Abstract

In this study, 20 wt.% of Nb was incorporated into a CrFeNi medium-entropy alloy (MEA) powder system to prepare CrFeNi-Nb composite coatings on a Q235B mild steel substrate by laser cladding technology. The effects of Nb addition on the phase composition, microstructure, and wear resistance of CrFeNi coatings were systematically investigated. Microstructural characterization revealed that the CrFeNi coating exhibited a single face-centered cubic (FCC) phase structure, while the CrFeNi-Nb composite coating demonstrated a dual-phase structure comprising FCC phase and Laves phase. The Laves phase significantly enhanced the microhardness and wear resistance of the coating. The average microhardness of the CrFeNi-Nb coating increased by 259.62% compared to the substrate and 190.58% compared to the Nb-free CrFeNi coating. The average coefficient of friction (COF) of the coating decreased from 0.74 to 0.68; the wear rate reduced from 5.77 × 10−4 mm3 N−1 m−1 to 2.26 × 10−4 mm3 N−1 m−1; and the weight loss decreased from 10.77 mg to 4.3 mg. The experimental results demonstrated that the addition of Nb promoted the formation of the Laves phase in the CrFeNi MEA, which effectively improved the wear resistance of the coating.

1. Introduction

In recent years, high entropy alloys (HEAs) have become a hot research topic in the field of surface engineering by virtue of the “cocktail effect” and “high entropy effect” [1], which breaks through the design framework of traditional alloys centered on a single major element. However, its tetrameric and more equimolar multi-component composition is prone to phase structure instability, and the high preparation cost limits the large-scale application. In contrast, the optimization of medium entropy alloys (MEAs) into ternary equimolar systems, while retaining the core properties of high strength, excellent plasticity, and corrosion resistance [2], significantly reduces the difficulty of component regulation and process costs and provides a more universal solution for the practical needs in the fields of industrial protection, structural materials, and so on [3].

In recent decades, MEAs have attracted the attention of more and more researchers due to their simpler crystal structure and superior combination of mechanical properties [1,2]. CrFeNi exhibits a single FCC phase structure in the as-cast or solid solution state [4] and has a Cr content of up to 33 at%. This means that CrFeNi MEA has outstanding corrosion resistance and is positioning it as an ideal candidate for marine environments and aerospace [5,6]. Despite the good corrosion resistance of CrFeNi MEA, a single FCC phase usually results in a coating with low microhardness and relatively poor wear resistance [7]. Such poor mechanical properties have largely limited the application and development of CrFeNi MEA. Enhancing the coating properties by adding other elements is a common approach [8,9,10]. Wang et al. [11] successfully achieved simultaneous enhancement of tribological and anti-corrosion performance in CrFeNi MEA through B/Si alloying; Cheng et al. [12] examined the dual-element synergistic effects of Co and Cu double doping on the mechanical and tribological properties of CrFeNi. They found that the addition of Co can refine the grain size of CrFeNi alloys, reduce stress concentration, and improve ductility and tensile strength. However, the simultaneous doping of Co and Cu accelerates the phase transformation and reduces the plastic deformation ability of the alloy; Duan et al. [13] promoted the generation of coating σ-phase by adding Mo with a large atomic radius to CrFeNi MEA to improve the mechanical properties of the coating; Gao et al. [14] improved the mechanical properties of the coatings by adding Ti elements with a larger atomic radius in CoCrNi meso-entropic alloys, which induced crystal distortion and promoted the generation of BCC phases in the coatings.

Nb, as a refractory metal, is widely used in rocket systems due to its high thermal strength and excellent machining strength [15]. The relatively superior mechanical properties make Nb ideal for enhancing the performance of MEA. Interestingly, the elemental density of Nb is very similar to that of Fe, Cr, and Ni, but with a larger atomic radius, which means that the choice of adding Nb elements to enhance the FeCrNi MEA properties is highly advantageous [16].

With the advancements of laser systems and processing methods, this technology has gradually emerged in many fields. As one of the most advanced surface modification techniques, the distinctive benefits of laser cladding are low dilution rate, high density, and good metallurgical bonding between the cladding layer and the substrate [17,18,19]. This makes the process particularly effective and very suitable for the application of MEA surface engineering applications.

