Abstract

The long-term wear resistance of granite manufactured sand (HGY) concrete has not been sufficiently investigated. This deficiency makes it difficult to accurately predict and evaluate the service life and durability of such concrete pavements in practical engineering applications. Consequently, this study employed a self-developed indoor abrasion test device and combined it with scanning electron microscope (SEM) and X-ray diffraction (XRD) technologies. From the two dimensions of macroscopic performance and microscopic structure, the mechanisms’ influence of the effective sand ratio, stone powder content, and fine aggregate lithology on the wear resistance of HGY concrete were systematically investigated. The optimal content of the effective sand and stone powder content were determined, and the long-term evolution law of the wear resistance of HGY concrete was revealed. The results demonstrate that increasing the effective sand content will reduce the mass loss of concrete. When the stone powder content is 9%, the wear resistance of the concrete is optimal. The order of mass loss of different fine aggregate lithologies is river sand (HS) > limestone mechanism sand (SHY) > HGY, and the wear resistance of HGY is better than that of other fine aggregates. Increasing the effective sand content can enhance the bonding strength between the aggregate and the cement matrix and reduce the porosity, which is conducive to improving the wear resistance of the concrete. Under a relatively small stone powder content, as the amount of stone powder added increases, the pore structure becomes tighter, and the wear resistance of the concrete becomes better. Compared to HS, the manufactured sand (MS) containing stone powder can optimize the pore structure and hydration products of concrete, improve the pore structure of concrete, and improve the wear resistance.

1. Introduction

HS typically exhibits high compressive strength and wear resistance. Its smooth surface and rounded particle morphology contribute to improved workability in concrete mixtures, while simultaneously providing enhanced abrasion resistance [1]. However, the high sand consumption of more than 5 billion tons/year made it an increasingly scarce resource [2,3]. To achieve the low-carbon, economic, and sustainable development of the construction industry, manufactured sand (MS) concrete has emerged as the focus of research and application [4,5]. As the fundamental carrier for transportation, the wear resistance of road surfaces directly determines their service life and safety [6]. High-frequency vehicle loads, tire friction, and environmental erosion can lead to road surface damages, such as wear and potholes, reducing driving comfort, increasing fuel consumption and maintenance costs, and even triggering traffic accidents [7].

Kim et al. suggested that the microstructure of HGY concrete is denser, and its porosity is lower [8]. These characteristics help reduce water penetration and minimize drying shrinkage. In contrast, SHY concrete, due to its higher void ratio, is more susceptible to environmental influences, thereby compromising the durability of the concrete. Luo et al. postulated that the particle morphology of HGY is typically irregular, polygonal, and has a large aspect ratio, endowing concrete with potential wear resistance [9]. Binici et al. conducted a comparative study on HGY and SHY concrete and analyzed their durability, finding that concrete prepared with HGY exhibits better durability [10]. Sergii et al. discovered that HGY concrete possesses superior wear resistance compared to SHY concrete [11]. Therefore, HGY has high strength and hardness. If it is applied to concrete pavements, it will significantly enhance the wear resistance of the pavements, reducing the occurrence of pavement diseases [12,13].

However, the inherent characteristics of MS will also have an impact on the wear resistance of concrete pavements. Its surface is rough, and the edges are sharp, and it usually contains a certain proportion of stone powder. These factors will undergo complex changes during the long-term service of the concrete. When the stone powder content is too high, it may dilute the effective components of the cement and reduce the strength of the cement paste, making the concrete more vulnerable to wear [14]. On the other hand, if the stone powder content is too low, it cannot fully exert its functions of physical filling and promoting the hydration reaction, which is also not conducive to improving the wear resistance of the concrete [15].

In addition, an appropriate fine sand content helps to enhance the bonding force between the cement paste and aggregates, strengthening the overall wear resistance. If the fine sand content is too high, a large amount of fine sand will adsorb the cement paste, which may lead to the uneven distribution of the cement paste [16]. Some aggregate surfaces cannot be fully coated, resulting in weak bonding. On the other hand, if the fine sand content is too low, the contact area between the coarse aggregates and the cement paste is limited, and it is also difficult to form a high-strength bond. During the wear process, the aggregates can easily break away from the cement matrix, causing potholes, spalling, and other diseases on the pavement surface, and the wear resistance will decline sharply [17].

The sand content within the range of 0.075 mm to 2.36 mm is one of the key factors influencing concrete gradation [18]. Either an excessively high or low fine sand content will lead to an unreasonable gradation, thus affecting the wear resistance of the concrete [19]. Li et al. have shown that the wear resistance of MS concrete is closely correlated with its sand content. When the sand content is within an optimal range (e.g., 20%–35%), MS concrete exhibits better wear resistance, as this optimal sand content facilitates more uniform particle distribution and a denser microstructure [20]. Other studies have shown that appropriately increasing the content of coarse particles in MS can, to a certain extent, enhances the skeletal function of concrete [21]. Coarse particles can bear more external forces and play a certain resistant role when subjected to wear such as friction, contributing to the improvement of the initial wear resistance of concrete. However, if the content of coarse particles is too high, it will lead to excessively large voids between the particles, which are difficult to fully fill with fine particles and cement paste [22]. This will make the internal structure of the concrete loose. During long-term use, external moisture, dust, and other impurities can easily enter these voids, accelerating the wear and damage of the concrete.

Therefore, in some MS concrete pavements with high requirements for surface flatness and smoothness, an appropriate increase in the content of fine particles helps to reduce surface irregularities, lowering the friction coefficient and reducing wear [23]. Within an optimal range, limestone powder content can enhance the durability and density of concrete. However, exceeding this optimal threshold can detrimentally impact the hardened MS concrete’s wear resistance. Conversely, insufficient limestone powder content restricts its physical filling capacity and hydration-promoting effects, resulting in only marginal improvements to the mechanical and durability-related properties of MS concrete.

Global research has extensively confirmed that HGY concrete exhibits superior abrasion resistance. However, the optimal content of stone powder and fine sand required to maximize the abrasion resistance of HGY concrete remains unclear, with existing studies and experimental data failing to provide a precise range or standard value. Additionally, comparative analyses of the abrasion resistance of HGY concrete versus other types of mechanism sand (MS) concrete are extremely limited [11]. This scarcity of research hinders the comprehensive evaluation of the performance advantages and practical applicability of HGY concrete relative to other concrete types. Moreover, the current research focus on HGY concrete predominantly emphasizes its durability characteristics [24,25]. Systematic studies on the evolutionary trend of the abrasion resistance of HGY concrete pavements over extended periods of service, including factors such as the magnitude and rate of abrasion resistance changes at different service stages, have not been thoroughly conducted. This significant research gap restricts the accurate prediction and effective assessment of HGY concrete’s long-term performance in practical applications.

Based on this, in this study, a self-developed wear test device was used to simulate the wear behavior of concrete pavements under long-term service conditions. The macroscopic performance of concrete cube specimens was characterized by the quantitative analysis method of mass loss. Combined with SEM and XRD technologies, the microstructure of the cement matrix, the morphological characteristics of the interfacial transition zone (ITZ), and the composition of hydration products of HGY concrete were analyzed. The influence mechanisms of the effective sand ratio, stone powder content, and fine aggregate lithology on the wear resistance of concrete pavements were systematically explored at both the macroscopic and microscopic scales. The optimal range of the effective sand ratio and stone powder content for the wear resistance of granite manufactured sand concrete pavements was determined, and the evolution law of its long-term wear resistance was elucidated. The research results provide a theoretical basis and technical support for the large-scale application of HGY in concrete, which helps to improve its wear resistance and economic efficiency.

2. Materials and Methods

2.1. Materials

The cement used in this study is P.O 42.5 ordinary Portland cement produced in Nanning area, and the quality meets the relevant requirements of ‘general Portland cement’ GB175. The basic parameters are listed in Table 1. The chemical composition of cement was detected by X-ray fluorescence spectrometer (Germany, Belgium). The chemical composition is depicted in Table 2.

Table 1.

P.O 42.5 basic parameters of cement.

Table 2.

Chemical composition of P.O 42.5 (%).

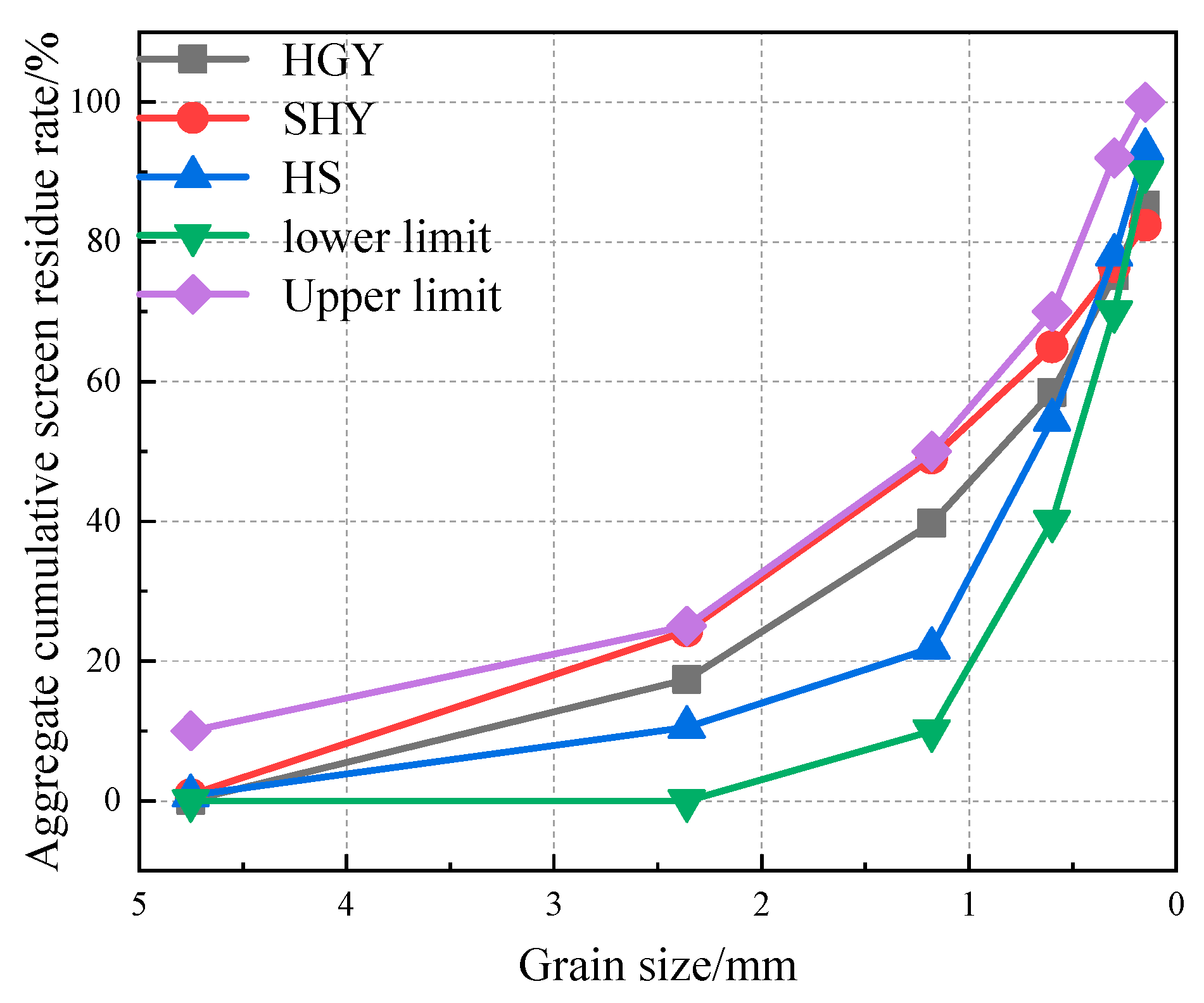

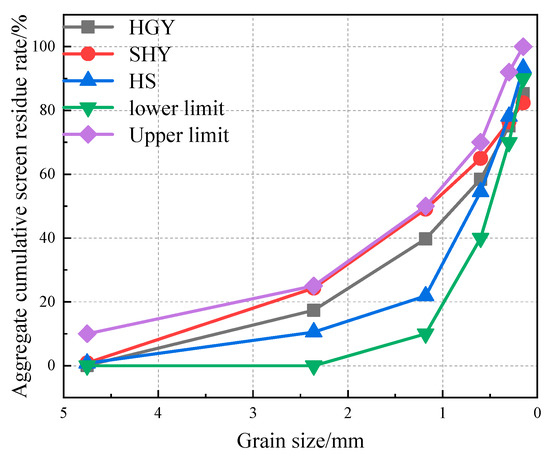

The fine aggregates utilized in this study comprise HGY, SHY, and HS. Specifically, HGY was sourced from the under-construction Cangwu-Rongxian Highway Project in Fucheng County, Wuzhou City, while SHY and HS were procured from the Old Man’s Village Sand, Stone, and Cement Store in Xixiangtang District, Nanning City. Sieve analysis tests were performed on the fine aggregates. The fineness modulus was calculated and used as the evaluation index to assess the coarseness and fineness of the aggregates. The cumulative sieve residue values and fineness modulus values for each grading level of the three types of fine aggregates are listed in Table 3. The results of the cumulative sieve residue of particles are shown in Figure 1.

