From Molecular Design to Scenario Adaptation: Cutting-Edge Exploration of Silicone-Modified Polyurethane in Smart Sports Fields

Abstract

1. Introduction

2. Preparation and Performance Regulation of Silicone-Modified PU

2.1. Modification Mechanisms and Chemical Pathways

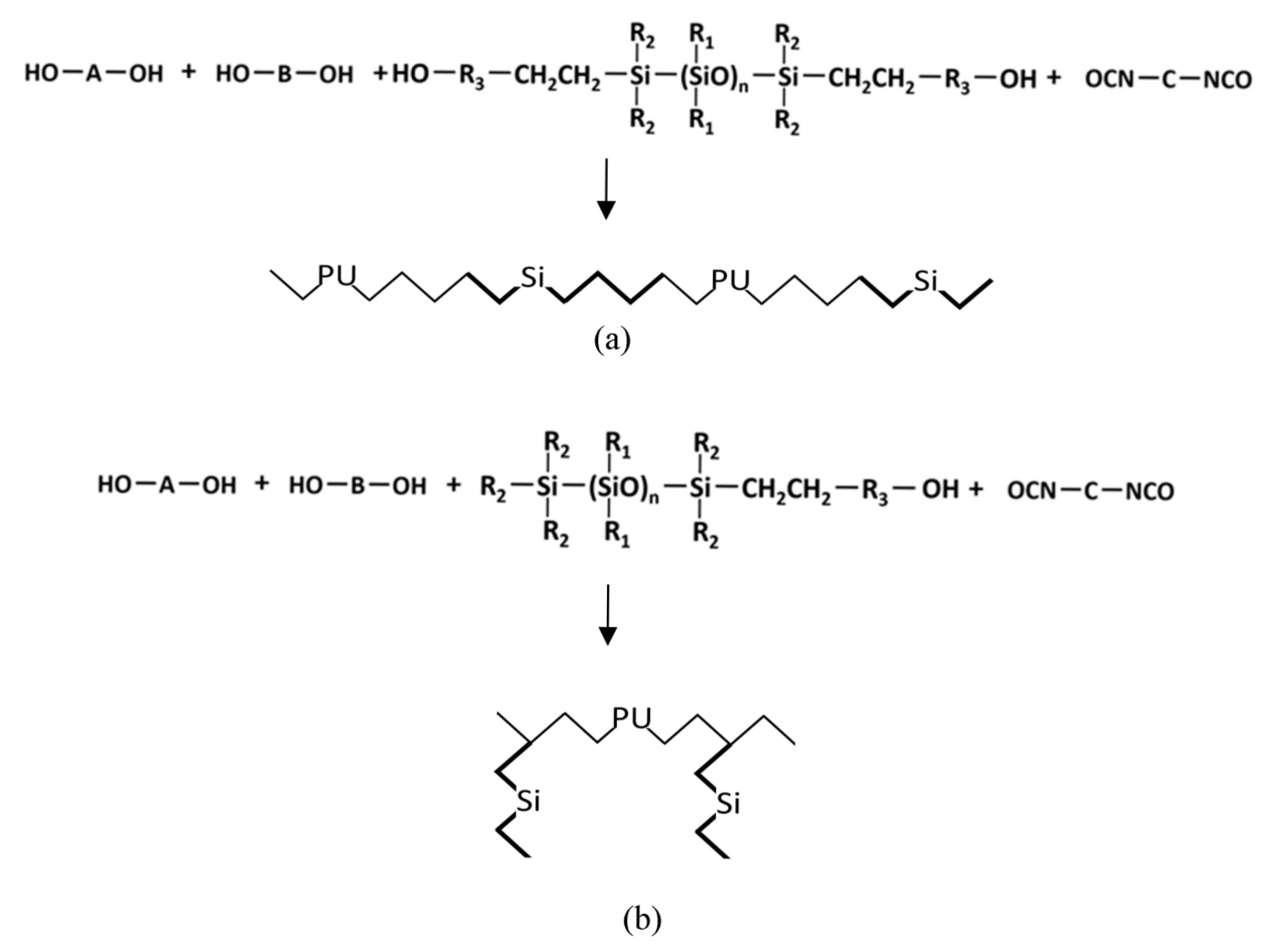

2.1.1. Principles of Copolymerization Modification

2.1.2. Technical Implementation of Physical Blending Method

2.1.3. Graft Modification Chemical Mechanism

2.2. Optimization of Key Preparation Processes

2.2.1. One-Step Synthesis Process

2.2.2. Prepolymer Chain Extension Technology

2.2.3. Synergistic Control of Process Parameters for Material Performance Optimization

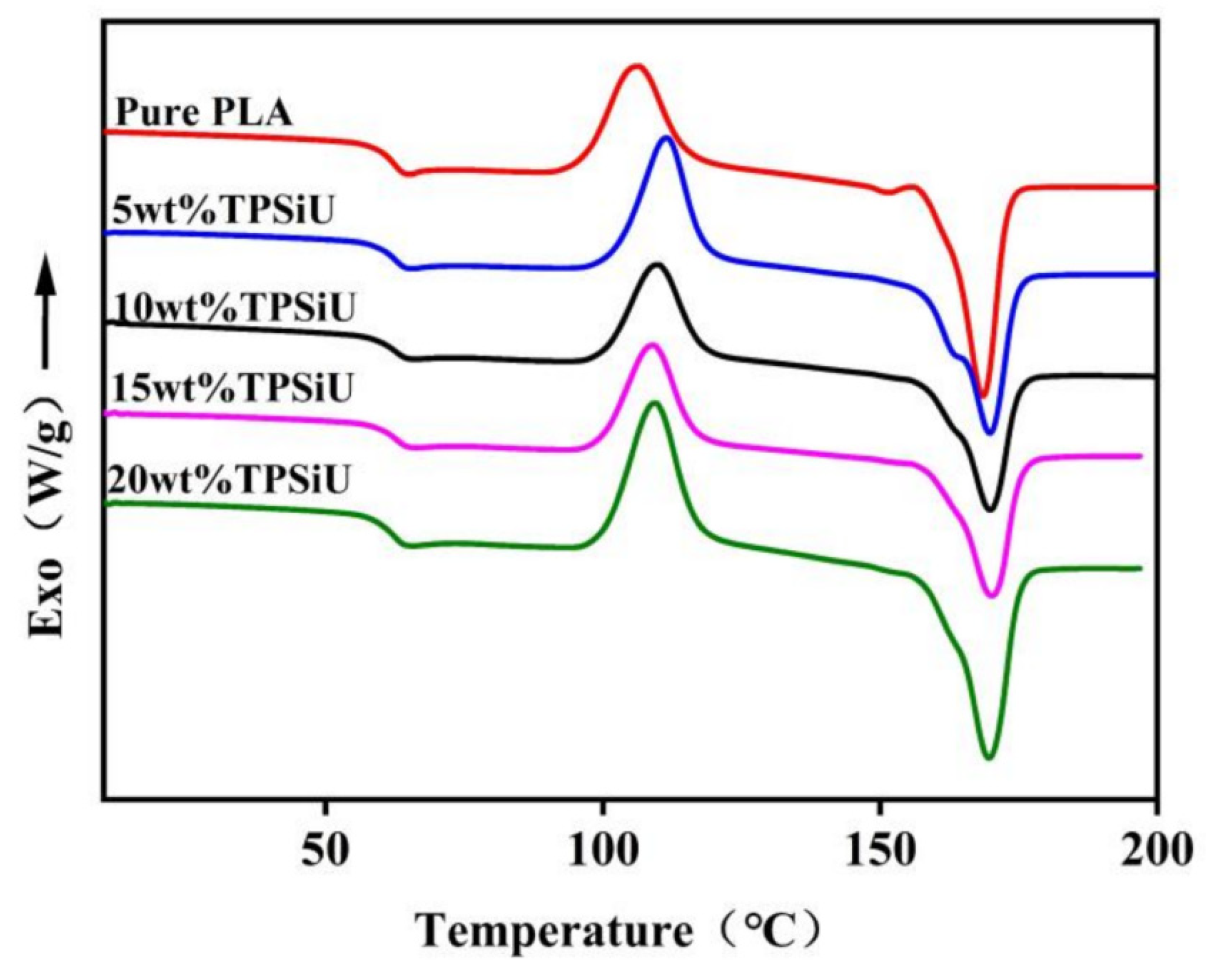

2.3. Performance Characterization System of Silicone-Modified Polyurethane

2.3.1. Comprehensive Evaluation of Mechanical Properties

2.3.2. Weather Resistance Evaluation

2.3.3. Degradation and Recycling Performance Analysis

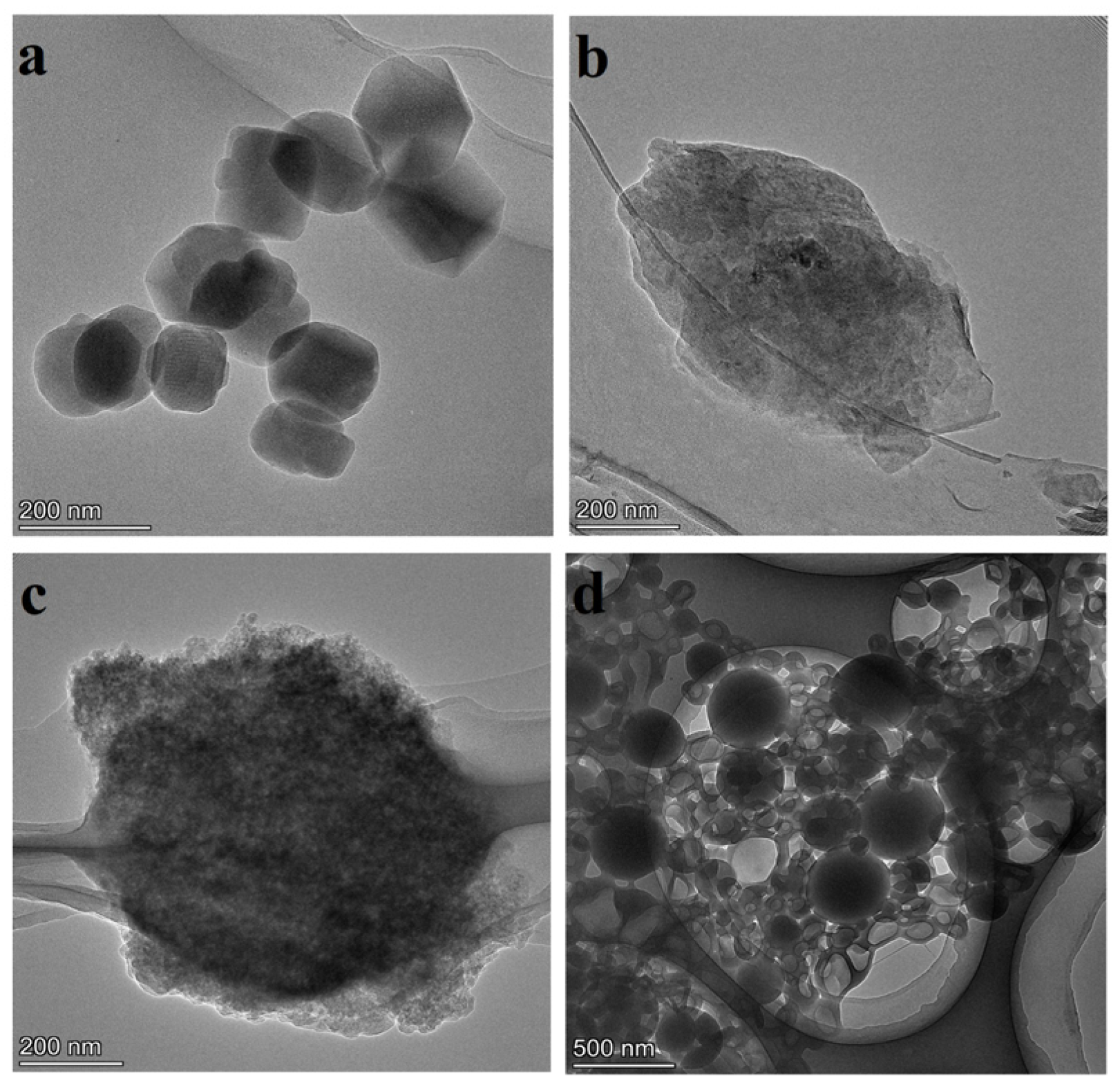

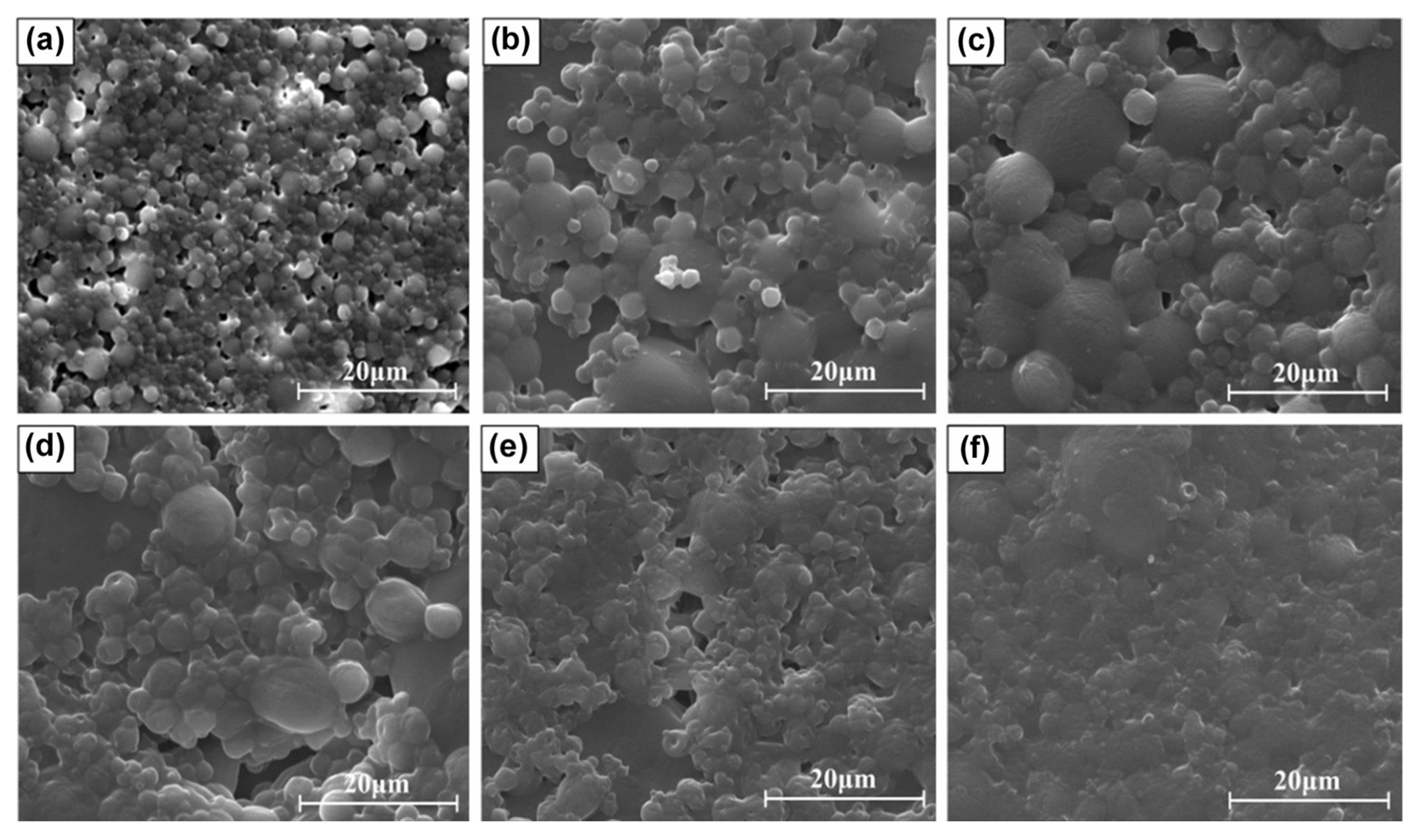

2.3.4. Microscopic Morphology Analysis

3. Application Scenarios of Silicone-Modified PU in Sports Fields

3.1. Application Scenarios of Silicone-Modified Polyurethane in Athletic Fields

3.2. Application of Silicone-Modified Polyurethane in Gymnasium Flooring Scenarios

3.3. Application of Silicone-Modified Polyurethane in Special Sports Venues

4. Challenges of Applying Silicone-Modified Polyurethane in Sports Venues

4.1. Compatibility Issues Between Silicone and PU

4.2. Cost Issues of Applying Silicone-Modified Polyurethane Materials to Sports Venues

4.3. Inadequate Quality Testing Standards for Silicone-Modified Polyurethane in Sports Venues

