Experimental Study on Two Types of Novel Prefabricated Counterfort Retaining Wall: Performance Characteristics and Earth Pressure Reduction Effect of Geogrids

Abstract

1. Introduction

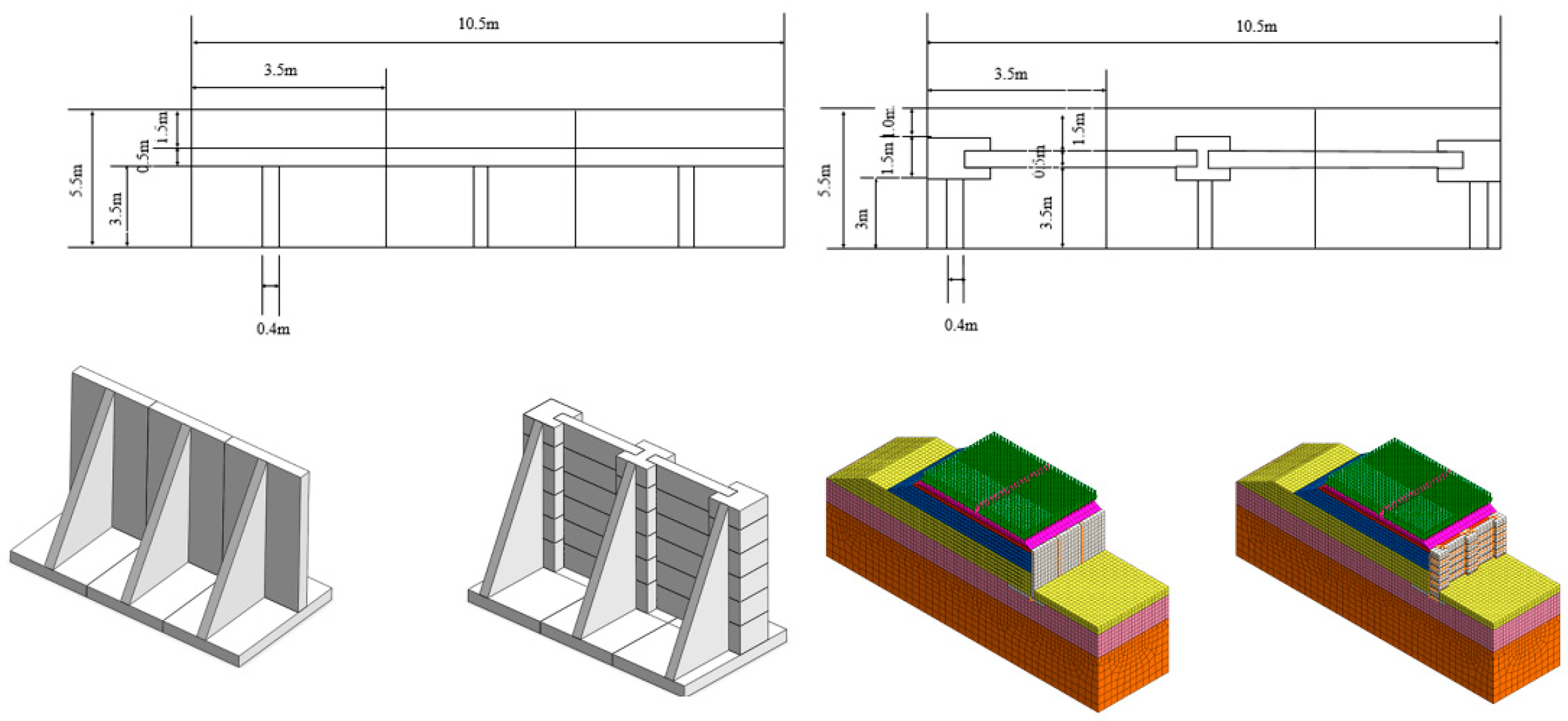

2. Introduction to Prefabricated Buttress Retaining Wall Structures

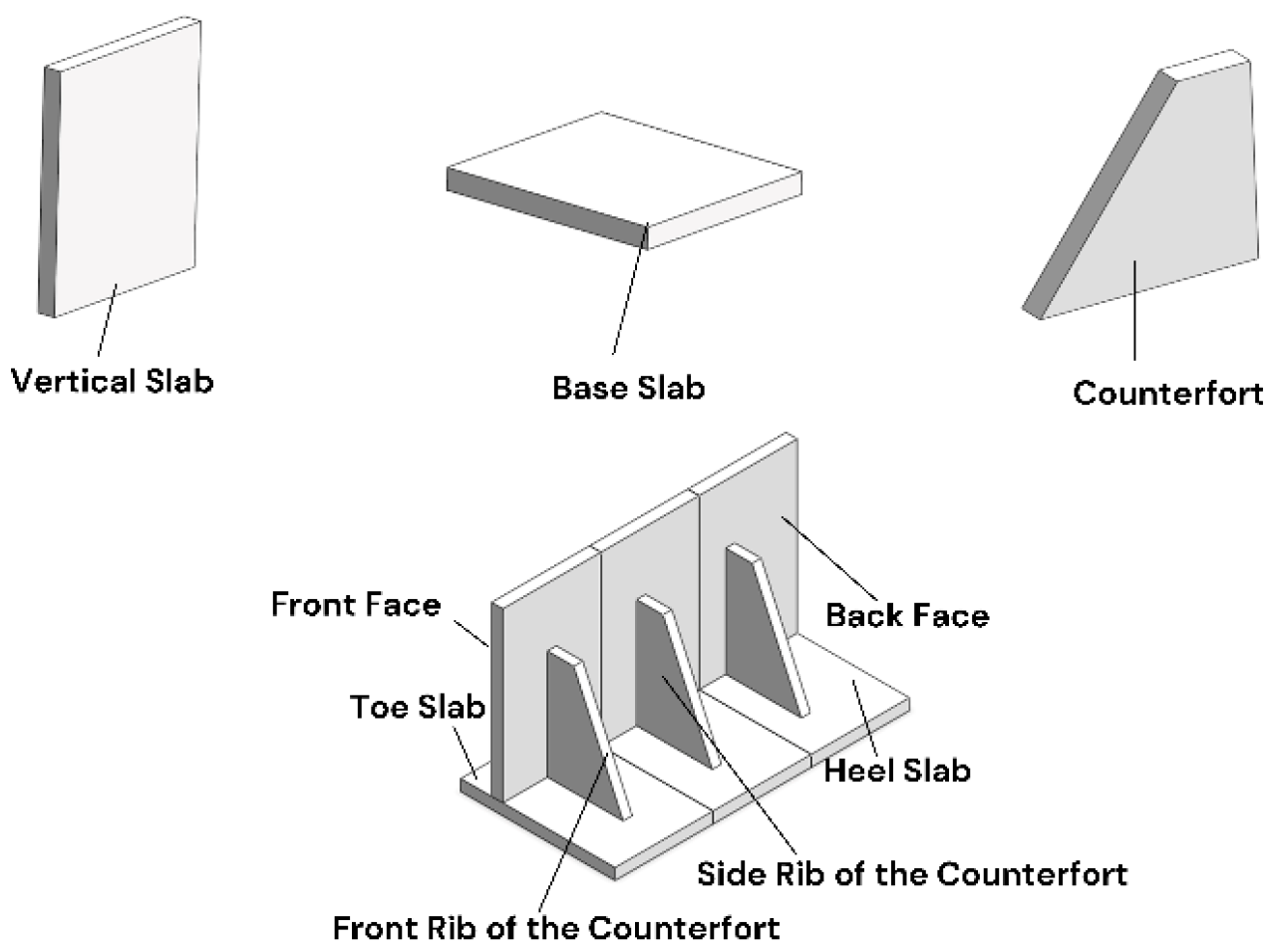

