Research Advancements of Wear-Resistant Coatings Fabricated on Aluminum and Its Alloys

Abstract

1. Introduction

2. One-Step Methods

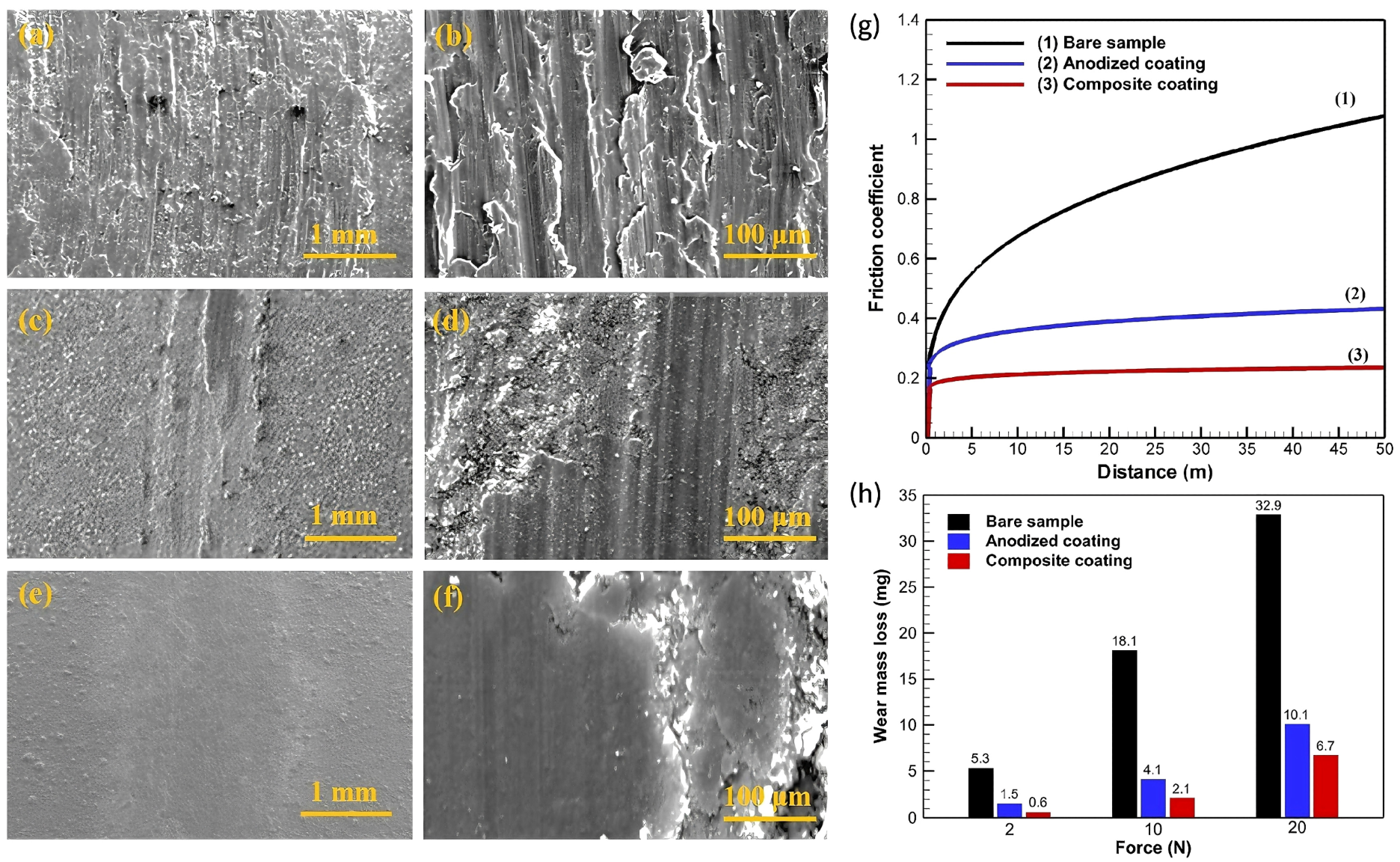

2.1. Anodic Oxidation (AO)

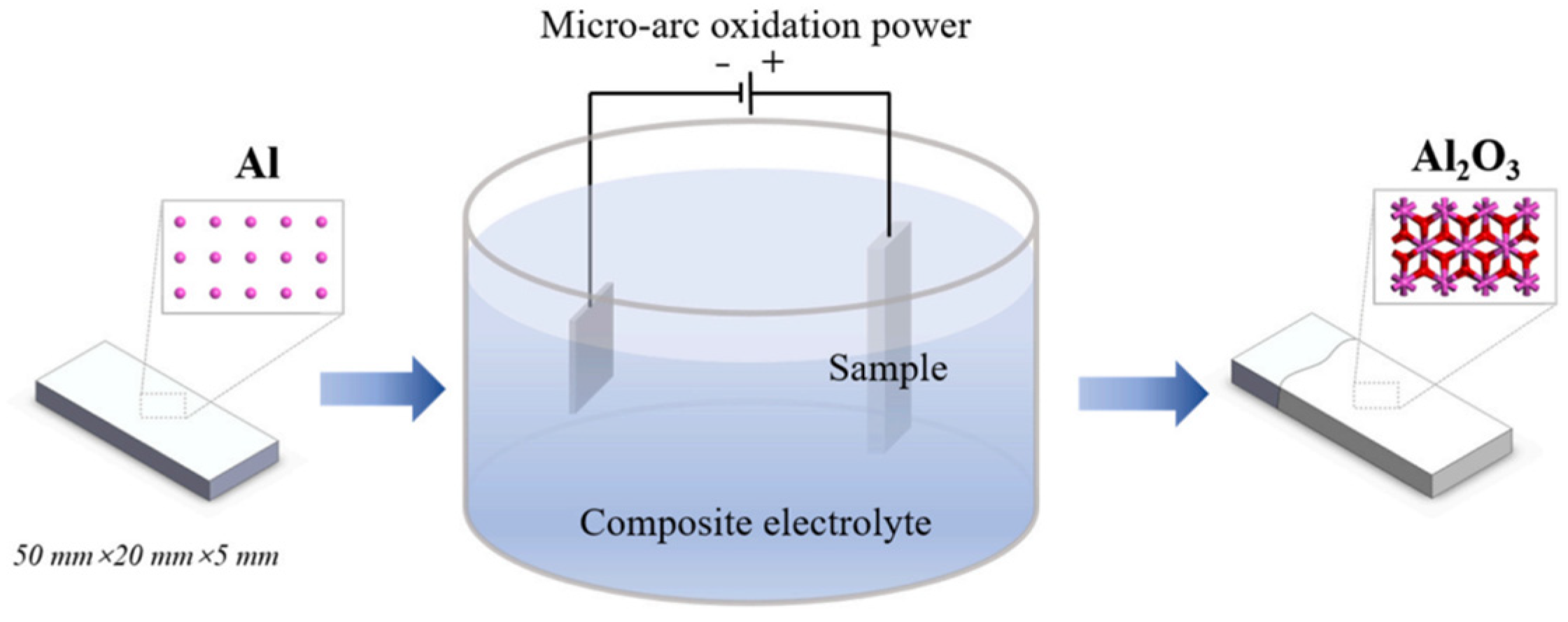

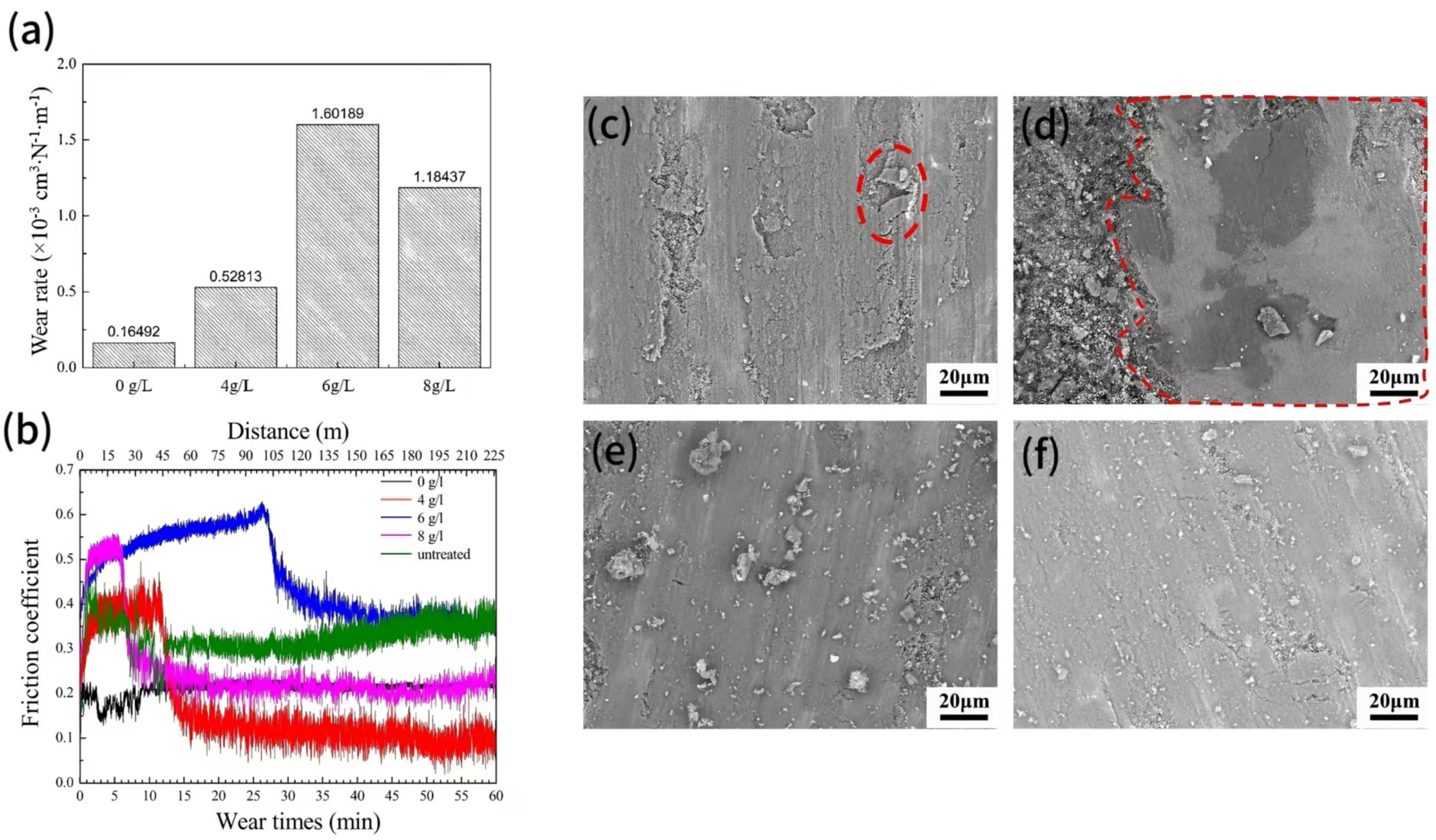

2.2. Micro-Arc Oxidation (MAO)

2.3. Laser Methods

2.3.1. Laser Surface Alloying (LSA)

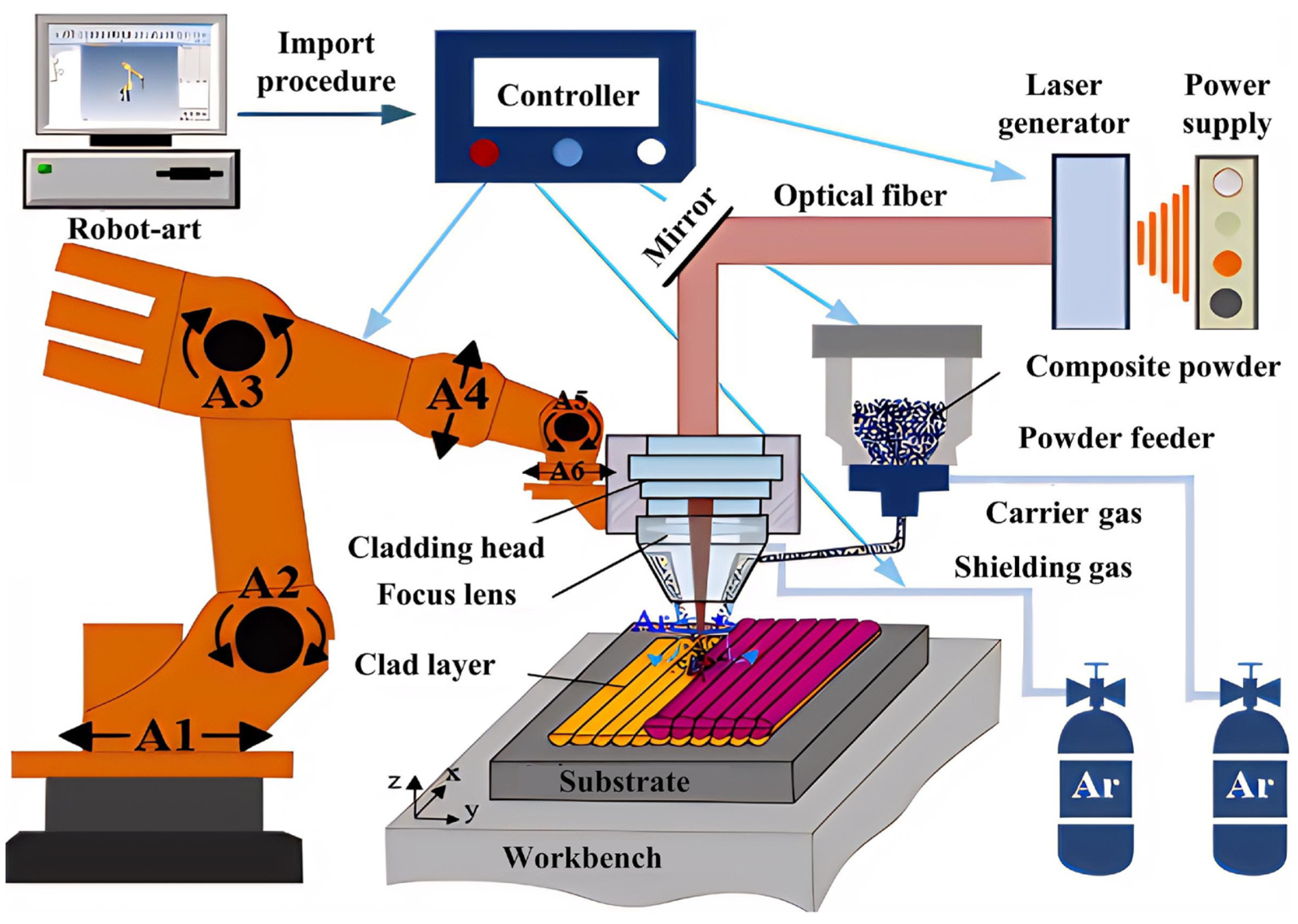

2.3.2. Laser Cladding (LC)

2.4. Spraying Methods

2.4.1. Cold Spraying (CS)

2.4.2. Plasma Spraying (PS)/Supersonic Plasma Spraying (SPS)

2.4.3. Other Spraying Methods

2.5. Deposition Methods

2.5.1. Electroless Plating (EP)

2.5.2. Electrochemical Deposition (ED)

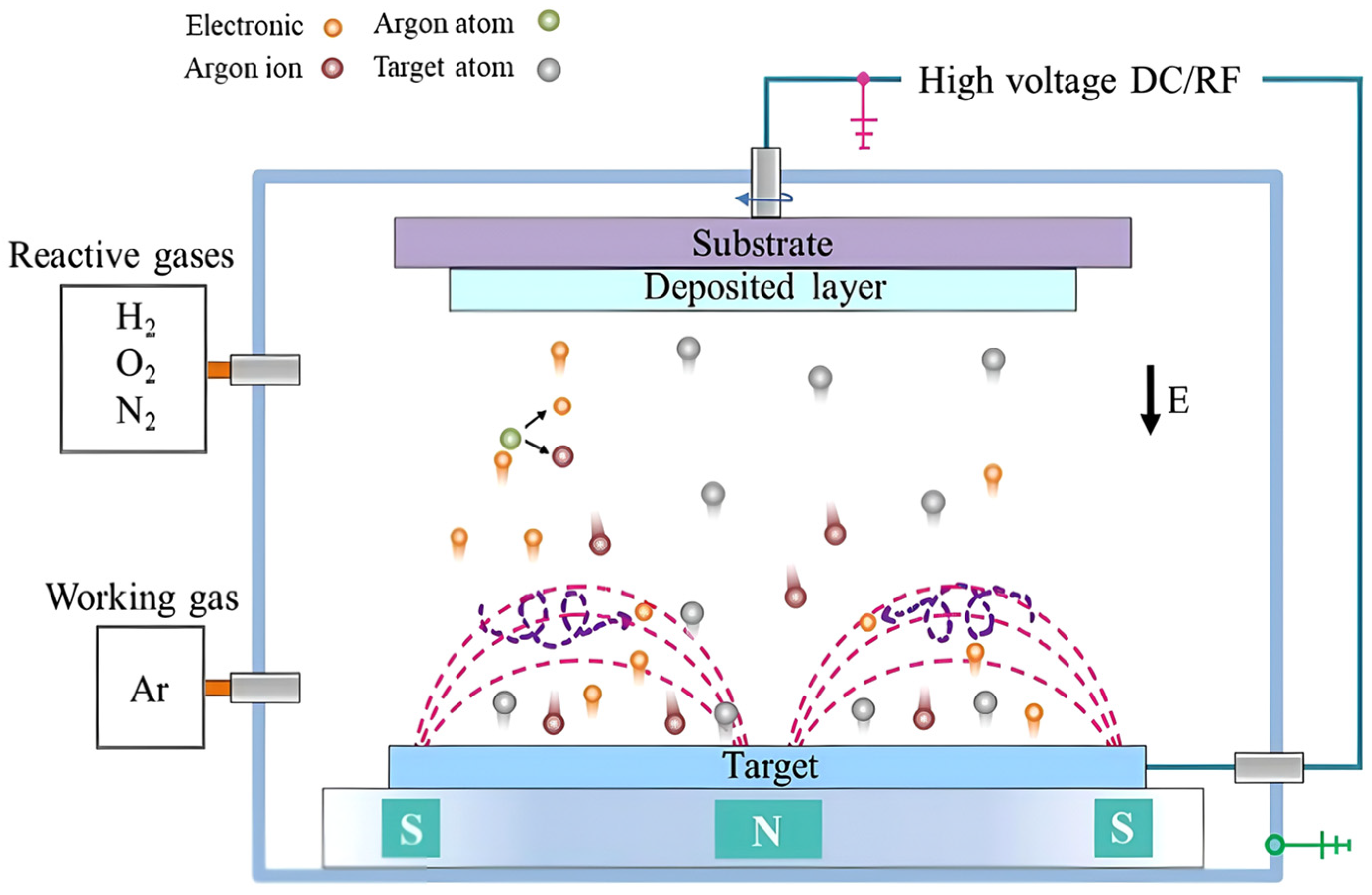

2.5.3. Physical Vapor Deposition (PVD)

2.5.4. Chemical Vapor Deposition (CVD)

2.6. Summary of the One-Step Methods

3. Two-Step Methods

3.1. AO + Post-Treatment

3.1.1. AO + MAO

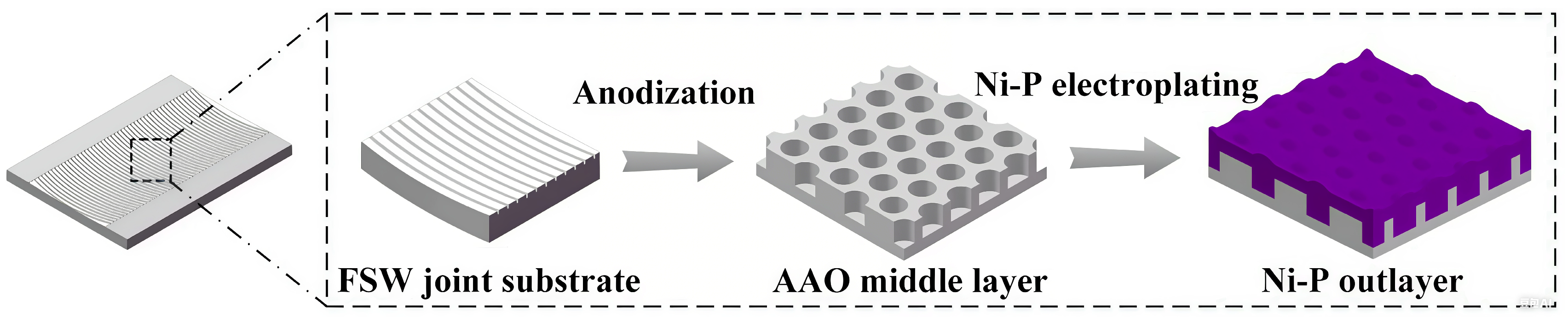

3.1.2. AO + ED

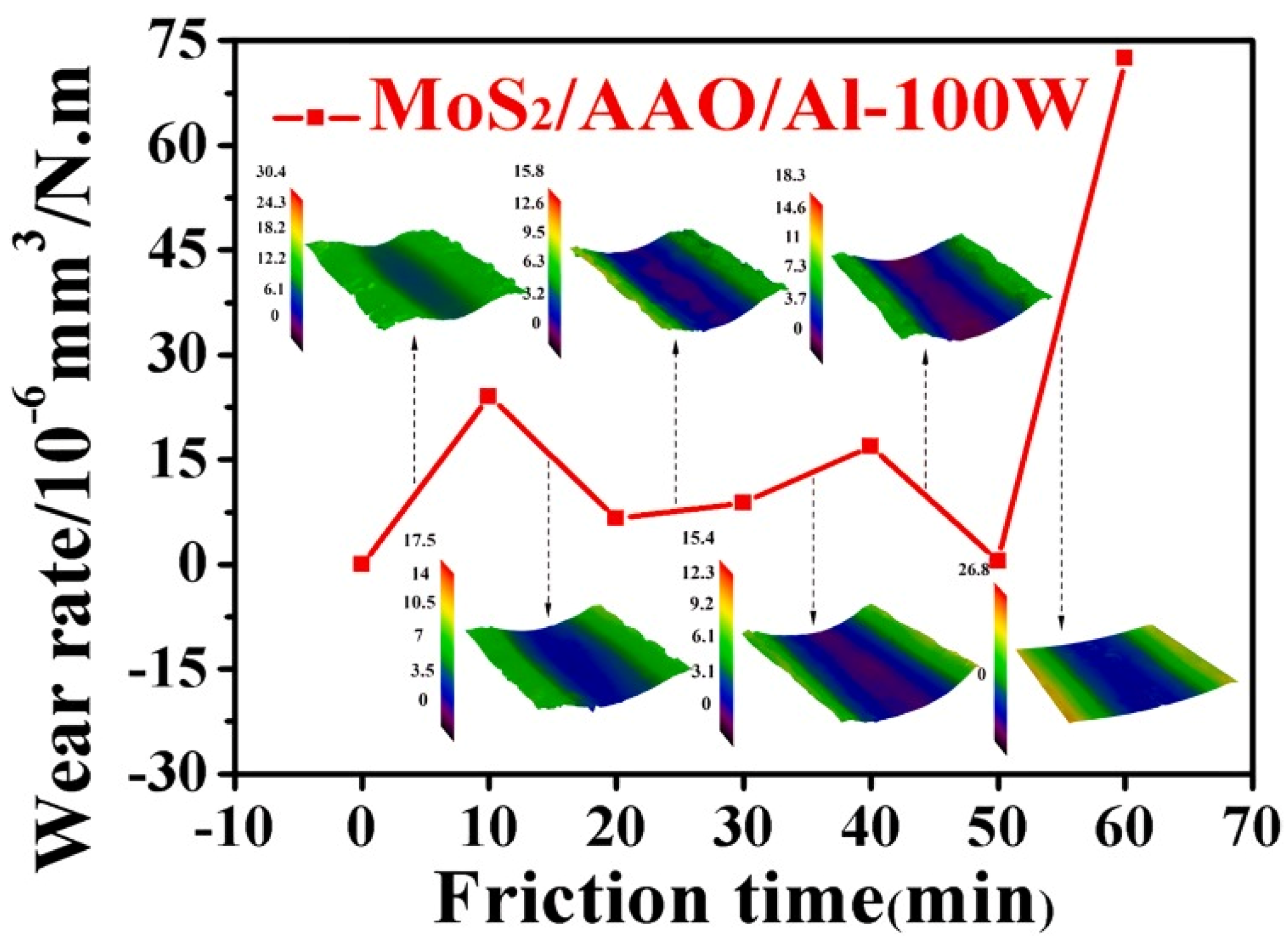

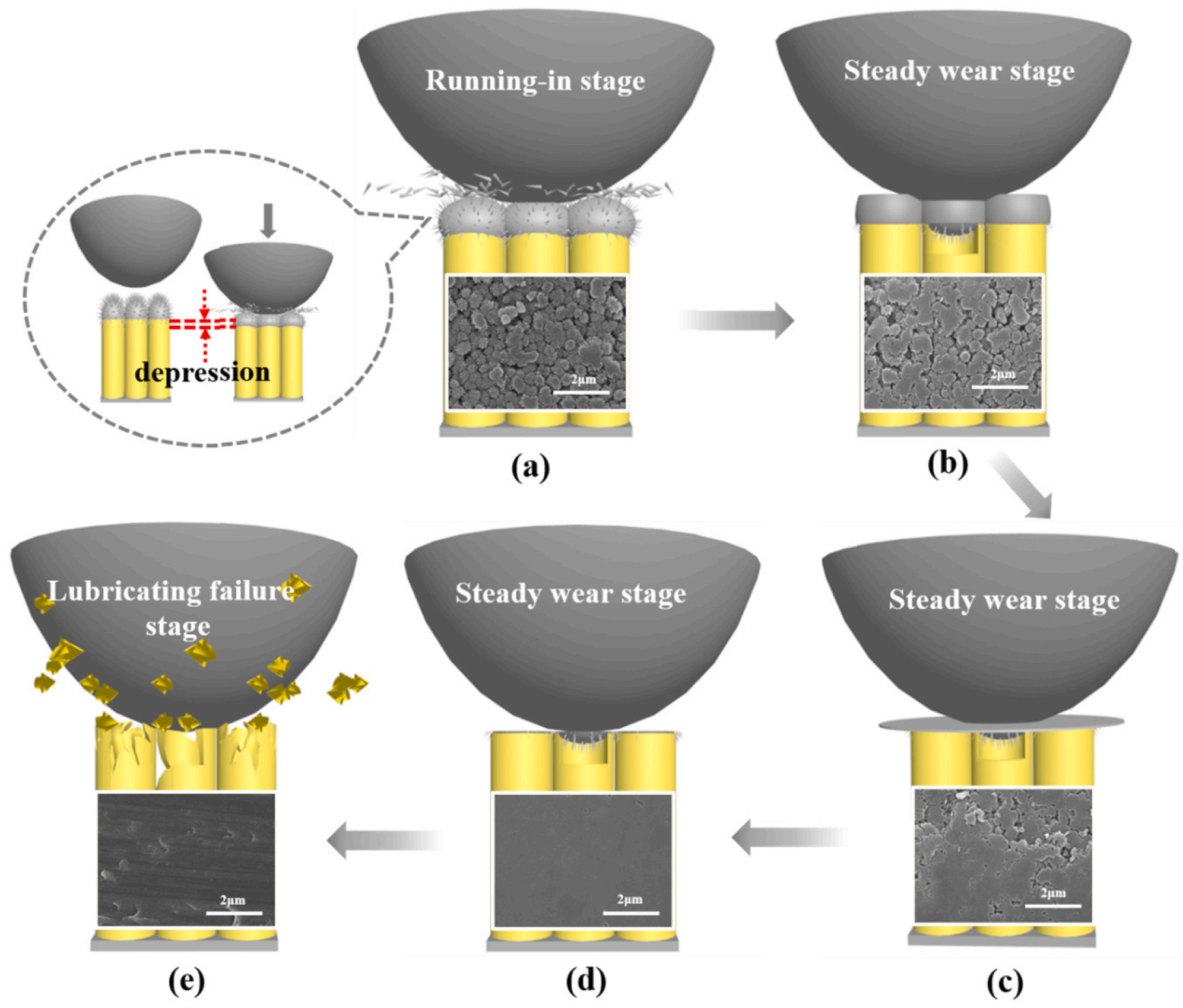

3.1.3. AO + PVD

3.2. MAO + Post-Treatment

3.2.1. MAO + Sealing

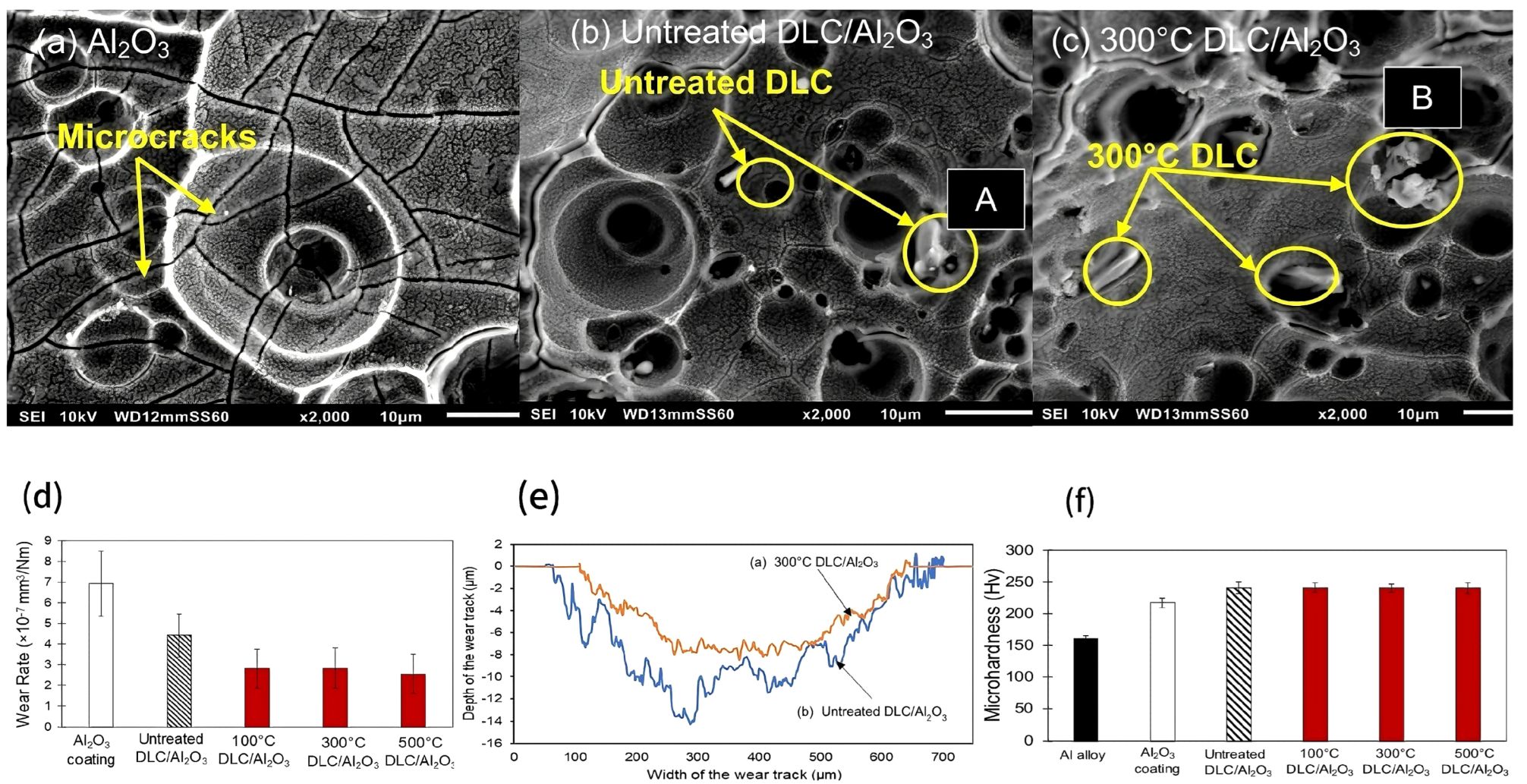

3.2.2. MAO + PVD

3.2.3. MAO + LC

3.3. Other Methods

3.3.1. CS + MAO

3.3.2. EP + PACVD

3.3.3. PS + LR

3.3.4. LACE + PTA

3.4. Summary of the Two-Step Methods

4. Summary and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Liu, Z.-Y.; Xiong, B.-Q.; Li, X.-W.; Yan, L.-Z.; Li, Z.-H.; Zhang, Y.-A.; Liu, H.-W. Deep drawing of 6A16 aluminum alloy for automobile body with various blank-holder forces. Rare Met. 2019, 38, 946–953. [Google Scholar] [CrossRef]

- Godbole, K.; Bhushan, B.; Narayana Murty, S.V.S.; Mondal, K. Al-Si controlled expansion alloys for electronic packaging applications. Prog. Mater. Sci. 2024, 144, 101268. [Google Scholar] [CrossRef]