4.4. Maintenance and Care Challenges of Organic Silicon-Modified Polyurethane for Sports Fields

5. Current Research Challenges and Future Directions

5.1. Innovative Design of Silicone-Modified Polyurethane Materials

5.2. Silicone-Modified Polyurethane Materials Must Meet Environmental Requirements

5.3. International Development Trends of Silicone-Modified Polyurethane Materials

5.4. Future Research Priorities for Silicone-Modified Polyurethane Materials in Sports Fields

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Berrocal, M.J.; Badr, I.H.A.; Gao, D.; Bachas, L.G. Reducing the Thrombogenicity of Ion-Selective Electrode Membranes through the Use of a Silicone-Modified Segmented Polyurethane. Anal. Chem. 2001, 73, 5328–5333. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Xu, J.; Fan, H.; Li, R.; Shi, M.; Liu, Y.; Wang, B.; Liu, P. Preparation of hydroxy-terminated polydimethylsiloxane and nano-SiO2 hydrophobic polyurethane coated urea and investigation of controlled nitrogen release. Chem. Eng. Sci. 2025, 302, 120728. [Google Scholar] [CrossRef]

- Fan, J.; Liang, X.; Yu, W.W.; Fu, D.; Yu, Y.; Liu, H.; Zhang, J. Partial crystalline organosilicon-based polysiloxane-polyurethane copolymers. Eur. Polym. J. 2023, 198, 112416. [Google Scholar] [CrossRef]

- Sikdar, P.; Dip, T.M.; Dhar, A.K.; Bhattacharjee, M.; Hoque, M.S.; Ali, S.B. Polyurethane (PU) based multifunctional materials: Emerging paradigm for functional textiles, smart, and biomedical applications. J. Appl. Polym. Sci. 2022, 139, e52832. [Google Scholar] [CrossRef]

- Zhang, Y.; Shang, J.; Lv, F.; Chu, P.K. Synthesis and characterization of novel organosilicon-modified polyurethane. J. Appl. Polym. Sci. 2012, 125, 1486–1492. [Google Scholar] [CrossRef]