Laser cladding technology provides a new solution to overcome the difficult-to-melt elements by virtue of its highly concentrated energy and precise focusing characteristics. Therefore, in this study, the effect of Nb on the phase composition, microstructure, and mechanical properties of FeCrNi MEA is investigated by using the cladding technology as the preparation process, with emphasis on the analysis of the enhancement mechanism of FeCrNi MEA by Nb elements. This study aims to provide unique insights and technical validation for the optimization of the properties of FeCrNi series alloys, to promote the wide application of MEA in more fields, and to promote its application value.

2. Experimental Procedures

2.1. Experimental Material Preparation

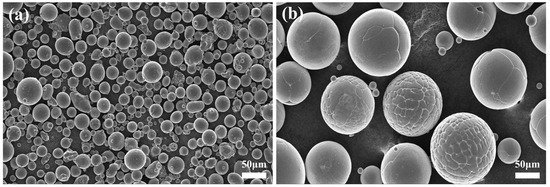

Q235B mild steel (size: 90 × 50 × 3 mm3) was used as the experimental substrate. In order to remove the impurities and oxide film on the surface of the substrate, it was sequentially ground with 80–1000 mesh sandpaper, then ultrasonic ethanol, and dried using a drying oven. Table 1 shows the chemical compositions of Q235B mild steel and CrFeNi MEA powder (CrFeNi, Sichuan Quanyue Matel Materials Co. Ltd., Mianyang, China), and the experiments were conducted using both Nb powder of 99.97% purity supplied by the company. Figure 1a,b illustrates the particulate features of CrFeNi and Nb powders.

Table 1.

Chemical composition of experimental materials.

Figure 1.

SEM images. (a) CrFeNi powder; (b) Nb powder.

2.2. Mixing and Coating Preparation of CrFeNi-Nb Powder

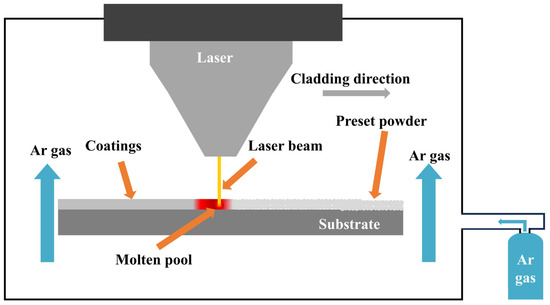

The blended powder mixture (20 wt.% Nb powder combined with a CrFeNi matrix) was subjected to planetary ball milling at 350 rpm for 3 h, followed by a 24 h drying process. As shown in Figure 2, the powder preset methodology was employed this experiment, and the mixed powder was uniformly applied to the surface of the substrate using a standard mold with a thickness of (2 ± 0.1) mm. The coating is then prepared by laser processing equipment (XL-F2000W). The parameters of the laser equipment are as follows: Laser power: 1200 W, scanning rate: 500 mm/min, spot diameter: 2.5 mm, defocus rate: +5 mm, overlap rate: 50%, number of melting channels: 17, melting length: 45 mm. Argon shielding at 6 L/min flow rate was maintained throughout the deposition process coating preparation. After the coating was prepared, the samples were divided by wire cutting, and finally the surface of the samples was mechanically ground and polished, respectively, for subsequent microstructure, mechanical properties, and corrosion resistance tests.

Figure 2.

Schematic diagram of laser cladding process.

3. Characterization

3.1. Microstructure and Elemental Distribution

The phase identification of the coatings was obtained by scanning the coatings using high-resolution X-ray diffraction (SmartLab 9 KW, Rigaku, Tokyo, Japan) at 40 kV and 40 mA with a scanning speed of 2°/min and scanning angles of 20–90°. The micro-morphology and elemental distribution of the coatings were characterized by a field emission scanning electron microscope (SEM, Zeiss, Baden-Württemberg, Germany, ZEISS Sigma) and an energy spectrometer (EDS, Oxford 30Xplore, Oxford, UK).

3.2. Mechanical Properties

Cross-sectional hardness measurements were performed on the MHVD-1000AT microhardness system (Yizong Precision Instruments, Shanghai, China) using a 200 gf diamond indenter with 10 s dwell cycles. Tribological evaluations utilized the SFT-2M tribological analyzer (Lanzhou Zhongkehua, Lanzhou, China) configured with a 4 mm GGr15 spherical counterface. Testing protocols included a 25 N applied load, a 2 mm orbital radius, a 200 rpm rotational frequency, and a 30 min sliding contact duration.