- Jiang, H.; Song, Y.; Zhang, L.; He, J.; Li, S.; Zhao, J. Efficient grain refinement of Al alloys induced by in-situ nanoparticles. J. Mater. Sci. Technol. 2022, 124, 14–25. [Google Scholar] [CrossRef]

- Zhang, H.H.; Zhang, X.F.; Zhao, X.H.; Tang, Y.M.; Zuo, Y. Preparation of Ti-Zr-Based Conversion Coating on 5052 Aluminum Alloy, and Its Corrosion Resistance and Antifouling Performance. Coatings 2018, 8, 397. [Google Scholar] [CrossRef]

- Chen, P.; Wu, Z.; Huang, Q.; Ji, S.; Weng, Y.; Wu, Z.; Ma, Z.; Chen, X.; Weng, M.; Fu, R.K.Y.; et al. A quasi-2D material CePO4 and the self-lubrication in micro-arc oxidized coatings on Al alloy. Tribol. Int. 2019, 138, 157–165. [Google Scholar] [CrossRef]

- Abd El Aal, M.I. Wear and mechanical properties of Al chips and Al chips composites recycled by high-pressure torsion. J. Mater. Res. Technol. 2021, 14, 407–427. [Google Scholar] [CrossRef]

- Rouhi, M.; Moazami-Goudarzi, M.; Ardestani, M. Comparison of effect of SiC and MoS2 on wear behavior of Al matrix composites. Trans. Nonferrous Met. Soc. China 2019, 29, 1169–1183. [Google Scholar] [CrossRef]

- Sun, Z.; Ma, Y.; Ma, S.; Xiong, H.; Chen, B. Mechanical properties and corrosion resistance enhancement of 2024 aluminum alloy for drill pipe after heat treatment and Sr modification. Mater. Today Commun. 2023, 36, 106805. [Google Scholar] [CrossRef]

- El-Garhy, G.; El Mahallawy, N.; Shoukry, M.K. Effect of grain refining by cyclic extrusion compression (CEC) of Al-6061 and Al-6061/SiC on wear behavior. J. Mater. Res. Technol. 2021, 12, 1886–1897. [Google Scholar] [CrossRef]

- Yuan, Y.H.; Zhang, P.; Zhao, G.P.; Gao, Y.; Tao, L.X.; Chen, H.; Zhang, J.L.; Zhou, H. Effects of Laser Energies on Wear and Tensile Properties of Biomimetic 7075 Aluminum Alloy. J. Mater. Eng. Perform. 2018, 27, 1361–1368. [Google Scholar] [CrossRef]

