Comprehensive Review of Thermally Induced Self-Healing Behavior in Asphalt Mixtures and the Role of Steel Slag

Abstract

1. Introduction

2. Fundamentals of Thermally Induced Self-Healing in Asphalt Mixtures

2.1. Mechanisms of Self-Healing

2.1.1. Key Stages of the Self-Healing Process

- Crack surface wetting and contact: At elevated temperatures (typically ≥ 50 °C), the surface energy gradient drives the initial wetting of crack surfaces by the softened asphalt binder [25]. As the binder’s viscosity decreases (following the Walther equation), it flows to fill microcavities and re-establish adhesive contact across crack faces. This stage is critical for overcoming the surface tension that maintains crack openness, with the binder’s polar functional groups (e.g., carboxylic acids) facilitating physical adsorption onto aggregate surfaces [26].

- Stress-driven crack closure: As the asphalt mixture is heated, the reduction in binder stiffness increases its ductility, allowing mechanical stresses (residual or induced) to drive crack closure [27]. In this phase, the viscoelastic binder undergoes creep deformation, gradually reducing the crack width through cohesive flow. Research using dynamic shear rheometry (DSR) has shown that the rate of crack closure is directly proportional to the temperature-induced decrease in complex shear modulus (|G*|), with a 50% reduction in |G*| at 80 °C compared to 25 °C [28].

- Molecular diffusion and mechanical recovery: The final stage involves molecular diffusion across the re-contacted crack interface, where asphaltenes and maltenes interpenetrate to restore cohesive strength [29]. At optimal healing temperatures (80–100 °C), the increased kinetic energy of binder molecules enhances interdiffusion, with small molecular weight maltenes (e.g., saturates and aromatics) migrating faster than asphaltenes, leading to a gradual recovery of mechanical properties [30]. Fourier transform infrared spectroscopy (FTIR) has confirmed the re-establishment of van der Waals interactions and hydrogen bonding across healed interfaces, with tensile strength recovery reaching 60–80% after 24 h of thermal treatment [31].

2.1.2. Theoretical Frameworks for Self-Healing

- Molecular diffusion theory: Rooted in polymer science, this theory posits that crack healing involves sequential stages of surface rearrangement, wetting, molecular diffusion, and randomization of polymer chains [32]. In asphalt, the complex mixture of high-molecular-weight asphaltenes and low-viscosity maltenes creates a heterogeneous diffusion environment. Maltenes, acting as a “solvent” for asphaltenes, facilitate the flow of binder across cracks, with diffusion kinetics governed by the Stokes–Einstein equation [33]. Experimental studies using fluorescent tracers have shown that diffusion rates increase exponentially with temperature, with a 30% acceleration observed when heating from 60 °C to 90 °C [34].

- Crack surface energy theory: From a fracture mechanics perspective, self-healing is defined as a reduction in crack surface energy (Γ), which is the energy required to create new crack surfaces [35]. The healing process minimizes Γ through the wetting and bonding of crack faces, described by the Young–Dupré equation for adhesive work. Schapery [36] extended this concept to viscoelastic materials, deriving the relationship. This theory highlights the role of temperature in reducing Γh by enhancing binder-aggregate adhesion, with studies showing a 15–20% decrease in surface energy for heated asphalt mixtures compared to unheated controls [37]. Furthermore, Luo et al. [38] conducted a comprehensive mechanical analysis of the asphalt healing process and developed a theoretical model to describe the healing behavior of asphalt mixtures. As illustrated in Figure 1, the internal actual stress and interfacial attraction are the two primary driving forces behind the self-healing of asphalt.

- Capillary flow theory: García [39] proposed a model where capillary pressure drives binder flow into cracks at elevated temperatures, assuming asphalt behaves as a Newtonian fluid. The capillary pressure (Pc) is provided by the Young–Laplace equation. As temperature increases, the contact angle decreases (improving wetting), and binder viscosity drops, enhancing Pc and flow rate. This theory is particularly applicable to microcracks (<2 mm width), where capillary forces dominate over gravitational or mechanical stresses. Experimental validation using microfluidic models has shown that cracks narrower than 500 μm are fully healed within 30 min at 90 °C, with flow rates increasing by 50% compared to room temperature [40].

2.1.3. Temperature and Time Dependencies

- Temperature thresholds: Dense-graded asphalt mixtures begin self-healing at 50 °C, with healing rates increasing monotonically up to 100 °C, where the binder transitions into a Newtonian fluid state [41]. Below 50 °C, viscosity remains too high for effective flow, while above 100 °C, excessive thermal aging may degrade binder properties, reducing long-term durability [42].

- Healing kinetics: The healing process follows a biphasic pattern: an initial rapid strength recovery (60–70% within 1 h) due to crack closure, followed by a slower diffusion-driven phase (additional 10–20% recovery over 24 h) [43]. Time-temperature superposition principles have been used to model this behavior, showing that a 10 °C increase in healing temperature is equivalent to a three-fold increase in healing time [44].

- Optimal Timing: Induction heating is most effective when applied at 30–70% of the pavement’s fatigue life, corresponding to the stage of microcrack propagation before macrocrack formation [45]. Premature activation (e.g., <20% fatigue life) may waste energy, while delayed activation (>80% fatigue life) may fail to repair critical damage, leading to structural failure [46].

2.2. Heating Methods for Enhanced Self-Healing

2.2.1. Electromagnetic Induction Heating

- Eddy current and hysteresis heating: Conductive fillers (e.g., steel fibers) generate heat through eddy current losses, while ferromagnetic components (e.g., magnetite) produce heat via hysteresis effects during magnetic field oscillations [49]. This targeted heating softens the asphalt binder, promoting crack closure and molecular diffusion.

- Void content optimization: Incorporation of dense, angular fillers reduces air voids, enhancing mechanical interlock and reducing pathways for moisture ingress. Studies indicate that each 4% increase in void content decreases repair efficiency by 10%, highlighting the importance of compact microstructure for effective healing [50].

- Thermal property modification: Fillers with low thermal conductivity and high heat-storage capacity prolong the duration of effective healing by retaining heat within the mixture. Microporous fillers, for example, interrupt heat transfer, maintaining optimal temperatures (50–100 °C) for extended periods [51].

2.2.2. Microwave Heating

- Dielectric heating efficiency: Materials with high ε″, such as aggregates containing metal oxides (e.g., Fe2O3, CaO), absorb microwaves more effectively, converting electromagnetic energy to heat at rates proportional to their loss properties [57]. This allows targeted activation of filler-rich zones, accelerating binder softening and crack repair.

- Porous structure enhancement: Porous fillers enhance microwave reflections and energy dissipation, creating a more uniform thermal environment. For instance, fillers with rough, interconnected pore structures improve heat distribution, reducing thermal gradients within the mixture [58].

- Moisture mitigation: While water can degrade healing by vaporizing at 100 °C, fillers with low water absorption restrict outward diffusion, maintaining stable thermal conditions for binder flow. Dense-graded mixtures, in particular, show better freeze–thaw resistance during microwave healing due to reduced void connectivity [59].

2.3. Limitations of Self-Healing Methods

3. Steel Slag as a Functional Aggregate for Enhanced Thermal Self-Healing

3.1. Physical and Chemical Properties of Steel Slag Aggregates

- Enhanced Mechanical Performance: When replacing coarse aggregates (particularly BOFS and EAFS), steel slag significantly improves the anti-rutting, fatigue resistance, and permanent deformation resistance of asphalt mixtures [81,82]. Its angular particles and rough surface enhance mechanical interlock among aggregates.

- Superior Skid Resistance: Steel slag’s wear resistance, high polishing resistance, and irregular surface morphology substantially improve pavement skid resistance (e.g., higher British Pendulum Number (BPN) and Mean Texture Depth (MTD) compared to conventional aggregates), making it suitable for high-traffic roads [83,84,85].