2.1. The Monolithic Prefabricated Counterfort Design

2.2. Modular Prefabricated Counterfort Retaining Wall

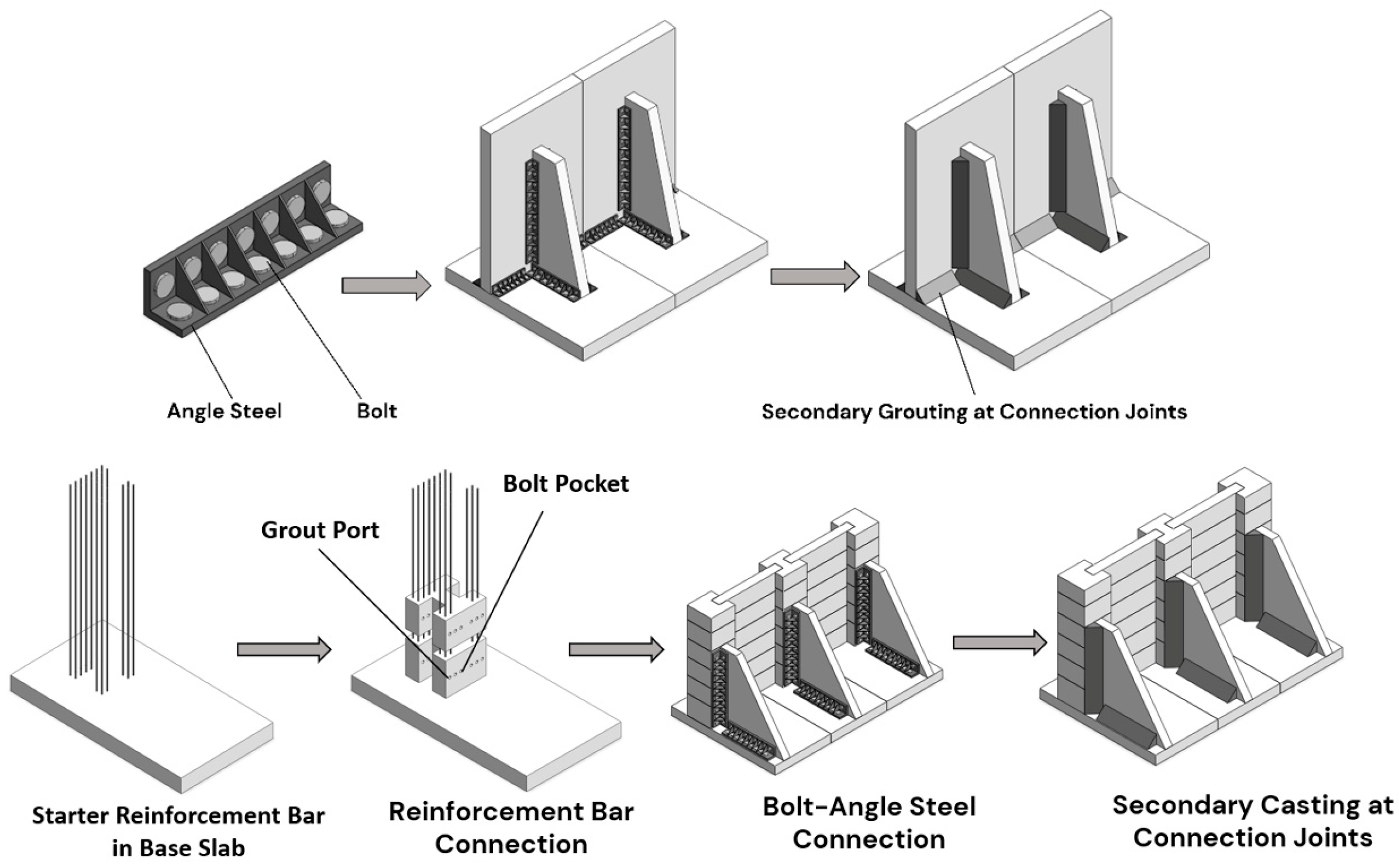

2.3. Connection Methods for Prefabricated Counterfort Retaining Walls

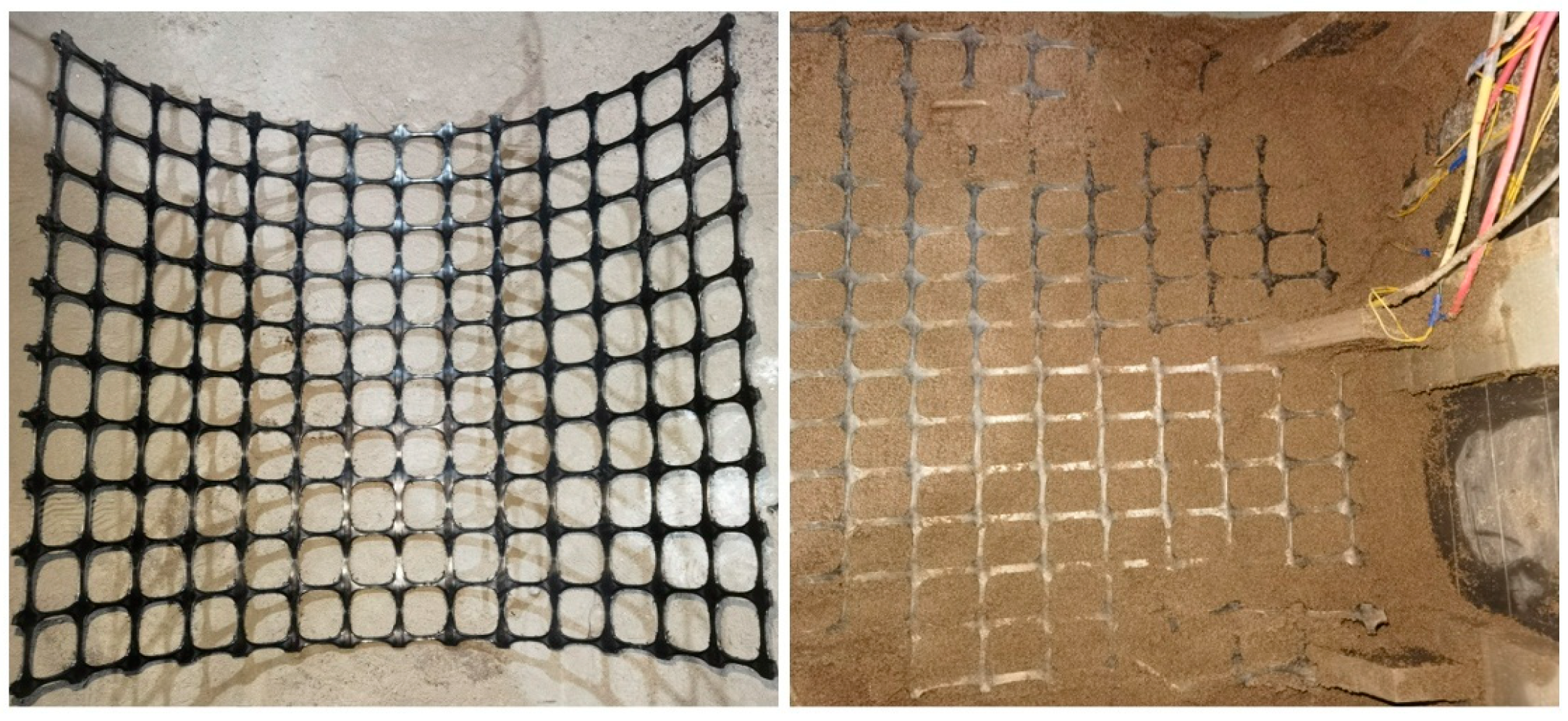

2.4. Geogrid Material

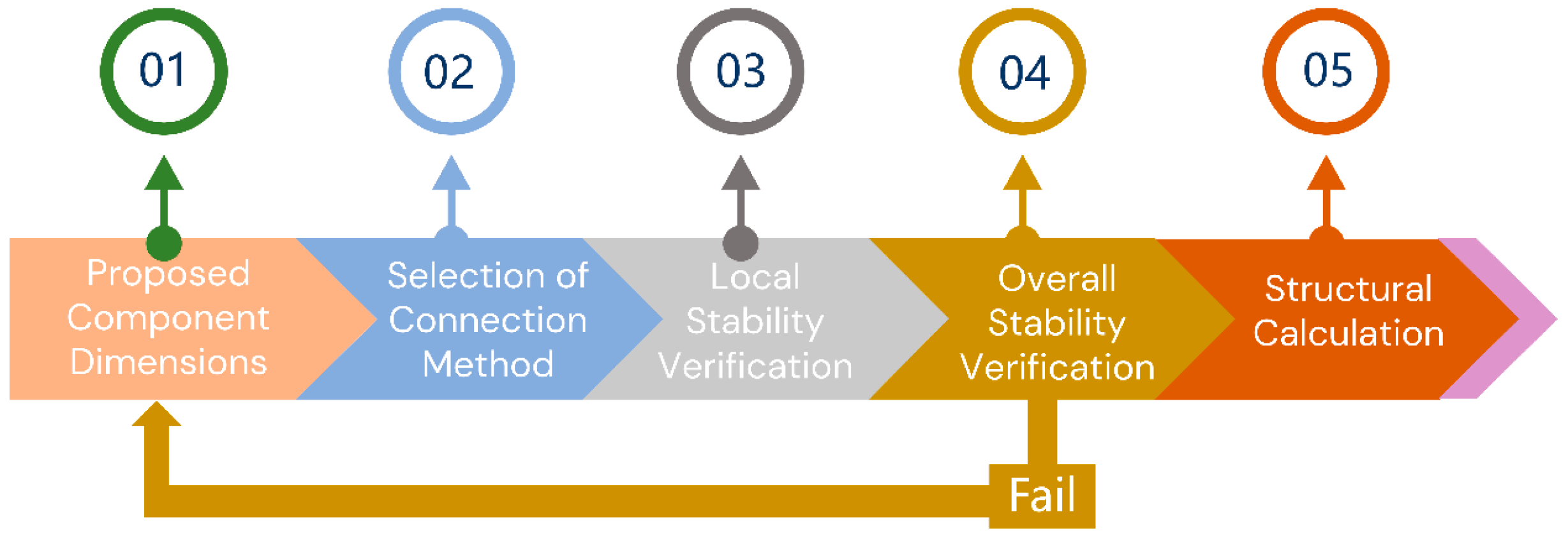