4. Result and Discussion

4.1. Phase Composition

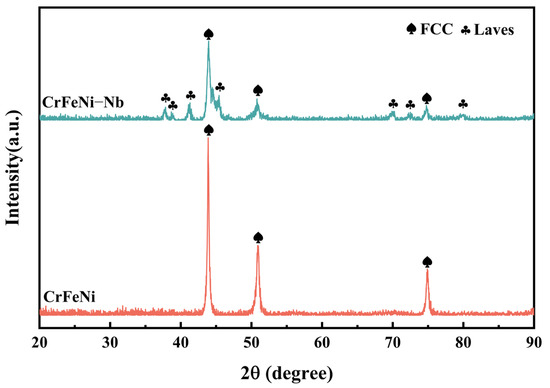

X-ray diffraction analysis (Figure 3) reveals distinct phase evolution patterns. The CrFeNi coating mainly exhibits the FCC phase. The rapid thermal cycling characteristic of laser deposition enhances elemental solubility thresholds, facilitating extensive solid solution formation as documented in reference [20]. Upon comparison, the intensity of the FCC peak of the CrFeNi-Nb coating was significantly reduced with the addition of Nb; the Laves phase appeared in the CrFeNi-Nb coating, which transformed the MEA from an initial single-phase FCC configuration into a duplex system comprising an FCC phase and a Laves phase. Upon fitting the peaks, the Laves phase mainly exhibits Fe2Nb (#PDF00-0908) and Nb2Ni (#PDF21-0587). This is due to the more negative enthalpy ΔHmix (kJ mol−1) between Nb and Fe, Ni in laser fusion cladding (Table 2), which leads to its preferential generation [21]. At the same time, Nb reacts with Fe, Cr, or Ni in solid solution [22] to form the intermetallic compound Laves phase, which exhibits higher structural entropy, reducing the content of the elements generating the FCC phase, and consequently decreasing the intensity of the FCC peak.

Figure 3.

XRD patterns of CrFeNi and CrFeNi-Nb coatings.

Table 2.

Enthalpy of mixing of elements.

4.2. Microscopic Morphology

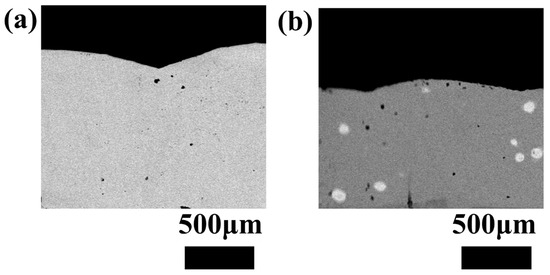

Figure 4 shows the low-magnification SEM image of the coating cross-section. Figure 4a shows the CrFeNi coating with an overall uniform coating; as in Figure 4b for CrFeNi-Nb, a small number of incompletely melted white Nb pellets are present at the bottom, middle, and top of the coating.

Figure 4.

Low magnification SEM images of the coating cross-sections. (a) CrFeNi coating; (b) CrFeNi-Nb coating.