- Temperature Adaptability: Steel slag mixtures exhibit higher dynamic modulus across a broad temperature range (−10–54 °C), extending their applicability to diverse climatic conditions [74].

- Volumetric Stability Risks: Free calcium/magnesium oxides in steel slag pose hydration-induced expansion risks, requiring pretreatment (e.g., carbonation) to mitigate swelling [88].

| Reference | Source | CaO (%) | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | MgO (%) | MnO (%) |

|---|---|---|---|---|---|---|---|

| [90] | Jiangsu, China | 39.53 | 17.62 | 8.62 | 16.75 | 7.81 | 2.85 |

| [91] | Rugao, China | 37.56 | 17.66 | 7.64 | 19.07 | 5.61 | 2.32 |

| [92] | Benxi, China | 42.49 | 16.05 | 6.81 | 23.33 | 5.34 | 2.18 |

| [93] | Nanjing, China | 45.87 | 19.76 | 2.51 | 14.10 | 5.47 | 2.35 |

| [94] | Shanxi, China | 45.50 | 13.50 | 2.31 | 24.30 | 5.80 | 2.24 |

| [95] | Wuhan, China | 37.88 | 28.05 | 9.60 | 9.53 | 8.70 | 3.02 |

| [96] | Binzhou, China | 41.59 | 13.30 | 4.48 | 24.19 | 5.90 | − |

| [97] | Tangshan, China | 44.24 | 12.00 | 4.05 | 29.74 | 4.51 | − |

| [98] | Zhanjiang, China | 42.92 | 11.63 | 9.46 | 23.36 | 5.35 | − |

| [98] | Xinyu, China | 41.35 | 11.04 | 1.35 | 25.43 | 8.62 | − |

| [99] | Korea | 35.59 | 14.60 | 3.52 | 33.82 | 5.06 | 3.70 |

| [100] | Canada | 46.5 | 23.3 | 4.02 | 7.71 | 11 | 1.20 |

| [100] | Canada | 28 | 18.7 | 12.6 | 18 | 7.84 | 0.39 |

| [101] | Netherlands | 41.55 | 11.47 | 2.24 | 31.35 | 3.78 | 4.78 |

| [102] | Netherlands | 40.87 | 15.91 | 2.35 | 25.21 | 5.21 | 5.00 |

| [103] | Brazil | 36.80 | 14.60 | 3.70 | 32.20 | 5.50 | 3.70 |

| [103] | Brazil | 27.40 | 19.00 | 6.50 | 33.50 | 5.60 | 4.00 |

| [104] | Italy | 49.00 | 23.00 | 10.80 | 5.20 | 8.50 | 1.0 |

| [105] | Finland | 54.59 | 12.99 | 1.15 | 21.35 | 1.86 | − |

| [105] | Finland | 55.40 | 15.19 | 2.15 | 16.06 | 1.64 | − |

3.2. Thermal and Electromagnetic Characteristics

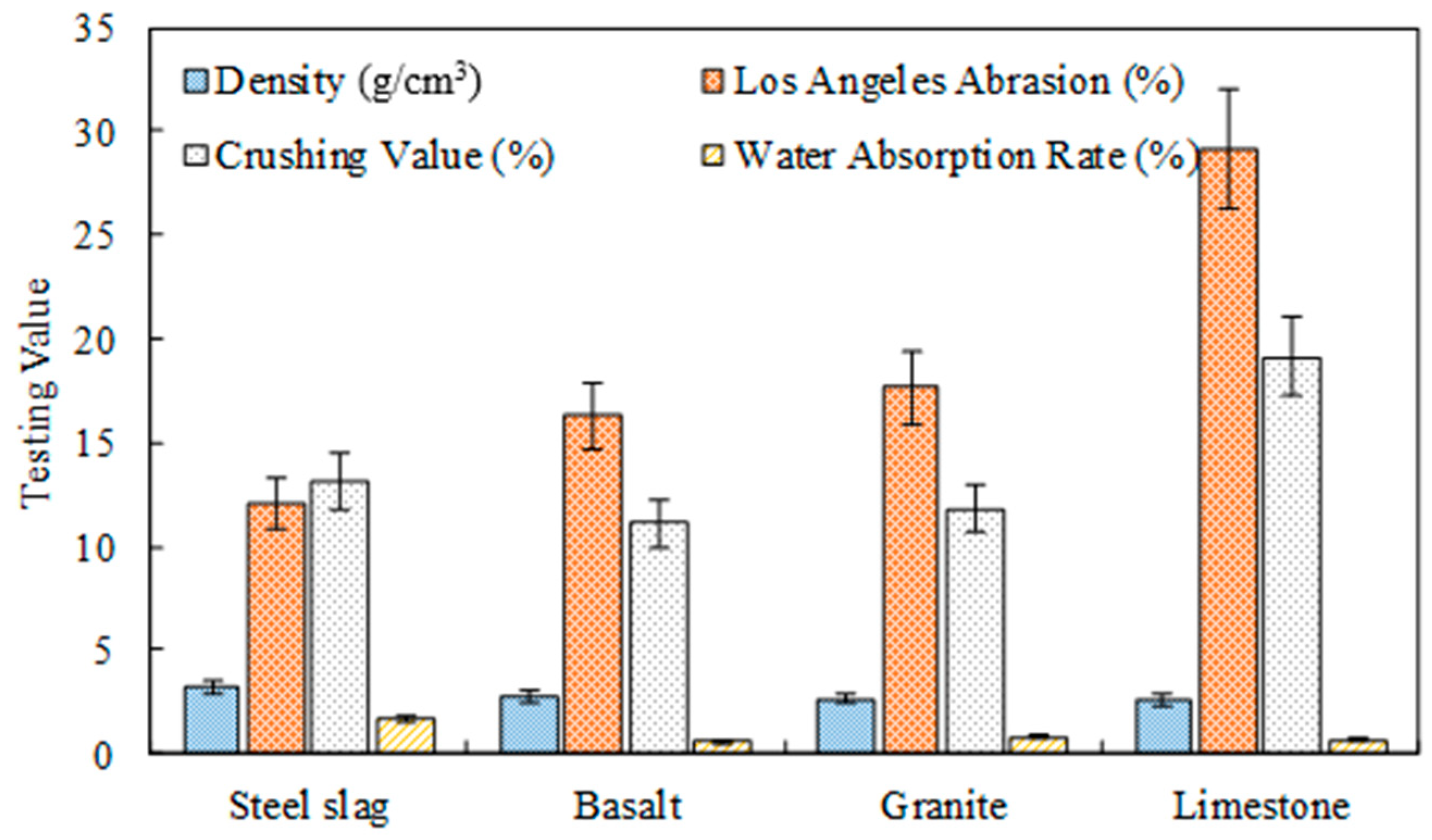

- Low thermal conductivity and diffusivity: Due to its porous microstructure with interconnected micropores, steel slag has lower thermal conductivity (1.2–1.5 W/(m·K)) and diffusivity (0.4–0.6 × 10-6 m2/s) compared to natural aggregates like limestone (2.0–2.5 W/(m·K)) and basalt (1.5–2.0 W/(m·K)) [107,108]. The pores disrupt heat-transfer pathways, slowing down heat dissipation and enhancing heat-storage capacity. This feature is advantageous during pavement construction, as it prolongs the temperature window for compaction, especially in cold climates, by maintaining workable temperatures for 10–15% longer than conventional mixtures [109]. Steel slag–asphalt mixtures, leveraging these properties (thermal conductivity, mechanical strength, and self-healing capabilities), exhibit particularly superior performance under specific road types and traffic conditions. Examples include urban roads, highways, sun-exposed parking lots, and bridge pavements in tropical or subtropical regions. This is attributed to the region’s relatively higher ambient temperatures, which enable faster pavement temperature elevation compared to colder regions, thereby enhancing the efficiency of self-healing mechanisms.

