1. Introduction

Fossil fuel combustion has long been the primary means of power generation and industrial production worldwide. However, burning coal and other carbon-based resources emits large volumes of sulfur dioxide (SO

2) and other air pollutants. Released into the atmosphere, SO

2 contributes to acid rain formation and climate change issues that threaten ecosystems and human health [

1,

2]. In response, stringent regulations have driven industries like iron/steel manufacturing and electricity generation to widely adopt flue gas desulfurization (FGD) technologies [

3].

FGD methods include dry, semi-dry, and wet processes [

4,

5,

6]. Circulating fluidized bed (CFB) flue gas desulfurization stands out for its high efficiency, low energy use, integrated desulfurization/particulate control, and production of ultra-clean flue gas [

7]. However, a large amount of CFB FGD ash (CFB-FGDA) is produced every year, posing significant challenges for disposal and utilization [

8]. CFB-FGDA contains unstable calcium sulfite hemihydrate that oxidizes over time, complicating long-term storage and use [

9,

10,

11]. Calcium sulfite exhibits instability during usage, as it readily undergoes slow oxidation to form calcium sulfate in moist surroundings. Moreover, it decomposes and liberates sulfur dioxide when exposed to acidic or elevated temperature conditions [

12].

Presently, the management of CFB-FGDA primarily entails stacking and landfill disposal, with limited effective utilization, thereby posing a risk of resource wastage and environmental contamination. Extensive studies have been conducted to promote the sustainable utilization of CFB-FGDA. Overseas, CFB-FGDA is commonly used for soil improvement, mining applications, and structural fill due to its self-hardening characteristics [

13]. Field trials in the U.S. showed CFB-FGDA altered soil chemistry temporarily without negative impacts [

14]. CFB-FGDA was employed for the reclamation of acidic abandoned coal mines, with extensive monitoring of surface runoff, plant and soil micro-organism characteristics over an extended period [

15,

16]. The findings indicated that the pH level of surface runoff water remained above 7, with initial increments in trace elements such as Ca and S concentrations in soil and plant tissues, followed by gradual reductions over time [

17]. Notably, the levels of heavy metals did not exhibit significant escalation throughout the monitoring phase. Application of CFB-FGDA for coal mine restoration substantially augmented bacterial population, diversity, and microbial biomass compared to untreated neighboring areas. Consequently, it can be inferred that the utilization of CFB-FGDA can effectively restore the ecological equilibrium of mining sites without adverse environmental repercussions.

Asphalt pavement is widely used for its smoothness, safety, durability and economy. Asphalt binder and mineral filler constitute asphalt mixtures, and modifying these through alternative fillers improves performance. Studies using coal combustion products (CCPs) like fly ash and FGDA materials partially replacing mineral filler in asphalt mixtures reported enhanced rutting resistance, aging resistance and fracture energy. Cloutier et al. [

18] conducted a study in which 10% of mineral powder in asphalt mixtures was replaced with spray dryer absorbers (SDA), by-products of flue gas desulfurization. SDA and FGDA, also a by-product of the same process, have differing desulfurization processes leading to variations in composition. Performance evaluations, including aging, fatigue, and low-temperature crack resistance tests, were performed. The findings indicated that SDA has no adverse impact on the workability of asphalt mixtures, while enhancing their aging resistance, water stability, and fatigue life. Bautista et al. [

19,

20] categorized CCPs into four groups: fly ash, bottom ash, boiler slag, and flue gas desulfurization materials. Fly ash is further classified into Class C and Class F types. Comparative analysis of the influence of limestone powder, fly ash (Class C, Class F), and FGDA on the strength and aging resistance of asphalt mastics revealed that the addition of CCPs can boost the high-temperature deformation resistance of asphalt materials, as well as enhance aging resistance and fatigue performance, with SDA exhibiting superior performance. Mistry and Roy [

21] demonstrated in experiments that substituting 4% rice husk ash and 6% Class F fly ash for mineral powder as fillers can effectively improve the deformation resistance and water damage resistance of asphalt mixtures. However, a further increase in the substitution ratio may lead to a decline in the performance of asphalt mixtures. Chen et al. [

22] conducted experiments by incorporating CFB-FGDA, primarily composed of calcium sulfate, as fillers in asphalt mixtures. The outcomes indicated that this type of CFB-FGDA can significantly enhance the high-temperature performance of asphalt mixtures. Nevertheless, due to the tendency of CaSO

4·2H

2O to undergo hydration reactions easily, it may compromise the water stability of asphalt mixtures.

Yet research on CCP additions has predominantly emphasized the high-temperature characteristics of asphalt materials, with insufficient consideration given to low-temperature cracking, which is particularly critical in cold climates. Furthermore, there is a lack of comprehensive understanding regarding the interaction mechanisms between unconventional fillers and asphalt binders. Lu et al. [

23] conducted a study on the production of modified asphalt by incorporating varying proportions (0%, 2%, 5%, 10%, and 15%) of rice husk ash (RHA) and 1% Styrene-Butadiene-Styrene (SBS). The performance of the SBS/RHA modified asphalt binder was assessed through penetration, softening point, ductility, rotational viscosity, and temperature scanning tests. The performance of the SBS/RHA modified asphalt mixture was evaluated using rutting tests, water stability tests, and tests for low-temperature cracking resistance. The findings revealed that the inclusion of RHA resulted in a reduction in penetration, an elevation in softening point and rotational viscosity of the asphalt binder, with a slight decrease in ductility. While the high-temperature performance of the SBS/RHA modified asphalt mixture outperformed that of the original asphalt mixture, the water stability and low-temperature performance showed marginal decreases. Woszuk et al. [

24] posited that the presence of Class C fly ash notably increased the void content in asphalt mixtures, potentially enhancing high-temperature stability while posing risks of compromising water damage resistance and low-temperature cracking resistance. It is recommended that the proportion of Class C fly ash in the filler should not exceed 50%. Furthermore, CFB-FGDA shares certain physical and chemical traits with these solid waste fly ash materials. Asphalt mastic, a key constituent of asphalt mixtures, plays a pivotal role in determining the overall pavement performance through its rheological properties. Therefore, evaluating CFB-FGDA effects on asphalt mastic low-temperature rheology and interaction processes could offer insights for utilization.

