Effect of Nb on Laves Phase Formation and Wear Resistance in Laser-Cladding CrFeNi Medium-Entropy Alloy Coatings

Abstract

1. Introduction

2. Experimental Procedures

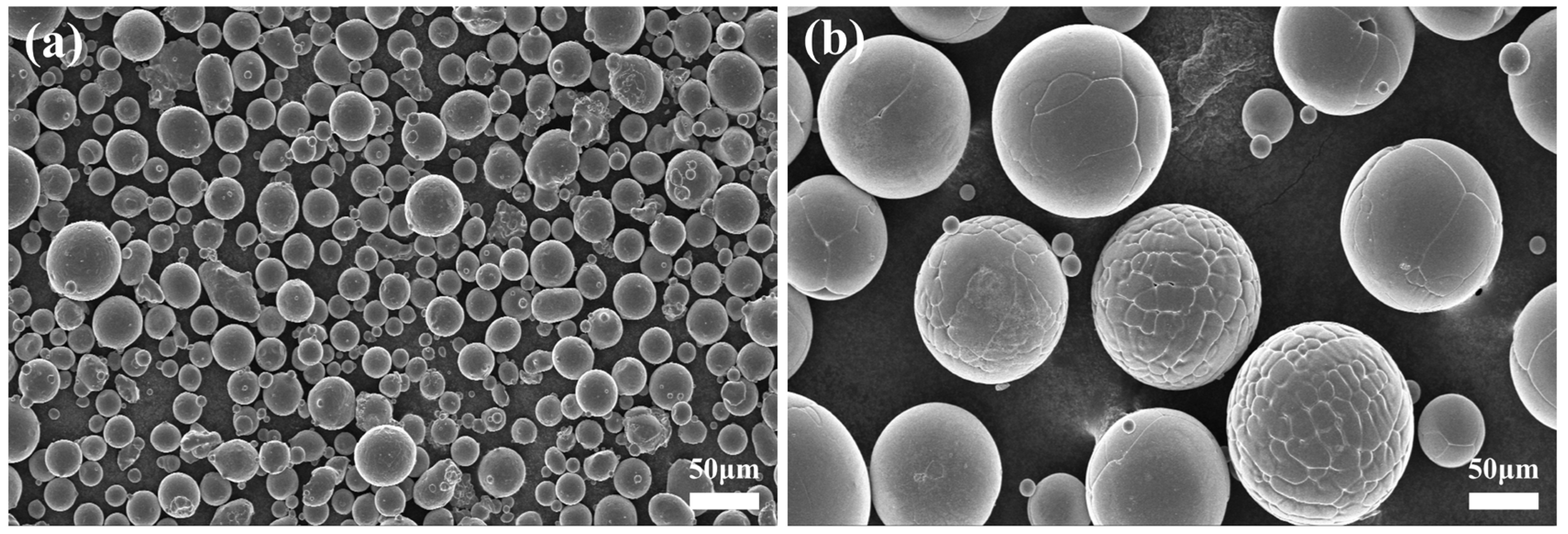

2.1. Experimental Material Preparation

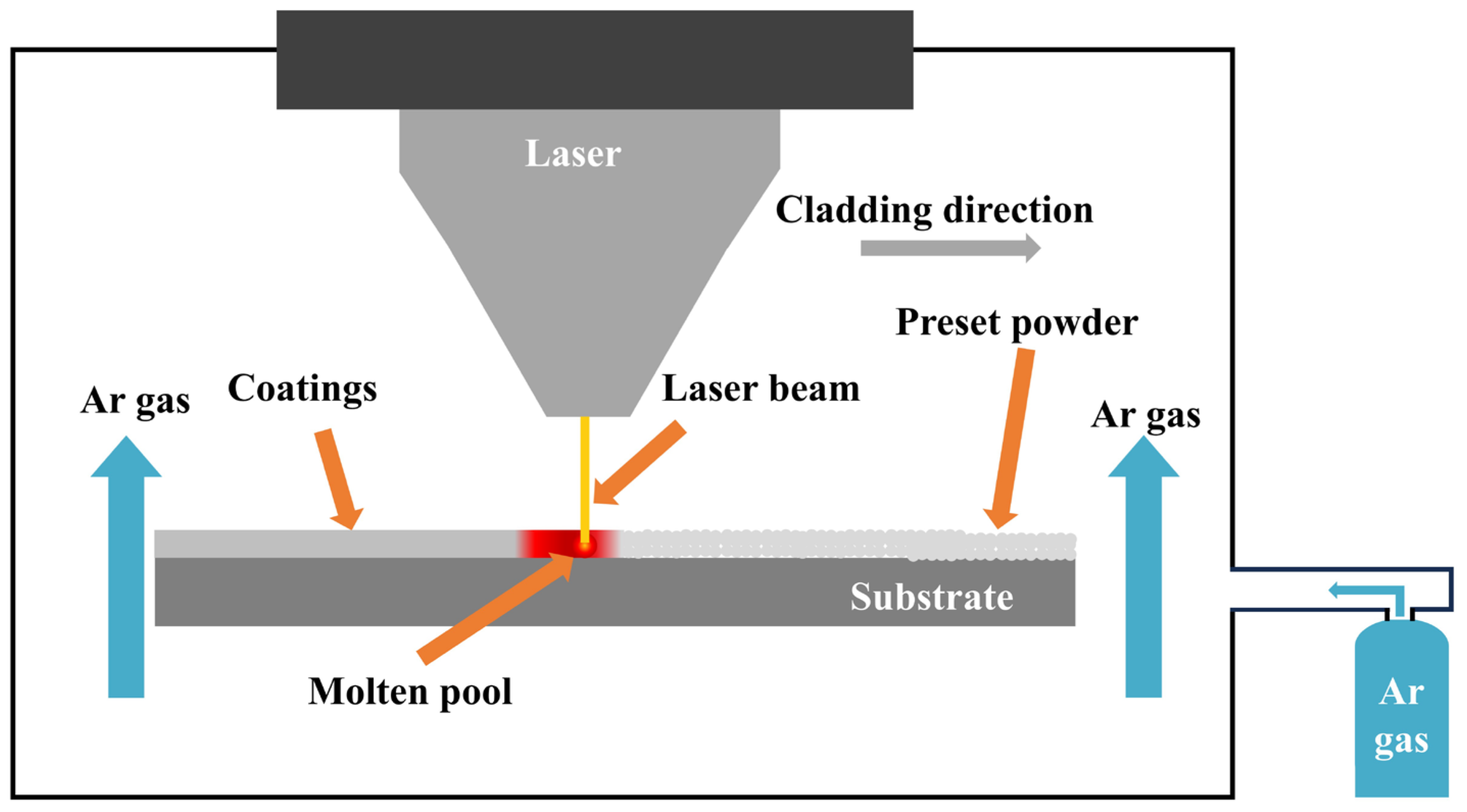

2.2. Mixing and Coating Preparation of CrFeNi-Nb Powder

3. Characterization

3.1. Microstructure and Elemental Distribution

3.2. Mechanical Properties

4. Result and Discussion

4.1. Phase Composition

4.2. Microscopic Morphology

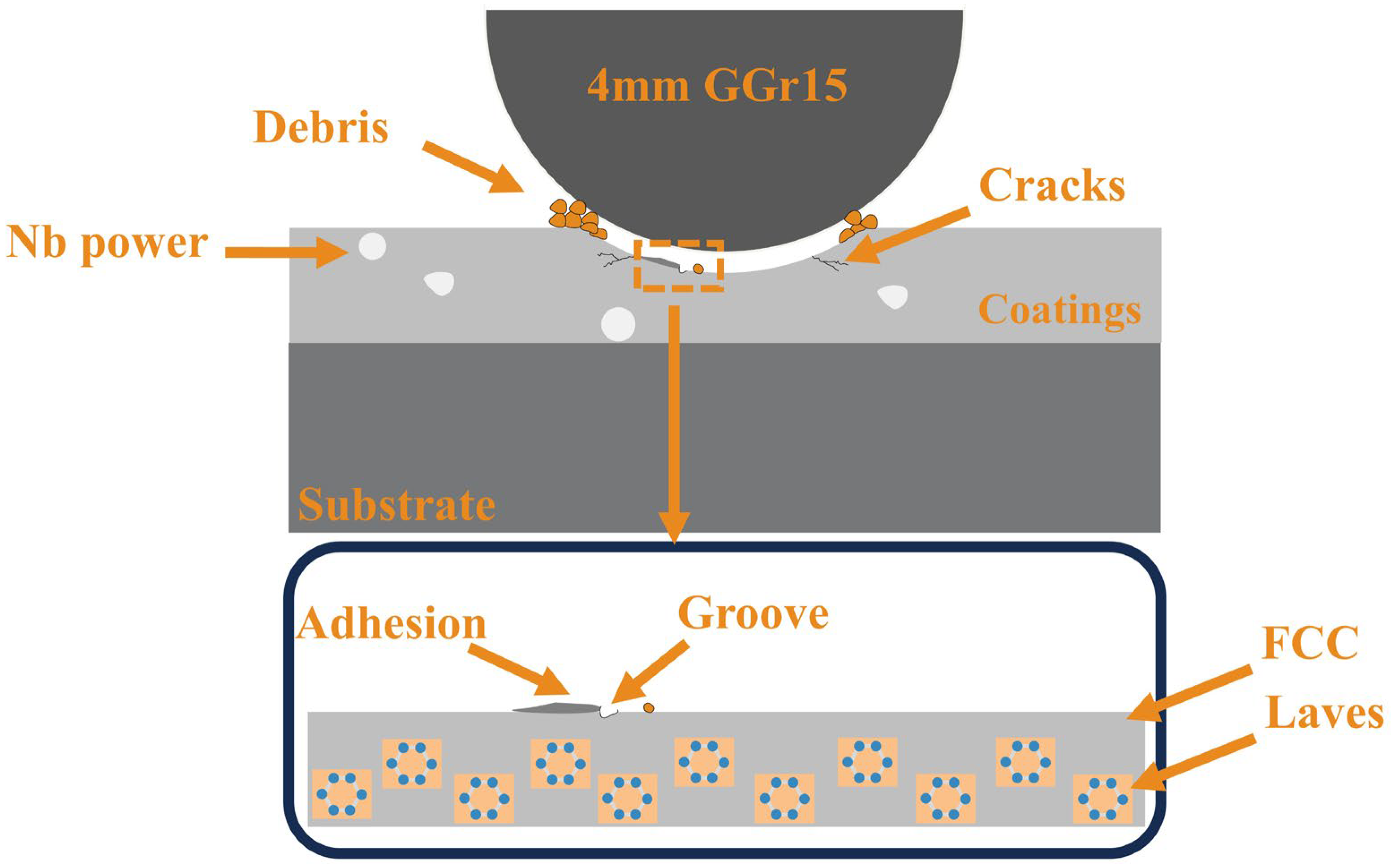

4.3. Microhardness and Nanoindentation

5. Conclusions

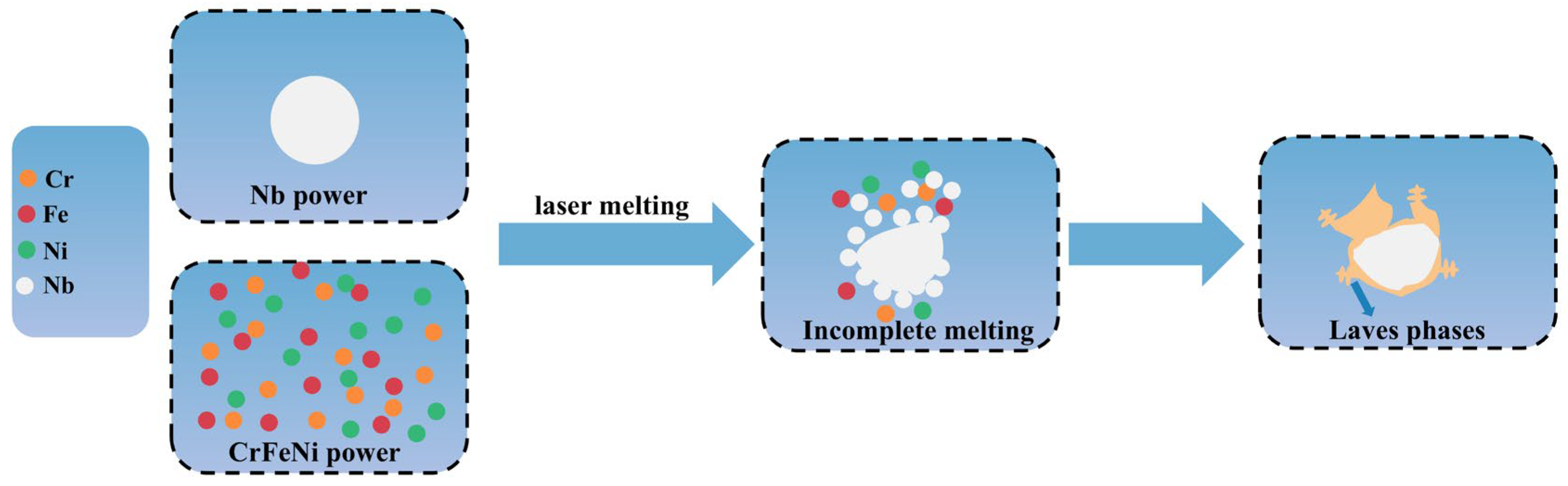

- (1)

