Optimizing Parameter Sets for Laser-Textured Piston Rings Using Design of Experiments and Multibody Dynamics Calculations

Abstract

1. Introduction

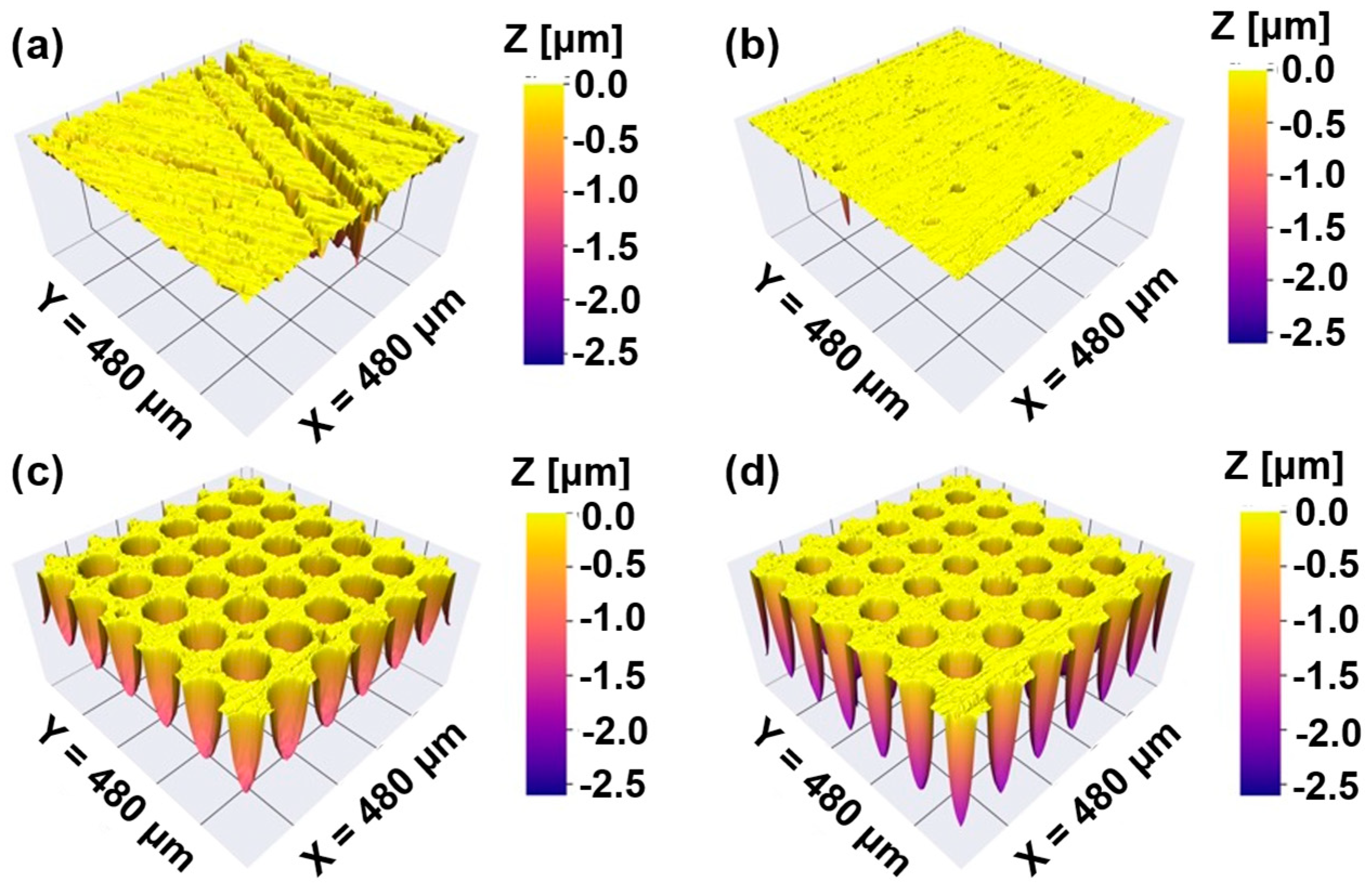

2. Materials, Methods and Parameters

Design of Experiments

3. Results and Discussion

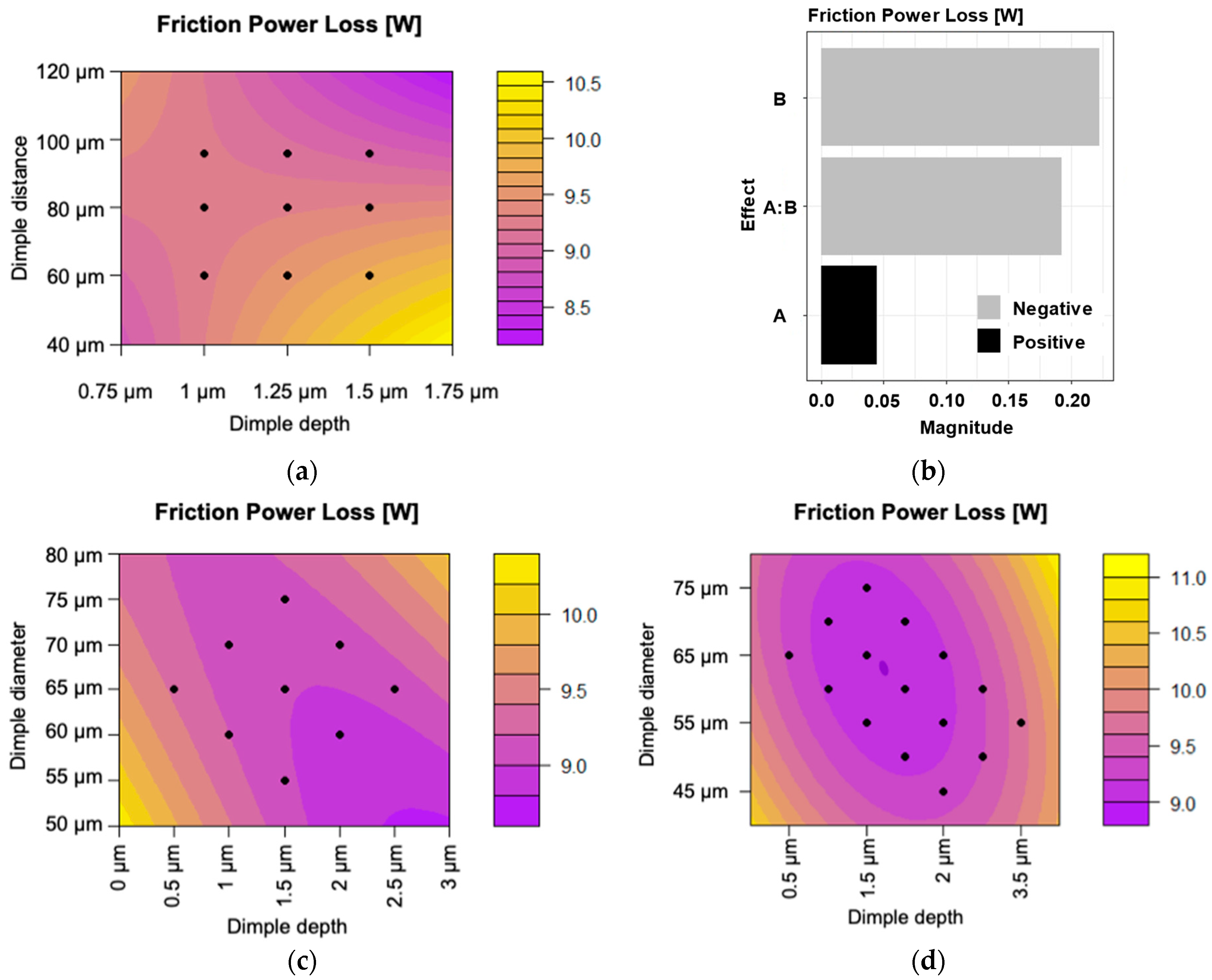

3.1. Screening with Box–Behnken Designs

3.2. Face-Centered Design for Boundary Definition

3.3. Central Composite Circumscribed Design for Finding the Optimum

4. Conclusions

- Utilizing a Box–Behnken experimental screening design, dimple distance was determined to have the largest influence over the system. A Face-Centered secondary model was introduced to understand the behavior of the system around the boundaries. Based on the insights of these steps, considering also some constraints arising from the utilized simulation workflow, an optimal dimple distance of 80 µm was chosen for further experimentation.

- A Central Composite Circumscribed design was then introduced to find an optimal depth and diameter configuration for a dimple distance of 80 µm. The initial nine-point model was extended with additional six points to find a local optimum, which is accepted to be a sweet spot, based on the findings of previous experimental investigations. An 8.3% improvement compared to the untextured surface was demonstrated using a depth of 2 µm, a center-to-center distance of 80 µm, and a diameter of 60 µm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SAE | Society of Automotive Engineers |