This study aimed to evaluate the influence of CFB-FGDA content on the low-temperature rheological properties of asphalt mastic. Mechanical testing and microscopic characterization techniques were employed, with the data from the bending beam rheometer tests being analyzed using the Burgers’ model to derive rheological parameters. Scanning electron microscopy and Fourier-transform infrared spectroscopy observations were utilized to investigate the interactions between CFB-FGDA and the asphalt binder. The findings of this study can enhance the fundamental understanding and promote the sustainable utilization of this industrial by-product in the design and construction of asphalt materials. The research sought to address knowledge gaps related to the impacts on low-temperature performance and gain mechanistic insights to guide the optimization of CFB-FGDA inclusion levels, balancing performance with environmental objectives.

3. Results

3.1. Ductility Test Results

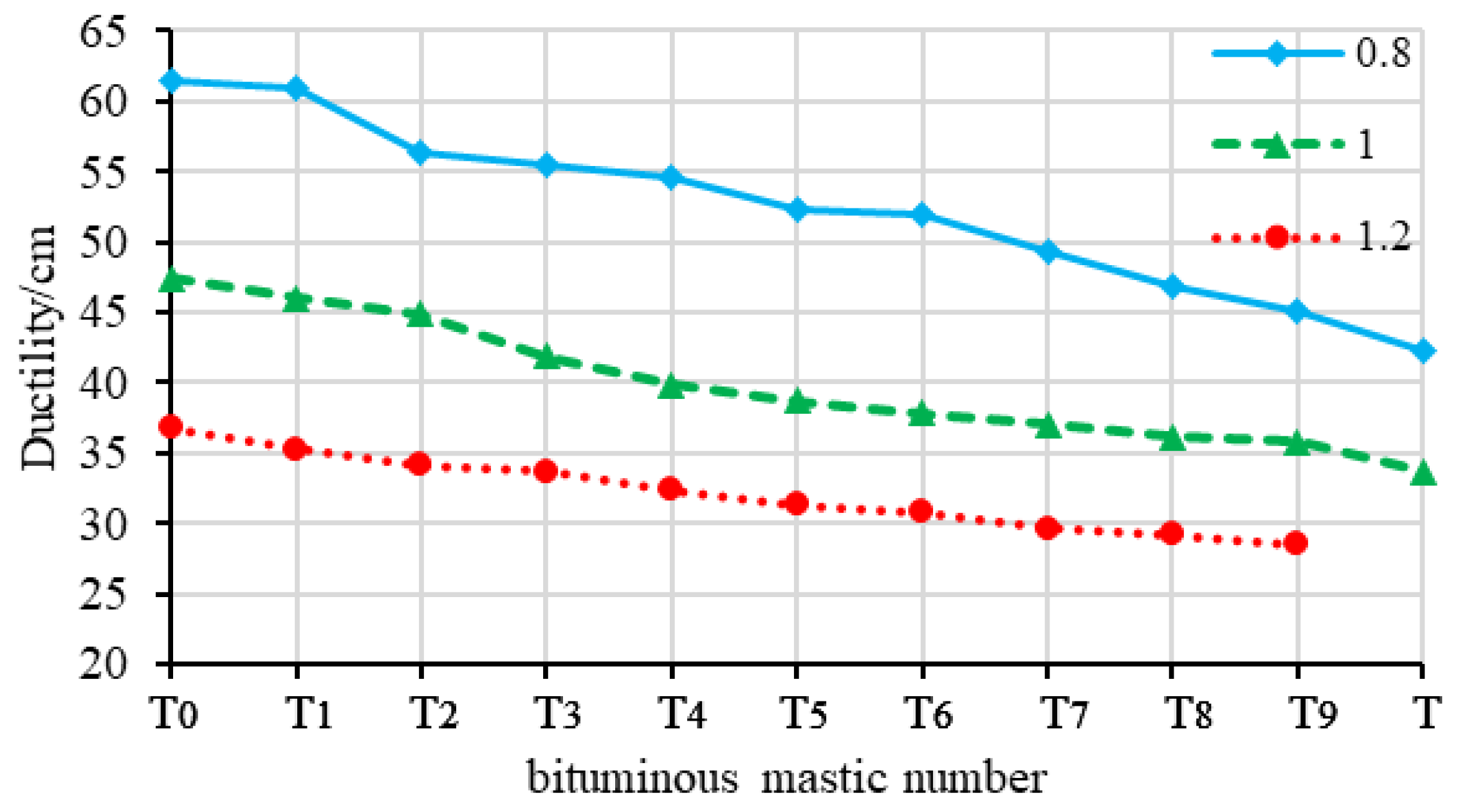

The ductility test can evaluate asphalt mortar deformation and cracking resistance at low temperatures. Higher ductility indicates stronger plasticity and flexibility to relieve internal stresses before fracture. Ductility values for the control and CFB-FGDA-modified asphalt mastics prepared at varied powder-to-binder ratios were measured at 10 °C and are plotted in

Figure 2 (All data points represent mean values derived from triplicate parallel experiments).

For all filler ratios, ductility exhibited a decreasing trend with rising CFB-FGDA content. This indicates that the stiffer CFB-FGDA particles contributed to additional hardening in the asphalt mastic, constraining molecular mobility and strain capacity. As the proportion of CFB-FGDA mixed into the asphalt slurry increased, the decrease in the ductility of the slurry gradually diminished. This suggests that CFB-FGDA reduced the plastic deformation capability of the asphalt slurry. Additionally, the most noticeable change in the ductility of the asphalt slurry occurred when a small amount of CFB-FGDA was mixed in.

Comparison of ductility curves across powder-binder mass ratios revealed ductility decline, diminishing at higher filler contents. This behavior aligns with expectations, as excess filler serves to dilute intermolecular binder interactions, enhancing brittleness. At greater powder loadings, individual particle impacts on asphalt properties are buffered to a degree. It follows that raising the filler ratio mitigates but does not negate the stiffening impact of substituting harder CFB-FGDA for mineral powder.

Overall, the ductility test results clearly demonstrated reduced plasticity and increased brittleness of asphalt mastics with rising CFB-FGDA content, indicative of compromised low-temperature performance. However, the severity of this effect was moderated as the powder loading increased, consistent with a protective filler dilution phenomenon.