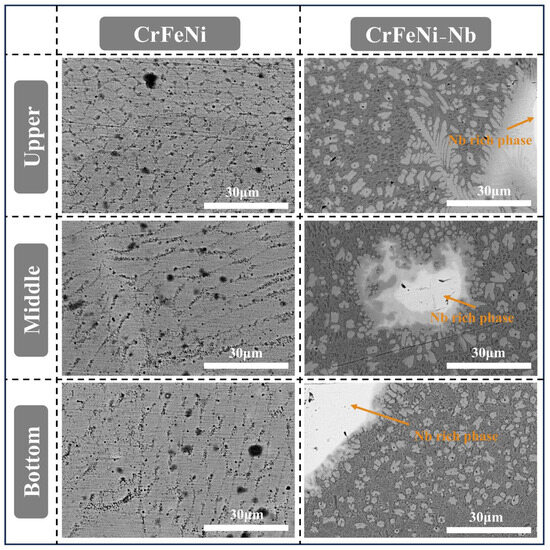

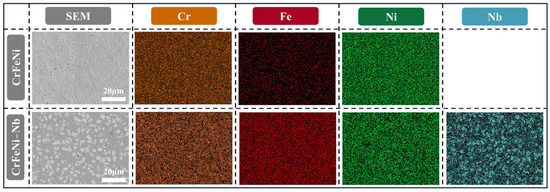

Microstructural evolution across coating cross-sections reveals distinct zonal characteristics (Figure 5). From the bottom to the middle and then to the upper of the CrFeNi coating, the crystals grow from planar to dendritic crystals. The microstructure of the coatings shows significant changes from the bottom to the center to the upper. For the CrFeNi coating from the bottom to the upper, the crystals grow from planar to equiaxed crystals; after the addition of Nb, the coating grows from planar to dendritic crystals. Proximity to the thermally conductive substrate during phase transition creates steep thermal gradients (G) near the interface coupled with reduced solidification velocities (R). Maximum thermal gradients occur near the substrate interface, while enhanced solidification kinetics dominate upper regions. The G/R ratio governs morphological selection in solidified microstructures. (planar crystals, dendritic crystals, or isometric crystals) [23]. Classical solidification principles [24] suggest nucleation grains preferentially extend against the direction of maximum heat dissipation, along the direction perpendicular to the melt pool, which is consistent with the crystal growth direction of CrFeNi coatings. Progressive G reduction coupled with R enhancement drives G/R diminution, inducing planar-to-columnar structural transitions. Such transitional behavior is evident in the Nb-containing coating shown in Figure 5. Figure 6 shows the results of the surface scanning of the coating cross-section. For the CrFeNi coating, the elements are uniformly distributed on the CrFeNi coating; after the addition of Nb, the coating generates many irregular white crystals. Combined with the EDS analysis, the white crystals are Nb-rich compounds, and combined with the XRD analysis in the previous section, it can be inferred that they are Laves phase crystals. Combined with the XRD analysis, it can be inferred that they are Laves phase crystals. Combined with the distribution of white crystals in the CrFeNi-Nb coating in Figure 5, it can be concluded that the Laves phase associated with Nb is uniformly distributed in the coating after the addition of Nb.

Figure 5.

SEM images of CrFeNi and CrFeNi-Nb coatings at different locations in the cross-section.

Figure 6.

Elemental distribution of CrFeNi and CrFeNi-Nb coating cross-sections.

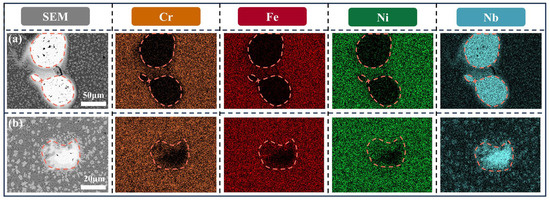

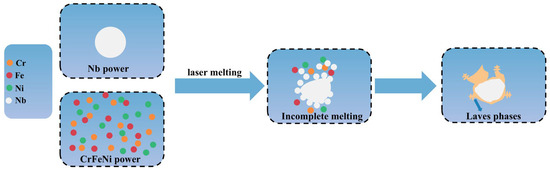

Figure 7 presents the EDS elemental mapping results of the white particles in the CrFeNi-Nb coating. The analysis clearly identifies these particles as incompletely melted Nb aggregates, attributed to the elevated Nb concentration in the localized regions. Correlating with previous XRD characterization data, the adjacent white crystalline phases surrounding the Nb aggregates are confirmed as Laves phases. Figure 7a illustrates spherical Nb aggregates retaining their original morphology, while Figure 7b shows partially reacted hemispherical Nb particles interacting with Cr/Fe/Ni matrix elements. This interfacial evolution supports the proposed mechanism of Laves phase formation in Nb-modified coatings, depicted schematically in Figure 8. The metallurgical process involves reactive diffusion at the Nb-CrFeNi interfaces during laser cladding, where dissolved Nb from partially melted aggregates chemically combines with matrix elements to nucleate Laves phases through solid-state precipitation [25].

Figure 7.

Elemental distribution of partially unfused powder.

Figure 8.

Laves phase generation mechanism.