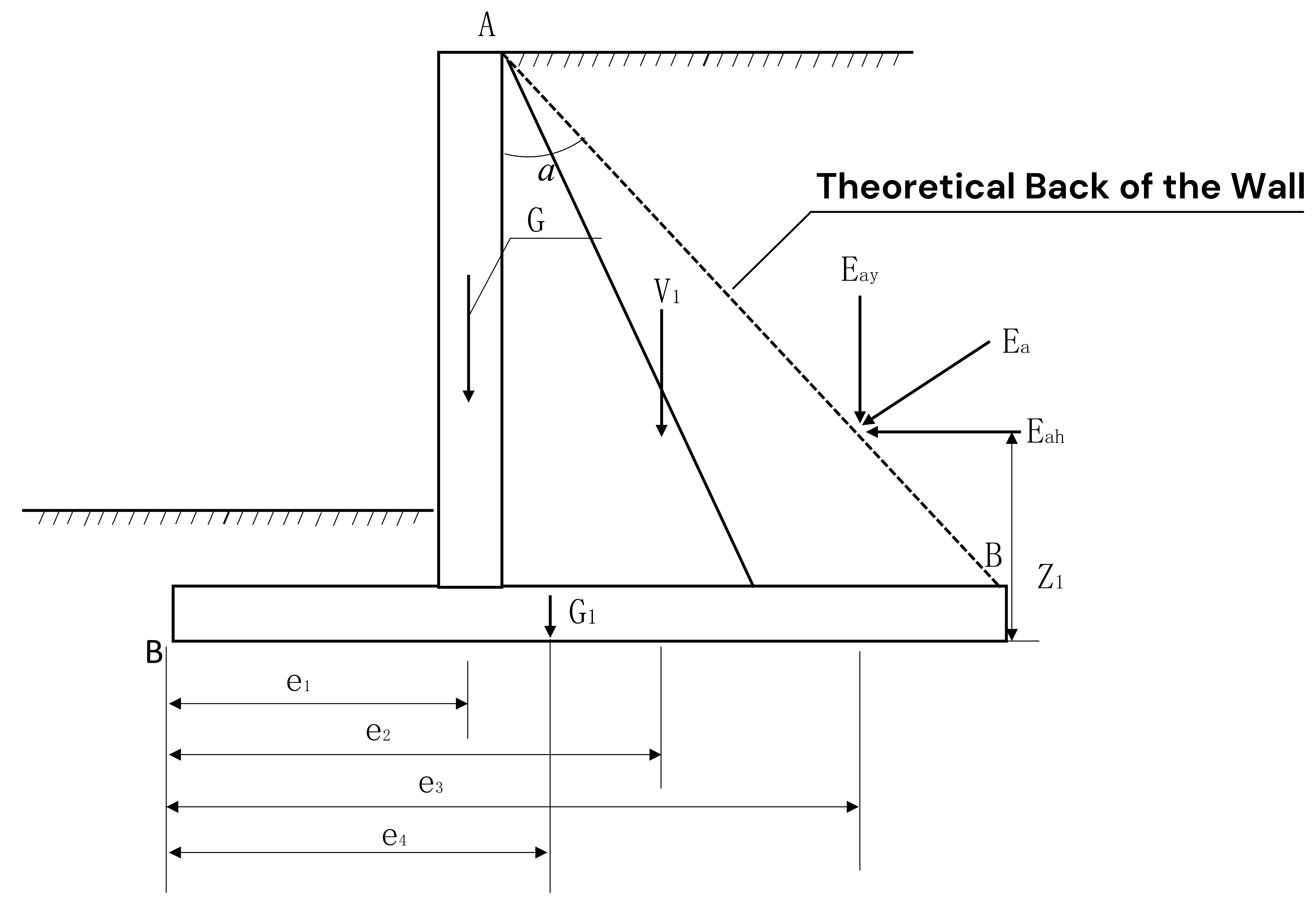

3. Design Methodology

3.1. Analytical Procedure

3.2. Sliding Stability Verification

3.3. Overturning Stability Verification

3.4. Foundation and Structural Analysis

- (1)

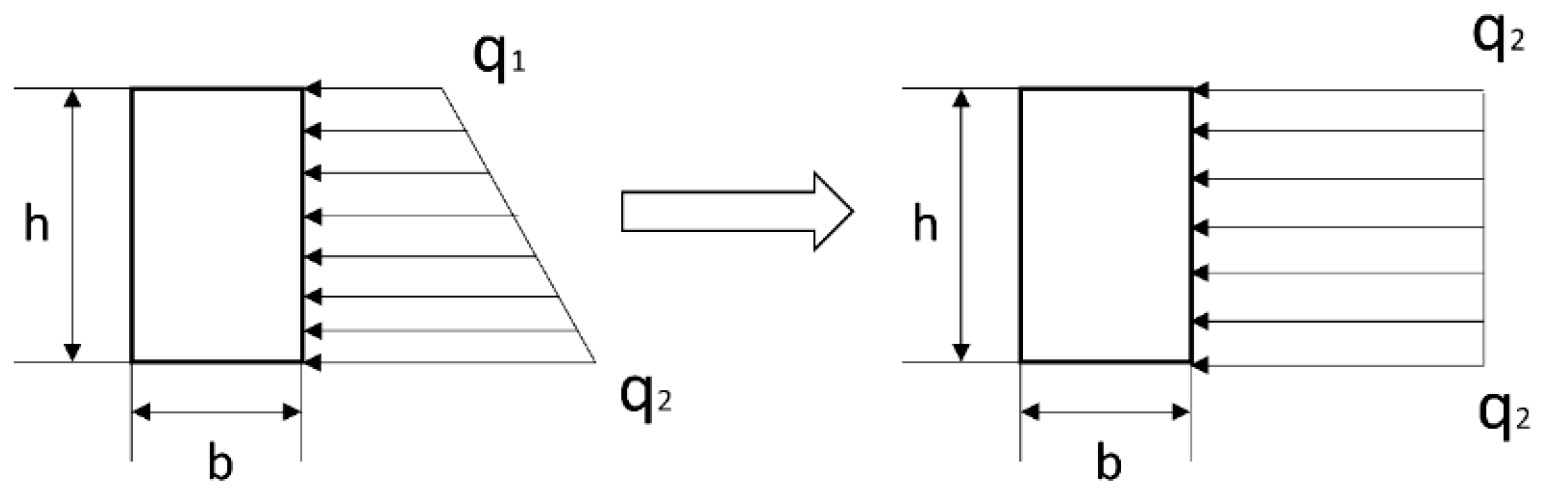

- Internal Force Calculation for the Vertical Slabs

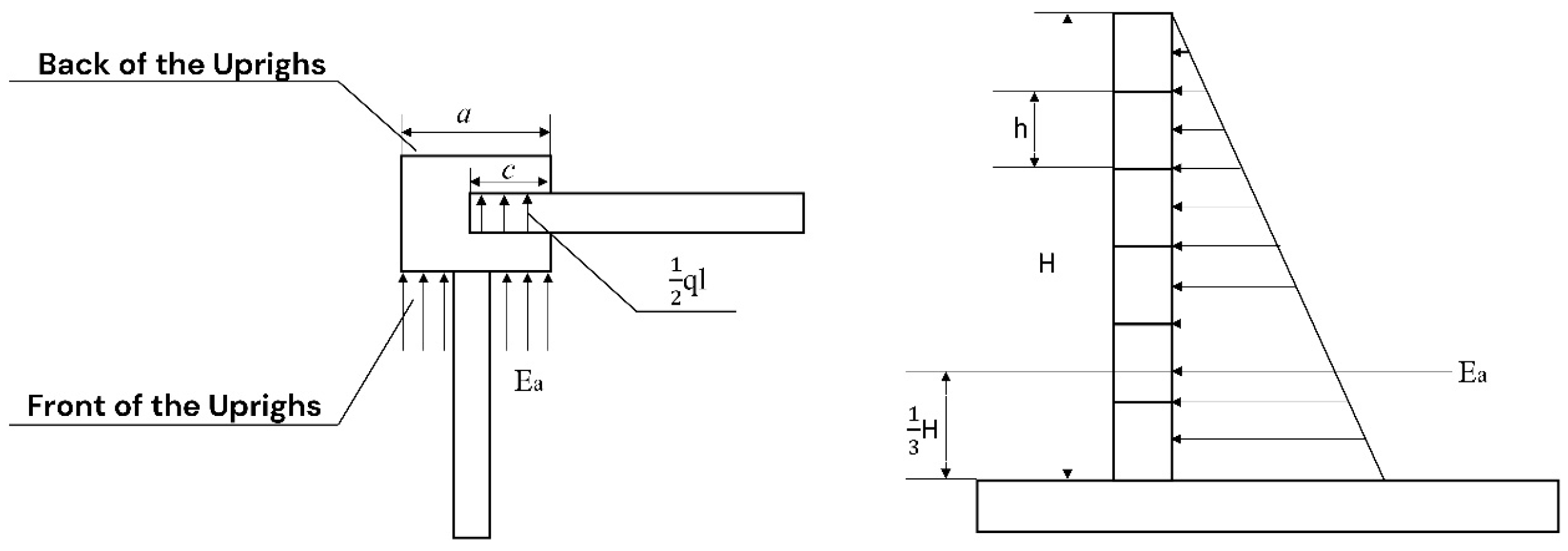

- (2)

