 157, 105925. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, D.; Wang, S.; Chen, X.; Wu, X.; Han, Z.; Liu, Y. Quantitative analysis of pore structure’s impact on early mechanical properties and durability of foam concrete: Macroscopic and mesoscopic insights. Constr. Build. Mater. 2025, 459, 139775. [Google Scholar] [CrossRef]

- Huang, X.; Yu, H.; Wang, H.; Xie, X.; Qi, C.; Xue, F.; Zhao, X. Recycle sludge incineration ash for efficient preparation of foam concrete: Performance, microstructure, and mechanisms. Next Sustain. 2025, 6, 100125. [Google Scholar]

- Liao, S.; Lu, W.; Chen, Y.; Shen, Y. Production of autoclaved aerated concrete by using municipal solid waste incinerator fly ash as an alternative raw material. Case Stud. Constr. Mater. 2024, 21, e03914. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Özel, H.B.; Benli, A.; Yılmazoğlu, M.; Türkel, İ.; Dal, B.; Şevik, H.; Kaplan, G. Sustainable foam concrete development: Enhancing durability and performance through pine cone powder and fly ash incorporation in alkali-activated geopolymers. Constr. Build. Mater. 2024, 457, 139422. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, L.; Mei, K.; Li, X.; Wang, Y.; Cheng, X.; Fu, X. Thermal conductivity and pore structure analysis of alkali-activated foam cement with supercritical CO2 modified slag: Feasibility evaluation for geothermal applications. Constr. Build. Mater. 2022, 347, 128506. [Google Scholar] [CrossRef]

- Ruan, M.; Tian, Q.; Zhang, M.; Wang, C.; Xu, G.; Cai, J.; Fu, Q. Fabrication and characterization of foam ceramics from recycled waste concrete powder and waste glass powder. Constr. Build. Mater. 2024, 451, 138807. [Google Scholar] [CrossRef]

- Messina, F.; Ferone, C.; Colangelo, F.; Roviello, G.; Cioffi, R. Alkali activated waste fly ash as sustainable composite: Influence of curing and pozzolanic admixtures on the early-age physico-mechanical properties and residual strength after exposure at elevated temperature. Compos. Part B Eng. 2018, 132, 161–169. [Google Scholar] [CrossRef]

- Dong, K.; Chen, S.; Liu, J.; Shi, X.; Zhang, J.; Meng, J. Effect of nano- and micron-materials on the thermal properties behavior in wet environments and heat transfer mechanism of foam concrete. J. Build. Eng. 2025, 107, 112725. [Google Scholar] [CrossRef]

- Kim, J.; Kim, T.; Park, J.; Kang, J. Durability evaluation of structural performance based on CO2 curing conditions. J. Build. Eng. 2025, 105, 112465. [Google Scholar] [CrossRef]

- Du, Z.; Liu, P.; Wang, P.; Jiang, S.; Shi, Y.; Sun, M.; Gao, M.; Fu, H. CSH/PCE nanoparticle as a novel foam stabilizer: Highly efficient interfacial adsorption and enhanced performance in foam concrete. Constr. Build. Mater. 2025, 469, 140509. [Google Scholar] [CrossRef]

- Song, Q.; Zou, Y.; Zhang, P.; Xu, S.; Yang, Y.; Bao, J.; Xue, S.; Liu, J.; Gao, S.; Lin, L. Novel high-efficiency solid particle foam stabilizer: Effects of modified fly ash on foam properties and foam concrete. Cem. Concr. Compos. 2025, 155, 105818. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, S.; Yang, L.; Wang, Y.; Guan, X.; Zhang, H.; Luo, S. Synergistic effects of fly ash-cement slurry and CO2 mineralization on coal gangue aggregate and its concrete properties. Constr. Build. Mater. 2025, 465, 140225. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Guler, S. Structural self-compacting lightweight concrete: Effects of fly ash and basalt fibers on workability, thermal and mechanical properties under ambient conditions and high temperatures. Constr. Build. Mater. 2025, 481, 141658. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, B.; Hou, G. Preparation of a novel foam concrete for the carbonation of steel slag with low thermal conductivity and enhanced CO2 capture. Mater. Lett. 2025, 394, 138658. [Google Scholar] [CrossRef]

- Wu, C.; Jierula, A.; Fu, Z.; Chen, Y.; Kuang, Y.; Xia, J. Study on the mechanism of anti sulfate freeze-thaw, dry wet cycle of polypropylene fiber foam concrete. Constr. Build. Mater. 2025, 463, 140144. [Google Scholar] [CrossRef]

- Obaidat, Y.T.; Hijazi, Y.F. Performance of bond between carbon fiber-reinforced polymer sheets and thermally shocked damaged foam concrete. Int. J. Adhes. Adhes. 2025, 140, 104042. [Google Scholar] [CrossRef]