Table 3.

Cumulative sieve residue and fineness modulus of fine aggregate grades.

Figure 1.

Fine aggregate grading curve.

According to the test procedures of ‘construction sand’ (GB/T 14684-2022) [26], the physical properties of fine aggregate were tested. The results are shown in Table 4.

Table 4.

Physical properties indicators of fine aggregate.

The coarse aggregate utilized for testing purposes was limestone aggregate, which was procured from the Old Man’s Village Sand and Cement Store in Xixiangtang District, Nanning City. Its particle size was classified into two grades, namely 9.5–19.0 mm and 4.75–9.5 mm, with a mixing ratio of 3:1 (by mass). In accordance with the test procedures stipulated in ‘Pebble and crushed stone for construction’ (GB/T 14685-2011) [27], its technical indicators are presented in Table 5.

Table 5.

Technical indicators of coarse aggregate.

The HGY portion within the fine aggregate was sieved to obtain particles smaller than 0.075 mm in size. The apparent density of these particles was measured at 2678 kg/m3 on average, and their specific surface area was determined to be 403 m2/kg on average. The chemical composition of these particles is listed in Table 6.

Table 6.

Chemical compositions of HGY stone powder. The chemical composition of HGY stone powder was detected by an X-ray fluorescence spectrometer.

The admixture utilized in this research is a WYF-H retarding superplasticizer (Nanning, China). WYF-H retarding high-efficiency water-reducing agent, which is a transparent or pale yellow liquid, was used with a dosage of 1.0%. This superplasticizer complies with the requirements specified in the standard ‘Concrete admixtures’ (GB8076-2008) [28]. The basic technical indices of the water-reducing agent are presented in Table 7.

Table 7.

Technical indicators of water reducing agent.

The test uses grade III fly ash as an admixture, according to the standard ‘Fly ash used for cement and concrete’ (GB1596-2005), all test items meet the standard [29]. The technical indexes of fly ash are shown in Table 8.

Table 8.

Technical indicators of fly ash.

The water used in this study is the local tap water in Nanning. The water has been strictly tested and meets the requirements of the ‘Standards for drinking water quality’ (GB5749-2006) [30]. The water quality is safe and reliable and can meet the water demand of this study.

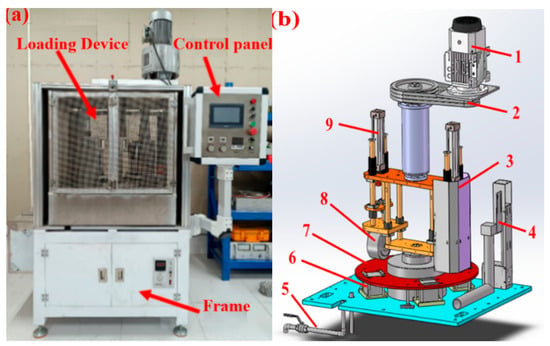

2.2. Indoor Abrasion Tester

2.2.1. Device Design and Structure

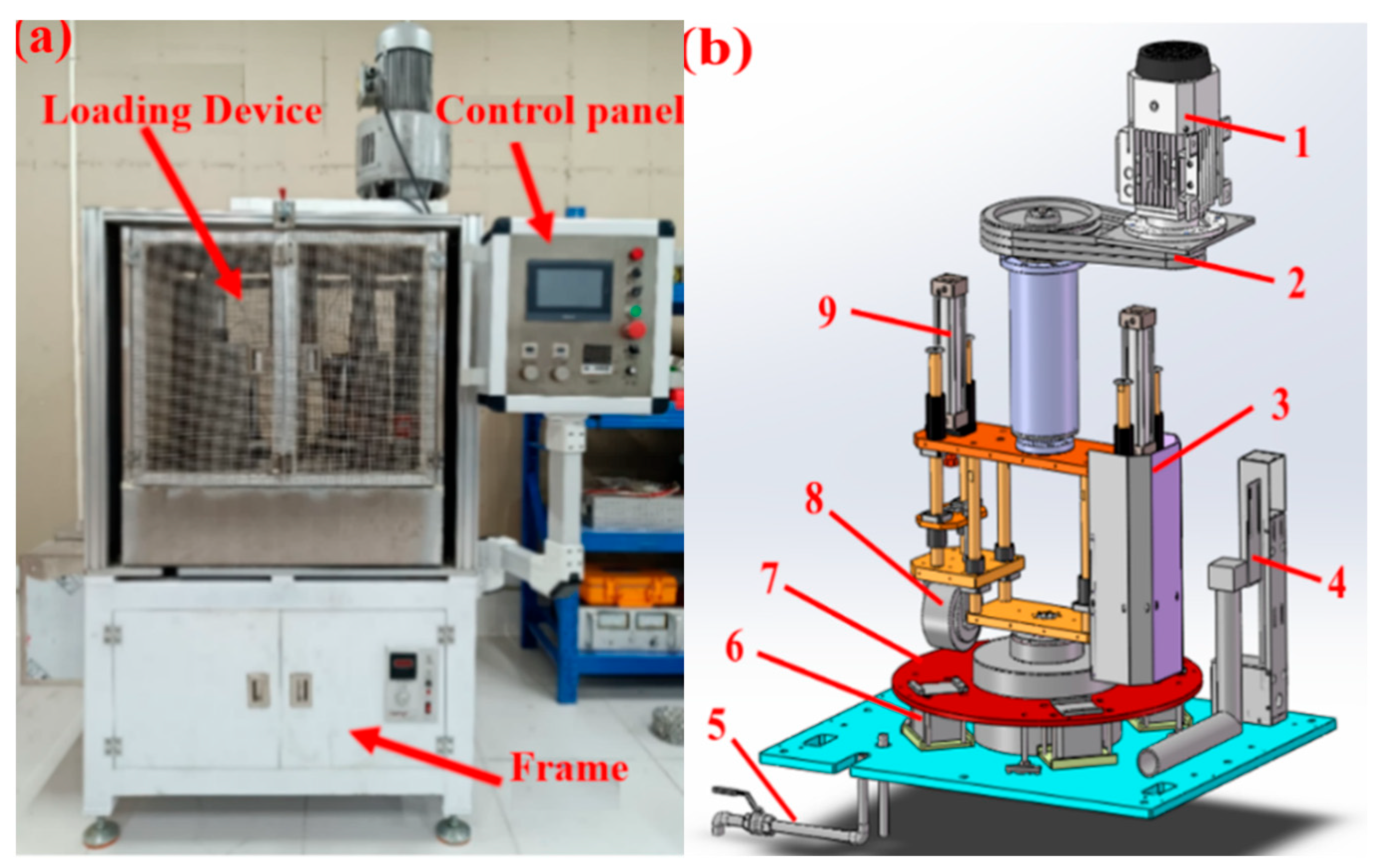

The schematic diagram of indoor abrasion tester (Nanning, China) is shown in Figure 2. As illustrated in Figure 2a, the device mainly consists of a loading device, a frame, and a console. The electric control box of the entire equipment set is located beneath the loading device and is safeguarded by the frame. The frame incorporates the control panel and the loading device. The control panel can govern the instrument switch, wheel elevation, vehicle load, wheel rotational speed, and water circulation. As illustrated in Figure 2b, the operational principle of the indoor abrasion tester encompasses drive components, pressure components, and a loading rotating platform. The drive components are composed of a motor, a drive belt, and a drive shaft. The motor is linked to the drive pulley on the drive shaft by means of the drive belt. The pressurizing components consist of a pressurizing cylinder, a slider, and a tire, which are sequentially connected from top to bottom. The pressurizing components are disposed in opposition to each asynchronized to each other and interconnected by upper and lower transverse steel plates. The drive shaft of the drive components is affixed to the upper transverse steel plate; the loading rotating platform comprises a central turntable and a steel plate track. The central turntable of the loading rotating platform is joined to the lower transverse steel plate, and the steel plate track is furnished with a specimen placement slot. The steel plate guide rail can serve as a test platform for embedding four 100 mm × 100 mm × 100 mm cubic specimens. The device can expedite the abrasion process of specimens.

Figure 2.

The schematic diagram of indoor abrasion tester. (a) Overall structure of the device. (b) Principle of the device. Note: 1—motor; 2—drive belt; 3—protective cover; 4—water recycling device; 5—drainage pipe; 6—concrete test cube; 7—steel plate guide rail; 8—loading tires; 9—pressurizing cylinder.

The travel path of the simulated wheel is designed as a circular trajectory. An angle of 15° is formed between the wheel’s travel direction and its alignment; specifically, the wheel is inclined at 15° towards the interior of the forward path. This design aims to apply both vertical and horizontal loads when the simulated wheel traverses the circular path. This results in both rolling friction and sliding friction [31], consequently and markedly augmenting the wear efficiency of the apparatus.

2.2.2. Device Test Steps

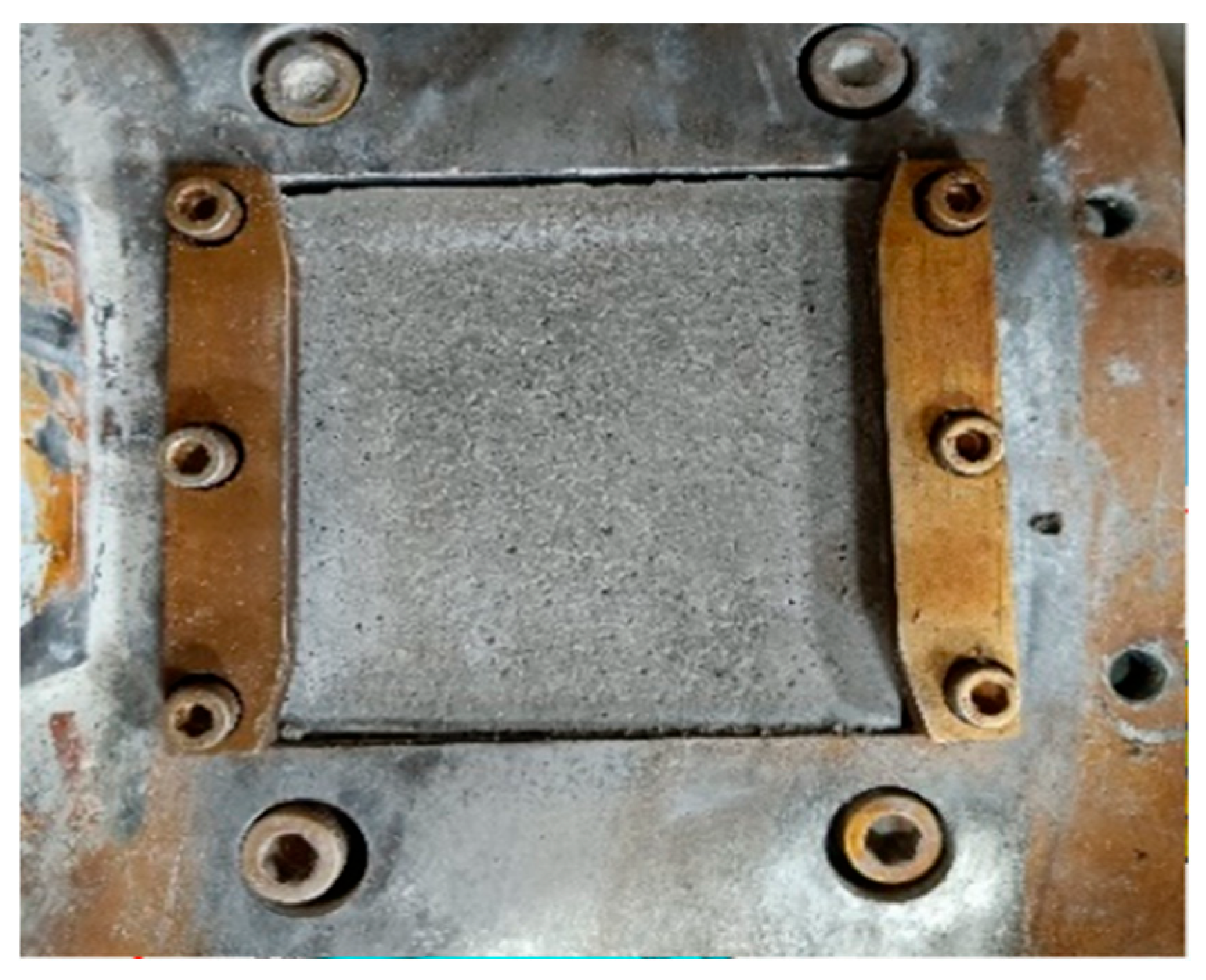

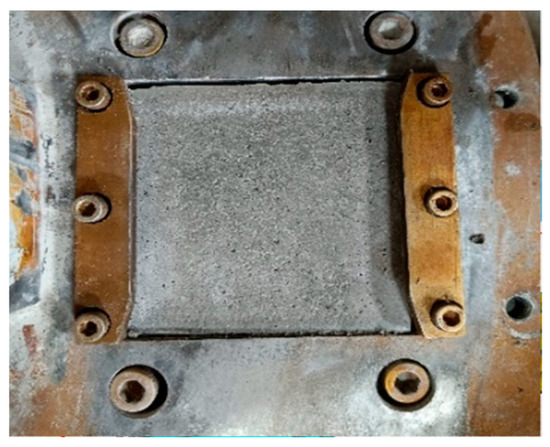

During the testing process, the wheel is subjected to a standard ground pressure of 0.7 MPa, and the rotational speed of the wheel is set at 50 revolutions per minute. With two wheels being simultaneously loaded onto the circular path, the wear frequency for each specimen amounts to 100 times per minute. The width of the tire is 80 mm. The specimens are secured with fixtures upon being placed (as illustrated in Figure 3). When the tire is inclined at an angle of 15°, and the cube specimen is embedded, the area abraded by the tire is approximately 0.00766 m2.