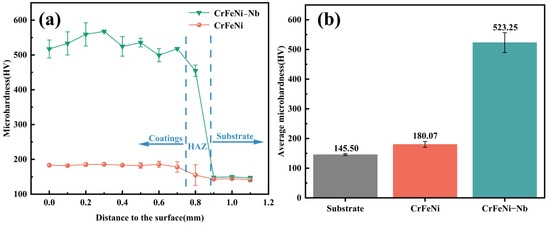

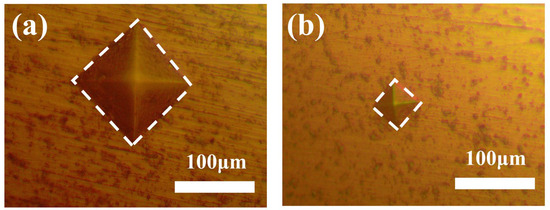

4.3. Microhardness and Nanoindentation

Figure 9 presents the mechanical characterization of coating systems through microindentation analysis. Figure 9a represents the microhardness profile of the coatings. The Nb-modified system exhibited superior microhardness characteristics in both deposited layers and HAZ compared to the baseline CrFeNi coating, demonstrating niobium’s hardening efficacy. Figure 9b represents the average microhardness of the coatings, which were all enhanced compared to the base material, by 23.76% for the CrFeNi coating and 259.62% for the CrFeNi-Nb coating. Figure 10 shows the indentation imprints of the coatings. Figure 10a CrFeNi as coating, after Nb doping, the indentation imprint of the CrFeNi-Nb coating is obviously much smaller (Figure 10b), which is consistent with the analysis of the results in Figure 9. This dramatic enhancement stems from Nb-induced phase evolution, where the original FCC structure transitions into a dual-phase system incorporating FCC and hard Laves phases.

Figure 9.

(a) Microhardness of CrFeNi and CrFeNi-Nb coatings. (b) Average microhardness of substrate, CrFeNi, and CrFeNi-Nb coatings.

Figure 10.

Coating indentation imprints. (a) CrFeNi as coating. (b) CrFeNi-Nb coating.

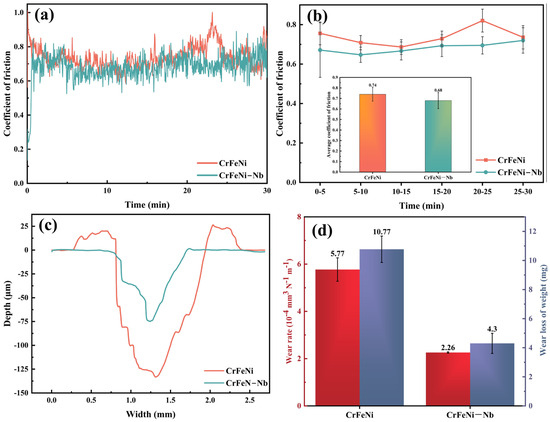

Figure 11a shows the COF curve of the coating. The COF of the sample fluctuates up and down within a certain range after a sharp increase. Comparative analysis in Figure 11b reveals that Nb alloying effectively diminishes the mean COF values. Figure 11c shows the wear profile of the coatings, and after measurement, the wear profile width of the CrFeNi coating is 1.71 mm and the depth is 132.62 μm; the wear profile width of the CrFeNi-Nb coating is 1.03 mm, and the depth is 74.66 μm. The test results show that the addition of Nb makes the wear profile width of the coatings narrower and the depth shallower. Volumetric wear quantification via Archard’s formulation [26] (Equation (1)) yields critical performance metrics. The comprehensive wear assessment in Figure 11d integrates specific wear rates with mass loss data. The wear rate of the CrFeNi coating is 5.77 × 10−4 mm3 N−1 m−1 and the wear rate of the CrFeNi-Nb coating is 2.26 × 10−4 mm3 N−1 m−1, which is a reduction of 60.83% in the amount of wear and a reduction in the wear loss of 60.07%. These synergistic improvements in tribological performance verify Nb-induced wear resistance enhancement through hard phase reinforcement mechanisms.

Figure 11.

(a) COF of coatings. (b) Average COF of coatings. (c) Wear profile of coatings. (d) Wear rate and weight loss of coatings.

The Archard’s model defines volumetric loss (V, mm3) as a function of normal force (N, N) and cumulative sliding distance (d, m).