- Duchaussoy, A.; Sauvage, X.; Edalati, K.; Horita, Z.; Renou, G.; Deschamps, A.; De Geuser, F. Structure and mechanical behavior of ultrafine-grained aluminum-iron alloy stabilized by nanoscaled intermetallic particles. Acta Mater. 2019, 167, 89–102. [Google Scholar] [CrossRef]

- Qi, X.; Takata, N.; Suzuki, A.; Kobashi, M.; Kato, M. Managing both high strength and thermal conductivity of a laser powder bed fused Al–2.5Fe binary alloy: Effect of annealing on microstructure. Mater. Sci. Eng. A 2021, 805, 140591. [Google Scholar] [CrossRef]

- Esquivel, J.; Darling, K.A.; Murdoch, H.A.; Gupta, R.K. Corrosion and Mechanical Properties of Al-5 At. Pct Cr Produced by Cryomilling and Subsequent Consolidation at Various Temperatures. Metall. Mater. Trans. A 2018, 49, 3058–3065. [Google Scholar] [CrossRef]

- Gupta, R.K.; Fabijanic, D.; Dorin, T.; Qiu, Y.; Wang, J.T.; Birbilis, N. Simultaneous improvement in the strength and corrosion resistance of Al via high-energy ball milling and Cr alloying. Mater. Des. 2015, 84, 270–276. [Google Scholar] [CrossRef]

- Esquivel, J.; Gupta, R.K. Influence of the V content on microstructure and hardness of high-energy ball milled nanocrystalline Al-V alloys. J. Alloys Compd. 2018, 760, 63–70. [Google Scholar] [CrossRef]

- Esquivel, J.; Wachowiak, M.G.; O’Brien, S.P.; Gupta, R.K. Thermal stability of nanocrystalline Al-5at.%Ni and Al-5at.%V alloys produced by high-energy ball milling. J. Alloys Compd. 2018, 744, 651–657. [Google Scholar] [CrossRef]

- Kang, N.; Coddet, P.; Liao, H.; Baur, T.; Coddet, C. Wear behavior and microstructure of hypereutectic Al-Si alloys prepared by selective laser melting. Appl. Surf. Sci. 2016, 378, 142–149. [Google Scholar] [CrossRef]

- Sfikas, A.K.; Gonzalez, S.; Lekatou, A.G.; Kamnis, S.; Karantzalis, A.E. A Critical Review on Al-Co Alloys: Fabrication Routes, Microstructural Evolution and Properties. Metals 2022, 12, 1092. [Google Scholar] [CrossRef]

- Esquivel, J.; Murdoch, H.A.; Darling, K.A.; Gupta, R.K. Excellent corrosion resistance and hardness in Al alloys by extended solid solubility and nanocrystalline structure. Mater. Res. Lett. 2018, 6, 79–83. [Google Scholar] [CrossRef]

- Mohammadi, I.; Afshar, A.; Ahmadi, S. Al2O3/Si3N4 nanocomposite coating on aluminum alloy by the anodizing route: Fabrication, characterization, mechanical properties and electrochemical behavior. Ceram. Int. 2016, 42, 12105–12114. [Google Scholar] [CrossRef]

- Remešová, M.; Tkachenko, S.; Kvarda, D.; Ročňáková, I.; Gollas, B.; Menelaou, M.; Čelko, L.; Kaiser, J. Effects of anodizing conditions and the addition of Al2O3/PTFE particles on the microstructure and the mechanical properties of porous anodic coatings on the AA1050 aluminium alloy. Appl. Surf. Sci. 2020, 513, 145780. [Google Scholar] [CrossRef]

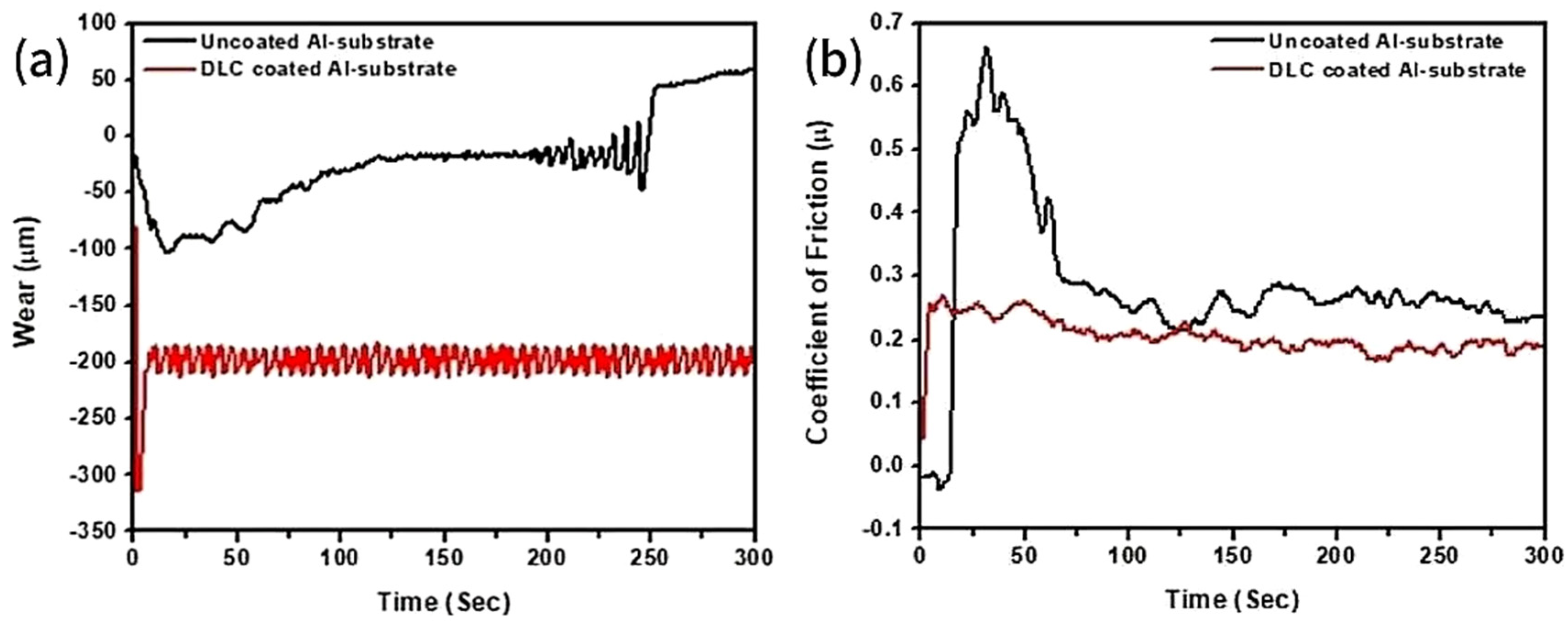

- Rawian, N.A.M.; Akasaka, H.; Liza, S.; Fukuda, K.; Zulkifli, N.A.; Tahir, N.A.M.; Yaakob, Y. Surface and tribological characterization of anodic aluminum oxide coating containing diamond-like carbon flakes. Diam. Relat. Mater. 2023, 132, 109674. [Google Scholar] [CrossRef]

- Dervishi, E.; McBride, M.; Edwards, R.; Gutierrez, M.; Li, N.; Buntyn, R.; Hooks, D.E. Mechanical and tribological properties of anodic Al coatings as a function of anodizing conditions. Surf. Coat. Technol. 2022, 444, 128652. [Google Scholar] [CrossRef]

- Rodriguez, L.; Vieu, A.; Balsarin, M.; Combes, P.; Alexis, J.; Esvan, J.; Lesko, S.; Denape, J.; Paris, J.-Y.; Delbé, K. Physico-chemical characterisation and tribological behaviour of ground micro-arc oxidation coating on aluminium alloy—Comparison with hard anodised oxidation. Wear 2023, 516–517, 204591. [Google Scholar] [CrossRef]

- Yang, F.; Xu, G.M.; Liu, P.; Nie, Z.H.; Pan, H.K.; Lu, H.L. Preparation of high pressure hard anodized aluminum oxide coating on 6061 aluminum alloy. J. Am. Ceram. Soc. 2025, 108, e20454. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, Y.; Bao, Y.; Yang, K. Sliding wear behaviour of plasma electrolytic oxidation coating on pure aluminium. Wear 2011, 271, 1667–1670. [Google Scholar] [CrossRef]

- Wang, C.; Lu, H.; Yang, H.; Xue, B.; Jia, E.; Chai, G. The effect of adding polyethylene glycol to electrolyte solution on micro-arc oxidation coating on pure aluminum. Appl. Surf. Sci. 2022, 599, 154047. [Google Scholar] [CrossRef]

- Wang, J.; Xu, G.S.; Jia, E.D.; Zhao, Z.Y.; Wang, Z.Z.; Lu, H.L. Preparation of wear-resistant ceramic coating by dynamically controlling the resistance during MAO. Int. J. Appl. Ceram. Technol. 2024, 21, 876–887. [Google Scholar] [CrossRef]

- Gao, Y.; Xiao, S.; Wu, H.; Wu, C.; Chen, G.; Yin, Y.; Chu, P.K. Effect of h-BN nanoparticles incorporation on the anti-corrosion and anti-wear properties of micro-arc oxidation coatings on 2024 aluminum alloy. Ceram. Int. 2023, 49, 37475–37485. [Google Scholar] [CrossRef]

- Xi, K.; Wu, H.; Zhou, C.; Qi, Z.; Yang, K.; Fu, R.K.Y.; Xiao, S.; Wu, G.; Ding, K.; Chen, G.; et al. Improved corrosion and wear resistance of micro-arc oxidation coatings on the 2024 aluminum alloy by incorporation of quasi-two-dimensional sericite microplates. Appl. Surf. Sci. 2022, 585, 152693. [Google Scholar] [CrossRef]

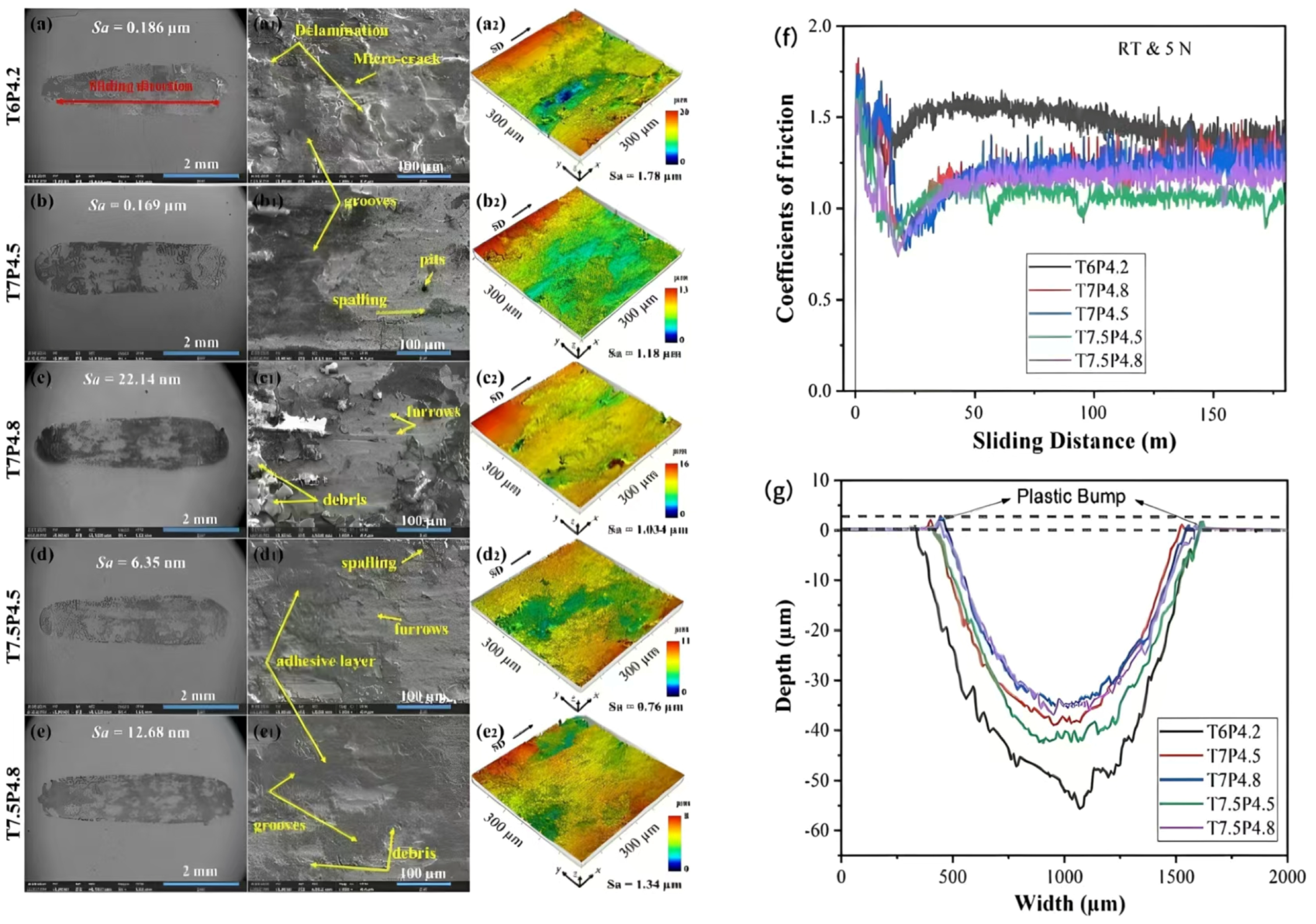

- Terleeva, O.P.; Slonova, A.I.; Rogov, A.B.; Matthews, A.; Yerokhin, A. Wear Resistant Coatings with a High Friction Coefficient Produced by Plasma Electrolytic Oxidation of Al Alloys in Electrolytes with Basalt Mineral Powder Additions. Materials 2019, 12, 2738. [Google Scholar] [CrossRef] [PubMed]

- Javidi, M.; Fadaee, H. Plasma electrolytic oxidation of 2024-T3 aluminum alloy and investigation on microstructure and wear behavior. Appl. Surf. Sci. 2013, 286, 212–219. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, X.; Zhang, S.; Hou, L.; Kim, K.H. One-step fabrication of wear resistant and friction-reducing Al2O3/MoS2 nanocomposite coatings on 2A50 aluminum alloy by plasma electrolytic oxidation with MoS2 nanoparticle additive. Surf. Coat. Technol. 2025, 497, 131796. [Google Scholar] [CrossRef]

- Li, X.-J.; Zhang, M.; Wen, S.; Mao, X.; Huo, W.-G.; Guo, Y.-Y.; Wang, Y.-X. Microstructure and wear resistance of micro-arc oxidation ceramic coatings prepared on 2A50 aluminum alloys. Surf. Coat. Technol. 2020, 394, 125853. [Google Scholar] [CrossRef]

- Egorkin, V.S.; Gnedenkov, S.V.; Sinebryukhov, S.L.; Vyaliy, I.E.; Gnedenkov, A.S.; Chizhikov, R.G. Increasing thickness and protective properties of PEO-coatings on aluminum alloy. Surf. Coat. Technol. 2018, 334, 29–42. [Google Scholar] [CrossRef]

- Hao, Y.; Ye, Z.; Ye, M.; Dong, H.; Wang, L.; Du, Y. Construction and growth of black PEO coatings on aluminum alloys for enhanced wear and impact resistance. Ceram. Int. 2023, 49, 30782–30793. [Google Scholar] [CrossRef]

- Treviño, M.; Garza-Montes-de-Oca, N.F.; Pérez, A.; Hernández-Rodríguez, M.A.L.; Juárez, A.; Colás, R. Wear of an aluminium alloy coated by plasma electrolytic oxidation. Surf. Coat. Technol. 2012, 206, 2213–2219. [Google Scholar] [CrossRef]

- Qi, X.; Gao, H.; He, Y.; Su, X.; Jiang, B.; Song, R. A self-sealing and lubricating MAO/TiO2/PTFE composite coating fabricated by microarc oxidation on a 6063 aluminum alloy for wear and corrosion resistance. J. Alloys Compd. 2025, 1017, 179163. [Google Scholar] [CrossRef]

- Mohedano, M.; Lopez, E.; Mingo, B.; Moon, S.; Matykina, E.; Arrabal, R. Energy consumption, wear and corrosion of PEO coatings on preanodized Al alloy: The influence of current and frequency. J. Mater. Res. Technol. 2022, 21, 2061–2075. [Google Scholar] [CrossRef]

- Arrabal, R.; Mohedano, M.; Matykina, E.; Pardo, A.; Mingo, B.; Merino, M.C. Characterization and wear behaviour of PEO coatings on 6082-T6 aluminium alloy with incorporated α-Al2O3 particles. Surf. Coat. Technol. 2015, 269, 64–73. [Google Scholar] [CrossRef]

- Yang, X.; Chen, L.; Jin, X.; Du, J.; Xue, W. Influence of temperature on tribological properties of microarc oxidation coating on 7075 aluminium alloy at 25 °C–300 °C. Ceram. Int. 2019, 45, 12312–12318. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, S. Preparation of wear and corrosion resistant micro-arc oxidation coating on 7N01 aluminum alloy. Surf. Coat. Technol. 2020, 388, 125453. [Google Scholar] [CrossRef]

- Cheng, Y.-L.; Xie, H.-J.; Cao, J.-H.; Cheng, Y.-L. Effect of NaOH on plasma electrolytic oxidation of A356 aluminium alloy in moderately concentrated aluminate electrolyte. Trans. Nonferrous Met. Soc. China 2021, 31, 3677–3690. [Google Scholar] [CrossRef]

- Truong, P.V.; Bo, N.V.; Minh, N.V.; Anh, N.V.; Suresh Kumar, G.; Shkir, M. Investigation of corrosion and wear resistance of PEO coated D16T aluminium alloys in the marine tropical climate conditions. Mater. Chem. Phys. 2022, 290, 126587. [Google Scholar] [CrossRef]