3.2. BBR Test Results

3.2.1. Stiffness Modulus (S) and Creep Rate (m)

The BBR test primarily assesses the low-temperature crack resistance of asphalt mastics through two indicators: the bending creep stiffness modulus

S and the creep rate

m. A smaller

S indicates better flexibility of the asphalt binder, allowing for greater deformation and, consequently, improved low-temperature crack resistance. The

m characterizes the relaxation performance of the asphalt binder, with a larger m value indicating faster release of internal stress, stronger relaxation ability, and better low-temperature crack resistance. The test results of

S and

m values of asphalt binders with different CFB-FGDA contents at test temperatures of −6 °C, −12 °C, and −18 °C are depicted in

Figure 3 (All data points represent mean values derived from triplicate parallel experiments).

In general, under identical powder-binder ratio conditions, the creep stiffness modulus of asphalt mastics gradually increased with the addition of CFB-FGDA at the same temperature, while the creep rate exhibited a decreasing trend. This indicated that the inclusion of CFB-FGDA compromised the low-temperature performance of asphalt mastics, aligning with the ductility test results. Moreover, as the temperature decreased, the creep stiffness of asphalt mastics with the same CFB-FGDA content notably increased, accompanied by a noticeable decrease in the creep rate. Specifically, the changes in creep stiffness and creep rate between −12 °C and −18 °C were more pronounced, highlighting an increased sensitivity of stiffness modulus and creep rate to temperature as it decreased.

At consistent temperature conditions, the creep stiffness modulus of asphalt mastics significantly increased with the rise in powder-binder ratio. Conversely, the creep rate parameter only exhibited a slight, insignificant decrease overall. When the powder-binder ratio was 1 and 1.2, an intersection was observed in the m value curve of asphalt mastics with varying CFB-FGDA content, indicating that increasing the powder-binder ratio reduced the resistance to deformation of asphalt mastics, while having minimal impact on the stress relaxation ability of asphalt mastics. This underscored the limitations of solely using S and m values to evaluate the low-temperature performance of CFB-FGDA-modified asphalt mastics.