- The addition of Nb can promote the generation of high-hardness Laves phase in CrFeNi meso-entropic alloy coatings.

- (2)

- The microhardness of the CrFeNi-Nb coating was increased by 259.62% over the substrate and 190.58% over the CrFeNi coating.

- (3)

- The addition of 20% Nb significantly reduced the wear rate by 60.83% and wear loss by 60.07%.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Senkov, O.N.; Senkova, S.V.; Dimiduk, D.M.; Woodward, C.; Miracle, D.B. Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy. J. Mater. Sci. 2012, 47, 6522–6534. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Li, W.; Xie, D.; Li, D.; Zhang, Y.; Gao, Y.; Liaw, P.K. Mechanical behavior of high-entropy alloys. Prog. Mater. Sci. 2021, 118, 100777. [Google Scholar] [CrossRef]

- Wen, D.; Jiang, B.; Huang, Z.; Kong, F.; Jiang, X.; Wang, A.; Liu, G.; Wang, B. Supersaturation and dissolvable α-Cr phase enable superior oxidation resistance in FeCrNi medium-entropy alloys. J. Alloys Compd. 2023, 954, 170216. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, B.; Guo, W.; Fu, A.; Duan, H.; Li, W. Corrosion behavior and mechanism of FeCrNi medium entropy alloy prepared by powder metallurgy. J. Alloys Compd. 2021, 867, 159094. [Google Scholar] [CrossRef]

- Liang, D.; Zhao, C.; Zhu, W.; Wei, P.; Jiang, F.; Zhang, Y.; Sun, Q.; Ren, F. Overcoming the strength-ductility trade-off via the formation of nanoscale Cr-rich precipitates in an ultrafine-grained FCC CrFeNi medium entropy alloy matrix. Mater. Sci. Eng. A 2019, 762, 138107. [Google Scholar] [CrossRef]

- Hu, Z.; Lin, Y.; Zhang, L.; Wang, A.; Wang, J.; Zhang, R.; Cai, M.; Yu, J.; Wu, B. Enhancing mechanical properties of high Cr dual-phase FeCrNi medium-entropy alloy through mutual phase transformation and grain refinement. Mater. Sci. Eng. A 2024, 907, 146745. [Google Scholar] [CrossRef]

- Fan, L.; Yang, T.; Luan, J.; Jiao, Z. Control of discontinuous and continuous precipitation of γ′-strengthened high-entropy alloys through nanoscale Nb segregation and partitioning. J. Alloys Compd. 2020, 832, 154903. [Google Scholar] [CrossRef]