- Internal Force Calculation for the Uprights

4. Experimental Methodology

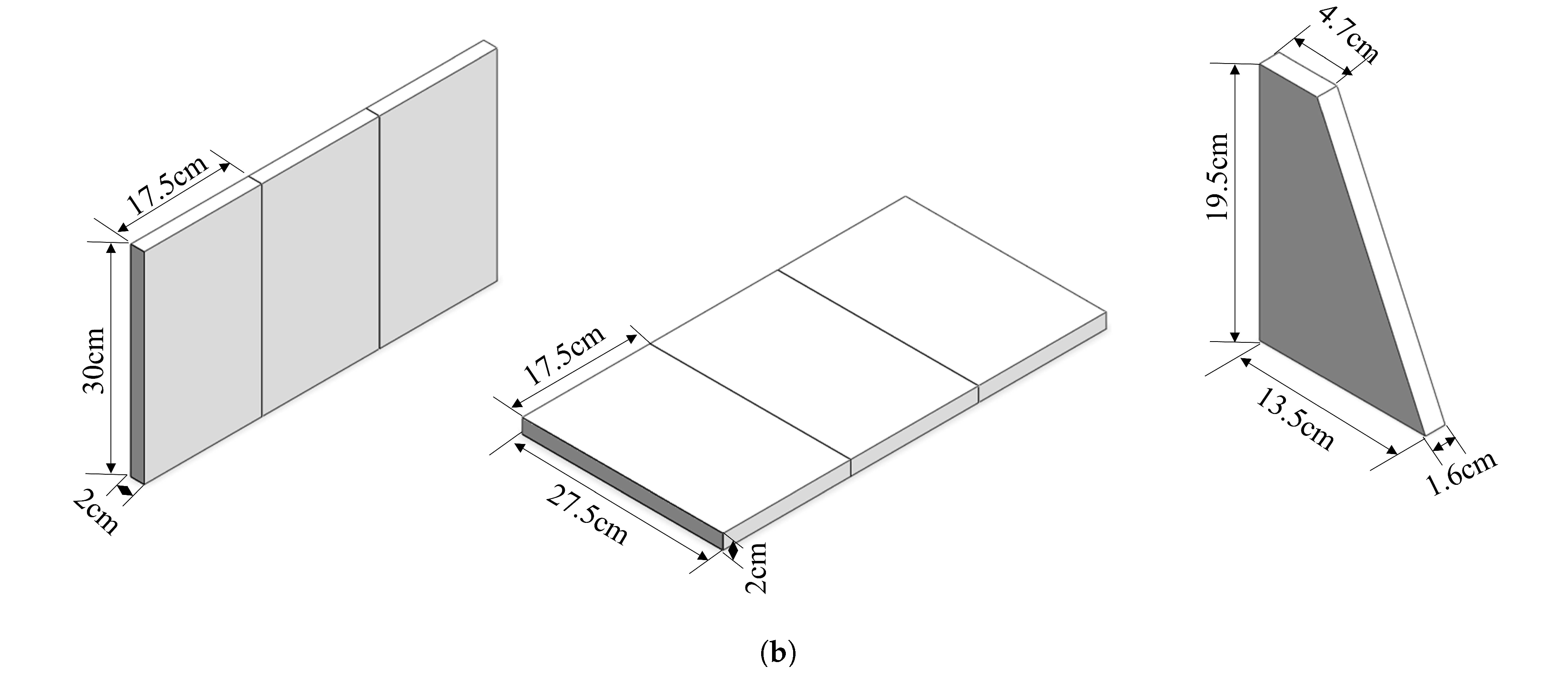

4.1. Scaled-Down Model Design

4.2. Geotechnical Properties of the Backfill Material

4.2.1. Moisture Content Determination

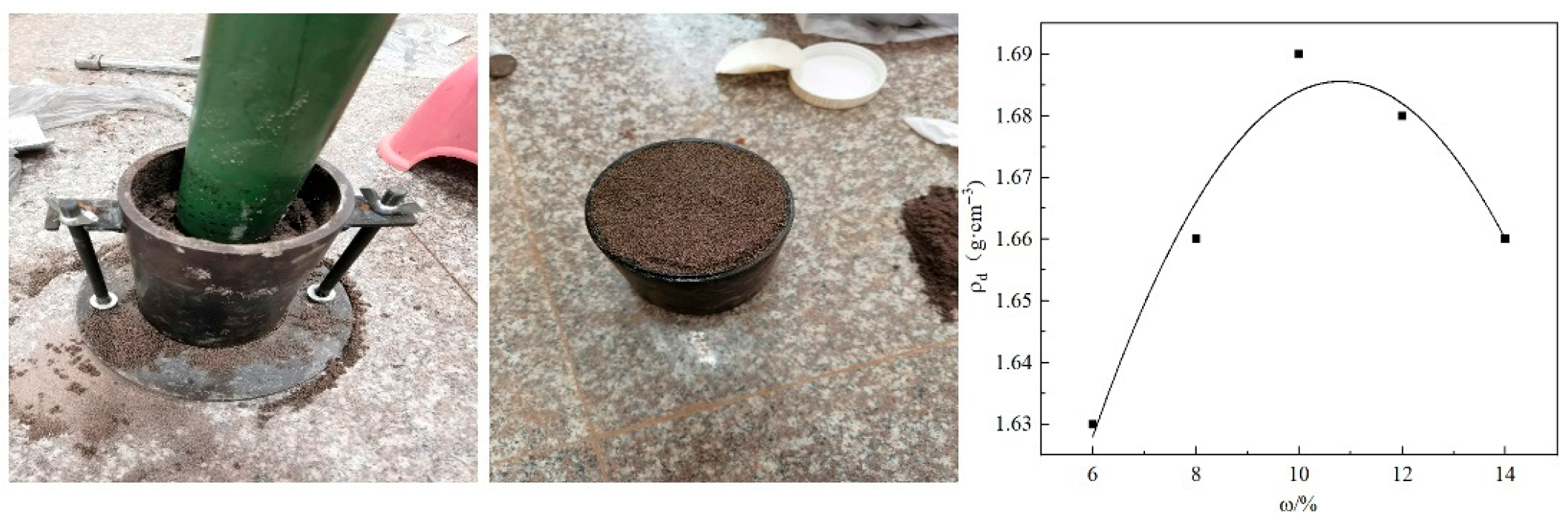

4.2.2. Standard Proctor Compaction Test

4.2.3. Direct Shear Test

4.3. Simulation of Prefabricated Connections

4.4. Measurement and Loading System

4.5. Scope and Validation of the Experimental Program

5. Results and Analysis

5.1. Failure Modes