Figure 3.

Specimen fixation method.

The main test steps are as follows:

- (1)

- After replacing it with a tire of the required specification, the direction of the tire should be adjusted. Ensure that the tire is tilted inward at an angle of 15° along the driving direction and then tighten the nut after fixing its position.

- (2)

- Place the specimen in the test area and secure it. Turn on the power switch. Using the operation console, place the tire on the surface of the test specimen and adjust the two tire load knobs to 0.7 MPa, and the speed reaches 50 revolutions per minute (r/min).

- (3)

- After the wear test of the specimen is completed, use the control console to stop the equipment. Finally, turn off the power supply.

2.3. Specimen Preparation and Mixing Proportions

2.3.1. Mixing Proportions and Testing Program

Based on the primary particle size range of HS, the particles within the manufactured sand (MS) with a particle size ranging from 0.075 mm to 2.36 mm are defined as the effective sand of the MS. The ratio of the mass of the effective sand to the total mass of the MS is referred to as the effective sand content. The MS employed in the test is screened and classified into the following three types: adjusted sand with a particle size range of 2.36 to 4.75 mm, effective sand with a particle size range of 0.075 to 2.36 mm, and stone powder with a particle size smaller than 0.075 mm. The alteration of the gradation is regulated by adjusting the content of the main body sand. The HGY utilized in the test exhibits a favorable gradation. According to the ‘Specification for mix proportion design of ordinary concrete’ (JGJ55-2011) [32], the proportion of each particle size range within the effective sand remains unaltered. The screened effective sand is blended with the adjusted sand. The effective sand content is set at 80%, 85%, 90%, 95%, and 100%, with an interval of 5%. These mixtures are designated as S80, S85, S90, S95, and S100, respectively. The fineness moduli are 1.91, 1.78, 1.65, 1.52, and 1.39, respectively. The specific mix is shown in Table 9. The content of stone powder is substituted with 0%, 3%, 5%, 7%, 9%, 12%, and 15% of the cement amount, and these mixtures are named J0, J3, J5, J7, J9, J12, and J15, respectively. The fine aggregate used is the MS with the stone powder screened out, and the specific mixing proportion is presented in Table 10. In accordance with the cumulative sieve residue of each particle size of HS, the gradation of MS is adjusted to be identical to that of HS, and the specific details are presented in Table 11.

Table 9.

Mix proportion of effective sand content concrete.

Table 10.

Mix proportion of stone powder content concrete.

Table 11.

Fine aggregate lithology concrete mix ratio.

The mass loss data of the cubic specimens are characterized by the average value of four groups of parallel specimens.

Through the self-made ring mold, the concrete was poured according to the ‘Highway Engineering Cement and Cement Concrete Test Regulations’, and the specimens were standardly cured for 28 days.

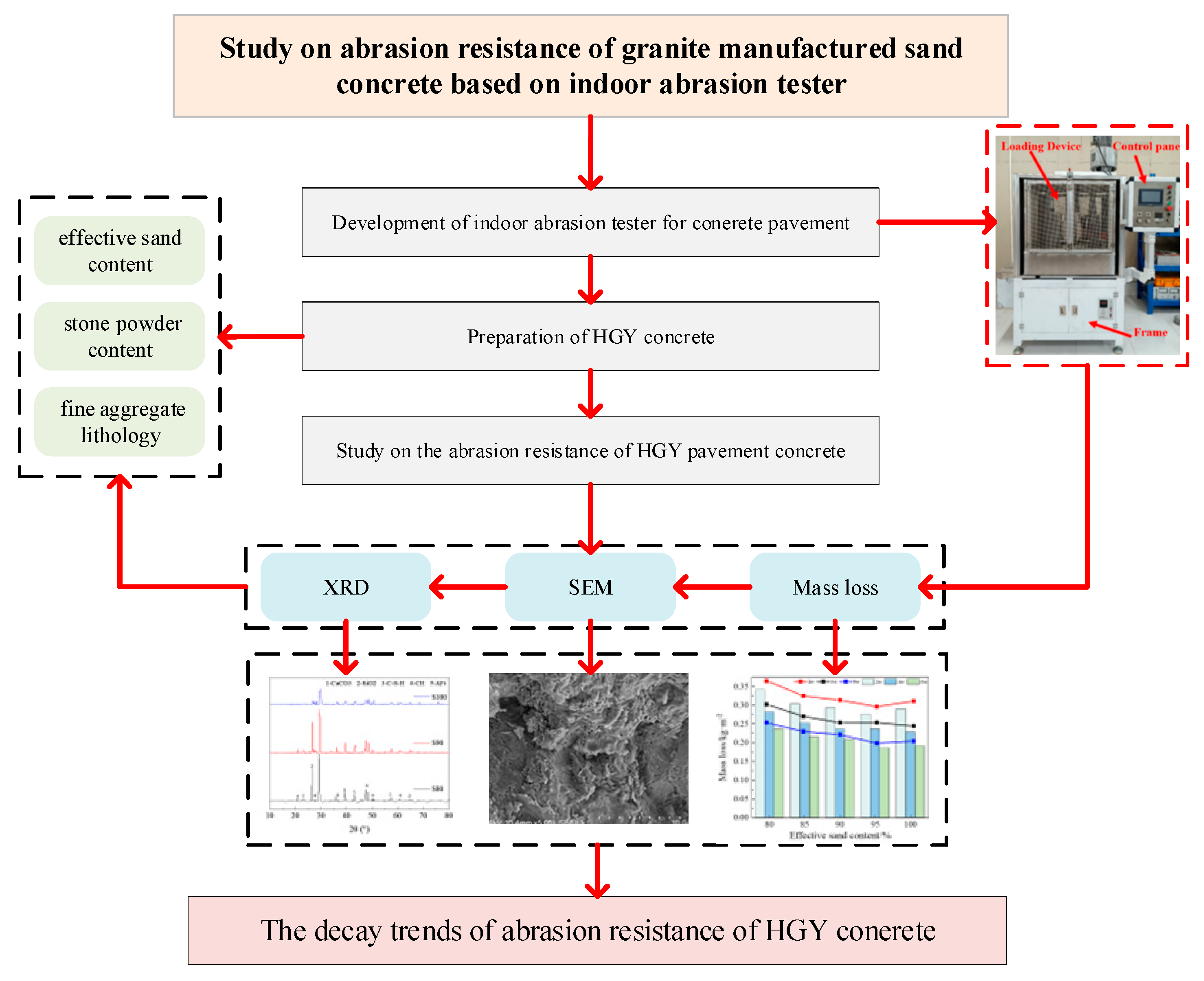

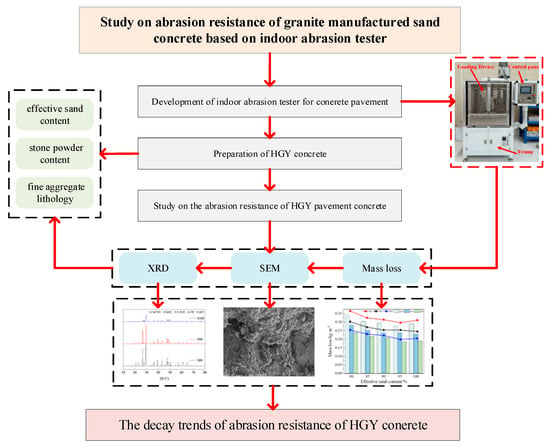

Upon the completion of specimen preparation, subsequent tests regarding abrasion resistance were then conducted. The research framework of this study is shown in Figure 4.

Figure 4.

Research framework.

2.3.2. Test Methods

- (1)

- Abrasion resistance test of concrete

A quantitative analysis was performed based on the mass loss per unit area of the concrete specimens before and after the wear test. The test procedures are as follows: After the specimen has been cured for 28 d, the initial mass of the specimen is measured. Subsequently, start the instrument to conduct the accelerated abrasion test on the specimen. When the wheel has passed over the surface of the specimen 20,000 times, the device is stopped. The specimen is then removed, and the residual slag on its surface is thoroughly cleaned. Subsequently, the mass of the worn specimen is measured again. The formula for calculating the mass loss per unit area of the concrete specimens before and after the abrasion test is as follows:

where ΔM—mass loss per unit area of concrete specimen before and after abrasion, kg/m2;

- M1—initial mass of concrete specimen, kg;

- M2—mass of concrete specimens after abrasion, kg;

- S—abrasion area of specimen (m2), the cube specimen takes 0.00766 m2.

- (2)

- SEM Analysis

The microscopic morphology of the cement matrix and the interfacial transition zone of the concrete with HGY was characterized by SEM. This study used an FEI Quattro S SEM to characterize the microstructure of the mortar specimens after curing for 28 d. The maximum resolution of this SEM was 1.5 nm at 15 kV, 2.0 nm at 15 kV, and 3.0 nm at 10 kV.

- (3)

- XRD Analysis

The crystal structure of concrete with HGY is characterized using a Bruker D8 Discover X-ray diffractometer. The maximum output power of the X-ray generator was 2.2 kW, its scanning rate was 10°/ min, its diffraction angle range was 10–90, and its X-ray wavelength (λ) was 0.154 nm. The applied step width was 0.02°, and the applied step time was 1 s.

3. Results and Discussion

3.1. Study on the Influencing Factors of Abrasion Resistance of HGY Concrete

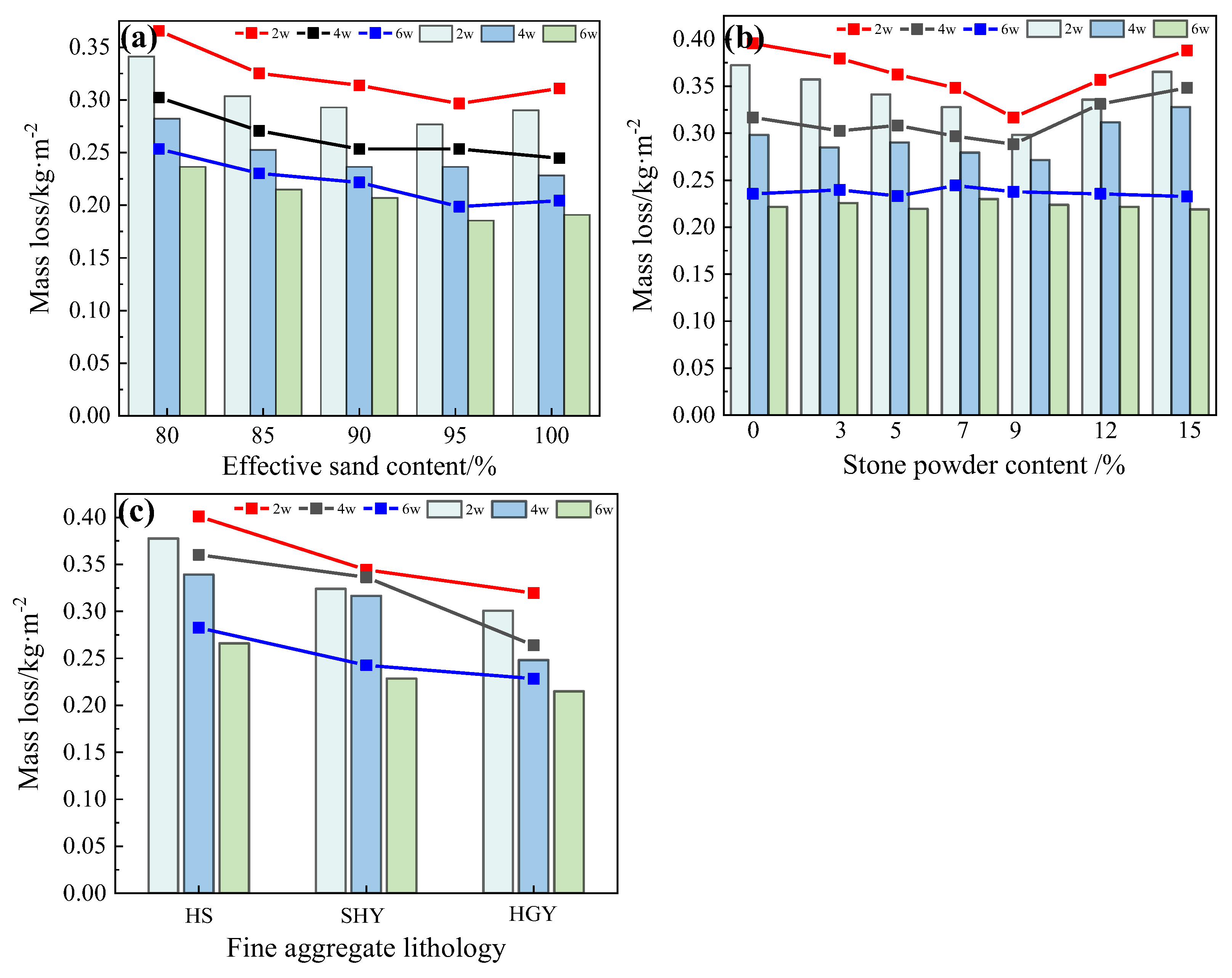

The effect of effective sand content, stone powder content, and fine aggregate lithology on the wear resistance of HGY concrete cube specimens is illustrated in Figure 5a–c.