- Enhanced heat storage: The high density of steel slag (2.95–3.5 g/cm3) combined with its porous structure provides it a specific heat capacity of 0.7–0.9 kJ/(kg·K), higher than natural aggregates [110]. This allows steel slag–modified mixtures to retain heat for extended periods, reducing energy consumption during transportation and enabling more efficient thermal activation of self-healing mechanisms [58].

- Dielectric properties: Steel slag has a high dielectric constant and loss factor across microwave frequencies, significantly higher than limestone and basalt [112]. The polar metal oxides within the slag interact with microwave fields, causing dipole rotation and friction that generate heat internally. This volumetric heating mechanism ensures uniform temperature rise, with mixtures containing 40% steel slag achieving a 15 °C temperature increase within 2 min of microwave exposure [60].

- Magnetic permeability: The complex magnetic permeability of steel slag is dominated by its ferromagnetic components, such as magnetite (Fe3O4) and metallic iron. The real part ranges from 1.05–1.09 at low frequencies, enabling efficient energy coupling in induction heating systems [113]. Iron-rich fractions in steel slag generate eddy currents under alternating magnetic fields, converting electrical energy to heat via resistive losses. In contrast, Fe3O4 relies on hysteresis losses, making it effective for magnetic induction even at micron scales [114].

- Particle size and content effects: Larger steel slag particles (9.5–16 mm) with higher iron content (25–30%) enhance induction heating depth (5–8 cm) due to reduced skin depth, while finer particles (0–2.36 mm) improve microwave absorption efficiency by increasing specific surface area [115]. Optimal steel slag content for balanced heating efficiency and workability is 30–50%, beyond which agglomeration may reduce uniformity [116].

3.3. Pretreatment of Steel Slag for Improved Performance

- Stabilizing microstructure: Reduced expansion ensures that thermal cycles do not induce secondary damage, maintaining the integrity of the aggregate–binder interface during heating [143].

- Optimizing moisture balance: Hydrophobic treatments (organic/inorganic) prevent water-induced disruptions to microwave/induction heating, ensuring consistent temperature distribution and binder flow [144].

- Enhancing thermal compatibility: Carbonated or aged slag exhibits more stable thermal expansion coefficients, reducing thermal stress during healing cycles [145].

4. Critical Factors Influencing Self-Healing Efficacy

4.1. Material Parameters

4.2. Operational Conditions

4.3. Economic and Environmental Trade-Offs

5. Challenges and Future Directions

5.1. Challenges of Thermally Induced Self-Healing

- Electromagnetic induction: Uneven temperature distribution due to steel slag agglomeration causes localized overheating (ΔT > 15 °C in clusters), risking binder oxidation and insufficient deep-layer repair [158]. The dependency on ferromagnetic components (e.g., Fe3O4) also limits its effectiveness with low-iron slag variants.

- Microwave heating: While offering uniform surface heating, prolonged exposure (≥10 min at 100 °C) accelerates asphalt aging, reducing binder ductility by 15–20% after five cycles. High energy consumption (0.5–1 kWh/m2 per healing session) from non-renewable sources contradicts sustainability goals, particularly for large-scale pavement networks.

5.2. Future Directions for Innovation

5.2.1. Advanced Pretreatment and Material Design for Predictable Performance

5.2.2. Optimized Self-Healing Systems for Energy Efficiency and Uniformity

5.2.3. Smart-Infrastructure Integration and Data-Driven Optimization

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, H.; Zhou, Y.; Huang, W.; Wen, P.; Li, J. Fracture characteristics of a cement concrete pavement plate considering subgrade modulus decay based on a meshless finite block method. Front. Mater. 2023, 10, 1157529. [Google Scholar] [CrossRef]

- Chang, J.; Li, J.; Yang, H.; Wang, Y.; Hu, H. Optimizing epoxy asphalt tack coat formulations for improved adhesion and working performance of ultrathin wearing course. J. Adhes. Sci. Technol. 2024, 1–26. [Google Scholar] [CrossRef]

- Yao, Y.; Fan, J.; Li, J. A Review of Advanced Soil Moisture Monitoring Techniques for Slope Stability Assessment. Water 2025, 17, 390. [Google Scholar] [CrossRef]

- Wei, H.; Xu, B.; Li, J.; Zheng, J.; Liu, Y.; Lu, R. Effect of temperature on fatigue damage evolution of asphalt mixture based on cluster analysis and acoustic emission parameters. Eng. Fract. Mech. 2025, 317, 110954. [Google Scholar] [CrossRef]

- Crucho, J.M.L.; de Picado-Santos, L.G.; das Neves, J.M.C.; Capitão, S.D. The TEAGE ageing method for asphalt mixtures. Transp. Eng. 2020, 2, 100030. [Google Scholar] [CrossRef]

- He, Y.; Xiong, K.; Zhang, J.; Guo, F.; Li, Y.; Hu, Q. A state-of-the-art review and prospectives on the self-healing repair technology for asphalt materials. Constr. Build. Mater. 2024, 421, 135660. [Google Scholar] [CrossRef]

- Li, J.; Sha, A.; Wang, Z.; Song, R.; Cao, Y. Investigation of the self-healing, road performance and cost–benefit effects of an iron tailing/asphalt mixture in pavement. Constr. Build. Mater. 2024, 422, 135788. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, Y.; Kong, L.; Cannone Falchetto, A.; Yuan, D.; Wang, W. Study on Multiple Effects of Self-Healing Properties and Thermal Characteristics of Asphalt Pavement. Buildings 2024, 14, 1313. [Google Scholar] [CrossRef]

- Zhao, T.; Peng, J.; Zhang, Y.; Song, Y.; Zhang, H.; Yang, E.; Qiu, Y.; Ma, B. Improvement in Anti-Icing Performance of Electromagnetic Induction Heating through Optimization of Energy Transfer in Asphalt Pavement. J. Mater. Civ. Eng. 2025, 37, 04025147. [Google Scholar] [CrossRef]

- Jahanbakhsh, H.; Moghadas Nejad, F.; Khodaii, A.; Karimi, M.M.; Naseri, H. Sustainable induction-heatable cold patching using microwave and reclaimed asphalt pavement. J. Mater. Civ. Eng. 2024, 36, 04023607. [Google Scholar] [CrossRef]

- Wei, H.; Lu, R.; Li, J.; Yao, Z.; Zheng, J. Investigation on synergistic flame retardancy of modified asphalt using tungsten mine tailings and aluminum trihydrate. Constr. Build. Mater. 2024, 451, 138891. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Liang, C.; Hu, X. Effect of coarse recycled aggregate on failure strength for asphalt mixture using experimental and DEM method. Coatings 2021, 11, 1234. [Google Scholar] [CrossRef]

- Gao, W.; Zhou, W.; Lyu, X.; Liu, X.; Su, H.; Li, C.; Wang, H. Comprehensive utilization of steel slag: A review. Powder Technol. 2023, 422, 118449. [Google Scholar] [CrossRef]

- Yue, Q.; Chai, X.; Zhang, Y.; Wang, Q.; Wang, H.; Zhao, F.; Ji, W.; Lu, Y. Analysis of iron and steel production paths on the energy demand and carbon emission in China’s iron and steel industry. Environ. Dev. Sustain. 2023, 25, 4065–4085. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Z.; Guo, H.; Xu, X.; Wang, X.; Zhang, B.; Liu, J.; Wan, C. Steel slag aggregate property improvement in cold mixed asphalt mixtures through surface modification treatment. J. Clean. Prod. 2024, 477, 143889. [Google Scholar] [CrossRef]

- Liu, J.; Xu, J.; Liu, Q.; Wang, S.; Yu, B. Steel slag for roadway construction: A review of material characteristics and application mechanisms. J. Mater. Civ. Eng. 2022, 34, 03122001. [Google Scholar] [CrossRef]