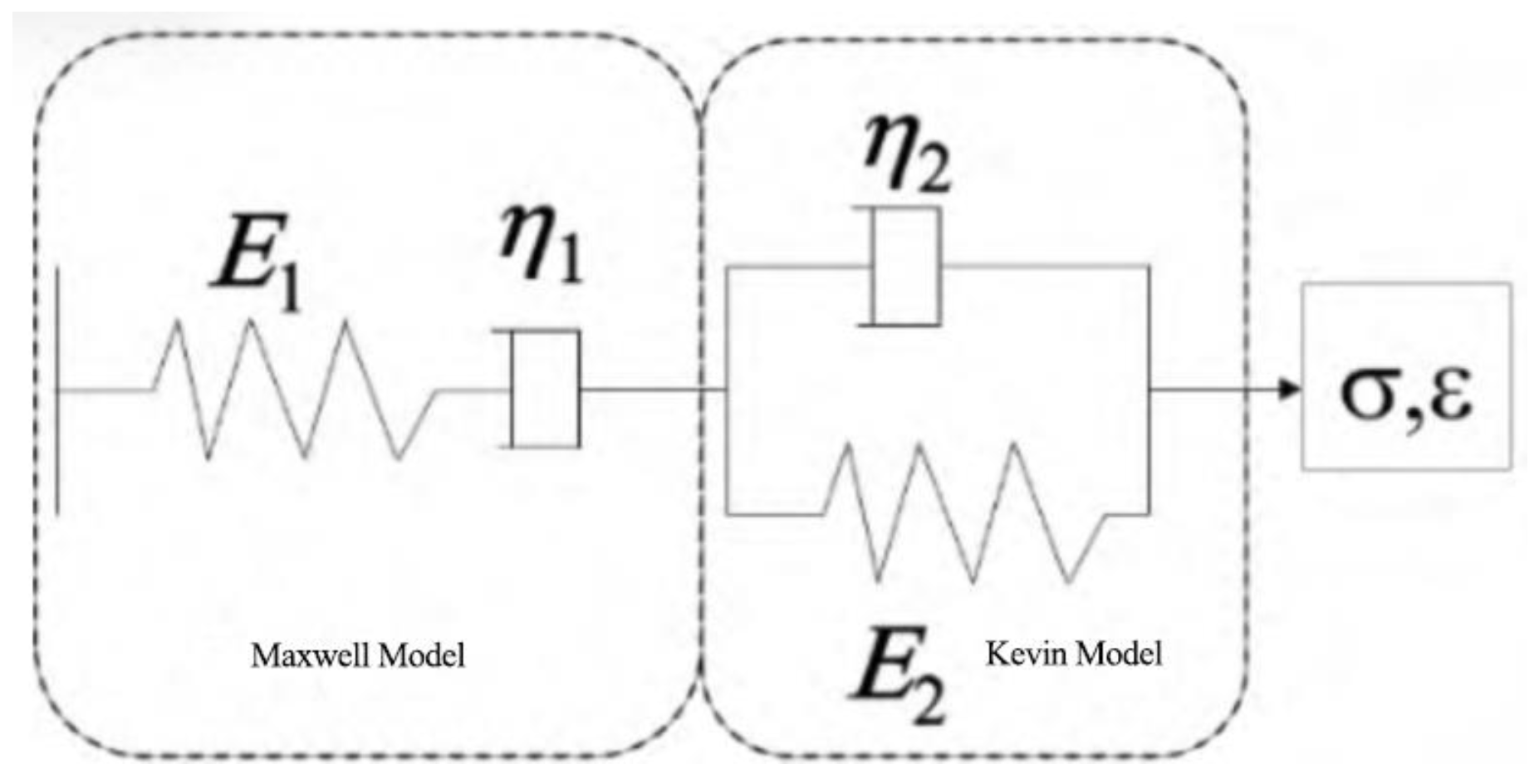

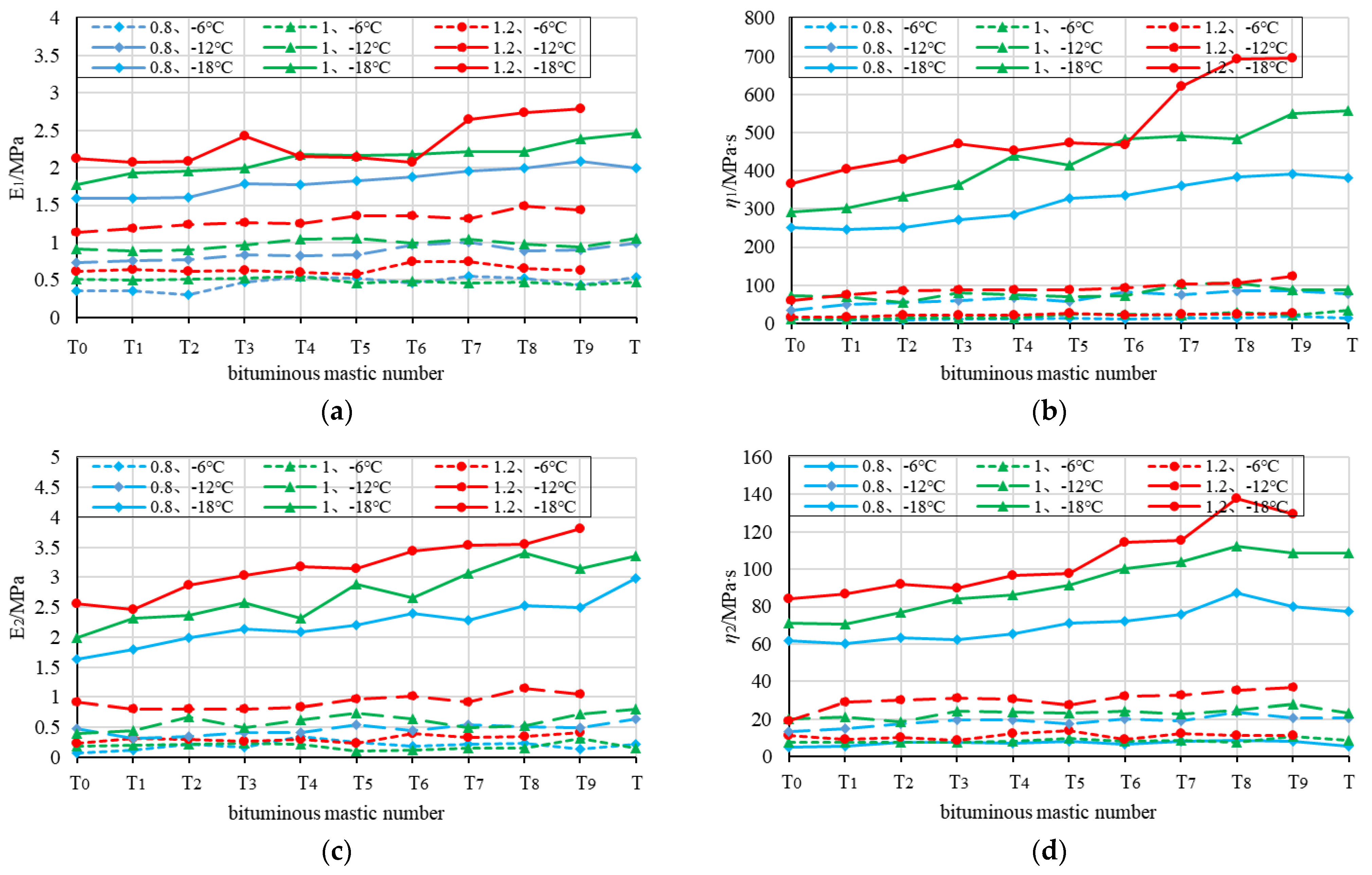

3.2.2. Burgers’ Model Parameters

The composition of asphalt mastics is highly intricate, characterized by a broad molecular weight distribution and exhibiting viscosity and elasticity properties. In the exploration of the rheological characteristics of asphalt mastics, the Burgers’ model is commonly employed to depict the mechanical behavior of asphalt mastics within specific temperature ranges. Comprising the Maxwell model and the Kelvin model in series, the Burgers’ model was utilized to determine the constitutive equation for predicting the stress-strain relationship of the material by solving the viscoelastic parameters of mechanics. Through the utilization of Excel software to fit the results of BBR tests, the elastic modulus (

E1 and

E2) and viscosity coefficients (

η1 and

η2) of the Burgers’ model under various temperature conditions were derived, as depicted in

Figure 4. The Burgers’ model demonstrated excellent agreement with experimental data, evidenced by coefficient of determination (R

2) values exceeding 0.997 for all fitted creep compliance curves, statistically validating its capacity to replicate the time-dependent viscoelastic behavior observed in BBR tests.

From the proportion of viscoelastic parameters in

Figure 4, it could be observed that

η1 and

η2 accounted for a larger proportion than

E1 and

E2. This indicated that in the Burgers’ model, composed of the Maxwell and Kelvin models, the viscous characteristic parameters of the asphalt mastic were higher than the elastic characteristic parameters. Under the same powder-binder ratio, as the test temperature decreased, the values of

η1,

η2,

E1, and

E2 for asphalt mastic samples with different CFB-FGDA contents all showed an increasing trend. The increase in

E1 and

E2 was smaller than that of

η1 and

η2, indicating that the temperature drop had less influence on the instantaneous elasticity of the asphalt mastic. Under the same temperature conditions, with the increase in the powder-binder ratio, all four parameters of the binder system increased, and the increase in

η1 and

η2 was greater, indicating an increasingly apparent viscous characteristic of the binder system. This suggested that the increased powder-binder ratio reduced the low-temperature cracking resistance of the asphalt mastic. Under the same powder-binder ratio and temperature conditions, the increase in CFB-FGDA content led to a fluctuating and increasing state for all four parameters of the Burgers model, indicating that CFB-FGDA had a comparable impact on the viscoelastic characteristics of the asphalt mastic as mineral powder.