Figure 5.

Mass loss. (a) Effective sand content; (b) stone powder content; (c) fine aggregate lithology. Note: 2 w—the cube specimen was worn 20,000 times; 4w—the cube specimen was worn 40,000 times; 6 w—the cube specimen was worn 60,000 times.

As can be seen from Figure 5a, for the same number of abrasion cycles, the mass loss of each specimen decreases as the effective sand content increases. The variation in mass loss among specimens with different effective sand contents can be attributed to the ability of particles within the effective sand diameter range to fill the gaps more effectively between coarse aggregates. The filling effect of the adjustment sand in the particle size range of 2.36~4.75 mm on the coarse aggregates is slightly worse than that of the smaller particle size particles [33]. As the effective sand content increases, a higher proportion of fine aggregates with smaller particle sizes is present, leading to an enhancement in the strength of the cement paste [34,35]. Consequently, the mass loss during abrasion decreases.

Figure 5b shows that after 20,000 abrasion cycles, as the number of abrasion cycles increases, the mass loss of each specimen decreases. This is because in the initial stage of wear (20,000 wear cycles), pores and cracks are the main sources of concrete mass loss, as wear particles tend to detach easily from these weak areas. As the number of wear cycles increases, stone powder fills and blocks these pores and cracks, thereby densifying the internal structure of the material [36]. The mass loss initially decreases and then increases with increasing stone powder content. Specifically, compared to specimens without stone powder, the J5, J7, and J9 specimens show a reduction in mass loss. Among them, the J9 specimen exhibits the smallest mass loss, and the mass loss among specimens with varying stone powder contents is relatively similar after 60,000 abrasion cycles. In contrast, when the stone powder content is 9%, it effectively reduces the mass loss of concrete within 60,000 abrasion cycles and enhances the wear resistance [37].

Figure 5c indicate that, for the same number of abrasion cycles, the mass loss of the different fine aggregates follows the descending order HS > SHY > HGY concrete specimens. For HS and SHY, the quality loss during the first 40,000 abrasion cycles is higher, with a significant reduction in quality loss observed after reaching 60,000 abrasions. In contrast, the quality loss of the HGY specimens decreases more consistently as the number of abrasion cycles increases. This suggests that the surface abrasion of the HS and SHY specimens transitions from the lower strength cement paste to the slightly higher-strength aggregate–slurry zone between 40,000 and 60,000 abrasion cycles. Meanwhile, the HGY specimens exhibit a more uniform reduction in mass loss due to the enhanced wear resistance provided by HGY, which better improves the durability of the cement paste [38]. When HGY is used as a fine aggregate in concrete, the overall strength of the concrete, formed by the combination with cement, is generally higher [12].

3.2. Microstructural Analysis of T Concrete with HGY

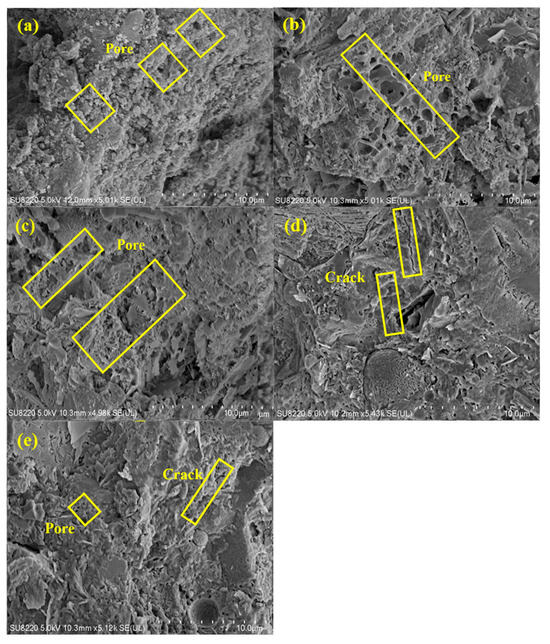

3.2.1. Analysis of the Microscopic Morphology of the Cement Matrix

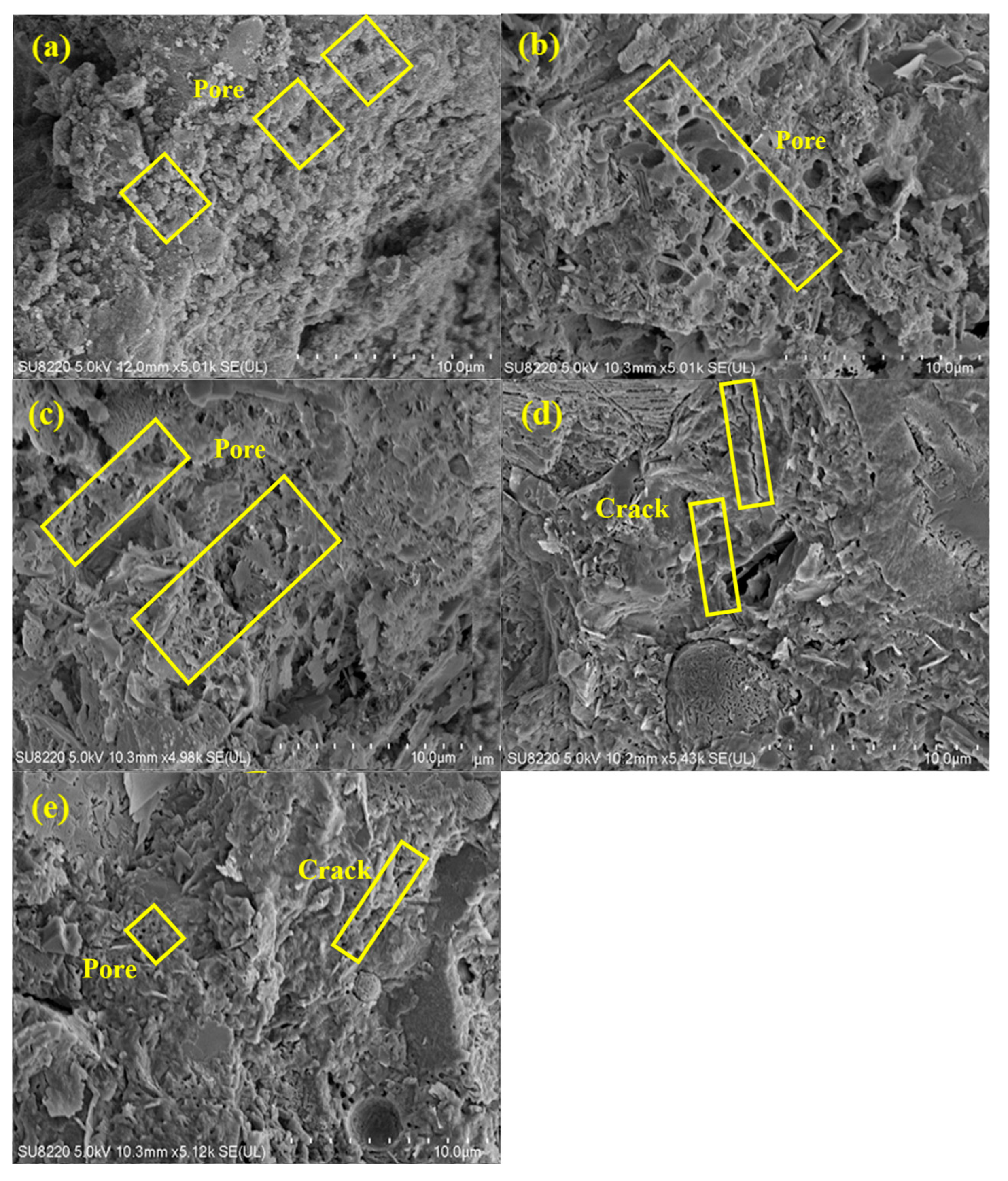

The cube concrete specimens that have been maintained for 28 days were smashed, the coarse aggregate was removed, and the cement stone between the aggregates was collected. After grinding into a powder, the SEM test was performed.

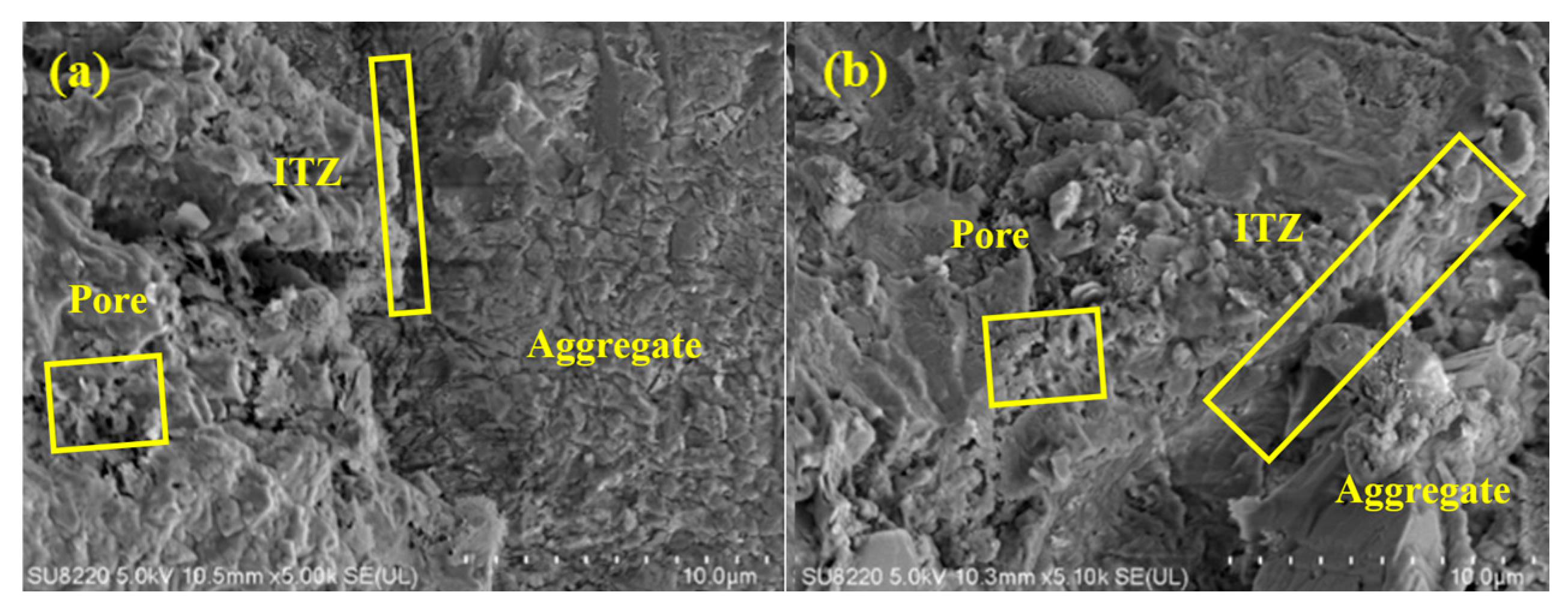

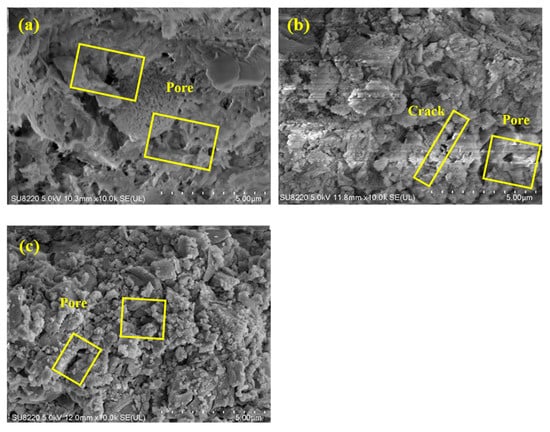

The microstructures of the cement stone in HGY concrete with different effective sand contents are shown in Figure 6. By comparing the microscopic morphology of the cement stone in specimens with different effective sand contents, when the effective sand content continuously increases, the microscopic morphology of the cement stone surface becomes more compact. When the effective sand content ranges from 80% to 90%, the hydration products are randomly and loosely piled on the surface of the cement stone, resulting in many small pores. When the effective sand content is 95% and 100%, the microscopic morphology of the cement stone surface is dense. Although there are still pores and cracks of various sizes, the overall porosity decreases. This indicates that when fine aggregate particles fill the voids between coarse aggregates, fine aggregates of smaller particle size grades give priority to playing the filling role. Therefore, the larger the effective sand content is, the better the optimization effect of the pore structure will be, and the wear resistance of the concrete will be the best.