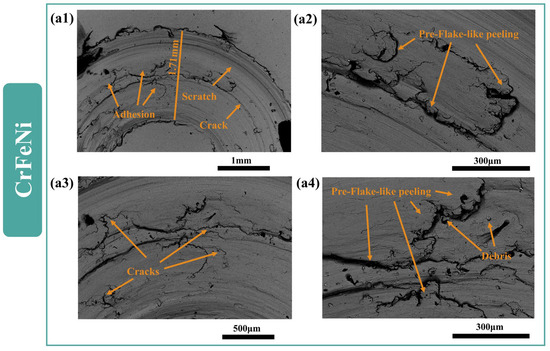

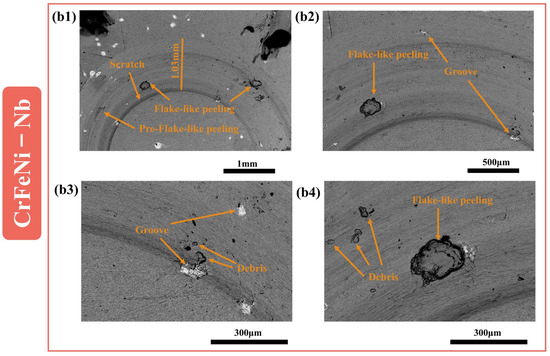

Figure 12 and Figure 13 present the surface wear profiles of the CrFeNi coating and CrFeNi-Nb coating, respectively. It can be seen that the wear profile of the CrFeNi-Nb coating is narrower and shallower (Figure 12(a1) and Figure 13(b1)), consistent with the results of the previous analysis in Figure 11c, exhibiting good abrasion resistance. As a single-phase FCC structure, the CrFeNi coating has low microhardness and poor resistance to micro-cutting, likely to generate more wear debris during the wear process [16] (Figure 12(a4)). Following the introduction of Nb, the formation of a high-microhardness Laves phase contributes to grain refinement. This process effectively hinders dislocation movement, thereby enhancing the coating’s resistance to micro-cutting and reducing the amount of debris produced during wear. Consequently, there is a decrease in the coefficient of friction (COF) curve for the coating [27], leading to an overall enhancement in its wear resistance capabilities. More microcracks and obvious delamination spalling were found in the CrFeNi coatings (Figure 12(a2,a4)), which showed typical adhesive wear [28]. The CrFeNi-Nb coatings showed less delamination spalling and wear debris and mainly exhibited abrasive wear.

Figure 12.

(a1) SEM images of surface wear of CrFeNi coating; (a2–a4) local magnified images.

Figure 13.

(b1,b2) SEM images of surface wear of CrFeNi coating; (b3,b4) local magnified images.

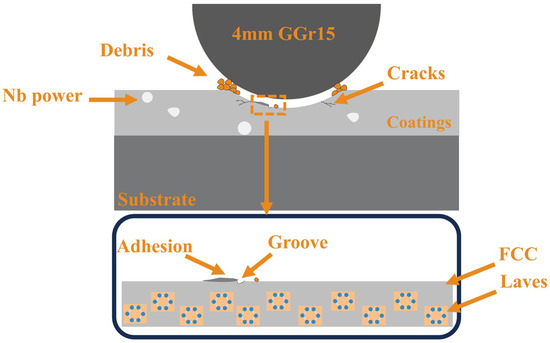

Figure 14 schematically illustrates the wear protection architecture inherent to the Nb-alloyed coating system. The interface between the coating and sphere experiences plastic deformation and fracture under varying tangential stresses during wear, leading to the formation of wear debris. Laser processing induces localized energy accumulation and transient heat transfer dynamics, driving instantaneous melting and subsequent solidification of feedstock material. This results in spatially heterogeneous thermal profiles across the coating, accompanied by steep thermal gradients and residual thermomechanical stresses. Tribological interactions at the coating-counterface interface induce crack nucleation due to localized shear stress intensification and compressive loading during sliding contact. When the yield limit is exceeded, the coating in the vicinity of the crack is spalled to form a crater [29] (Figure 13(b3)).

Figure 14.

Tribological mechanism diagram for CrFeNi-Nb coatings.

5. Conclusions

In this investigation, CrFeNi-Nb composite coatings were fabricated on Q235B steel substrates using laser cladding. Microstructural analysis revealed distinct phase transformations between the two coatings: The CrFeNi coating predominantly consists of FCC structures with planar and equiaxed crystal formations [3], while Nb-modified coatings display dendritic growth patterns along with dispersed irregular Laves phase precipitates. Mechanical property evaluations demonstrated that the single-phase FCC structure in CrFeNi coatings exhibits relatively low microhardness. However, Nb incorporation induces the formation of hard Laves phases, substantially enhancing the coating’s microhardness through dispersion strengthening. Tribological testing further indicated that the FCC-dominated CrFeNi coating shows limited resistance to abrasive wear mechanisms. Conversely, the Nb-containing coating demonstrates superior wear resistance due to the dense stacking architecture of Laves phases, which effectively hinders dislocation motion and mitigate microcutting damage during frictional contact. These findings highlight the critical role of Nb-induced phase modifications in optimizing coating performance. The following conclusions were obtained:

- (1)

- The addition of Nb can promote the generation of high-hardness Laves phase in CrFeNi meso-entropic alloy coatings.

- (2)

- The microhardness of the CrFeNi-Nb coating was increased by 259.62% over the substrate and 190.58% over the CrFeNi coating.

- (3)

- The addition of 20% Nb significantly reduced the wear rate by 60.83% and wear loss by 60.07%.