- Zhang, Z.; Zheng, X.; Li, J.; Xu, G.; Tan, L. Mechanism of reinforced interfacial adhesion between steel slag and highly devulcanized waste rubber modified asphalt and its influence on the volume stability in steel slag asphalt mixture. Constr. Build. Mater. 2024, 447, 138129. [Google Scholar] [CrossRef]

- Wang, L.; Yao, Y.; Li, J.; Tao, Y.; Liu, K. Review of visualization technique and its application of road aggregates based on morphological features. Appl. Sci. 2022, 12, 10571. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, T.; Guo, H.; Wang, Z.; Wang, X. Evaluation of self-healing properties of asphalt mixture containing steel slag under microwave heating: Mechanical, thermal transfer and voids microstructural characteristics. J. Clean. Prod. 2022, 342, 130932. [Google Scholar] [CrossRef]

- Wei, H.; Liu, Y.; Li, J.; Wang, F.; Zheng, J.; Yuan, Z. Characterizing fatigue damage evolution in asphalt mixtures using acoustic emission and Gaussian mixture model analysis. Constr. Build. Mater. 2023, 409, 133973. [Google Scholar] [CrossRef]

- Xu, H.; Sun, M.; Luo, G. Enhanced Induction Heating and Self-Healing properties of steel slag powder based asphalt and asphalt mixture under microwave irradiation. Materials 2023, 16, 3312. [Google Scholar] [CrossRef] [PubMed]

- Gu, F.; Xie, J.; Vuye, C.; Wu, Y.; Zhang, J. Synthesis of geopolymer using alkaline activation of building-related construction and demolition wastes. J. Clean. Prod. 2023, 420, 138335. [Google Scholar] [CrossRef]

- He, L.; Li, G.; Lv, S.; Gao, J.; Kowalski, K.J.; Valentin, J.; Alexiadis, A. Self-healing behavior of asphalt system based on molecular dynamics simulation. Constr. Build. Mater. 2020, 254, 119225. [Google Scholar] [CrossRef]

- Ding, S.; Wang, Z.; Zhu, G.; Zhang, X.; Zhang, J.; Zhang, Y.; Cen, Z.; Zhou, L.; Luo, Y. Accelerating Self-Healing Driven by Surface Energy Using Bulky Ester Groups in Polymer Materials. J. Phys. Chem. C 2021, 125, 28048–28058. [Google Scholar] [CrossRef]

- Nalbandian, K.M.; Carpio, M.; González, Á. Analysis of the scientific evolution of self-healing asphalt pavements: Toward sustainable road materials. J. Clean. Prod. 2021, 293, 126107. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. A novel self-healing system: Towards a sustainable porous asphalt. J. Clean. Prod. 2020, 259, 120815. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, W.; Wang, L. Fatigue damage evolution and self-healing performance of asphalt materials under different influence factors and damage degrees. Int. J. Fatigue 2023, 171, 107577. [Google Scholar] [CrossRef]

- Luo, X.; Xu, J.; Ma, F. Thermodynamics of healing of asphalt binders with free energy. Mech. Mater. 2023, 185, 104757. [Google Scholar] [CrossRef]

- Deng, Y.; Xu, L.; Ni, H.; Tian, Y.; Sun, D. Extended Research on Microwave Heating-Healing Capacity of Asphalt Mixture: Asphalt Flow Analysis Combining Capillary Flow Test with Temperature Distribution. J. Mater. Civ. Eng. 2024, 36, 04024166. [Google Scholar] [CrossRef]

- Al-Mansoori, T.; Norambuena-Contreras, J.; Garcia, A. Effect of capsule addition and healing temperature on the self-healing potential of asphalt mixtures. Mater. Struct. 2018, 51, 53. [Google Scholar] [CrossRef]

- Ayar, P.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Exploring the recovery of fatigue damage in bituminous mixtures: The role of rest periods. Mater. Struct. 2018, 51, 25. [Google Scholar] [CrossRef]

- Penalva-Salinas, M.; Llopis-Castelló, D.; Alonso-Troyano, C.; García, A. Induction Heating Optimization for Efficient Self-Healing in Asphalt Concrete. Materials 2024, 17, 5602. [Google Scholar] [CrossRef] [PubMed]

- Fakhri, M.; Javadi, S.; Sedghi, R.; Sassani, A.; Arabzadeh, A.; Baveli Bahmai, B. Microwave induction heating of polymer-modified asphalt materials for self-healing and deicing. Sustainability 2021, 13, 10129. [Google Scholar] [CrossRef]

- Yang, C.; Wu, S.; Xie, J.; Amirkhanian, S.; Liu, Q.; Zhang, J.; Xiao, Y.; Zhao, Z.; Xu, H.; Li, N. Enhanced induction heating and self-healing performance of recycled asphalt mixtures by incorporating steel slag. J. Clean. Prod. 2022, 366, 132999. [Google Scholar] [CrossRef]

- Grossegger, D.; Garcia, A. Influence of the thermal expansion of bitumen on asphalt self-healing. Appl. Therm. Eng. 2019, 156, 23–33. [Google Scholar] [CrossRef]

- Schapery, R. On the mechanics of crack closing and bonding in linear viscoelastic media. Int. J. Fract. 1989, 39, 163–189. [Google Scholar] [CrossRef]

- Jayabalakrishnan, D.; Muruga, D.N.; Bhaskar, K.; Pavan, P.; Balaji, K.; Rajakumar, P.; Priya, C.; Deepa, R.; Sendilvelan, S.; Prabhahar, M. Self-Healing materials—A review. Mater. Today Proc. 2021, 45, 7195–7199. [Google Scholar] [CrossRef]

- Luo, X.; Luo, R.; Lytton, R.L. Mechanistic modeling of healing in asphalt mixtures using internal stress. Int. J. Solids Struct. 2015, 60, 35–47. [Google Scholar] [CrossRef]

- García, Á. Self-healing of open cracks in asphalt mastic. Fuel 2012, 93, 264–272. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Garcia, A. Self-healing of asphalt mixture by microwave and induction heating. Mater. Des. 2016, 106, 404–414. [Google Scholar] [CrossRef]

- Jian, R.; Hu, X.; Han, T.; Wan, J.; Gan, W.; Chen, Z.; Zhang, Y.; Cao, C. Optimization of induction heating parameters for improving Self-healing performance of asphalt mixture through partial least square model. Constr. Build. Mater. 2023, 365, 130019. [Google Scholar] [CrossRef]

- Ye, X.; Li, X.; Chen, Y.; Yang, H.; Xiang, Y.; Ye, Z.; Hu, C. Optimum moment to heal cracks in asphalt pavement by means of waste carbon fiber-enhanced electromagnetic induction heating during multiple damage-healing cycles. J. Clean. Prod. 2024, 470, 143265. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Jing, H.; Jia, H.; Zhou, L.; Chen, H.; Zhang, L. Microwave self-healing characteristics of bituminous mixtures with different steel slag aggregate and waste ferrite filler. Constr. Build. Mater. 2023, 407, 133304. [Google Scholar] [CrossRef]

- Miglietta, F.; Tsantilis, L.; Baglieri, O.; Santagata, E. A new approach for the evaluation of time–temperature superposition effects on the self-healing of bituminous binders. Constr. Build. Mater. 2021, 287, 122987. [Google Scholar] [CrossRef]

- Tang, J.; Liu, Q.; Wu, S.; Ye, Q.; Sun, Y.; Schlangen, E. Investigation of the optimal self-healing temperatures and healing time of asphalt binders. Constr. Build. Mater. 2016, 113, 1029–1033. [Google Scholar] [CrossRef]

- Grossegger, D. Fatigue damage self-healing analysis and the occurrence of an optimal self-healing time in asphalt concrete. J. Mater. Civ. Eng. 2021, 33, 04021098. [Google Scholar] [CrossRef]