5.2. Analysis of Internal Forces

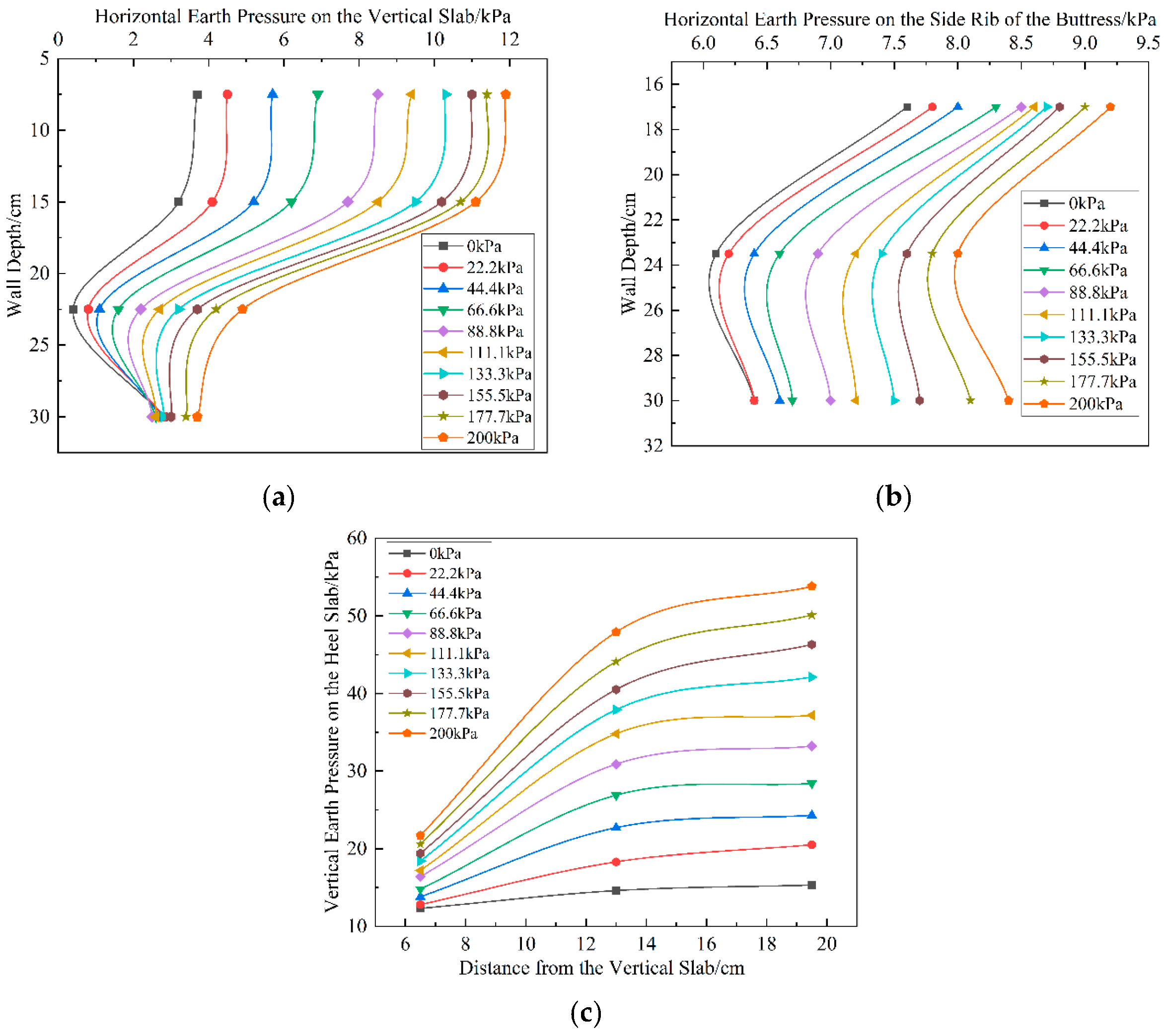

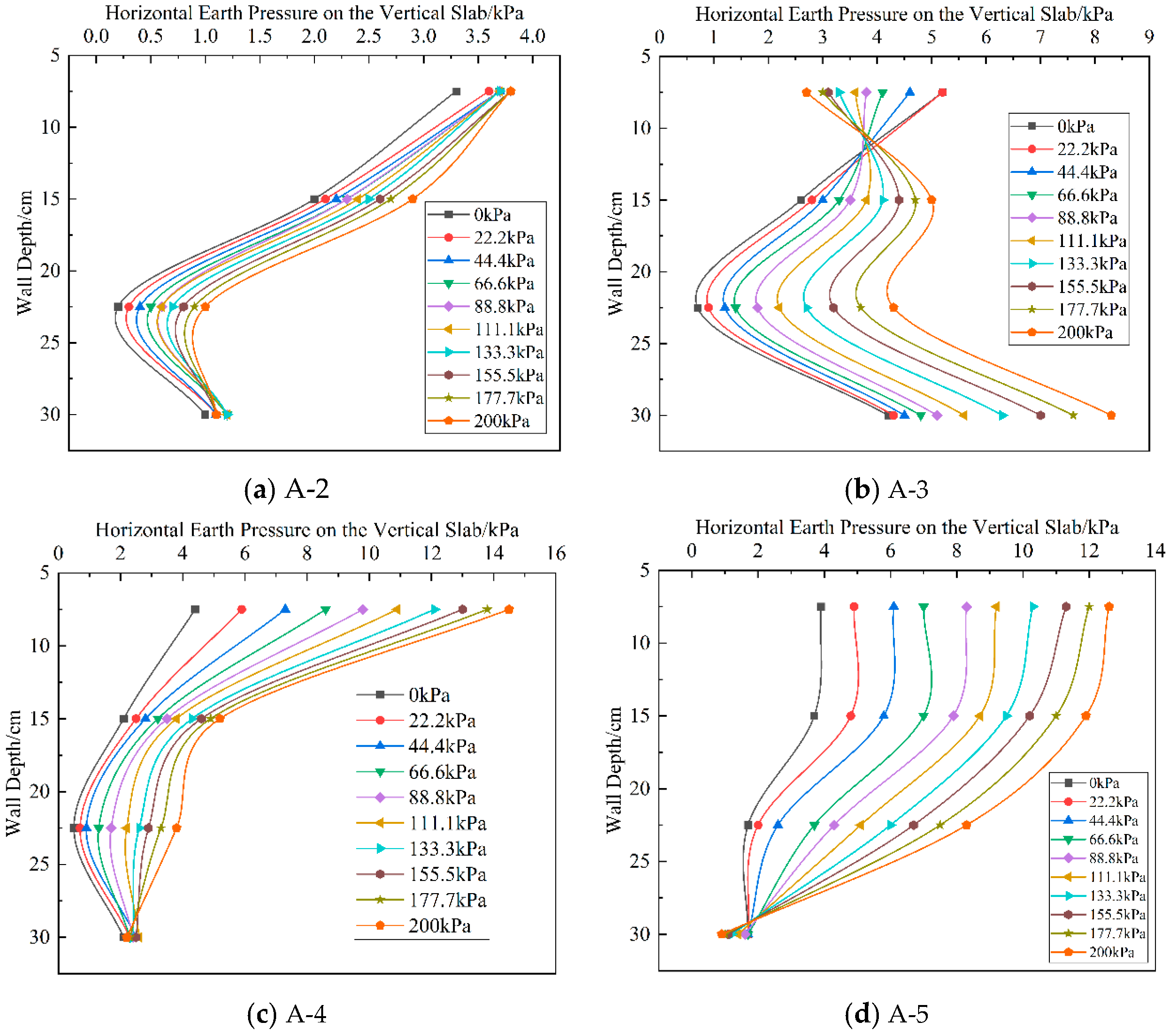

5.2.1. Earth Pressure Analysis

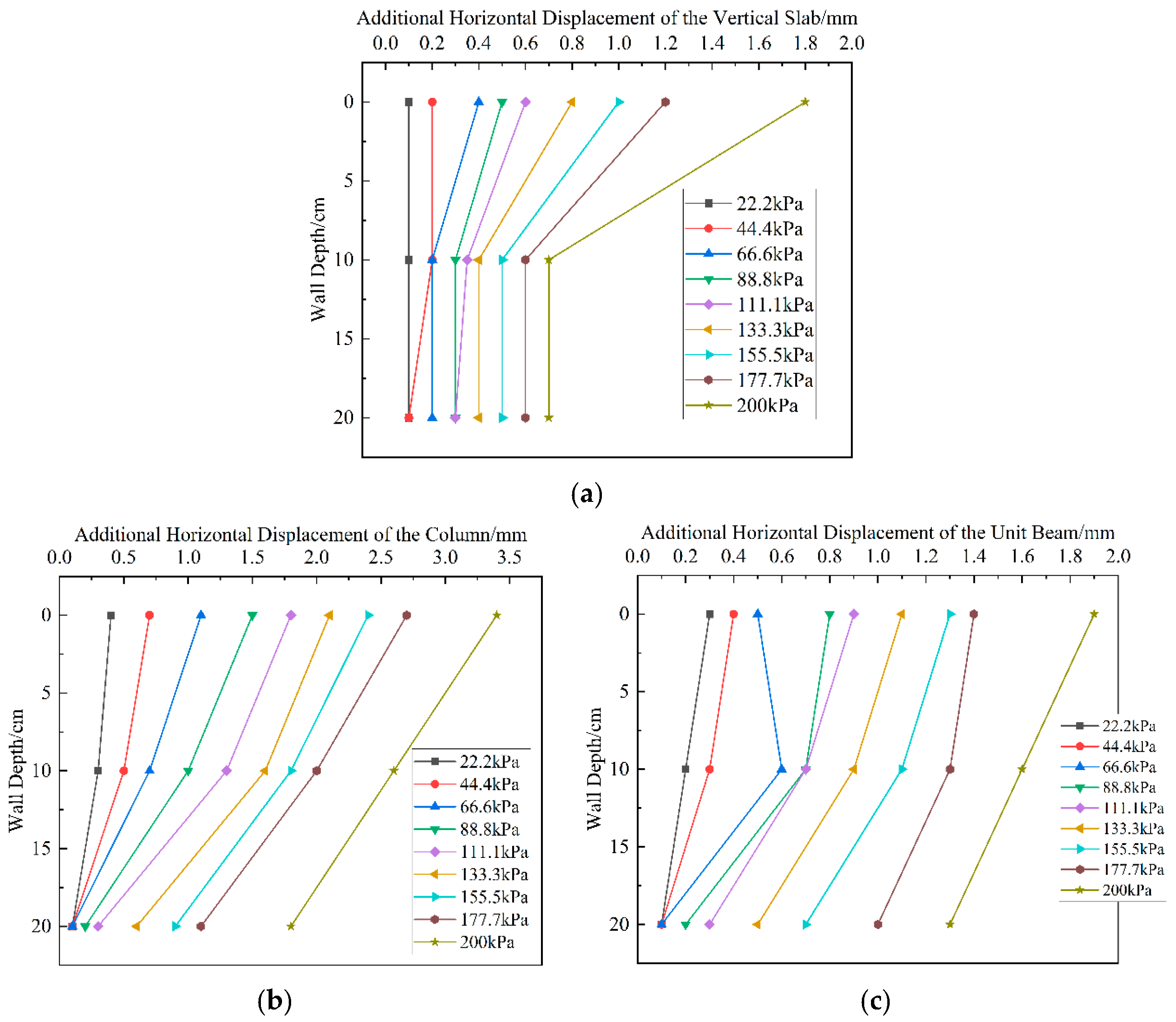

5.2.2. Additional Horizontal Displacement Analysis

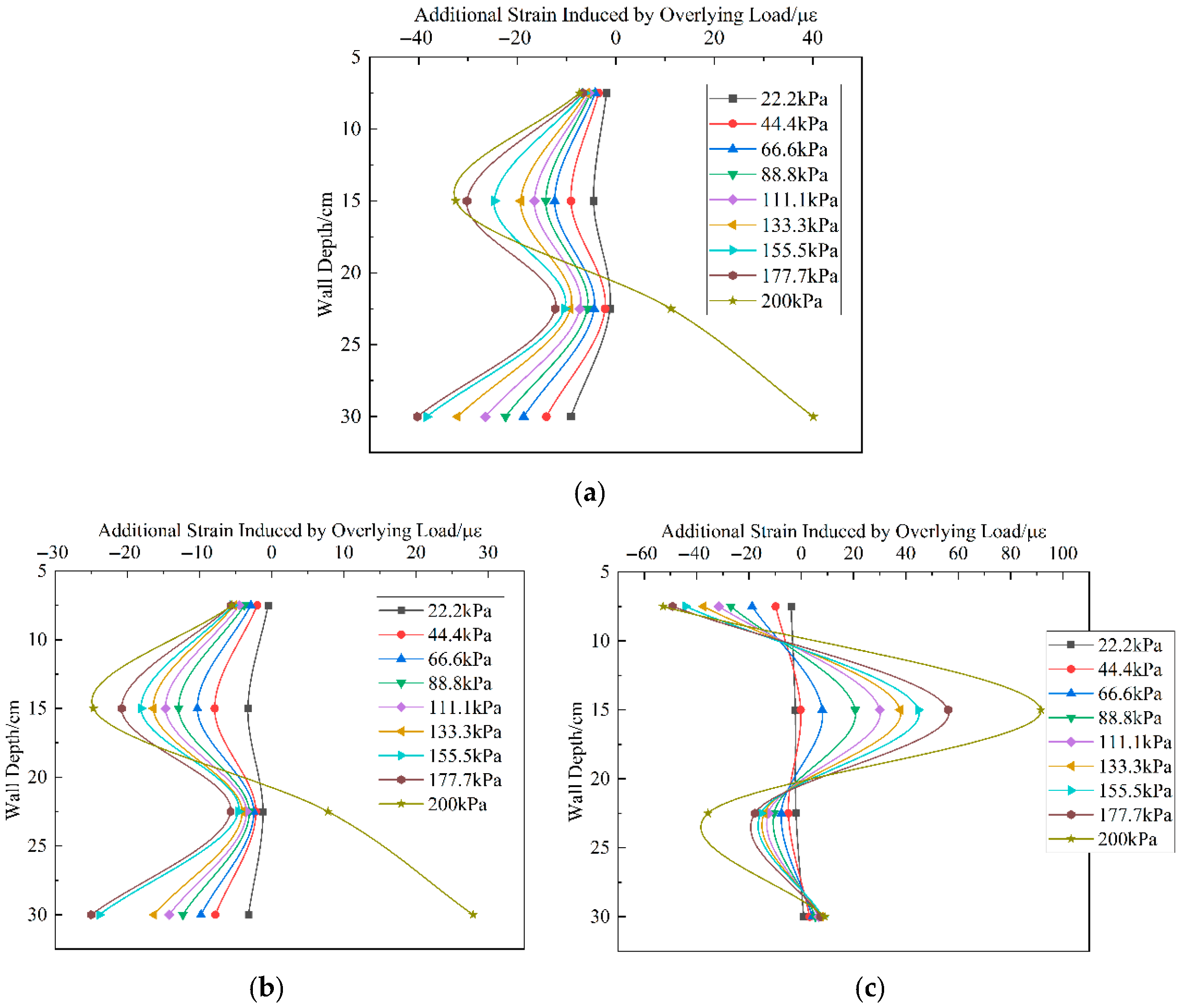

5.2.3. Additional Strain Analysis

5.3. Influence of Geogrid Reinforcement

5.3.1. Geogrid Reinforcement Configurations

- (1)

- Case A-2 (Uniform Distribution): A dense reinforcement layout consisting of nine geogrid layers, uniformly spaced at 3 cm intervals throughout the entire height of the backfill.

- (2)

- Case A-3 (Upper Zone Reinforcement): Three geogrid layers were concentrated in the upper third of the backfill at depths of 3 cm, 6 cm, and 9 cm.

- (3)

- Case A-4 (Middle Zone Reinforcement): Three geogrid layers were concentrated in the middle third of the backfill at depths of 12 cm, 15 cm, and 18 cm.

- (4)

- Case A-5 (Lower Zone Reinforcement): Three geogrid layers were concentrated in the lower third of the backfill at depths of 21 cm, 24 cm, and 27 cm.