Author Contributions

Conceptualization, Z.C. and F.L.; methodology, F.L.; software, Zhen Peng.; validation, F.L. and H.J.; formal analysis, Z.C.; investigation, H.J.; resources, F.L.; data curation, H.J.; writing—original draft preparation, Z.C.; writing—review and editing, J.H.; visualization, Z.P.; supervision, J.H.; project administration, F.L.; funding acquisition, W.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Guangdong Ocean University Excellent Graduate Thesis Cultivation Project (No. 202534), the National Natural Science Foundation of China (No. 62073089), the Fund of Guangdong Provincial Key Laboratory of Intelligent Equipment for South China Sea Marine Ranching (Grant No. 2023B1212030003), and the Laser Processing Team Project of Guangdong Ocean University (No. CCTD201823).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Senkov, O.N.; Senkova, S.V.; Dimiduk, D.M.; Woodward, C.; Miracle, D.B. Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy. J. Mater. Sci. 2012, 47, 6522–6534. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Li, W.; Xie, D.; Li, D.; Zhang, Y.; Gao, Y.; Liaw, P.K. Mechanical behavior of high-entropy alloys. Prog. Mater. Sci. 2021, 118, 100777. [Google Scholar] [CrossRef]

- Wen, D.; Jiang, B.; Huang, Z.; Kong, F.; Jiang, X.; Wang, A.; Liu, G.; Wang, B. Supersaturation and dissolvable α-Cr phase enable superior oxidation resistance in FeCrNi medium-entropy alloys. J. Alloys Compd. 2023, 954, 170216. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, B.; Guo, W.; Fu, A.; Duan, H.; Li, W. Corrosion behavior and mechanism of FeCrNi medium entropy alloy prepared by powder metallurgy. J. Alloys Compd. 2021, 867, 159094. [Google Scholar] [CrossRef]

- Liang, D.; Zhao, C.; Zhu, W.; Wei, P.; Jiang, F.; Zhang, Y.; Sun, Q.; Ren, F. Overcoming the strength-ductility trade-off via the formation of nanoscale Cr-rich precipitates in an ultrafine-grained FCC CrFeNi medium entropy alloy matrix. Mater. Sci. Eng. A 2019, 762, 138107. [Google Scholar] [CrossRef]

- Hu, Z.; Lin, Y.; Zhang, L.; Wang, A.; Wang, J.; Zhang, R.; Cai, M.; Yu, J.; Wu, B. Enhancing mechanical properties of high Cr dual-phase FeCrNi medium-entropy alloy through mutual phase transformation and grain refinement. Mater. Sci. Eng. A 2024, 907, 146745. [Google Scholar] [CrossRef]

- Fan, L.; Yang, T.; Luan, J.; Jiao, Z. Control of discontinuous and continuous precipitation of γ′-strengthened high-entropy alloys through nanoscale Nb segregation and partitioning. J. Alloys Compd. 2020, 832, 154903. [Google Scholar] [CrossRef]

- Xu, Z.; Hou, Y.; Li, G. Atomic-scale investigation of the synergistic impact of Mo and Nb addition on enhancing the performance of laser cladding FeCoCrNi-based high entropy alloy coatings. Surf. Coat. Technol. 2024, 490, 131162. [Google Scholar] [CrossRef]

- Luo, F.; Wang, S.; Shi, W.; Xiong, Z.; Huang, J. Corrosion resistance and wear behavior of CoCrFeNiMn@Gr high entropy alloy-based composite coatings prepared by laser cladding. J. Mater. Res. Technol. 2024, 33, 3769–3789. [Google Scholar] [CrossRef]

- Ye, Z.; Li, C.; Zhang, X.; Liao, Y.; Gu, J. The influence of vanadium element on the microstructure and mechanical properties of (FeCoNi)100-xVx high-entropy alloys. Mater. Charact. 2022, 192, 112232. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, X.B.; Zhang, F.Z.; Li, X.-G.; Liang, J.-X.; Liu, X.-Y.; Zheng, J.; Zhu, J.-P. Mechanical properties, nano-tribological behavior and deformation mechanism of FeCrNi MEA with the addition of Co/Cu: Molecular dynamics simulation. J. Manuf. Process. 2024, 131, 1348–1359. [Google Scholar] [CrossRef]

- Duan, B.; Lin, N.; Zhao, H.; Zhou, L.; Wang, X.; Ma, G.; Wang, H.; Shi, Q.; Wu, Y. Microstructure and tribological performance of FeCrNiMox medium-entropy alloy (MEA) coatings by high-speed laser cladding: Effect of molybdenum content. J. Alloys Compd. 2025, 1031, 181001. [Google Scholar] [CrossRef]