- Li, H.; Yu, J.; Wu, S.; Liu, Q.; Li, Y.; Wu, Y.; Xu, H. Investigation of the effect of induction heating on asphalt binder aging in steel fibers modified asphalt concrete. Materials 2019, 12, 1067. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gonzalez-Torre, I. Influence of the microwave heating time on the self-healing properties of asphalt mixtures. Appl. Sci. 2017, 7, 1076. [Google Scholar] [CrossRef]

- Wan, J.; Wu, S.; Xiao, Y.; Chen, Z.; Zhang, D. Study on the effective composition of steel slag for asphalt mixture induction heating purpose. Constr. Build. Mater. 2018, 178, 542–550. [Google Scholar] [CrossRef]

- Phan, T.M.; Le, T.H.M.; Park, D.-W. Evaluation of cracking resistance of healed warm mix asphalt based on air-void and binder content. Road Mater. Pavement Des. 2022, 23, 47–61. [Google Scholar] [CrossRef]

- Xu, H.; Wu, S.; Li, H.; Zhao, Y.; Lv, Y. Study on recycling of steel slags used as coarse and fine aggregates in induction healing asphalt concretes. Materials 2020, 13, 889. [Google Scholar] [CrossRef] [PubMed]

- Cabette, M.; Pais, J.; Micaelo, R. Extrinsic healing of asphalt mixtures: A review. Road Mater. Pavement Des. 2024, 25, 1145–1173. [Google Scholar] [CrossRef]

- Benedetto, A.; Calvi, A. A pilot study on microwave heating for production and recycling of road pavement materials. Constr. Build. Mater. 2013, 44, 351–359. [Google Scholar] [CrossRef]

- Lu, D.; Jiang, X.; Leng, Z. Sustainable microwave-heating healing asphalt concrete fabricated with waste microwave-sensitive fillers. J. Clean. Prod. 2024, 434, 140343. [Google Scholar] [CrossRef]

- Yıldız, K.; Atakan, M. Improving microwave healing characteristic of asphalt concrete by using fly ash as a filler. Constr. Build. Mater. 2020, 262, 120448. [Google Scholar] [CrossRef]

- Wang, R.; Xiong, Y.; Ma, X.; Guo, Y.; Yue, M.; Yue, J. Investigating the differences between steel slag and natural limestone in asphalt mixes in terms of microscopic mechanism, fatigue behavior and microwave-induced healing performance. Constr. Build. Mater. 2022, 328, 127107. [Google Scholar] [CrossRef]

- Phan, T.M.; Park, D.-W.; Le, T.H.M. Crack healing performance of hot mix asphalt containing steel slag by microwaves heating. Constr. Build. Mater. 2018, 180, 503–511. [Google Scholar] [CrossRef]

- Boquera, L.; Castro, J.R.; Fernandez, A.G.; Navarro, A.; Pisello, A.L.; Cabeza, L.F. Thermo-mechanical stability of concrete containing steel slag as aggregate after high temperature thermal cycles. Sol. Energy 2022, 239, 59–73. [Google Scholar] [CrossRef]

- Lou, B.; Sha, A.; Barbieri, D.M.; Liu, Z.; Zhang, F.; Jiang, W.; Hoff, I. Characterization and microwave healing properties of different asphalt mixtures suffered freeze-thaw damage. J. Clean. Prod. 2021, 320, 128823. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Zhang, Y.; Feng, S.; Lu, G.; Cao, L. Laboratory and numerical investigation of microwave heating properties of asphalt mixture. Materials 2019, 12, 146. [Google Scholar] [CrossRef]

- Gao, J.; Sha, A.; Wang, Z.; Tong, Z.; Liu, Z. Utilization of steel slag as aggregate in asphalt mixtures for microwave deicing. J. Clean. Prod. 2017, 152, 429–442. [Google Scholar] [CrossRef]

- Liu, W.; Miao, P.; Wang, S.-Y. Increasing microwave heating efficiency of asphalt-coated aggregates mixed with modified steel slag particles. J. Mater. Civ. Eng. 2017, 29, 04017171. [Google Scholar] [CrossRef]

- Little, D.; Bhasin, A.; Darabi, M. Damage healing in asphalt pavements: Theory, mechanisms, measurement, and modeling. In Advances in Asphalt Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 205–242. [Google Scholar]

- Sun, D.; Yu, F.; Li, L.; Lin, T.; Zhu, X. Effect of chemical composition and structure of asphalt binders on self-healing. Constr. Build. Mater. 2017, 133, 495–501. [Google Scholar] [CrossRef]

- Zhang, Z.; Cheng, P.; Yang, Z.; Xu, J.; Li, Y. Self-healing properties of nano-montmorillonite-enhanced asphalt binders from the perspective of energetics and morphology. Mater. Struct. 2021, 54, 77. [Google Scholar] [CrossRef]

- Zhang, Z.; Zheng, X.; Chen, Y. A Review on the Application of Steel Slag in Road Asphalt Mixture. Shanghai Highw. 2023, 4, 134–140. [Google Scholar]

- Neves, J.; Crucho, J. Performance Evaluation of Steel Slag Asphalt Mixtures for Sustainable Road Pavement Rehabilitation. Appl. Sci. 2023, 13, 5716. [Google Scholar] [CrossRef]

- Wang, H.; Qian, J.; Liu, J.; Nan, X.; Qu, S.; Li, X.; Liu, Y. Wear resistance analysis of steel slag aggregates based on morphology characteristics. Constr. Build. Mater. 2023, 409, 133649. [Google Scholar] [CrossRef]

- Kumar, H.; Varma, S. A review on utilization of steel slag in hot mix asphalt. Int. J. Pavement Res. Technol. 2021, 14, 232–242. [Google Scholar] [CrossRef]

- Salas, I.; Cifrian, E.; Lastra-González, P.; Castro-Fresno, D.; Andrés, A. Assessment of Dynamic Surface Leaching of Asphalt Mixtures Incorporating Electric Arc Furnace Steel Slag as Aggregate for Sustainable Road Construction. Sustainability 2025, 17, 3737. [Google Scholar] [CrossRef]

- Gan, Y.; Li, C.; Zou, J.; Wang, W.; Yu, T. Evaluation of the impact factors on the leaching risk of steel slag and its asphalt mixture. Case Stud. Constr. Mater. 2022, 16, e01067. [Google Scholar] [CrossRef]

- Hu, R.; Xie, J.; Wu, S.; Yang, C.; Yang, D. Study of Toxicity Assessment of Heavy Metals from Steel Slag and Its Asphalt Mixture. Materials 2020, 13, 2768. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Qian, J.; Zhang, H.; Nan, X.; Chen, G.; Li, X. Exploring skid resistance over time: Steel slag as a pavement aggregate—Comparative study and morphological analysis. J. Clean. Prod. 2024, 464, 142779. [Google Scholar] [CrossRef]

- Kim, K.; Jo, S.H.; Kim, N.; Kim, H. Characteristics of hot mix asphalt containing steel slag aggregate according to temperature and void percentage. Constr. Build. Mater. 2018, 188, 1128–1136. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, M.; Yao, J.; Zhang, X.; Wen, W.; Yin, J.; Liang, Z. Research on water stability and moisture damage mechanism of a steel slag porous asphalt mixture. Sustainability 2023, 15, 14958. [Google Scholar] [CrossRef]

- O’Connor, J.; Nguyen, T.B.T.; Honeyands, T.; Monaghan, B.; O’Dea, D.; Rinklebe, J.; Vinu, A.; Hoang, S.A.; Singh, G.; Kirkham, M. Production, characterisation, utilisation, and beneficial soil application of steel slag: A review. J. Hazard. Mater. 2021, 419, 126478. [Google Scholar] [CrossRef]

- Hildor, F.; Leion, H.; Mattisson, T. Steel converter slag as an oxygen carrier—Interaction with sulfur dioxide. Energies 2022, 15, 5922. [Google Scholar] [CrossRef]