- Wang, L.; Wang, G.; Dong, H.; Ye, M.; Li, X.; Liu, L.; Pan, J.; Ye, Z. Plasma electrolytic oxidation coatings on additively manufactured aluminum–silicon alloys with superior tribological performance. Surf. Coat. Technol. 2022, 435, 128246. [Google Scholar] [CrossRef]

- Rajamure, R.S.; Vora, H.D.; Gupta, N.; Karewar, S.; Srinivasan, S.G.; Dahotre, N.B. Laser surface alloying of molybdenum on aluminum for enhanced wear resistance. Surf. Coat. Technol. 2014, 258, 337–342. [Google Scholar] [CrossRef]

- Zhang, T.T.; Feng, K.; Li, Z.G.; Kokawa, H. Effects of rare earth elements on the microstructure and wear properties of TiB2 reinforced aluminum matrix composite coatings: Experiments and first principles calculations. Appl. Surf. Sci. 2020, 530, 147051. [Google Scholar] [CrossRef]

- Chi, Y.M.; Gong, G.H.; Zhao, L.J.; Yu, H.J.; Tian, H.F.; Du, X.Y.; Chen, C.Z. In-situ TiB2-TiC reinforced Fe-Al composite coating on 6061 aluminum alloy by laser surface modification. J. Mater. Process. Technol. 2021, 294, 117107. [Google Scholar] [CrossRef]

- Li, Y.Z.; Shi, Y. Microhardness, wear resistance, and corrosion resistance of AlxCrFeCoNiCu high-entropy alloy coatings on aluminum by laser cladding. Opt. Laser Technol. 2021, 134, 106632. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, P.; Bai, P.; Wu, L.; Liu, B.; Zhao, Z. Microstructure and properties of Ti/TiBCN coating on 7075 aluminum alloy by laser cladding. Surf. Coat. Technol. 2018, 334, 142–149. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, J.; Li, W.; Xu, Y.; Yang, X.; Su, Y. Morphology of ceramic regulates the deposition behavior and mechanical properties of cold spray additive manufactured Al2O3/2024 aluminum matrix composites. Mater. Charact. 2024, 215, 114197. [Google Scholar] [CrossRef]

- Mengiste, B.T.; Arab, A.; Chen, P.; Xie, J. Effect of cold spray deposition parameters on wear performance of CrMnFeCoNi high entropy alloy. Tribol. Int. 2025, 204, 110465. [Google Scholar] [CrossRef]

- Wang, H.P.; Li, P.; Ma, G.Z.; Guo, W.L.; Li, H.Q.; Wang, H.D. Influences of Ti3AlC2 content on tribological behavior of cold-sprayed Ni-Ti3AlC2 composite coatings. Surf. Coat. Technol. 2024, 494, 131520. [Google Scholar] [CrossRef]

- Singh, S.; Rai, H.; Pandey, K.K.; Keshri, A.K.; Gosvami, N.N. Improving Tribological Properties of Al alloys via Robust One Step Graphene Coatings using Plasma Spraying. Tribol. Lett. 2023, 71, 42. [Google Scholar] [CrossRef]

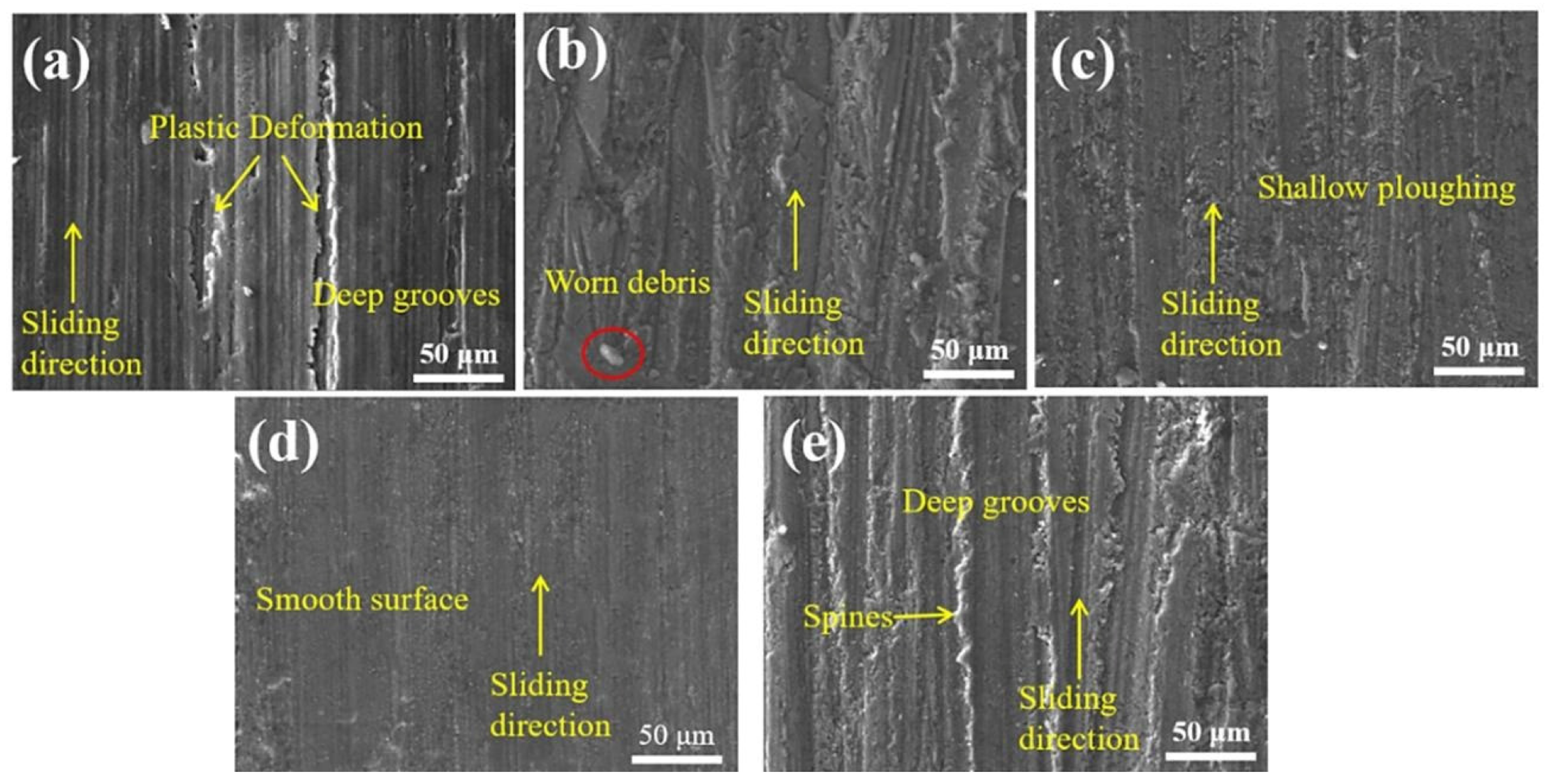

- Dong, T.S.; Liu, M.; Feng, Y.; Li, G.L.; Li, X.B. Microstructure and properties of a wear resistant Al-25Si-4Cu-1Mg coating prepared by supersonic plasma spraying. Int. J. Miner. Metall. Mater. 2020, 27, 1287–1294. [Google Scholar] [CrossRef]

- Yang, G.W.; Fu, B.G.; Dong, T.S.; Li, G.L. Preparation of AlSi30Cu5 coating with fine microstructure using plasma spraying technology. Mater. Lett. 2024, 357, 135800. [Google Scholar] [CrossRef]

- He, L.; Tan, Y.; Wang, X.; Xu, T.; Hong, X. Microstructure and wear properties of Al2O3-CeO2/Ni-base alloy composite coatings on aluminum alloys by plasma spray. Appl. Surf. Sci. 2014, 314, 760–767. [Google Scholar] [CrossRef]

- Peng, Q.Q.; Liu, M.; Huang, Y.F.; Zhou, X.Y.; Ma, G.Z.; Wang, H.D.; Xing, Z.G. Effect of Heat Treatment on Microstructure and Properties of Al-25Si Wear-Resistant Coatings Sprayed by Supersonic Plasma. J. Therm. Spray Technol. 2023, 32, 1078–1092. [Google Scholar] [CrossRef]

- Han, B.-y.; Wu, H.-d.; Chen, S.-y.; Gao, X.-h.; Zhao, H.-c.; Wang, R.; Zhao, Y.-l. Supersonic plasma-sprayed TiO2 coating: Performance optimization based on response surface methodology and tribological properties. Ceram. Int. 2024, 50, 33736–33750. [Google Scholar] [CrossRef]

- Han, B.-y.; Gao, X.-h.; Chen, S.-y.; Cong, M.-q.; Li, R.-x.; Liu, X.; Hang, W.-x.; Cui, F.-f. Microstructure and tribological behavior of plasma spray Ni60 alloy coating deposited on ZL109 aluminum alloy substrate. Tribol. Int. 2022, 175, 107859. [Google Scholar] [CrossRef]

- Abbas, S.M.; Elayaperumal, A.; Issac, R.F.; Arulvel, S.; Manikandan, R. Tribology Characterization of Plasma Sprayed Zirconia-Alumina and Fused Zirconia-Alumina Composite Coated Al-Si Alloy at Different Sliding Velocity and Load Conditions. Silicon 2022, 14, 4707–4722. [Google Scholar] [CrossRef]

- Si, C.; Zhang, Y.; Li, L.; Zhang, T.; Liu, H.; Men, A.; Fan, X.; Zhu, M. Multifunctional hybrid T-PI-MPS composite coating: Corrosion resistance, low-wear/friction and heat-resistance. Prog. Org. Coat. 2024, 187, 108181. [Google Scholar] [CrossRef]

- Si, C.; Cai, M.; Liu, G.; Zhang, Y.; Fan, X.; Zhu, M. PDMS-PI composite coating toward multi-purpose development: Hydrophobic, low-friction/wear, and heat-resistance. Tribol. Int. 2023, 189, 108919. [Google Scholar] [CrossRef]

- Ansari, M.I.; Thakur, D.G. Tribological Properties of Electroless Nanocomposite Deposits with Influence of Aliquat 336 on 6061 Aluminium Alloy. Trans. Indian Inst. Met. 2018, 71, 1348–1353. [Google Scholar] [CrossRef]

- Pancrecious, J.K.; Deepa, J.P.; Jayan, V.; Bill, U.S.; Rajan, T.P.D.; Pai, B.C. Nanoceria induced grain refinement in electroless Ni-B-CeO2 composite coating for enhanced wear and corrosion resistance of Aluminium alloy. Surf. Coat. Technol. 2018, 356, 29–37. [Google Scholar] [CrossRef]

- Rajendran, R.; Sha, W.; Elansezhian, R. Abrasive wear resistance of electroless Ni–P coated aluminium after post treatment. Surf. Coat. Technol. 2010, 205, 766–772. [Google Scholar] [CrossRef]

- Ma, L.; Huang, J.; Fan, X.; Li, J.; Zhu, H.; Xiong, D. Properties of thick ceramic composite coatings synthesized on an aluminium alloy by cathodic plasma electrolytic deposition. Surf. Coat. Technol. 2018, 356, 80–88. [Google Scholar] [CrossRef]

- Pratapa Reddy, Y.; Lakshmi Narayana, K.; Kedar Mallik, M. Prediction of influence of Co-Cr-Mo alloy coating on the wear rate of aluminium with HCl solution. Mater. Today Proc. 2021, 42, 1287–1296. [Google Scholar] [CrossRef]

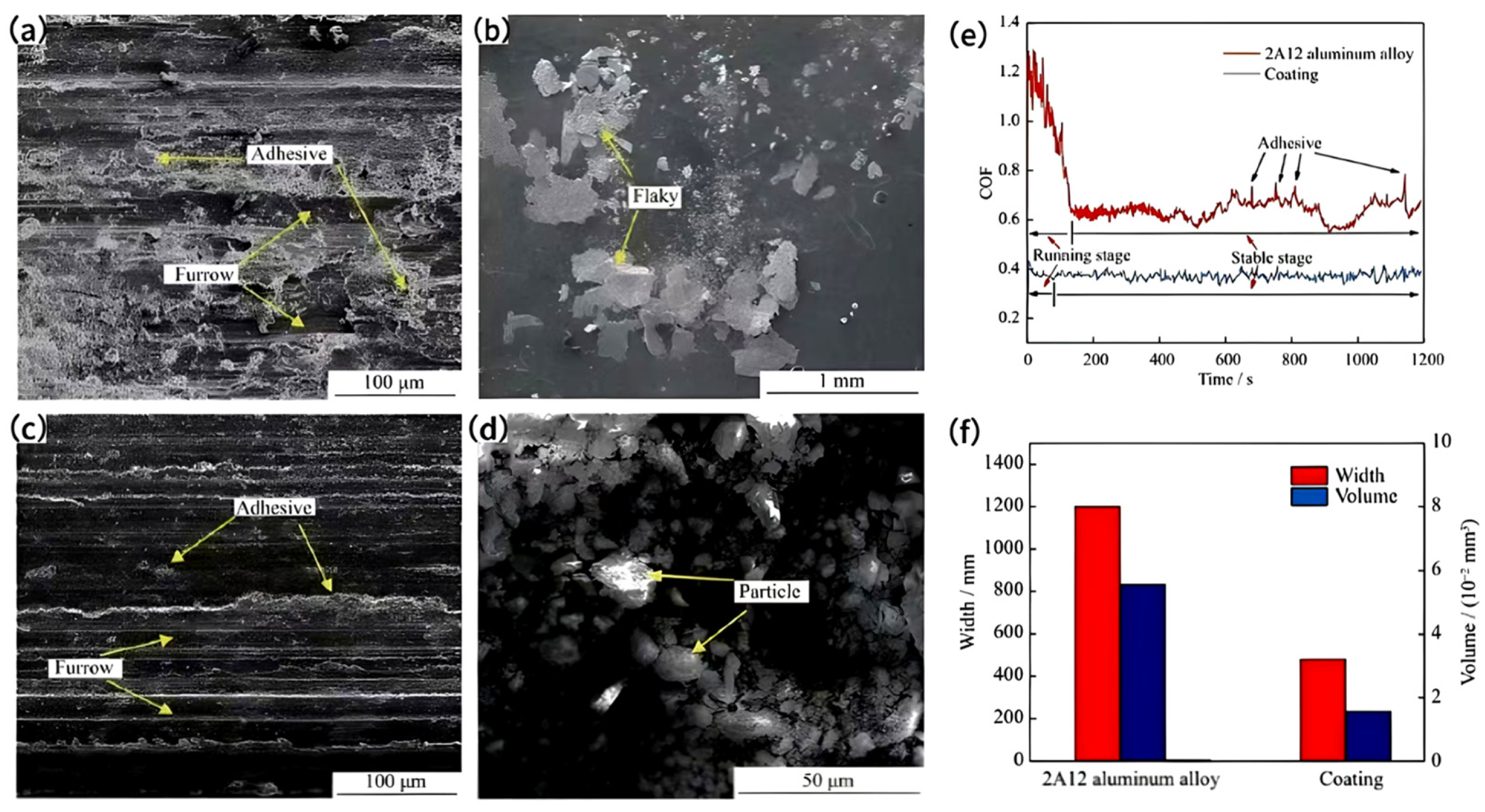

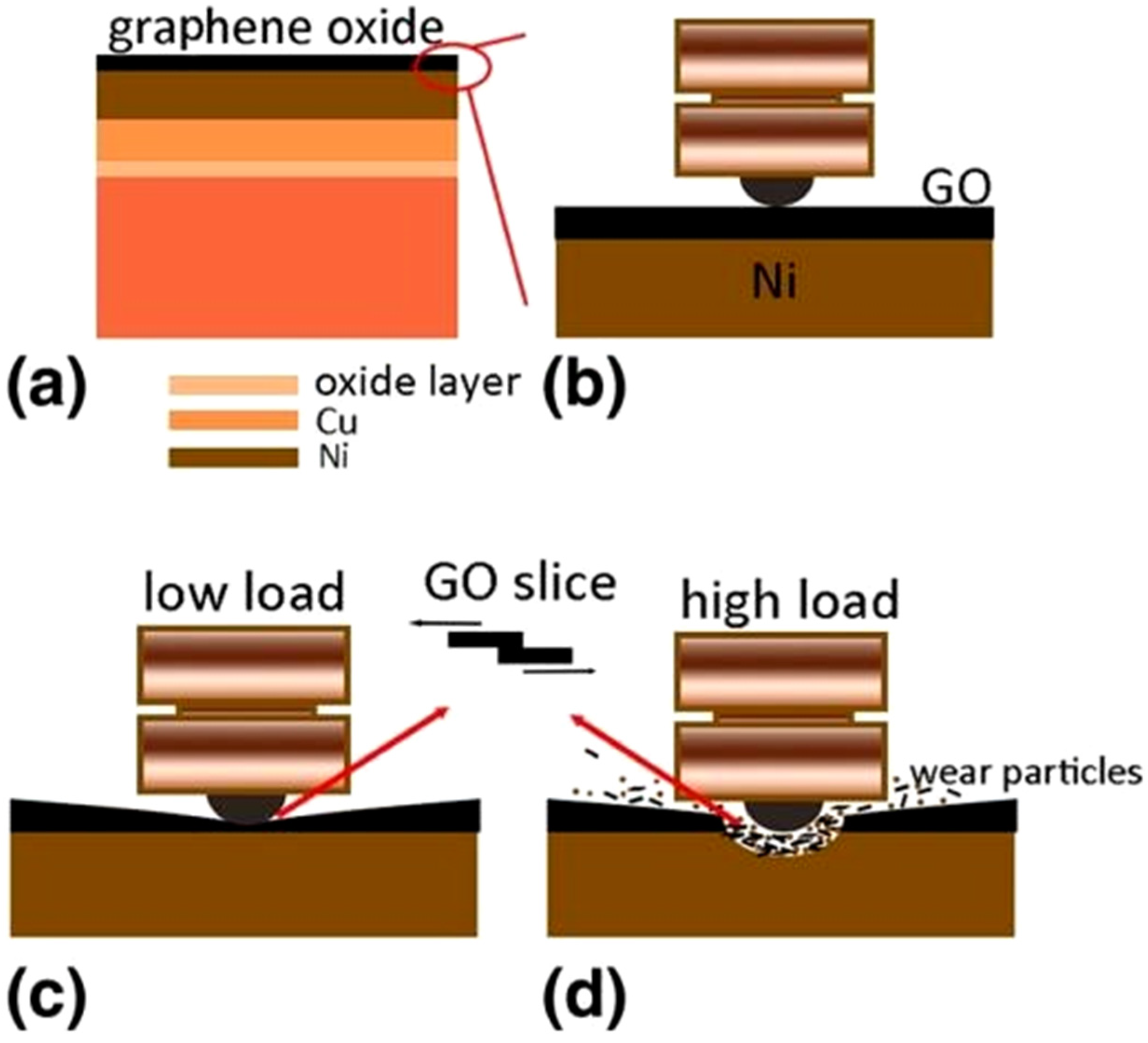

- Luo, Y.; Sun, Y.; Gu, Y.H.; Zhao, J.; Liang, J.; Yue, W. Enhanced Tribological Performance of a Ni/GO-Coated 2024 Alloy. J. Mater. Eng. Perform. 2020, 29, 2947–2956. [Google Scholar] [CrossRef]