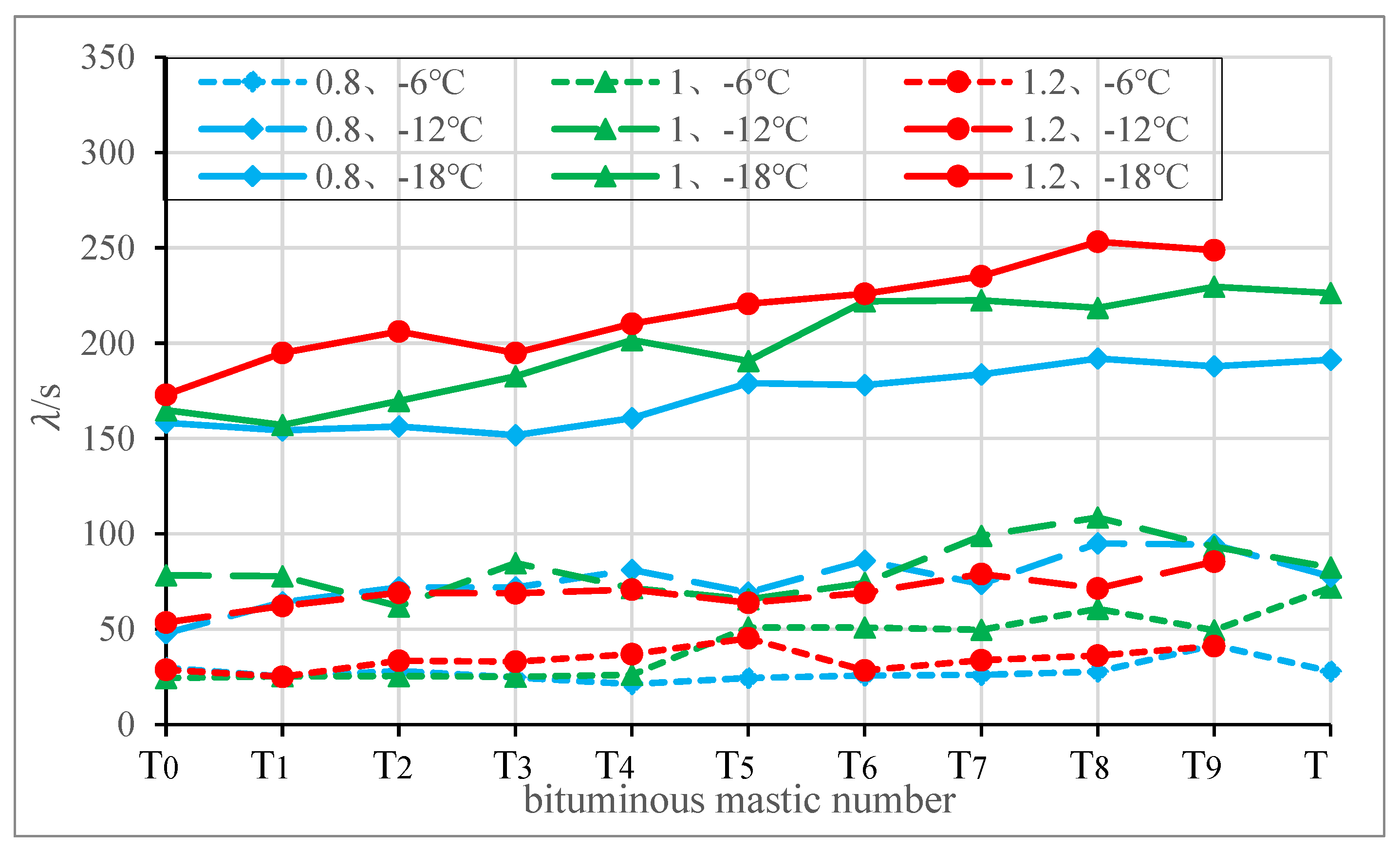

3.2.3. Relaxation Time (λ)

The relaxation time (

λ) signifies the stress dissipation capability of the asphalt mastic. Serving as an internal time parameter of the asphalt mastic, it mirrors the stress variation over time in the asphalt mastic. A shorter relaxation time corresponds to a higher stress relaxation rate, facilitating rapid stress dissipation within the asphalt mastic, thereby indicating superior low-temperature performance. The computation of the relaxation time

λ of asphalt mastic is presented in Equation (4). The calculation results for the relaxation time

λ of asphalt mastic with different CFB-FGDA content are summarized in

Figure 5.

From

Figure 5, it was observed that the relaxation time of asphalt mastics with the same powder-binder ratio gradually increased as the temperature decreased. Moreover, the lower the temperature, the more pronounced the increase, indicating a significant effect of temperature on the stress relaxation capacity of the asphalt mastics. On the one hand, this was due to the decrease in ambient temperature, which increased the internal frictional resistance to the movement of asphalt molecular chains, thereby reducing the stress relaxation capacity. On the other hand, the rate of energy release decreased, leading to an increase in relaxation time, and as the temperature continued to decrease, this effect became more pronounced.

When comparing the relaxation time curves of asphalt mastics with different CFB-FGDA contents under the same powder-binder ratio and temperature conditions, it was found that the CFB-FGDA content generally had an upward trend on the stress relaxation time of the modified asphalt. This indicated that the addition of CFB-FGDA may reduce the low-temperature performance of asphalt mastics, but the impact was not significant.

When comparing the relaxation time curves of asphalt mastics with different powder-binder mass ratios at the same temperature, it was observed that at −18 °C, the higher the powder-binder ratio, the longer the relaxation time. At −6 °C and −12 °C, the relaxation times for each powder-binder ratio intersected, indicating a relatively small impact of the powder-binder ratio on the stress relaxation time of asphalt mastics.