5.3.2. Analysis of Structural Performance with Geogrid Reinforcement

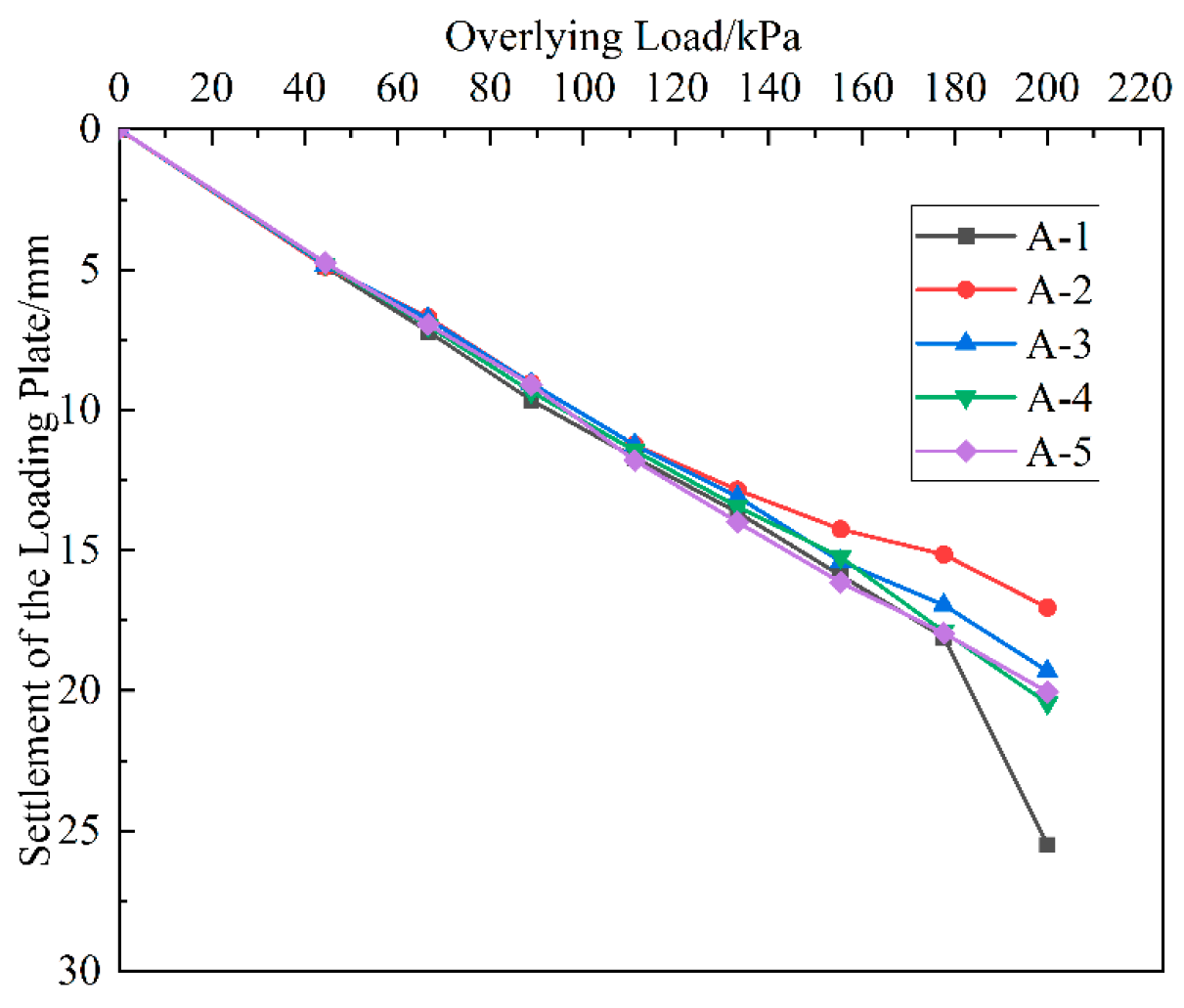

5.3.3. Analysis of Backfill Settlement

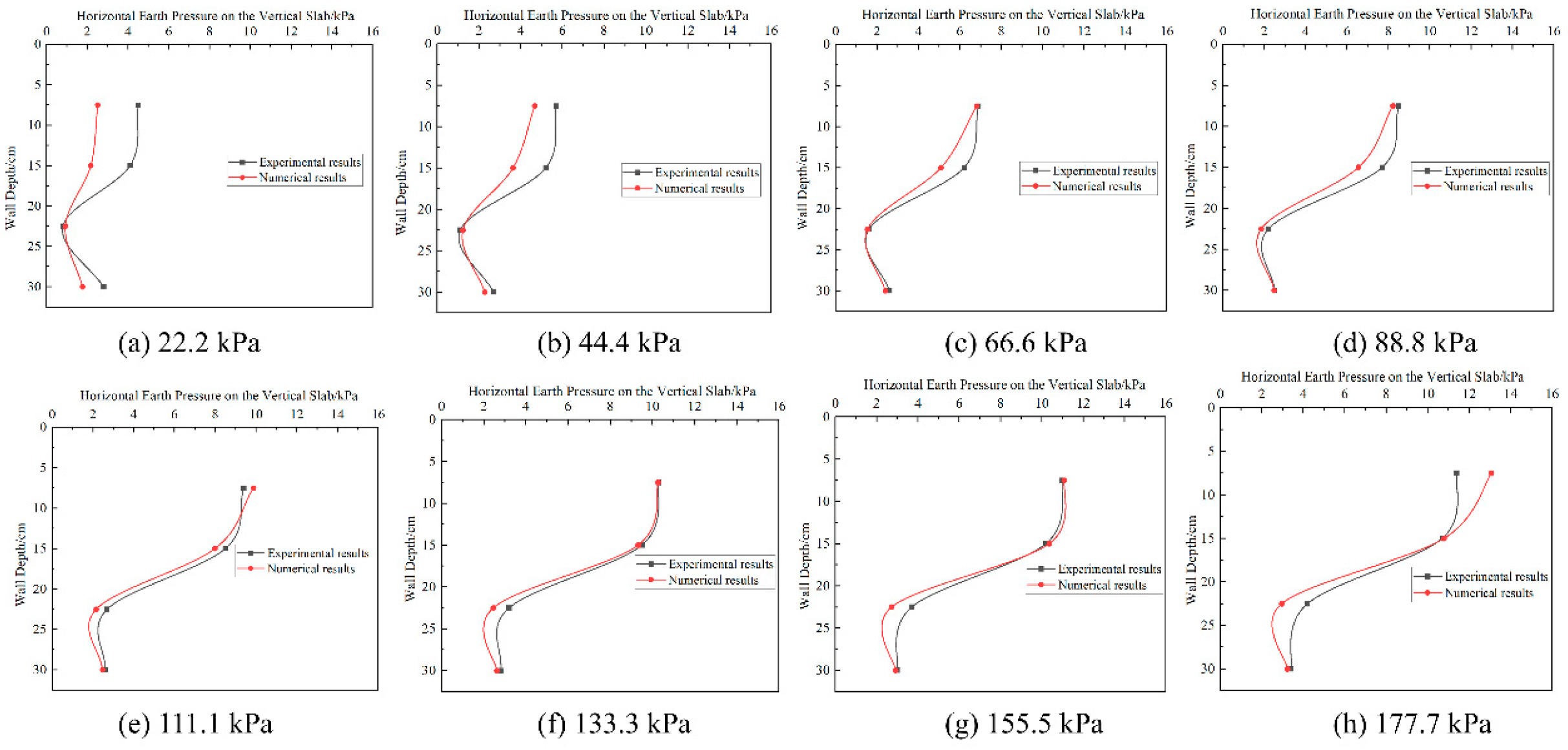

5.4. Finite Element Analysis

5.4.1. Validation of the Experimental Results

5.4.2. Full-Scale Structural Analysis

5.5. Scalability of Core Findings

6. Conclusions

- A two-stage design methodology is required for prefabricated systems. First, the structural integrity of the specific connection details must be verified through local stability calculations. Once qualified, the entire wall can be simplified into a structurally equivalent model for global stability analysis, potentially using established methods for cast-in-place walls if the geometries are analogous, or requiring bespoke analysis if they are not.

- The structural configuration directly governs failure vulnerability. The monolithic design concentrates stress at a few critical connection points, making the slab–counterfort interface highly susceptible to failure. In contrast, the modular design distributes loads across numerous connection interfaces, reducing the stress concentration at any single point and improving overall robustness.

- The most critical structural component is the connection between the counterfort and the upper portion of the wall facing. This area behaves as an unsupported cantilever, making it highly vulnerable to bending forces from horizontal earth pressure. Conversely, while the vertical pressures on the heel slab are immense, the connection stresses at the base are comparatively low, provided the slab is in full contact with the foundation subgrade.

- The onset of backfill failure induces a complex stress state that can cause detrimental tensile forces on the wall facing, a phenomenon particularly pronounced in the slender, protruding uprights of the modular system. The implementation of geogrid reinforcement is essential to create a composite soil–structure system that enhances the backfill’s bearing capacity and prevents this adverse loading condition. Based on the comprehensive analysis of both structural stresses and backfill settlement, the optimal reinforcement strategy is to concentrate geogrid layers in the upper third of the backfill, where they most effectively counteract the primary failure mechanisms of the wall system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, Q. Investigation of stability alarming for retaining wall structures with damage. Shock. Vib. 2017, 2017, 4691947. [Google Scholar] [CrossRef]

- Ma, X.; Liu, Y.; Hao, Z.; Wang, X.; Yang, Y. Study on stress and deformation characteristics of existing-new two-stage cantilever retaining wall. PLoS ONE 2024, 19, e0296330. [Google Scholar] [CrossRef]

- Yang, M.; Wang, Y.; Xiao, S.; Guo, H.; Dong, J. Mechanical characteristics of counterfort-relief shelf composite retaining wall. Environ. Earth Sci. 2024, 83, 23. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Lu, Z.; Fan, Q.; Tian, W.; Li, J. Seismic performance analysis of steel frame installed with prefabricated external walls and new connection type. J. Build. Eng. 2024, 84, 108471. [Google Scholar] [CrossRef]

- Chen, J.; Xu, C.; El Naggar, H.M.; Du, X. Study on seismic performance and index limits quantification for prefabricated subway station structures. Soil Dyn. Earthq. Eng. 2022, 162, 107460. [Google Scholar] [CrossRef]

- Chen, J.; Xu, C.; El Naggar, H.M.; Du, X. Comparative study on seismic performance of prefabricated and cast-in-place underground structures under different site conditions. Soil Dyn. Earthq. Eng. 2023, 171, 107998. [Google Scholar] [CrossRef]

- Yang, X.; Lin, F. Research on prefabricated metro station structure and key assembly technologies. Tunn. Undergr. Space Technol. 2024, 153, 106029. [Google Scholar] [CrossRef]

- Zhao, N.; Xu, Y.; Xiang, S.; Song, Y. Pressure distribution lawon vertical plate of cellular-counterfort retaining structure. Alex. Eng. J. 2022, 61, 3735–3745. [Google Scholar] [CrossRef]

- Qu, L.; Li, X.; Kouroussis, G.; Zhao, X.; Peng, Y.; Yang, C.; Ding, X.; Connolly, D. Vertical Dynamic Impedance for Piles in Radially Weakened Soil. Int. J. Numer. Anal. Methods Geomech. 2025, 49, 2620–2633. [Google Scholar]