- Chen, Z.; Leng, Z.; Jiao, Y.; Xu, F.; Lin, J.; Wang, H.; Cai, J.; Zhu, L.; Zhang, Y.; Feng, N. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers. J. Clean. Prod. 2022, 344, 131124. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhu, H.; Xu, P. The interfacial adhesion performance and mechanism of a modified asphalt–steel slag aggregate. Materials 2020, 13, 1180. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Pomoni, M. An Overview of the Recyclability of Alternative Materials for Building Surface Courses at Pavement Structures. Buildings 2024, 14, 1571. [Google Scholar] [CrossRef]

- Qazizadeh, M.J.; Farhad, H.; Kavussi, A.; Sadeghi, A. Evaluating the fatigue behavior of asphalt mixtures containing electric arc furnace and basic oxygen furnace slags using surface free energy estimation. J. Clean. Prod. 2018, 188, 355–361. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Plati, C.; Pomoni, M.; Stergiou, T. From mean texture depth to mean profile depth: Exploring possibilities. In Bituminous Mixtures and Pavements VII; CRC Press: Boca Raton, FL, USA, 2019; pp. 660–665. [Google Scholar]

- Kehagia, F. Skid resistance performance of asphalt wearing courses with electric arc furnace slag aggregates. Waste Manag. Res. 2009, 27, 288–294. [Google Scholar] [CrossRef]

- Liapis, I.; Likoydis, S. Use of electric arc furnace slag in thin skid–resistant surfacing. Procedia-Soc. Behav. Sci. 2012, 48, 907–918. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Autelitano, F.; Giuliani, F. Optimization of electric arc furnace aggregates replacement in dense-graded asphalt wearing courses. Int. J. Pavement Res. Technol. 2021, 14, 309–317. [Google Scholar] [CrossRef]

- Piao, Z.; Mikhailenko, P.; Kakar, M.R.; Bueno, M.; Hellweg, S.; Poulikakos, L.D. Urban mining for asphalt pavements: A review. J. Clean. Prod. 2021, 280, 124916. [Google Scholar] [CrossRef]

- Sun, J.; Huang, W.; Wang, X.; Hu, J.; Wang, Y.; Zhang, Z.; Luo, S. Feasibility of pretreated steel slag for asphalt pavement application and risk assessment of hazardous substance leaching. Chem. Eng. J. 2024, 498, 155497. [Google Scholar] [CrossRef]

- Liu, P.; Mo, L.; Zhang, Z. Effects of carbonation degree on the hydration reactivity of steel slag in cement-based materials. Constr. Build. Mater. 2023, 370, 130653. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiong, Y.; Jia, Z.; Cao, R.; Gao, Y.; Maruyama, I.; Zhang, Y.; Wang, W. In-situ wet carbonation of steel slag powder paste made with carbonated water: Interaction mechanism between carbonation and hydration. Cem. Concr. Compos. 2024, 152, 105677. [Google Scholar] [CrossRef]

- Fang, Y.; Shan, J.; Wang, Q.; Zhao, M.; Sun, X. Semi-dry and aqueous carbonation of steel slag: Characteristics and properties of steel slag as supplementary cementitious materials. Constr. Build. Mater. 2024, 425, 135981. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, J.; Wei, C. Material properties of cement doped with carbonated steel slag through the slurry carbonation process: Effect and quantitative model. Metall. Mater. Trans. B 2022, 53, 1681–1690. [Google Scholar] [CrossRef]

- Li, Y.; Liao, H.; Guo, Y. Aqueous carbonation of steel slag and preparation of calcium carbon: A new strategy for the utilization of steel slag. J. Environ. Chem. Eng. 2025, 13, 115951. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, C.; Li, Z.; Liu, G.; Zhang, W.; Xie, G.; Xing, F. Carbonation of steel slag at low CO2 concentrations: Novel biochar cold-bonded steel slag artificial aggregates. Sci. Total Environ. 2023, 902, 166065. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, H.; Liu, M.; Fu, Y.; Si, Z.; Zhang, X.; Zhong, Q. The characterization and mechanism of carbonated steel slag and its products under low CO2 pressure. Mater. Today Commun. 2023, 35, 105827. [Google Scholar] [CrossRef]

- Chen, Z.; Li, R.; Liu, J. Preparation and properties of carbonated steel slag used in cement cementitious materials. Constr. Build. Mater. 2021, 283, 122667. [Google Scholar] [CrossRef]

- Chen, Z.; Li, R.; Zheng, X.; Liu, J. Carbon sequestration of steel slag and carbonation for activating RO phase. Cem. Concr. Res. 2021, 139, 106271. [Google Scholar] [CrossRef]

- Kim, S.; Kim, J.; Jeon, D.; Yang, J.; Moon, J. Enhanced mechanical property of steel slag through glycine-assisted hydration and carbonation curing. Cem. Concr. Compos. 2024, 149, 105532. [Google Scholar] [CrossRef]

- Zhang, S.; Ghouleh, Z.; Mucci, A.; Bahn, O.; Provençal, R.; Shao, Y. Production of cleaner high-strength cementing material using steel slag under elevated-temperature carbonation. J. Clean. Prod. 2022, 342, 130948. [Google Scholar] [CrossRef]

- Liu, G.; Tang, Y.; Wang, J. Effects of carbonation degree of semi-dry carbonated converter steel slag on the performance of blended cement mortar–reactivity, hydration, and strength. J. Build. Eng. 2023, 63, 105529. [Google Scholar] [CrossRef]

- Ferrara, G.; Belli, A.; Keulen, A.; Tulliani, J.-M.; Palmero, P. Testing procedures for CO2 uptake assessment of accelerated carbonation products: Experimental application on basic oxygen furnace steel slag samples. Constr. Build. Mater. 2023, 406, 133384. [Google Scholar] [CrossRef]

- Andrade, H.D.; de Carvalho, J.M.F.; Costa, L.C.B.; da Fonseca Elói, F.P.; e Silva, K.D.d.C.; Peixoto, R.A.F. Mechanical performance and resistance to carbonation of steel slag reinforced concrete. Constr. Build. Mater. 2021, 298, 123910. [Google Scholar] [CrossRef]

- Biava, G.; Zacco, A.; Zanoletti, A.; Sorrentino, G.P.; Capone, C.; Princigallo, A.; Depero, L.E.; Bontempi, E. Accelerated direct carbonation of steel slag and cement kiln dust: An industrial symbiosis strategy applied in the bergamo–brescia area. Materials 2023, 16, 4055. [Google Scholar] [CrossRef]

- Srivastava, S.; Cerutti, M.; Nguyen, H.; Carvelli, V.; Kinnunen, P.; Illikainen, M. Carbonated steel slags as supplementary cementitious materials: Reaction kinetics and phase evolution. Cem. Concr. Compos. 2023, 142, 105213. [Google Scholar] [CrossRef]

- Khasawneh, M.A.; Sawalha, A.A.; Aljarrah, M.T.; Alsheyab, M.A. Effect of aggregate gradation and asphalt mix volumetrics on the thermal properties of asphalt concrete. Case Stud. Constr. Mater. 2023, 18, e01725. [Google Scholar] [CrossRef]

- Mirnezami, S.; Hassani, A.; Bayat, A. Evaluation of the effect of metallurgical aggregates (steel and copper slag) on the thermal conductivity and mechanical properties of concrete in jointed plain concrete pavements (JPCP). Constr. Build. Mater. 2023, 367, 129532. [Google Scholar] [CrossRef]

- Liu, Q.; Li, B.; Schlangen, E.; Sun, Y.; Wu, S. Research on the mechanical, thermal, induction heating and healing properties of steel slag/steel fibers composite asphalt mixture. Appl. Sci. 2017, 7, 1088. [Google Scholar] [CrossRef]