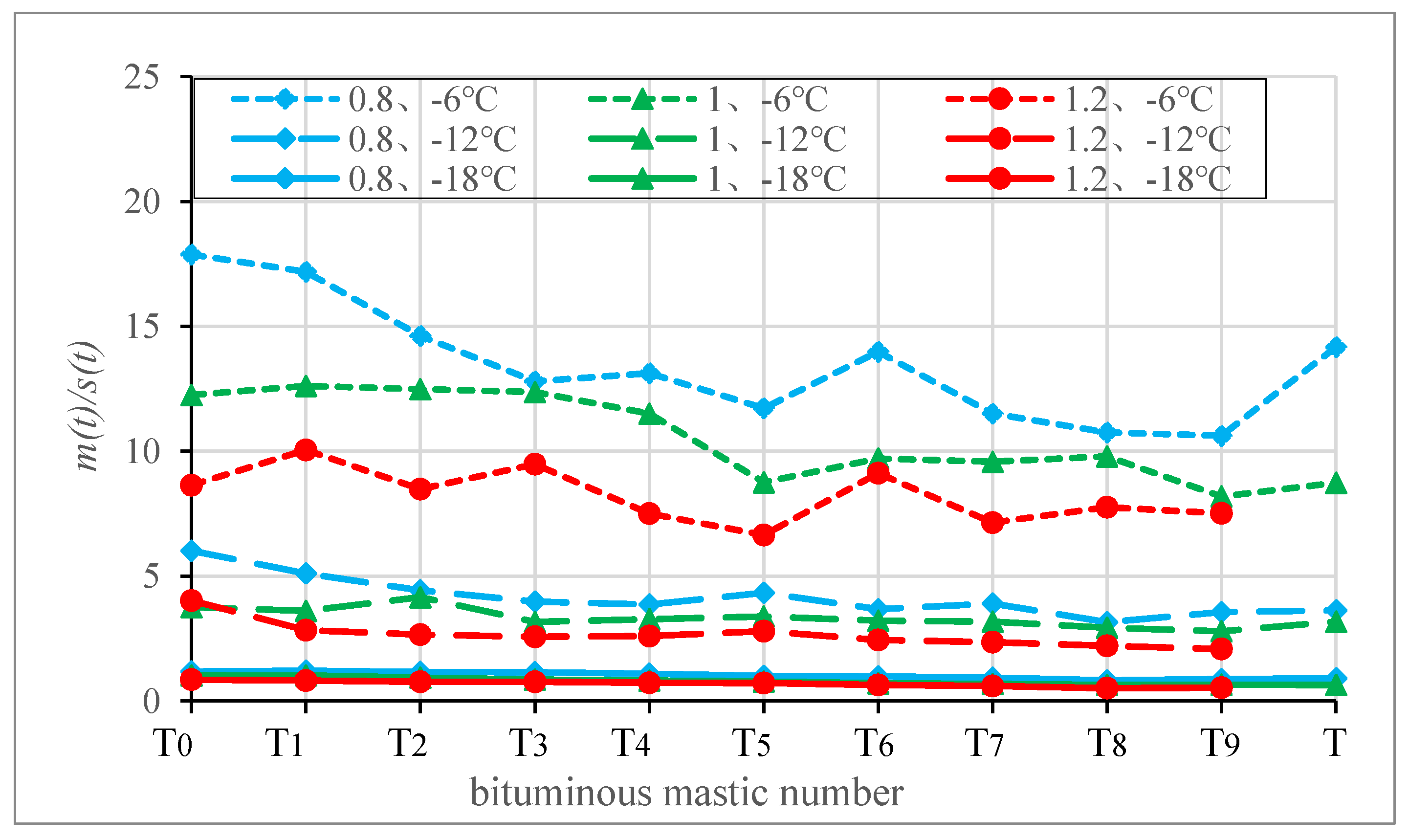

3.2.4. Index of m(t)/S(t)

The

m(

t)/

S(

t) index proposed in previous studies provides a more comprehensive evaluation of low-temperature performance than

m or

S values individually. It was calculated by Equation (5). The lower the value of

m(

t)/

S(

t), the worse the low-temperature performance of asphalt mastics. The calculation results are shown in

Figure 6.

where

η1,

η2,

E2 are Burgers’ model parameters obtained from BBR curve fitting.

As shown in

Figure 6,

m(

t)/

S(

t) decreased with rising temperature for all asphalt mastics, reflecting enhanced deformation capacity at warmer conditions. At a given temperature,

m(

t)/

S(

t) also declined gradually but modestly with increasing CFB-FGDA content. This revealed the ash imposed a minor reduction in relaxation versus loading response over temperature-time, though not as drastic as indicated by individual

S and

m values alone.

Comparison of m(t)/S(t) curves across different powder-binder mass ratios demonstrated values converged at the lowest −18 °C testing point. This finding aligns with previous relaxation time observations, where filler effects lessened under more constrained molecular conditions. CFB-FGDA has a slightly adverse effect on the low-temperature performance of asphalt mastics compared to mineral powder, although the degree of impact is not substantial. Additionally, as the temperature decreases further, the magnitude of this influence also lessens.

In summary, the m(t)/S(t) index, which incorporates both deformation and relaxation aspects, portrayed the worsening influence of desulfurization ash addition on mastic flexibility in a more moderate manner versus stiffness or creep rate independently. However, temperature dominance overwhelms filler impacts under severely restricted low-temperature situations.