| Ra | Arithmetic mean roughness in µm |

| DoE | Design of Experiments |

| CCC | Central Composite Circumscribed (experimental design) |

| FCD | Face-Centered Design (experimental design) |

| R2 | Coefficient of determination |

References

- Sonawane, U.; Agarwal, A.K. Engine Emission Control Devices for Particulate Matter and Oxides of Nitrogen: Challenges and Emerging Trends. In Novel Internal Combustion Engine Technologies for Performance Improvement and Emission Reduction; Singh, A.P., Agarwal, A.K., Eds.; Springer: Singapore, 2021; pp. 197–220. [Google Scholar] [CrossRef]

- Morgunov, B.; Chashchin, V.; Gudkov, A.; Chashchin, M.; Popova, O.; Nikanov, A.; Thomassen, Y. Health Risk Factors of Emissions from Internal Combustion Engine Vehicles: An Up-to-Date Status of the Problem. Здoрoвье Населения И Среда Обитания-ЗНиСО/Public Health Life Environ. 2022, 30, 7–14. [Google Scholar] [CrossRef]

- Sitdikov, V.M.; Dudareva, N.Y.; Ishemguzhin, A.A.; Dautov, I. Emission Control and Reduction in the Combustion Chamber of an Internal Combustion Engine. Trudy NAMI 2023, 4, 83–95. [Google Scholar] [CrossRef]

- Vorob’ev, Y.V.; Dunaev, A.V. Reducing Motor Fuel Consumption Using Mechanochemical Methods. J. Mach. Manuf. Reliab. 2019, 48, 268–274. [Google Scholar] [CrossRef]