- Pathak, R.; Punetha, V.D.; Bhatt, S.; Punetha, M. A review on carbon nanofiller-based hyperbranched polyurethane nanocomposites: Synthesis strategies, applications and challenges. Mater. Sci. 2024, 59, 16069–16111. [Google Scholar] [CrossRef]

- Kayan, A.; Hoebbel, D.; Schmidt, H. Complexation of titanium alkoxides with pentenoic acid and allylacetoacetate and their hydrolysis and addition reactions with H-silanes. J. Appl. Polym. Sci. 2005, 95, 790–796. [Google Scholar] [CrossRef]

- Ghosh, T.; Voit, B.; Karak, N. Polystyrene/thermoplastic polyurethane interpenetrating network-based nanocomposite with high-speed, thermo-responsive shape memory behavior. Polymer 2020, 200, 122575. [Google Scholar] [CrossRef]

- Li, Y.; Zhuo, H.; Chen, H.; Chen, S. Novel photo-thermal staged-responsive supramolecular shape memory polyurethane complex. Polymer 2019, 179, 121671. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Q.; Li, J.; Ling, L.; Zhang, G.; Sun, R.; Wong, C.P. UV-triggered self-healing polyurethane with enhanced stretchability and elasticity. Polymer 2019, 172, 187–195. [Google Scholar] [CrossRef]

- Yin, C.; Okamoto, R.; Kondo, M.; Tanaka, T.; Hattori, H.; Tanaka, M.; Sato, H.; Iino, S.; Koshiro, Y. Electrospinning of Block and Graft Type Silicone Modified Polyurethane Nanofibers. Nanomaterials 2018, 9, 34. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Chen, H.; Chen, S. New zwitterionic polyurethanes containing pendant carboxyl-pyridinium with shape memory, shape reconfiguration, and self-healing properties. Polymer 2019, 180, 121727. [Google Scholar] [CrossRef]