Figure 6.

Microstructures of the cement stone in concrete with different effective sand contents ((a) S80, (b) S85, (c) S90, (d) S95, (e) S100).

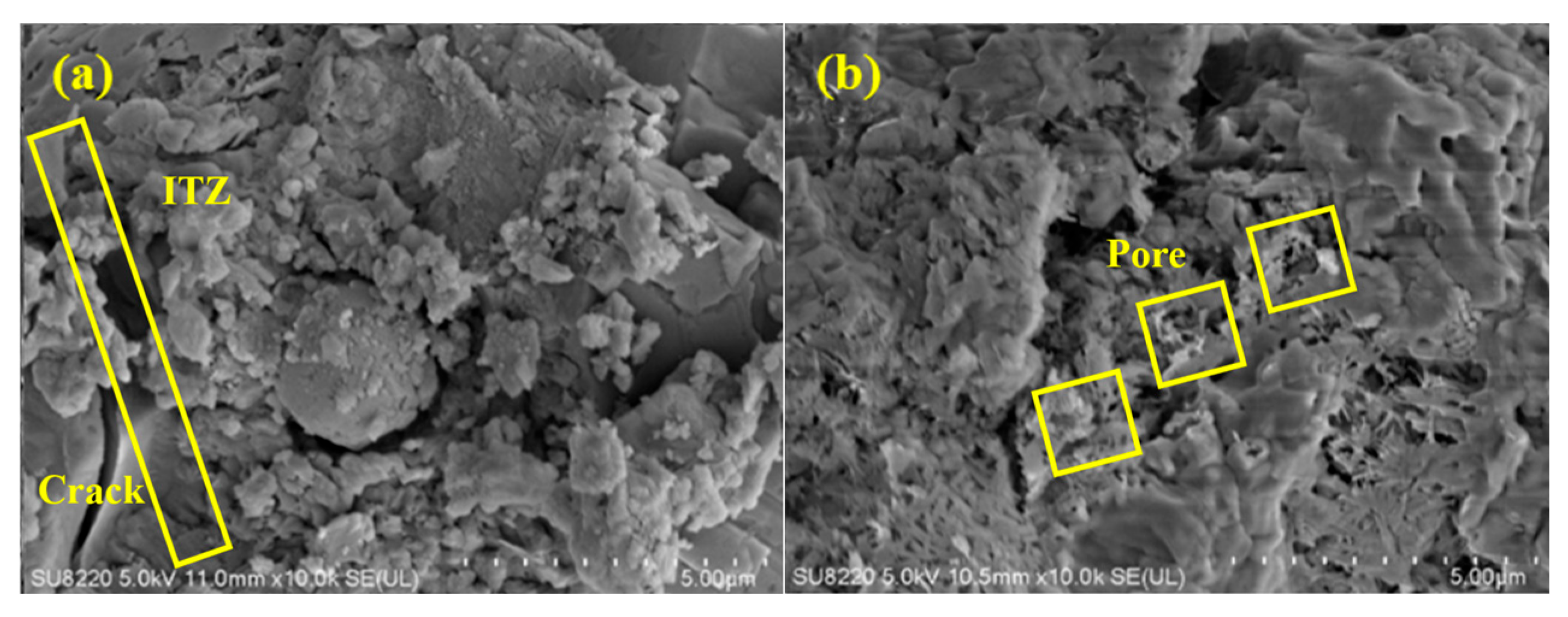

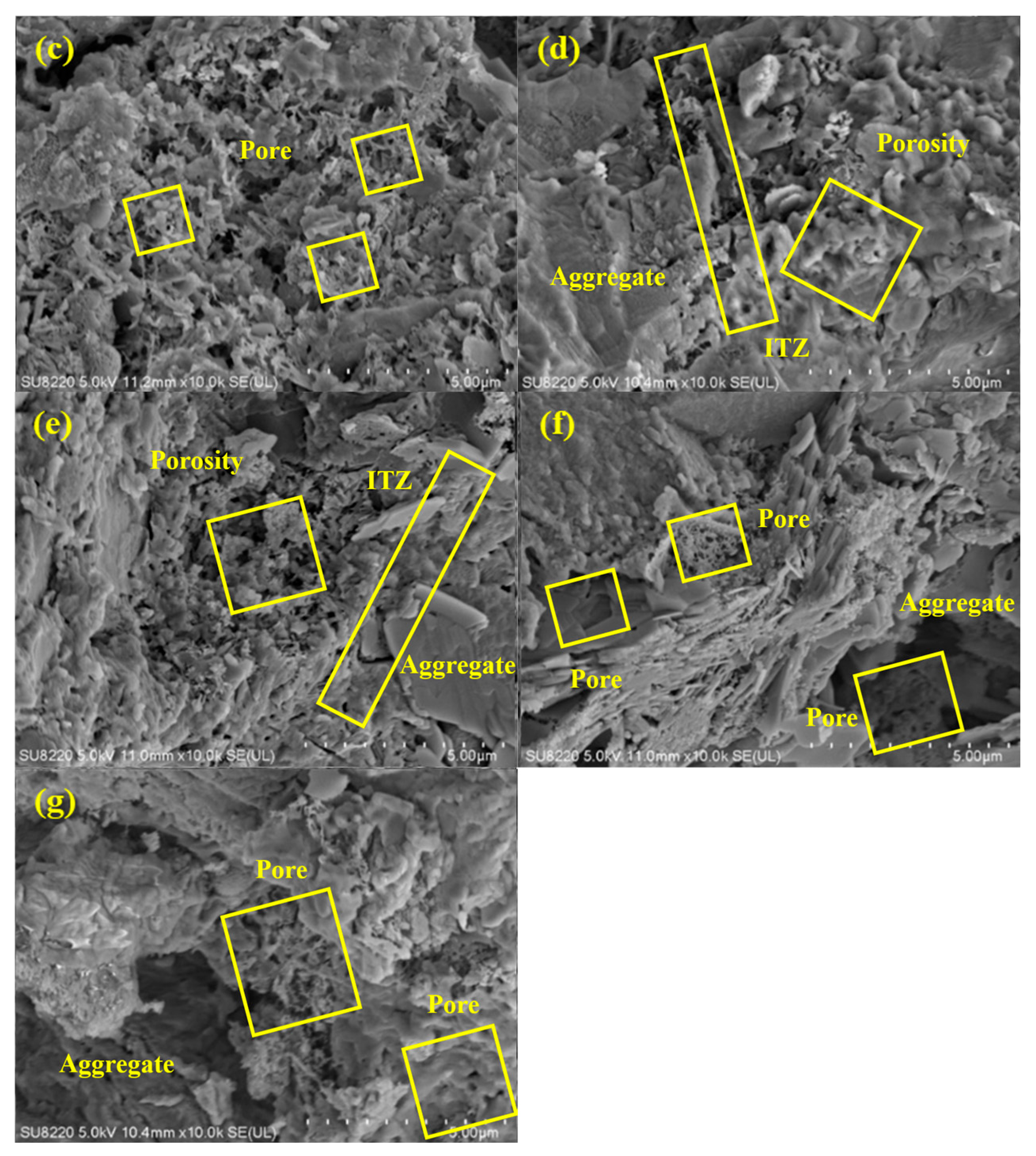

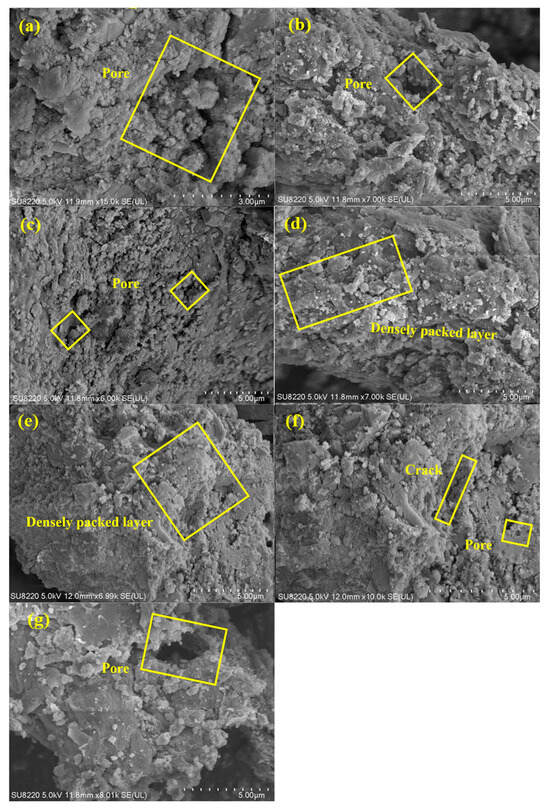

The microstructures of the cement stone in HGY concrete with different stone powder contents are shown in Figure 7. The comparative analysis of cement stone microstructures revealed that hydration products dominate the surface morphology, forming a densely packed matrix. As shown in Figure 7a, HGY concrete devoid of stone powder exhibits a porous microstructure characterized by interconnected macro-pores. At 3% and 5% stone powder content (Figure 7b,c), pore volume initially decreases, transitioning to smaller, isolated pores, though the microstructure remains loosely consolidated. At 7% and 9% stone powder content (Figure 6d,e), hydration products form a continuous, densely packed layer, significantly reducing porosity. At 12% and 15% stone powder content (Figure 7f,g), microcracks and localized pore coalescence emerge, culminating in macropore formation at 15% content, accompanied by diminished hydration product density. These findings demonstrate that moderate stone powder additions (≤9%) optimize the pore structure of HGY concrete, enhancing its abrasion resistance; whereas, excessive dosages (>9%) degrade microstructural integrity. However, when the content of stone powder is too high, the stone powder particles themselves are relatively fine. Too much stone powder will cause the particle gradation inside the concrete to be unbalanced, and it cannot play an ideal filling role in the skeleton, resulting in the formation of large voids or holes inside the concrete. Moreover, the addition of a large amount of stone powder will impede the cement hydration process and reduce the generation of hydration products [39].

Figure 7.

Microstructures of the cement stone in HGY concrete with different stone powder content ((a) J0, (b) J3, (c) J5, (d) J7, (e) J9, (f) J12, (g) J15).