- Wen, C.; Li, J.; Meng, Q.; Yang, S.; Chen, Z.; Wang, X.; Li, Y.; Wang, X.; Sun, X.; Mu, L.; et al. Study of macro-/micro-properties and in-situ mineralization mechanism of CO2 foam concrete based on solid waste-derived SAC-gypsum composite. Constr. Build. Mater. 2025, 486, 141911. [Google Scholar] [CrossRef]

- Miah, M.J.; Pei, J.; Kim, H.; Jang, J.G. Flexural behavior, porosity, and water absorption of CO2-cured amorphous metallic-fiber-reinforced belite-rich cement composites. Constr. Build. Mater. 2023, 387, 131668. [Google Scholar] [CrossRef]

- Azevedo, A.G.S.; Baltazar, L.; Faria, P.; Savastano, H. Durability assessment of MgO-based fiber cement reinforced with lignocellulosic fibers and cured in a CO2-rich atmosphere. J. Build. Eng. 2025, 104, 112327. [Google Scholar] [CrossRef]

- Ser, M.; Hussin, A.E.; Said, A.; Kohail, M. Enhancing the sustainable production of Foamed Concrete by using different waste materials as a full sand replacement. Constr. Build. Mater. 2025, 462, 139890. [Google Scholar] [CrossRef]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Sun, X.; Zhong, J.; Zhang, W.; Li, G.; Cao, H.; Gao, P. Deformation and mechanical properties of foamed concrete under various components and pore structure. J. Build. Eng. 2024, 94, 109920. [Google Scholar] [CrossRef]

- He, S.; Lei, X.; Zhang, H.; Yu, P.; Zhou, Y.; Huang, X. Durability and heavy metals long-term stability of alkali-activated sintered municipal solid waste incineration fly ash concrete in acidic environments. Constr. Build. Mater. 2025, 462, 139990. [Google Scholar] [CrossRef]

- He, P.; Drissi, S.; Hu, X.; Liu, J.; Shi, C. Properties of CO2-cured cement incorporating fly ash and slag subjected to further water curing. Cem. Concr. Compos. 2024, 152, 105633. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, K.; Yuan, Z.; Liu, S. Investigations into magnesium oxide carbon sequestration foamed concrete: Mechanical performance, microstructure and environmental benefits. Constr. Build. Mater. 2024, 421, 135679. [Google Scholar] [CrossRef]

- Zhou, Z.; Xiao, J.; Ye, T.; Wang, J.; Choi, D. Influence of recycled concrete powder and CO2 curing on the properties of thermal insulation mortars. Constr. Build. Mater. 2024, 414, 134907. [Google Scholar] [CrossRef]

- Yılmazoğlu, M.U.; Kara, H.O.; Benli, A.; Demirkıran, A.R.; Bayraktar, O.Y.; Kaplan, G. Sustainable alkali-activated foam concrete with pumice aggregate: Effects of clinoptilolite zeolite and fly ash on strength, durability, and thermal performance. Constr. Build. Mater. 2025, 464, 140160. [Google Scholar] [CrossRef]

- An, S.; Wang, B.; Chen, W. The cementitious properties of alkali-activated municipal solid waste incineration fly ash-phosphorus slag-secondary aluminum dross matrix composites and the mechanism of solidification of heavy metals. Constr. Build. Mater. 2024, 438, 137254. [Google Scholar]

- Kamisetty, A.; Gandhi, I.S.R.; Kumar, A. Combined effect of fly ash and fiber on spreadability, strength and water permeability of foam concrete. J. Build. Eng. 2023, 78, 107607. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.; Li, Y.; Liu, Y. An orthogonal experimental study on the influence of steam-curing on mechanical properties of foam concrete with fly ash. Case Stud. Constr. Mater. 2024, 20, e02665. [Google Scholar] [CrossRef]

- Cao, X.; Jiang, T.; Shimada, H.; Sasaoka, T.; Hamanaka, A. Influence of CO2 nano-bubble water concentration and curing time on the macroscopic and microscopic mechanical properties of cemented backfill materials. J. Build. Eng. 2024, 98, 111099. [Google Scholar] [CrossRef]

- Liu, Y.; Li, C.; Zhai, H.; Ahmad, M.R.; Guo, D.; Dai, J. Production and performance of CO2 modified foam concrete. Constr. Build. Mater. 2023, 389, 131671. [Google Scholar] [CrossRef]

- Gołaszewska, M.; Gołaszewski, J.; Klemczak, B.; Koenders, E.A.B. Effect of foaming agent and admixtures on hydration in ultralight foam concrete with cement-metakaolin binders. J. Build. Eng. 2025, 104, 112365. [Google Scholar] [CrossRef]