- Zhuo, H.; Mei, Z.; Chen, H.; Chen, S. Chemically-crosslinked zwitterionic polyurethanes with excellent thermally-induced multi-shape memory effect and moisture-induced shape memory effect. Polymer 2018, 148, 119–126. [Google Scholar] [CrossRef]

- Go, C.W.; Yang, J.H.; Kwak, D.; Kim, G.-W.; Jeong, H.M. Waterborne polyurethane modified with silicone macromer and the nylon airbag coated with it. Text. Res. J. 2016, 86, 2015–2021. [Google Scholar] [CrossRef]

- Li, Y.; Gu, J.; Cao, K.; Qin, X. Effects of fluorosilane addition on polyurethane electrospun membranes with waterproof and breathable performance. Text. Res. J. 2024, 94, 1761–1770. [Google Scholar] [CrossRef]

- Bao, Y.; Gao, L.; Han, P.; Liu, F.; Zhou, J.; Zhang, W. Multi-color photochromic waterborne polyurethane with high color fastness from hydroxyl-functionalized trichromatic spiropyrans. Dyes Pigm. 2025, 235, 112577. [Google Scholar] [CrossRef]

- Hu, J.; Zhou, H.; Wang, X.; Cui, S.; Pu, S. Preparation of photochromic microcapsules with a diarylethene and polyurethane/chitosan for smart textiles. Dyes Pigm. 2025, 234, 112546. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, R.; Li, H.; Shi, Y.; Liu, Y.; Zhou, C. Investigation of the migration ability of silicone and properties of waterborne polyurethanes. Int. J. Adhes. Adhes. 2020, 102, 102654. [Google Scholar] [CrossRef]

- Semlali Aouragh Hassani, F.Z.; Ouarhim, W.; El Achaby, M.; Tamraoui, Y.; Bensalah, M.-O.; Rodrigue, D.; Bouhfid, R.; el Kacem Qaiss, A. Recycled tires shreds based polyurethane binder: Production and characterization. Mech. Mater. 2020, 144, 103351. [Google Scholar] [CrossRef]

- Diao, S.; Zhang, Y.; Zhao, C.; Wang, M.; Yu, J. Preparation of waterborne polyurethane with high solid content: The crystallinity control of soft segment and the organosilicon modification. Polym. Bull. 2023, 81, 317–333. [Google Scholar] [CrossRef]

- Yin, C.; Rozet, S.; Okamoto, R.; Kondo, M.; Tamada, Y.; Tanaka, T.; Hattori, H.; Tanaka, M.; Sato, H.; Iino, S. Physical Properties and In Vitro Biocompatible Evaluation of Silicone-Modified Polyurethane Nanofibers and Films. Nanomaterials 2019, 9, 367. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhu, L.-l.; He, Y.; Cheng, B. A novel method for fabricating elastic conductive polyurethane filaments by in-situ reduction of polydopamine and electroless silver plating. Mater. Des. 2017, 113, 254–263. [Google Scholar] [CrossRef]

- Wang, S.; Chen, X.; Guo, L.; Wang, S.; Dong, F.; Liu, H.; Xu, X. A human muscle-inspired, high strength, good elastic recoverability, room-temperature self-healing, and recyclable polyurethane elastomer based on dynamic bonds. Compos. Sci. Technol. 2024, 248, 110457. [Google Scholar] [CrossRef]

- Fei, J.; Rong, Y.; Du, X.; Li, H.; Zhang, X.; Cui, P.; Huang, X. Vat photopolymerization printing of strong tear-resistance and stretchable polyurethane elastomer for highly sensitive strain sensors. Polym. Compos. 2023, 45, 2615–2628. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, Z.H.; Cui, Y.Y.; Zhang, M.Y.; Sheng, M.Q.; Li, H.J.; Wu, Y.C. Composite coatings based on silicone-modified polyurethane and marine natural product chlorogentisyl alcohol for marine antifouling. Prog. Org. Coat. 2025, 198, 108906. [Google Scholar] [CrossRef]

- Ghosh, T.; Karak, N. Cashew nut shell liquid terminated self-healable polyurethane as an effective anticorrosive coating with biodegradable attribute. Prog. Org. Coat. 2020, 139, 105472. [Google Scholar] [CrossRef]

- Guo, J.; Wang, C.; Yu, H.; Li, X. Preparation of a wear-resistant, superhydrophobic SiO2/silicone-modified polyurethane composite coating through a two-step spraying method. Prog. Org. Coat. 2020, 146, 105710. [Google Scholar] [CrossRef]

- Król, P.; Król, B.; Kozakiewicz, J.; Zapotoczny, S.; Pilch-Pitera, B.; Kozdra, S. Composites prepared from polyurethanes modified with silicone-acrylic nanopowders. Prog. Org. Coat. 2015, 81, 72–79. [Google Scholar] [CrossRef]

- Liu, S.; Chen, R.; Liu, Q.; Liu, J.; Zhu, J.; Sun, G.; Zhang, H.; Wang, J. Schiff base modified polyurethane coating with enhanced mechanical property for marine antifouling application. Prog. Org. Coat. 2025, 203, 109138. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, Y.; Chen, K.; Hong, Y.; Zhou, X. Synthesis and application of silicone-modified polyurethane as a slip-elastic finishing agent for polyamide fabrics. Prog. Org. Coat. 2024, 191, 108420. [Google Scholar] [CrossRef]

- Xing, Y.; Li, X.; Xu, J.; Zhang, F. Organosilicon-modified double crosslinked waterborne polyurethane coatings. Prog. Org. Coat. 2024, 190, 108372. [Google Scholar] [CrossRef]

- Wang, H.; Li, X.; Zhang, E.; Shi, J.; Xiong, X.; Kong, C.; Ren, J.; Li, C.; Wu, K. Strong Thermo-tolerant Silicone-Modified Waterborne Polyurethane/Polyimide Pressure-Sensitive Adhesive. Langmuir 2023, 39, 17611–17621. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Cheng, J.; Liu, H.; Xu, J.; Zhang, F. Preparation and properties of organosilicon and castor-oil-modified rosin-based waterborne polyurethane coatings. Ind. Crops Prod. 2024, 211, 118230. [Google Scholar] [CrossRef]

- Luo, J.; Gao, W.; Wang, Z.L. The Triboelectric Nanogenerator as an Innovative Technology toward Intelligent Sports. Adv. Mater. 2021, 33, 2004178. [Google Scholar] [CrossRef]

- Fadaei, H.S.; Shahgholi, M.; Salehi, M.; Galehdari, S.A. Effect of polycaprolactone percentage on thermal and mechanical behavior of polyurethane/polycaprolactone/graphene oxide nanocomposite utilizing molecular dynamics simulation. Eng. Anal. Bound. Elem. 2024, 161, 179–187. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, H.; Yin, H.; Sun, B.; Gu, B.; Zhang, W. A flexible, high-strength, conductive shape memory composite fabric based on continuous carbon fiber/polyurethane yarn. Smart Mater. Struct. 2020, 29, 085044. [Google Scholar] [CrossRef]