- Gao, S.; Kong, T.; Zhang, M.; Chen, X.; Sui, Y.W.; Ren, Y.J.; Qi, J.Q.; Wei, F.X.; He, Y.Z.; Meng, Q.K.; et al. Effects of titanium addition on microstructure and mechanical properties of CrFeNiTix (x = 0.2–0.6) compositionally complex alloys. J. Mater. Res. 2019, 34, 819–828. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Liu, W.; Yu, Y.; Sha, J. Mechanical properties and deformation behavior of additively manufactured TiC nanoparticles reinforced Nb at 1000 °C. J. Mater. Res. Technol. 2025, 36, 4241–4254. [Google Scholar] [CrossRef]

- Singh, I.; Dabhade, V.; Debata, M.; Panigrahi, A. The influence of Mo and Nb on liquid phase sintering and mechanical properties of W-Ni-Fe-co based tungsten heavy alloy. Mater. Charact. 2025, 224, 115034. [Google Scholar] [CrossRef]

- Yan, Q.; Yang, K.; Wang, Z.; Chen, M.; Sun, G.; Ni, Z. Surface roughness optimization and high-temperature wear performance of H13 coating fabricated by extreme high-speed laser cladding. Opt. Laser Technol. 2022, 149, 107823. [Google Scholar] [CrossRef]

- Tan, Q.; Tan, Q.; Liu, K.; Liu, K.; Li, J.; Li, J.; Geng, S.; Geng, S.; Sun, L.; Sun, L.; et al. A review on cracking mechanism and suppression strategy of nickel-based superalloys during laser cladding. J. Alloys Compd. 2024, 1001, 175164. [Google Scholar] [CrossRef]

- Jin, H.; Luo, F.; Chen, Z.; Luo, Y.; Shi, W.; Huang, J. Mechanical properties and corrosion resistance analysis of Fe-based amorphous −2% CNTs coatings with low crack prepared by laser cladding. Diam. Relat. Mater. 2025, 155, 112288. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, L.; Cai, Y.; Yan, Y.; Ge, F.; Shan, M.; Tian, Y.; Han, J.; Jiang, Z. Tribology comparison of laser-cladded CrMnFeCoNi coatings reinforced by three types of ceramic (TiC/NbC/B4C). Surf. Coat. Technol. 2022, 450, 129013. [Google Scholar] [CrossRef]

- Feng, M.; Yang, X.; Lian, G.; Chen, C. Microstructure and Properties of Laser Cladding CoCrNi-based Medium-Entropy Alloy Enhanced by Nb. J. Mater. Res. Technol. 2025, 35, 5015–5033. [Google Scholar] [CrossRef]

- Lian, G.; Zeng, J.; Yue, K.; Chen, C.; Huang, X.; Kong, L. Microstructure and properties of composite carbide (Ti,V) C enhanced Ni-based coatings by laser cladding. J. Mater. Res. Technol. 2023, 24, 1223–1239. [Google Scholar] [CrossRef]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Metall. 1986, 34, 823–830. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, T.; Xiao, M.; Shen, Y. Effect of Nb content on microstructure and properties of laser cladding FeNiCoCrTi0.5Nbx high-entropy alloy coating. Optik 2019, 198, 163316. [Google Scholar] [CrossRef]

- Ma, Q.; Zhao, W.; Li, X.; Gao, W.; Zhang, H.; Ma, X.; Lv, Y.; Xiao, G. Impact of Nb and Zr on the precipitation evolution of Laves phase and the properties of laser cladding coating of AlCoCrFeNi high entropy alloy. Mater. Charact. 2024, 215, 114146. [Google Scholar] [CrossRef]

- Yang, C.M.; Liu, X.B.; Zhu, Z.X.; Zhou, A.; Zhou, H.-B.; Zhang, S.-H. Study of tribological property of laser-cladded FeCoCrNiMnx high-entropy alloy coatings via experiment and molecular dynamics simulation. Tribol. Int. 2024, 191, 109106. [Google Scholar] [CrossRef]

- Sun, S.; Fu, H.; Ping, X.; Lin, J.; Lei, Y.; Wu, W.; Zhou, J. Reinforcing behavior and microstructure evolution of NbC in laser cladded Ni45 coating. Appl. Surf. Sci. 2018, 455, 160–170. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).