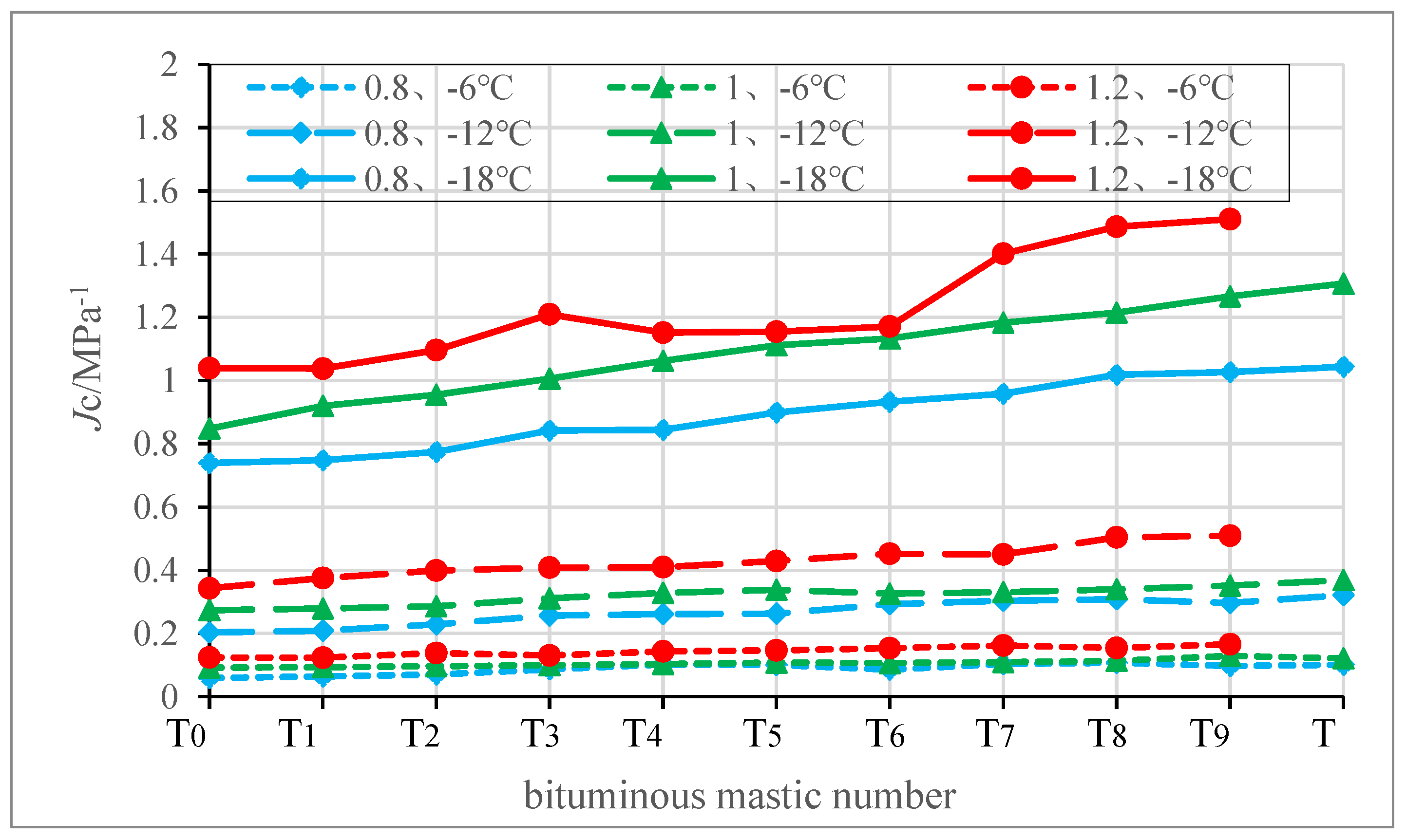

3.2.5. Low Temperature Compliance Parameter (Jc)

The low-temperature compliance parameter (

Jc) offers a means of quantifying mastic viscoelasticity based on Burgers’ model deformation ratios. The lower the low-temperature compliance parameter of asphalt mastics, the better its low-temperature performance. The calculation method for the low-temperature compliance parameter

Jc is depicted in Equation (6), and the calculation results are presented in

Figure 7 (All results are based on mean values of triplicate tests, ensuring statistical reliability).

where

Jv,

Je,

JDe represent viscous, elastic, and damping compliances from Burgers’ model.

From

Figure 7, it was observed that with the increase in temperature, the

Jc of asphalt mastics with the same powder-binder decreased. Under the same temperature conditions, the smaller the powder-binder ratio, the smaller the

Jc of the asphalt mastic, indicating that at this point, the asphalt mastic exhibited a higher elastic proportion and lower viscous proportion under low-temperature conditions. Viscous flow accounted for a higher proportion, making the asphalt mastic more capable of withstanding tensile stress through flow, thereby reducing the occurrence of low-temperature cracking.

When comparing the Jc of asphalt mastics with different CFB-FGDA contents under the same powder-binder ratio and temperature, it was observed that as the CFB-FGDA content increased, the Jc also increased continuously. This phenomenon was more pronounced with a higher powder-binder ratio, indicating that the increase in CFB-FGDA content weakened the low-temperature performance of the asphalt mastic, and the weakening effect was more pronounced with a higher powder-binder ratio. This was because compared to mineral powder, CFB-FGDA had more surface pores, which could absorb more light components in the asphalt, leading to increased hardening of the asphalt mastic, reduced flowability, more prominent elastic characteristics of the asphalt mastic, and ultimately poorer resistance to low-temperature cracking.

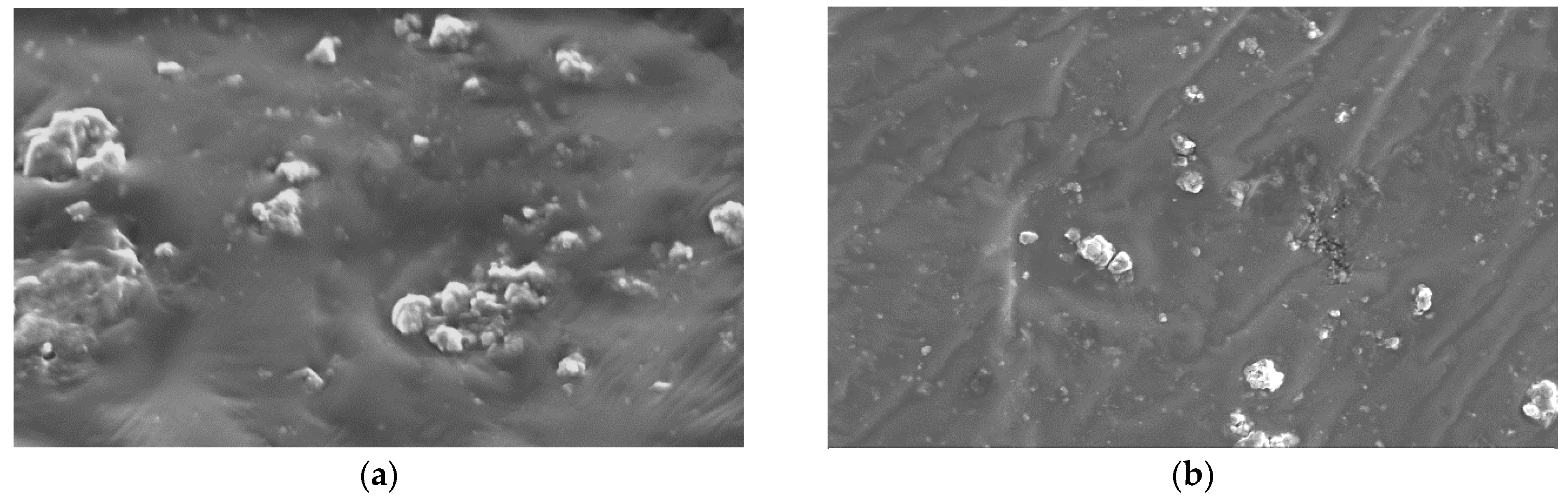

3.3. SEM Analysis

SEM offered microscopic characterization of asphalt mastic microstructures.

Figure 8 presents SEM images of the control and 100% CFB-FGDA replacement asphalt mastics at 2000× magnification.