- Jiao, X.; Song, Y.; He, N.; Wang, X.; Huang, M.; Zhang, L.; Li, X.; Xu, J.; Chen, J.; Li, W.; et al. High Tensile Strength UV-Cured Castor Oil-Based Silicone-Modified Polyurethane Acrylates. ACS Omega 2022, 7, 12680–12689. [Google Scholar] [CrossRef]

- Xiong, X.; Li, X.; Zhu, Z.; Zhang, E.; Shi, J.; Lu, M. Antibacterial and Alkali-responsive Cationic Waterborne Polyurethane Based on Modification of Aloe Emodin. Chem. Res. Chin. Univ. 2022, 39, 266–275. [Google Scholar] [CrossRef]

- Xian, C.; Deng, T.; Sun, B.; Yang, W.; Li, B.; Li, Y.; Xia, T.; Yang, C.; Yang, Y. Castor oil-segmented polyurethanes with disulfide bonds: Excellent self-healing and mechanical properties. J. Polym. Res. 2025, 32, 114. [Google Scholar] [CrossRef]

- Marukha, M.V. Characteristics of organosilicon urethane composite materials and coatings. Mater. Sci. 2007, 43, 823–828. [Google Scholar] [CrossRef]

- Gao, H.; Liu, G.; Cui, C.; Wang, M.; Gao, J. Preparation and properties of a polyurethane film based on novel photochromic spirooxazine chain extension. New J. Chem. 2022, 46, 9128–9137. [Google Scholar] [CrossRef]

- Tang, J.; Wu, Y.; Ma, S.; Yan, T.; Pan, Z. Flexible strain sensor based on CNT/TPU composite nanofiber yarn for smart sports bandage. Compos. Part. B-Eng. 2022, 232, 109605. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, F.; Yang, D.; Bai, C.; Wang, X.; Li, G.; Luo, Y. Research on the Thermal Aging Performance of a GAP-Based Polyurethane Elastomer. Polymers 2024, 16, 795. [Google Scholar] [CrossRef] [PubMed]

- Nicholas, J.; Mohamed, M.; Dhaliwal, G.S.; Anandan, S.; Chandrashekhara, K. Effects of accelerated environmental aging on glass fiber reinforced thermoset polyurethane composites. Compos. Part. B-Eng. 2016, 94, 370–378. [Google Scholar] [CrossRef]

- Nicoleta, I. Accelerated versus Slow In Vitro Aging Methods and Their Impact on Universal Chromatic, Urethane-Based Composites. Materials 2023, 16, 2143. [Google Scholar] [CrossRef]

- Trzaskowska, P.M.; Robakowska, M.; Gierz, L.; Pach, J.; Mazur, E. Observation of the Effect of Aging on the Structural Changes of Polyurethane/Polyurea Coatings. Polymers 2024, 16, 23. [Google Scholar] [CrossRef]

- Qiu, C.; Luo, J.; Ling, Y.; Lu, Z.; Ni, L.; Chen, Y.; Zou, H.; Heng, Z.; Liang, M. Thermal Degradation Behavior and Mechanism of Organosilicon Modified Epoxy Resin. Macromol. Chem. Phys. 2022, 223, 2200164. [Google Scholar] [CrossRef]

- Klodwig, F.; Finck, L.; Ehlert, N.; Behrens, P.; Menzel, H.; Polarz, S. Photorheologic Silicone Composites with Adaptive Properties by Utilizing Light-Degradable Organosilica Nanoparticles as Fillers. Adv. Mater. Interfaces 2024, 12, 2400574. [Google Scholar] [CrossRef]

- Li, K.X.; Zhang, B.Y.; Yang, Z.Y.; Jiang, X.Y.; Li, X.W. Degradation behaviors of silicone gel encapsulation material with moisture intrusion. Polym. Degrad. Stab. 2022, 206, 110197. [Google Scholar] [CrossRef]

- Tamer, A.K.; Paola, L.; Marianna, A.; Silvia, V.; Walter, B.; Massimo, B.; Giorgio, S. Analysis of oxidative degradation and calcification behavior of a silicone polycarbonate polyurethane-polydimethylsiloxane material. Biomed. Mater. Res. A 2022, 110, 1109–1120. [Google Scholar]

- Gao, X.; Qian, H.; Wang, J.; Hong, Y.; Chen, Y.; Zhao, L.; Hu, D. Self-reinforced thermoplastic polyurethane composite with excellent mechanical properties, heat resistance and sustainable recycling. Compos. Part. B-Eng. 2025, 297, 112342. [Google Scholar] [CrossRef]

- Liao, Y.; Li, Y.; Ruan, H. Eco-friendly and recyclable thermosetting polyurethane composites for human motion monitoring. J. Mater. Sci. Mater. Electron. 2025, 36, 161. [Google Scholar] [CrossRef]

- Raymond, H.; Raphael, B.; Rodolphe, S.; Claire, L.; François, G. Silicone-recycled pyrolyzed fillers for enhanced thermal–and flame—Resistant silicone elastomers. Polym. Degrad. Stab. 2022, 200, 109947. [Google Scholar]

- Guo, S.Y.; Wang, H.B.; Liu, Y.; Fu, Y.; Zhang, X.F.; Qin, B.; Liu, T. Preparation and Closed-Loop Recycling of Ultra-High-Filled Wood Flour/Dynamic Polyurethane Composites. Polymers 2023, 15, 1418. [Google Scholar] [CrossRef]

- Menon, A.V.; Madras, G.; Bose, S. Shape memory polyurethane nanocomposites with porous architectures for enhanced microwave shielding. Chem. Eng. 2018, 352, 590–600. [Google Scholar] [CrossRef]

- Chen, B.; Xiong, W.T.; Zhou, C.L.; Zhang, H.J.; Pan, X.Y.; Peng, J.; Luo, X.H.; Xie, Z.H.; Liu, Y.L. High solid and low viscosity waterborne polyurethane acrylate with excellent anti-corrosion and anti-bacterial performances. Prog. Org. Coat. 2023, 183, 107767. [Google Scholar] [CrossRef]

- Sun, M.T.; Huang, S.; Yu, M.H.; Hang, K.Q. Toughening Modification of Polylactic Acid by Thermoplastic Silicone Polyurethane Elastomer. Polymers 2021, 13, 1953. [Google Scholar] [CrossRef]

- Zheng, C.; Ju, M.; Zhang, X.; Xie, K.; Hou, A.; Gao, A. A multi-stimulus responsive nanogel actuator with the π-π stacking interaction self-assembly and application for bioinspired smart skin with light, heat and humidity responses and superb UV resistance. Chem. Eng. 2024, 499, 156092. [Google Scholar] [CrossRef]

- Xu, S.; Dong, X.; Zhao, Y.; Han, J.; Ji, Y.; Kuang, R.; Zhang, S.; Ma, S. Preparation of Environmentally Friendly Anticorrosive Coatings with Aniline Trimer-Modified Waterborne Polyurethane. Coatings 2024, 14, 1380. [Google Scholar] [CrossRef]