- Huang, P.-C.; Hou, K.-H.; Hong, J.-J.; Lin, M.-H.; Wang, G.-L. Study of fabrication and wear properties of Ni–SiC composite coatings on A356 aluminum alloy. Wear 2021, 477, 203772. [Google Scholar] [CrossRef]

- Kaczmarek, Ł.; Kopia, A.; Kyzioł, K.; Szymański, W.; Kołodziejczyk, Ł.; Gawroński, J.; Kleczewska, J. Wear resistant carbon coatings deposited at room temperature by pulsed laser deposition method on 7075 aluminum alloy. Vacuum 2013, 97, 20–25. [Google Scholar] [CrossRef]

- Dinesh, D.; Bhaskar, G.B.; Vasumathi, M.; Rashia Begum, S. Investigation on tribological characteristics of Al 7075 coated with aluminium chromium nitride (AlCrN) by magnetron sputtering. Mater. Today Proc. 2024. [CrossRef]

- Mehran, Q.M.; Bushroa, A.R.; Fazal, M.A. Evaluation of CrAlN multilayered coatings deposited by PVD magnetron sputtering. J. Adhes. Sci. Technol. 2015, 29, 2076–2089. [Google Scholar] [CrossRef]

- Xu, F.; Gong, D. Improved the elevated temperature mechanical properties of Al-Si alloy deposited with Al-Si coating by magnetron sputtering. Vacuum 2018, 150, 1–7. [Google Scholar] [CrossRef]

- Tokuta, Y.; Itoh, T.; Shiozaki, T.; Kawaguchi, M.; Sasaki, S. Low friction mechanism of chlorine-doped amorphous carbon films sliding against an aluminium alloy. Tribol. Int. 2017, 115, 573–579. [Google Scholar] [CrossRef]

- Salerno, E.; Casotti, D.; Paolicelli, G.; Gualtieri, E.; Ballestrazzi, A.; Gazzadi, G.C.; Bolelli, G.; Lusvarghi, L.; Valeri, S.; Rota, A. Friction and wear of DLC films deposited on additive manufactured AlSi10Mg: The role of surface finishing. Surf. Coat. Technol. 2023, 463, 129531. [Google Scholar] [CrossRef]

- Li, A.; Chen, Q.; Wu, G.; Huang, X.; Wang, Y.; Lu, Z.; Zhang, G.; Nie, X. Effect of the Variation of Film Thickness on the Properties of Multilayered Si-Doped Diamond-Like Carbon Films Deposited on SUS 304, Al and Cu Substrates. J. Mater. Eng. Perform. 2020, 29, 8473–8483. [Google Scholar] [CrossRef]

- Solomon, I.; Sarma, A. Tribological and corrosion performance of DLC coating on sintered Al alloy. Mater. Res. Express 2019, 6, 046412. [Google Scholar] [CrossRef]

- Fayed, S.M.; Chen, D.X.; Li, S.L.; Zhou, Y.W.; Wang, H.B. Effect of Bias Voltage on Characteristics of Multilayer Si-DLC Film Coated on AA6061 Aluminum Alloy. J. Mater. Eng. Perform. 2021, 30, 743–759. [Google Scholar] [CrossRef]

- Kottfer, D.; Marton, M.; Ferdinandy, M.; Trebuňa, P.; Kaczmarek, L. A study of structural and wear properties of PACVD deposited a-C:H thin films for application as protective layers on Al alloys. Phys. Status Solidi A 2015, 212, 2271–2277. [Google Scholar] [CrossRef]

- Zhao, D.; Yamaguchi, T.; Shu, J.; Tokunaga, T.; Danjo, T. Rapid fabrication of the continuous AlFeCrCoNi high entropy alloy coating on aluminum alloy by resistance seam welding. Appl. Surf. Sci. 2020, 517, 145980. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Z.; Li, Y.; Wang, D.; Li, M.; Chen, Q. Wear Behavior of Fe-WC/Metal Double Layer Coatings Fabricated by Resistance Seam Weld Method. Acta Metall Sin. 2019, 55, 537–546. [Google Scholar] [CrossRef]

- Yi, L.; Song, S.; Liu, Y. Fabrication of functionalized boron nitride modified self-healing composite coating for corrosion and wear protection. Compos. Part A Appl. Sci. Manuf. 2025, 191, 108747. [Google Scholar] [CrossRef]

- Ma, Z.S.; Xia, C.Q.; Yang, T.; Liu, N.; Wang, H.S.; Liang, C.Y.; Wang, G.; Li, Q. Effects of Zr-based and Ni-based amorphous alloy powders on the wear resistance and corrosion behavior of polyurethane composite coatings on aluminum alloys. Colloids Surf. A Physicochem. Eng. Asp. 2024, 685, 133178. [Google Scholar] [CrossRef]

- Sieber, M.; Scharf, I.; Herold, F.; Schmidt, A.; Böttger, D.; Böttger, S.; Böttger, E.; Götze, U.; Lampke, T. Anodic oxidation of AlMgSi1—Coatings’ mechanical properties, process costs and energy consumption of the oxide formation. Mater. Des. 2016, 89, 1259–1269. [Google Scholar] [CrossRef]

- Santos, J.S.; Araújo, P.D.; Pissolitto, Y.B.; Lopes, P.P.; Simon, A.P.; Sikora, M.D.; Trivinho-Strixino, F. The Use of Anodic Oxides in Practical and Sustainable Devices for Energy Conversion and Storage. Materials 2021, 14, 383. [Google Scholar] [CrossRef]

- Sola, R.; Tonelli, L.; Shashkov, P.; Bogdanoff, T.H.; Martini, C. Anodizing of AA6082-T5 by conventional and innovative treatments: Microstructural characterization and dry sliding behaviour. Wear 2020, 458–459, 203423. [Google Scholar] [CrossRef]

- Qin, J.; Zhou, X.; Curioni, M. Investigation of oxide growth during hard anodizing using in-situ and ex-situ EIS measurements. Surf. Coat. Technol. 2023, 470, 129851. [Google Scholar] [CrossRef]

- Chiang, M.-H.; Yeh, C.-C.; Lee, C.-L. Improvement in the abrasive wear resistance of an aluminum alloy casting for a continuously-variable transmission using heat treatment and pulsed anodizing. Wear 2020, 442–443, 203137. [Google Scholar] [CrossRef]

- Mora-Sanchez, H.; del Olmo, R.; Rams, J.; Torres, B.; Mohedano, M.; Matykina, E.; Arrabal, R. Hard Anodizing and Plasma Electrolytic Oxidation of an Additively Manufactured Al-Si alloy. Surf. Coat. Technol. 2021, 420, 127339. [Google Scholar] [CrossRef]

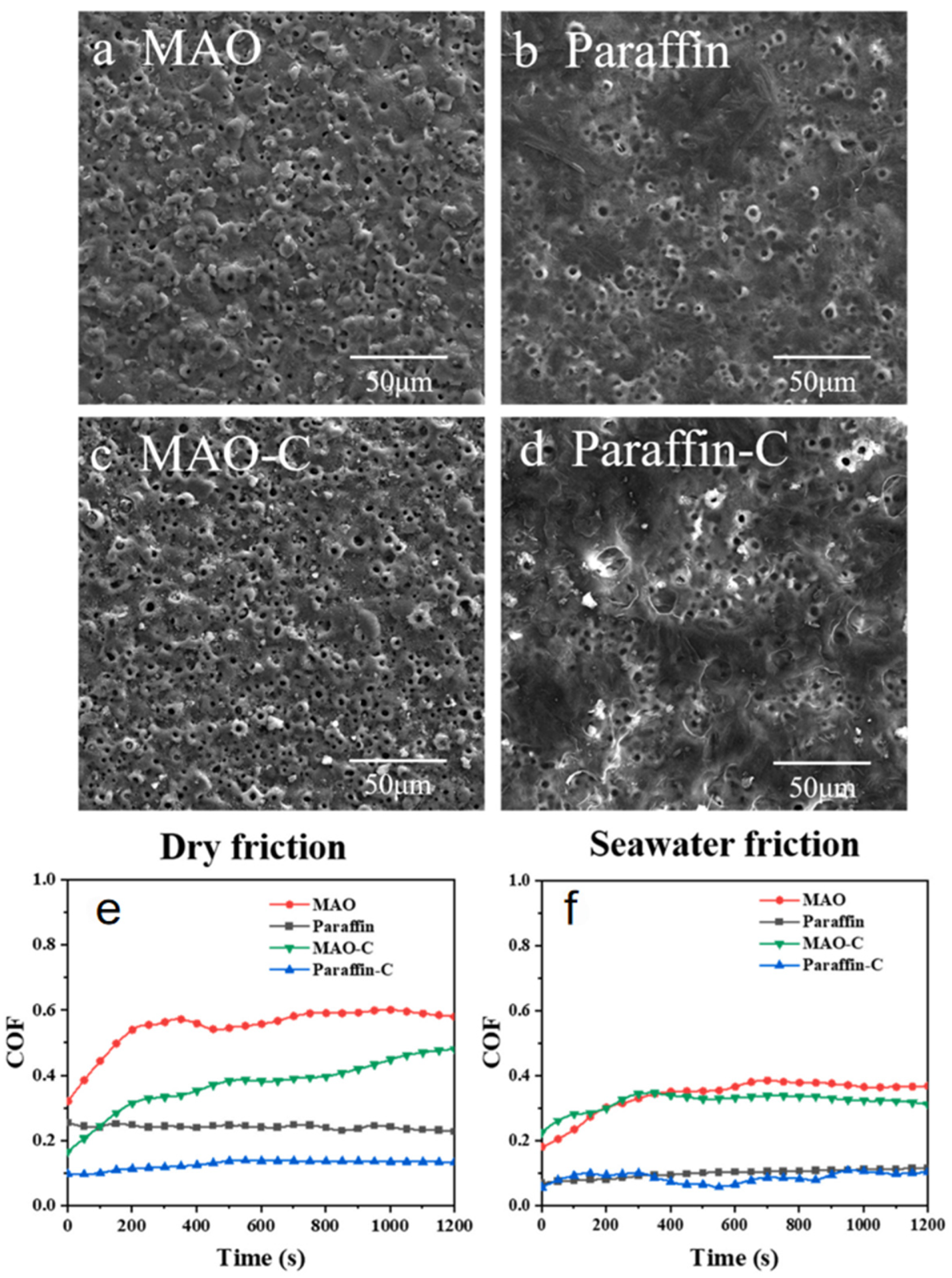

- Guo, Z.; Song, J.; Wang, G.; Zhao, G. Enhancing the tribological and corrosion properties of 2A12 aluminum alloy via micro-arc oxidation and paraffin sealing. Colloids Surf. A Physicochem. Eng. Asp. 2025, 712, 136476. [Google Scholar] [CrossRef]

- Alves, S.A.; Fernández-Lopéz, P.; Lopéz-Ortega, A.; Fernández, X.; Quintana, I.; San-José, T.; Bayón, R. Enhanced tribological performance of cylinder liners made of cast aluminum alloy with high silicon content through plasma electrolytic oxidation. Surf. Coat. Technol. 2022, 433, 128146. [Google Scholar] [CrossRef]

- Cheng, Y.-l.; Cao, J.-h.; Mao, M.-k.; Peng, Z.-m.; Skeldon, P.; Thompson, G.E. High growth rate, wear resistant coatings on an Al–Cu–Li alloy by plasma electrolytic oxidation in concentrated aluminate electrolytes. Surf. Coat. Technol. 2015, 269, 74–82. [Google Scholar] [CrossRef]

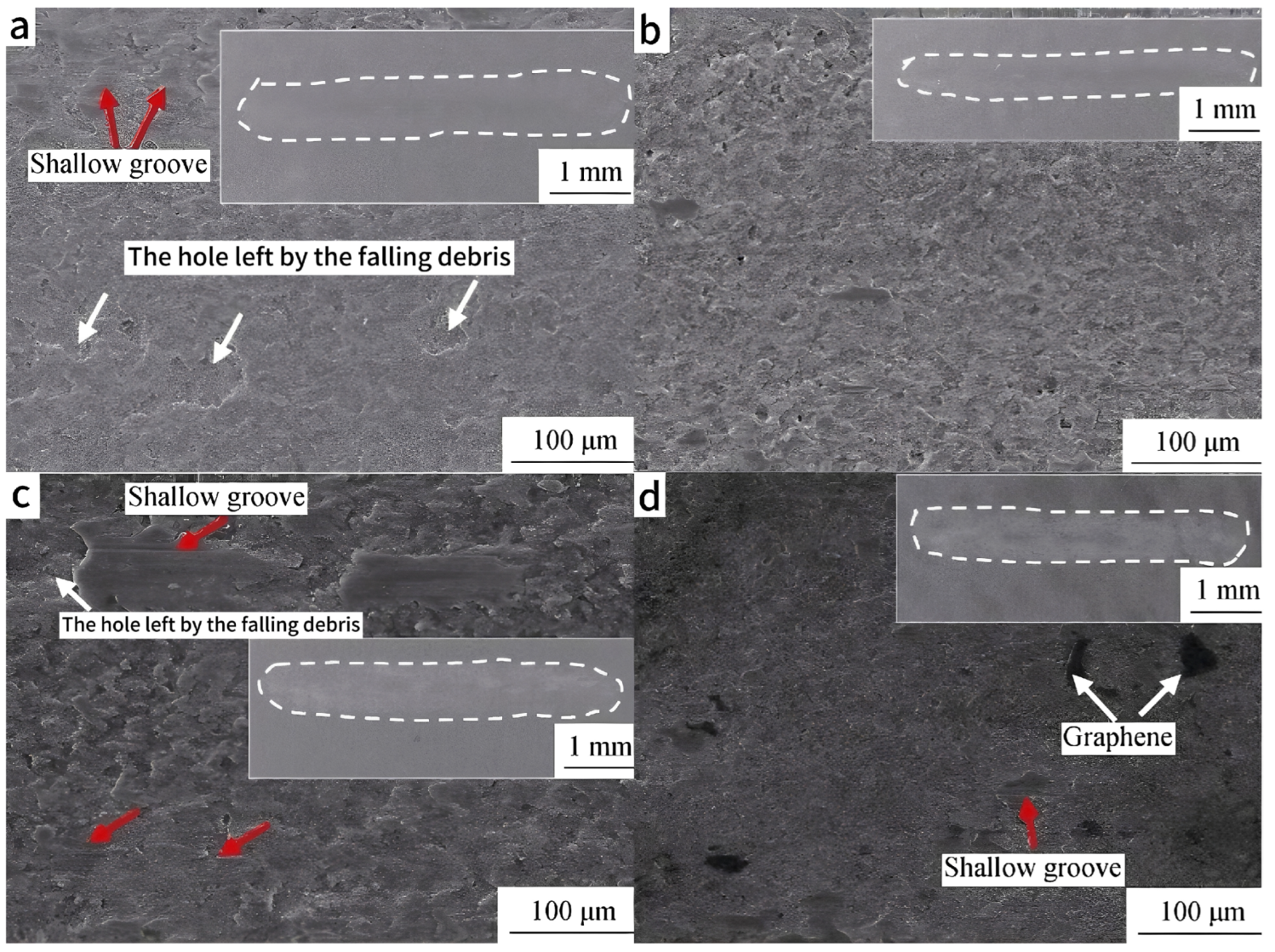

- Haghighat-Shishavan, B.; Azari-Khosrowshahi, R.; Haghighat-Shishavan, S.; Nazarian-Samani, M.; Parvini-Ahmadi, N. Improving wear and corrosion properties of alumina coating on AA7075 aluminum by plasma electrolytic oxidation: Effects of graphite absorption. Appl. Surf. Sci. 2019, 481, 108–119. [Google Scholar] [CrossRef]

- Ji, R.; Wang, S.; Zou, Y.; Chen, G.; Wang, Y.; Ouyang, J.; Jia, D.; Zhou, Y. One-step fabrication of amorphous/ITO-CNTs coating by plasma electrolytic oxidation with particle addition for excellent wear resistance. Appl. Surf. Sci. 2023, 640, 158274. [Google Scholar] [CrossRef]

- Liu, W.-Y.; Liu, Y.; Blawert, C.; Zheludkevich, M.-L.; Fan, C.-L.; Talha, M.; Lin, Y.-H. Microstructure, wear and corrosion performance of plasma electrolytic oxidation coatings formed on D16T Al alloy. Rare Met. 2020, 39, 1425–1439. [Google Scholar] [CrossRef]