- Galovic, J.; Hofmann, P. Thermochemical Heat Storage for Consumption Reduction in Internal Combustion Engines. MTZ Worldw. 2019, 80, 134–139. [Google Scholar] [CrossRef]

- El Mansori, M.; Goeldel, B.; Sabri, L. Performance impact of honing dynamics on surface finish of precoated cylinder bores. Surf. Coat. Technol. 2013, 215, 334–339. [Google Scholar] [CrossRef]

- Zhmud, B.; Tomanik, E.; Grabon, W.; Schorr, D.; Brodmann, B. Optimizing the piston/bore tribology: The role of surface specifications, ring pack, and lubricant. In SAE Technical Paper; SAE: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Yousfi, M.; Ţălu, Ş. The impact of helical slide honing on surface microtexture compared to plateau honing process through relevant characterization methods. Microsc. Res. Tech. 2022, 85, 2397–2408. [Google Scholar] [CrossRef]

- Kim, E.S.; Kim, S.M.; Lee, Y.Z. The effect of plateau honing on the friction and wear of cylinder liners. Wear 2018, 400, 207–212. [Google Scholar] [CrossRef]

- Baby, A.K.; Rajendrakumar, P.K. Influence of honing angle on tribological behaviour of cylinder liner–piston ring pair: Experimental investigation. Tribol. Int. 2022, 167, 107355. [Google Scholar] [CrossRef]

- Specification and Measurement of Plateau Honed Surfaces. Available online: https://digitalmetrology.com/tutorials/plateauhoning (accessed on 10 April 2025).