- Yang, P.; Xiang, S.; Li, R.; Ruan, H.; Chen, D.; Zhou, Z.; Huang, X.; Liu, Z. Highly Stretchable and Sensitive Flexible Strain Sensor Based on Fe NWs/Graphene/PEDOT:PSS with a Porous Structure. Int. J. Mol. Sci. 2022, 23, 8895. [Google Scholar] [CrossRef]

- Niu, P.; Pan, W.; Wang, W.; Wang, M.; Zhang, B.; Yang, J.; Peng, X. Synthesis and characterization of organosilicon-modified self-matting waterborne polyurethane with excellent wear resistance. J. Coat. Technol. Res. 2023, 20, 1963–1976. [Google Scholar] [CrossRef]

- Mendes, J.J.; Vieira, M.; Pires, M.; Stevan, S., Jr. Sensor Fusion and Smart Sensor in Sports and Biomedical Applications. Sensors 2016, 16, 1569. [Google Scholar] [CrossRef] [PubMed]

- Pinelli, S.; Mandorino, M.; Lacome, M.; Fantozzi, S. Evaluation of WIMU Sensor Performance in Estimating Running Stride and Vertical Stiffness in Football Training Sessions: A Comparison with Smart Insoles. Sensors 2024, 24, 8087. [Google Scholar] [CrossRef] [PubMed]

- Poirot, A.; Bedrici, N.; Walrick, J.C.; Arrigoni, M. Piezoresistive Behavior of a Conductive Polyurethane Based-Foam for Real-Time Structural Monitoring. Sensors 2023, 23, 5161. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, Y.; Bo, L.; Qi, J.; Zhu, Y. Research Progress on Applying Intelligent Sensors in Sports Science. Sensors 2024, 24, 7338. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, J.; Lee, J.; Chen, X.; Seo, B.; Choi, W. Recent Progress on 2D-Material-Based Smart Textiles: Materials, Methods, and Multifunctionality. Adv. Eng. Mater. 2025, 27, 2500188. [Google Scholar] [CrossRef]

- Wang, X.; He, Y.; Leng, J. Smart Shape Memory Polyurethane with Photochromism and Mechanochromism Properties. Macromol. Mater. Eng. 2022, 307, 2100778. [Google Scholar] [CrossRef]

- Xia, H.; Hashimoto, Y.; Ni, Q.Q. Electrically Triggered Actuation of Plasticized Thermoplastic Polyurethane Gels. Macromol. Mater. Eng. 2016, 301, 864–869. [Google Scholar] [CrossRef]

- Ye, J.; Lin, G.; Lin, Z.; Deng, H.; Huang, J.; Xiang, H.; Rong, M.Z.; Zhang, M.Q. UV-Curable Polyurethane Elastomer with UV-Irradiation/Thermo Dual-Activated Self-Healability. Macromol. Mater. Eng. 2022, 307, 2100874. [Google Scholar] [CrossRef]

- Zhang, N.; Cheng, H.; Han, W.; Ge, F.; Yin, Y.; Wang, C. Electrical-Triggered Multicolor Reversible Color-Changing Ag Nanoparticles/Reduced Graphene Oxide/Polyurethane Conductive Fibers. Macromol. Mater. Eng. 2022, 308, 2200438. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, S.; You, B.; Wu, L. Preparation and surface properties of silicone-modified polyester-based polyurethane coats. J. Coat. Technol. Res. 2006, 3, 333–339. [Google Scholar] [CrossRef]

- Kim, H.M.; Park, J.; Huang, Z.M.; Youn, J.R.; Song, Y.S. Carbon Nanotubes Embedded Shape Memory Polyurethane Foams. Macromol. Res. 2019, 27, 919–925. [Google Scholar] [CrossRef]

- Chen, X.; Zeng, X.; Luo, K.; Chen, T.; Zhang, T.; Yan, G.; Wang, L. A Multiple Remotely Controlled Platform from Recyclable Polyurethane Composite Network with Shape-Memory Effect and Self-Healing Ability. Small 2022, 18, e2205286. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Wei, H.; Zhang, P.; Wei, A.; Zhao, S.; Wang, Q.; Liu, J.; Yu, Y. Designing Strong yet Tough, Multifunctional and Printable Dynamic Cross-Linking Waterborne Polyurethane for Customizable Smart Soft Devices. Adv. Funct. Mater. 2025, 10, 2502720. [Google Scholar] [CrossRef]

- Jing, Z.; Guo, Y.; Ren, M.; Zhao, X.; Shao, H.; Zhou, Y.; Shuai, M. Improving mechanical and water vapor barrier properties of the parylene C film by UV-curable polyurethane acrylate coating. Polymers 2021, 21, 830–844. [Google Scholar] [CrossRef]

- Wen, Y.; Zhang, M.; Xie, Z.; An, Z.; Liu, B.; Sun, F.; Zhao, T.; Yu, Z.; Wang, F.; Mao, Y. Intelligent interaction system based on multimodal conformal triboelectric nanogenerator patch for disabled sports and life. Sci. China Technol. Sci. 2025, 68, 1221101. [Google Scholar] [CrossRef]

- Chen, S.; Mei, Z.; Ren, H.; Zhuo, H.; Liu, J.; Ge, Z. Pyridine type zwitterionic polyurethane with both multi-shape memory effect and moisture-sensitive shape memory effect for smart biomedical application. Polym. Chem. 2016, 7, 5773–5782. [Google Scholar] [CrossRef]

- Zhang, R.; Wei, J.; Tian, N.; Liang, W.; Zhang, J. Facile Preparation of Robust Superamphiphobic Coatings on Complex Substrates via Nonsolvent-Induced Phase Separation. Acs Appl. Mater. Interfaces 2022, 14, 49047–49058. [Google Scholar] [CrossRef]

- Park, Y.J.; Yoon, J.Y.; Kang, B.H.; Kim, G.W.; Choi, S.B. A Tactile Device Generating Repulsive Forces of Various Human Tissues Fabricated from Magnetic-Responsive Fluid in Porous Polyurethane. Materials 2020, 13, 1062. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.H. Shape memory polyurethanes crosslinked with castor oil-based multifunctional polyols. Sci. Rep. 2023, 13, 14983. [Google Scholar] [CrossRef]

- Seo, E.; Choi, J.; Lee, B.; Son, Y.-A.; Lee, K.J. Dye Clicked Thermoplastic Polyurethane as a Generic Platform toward Chromic-Polymer Applications. Sci. Rep. 2019, 9, 18648. [Google Scholar] [CrossRef] [PubMed]

- Gong, Q.; Wu, J.; Gong, X.; Fan, Y.; Xia, H. Smart polyurethane foam with magnetic field controlled modulus and anisotropic compression property. RSC Adv. 2013, 3, 3241. [Google Scholar] [CrossRef]