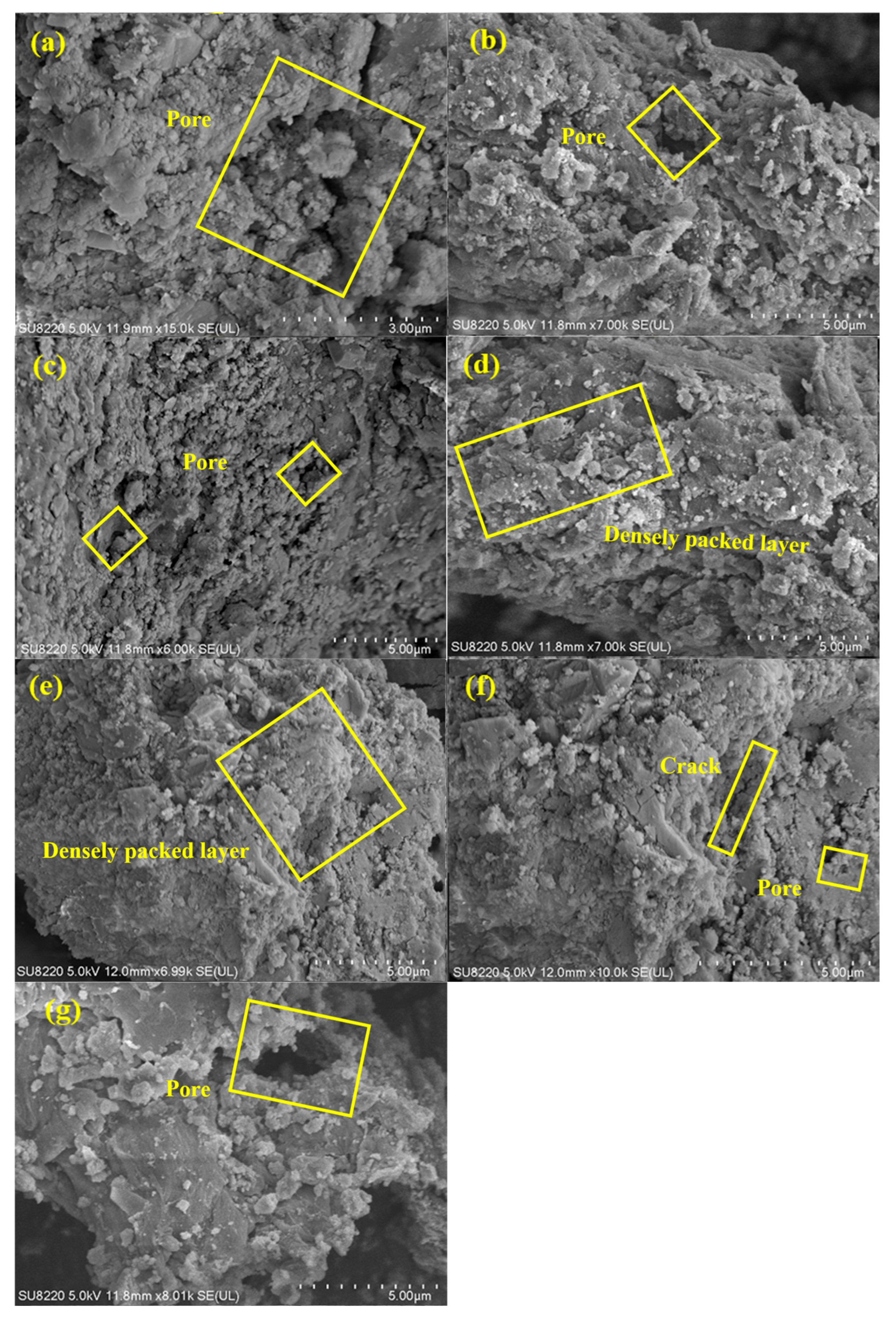

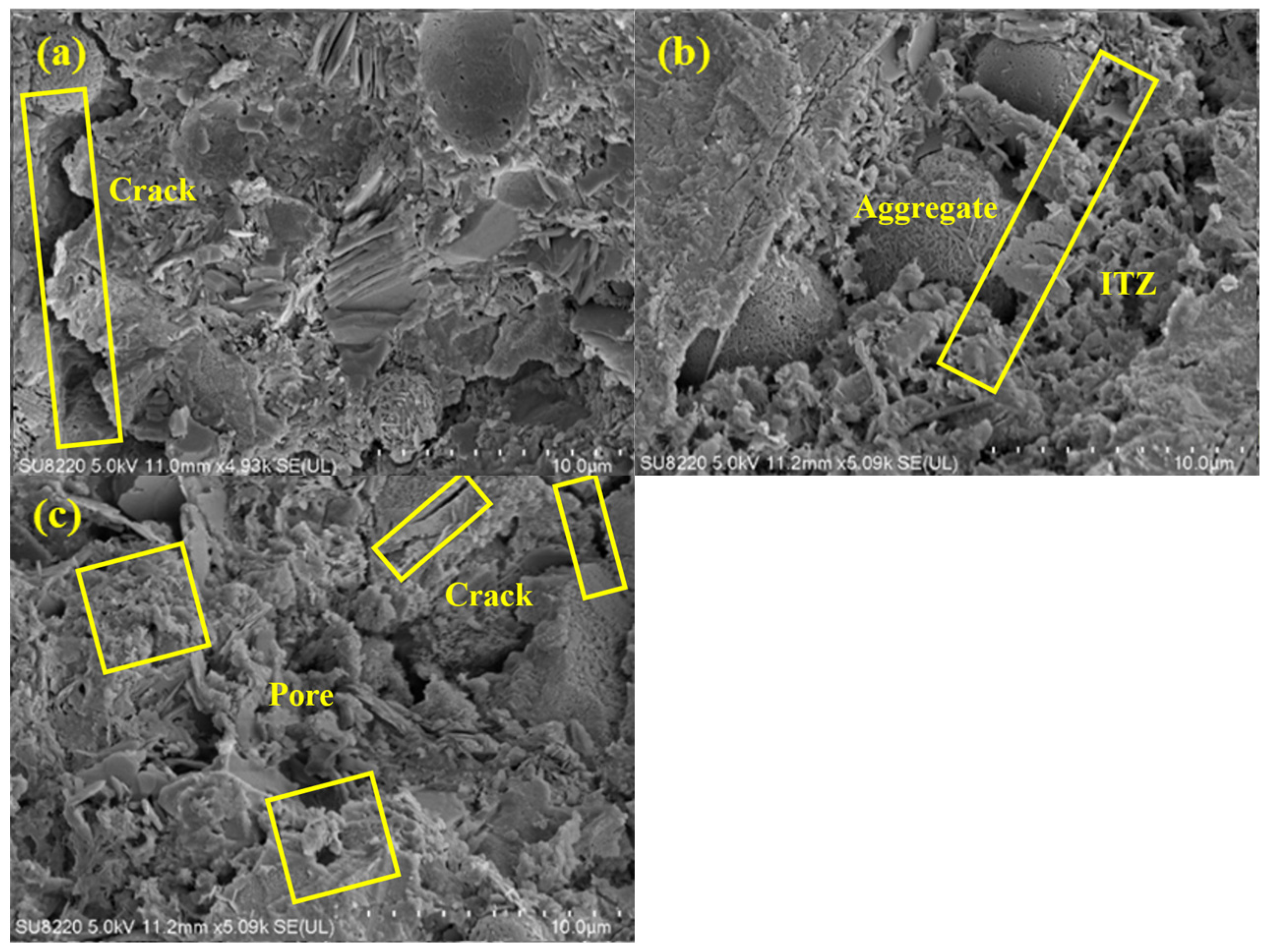

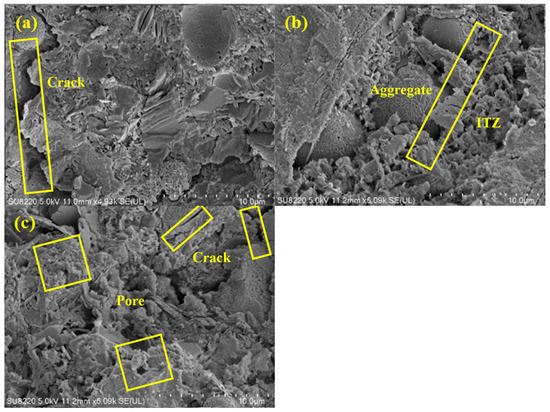

The microstructures of the cement stone in concrete with different fine aggregate lithology are shown in Figure 8. By comparing the microscopic morphology of the cement stone in specimens with different fine aggregate lithologies, it is found that compared to HS concrete, the microscopic morphology of the cement stone in MS concrete is denser. The hydration products on the surface of HS concrete are loosely stacked. This is because the stone powder contained in MS acts as crystal nuclei during the cement hydration process, thereby promoting the formation of cement hydration products [9]. At the same time, there are relatively large particles of hydration products on the surface of the SHY concrete, while the volume of the hydration products on the surface of the HGY concrete is smaller. This is attributed to the fact that limestone powder exhibits a certain degree of reactivity, allowing it to react with the components in cement. The substantial volume of the generated carboaluminate effectively reduces concrete porosity and optimizes the pore structure.

Figure 8.

Microstructures of the cement stone in concrete with different fine aggregate lithology ((a) HS, (b) SHY, (c) HGY).

3.2.2. Analysis of the Microscopic Morphology of the Interface Transition Zone

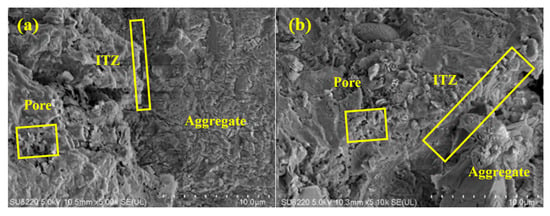

The cubic concrete specimens cured for 28 days were smashed, and fine fragments containing both cement paste and aggregate particles were collected for preparing flake specimens, representing the interfacial transition zone. The microstructure of the interfacial transition zone was analyzed using SEM.

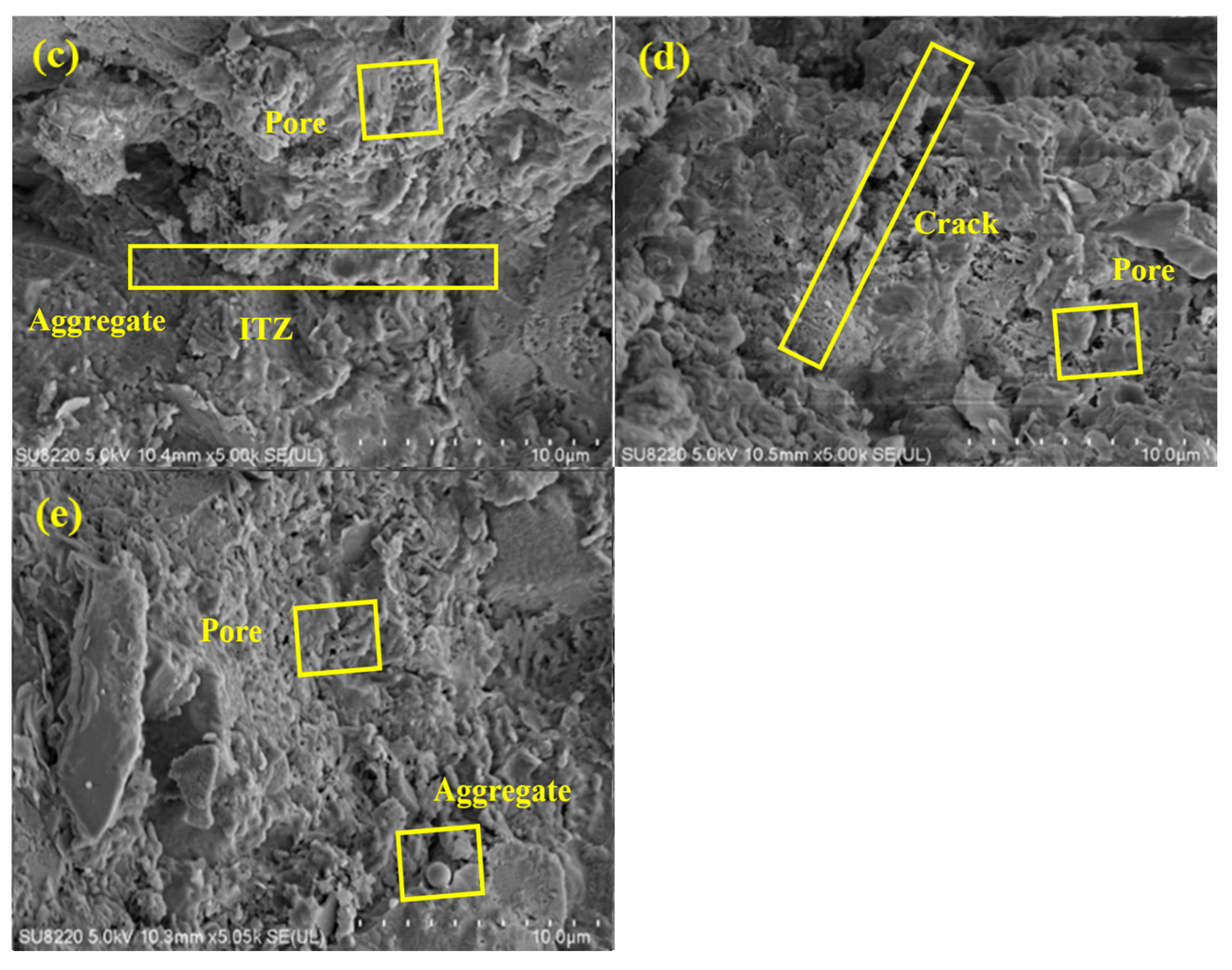

The microscopic morphology of the interface transition zone of HGY concrete with different effective sand contents are shown in Figure 9. By comparing the microscopic morphology of the interface transition zone in specimens with different effective sand contents, when the effective sand content is 80%, the boundary of the interface transition zone can still be clearly observed. The hydration products on the surface of the aggregate are densely packed, while there are many pores in the hydration products of the cement matrix. When the effective sand content is 85% and 90%, the hydration products in the cement matrix gradually develop towards the interface transition zone and the surface of the aggregate, and at this time, the boundary of the interface transition zone can still be distinguished. When the effective sand content is 95% and 100%, the coverage range of the hydration products is relatively wide, it is impossible to determine the boundary of the interface transition zone, and the pores among the hydration products gradually decrease.

Figure 9.

Morphology of interface transition zone in concrete with different effective sand contents ((a) S80, (b) S85, (c) S90, (d) S95, (e) S100).

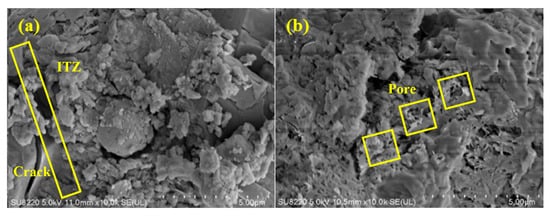

The microscopic morphology of the interface transition zone of HGY concrete with different contents of stone powder are shown in Figure 10. By comparing the microscopic morphology of the interface transition zone in specimens with different contents of stone powder, when the content of stone powder is 0%, there are obvious penetrating cracks in the interface transition zone, and the boundary of the aggregate can be clearly seen. When the content of stone powder is 3%, the hydration products in the interface transition zone increase, and part of the cracks are covered by the accumulated hydration products. When the content of stone powder is 5%, the coverage range of the high-quality hydration products is further expanded, and currently, it is difficult to distinguish the boundary of the interface transition zone, leaving only some holes. When the content of stone powder is 7% and 9%, the hydration products gradually accumulate to fill the holes. Currently, the pore structure is relatively small, and the hydration products in the interface transition zone gradually develop towards the aggregate area. When the content of stone powder is 12% and 15%, the accumulation of hydration products is concentrated, and larger holes are formed. This indicates that the added stone powder plays the role of a crystal nucleus, and a large amount of hydration products can accumulate on the cement matrix and even on the surface of the aggregate. When the content of stone powder is small, it can strengthen the strength of the interface transition zone. However, when the content of stone powder is too high, which leads to the formation of relatively large holes in the formed concrete, it will instead reduce the bonding strength between the aggregate and the cement matrix.