- Qiu, Z.; Liu, Y.; Meng, Q.; Li, Y.; Guo, W.; Cao, T. Study on the synergistic evolution of shape and size during particle breakage. Powder Technol. 2025, 465, 121343. [Google Scholar] [CrossRef]

- Qiu, Z.; Meng, Q.; Liu, Y.; Ma, A. Influence of stone content, relative density, and gradation on shear dilatancy characteristics of rock–soil mixtures. Mar. Georesources Geotechnol. 2025, 1–16. [Google Scholar] [CrossRef]

- Fu, T.; Saracho, A.C.; Haigh, S.K. Microbially induced carbonate precipitation (MICP) for soil strengthening: A comprehensive review. Biogeotechnics 2023, 1, 100002. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, Y.; Shi, W.; Bian, H.; Shi, L.; Wu, L.; Han, Z.; Zheng, J.; He, X. Strength and uniformity of EICP-treated sand under multi-factor coupling effects. Biogeotechnics 2023, 1, 100007. [Google Scholar] [CrossRef]

- Jacobs, F.; Ruiken, A.; Ziegler, M. Investigation of kinematic behavior and earth pressure development of geogrid reinforced soil walls. Transp. Geotech. 2016, 8, 57–68. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Zhang, D.; Liu, Z. The long-term mechanical performance of geogrid-reinforced soil retaining walls under cyclic footing loading. Case Stud. Constr. Mater. 2022, 17, e01642. [Google Scholar] [CrossRef]

- Johari, A.; Maroufi, M. System reliability analysis of geogrid reinforced retaining wall using random finite element method. Transp. Geotech. 2024, 48, 101316. [Google Scholar] [CrossRef]

- Yang, G.; Zhao, Y.; Wang, Z.; Wang, H. Performance of back-to-back geogrid reinforced soil retaining walls for railways during service. Transp. Res. Rec. 2021, 2675, 1115–1125. [Google Scholar] [CrossRef]

- Viswanadham, B.V.S.; Razeghi, H.R.; Mamaghanian, J.; Manikumar, C.H.S.G. Centrifuge model study on geogrid reinforced soil walls with marginal backfills with and without chimney sand drain. Geotext. Geomembr. 2017, 45, 430–446. [Google Scholar] [CrossRef]

- Cai, X.; Li, S.; Xu, H.; Jing, L.; Huang, X.; Zhu, C. Shaking table study on the seismic performance of geogrid reinforced soil retaining walls. Adv. Civ. Eng. 2021, 2021, 6668713. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Zhu, C.; Diao, H.; Wang, K.; Huang, T.; Tu, J.; Que, Y. Full-Scale Experimental Study on Prefabricated Greening Ecological Retaining Walls. Sustainability 2022, 14, 11841. [Google Scholar] [CrossRef]

- Tiwary, A.K.; Bhatia, S.; Singh, S.; Chohan, J.S.; Kumar, R.; Sharma, S.; Chattopadhyaya, S.; Rajkumar, S. Performance comparison and critical finite element based experimental analysis of various forms of reinforcement retaining structural system. Math. Probl. Eng. 2022, 2022, 4434679. [Google Scholar] [CrossRef]

- Farhat, M.; Issa, M. Design principles of totally prefabricated counterfort retaining wall system compared with existing cast-in-place concrete structures. PCI J. 2017, 62, 89–106. [Google Scholar] [CrossRef]

- Lu, X.; Wu, H. Study on seismic performance of prestressed precast concrete walls through cyclic lateral loading test. Mag. Concr. Res. 2017, 69, 878–891. [Google Scholar] [CrossRef]

- Ferdous, W.; Almutairi, A.D.; Huang, Y.; Bai, Y. Short-term flexural behaviour of concrete filled pultruded GFRP cellular and tubular sections with pin-eye connections for modular retaining wall construction. Compos. Struct. 2018, 206, 1–10. [Google Scholar] [CrossRef]

- Javadi, M.; Hassanli, R.; Rahman, M.M.; Karim, M.R. Experimental study on cyclic behavior of post-tensioned segmental retaining walls (PSRWs). Eng. Struct. 2021, 229, 111619. [Google Scholar] [CrossRef]

- Ling, H.; Wang, X.; Lv, C.; Sun, Z.; Liu, L.; Wang, J. Predicting the fracture load of asphalt concrete under TPB test using POA-optimized machine learning methods. Constr. Build. Mater. 2025, 470, 140580. [Google Scholar] [CrossRef]

| Category | Physical Quantity | Dimension | Similarity Relation |

|---|---|---|---|

| Material Properties | Stress () | ||

| Strain () | —— | ||

| Elastic Modulus (E) | |||

| Poisson’s Ratio () | —— | ||

| Mass Density () | |||

| Geometric Properties | Length (l) | L | |

| Linear Displacement (x) | L | ||

| Area (A) | |||

| Moment of Inertia (I) | |||

| Loading | Concentrated Load (F) | F | |

| Line Load (q) | |||

| Area Load (p) | |||

| Moment (M) | FL |

| Parameter | Geometric Scale | Elastic Modulus | Unit Weight | Stress | Linear Displacement | Area Load |

|---|---|---|---|---|---|---|

| Similarity Constant | ||||||

| Similarity Ratio | 20 | 10 | 1 | 10 | 20 | 10 |

| Specimen Number | Condition | Mass of Container + Sand (g) | Mass of Container (g) | Mass of Sands (g) | Moisture Content (%) | Average Moisture Content (%) |

|---|---|---|---|---|---|---|

| 1 | Before oven-drying | 66.31 | 9.41 | 56.90 | 0.71 | 0.68 |

| After oven-drying | 65.91 | 9.41 | 56.50 | |||

| 2 | Before oven-drying | 84.70 | 11.30 | 73.40 | 0.69 | |

| After oven-drying | 84.20 | 11.30 | 72.90 | |||

| 3 | Before oven-drying | 69.14 | 8.92 | 60.22 | 0.65 | |

| After oven-drying | 68.75 | 8.92 | 59.83 |

| Case Number | Case Name |

|---|---|

| A-1 | No geogrid installed |

| A-2 | 9 layers of geogrid evenly distributed |

| A-3 | 3 layers of geogrid installed in the upper part of the fill material |

| A-4 | 3 layers of geogrid installed in the middle part of the fill material |

| A-5 | 3 layers of geogrid installed in the lower part of the fill material |

| Component | , kN/m3 | Cohesion, c, kPa | Angle of Internal Friction, , ° | ||

|---|---|---|---|---|---|

| Retaining Wall | 16 | —— | —— | —— | —— |

| Backfill | 18.6 | 20.56 | 22.27 | —— | —— |

| Interface Elements | —— | —— | —— | 1.27 × 108 | 1.15 × 107 |

| Component | Unit Weight, , kN/m3 | Cohesion, c, kPa | Angle of Internal Friction, , ° | ||

|---|---|---|---|---|---|

| Retaining Wall | 24 | —— | —— | —— | —— |

| Reinforcement Layer | 23 | —— | —— | —— | —— |

| Pavement | 25 | —— | —— | —— | —— |

| Weathered Rock Layer | 23 | 100 | 37 | —— | —— |

| Foundation Soil | 20 | 20 | 30 | —— | —— |

| Subgrade | 20 | 0 | 40 | —— | —— |

| Roadbed | 21 | 0 | 35 | —— | —— |

| Interface Element | —— | —— | —— | 1.41 × 109 | 1.28 × 108 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, A.; Feng, Y.; Liu, D.; Wang, J.; Wang, S.; Ling, H.; Huang, S. Experimental Study on Two Types of Novel Prefabricated Counterfort Retaining Wall: Performance Characteristics and Earth Pressure Reduction Effect of Geogrids. Coatings 2025, 15, 841. https://doi.org/10.3390/coatings15070841

Luo A, Feng Y, Liu D, Wang J, Wang S, Ling H, Huang S. Experimental Study on Two Types of Novel Prefabricated Counterfort Retaining Wall: Performance Characteristics and Earth Pressure Reduction Effect of Geogrids. Coatings. 2025; 15(7):841. https://doi.org/10.3390/coatings15070841

Chicago/Turabian StyleLuo, Ao, Yutao Feng, Detan Liu, Junjie Wang, Shi Wang, Huikun Ling, and Shiyuan Huang. 2025. "Experimental Study on Two Types of Novel Prefabricated Counterfort Retaining Wall: Performance Characteristics and Earth Pressure Reduction Effect of Geogrids" Coatings 15, no. 7: 841. https://doi.org/10.3390/coatings15070841

APA StyleLuo, A., Feng, Y., Liu, D., Wang, J., Wang, S., Ling, H., & Huang, S. (2025). Experimental Study on Two Types of Novel Prefabricated Counterfort Retaining Wall: Performance Characteristics and Earth Pressure Reduction Effect of Geogrids. Coatings, 15(7), 841. https://doi.org/10.3390/coatings15070841