- Abbas, F.A.; Alhamdo, M.H. Enhancing the thermal conductivity of hot-mix asphalt. Results Eng. 2023, 17, 100827. [Google Scholar] [CrossRef]

- Zheng, H.; Liang, L.; Du, J.; Zhou, S.; Jiang, X.; Gao, Q.; Shen, F. Mineral transform and specific heat capacity characterization of blast furnace slag with high Al2O3 in heating process. Steel Res. Int. 2021, 92, 2000448. [Google Scholar] [CrossRef]

- Wan, J.; Xiao, Y.; Song, W.; Chen, C.; Pan, P.; Zhang, D. Self-healing property of ultra-thin wearing courses by induction heating. Materials 2018, 11, 1392. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Guo, H.; Yan, F. Thermal transfer characteristics of asphalt mixtures containing hot poured steel slag through microwave heating. J. Clean. Prod. 2021, 308, 127225. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Y.; Liu, Z.; Dong, Q.; Zhao, X. Temperature analyses of porous asphalt mixture using steel slag aggregates heated by microwave through laboratory tests and numerical simulations. J. Clean. Prod. 2022, 338, 130614. [Google Scholar] [CrossRef]

- Miao, P.; Liu, W.; Wang, S. Improving microwave absorption efficiency of asphalt mixture by enriching Fe3O4 on the surface of steel slag particles. Mater. Struct. 2017, 50, 134. [Google Scholar] [CrossRef]

- Luo, W.; Huang, S.; Liu, Y.; Peng, H.; Ye, Y. Three-dimensional mesostructure model of coupled electromagnetic and heat transfer for microwave heating on steel slag asphalt mixtures. Constr. Build. Mater. 2022, 330, 127235. [Google Scholar] [CrossRef]

- Loureiro, C.D.; Silva, H.M.; Oliveira, J.R.; Costa, N.L.; Palha, C.A. The effect of microwave radiation on the self-healing performance of asphalt mixtures with steel slag aggregates and steel fibers. Materials 2023, 16, 3712. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Liu, W.; Wu, S. Analysis on factors affecting moisture stability of steel slag asphalt concrete using grey correlation method. J. Clean. Prod. 2023, 397, 136490. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, P.; Wang, Y.; Zhao, X.; Liu, J. Effect of Fe and Mn on the hydration activity of f-CaO in steel slag. Constr. Build. Mater. 2024, 421, 135719. [Google Scholar] [CrossRef]

- Feng, P.; Li, Z.; Zhang, S.; Yang, J.-Q. Steel slag aggregate concrete filled-in FRP tubes: Volume expansion effect and axial compressive behaviour. Constr. Build. Mater. 2022, 318, 125961. [Google Scholar] [CrossRef]

- Sun, X.; Liu, J.; Zhao, Y.; Zhao, J.; Li, Z.; Sun, Y.; Qiu, J.; Zheng, P. Mechanical activation of steel slag to prepare supplementary cementitious materials: A comparative research based on the particle size distribution, hydration, toxicity assessment and carbon dioxide emission. J. Build. Eng. 2022, 60, 105200. [Google Scholar] [CrossRef]

- Wang, X.; Hu, L.; Cheng, Y.; Wang, P. Volume expansibility of asphalt mixture mixed with steel slag. Sci. Technol. Eng. 2024, 24, 6901–6906. [Google Scholar]

- Yang, C.; Wu, S.; Cui, P.; Amirkhanian, S.; Zhao, Z.; Wang, F.; Zhang, L.; Wei, M.; Zhou, X.; Xie, J. Performance characterization and enhancement mechanism of recycled asphalt mixtures involving high RAP content and steel slag. J. Clean. Prod. 2022, 336, 130484. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Wen, J.; Zhao, M.; Yi, M.; Wan, J. Utilization of gneiss coarse aggregate and steel slag fine aggregate in asphalt mixture. Constr. Build. Mater. 2015, 93, 911–918. [Google Scholar] [CrossRef]

- Li, W.; Cao, M.; Wang, D.; Chang, J. Increase in volume stability of RO phases in steel slag by combined treatment of alkali and dry carbonation. Constr. Build. Mater. 2023, 396, 132345. [Google Scholar] [CrossRef]

- Chen, W.; Wei, J.; Xu, X.; Zhang, X.; Han, W.; Yan, X.; Hu, G.; Lu, Z. Study on the optimum steel slag content of sma-13 asphalt mixes based on road performance. Coatings 2021, 11, 1436. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Z.; Li, S.; Ding, Z.; Huang, H. Study on the inhibition of steel slag’s volume expansion caused by plant urease and the properties of asphalt mixture. Constr. Build. Mater. 2025, 469, 140443. [Google Scholar] [CrossRef]

- Dong, R.; Yan, F.; Wang, S. Research status of steel slag in intermittent graded asphalt mixtures. In Advances in Traffic Transportation and Civil Architecture; CRC Press: Boca Raton, FL, USA, 2023; pp. 636–644. [Google Scholar]

- Li, J.; Hou, Q.; Zhang, X.; Zhang, X. Microbial-Induced Mineral Carbonation: A Promising Approach for Improving Carbon Sequestration and Performance of Steel Slag for Its Engineering Utilization. Dev. Built Environ. 2025, 21, 100615. [Google Scholar] [CrossRef]

- Belhadj, E.; Diliberto, C.; Lecomte, A. Characterization and activation of basic oxygen furnace slag. Cem. Concr. Compos. 2012, 34, 34–40. [Google Scholar] [CrossRef]

- Wei, M.; Wu, S.; Xu, H.; Li, H.; Yang, C. Characterization of steel slag filler and its effect on aging resistance of asphalt mastic with various aging methods. Materials 2021, 14, 869. [Google Scholar] [CrossRef]

- Chen, G.; Wang, S. Research on macro-microscopic mechanical evolution mechanism of cement-stabilized steel slag. J. Build. Eng. 2023, 75, 107047. [Google Scholar] [CrossRef]

- Fang, Y.; Su, W.; Zhang, Y.; Zhang, M.; Ding, X.; Wang, Q. Effect of accelerated precarbonation on hydration activity and volume stability of steel slag as a supplementary cementitious material. J. Therm. Anal. Calorim. 2022, 147, 6181–6191. [Google Scholar] [CrossRef]

- Chen, J.; Xing, Y.; Wang, Y.; Zhang, W.; Guo, Z.; Su, W. Application of iron and steel slags in mitigating greenhouse gas emissions: A review. Sci. Total Environ. 2022, 844, 157041. [Google Scholar] [CrossRef]

- Wang, Z.; Cui, L.; Liu, Y.; Hou, J.; Li, H.; Zou, L.; Zhu, F. High-efficiency CO2 sequestration through direct aqueous carbonation of carbide slag: Determination of carbonation reaction and optimization of operation parameters. Front. Environ. Sci. Eng. 2024, 18, 12. [Google Scholar] [CrossRef]

- Chen, Z.; Gong, Z.; Jiao, Y.; Wang, Y.; Shi, K.; Wu, J. Moisture stability improvement of asphalt mixture considering the surface characteristics of steel slag coarse aggregate. Constr. Build. Mater. 2020, 251, 118987. [Google Scholar] [CrossRef]

- Nunes, V.A.; Cimentada, A.; Thomas, C.; Borges, P.H. Pre-treatment of BOF steel slag aggregates and effect on the mechanical and microstructure properties of alkali-activated mortars. J. Build. Eng. 2024, 91, 109562. [Google Scholar] [CrossRef]

- Biskri, Y.; Achoura, D.; Chelghoum, N.; Mouret, M. Mechanical and durability characteristics of High Performance Concrete containing steel slag and crystalized slag as aggregates. Constr. Build. Mater. 2017, 150, 167–178. [Google Scholar] [CrossRef]