- Li, Q.; Ahmed, I.; Minh Ngoc, P.; Phuong Hoa, T.; Vinh Dieu, T.; Irshad, M.S.; Xuan Nang, H.; Dao, V.-D. Contemporary advances in polymer applications for sporting goods: Fundamentals, properties, and applications. RSC Adv. 2024, 14, 37445–37469. [Google Scholar] [CrossRef] [PubMed]

- Mao, R.; Wang, H.; Zhang, G.; Ye, X.; Wang, J. Magneto-induced rheological properties of magnetorheological gel under quasi-static shear with large deformation. RSC Adv. 2020, 10, 31691–31704. [Google Scholar] [CrossRef]

- Ravichandran, D.; Ahmed, R.J.; Banerjee, R.; Ilami, M.; Marvi, H.; Miquelard-Garnier, G.; Golan, Y.; Song, K. Multi-material 3D printing-enabled multilayers for smart actuation magnetic and thermal stimuli. J. Mater. Chem. C 2022, 10, 13762–13770. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Z.; Zhang, L.; Guo, Y.; Song, J.; Lou, J.; Guan, Q.; He, C.; You, Z. Strong, detachable, and self-healing dynamic crosslinked hot melt polyurethane adhesive. Mater. Chem. Front. 2019, 3, 1833–1839. [Google Scholar] [CrossRef]

- Li, F.; Weng, K.; Nakamura, A.; Ono, K.; Tanaka, T.; Noda, D.; Tanaka, M.; Irifune, S.; Sato, H. Preparation of Waterborne Silicone-Modified Polyurethane Nanofibers and the Effect of Crosslinking Agents on Physical Properties. Polymers 2024, 16, 1500. [Google Scholar] [CrossRef]

- Li, F.; Weng, K.; Tanaka, T.; He, J.; Zheng, H.; Noda, D.; Irifune, S.; Sato, H. Fabrication of Waterborne Silicone-Modified Polyurethane Nanofibers for Nonfluorine Elastic Waterproof and Breathable Membranes. Polymers 2024, 16, 1505. [Google Scholar] [CrossRef]

- Liu, H.; Xiong, H.; Chang, Y.; Xu, J.; Xu, C.; Liu, Y. Fabrication of Superhydrophobic Coating Based on Waterborne Silicone-Modified Polyurethane Dispersion and Silica Nanoparticles. Polymers 2022, 15, 22. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, F.; Dai, J.; Zhang, Q.; Jiang, M.; Xiong, Y. Recycled-Oil-Based Polyurethane Modified with Organic Silicone for Controllable Release of Coated Fertilizer. Polymers 2019, 11, 454. [Google Scholar] [CrossRef]

- Xu, T.; Shen, W.; Lin, X.; Xie, Y.M. Mechanical Properties of Additively Manufactured Thermoplastic Polyurethane (TPU) Material Affected by Various Processing Parameters. Polymers 2020, 12, 3010. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Han, Z.; Jia, C.; Wang, T.; Wang, X.; Hu, F.; Zhang, H.; Zhao, J.; Zhang, X. Preparation and Characterization of Body-Temperature-Responsive Thermoset Shape Memory Polyurethane for Medical Applications. Polymers 2023, 15, 3193. [Google Scholar] [CrossRef] [PubMed]

- Pekas, D.; Radaš, J.; Baić, M.; Barković, I.; Čolakovac, I. The Use of Wearable Monitoring Devices in Sports Sciences in COVID Years (2020–2022): A Systematic Review. Appl. Sci. 2023, 13, 12212. [Google Scholar] [CrossRef]

- Rajšp, A.; Fister, I. A Systematic Literature Review of Intelligent Data Analysis Methods for Smart Sport Training. Appl. Sci. 2020, 10, 3013. [Google Scholar] [CrossRef]

- Hao, G.; Li, X.; Wang, S.; Wang, S.; Ryu, M.; Yang, J. Surface Modification of Carbon Nanotubes in Silicone–Polyurethane for Improved Mechanical and Anticorrosion Properties. Coatings 2023, 13, 634. [Google Scholar] [CrossRef]

- Carbonaro, N.; Lorussi, F.; Tognetti, A. Assessment of a Smart Sensing Shoe for Gait Phase Detection in Level Walking. Electronics 2016, 5, 78. [Google Scholar] [CrossRef]

- Sun, F.; Zhu, Y.; Jia, C.; Ouyang, B.; Zhao, T.; Li, C.; Ba, N.; Li, X.; Chen, S.; Che, T.; et al. A Flexible Lightweight Triboelectric Nanogenerator for Protector and Scoring System in Taekwondo Competition Monitoring. Electronics 2022, 11, 1306. [Google Scholar] [CrossRef]

- Xia, S.; Wei, C.; Tang, J.; Yan, J. Tensile Stress-Gated Electromagnetic Interference Shielding Fabrics with Real-Time Adjustable Shielding Efficiency. Acs Sustain. Chem. Eng. 2021, 9, 13999–14005. [Google Scholar] [CrossRef]

- Thomas, D.; Reshmy, R.; Philip, E.; Sindhu, R.; Ulaeto, S.B.; Pugazhendhi, A.; Awasthi, M.K. Developments in smart organic coatings for anticorrosion applications: A review. Biomass Convers. Biorefin. 2022, 12, 4683–4699. [Google Scholar] [CrossRef]

- Wu, W.; Wen, S.; Wei, Y.; Ruan, L.; Li, F.; Cao, X.; Wang, Z.L.; Zhang, L. A volatile organic compound free unibody triboelectric nanogenerator and its application as a smart green track. Nano Energy 2023, 105, 108001. [Google Scholar] [CrossRef]

- Albert, V.; Wilson, E.G.; Noël, D. Review of emerging materials for PVDF-based energy harvesting. Energy Rep. 2022, 8, 12853–12870. [Google Scholar]

- Nikola, P.; Tatiana, P.; Erik, Š.; Dinara, S.; Ştefan, Ţ.; Rashid, D.; Klára, Č.; Petr, S. A Brief Introduction and Current State of Polyvinylidene Fluoride as an Energy Harvester. Coatings 2022, 12, 1429. [Google Scholar] [CrossRef]

- Dong, Y.; Zhu, Y.; Liu, M.; Dong, Q.; Li, R.; Fu, Y. Constitutive model for shape memory polyurethane based on phase transition and one-dimensional non-linear viscoelastic. Mater. Today Commun. 2018, 17, 133–139. [Google Scholar] [CrossRef]

- Cao, X.; Yan, K.; Chen, H.; Xu, Q.; Zong, Y.; Sun, X.; Li, X. Passive radiation heating smart fabric with underwater sensor and electromagnetic wave absorption. Appl. Mater. Today 2025, 42, 102550. [Google Scholar] [CrossRef]

- Wang, X.; Tao, Y.; Pan, S.; Fang, X.; Lou, C.; Xu, Y.; Wu, J.; Sang, M.; Lu, L.; Gong, X.; et al. Biocompatible and breathable healthcare electronics with sensing performances and photothermal antibacterial effect for motion-detecting. npj Flex. Electron. 2022, 6, 95. [Google Scholar] [CrossRef]