Figure 10.

Morphology of interface transition zone in concrete with different stone powder content ((a) J0, (b) J3, (c) J5, (d) J7, (e) J9, (f) J12, (g) J15).

The microscopic morphology of the interface transition zone of HGY concrete with different fine aggregate lithologies is shown in Figure 11. By comparing the microscopic morphology of the interface transition zone in specimens with different fine aggregate lithologies, there are obvious cracks in the interface transition zone of the river sand specimen, obvious cracks and holes exist in the interface transition zone of the HGY specimen, while there are greater accumulations of hydration products in the interface transition zone of the SHY specimen, and its holes are relatively small. This is because the stone powder contained in the MS optimizes the interface transition zone, and the limestone powder can also participate in the hydration reaction to form hydrotalcite-like compounds, namely carbonate–aluminate hydrates, of relatively large volume, reducing the porosity of the interface transition zone.

Figure 11.

Morphology of ITZ in concrete with different fine aggregate lithologies ((a) HS, (b) SHY, (c) HGY).

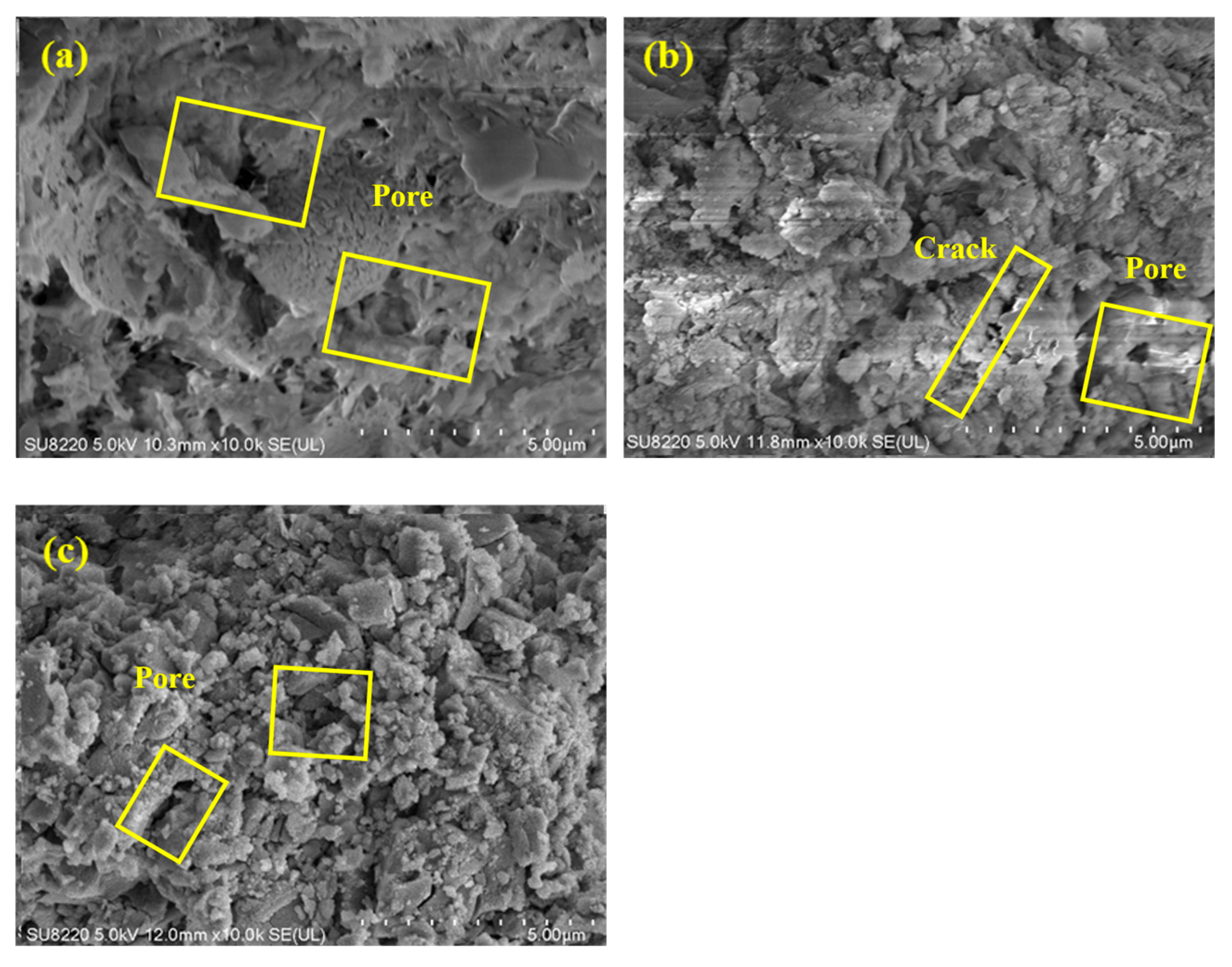

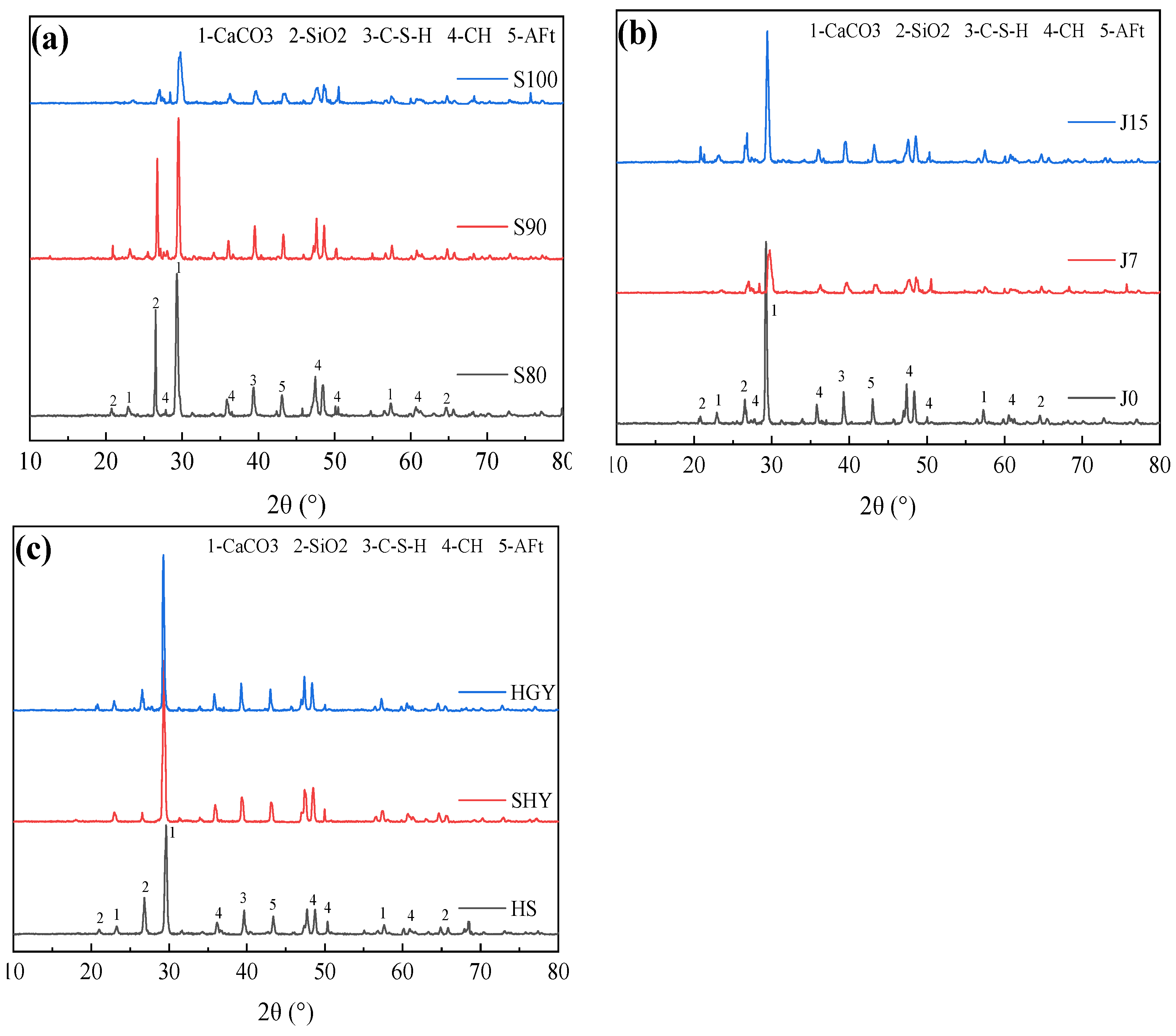

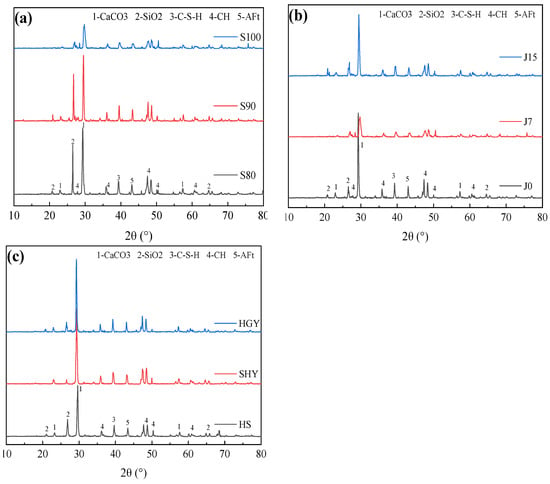

3.2.3. Analysis of the Hydration Degree by XRD

To further explore the internal hydration degree of specimens with different effective sand contents, stone powder contents, and fine aggregate lithologies. The cube concrete specimens cured for 28 days were crushed, rolled, and ground into powder for an X-ray diffraction (XRD) test.

S80, S90, and S100 were selected to compare the XRD patterns of HGY concrete under different effective sand contents, as shown in Figure 12a. As can be seen from Figure 12a, the types of characteristic peaks in the XRD patterns of the specimens in each group are similar, indicating that different effective sand contents have no effect on the types of hydration products of HGY concrete. The silica in the sand used mainly exists as quartz, a crystalline silica with high chemical stability that typically does not react directly with calcium hydroxide under conventional concrete curing conditions [40]. However, the peak values of the characteristic peaks vary, especially for the carbonized products represented by CaCO3 and the minerals of fine aggregates represented by SiO2. When the effective sand content increases to 100%, the contents of CaCO3 and SiO2 decrease significantly. In specimens with low effective sand content, calcium hydroxide (Ca(OH)2) mainly participates in the carbonation reaction. In high effective sand content conditions, quartz alters the concrete’s pore structure and local chemical environment [41]. This indirectly affects the hydration process by possibly promoting the formation or transformation of other hydration products, thus increasing the overall hydration degree. Therefore, for the concrete with a high effective sand content, the hydration degree is high, and the structure is dense, which can enhance the durability of the concrete.

Figure 12.

XRD patterns of concrete. ((a) effective sand content; (b) stone powder content; (c) fine aggregate lithology)).

J0, J7, and J15 were selected to compare the XRD patterns of concrete under different stone powder contents, as shown in Figure 12b. It can be observed from Figure 12b that the XRD patterns of the specimens under different stone powder contents are significantly different. For the specimen (J7) with a stone powder content of 7%, after 28 days of hydration, the content of CaCO₃ was evidently lower than that of the specimens with a low stone powder content (J7) and a high stone powder content (J15). Studies have shown that stone powder particles, with their large specific surface area, can adsorb cement hydration products and provide more active surfaces for cement hydration, thus accelerating the cement hydration reaction [42]. In addition, the filling action of stone powder can refine the pore structure within concrete, reduce the number of large pores, and enable cement hydration products to diffuse and fill these pores, thereby promoting further cement hydration more easily [43]. Consequently, adding an appropriate amount of stone powder to concrete can effectively promote cement hydration, increase the compactness of the concrete, and reduce the formation of CaCO3 carbonation products at 28 days.

The XRD patterns of concrete with three different fine aggregate lithologies, namely river sand, SHY, and HGY, were compared, as shown in Figure 12c. It can be observed from Figure 11c that among the XRD patterns of concrete with different fine aggregate lithologies, the content of SiO₂ in the concrete with SHY is relatively low, followed by that in the concrete with HGY, and the content of SiO2 in the river sand concrete is relatively high. The SiO2 in sand predominantly exists in the form of quartz crystals. Variations in geological formation environments and processing techniques among different fine aggregates (HS, SHY, HGY) may lead to differences in quartz crystal content and intrinsic characteristics, which could influence the diffraction signal intensity of SiO2 in XRD patterns. Additionally, the limestone powder present in MS may act as nucleation sites during cement hydration, thereby accelerating the hydration process. This may result in a reduction in SiO2 content, an increase in silicate hydration products, and enhanced consumption of SiO2 due to the participation of limestone powder in hydration reactions. Consequently, the microstructure of the cement paste in MS concrete with a higher hydration degree may exhibit increased densification.