- Xu, Z.; Hou, Y.; Li, G. Atomic-scale investigation of the synergistic impact of Mo and Nb addition on enhancing the performance of laser cladding FeCoCrNi-based high entropy alloy coatings. Surf. Coat. Technol. 2024, 490, 131162. [Google Scholar] [CrossRef]

- Luo, F.; Wang, S.; Shi, W.; Xiong, Z.; Huang, J. Corrosion resistance and wear behavior of CoCrFeNiMn@Gr high entropy alloy-based composite coatings prepared by laser cladding. J. Mater. Res. Technol. 2024, 33, 3769–3789. [Google Scholar] [CrossRef]

- Ye, Z.; Li, C.; Zhang, X.; Liao, Y.; Gu, J. The influence of vanadium element on the microstructure and mechanical properties of (FeCoNi)100-xVx high-entropy alloys. Mater. Charact. 2022, 192, 112232. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, X.B.; Zhang, F.Z.; Li, X.-G.; Liang, J.-X.; Liu, X.-Y.; Zheng, J.; Zhu, J.-P. Mechanical properties, nano-tribological behavior and deformation mechanism of FeCrNi MEA with the addition of Co/Cu: Molecular dynamics simulation. J. Manuf. Process. 2024, 131, 1348–1359. [Google Scholar] [CrossRef]

- Duan, B.; Lin, N.; Zhao, H.; Zhou, L.; Wang, X.; Ma, G.; Wang, H.; Shi, Q.; Wu, Y. Microstructure and tribological performance of FeCrNiMox medium-entropy alloy (MEA) coatings by high-speed laser cladding: Effect of molybdenum content. J. Alloys Compd. 2025, 1031, 181001. [Google Scholar] [CrossRef]

- Gao, S.; Kong, T.; Zhang, M.; Chen, X.; Sui, Y.W.; Ren, Y.J.; Qi, J.Q.; Wei, F.X.; He, Y.Z.; Meng, Q.K.; et al. Effects of titanium addition on microstructure and mechanical properties of CrFeNiTix (x = 0.2–0.6) compositionally complex alloys. J. Mater. Res. 2019, 34, 819–828. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Liu, W.; Yu, Y.; Sha, J. Mechanical properties and deformation behavior of additively manufactured TiC nanoparticles reinforced Nb at 1000 °C. J. Mater. Res. Technol. 2025, 36, 4241–4254. [Google Scholar] [CrossRef]

- Singh, I.; Dabhade, V.; Debata, M.; Panigrahi, A. The influence of Mo and Nb on liquid phase sintering and mechanical properties of W-Ni-Fe-co based tungsten heavy alloy. Mater. Charact. 2025, 224, 115034. [Google Scholar] [CrossRef]

- Yan, Q.; Yang, K.; Wang, Z.; Chen, M.; Sun, G.; Ni, Z. Surface roughness optimization and high-temperature wear performance of H13 coating fabricated by extreme high-speed laser cladding. Opt. Laser Technol. 2022, 149, 107823. [Google Scholar] [CrossRef]

- Tan, Q.; Tan, Q.; Liu, K.; Liu, K.; Li, J.; Li, J.; Geng, S.; Geng, S.; Sun, L.; Sun, L.; et al. A review on cracking mechanism and suppression strategy of nickel-based superalloys during laser cladding. J. Alloys Compd. 2024, 1001, 175164. [Google Scholar] [CrossRef]

- Jin, H.; Luo, F.; Chen, Z.; Luo, Y.; Shi, W.; Huang, J. Mechanical properties and corrosion resistance analysis of Fe-based amorphous −2% CNTs coatings with low crack prepared by laser cladding. Diam. Relat. Mater. 2025, 155, 112288. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, L.; Cai, Y.; Yan, Y.; Ge, F.; Shan, M.; Tian, Y.; Han, J.; Jiang, Z. Tribology comparison of laser-cladded CrMnFeCoNi coatings reinforced by three types of ceramic (TiC/NbC/B4C). Surf. Coat. Technol. 2022, 450, 129013. [Google Scholar] [CrossRef]