- Nie, Z.; Lu, H.; Liu, Q.; Chai, G.; Ding, Y.; Xu, G.; Guo, J. Effect of copper introduction on the properties of micro-arc oxidation coating on powder metallurgy aluminum disk. Surf. Coat. Technol. 2024, 479, 130520. [Google Scholar] [CrossRef]

- Sabatini, G.; Ceschini, L.; Martini, C.; Williams, J.A.; Hutchings, I.M. Improving sliding and abrasive wear behaviour of cast A356 and wrought AA7075 aluminium alloys by plasma electrolytic oxidation. Mater. Des. 2010, 31, 816–828. [Google Scholar] [CrossRef]

- Shin, Y.; Bae, K.; Lee, S.; Kim, H.; Shin, D.; Kim, D.; Choi, E.; Moon, H.-S.; Lee, J. Healable Anti-Corrosive and Wear-Resistant Silicone-Oil-Impregnated Porous Oxide Layer of Aluminum Alloy by Plasma Electrolytic Oxidation. Nanomaterials 2023, 13, 2582. [Google Scholar] [CrossRef]

- Sieber, M.; Simchen, F.; Morgenstern, R.; Scharf, I.; Lampke, T. Plasma Electrolytic Oxidation of High-Strength Aluminium Alloys-Substrate Effect on Wear and Corrosion Performance. Metals 2018, 8, 356. [Google Scholar] [CrossRef]

- Sobolev, A.; Kossenko, A.; Zinigrad, M.; Borodianskiy, K. Comparison of plasma electrolytic oxidation coatings on Al alloy created in aqueous solution and molten salt electrolytes. Surf. Coat. Technol. 2018, 344, 590–595. [Google Scholar] [CrossRef]

- Wu, M.; Jiang, F. Effect of the alloying element Sc and Zr in 5B70 Al alloy on the microstructure, toughness and tribological properties of MAO ceramic film. Mater. Charact. 2024, 215, 114218. [Google Scholar] [CrossRef]

- Wu, M.J.; Jiang, F. Effect of SiC addition in electrolyte on the microstructure and tribological properties of micro-arc oxidation coatings on Al-Mg-Sc alloy. Surf. Topogr. Metrol. Prop. 2021, 9, 035043. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, D.; Wu, S.; Lu, H.; Yao, R.; Yang, J.; Jiang, F.; Takao, A. Research progress on defect formation mechanism and process optimization of laser cladding high entropy alloy coatings. Opt. Laser Technol. 2025, 187, 112819. [Google Scholar] [CrossRef]

- Wang, J.; Jin, G.; Feng, X.; Cui, X.; Wen, X.; Zhao, Y. Al–Cu-based in-situ reinforced gradient coating on aluminum alloy by laser cladding: Tribological behavior under gradient loading and thermal conditions. Mater. Chem. Phys. 2023, 301, 127595. [Google Scholar] [CrossRef]

- Chen, M.L.; Yang, X.F.; Zhang, Z.Q.; Gu, Y.G.; Li, K.J.; Liu, Y.S.; Ma, J.B. Research status of laser cladding technology on aluminum alloy surface. Int. J. Adv. Manuf. Technol. 2025, 137, 1–21. [Google Scholar] [CrossRef]

- Yue, T.M.; Huang, K.J.; Man, H.C. Laser cladding of Al2O3 coating on aluminium alloy by thermite reactions. Surf. Coat. Technol. 2005, 194, 232–237. [Google Scholar] [CrossRef]

- Jafari, R.; Cizek, J.; Lukac, F.; Cvrcek, L.; Buril, M.; Walter, J.; Honkanen, M.; Vippola, M.; Koivuluoto, H. A Comparative Study on Wear Resistance of Cold-Sprayed Aluminum/Quasicrystal Composite Coatings. J. Therm. Spray Technol. 2024, 33, 705–718. [Google Scholar] [CrossRef]

- Kumar, S.; Reddy, S.K.; Joshi, S.V. Microstructure and performance of cold sprayed Al-SiC composite coatings with high fraction of particulates. Surf. Coat. Technol. 2017, 318, 62–71. [Google Scholar] [CrossRef]

- Qiu, X.; Tariq, N.U.; Wang, J.Q.; Tang, J.R.; Gyansah, L.; Zhao, Z.P.; Xiong, T.Y. Microstructure, microhardness and tribological behavior of Al2O3 reinforced A380 aluminum alloy composite coatings prepared by cold spray technique. Surf. Coat. Technol. 2018, 350, 391–400. [Google Scholar] [CrossRef]

- Aliyu, I.K.; A, M.K.; Mohammed, A.S. Wear and corrosion resistance performance of UHMWPE/GNPs nanocomposite coatings on AA2028 Al alloys. Prog. Org. Coat. 2021, 151, 106072. [Google Scholar] [CrossRef]

- Abdul Samad, M.; Satyanarayana, N.; Sinha, S.K. Tribology of UHMWPE film on air-plasma treated tool steel and the effect of PFPE overcoat. Surf. Coat. Technol. 2010, 204, 1330–1338. [Google Scholar] [CrossRef]

- Arumugam, A.; Lakshmanan, P.; Palani, S.; Parthiban, K. Wear behavior of Ni-P and Al2O3 electroless nano coating on aluminium alloy. Mater. Today Proc. 2021, 46, 1066–1070. [Google Scholar] [CrossRef]

- Mohanty, S.; Singh, G.; Dwivedi, S.; Dixit, A.R.; Singh, R.K. Electroless Ni-P-MoS2 composite coating of Al-alloys: Effect of surface textures and bath composition. Phys. Scr. 2023, 98, 105951. [Google Scholar] [CrossRef]

- Parthiban, K.; Lakshmanan, P.; Palani, S.; Arumugam, A. Electroless deposition of SiC Nano Coating on Aluminium alloy and evaluation of wear resistance and electroless characteristics. Mater. Today Proc. 2021, 46, 1096–1100. [Google Scholar] [CrossRef]

- Pathak, B.N.; Chandra, A.; Kumar Mishra, A.; Saxena, A.; Kandpal, B. Study on wear behaviour of aluminium-based piston alloy using different coatings. Mater. Today Proc. 2023. [CrossRef]

- Wang, Y.; Sun, W.C.; Wang, C.A.; Huang, Y.; Xu, J.M. Microstructure, friction, and wear properties of Ni-Al2O3-MoS2 composite coatings. Int. J. Appl. Ceram. Technol. 2017, 14, 889–898. [Google Scholar] [CrossRef]

- Zin, V.; Miorin, E.; Deambrosis, S.M.; Montagner, F.; Fabrizio, M. Mechanical properties and tribological behaviour of Mo-N coatings deposited via high power impulse magnetron sputtering on temperature sensitive substrates. Tribol. Int. 2018, 119, 372–380. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, S.; Wang, J. Magnetron sputtered transition-metal-nitrides thin films as electrode materials for supercapacitors: A review. J. Energy Storage 2024, 104, 114476. [Google Scholar] [CrossRef]

- Saravanan, I.; Elaya Perumal, A.; Vettivel, S.C.; Selvakumar, N.; Baradeswaran, A. Optimizing wear behavior of TiN coated SS 316L against Ti alloy using Response Surface Methodology. Mater. Des. 2015, 67, 469–482. [Google Scholar] [CrossRef]

- Kyzioł, K.; Koper, K.; Kaczmarek, Ł.; Grzesik, Z. Plasmochemical modification of aluminum-zinc alloys using NH3-Ar atmosphere with anti-wear coatings deposition. Mater. Chem. Phys. 2017, 189, 198–206. [Google Scholar] [CrossRef]

- Kaczmarek, Ł.; Kyzioł, K.; Sawicki, J.; Stegliński, M.; Radziszewska, H.; Szymański, W.; Kołodziejczyk, Ł.; Atraszkiewicz, R.; Kottfer, D.; Zawadzki, P. The influence of chemical groups on the mechanical properties of SiCNH coatings deposited on 7075 aluminum alloy. Thin Solid Film. 2013, 534, 15–21. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Shen, Q. Enhancing tribological performance by anodizing micro-textured surfaces with nano-MoS2 coatings prepared on aluminum-silicon alloys. Tribol. Int. 2018, 122, 84–95. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Gao, W.; Wang, D.; Chen, S.; Luan, J. A newly designed NiP duplex coating on friction stir welding joint of 6061-T6 aluminum. Surf. Coat. Technol. 2022, 448, 128940. [Google Scholar] [CrossRef]

- He, J.; Zhou, W.; Chen, S.; Wu, A.; Zhou, Y.; Chen, Y.; Wang, J.; Li, H. Tribological properties of MoS2 nano-flowers supported by porous alumina aperture array. Tribol. Int. 2021, 161, 107093. [Google Scholar] [CrossRef]

- Sopchenski, L.; Robert, J.; Touzin, M.; Tricoteaux, A.; Olivier, M.-G. Improvement of wear and corrosion protection of PEO on AA2024 via sol-gel sealing. Surf. Coat. Technol. 2021, 417, 127195. [Google Scholar] [CrossRef]

- Akbarzadeh, S.; Klumpp, R.E.; Mégret, A.; Ölmez, V.; Vitry, V.; Olivier, M.-G. Breakthrough in aluminum protection: Electrochemical and wear insights into sol-gel sealed PEO-coated AA2024-T3 and AA2198-T851. Surf. Coat. Technol. 2024, 494, 131510. [Google Scholar] [CrossRef]

- Shirani, A.; Joy, T.; Rogov, A.; Lin, M.; Yerokhin, A.; Mogonye, J.-E.; Korenyi-Both, A.; Aouadi, S.M.; Voevodin, A.A.; Berman, D. PEO-Chameleon as a potential protective coating on cast aluminum alloys for high-temperature applications. Surf. Coat. Technol. 2020, 397, 126016. [Google Scholar] [CrossRef]

- Lin, M.; Nemcova, A.; Voevodin, A.A.; Korenyi-Both, A.; Liskiewicz, T.W.; Laugel, N.; Matthews, A.; Yerokhin, A. Surface characteristics underpinning fretting wear performance of heavily loaded duplex chameleon/PEO coatings on Al. Tribol. Int. 2021, 154, 106723. [Google Scholar] [CrossRef]

- Lu, C.; Feng, X.; Yang, J.; Jia, J.; Yi, G.; Xie, E.; Sun, Y. Influence of surface microstructure on tribological properties of PEO-PTFE coating formed on aluminum alloy. Surf. Coat. Technol. 2019, 364, 127–134. [Google Scholar] [CrossRef]

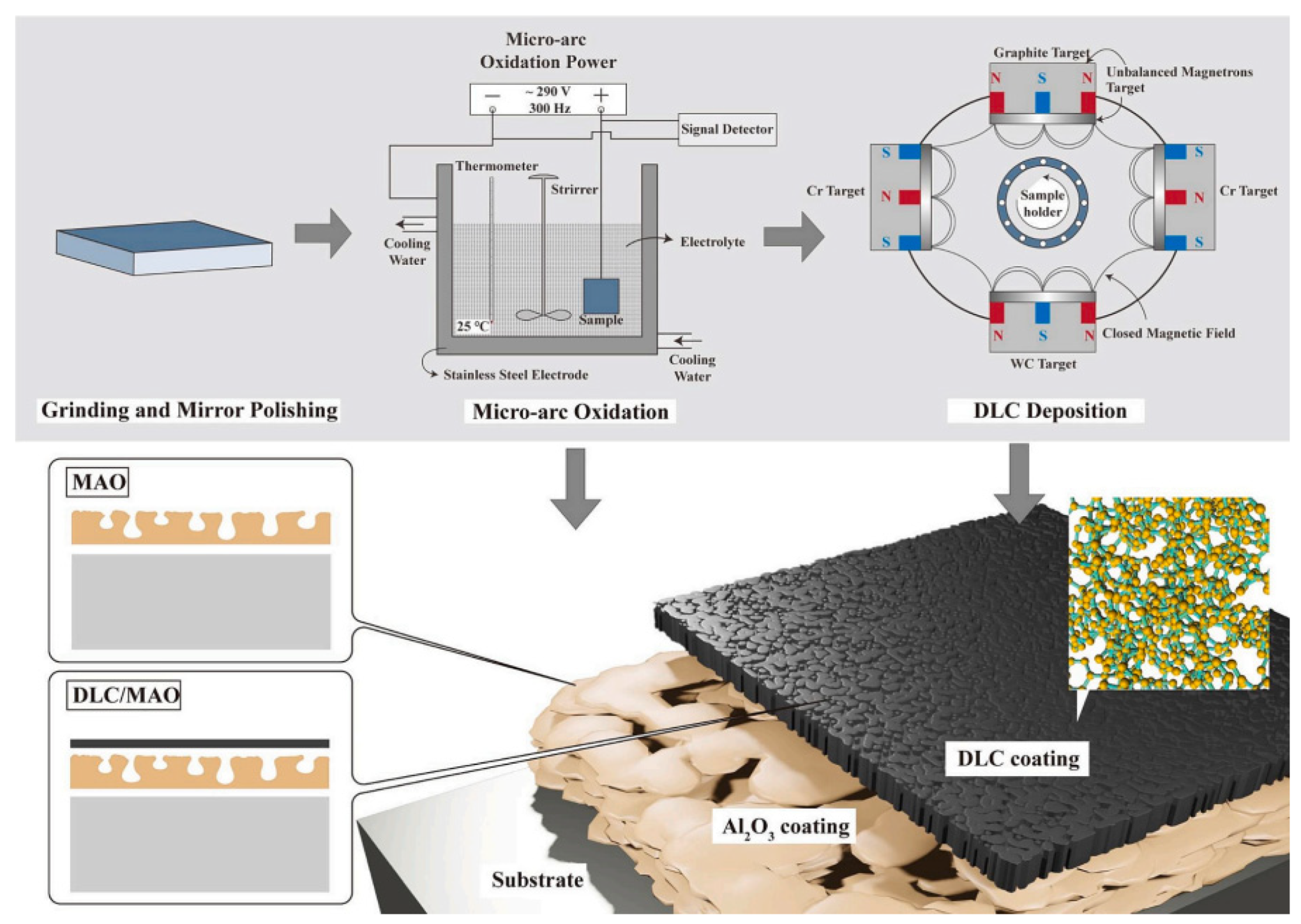

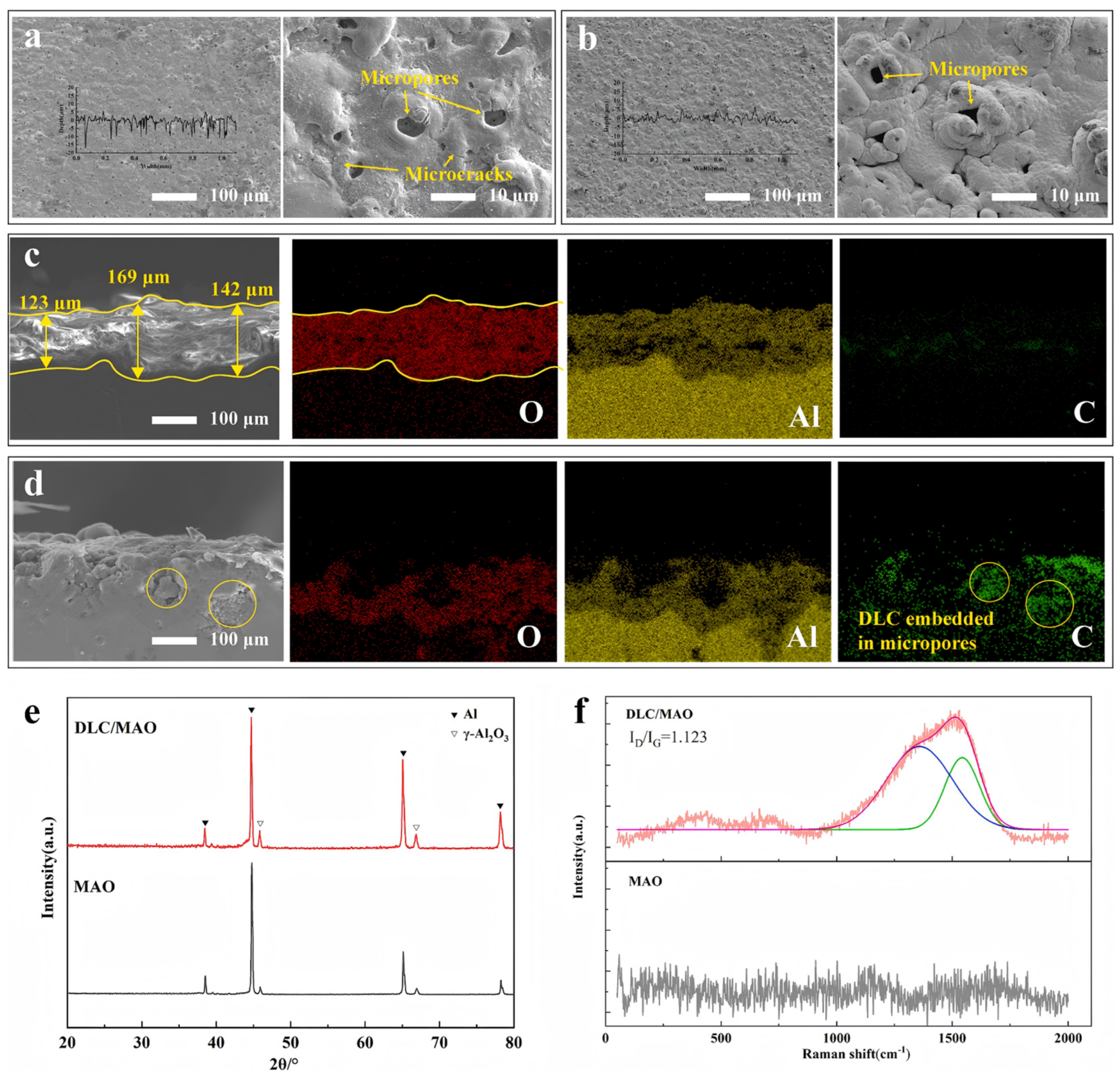

- Jin, L.; Li, Y.; Liu, C.; Fan, X.; Zhu, M. Friction mechanism of DLC/MAO wear-resistant coatings with porous surface texture constructed in-situ by micro-arc oxidation. Surf. Coat. Technol. 2023, 473, 130010. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, Y.; Xu, X.; Zhang, W.; Feng, R.; Li, H.; Gao, Z. Improving corrosion and wear resistances of 2195 Al–Li alloy by PEO and LDHs composite coating. J. Mater. Res. Technol. 2024, 28, 1044–1061. [Google Scholar] [CrossRef]