- Zhu, X.; Peng, X. Strategic assessment model of smart stadiums based on genetic algorithms and literature visualization analysis: A case study from Chengdu, China. Heliyon 2024, 10, e31759. [Google Scholar] [CrossRef]

- Yu, Y.; Liao, X.; Feng, W. Recent development of elastomer-based smart sensing materials and structures. Adv. Compos. Hybrid Mater. 2025, 8, 138. [Google Scholar] [CrossRef]

- Cui, Y.; Li, Y.; Huan, D.; Zeng, D.; Yang, Y.; Zhu, C.; Wang, J. Fabrication of silicone modified polyurethane matrix superhydrophobic coating with hydroxy-terminated polydimethylsiloxane modified SiO2 nanoparticles. Polym.-Plast. Technol. Mater. 2021, 61, 482–496. [Google Scholar] [CrossRef]

- Wang, H.; Chen, L.; Yi, Y.; Fu, Y.; Xiong, J.; Li, N. Durable Polyurethane/SiO2 Nanofibrous Membranes by Electrospinning for Waterproof and Breathable Textiles. Acs Appl. Nano Mater. 2022, 5, 10686–10695. [Google Scholar] [CrossRef]

- Zhu, X.; Zhou, C.; Pan, Z.; Yuan, J.; Pan, M. Multifunctional Waterborne Polyurethane with Robustness, Adhesiveness, and Self-Healability Based on a Dual Cross-Linked Network Containing Multiple Dynamic Bonds. Acs Appl. Polym. Mater. 2024, 6, 13389–13400. [Google Scholar] [CrossRef]

- Chen, M.; Ren, M.; Chen, J.; Lu, Y.; Shi, Q.; Wu, L. Self-healing waterborne polyurethane elastomers based on synergistic hydrogen, disulfide and borate bonding for composite conductors. Polym. Sci. 2024, 62, 3381–3398. [Google Scholar] [CrossRef]

| Component Parameters | Molecular Structural Characteristics | Key Performance Influences | Performance Variation Patterns and Mechanisms |

|---|---|---|---|

| Siloxane chain content (silicone ratio) | Si–O–Si bond ratio, proportion of flexible chain segments | Modulus, impact resistance | With increased silicon content, material flexibility improves, enhancing elongation at break and impact resistance while improving thermal stability; due to increased flexible chain segments, modulus may appropriately decrease. |

| Types of silicone functional groups | Different functional groups such as methyl, vinyl, phenyl, etc. | Mechanical strength, weather resistance | Phenyl groups enhance rigidity and high-temperature resistance, increasing modulus; methyl groups improve flexibility and impact resistance; vinyl groups can participate in crosslinking, enhancing strength and wear resistance. |

| Polyurethane hard segment content | Proportion of rigid isocyanate segments | Modulus, tensile strength | Increasing hard segment content enhances hydrogen bonding between polymer chains, improving modulus and strength, but may lead to increased brittleness and reduced impact resistance. |

| Type and molecular weight of soft segments | Selection of soft segments (polyether or polyester) and molecular weight | Elasticity and fatigue resistance | As the molecular weight of soft segments increases, the flexibility of long chains improves, enhancing elasticity and fatigue resistance; polyether soft segments exhibit better hydrolysis resistance, while polyester soft segments offer superior wear resistance and strength but poorer hydrolysis stability. |

| Combination methods of silicone and polyurethane | Graft copolymerization vs. physical doping | Performance stability, weather resistance | Chemical covalent grafting enhances interfacial bonding strength, resulting in more uniform and stable material properties with improved aging resistance; physical doping may lead to phase separation and performance degradation. |

| Crosslinking degree | The extent to which active groups at silicone terminals participate in crosslinking | Modulus, heat resistance, solvent resistance | High crosslinking density improves modulus and heat resistance but reduces flexibility; low crosslinking density enhances toughness and impact resistance but decreases solvent resistance. |

| Indicator | Traditional PU Track | Silicone-Modified PU Track | International Standard Requirements |

|---|---|---|---|

| Resilience rate | 45%–50% | 65%–75% | ≥35% |

| Wet friction coefficient | 0.6–0.7 | 0.8–0.9 | ≥0.5 |

| Yellowing resistance (ΔE/3000 h) | 4–6 | <2 | ≤5 |

| VOC emissions (g/L) | 60~80 | <50 | ≤80 |

| Maintenance cycle (years) | 2–3 | 4–5 | - |

| Application Scenarios | Project Cases | Technical Solutions | Performance Improvement |

|---|---|---|---|

| Basketball court main floor | Beijing Wukesong Stadium renovation | Three-layer composite structure (cushioning layer + elastic layer + wear-resistant layer) | Impact absorption rate 52%, ball rebound rate 93% |

| Gym floor | Shanghai One Wellness Fitness Center | Silicon carbide reinforced silicone-PU | Wear resistance increased by 3 times, maintenance cycle extended to 5 years |

| Performance | Silicone-Modified PU | Concrete/Asphalt | Ethylene Propylene Diene Monomer Granules |

|---|---|---|---|

| Impact absorption rate | 55%–65% | <10% | 30%–40% |

| Surface temperature (summer) | 15–20 °C lower than asphalt (resistant to high-temperature softening) | Can exceed 60 °C | 50–55 °C |

| Maintenance cost | Low (only requires regular cleaning) | High (frequent crack repairs) | Medium (particles prone to falling off) |

| Environmental adaptability | Frost-thaw resistance, salt spray resistance (coastal areas) | Prone to freeze cracking and corrosion | Average weather resistance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, G.; Huang, G.; Wu, H.; Chen, Y.; Wu, J.; Hu, Y. From Molecular Design to Scenario Adaptation: Cutting-Edge Exploration of Silicone-Modified Polyurethane in Smart Sports Fields. Coatings 2025, 15, 737. https://doi.org/10.3390/coatings15070737

Yan G, Huang G, Wu H, Chen Y, Wu J, Hu Y. From Molecular Design to Scenario Adaptation: Cutting-Edge Exploration of Silicone-Modified Polyurethane in Smart Sports Fields. Coatings. 2025; 15(7):737. https://doi.org/10.3390/coatings15070737

Chicago/Turabian StyleYan, Guobao, Guoyuan Huang, Huibin Wu, Yang Chen, Jiaxun Wu, and Yangxian Hu. 2025. "From Molecular Design to Scenario Adaptation: Cutting-Edge Exploration of Silicone-Modified Polyurethane in Smart Sports Fields" Coatings 15, no. 7: 737. https://doi.org/10.3390/coatings15070737

APA StyleYan, G., Huang, G., Wu, H., Chen, Y., Wu, J., & Hu, Y. (2025). From Molecular Design to Scenario Adaptation: Cutting-Edge Exploration of Silicone-Modified Polyurethane in Smart Sports Fields. Coatings, 15(7), 737. https://doi.org/10.3390/coatings15070737