- Feng, M.; Yang, X.; Lian, G.; Chen, C. Microstructure and Properties of Laser Cladding CoCrNi-based Medium-Entropy Alloy Enhanced by Nb. J. Mater. Res. Technol. 2025, 35, 5015–5033. [Google Scholar] [CrossRef]

- Lian, G.; Zeng, J.; Yue, K.; Chen, C.; Huang, X.; Kong, L. Microstructure and properties of composite carbide (Ti,V) C enhanced Ni-based coatings by laser cladding. J. Mater. Res. Technol. 2023, 24, 1223–1239. [Google Scholar] [CrossRef]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Metall. 1986, 34, 823–830. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, T.; Xiao, M.; Shen, Y. Effect of Nb content on microstructure and properties of laser cladding FeNiCoCrTi0.5Nbx high-entropy alloy coating. Optik 2019, 198, 163316. [Google Scholar] [CrossRef]

- Ma, Q.; Zhao, W.; Li, X.; Gao, W.; Zhang, H.; Ma, X.; Lv, Y.; Xiao, G. Impact of Nb and Zr on the precipitation evolution of Laves phase and the properties of laser cladding coating of AlCoCrFeNi high entropy alloy. Mater. Charact. 2024, 215, 114146. [Google Scholar] [CrossRef]

- Yang, C.M.; Liu, X.B.; Zhu, Z.X.; Zhou, A.; Zhou, H.-B.; Zhang, S.-H. Study of tribological property of laser-cladded FeCoCrNiMnx high-entropy alloy coatings via experiment and molecular dynamics simulation. Tribol. Int. 2024, 191, 109106. [Google Scholar] [CrossRef]

- Sun, S.; Fu, H.; Ping, X.; Lin, J.; Lei, Y.; Wu, W.; Zhou, J. Reinforcing behavior and microstructure evolution of NbC in laser cladded Ni45 coating. Appl. Surf. Sci. 2018, 455, 160–170. [Google Scholar] [CrossRef]

| Material | Composition (Mass.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Mn | O | N | C | S | P | |

| Q235B | Bal. | − | 0.15 | 0.25 | − | − | 0.15 | 0.11 | 0.12 |

| CrFeNi | Bal. | 30.98 | 35.27 | − | 0.0025 | 0.0029 | 0.01 | 0.0029 | − |

| Element | ΔHmix(KJ·mol−1) | r/Å | |||

|---|---|---|---|---|---|

| Cr | Fe | Ni | Nb | ||

| Cr | − | −1 | −7 | −7 | 1.249 |

| Fe | − | − | −2 | −16 | 1.241 |

| Ni | − | − | − | −30 | 1.246 |

| Nb | − | − | − | − | 1.429 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Luo, F.; Jin, H.; Peng, Z.; Shi, W.; Huang, J. Effect of Nb on Laves Phase Formation and Wear Resistance in Laser-Cladding CrFeNi Medium-Entropy Alloy Coatings. Coatings 2025, 15, 667. https://doi.org/10.3390/coatings15060667

Chen Z, Luo F, Jin H, Peng Z, Shi W, Huang J. Effect of Nb on Laves Phase Formation and Wear Resistance in Laser-Cladding CrFeNi Medium-Entropy Alloy Coatings. Coatings. 2025; 15(6):667. https://doi.org/10.3390/coatings15060667

Chicago/Turabian StyleChen, Zehuan, Fangyan Luo, Hongtao Jin, Zhen Peng, Wenqing Shi, and Jiang Huang. 2025. "Effect of Nb on Laves Phase Formation and Wear Resistance in Laser-Cladding CrFeNi Medium-Entropy Alloy Coatings" Coatings 15, no. 6: 667. https://doi.org/10.3390/coatings15060667

APA StyleChen, Z., Luo, F., Jin, H., Peng, Z., Shi, W., & Huang, J. (2025). Effect of Nb on Laves Phase Formation and Wear Resistance in Laser-Cladding CrFeNi Medium-Entropy Alloy Coatings. Coatings, 15(6), 667. https://doi.org/10.3390/coatings15060667