- Li, W.; Yan, Z.; Shen, D.; Zhang, Z.; Yang, R. Microstructures and tribological properties of MoS2 overlayers on MAO Al alloy. Tribol. Int. 2023, 181, 108348. [Google Scholar] [CrossRef]

- Wang, G.; Guo, L.; Ruan, Y.; Zhao, G.; Zhang, X.; Liu, Y.; Kim, D.-E. Improved wear and corrosion resistance of alumina alloy by MAO and PECVD. Surf. Coat. Technol. 2024, 479, 130556. [Google Scholar] [CrossRef]

- Sun, J.; Lu, H.; Tu, N.; Yang, H.; Wang, W.; Guo, F. Friction and corrosion characteristics of microarc oxidation/laser cladding palygorskite coating on 6061 aluminum alloy substrates. Surf. Coat. Technol. 2024, 487, 130992. [Google Scholar] [CrossRef]

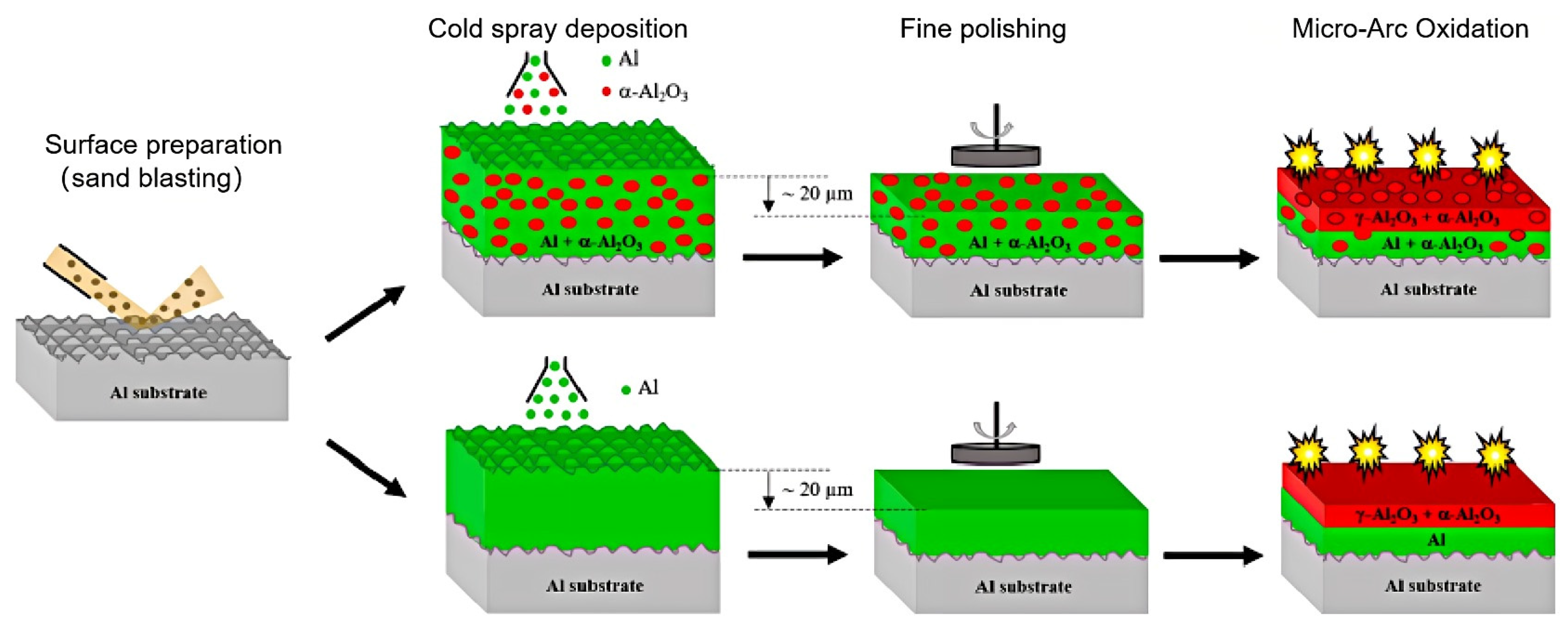

- Rao, Y.; Wang, Q.; Oka, D.; Ramachandran, C.S. On the PEO treatment of cold sprayed 7075 aluminum alloy and its effects on mechanical, corrosion and dry sliding wear performances thereof. Surf. Coat. Technol. 2020, 383, 125271. [Google Scholar] [CrossRef]

- Maizeray, A.; Marcos, G.; Cappella, A.; Planche, M.P.; Liao, H.; Henrion, G.; Czerwiec, T.; Martin, J. Effects of dispersed α-Al2O3 particles into a cold-sprayed aluminium coating on its subsequent oxidation by the PEO process. Surf. Coat. Technol. 2024, 482, 130713. [Google Scholar] [CrossRef]

- Staia, M.H.; Puchi Cabrera, E.S.; Iost, A.; Zairi, A.; Belayer, S.; Van Gorp, A. Tribological response of AA 2024-T3 aluminium alloy coated with a DLC duplex coating. Tribol. Int. 2015, 85, 74–87. [Google Scholar] [CrossRef]

- Lu, C.; Yao, J.W.; Wang, Y.X.; Zhu, Y.D.; Guo, J.H.; Wang, Y.; Fu, H.Y.; Chen, Z.B.; Yan, M.F. A novel anti-frictional multiphase layer produced by plasma nitriding of PVD titanium coated ZL205A aluminum alloy. Appl. Surf. Sci. 2018, 431, 32–38. [Google Scholar] [CrossRef]

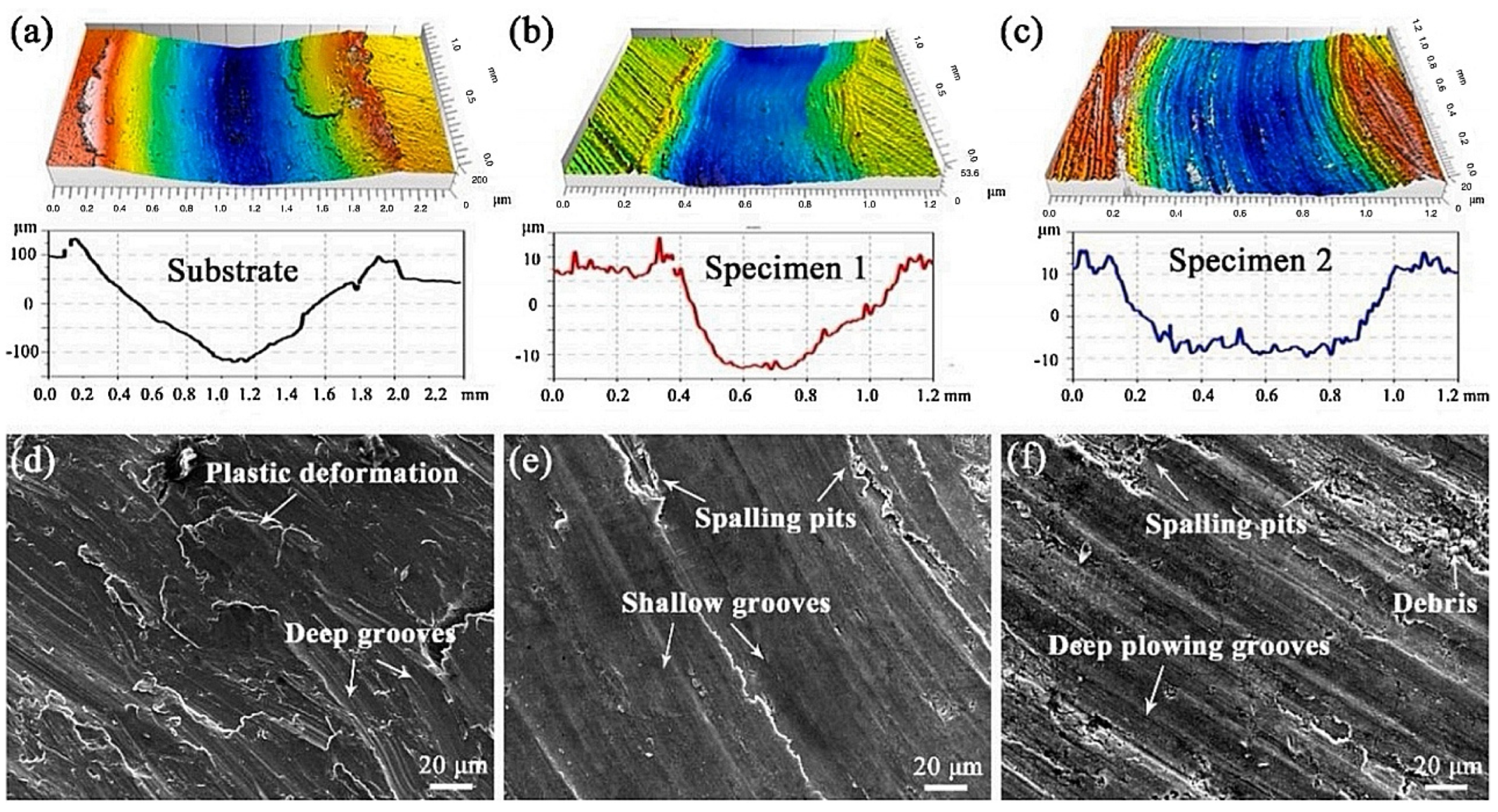

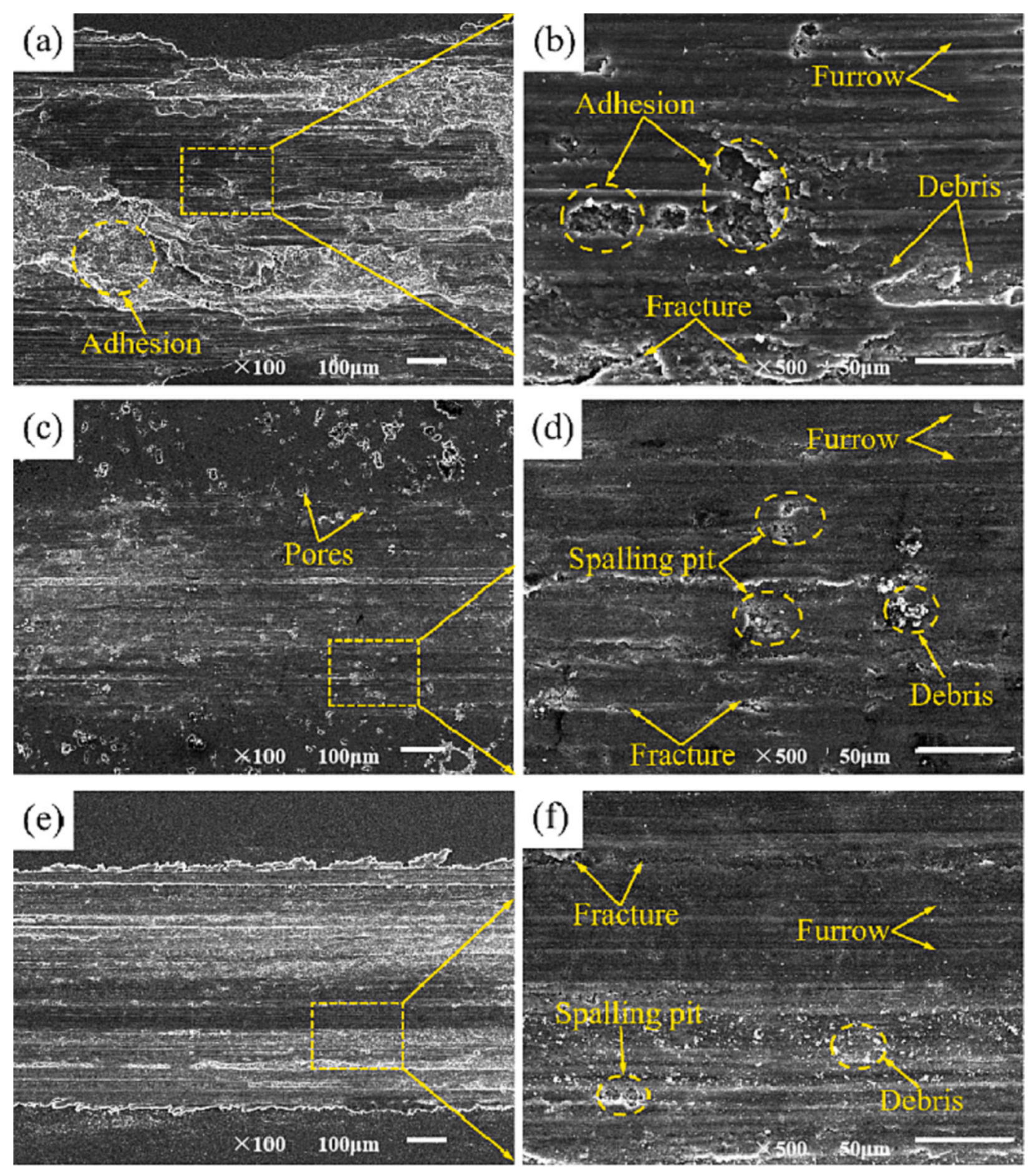

- Dong, T.-s.; Ma, Q.-l.; Fu, B.-g.; Li, J.-k.; Li, G.-l.; Lu, P.-w. Al-20Si/Cu-8P high-silicon aluminum alloy coating enhanced by laser remelting and refinement: Microstructure, mechanical properties and wear resistance. Surf. Coat. Technol. 2023, 475, 130120. [Google Scholar] [CrossRef]

- Yang, G.; Fu, B.; Dong, T.; Li, G. Effect of laser remelting on the microstructure and properties of the aluminum high silicon alloy coating. J. Mater. Process. Technol. 2024, 324, 118278. [Google Scholar] [CrossRef]

- Kaczmarek, Ł.; Adamczyk-Cieślak, B.; Mizera, J.; Stegliński, M.; Kyzioł, K.; Miedzińska, D.; Kołodziejczyk, Ł.; Szymański, W.; Kozanecki, M. Influence of chemical composition of Ti/TiC/a-C:H coatings deposited on 7075 aluminum alloy on their selected mechanical properties. Surf. Coat. Technol. 2015, 261, 304–310. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Maier, H.J.; Poll, G.; Wriggers, P.; Aldakheel, F.; Klose, C.; Nürnberger, F.; Pape, F.; Böhm, C.; Chugreeva, A.; et al. Numerical investigations regarding a novel process chain for the production of a hybrid bearing bushing. Prod. Eng. 2020, 14, 569–581. [Google Scholar] [CrossRef]

- Coors, T.; Mildebrath, M.; Büdenbender, C.; Saure, F.; Faqiri, M.Y.; Kahra, C.; Prasanthan, V.; Chugreeva, A.; Matthias, T.; Budde, L.; et al. Investigations on Tailored forming of AISI 52100 as Rolling Bearing Raceway. Metals 2020, 10, 1363. [Google Scholar] [CrossRef]

| One-Step Methods | Substrate | Coating | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Alloy Grade | COF | Wear Rate | Composition | Thickness | COF | Wear Rate | |||

| AO | AA1050 | - | 5.3~32.9 mg | Al, Al2O3, Si3N4 | - | 0.2 | 0.6~6.7 mg | [21] | |

| ~1.16 | 1.5 mm3 | Al2O3, PTFE | 14~24 μm | ~0.9 | 0.002 mm3 | [22] | |||

| AA2017-T4 | - | - | Al2O3, DLC | - | 0.44~0.72 | - | [23] | ||

| AA5052 | 1 | - | Al, O | 4~15 μm | 0.75~1 | - | [24] | ||

| 5086 | 1~1.4 | - | Al, Al(OH)3, Amorphous phase | 52 ± 1 μm | 0.73 ± 0.13 | 6.7 × 10−4 mm3/N·m | [25] | ||

| 6061 | - | - | Al2O3 | 18 μm | 0.12~0.7 | 0.01~0.2 mm3 | [26] | ||

| MAO | Pure Al | - | - | Al2O3, Al, Si, Fe, O | - | 0.25~0.38 | 2 mg | [27] | |

| - | - | Al, α-Al2O3, γ-Al2O3, AlPO4, Na, O, C, P, Si | - | 0.217~0.705 | [28] | ||||

| 1060 | - | - | α-Al2O3, γ-Al2O3, Si, P | 5.95~7.95 μm | 0.31~0.79 | - | [29] | ||

| 2024 | - | - | α-Al2O3, γ-Al2O3, Si, P, h-BN | 12.26~19.85 μm | 0.4~0.6 | 4.3 × 10−4~1 × 10−3 mm3/N·m | [30] | ||

| 0.3~0.5 | - | α-Al2O3, γ-Al2O3, AlPO4, KSi3Al3O10(OH)2 | - | 0.3~0.5 | [31] | ||||

| 0.88~0.9 | 4.5 × 10−4 mm3/N·m | α-Al2O3, γ-Al2O3, Na, Si, K, Ca, Fe, P | 180 μm | 0.55~0.85 | 10−5~10−7 mm3/N·m | [32] | |||

| 2024-T3 | 0.46 | 1 mg | α-Al2O3, x-Al2O3, Al3.21Si0.47, amorphous phase | ~40 μm | 0.08 | 0.2 mg | [33] | ||