For the control asphalt mastic containing mineral powder only, particles exhibited some separation from the asphalt binder phase with noticeable interfacial aureoles. This suggests less complete coverage of powder surfaces could promote localized stress concentrations, compromising flexibility at low temperatures. In contrast, the 100% CFB-FGDA asphalt mastic displayed more homogenous dispersion of desulfurization ash with binder thoroughly wetting particle exteriors. The enhanced adhesion implied stronger interfacial bonding, translating to higher composite integrity. This micromechanical feature may partly explain why ductility and creep decreases were attenuated at higher filler levels.

In conclusion, SEM outputs elucidated how differing surface morphologies and wetting between CFB-FGDA versus mineral powder could impact asphalt mastic microstructure development and internal stress state. The inferior properties indicated by mechanical testing appeared to be related to poorer interfacial properties for mineral powder. This mechanistic insight aids material design through manipulating filler-binder interactions.

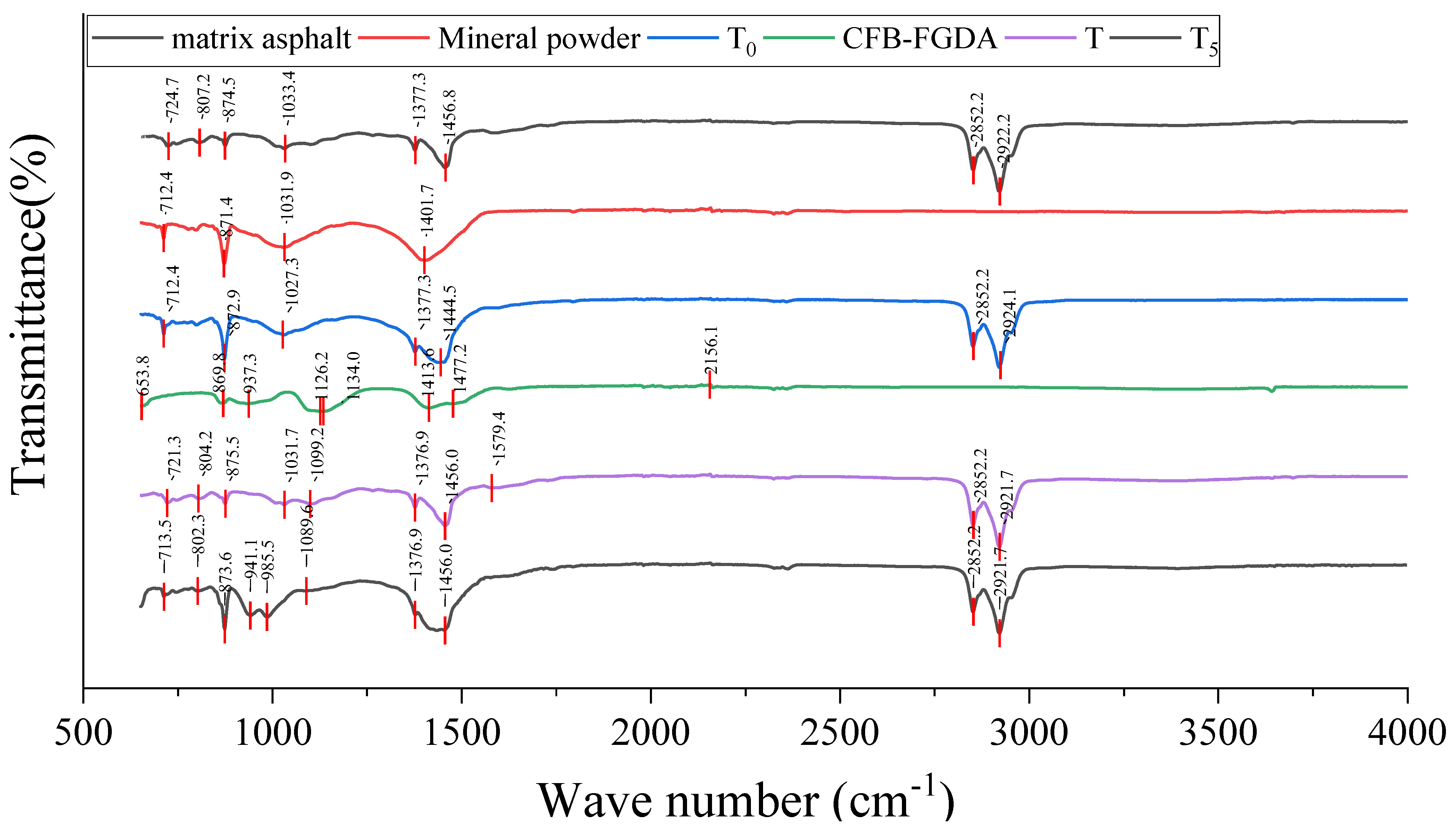

3.4. FTIR Analysis

FTIR provided molecular-level examination of functional group changes upon ash modification.

Figure 9 overlays FTIR spectra for base asphalt, mineral powder, and CFB-FGDA-modified (T

0, T

5 and T) asphalt mastics.

From

Figure 9, it was observed that the distribution of the main peak positions of base asphalt and several types of asphalt mastics. By comparing base asphalt, mineral powder, and mineral powder modified asphalt mastic, it was found that the mineral powder modified asphalt mastic had two additional peaks at 1436 cm

−1 and 872 cm

−1, respectively. These peaks were generated by the carbonate in the mineral powder, indicating that no new peaks were generated. It could be inferred that there was no chemical reaction between the limestone mineral powder and the base asphalt. Similarly, it could also be inferred that the CFB-FGDA had not undergone a chemical reaction with the base asphalt. This suggested that the mechanism of action of CFB-FGDA asphalt mastic, CFB-FGDA/mineral powder composite asphalt mastic, and mineral powder asphalt mastic was similar, mainly involving physical mixing between CFB-FGDA and base asphalt. Therefore, the performance of CFB-FGDA asphalt mastic mainly depended on the degree of swelling between CFB-FGDA and the base asphalt. By comparing the peak sizes of characteristic peaks in the spectra of the three asphalt mastics, it was observed that the addition of CFB-FGDA had a significant impact on the absorption peak at 1605 cm

−1, which characterized aromatic hydrocarbons, and the benzene ring substitution region of 900–650 cm

−1, compared to mineral powder. This was also the main reason for the change in asphalt performance caused by the addition of desulfurized ash.