- Zhao, W.; Wen, W.; Li, H.; Hu, J. Research on the performance of asphalt mixture with acid-treated steel slag based on microscopic properties. Constr. Build. Mater. 2024, 455, 139134. [Google Scholar] [CrossRef]

- Ma, L.; Xu, D.; Wang, S.; Gu, X. Expansion inhibition of steel slag in asphalt mixture by a surface water isolation structure. Road Mater. Pavement Des. 2020, 21, 2215–2229. [Google Scholar] [CrossRef]

- Yao, D.; Yu, H.; Chen, X.; Yu, X.; Yao, J.; Zheng, X.; Zhang, C.; Gong, L. Effect of surface modification on properties of steel slag aggregate and mixture. Constr. Build. Mater. 2023, 402, 133058. [Google Scholar] [CrossRef]

- Jiang, L.; Dong, C.-L.; Wang, S.-Y. Reducing volume expansion of steel slag by using a surface hydrophobic waterproof structure. J. Mater. Civ. Eng. 2020, 32, 04020303. [Google Scholar] [CrossRef]

- Sun, J.; Luo, S.; Wang, Y.; Dong, Q.; Zhang, Z. Pre-treatment of steel slag and its applicability in asphalt mixtures for sustainable pavements. Chem. Eng. J. 2023, 476, 146802. [Google Scholar] [CrossRef]

- Anupam, B.; Sahoo, U.C.; Chandrappa, A.K. A methodological review on self-healing asphalt pavements. Constr. Build. Mater. 2022, 321, 126395. [Google Scholar] [CrossRef]

- Chen, C.; Deng, Q.; Li, C.; Yi, S.; Liu, L. Research on the preparation and self-healing performance of microwave-induced functional steel slag asphalt mixture. Case Stud. Constr. Mater. 2024, 20, e03038. [Google Scholar] [CrossRef]

- Lou, B.; Liu, Z.; Sha, A.; Jia, M.; Li, Y. Microwave absorption ability of steel slag and road performance of asphalt mixtures incorporating steel slag. Materials 2020, 13, 663. [Google Scholar] [CrossRef]

- Tan, Y.; Shan, L.; Kim, Y.R.; Underwood, B.S. Healing characteristics of asphalt binder. Constr. Build. Mater. 2012, 27, 570–577. [Google Scholar] [CrossRef]

- Zhu, H.; Yuan, H.; Wei, Q. Analysis on influence factors of asphalt mixture fracture microwave-healing performance. Sci. Technol. Eng. 2020, 20, 4547–4552. [Google Scholar]

- Chen, R.; Cui, Y.; Feng, L. Fatigue and self-healing properties of asphalt mixture under effect of aging. J. Build. Mater. 2019, 22, 487–492. [Google Scholar]

- Cui, Y.; Li, M.; Zhang, S.; Guo, J. Multi-scale evaluation of aging and damage-healing performance of asphalt mixtures of various gradations. J. Test. Eval. 2022, 50, 1485–1496. [Google Scholar] [CrossRef]

- Wang, A.; Guan, B.; Zhao, H.; He, Z.; Ding, D.; Gai, W. Microwave self-healing characteristics of the internal voids in steel slag asphalt mixture subjected to salt-freeze-thaw cycles. Constr. Build. Mater. 2024, 449, 138362. [Google Scholar] [CrossRef]

- Karimi, M.M.; Jahanbakhsh, H.; Jahangiri, B.; Nejad, F.M. Induced heating-healing characterization of activated carbon modified asphalt concrete under microwave radiation. Constr. Build. Mater. 2018, 178, 254–271. [Google Scholar] [CrossRef]

- Maliszewski, M.; Zofka, A.; Maliszewska, D.; Sybilski, D.; Salski, B.; Karpisz, T.; Rembelski, R. Full-scale use of microwave heating in construction of longitudinal joints and crack healing in asphalt pavements. Materials 2021, 14, 5159. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; González, A.; Concha, J.; Gonzalez-Torre, I.; Schlangen, E. Effect of metallic waste addition on the electrical, thermophysical and microwave crack-healing properties of asphalt mixtures. Constr. Build. Mater. 2018, 187, 1039–1050. [Google Scholar] [CrossRef]

- Zhu, X.; Cai, Y.; Zhong, S.; Zhu, J.; Zhao, H. Self-healing efficiency of ferrite-filled asphalt mixture after microwave irradiation. Constr. Build. Mater. 2017, 141, 12–22. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, S.; Liu, Q.; Li, B.; Fang, H.; Ye, Q. The healing properties of asphalt mixtures suffered moisture damage. Constr. Build. Mater. 2016, 127, 418–424. [Google Scholar] [CrossRef]

- Fakhri, M.; Ahmadi, A. Evaluation of fracture resistance of asphalt mixes involving steel slag and RAP: Susceptibility to aging level and freeze and thaw cycles. Constr. Build. Mater. 2017, 157, 748–756. [Google Scholar] [CrossRef]

- Georgiou, P.; Loizos, A. Characterization of sustainable asphalt mixtures containing high reclaimed asphalt and steel slag. Materials 2021, 14, 4938. [Google Scholar] [CrossRef]

- Liu, W.; Wan, P.; Wu, S.; Liu, Q.; Wang, J.; Jiang, Q. Research on the Induction Heating Thermal Properties of Asphalt Concrete via Pixel-Level Analysis. J. Mater. Civ. Eng. 2024, 36, 04024351. [Google Scholar] [CrossRef]

| Heating Method | Mechanism | Advantages | Limitations | Optimal Applications |

|---|---|---|---|---|

| Electromagnetic Induction | Eddy currents/hysteresis in conductive/ ferromagnetic fillers | Deep heating (5–10 cm), rapid temperature rise | Localized overheating, filler agglomeration | Subsurface crack repair, thick pavement layers |

| Microwave Heating | Dielectric/magnetic losses in polar/lossy materials | Uniform volumetric heating, surface/ mid-depth repair | Dependence on filler dielectric properties | Surface/mid-depth cracks, thin overlays |

| Method | Mechanism | Advantages | Limitations | Optimal Application |

|---|---|---|---|---|

| Natural Aging | Gradual hydration/ carbonation | Low cost, environmental compatibility | Long treatment time (6–12 months) | Large-scale storage facilities |

| Carbonation Modification | CO2-induced calcium carbonate formation | Rapid stabilization, CO2 utilization | High-energy autoclave requirements | Industrial sites with CO2 waste streams |

| Inorganic Modification | Pozzolanic reaction/acid etching | Improved mechanical properties, cost-effective | Potential alkalinity changes | Heavy-duty pavements requiring high strength |

| Organic Modification | Hydrophobic surface coating | Excellent moisture resistance, binder adhesion | Higher treatment cost, potential aging sensitivity | Moisture-prone environments (coastal, high-rain areas) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Li, W.; Liu, C.; Pan, B. Comprehensive Review of Thermally Induced Self-Healing Behavior in Asphalt Mixtures and the Role of Steel Slag. Coatings 2025, 15, 668. https://doi.org/10.3390/coatings15060668

Yan Y, Li W, Liu C, Pan B. Comprehensive Review of Thermally Induced Self-Healing Behavior in Asphalt Mixtures and the Role of Steel Slag. Coatings. 2025; 15(6):668. https://doi.org/10.3390/coatings15060668

Chicago/Turabian StyleYan, Yihong, Wenbo Li, Chaochao Liu, and Boyang Pan. 2025. "Comprehensive Review of Thermally Induced Self-Healing Behavior in Asphalt Mixtures and the Role of Steel Slag" Coatings 15, no. 6: 668. https://doi.org/10.3390/coatings15060668

APA StyleYan, Y., Li, W., Liu, C., & Pan, B. (2025). Comprehensive Review of Thermally Induced Self-Healing Behavior in Asphalt Mixtures and the Role of Steel Slag. Coatings, 15(6), 668. https://doi.org/10.3390/coatings15060668