| 2A50 | 0.4 | - | α-Al2O3, γ-Al2O3, MoS2, Al6Si2O13 | 20~75 μm | 0.1 | 5.28 × 10−4 cm3/N·m | [34] | ||

| - | - | γ-Al2O3 | 45 μm | 0.35~0.55 | - | [35] | |||

| 5086 | 1~1.4 | - | α-Al2O3, γ-Al2O3, etc | 58 ± 1 μm | 0.92 ± 0.06 | 2.7 × 10−5 mm3/N·m | [25] | ||

| 5754 | - | - | γ-Al2O3, β-Al2O3, AlPO4, Al2Mo3C | 3.6~11.6 μm | - | 3.09 × 10−3~3.54 × 10−3 mm3/N·m | [36] | ||

| 6061 | 0.5~0.75 | 3.91 × 10−3 mm3/N·m | α-Al2O3, γ-Al2O3, AlPO4 | 21.3 ± 2.9 μm | 0.35 | 4.8 × 10−5 mm3/N·m | [37] | ||

| 0.4~0.5 | 30.7~93.5 mg | Al6Si2O13, α-Al2O3, γ-Al2O3, Amorphous alumina | 125 μm | - | 18.2~86.6 mg | [38] | |||

| 6063 | - | - | Al2O3, TiO2, PTFE | ~31.4 μm | 0.28 | (0.92 ± 0.23) × 10−7 mm3/N·m | [39] | ||

| 6082 | - | - | α-Al2O3, γ-Al2O3, 2Al2O3, Al6Si2O13 | 40 ~113 μm | 0.75~0.83 | 4.75 × 10−6~4.23 × 10−5 mm3/N·m | [40] | ||

| 6082-T6 | 0.4~0.5 | 3.9 × 10−4~5.5 × 10−4 mm3/N·m | α-Al2O3, γ-Al2O3, Al6Si2O13 | ~90 μm | 0.5~0.75 | 9.3 × 10−6~1.6 × 10−5 mm3/N·m | [41] | ||

| 7075 | 0.1~1.4 | - | α-Al2O3, γ-Al2O3, Al6Si2O13 | 58 ± 3 μm | 0.09~0.75 | 2.4 × 10−5 ~7.31 × 10−4 mm3/N·m | [42] | ||

| 7N01 | 0.4~0.6 | 2.07 × 10−4 g/min | α-Al2O3, γ-Al2O3 | 3.8~9.3 μm | 0.2~0.3 | 2.35 × 10−5 g/min | [43] | ||

| A356 | 0.46~0.74 | 2.94 × 10−5 mm3/N·m | - | 28~31 μm | 0.25~0.73 | 4.1 × 10−7~2.59 × 10−5 mm3/N·m | [44] | ||

| D16T | - | 32.5 ± 2.1 mg | α-Al2O3, γ-Al2O3, SiO2, etc | 60~65 μm | 0.346~0.379 | 7.1 ± 0.6~4.8 ± 0.3 mg | [45] | ||

| AlSi10Mg | 0.35~0.4 | 2.1 × 10−3 mm3/N·m | γ-Al2O3, 3Al2O3·2SiO2, amorphous phases | 9~13 μm | 0.2~0.5 | 2.1 × 10−5~3.6 × 10−4 mm3/N·m | [46] | ||

| Laser methods | LSA | 1100 | - | 4.85 × 10−8 g/mm | Al8Mo3, Al5Mo, AlMo3, α-Al | 120~200 μm | - | 9.60 × 10−9 ~1.51 × 10−8 g/mm | [47] |

| 6061 | - | - | Ti, B, Al, Sc | - | 0.4 | 24.8 mg/h | [48] | ||

| 0.46 | 2.48 × 10−9 m3 | TiB2, TiC, Fe4Al13, Cr2B, Cr7C3, α-Al | - | 0.25~0.32 | 1.8 × 10−10 m3 | [49] | |||

| LC | 5083 | - | 3.5 × 10−4 mm3/N·m | Al, Cr, Fe, Co, Ni, Cu | - | - | 6.6 × 10−7~9.4 × 10−5 mm3/N·m | [50] | |

| 7075 | - | 8.2 mg | Ti, TiBCN | - | 0.182 | 2.4 mg | [51] | ||

| Spraying methods | CS | 2024 | 0.45~1.2 | - | Al2O3 | ~5 mm | - | 6.5 mm3/N·m | [52] |

| 6061 | CoCrFeMnNi | ~1 mm | 0.3~0.7 | 5.10 × 10−5 mm3/N·m | [53] | ||||

| ADC12 | ~1.06 | 8.96 × 10−4 mm3/N·m | Ni, Ti3AlC2 | 500~800 μm | 0.64~0.84 | 1.87 × 10−5~1.38 × 10−4 mm3/N·m | [54] | ||

| PS/SPS | Al 2014 | 0.73 | - | GNs | 1.9~3.1 µm | 0.06~0.17 | - | [55] | |

| 2A12 | 0.6 ± 0.2 | 5.56 × 10−2 mm3 | α-Al, β-Si, Al9Si, Al3.21Si0.47, CuAl2 | 500 μm | 0.4 ± 0.06 | 1.56 × 10−2 mm3 | [56] | ||

| 6061 | 0.46 | 8.26 × 10−3 mm3/N·m | α-Al, β-Si, θ-Al2Cu | - | 0.31 | 1.62 × 10−3 mm3/N·m | [57] | ||

| 7005 | 0.4~0.5 | 7.6~16.4 mg | 83 wt.% Ni60, 15 wt.% Al2O3, 2 wt.% CeO2 | - | 0.15~0.3 | 0.7~0.9 mg | [58] | ||

| YL113 | - | - | Al-25Si-4Cu-0.9Mg | - | 0.177 | 1.46 × 10−3 mm3 | [59] | ||

| ZL109 | - | - | TiO2, TiO, Ti2O3 | ~400 μm | 0.05~0.09 | 2.1 × 10−6~3.5 × 10−6 mm3/N·m | [60] | ||

| ZL109 | 0.1~0.25 | - | Ni60 alloy | 300 μm | 0.1~0.25 | 6.45~14.4 mg | [61] | ||

| Al-Si | 0.60~0.81 | 3.31 × 10−4~5.9 × 10−4 g/m | ZAC | 251 ± 0.07 μm | 0.44~0.62 | 9.1 × 10−5~2 × 10−4 g/m | [62] | ||

| FZA | 253 ± 0.05 μm | 0.36~0.47 | 7.8 × 10−5~9.8 × 10−5 g/m | ||||||

| Spray | 7050 | - | - | Ti3AlC2, PI, MPS | - | 0.58 | 2.03 × 10−5 mm3/N·m | [63] | |

| - | - | PDMS, PI | - | 0.07 | 4.8 × 10−7 mm3/N·m | [64] | |||

| Deposition methods | EP | 6061 | - | - | Ni, P, ZnO, Aliquat 336 | - | - | ~10−7~2.5 × 10−4 mm3/N·m | [65] |

| A356 | 0.64 | - | Ni, B, CeO2 | 40 μm | 0.531 | - | [66] | ||

| LM24 | - | 4.90 × 10−12 m3/N·m | Ni, P | ~15 μm | - | 0.52 × 10−12 m3/N·m | [67] | ||

| ED | 1060 | 0.85~1.25 | 3.1 × 10−3 mm3/N·m | Al3C4, Al2O3, ZrO2 | ~50 μm | ~0.2 | 2.3 × 10−4 mm3/N·m | [68] | |

| Al3C4, Al2O3 | ~65 μm | ~0.37 | 1.4 × 10−4 mm3/N·m | ||||||

| 1100 | 0.5 | 300 μm | Co-Cr-Mo alloy | - | 0.35 | 160 μm | [69] | ||

| 2024-T6 | 0.29 | 4.73 × 107 μm3 | Ni | 25 μm | 0.07 | 1.87 × 107 μm3 | [70] | ||

| Ni, GO | 41.6 ~51.6 μm | 0.06 | 1.48 × 107 μm3 | ||||||

| A356 | - | - | Ni, SiC | ~100 ± 5 μm | 0.527 | 1.63 × 10−5 mm3/N·m | [71] | ||

| PVD | 7075 | - | - | Ti, C | - | 0.16 | 5 × 107 mm3/N·m | [72] | |

| Ti, C, N | - | 0.13~0.15 | 1.43 × 108~2.11 × 108 mm3/N·m | ||||||

| 0.156 | - | Al, Cr, N | 2.566 μm | 0.133 | - | [73] | |||

| Al-Si | 0.34 ± 0.01 | 4.22 × 10−3 mm3/N·m | Cr, Al, N | 2.79 μm | 0.18 ± 0.02 | 8.69 × 10−4 mm3/N·m | [74] | ||

| - | 6.4 × 10−6 ~9.8 × 10−6 mm3/N·m | Al, Si | ~4 mm | 0.23~0.35 | 0.9 × 10−6~1.4 × 10−6 mm3/N·m | [75] | |||

| AlMg1SiCu | - | - | a-C:H, C6H5CH3, C2Cl4/C2Cl4 | >1 μm | 0.042~0.070 | - | [76] | ||

| AlSi10Mg | 0.6~0.9 | 10−2 mm3/N·m | C, O | 1.7 μm | 0.15~0.41 | 1 × 10−6~1.2 × 10−5 mm3/N·m | [77] | ||

| CVD | 3004 | - | - | Si-doped DLC | 5.5~28.3 μm | - | 6.1 × 10−7~8.8 × 10−7 mm3/N·m | [78] | |

| 6061 | 0.65 | - | C | - | 0.2~0.25 | - | [79] | ||

| AA6061 | 0.6 | - | (Si-CH3), Si-(CH3)3, (C=C), (C≡C), (C-H) | 1.61~2.39 μm | ~0.17 | - | [80] | ||

| 7075 | 0.52 | 5.33 × 10−4 mm3/N·m | a-C:H, CH4 | 4 ~28 μm | 0.05~0.15 | 1.05 × 10−8~8.51 × 10−8 mm3/N·m | [81] | ||

| Other One-step methods | Resistance seam welding | A6061 | - | 5.66 × 10−4 mm3/N·m | Al, Fe, Cr, Co, Ni | 420 μm | - | 0.29 × 10−4 mm3/N·m | [82] |

| Al7075 | - | - | WC, SHA | 600 μm | - | 0.2 × 10−11~1.5 × 10−11 mm3/N·m | [83] | ||

| Spin coating | 6061 | - | - | AFD, f-BNNs-ZIF-8@BTA | - | 0.64 | 5.00 × 10−5 mm3/N·m | [84] | |

| Two-component synthesis method | - | 6.62 × 10−3 mm3/N·m | PU, Al, NiAA | 120 μm | 2.00 × 10−3~5.33 × 10−3 mm3/N·m | [85] | |||

| Two-Step Method | Substrate | Coating | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Alloy Grade | COF | Wear Rate | Composition | Thickness | COF | Wear Rate | |||

| AO + Post-treatment | AO + Ultrasonic Impregnation | ZL109 | 0.63 | 6.4 × 10−6 mm3/N·m | Nano-MoS2, Al, Si, O | 3 µm | 0.48 | 3.4 × 10−6 mm3/N·m | [124] |

| AO + MAO | 6082 | - | - | γ-Al2O3, Na, Si, P, K | 40–100 µm | 0.75–0.83 | 4.752 × 10−7 mm3/N·m | [40] | |

| AO + ED | 6061-T6 | 0.84 | 0.66 × 10−2 mm3/N·m | AAO, Ni-P | 5.51 µm | 0.75 | 0.08 × 10−2 mm3/N·m | [125] | |

| AO + PVD | 6061 | - | - | MoS2, AAO, Al | 50.35–50.4 µm | 0.15 | 1.1 × 10−5~2.4 × 10−5 mm3/N·m | [126] | |

| MAO + Post-treatment | MAO + Sealing | AA2024 | 0.9 | 5.7 × 10−4 mm3/N·m | γ-Al2O3, α-Al2O3, Mg, Cu, Si, Na, K, GPTMS, TEOS | 19.596 ± 9.192 µm | 0.6–0.65 | 1.66 × 10−6~1.86 × 10−6 mm3/N·m | [127] |

| AA2024-T3 | 0.6–0.8 | - | α-Al2O, γ-Al2O3, amorphous alumina, TEOS, GPTMS | 11.94 ± 4.7 µm | 0.5 | - | [128] | ||

| AA2098-T851 | 0.6–0.8 | - | α-Al2O, γ-Al2O3, amorphous alumina, TEOS, GPTMS | 11.38 ± 4.6 µm | 0.6 | - | [128] | ||

| 2A12 | - | - | Al2O3, Paraffin | 19.59 µm | 0.1–0.2 | - | [92] | ||

| MAO + Burnishing | A356 | 0.4–0.9 | - | Al2O3, Graphite, MoS2, Sb2O3 | 33–40 µm | 0.08–0.2 | - | [129] | |

| 6082 | - | - | α-Al2O, γ-Al2O3, Pure Graphite, MoS2, Sb2O3 | 26.7 ± 1.6 µm | 0.07–0.15 | - | [130] | ||

| MAO + VI | 2024 | - | - | Al, γ-Al2O3, PTFE | 56.35 ± 2.1 µm | 0.13 | 7.47 × 10−16 mm3/N·m | [131] | |

| MAO + Silicone Oil Impregnation | 6061 | 0.691 ± 0.060 | - | α-Al2O, γ-Al2O3, 3Al2O3·2SiO2 | 17 ± 5 μm | 0.137 ± 0.016 | - | [100] | |

| MAO + PVD | Untreated Al Alloy | - | - | Al, γ-Al2O3, DLC | - | 0.17 | - | [132] | |

| MAO + HS | 2019Al-Li | 0.8 | 3.01 × 10−2 mm3/N·m | Al2O3, SiO2, Mg/Al LDHs | 17.9–18 µm | 0.48 | 3.17 × 10−4 mm3/N·m | [133] | |

| 6063 | - | - | MoS2, γ-Al2O3, Mullite Phases | 8.8 µm | 0.21 | 2.94 × 10−7 mm3/N·m | [134] | ||

| MAO + PECVD | 2A12 | 0.375 | - | α-Al2O3, γ-Al2O3, Si-CH3, C-H, Si-O-Si | 11.25 µm | 0.23 | 2.04 × 10−6 mm3/N·m | [135] | |

| MAO + LC | 6061 | 0.59 | 412.106 × 10−6 mm3/N·m | Al, α-Al2O3, γ-Al2O3, Pal | - | 0.15–0.43 | 7.873 × 10−6 mm3/N·m | [136] | |

| Other methods | CS + MAO | 7075 | 0.35–0.5 | - | γ-Al2O3, α-Al2O3 | 15–20 µm | 0.64–0.68 | 1.22 × 10−6 mm3/N·m | [137] |

| 2017 | 0.63 | 1.1 × 10−3 ± 4 × 10−4 mm3/N·m | α-Al2O3, γ-Al2O3, Si, Na, K | 23 ± 5 µm | 0.65 | 7.0 × 10−3 ± 3 × 10−4 mm3/N·m | [138] | ||

| EP + PACVD | AA2024-T3 | 0.8 | 215 × 10−14 m3/N·m | DLC, CNiPCr, Ni-P | 56.2–78.2 µm | 0.12 | 1.8 × 10−17 m3/N·m | [139] | |

| MS + PN | ZL205A | 0.75 | 5.56 × 10−8 g/r·N | TiN, TiN0.3, Al3Ti | 24 µm | 0.45 | 2.49 × 10−8 g/r·N | [140] | |

| Solution Mixed + EST | AA2028 | - | - | UHMWPE, GNPs | 96.4 ± 4.3 µm | 0.18 | 1.3 × 10−4 mm3/N·m | [112] | |

| PS + LR | A356 | 0.48 | - | α-Al, β-Si, Al2Cu, AlP | 600 µm | 0.41–0.44 | - | [141] | |

| 6061 | - | - | α-Al, β-Si, θ-Al2Cu | - | 0.31 | 1.02 × 10−5 mm3/N·m | [142] | ||

| RF PACVD + PVD | 7075 | - | - | Ti, TiC, a-C:H, TiAl3 | 1 µm | 0.05 | 9.0 × 10−5 mm3/N·m | [143] | |

| Depth/μm | Width/μm | Volume/μm3 | Wear Rate/× 10−5 mm3/N·m | |

|---|---|---|---|---|

| Sprayed | 32.96 | 746.18 | 5.32 × 107 | 1.64 |

| Remelted | 19.35 | 666.92 | 3.29 × 107 | 1.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, B.; Ren, R.; Zhang, H.; Man, T.; Cui, X.; Liu, T.; Zhao, T.; Luhovskyi, Y.; Nong, Z. Research Advancements of Wear-Resistant Coatings Fabricated on Aluminum and Its Alloys. Coatings 2025, 15, 750. https://doi.org/10.3390/coatings15070750

Jia B, Ren R, Zhang H, Man T, Cui X, Liu T, Zhao T, Luhovskyi Y, Nong Z. Research Advancements of Wear-Resistant Coatings Fabricated on Aluminum and Its Alloys. Coatings. 2025; 15(7):750. https://doi.org/10.3390/coatings15070750

Chicago/Turabian StyleJia, Bohao, Ruoqi Ren, Hongliang Zhang, Tiannan Man, Xue Cui, Teng Liu, Tianzhang Zhao, Yurii Luhovskyi, and Zhisheng Nong. 2025. "Research Advancements of Wear-Resistant Coatings Fabricated on Aluminum and Its Alloys" Coatings 15, no. 7: 750. https://doi.org/10.3390/coatings15070750

APA StyleJia, B., Ren, R., Zhang, H., Man, T., Cui, X., Liu, T., Zhao, T., Luhovskyi, Y., & Nong, Z. (2025). Research Advancements of Wear-Resistant Coatings Fabricated on Aluminum and Its Alloys. Coatings, 15(7), 750. https://doi.org/10.3390/coatings15070750