4. Conclusions

In this study, a self-developed indoor abrasion tester for concrete pavements was employed. Using mass loss as the evaluation metric, combined with scanning electron microscopy (SEM) and X-ray diffraction (XRD) analyses, this study elucidated the mechanisms by which effective sand content, limestone powder content, and fine aggregate lithology influence the abrasion resistance of high-grade granite (HGY) concrete. The study identified optimal thresholds for effective sand and limestone powder ratios and quantified the long-term degradation kinetics of abrasion resistance in HGY concrete pavements. These findings enhance road safety and durability, while reducing maintenance costs, offering actionable insights for optimizing HGY concrete in engineering applications. The principal findings can be summarized as follows:

- (1)

- Under varying wear times, an increase in effective sand content reduces the mass loss of concrete; when the stone powder content reaches 9%, the wear resistance of concrete is optimal. In comparison to SHY and HS concrete, HGY concrete exhibits superior wear resistance. When the effective sand content is 100% and 9% stone powder is incorporated, the mass loss of concrete can be effectively reduced, and the wear resistance can be improved.

- (2)

- The higher the effective sand content, the finer the average particle size of the fine aggregate. It can better fill the voids in the concrete, leading to a higher degree of hydration. The microscopic morphologies of the cement matrix and the interfacial transition zone become denser, which can enhance the bonding strength between the aggregate and the cement matrix and reduce the porosity. This is conducive to improving the wear resistance of the concrete.

- (3)

- The incorporation of stone powder can effectively optimize the internal pore structure of the concrete and improve its wear resistance when the content is small. However, when the content is too high, resulting in relatively large holes in the formed concrete, the stone powder cannot fully fill them. Moreover, a large amount of stone powder incorporated will dilute the cement hydration process and reduce the generation of hydration products.

- (4)

- The stone powder in MS can serve as crystal nuclei during the cement hydration process, facilitating the formation and crystallization of hydration products. Limestone stone powder possesses chemical activity and can react with cement minerals to produce voluminous carboaluminates, reducing the porosity and optimizing the pore structure. Meanwhile, the stone powder improves the ITZ. By generating carboaluminates, it decreases the porosity and enhances the compactness, thereby enhancing the overall wear resistance of the concrete.

Author Contributions

Methodology, Y.W.; Software, X.Y.; Validation, J.L.; Formal analysis, M.P.; Investigation, Y.C.; Resources, Y.C.; Data curation, M.P.; Writing—original draft, Z.L.; Writing—review & editing, Z.L.; Project administration, Y.C.; Funding acquisition, Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Guangxi Science and Technology Program (Grant No. GuikeAB24010355).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated and/or analyzed during the current study are not publicly available due to some data related to personal privacy but are available from the corresponding author on reasonable request.

Acknowledgments

The authors thank the reviewers of this paper for their comments and suggestions.

Conflicts of Interest

Authors Zhitang Li and Yuankuo Wang were employed by Poly Changda Engineering Co., Ltd. Author Minqiang Pan was employed by China Railway Communications Investment Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yang, X.; Liu, Y.; Liang, J.; Meng, Y.; Rong, H.; Li, D.; Chen, Y.; Lv, J.; Jiang, Y.; Liu, Y. Straightening Methods for RCA and RAC—A Review. Cem. Concr. Compos. 2023, 141, 105145. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Huang, F.; Yi, Z.; Xie, Y.; Sun, D.; Sun, R. Impact of Different Lithological Manufactured Sands on High-Speed Railway Box Girder Concrete. Constr. Build. Mater. 2020, 230, 116943. [Google Scholar] [CrossRef]

- Li, Z.; Lao, J.; Wang, L.; Lim, N.S.; Tan, K.H.; Qian, S. A Review on Substitution of Natural Sand with Granite Fines in Sustainable Concrete. Constr. Build. Mater. 2022, 346, 128417. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Khasani, R.R. An Innovative Moment Balanced Inference Engine for Predicting Recycled Concrete Aggregate Strength and Minimizing Mixture CO2 Emissions. Constr. Build. Mater. 2024, 441, 137482. [Google Scholar] [CrossRef]

- Ke, G.; Lu, Z.; Hao, Y.; Li, B.; Wang, J. Gray Relation Analysis in Influential Factors of Abrasion Resistance of Pavement Manufactured Sand Cement Concrete. Bull. Chin. Ceram. Soc. 2011, 30, 216–219. [Google Scholar]

- Pomoni, M. Exploring Smart Tires as a Tool to Assist Safe Driving and Monitor Tire-Road Friction. Vehicles 2022, 4, 744–765. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, R. Investigation of Long-Term Performance and Deicing Longevity Prediction of Self-Ice-Melting Asphalt Pavement. Materials 2022, 15, 6026. [Google Scholar] [CrossRef]

- Kim, S.; Qudoos, A.; Jakhrani, S.; Lee, J.; Kim, H. Influence of Coarse Aggregates and Silica Fume on the Mechanical Properties, Durability, and Microstructure of Concrete. Materials 2019, 12, 3324. [Google Scholar] [CrossRef]

- Luo, G.; Xie, J.; Chen, Z.; Zhang, Y. Abrasion Resistance of Manufactured Sand (MS) Concrete and Its Influence Factors. IOP Conf. Ser. Mater. Sci. Eng. 2019, 562, 012065. [Google Scholar] [CrossRef]

- Binici, H.; Shah, T.; Aksogan, O.; Kaplan, H. Durability of Concrete Made with Granite and Marble as Recycle Aggregates. J. Mater. Process. Technol. 2008, 208, 299–308. [Google Scholar] [CrossRef]

- Tolmachov, S.; Belichenko, O.; Tolmachov, D. Abrasion of Cement-Concrete and His Contents Investigation. Matec Web Conf. 2018, 230, 02033. [Google Scholar] [CrossRef]

- Subhanalisha, S.; Vamsikrishna, V.; Narayanaarya, D.; Harikachowdary, M. Experimental Study on Improvement of Compressive Strenght of Concrete Using and Durability of Concrete of Specified Concrete with Adding Waste Spent Fire Brick, Granite and Marble. Int. J. Sci. Res. Sci. Eng. Technol. 2016, 2, 57–64. [Google Scholar]

- Awan, M.; Awan, M.; Khan, A.; Umer, M.; Zia, M.; Bux, M. Frequency limited impulse response gramians based model reduction. Mehran Univ. Res. J. Eng. Technol. 2023, 42, 71–74. [Google Scholar] [CrossRef]

- Lai, Y.; Liu, D.; Huang, L.; Wang, S. Rresearch on the influence of quality of manufactured tuff sand on concrete performance. Ind. Constr. 2020, 50, 88–93. [Google Scholar]

- Huang, J.; Xu, G.; Chen, S.; Yu, D.; Fu, T.; Feng, C.; Wang, Y. Enhancing Mechanical Properties and Microstructures of Mass-Manufactured Sand Concrete by Incorporating Granite Powder. Materials 2024, 17, 2234. [Google Scholar] [CrossRef]

- Jin, Q.; Chen, L. A Review of the Influence of Copper Slag on the Properties of Cement-Based Materials. Materials 2022, 15, 8594. [Google Scholar] [CrossRef]

- Yamanoi, Y.; Maekawa, K. Shear Bifurcation and Gravelization of Low-Strength Concrete. J. Adv. Concr. Technol. 2020, 18, 767–777. [Google Scholar] [CrossRef]

- Shen, W.; Liu, Y.; Wang, Z.; Cao, L.; Wu, D.; Wang, Y.; Ji, X. Influence of Manufactured Sand’s Characteristics on Its Concrete Performance. Constr. Build. Mater. 2018, 172, 574–583. [Google Scholar] [CrossRef]

- Zuo, H.; Li, J.; Zhu, L.; Cheng, D.; Chang, D. Identification Fluidity Method to Determine Suitability of Weathered and River Sand for Constructions Purposes. Coatings 2023, 13, 327. [Google Scholar] [CrossRef]

- Luo, T.; Tang, Y.; Xu, P.; Zhang, Y.; Deng, Z. Analysis on Research Status of Road Performance of Machine-Made Sand Concrete. IOP Conf. Ser. Earth Environ. Sci. 2020, 587, 012036. [Google Scholar] [CrossRef]

- Tang, L.; Chen, Y.; Zhou, Z.; Cheng, Z. Study on The Influence of Grain Size Composition on Engineering Properties of Granite Residual Soil. Pol. J. Environ. Stud. 2023, 32, 4291–4300. [Google Scholar] [CrossRef]

- Li, K.-R.; Hua, P.-L. Research on the Influence of Manufactured Sand Gradation on Concrete Performance. E3S Web Conf. 2021, 283, 01024. [Google Scholar] [CrossRef]

- Grinys, A.; Balamurugan, M.; Augonis, A.; Ivanauskas, E. Mechanical Properties and Durability of Rubberized and Glass Powder Modified Rubberized Concrete for Whitetopping Structures. Materials 2021, 14, 2321. [Google Scholar] [CrossRef]

- Zheng, S.; Chen, J.; Wang, W. Effects of Fines Content on Durability of High-Strength Manufactured Sand Concrete. Materials 2023, 16, 522. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Liu, Y. Effects of the Lithologic Character of Manufactured Sand on Properties of Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 1213–1218. [Google Scholar] [CrossRef]

- GB/T 14684-2022; Sand for Construction. The Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- GB/T 14685-2011; Pebble and Crushed Stone for Construction. The Standardization Administration of the People’s Republic of China: Beijing, China, 2011.

- GB 8076-2008; Concrete Admixtures. The Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 1596-2005; Fly Ash Used for Cement and Concrete. The Standardization Administration of the People’s Republic of China: Beijing, China, 2005.

- GB 5749-2006; Standards for Drinking Water Quality. The Standardization Administration of the People’s Republic of China: Beijing, China, 2006.

- Kim, S.H.; Shin, M.C. Steering Pull Model and Its Sensitivity Analysis. Appl. Sci. 2020, 10, 8072. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. The Standardization Administration of the People’s Republic of China: Beijing, China, 2011.

- Xing, F.; Liu, Y.; Yang, W.; Yu, L.; Li, X. Sand fineness and level matching the properties of fresh concrete impact study. Concrete 2015, 118, 121130. [Google Scholar]

- Qin, Y.; Wang, Q.; Xu, D.; Fan, X. Study of the Effects of Fine Coral Powder and Salinity on the Mechanical Behaviour of Coral Sand-Seawater Cement Mortar. Constr. Build. Mater. 2021, 313, 125476. [Google Scholar] [CrossRef]

- Chao, H.; Yu, L.; Chen, J.; Zhou, M.; Ouyang, X. New Insights into the Effects of Calcite Coral Powder on Hydration and Strength Development of Cement Pastes. J. Build. Eng. 2024, 92, 109649. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Jin, F.; Zhao, X. Impact of Stone Powder Content on Corrosion Resistance in Reinforced Concrete under Stray Current and Chloride Interactions. Materials 2024, 17, 196. [Google Scholar] [CrossRef]

- Wang, J.; Tian, B.; Ke, G.; Li, B. A Study on Effects of Manufactured Sand and Micro-fines: Contenton Abrasion Resistance of Pavement Cement Concrete. Highway 2011, 7, 207–211. [Google Scholar]

- Tsado, T.Y. A Comparative Analysis of Concrete Strength Using Igneous, Sedimentary and Metamorphic Rocks (Crushed Granite, Limestone and Marble Stone) as Coarse Aggregate. Int. J. Eng. Res. Technol. 2013, 11, 180–191. [Google Scholar]

- Guo, J.-H.; Li, G.-Z.; Gao, C.-Y. Study on the Effect of Iron Tailings Manufactured Sand Powder Content on Cement Hydration. IOP Conf. Ser. Mater. Sci. Eng. 2019, 592, 012006. [Google Scholar] [CrossRef]

- Lin, Y.; Bin, C.; Su, F.; Chen, Y.; Rong, H.; Huang, Y. Effects of Mineral Admixtures on the Alkali–Silica Reaction in Granite Manufactured Sand Mortar. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024, 49, 2555–2574. [Google Scholar] [CrossRef]

- Lin, R.-S.; Wang, X.-Y.; Zhang, G.-Y. Effects of Quartz Powder on the Microstructure and Key Properties of Cement Paste. Sustainability 2018, 10, 3369. [Google Scholar] [CrossRef]

- Liu, X.; Rong, Y.; Chen, X.; Chen, X.; Zhang, W. Recycling of Waste Stone Powder in High Fluidity Grouting Materials for Geotechnical Engineering Reinforcement. Buildings 2022, 12, 1887. [Google Scholar] [CrossRef]

- Dobiszewska, M.; Bagcal, O.; Beycioğlu, A.; Goulias, D.; Köksal, F.; Niedostatkiewicz, M.; Ürünveren, H. Influence of Rock Dust Additives as Fine Aggregate Replacement on Properties of Cement Composites—A Review. Materials 2022, 15, 2947. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).