- Kam, E.; Yaraş, A.; Ustaoğlu, A.; Hekimoğlu, G.; Sarı, A.; Erdoğmuş, E.; Gencel, O. Properties of foam concrete containing phase change material impregnated pumice. Constr. Build. Mater. 2024, 446, 137915. [Google Scholar] [CrossRef]

- Chen, B.; Liu, B.; Yang, L.; Zaland, S.; Ye, H. Solidification of heavy metal in municipal solid waste incineration fly ash and performance evolution of alkali-activated foam concrete. Process Saf. Environ. Prot. 2024, 190 Pt A, 850–862. [Google Scholar] [CrossRef]

- Bersisa, A.; Moon, K.; Kim, G.M.; Cho, J.; Park, S. Microstructural characterization of CO2-cured calcium silicate cement. Dev. Built Environ. 2024, 19, 100518. [Google Scholar] [CrossRef]

- Wang, H.; Wen, B.; Xu, P.; Gao, G.; Zhang, L.; Niu, D. Effect of CO2 curing on the strength and microstructure of composite waste glass concrete. Constr. Build. Mater. 2025, 463, 140042. [Google Scholar] [CrossRef]

- Du, Z.; Liu, P.; Wang, P.; Gao, M.; Shi, Y.; Sun, M.; Jiang, S.; Cui, L.; Lv, S. Enhancing foam stability and performance in foam concrete using para-aramid nanofiber. J. Build. Eng. 2025, 103, 112139. [Google Scholar] [CrossRef]

| Types | SiO2 | Al2O3 | MgO | CaO | SO3 | K2O | Na2O | Ti2O | CdO | CuO | ZnO | B2O3 | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GFA | 22.5 | 4.5 | 0.05 | 20.3 | 9.3 | 6.3 | 4.3 | 10.2 | 0.07 | 0.09 | 0.5 | 21.2 | 21.2 |

| Cement | 20.9 | 5.5 | 1.7 | 62.2 | 2.7 | - | - | - | - | - | - | 3.1 | 3.1 |

| River sand | 74.7 | 1.8 | - | 2.1 | - | 0.9 | 3.8 | - | - | - | - | 16.7 | - |

| Particle Size Types/μm | 0.3 | 0.6 | 1 | 4 | 8 | 64 | 100 | 360 |

| GFA | 0.13 | 0.5 | 2.2 | 17.2 | 31.3 | 97.5 | 100 | 100 |

| Cement | 0 | 0.33 | 2.66 | 15.01 | 28.77 | 93.59 | 100 | 100 |

| River sand | 0 | 0 | 0 | 0 | 0 | 0 | 22.5 | 100 |

| Water | P·O Cement | GFA | CO2-Cured GFA | Quartz Sand | Water-Reducing Agent |

|---|---|---|---|---|---|

| 444.4 | 740.7 | 0 | 370.3 | 977.9 | 16.3 |

| 444.4 | 740.7 | 74.1 | 296.2 | 977.9 | 16.3 |

| 444.4 | 740.7 | 148.1 | 222.2 | 977.9 | 16.3 |

| 444.4 | 740.7 | 222.2 | 148.1 | 977.9 | 16.3 |

| 444.4 | 740.7 | 296.2 | 74.1 | 977.9 | 16.3 |

| 444.4 | 740.7 | 370.3 | 0 | 977.9 | 16.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Xu, Z.; Yu, Y.; Xu, N.; Li, C.; Tian, X.; Wang, H.; Shi, F.; Xia, K. Influence of Carbonized Garbage Fly Ash on the Performance of Foam Concrete. Coatings 2025, 15, 736. https://doi.org/10.3390/coatings15070736

Wang D, Xu Z, Yu Y, Xu N, Li C, Tian X, Wang H, Shi F, Xia K. Influence of Carbonized Garbage Fly Ash on the Performance of Foam Concrete. Coatings. 2025; 15(7):736. https://doi.org/10.3390/coatings15070736

Chicago/Turabian StyleWang, Di, Zhiqiang Xu, Yehan Yu, Na Xu, Chuanqi Li, Xu Tian, Hui Wang, Feiting Shi, and Kangshuo Xia. 2025. "Influence of Carbonized Garbage Fly Ash on the Performance of Foam Concrete" Coatings 15, no. 7: 736. https://doi.org/10.3390/coatings15070736

APA StyleWang, D., Xu, Z., Yu, Y., Xu, N., Li, C., Tian, X., Wang, H., Shi, F., & Xia, K. (2025). Influence of Carbonized Garbage Fly Ash on the Performance of Foam Concrete. Coatings, 15(7), 736. https://doi.org/10.3390/coatings15070736