- Rastegar, F.; Craft, A.E. Piston ring coatings for high horsepower diesel engines. Surf. Coat. Technol. 1993, 61, 36–42. [Google Scholar] [CrossRef]

- Pawlus, P.; Koszela, W.; Reizer, R. Surface texturing of cylinder liners: A review. Materials 2022, 15, 8629. [Google Scholar] [CrossRef]

- Du, F.; Zhang, Y.; Gao, Z.; Wang, J.; Yang, Y.; Wang, J.; Shen, Y. Research on the Carbon Emission Reduction of Internal Combustion Engines by Reducing Friction Work. E3S Web Conf. 2024, 546, 1016. [Google Scholar] [CrossRef]

- Bhutta, M.U.; Najeeb, M.H.; Abdullah, M.U.; Shah, S.R.; Khurram, M.; Mufti, R.A.; Arshad, M. Experimental Investigation of Engine Valve Train Friction Considering Effects of Operating Conditions and WPC Surface Treatment. Materials 2023, 16, 3431. [Google Scholar] [CrossRef] [PubMed]

- Laki, G. A Review on Friction Reduction by Laser Textured Surfaces. Tribol. Online 2022, 17, 318–334. [Google Scholar] [CrossRef]

- Woś, S.; Koszela, W.; Dzierwa, A.; Pawlus, P. Effect of Zonal Laser Texturing on Friction Reduction of Steel Elements in Lubricated Reciprocating Motion. Materials 2024, 17, 2401. [Google Scholar] [CrossRef]

- Li, Q.; Lu, R.; Tani, H.; Kawada, S.; Koganezawa, S.; Liu, X.; Cong, P. Tribofilm Formation and Friction Reduction Performance on Laser-Textured Surface with Micro-Grooved Structures. Lubricants 2024, 12, 91. [Google Scholar] [CrossRef]

- Turali, N.; Saleem, S.; Muddada, V.; Naik, D.K.; Sreeramulu, D.; Duppala, A.; Dilawar, M.; Radha, K. Enhancing Tribological Performance of AISI 52100: The Role of Laser Surface Texturing in Dry and Lubricated Conditions. Eng. Res. Express 2024, 6, 045517. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, X.; He, K.; Dong, X.; Wang, Z.; Liao, K. Lipophilic and Friction Properties of 20CrMnTi Steel with Laser-Induced Texturing. Tribol. Int. 2024, 194, 109550. [Google Scholar] [CrossRef]

- Butler-Smith, P.; Burtt, N.; See, T. The Friction of Surface Textured Cylinder Liner Segments Modified by Direct Laser Writing and Direct Laser Interference Patterning Processes. J. Manuf. Process. 2024, 117, 366–374. [Google Scholar] [CrossRef]

- Ju, W.S.; Kim, C.H.; Han, K.S.; Yun, T.H.; Ro, K.I.; Ho, K.M.; Rim, K.C. Laser Surface Texturing in Graphite Cast Iron for Reduction of Friction and Wear: Effect of Dimple Density. Res. Sq. 2024, submitted. [CrossRef]

- Ancona, A.; Gaudiuso, C.; Volpe, A.; Mezzapesa, F.P.; Putignano, C.; Carbone, G. Laser Surface Texturing for Superhydrophobic, Icephobic and Friction Reduction Functionalization. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2023; Volume 1296, p. 012042. [Google Scholar] [CrossRef]

- Cheng, H.; Zhou, F.; Fei, Z. Dry Friction Properties of Friction Subsets and Angle Related to Surface Texture of Cemented Carbide by Femtosecond Laser Surface Texturing. Coatings 2023, 13, 741. [Google Scholar] [CrossRef]

- Berardo, A.; Borasso, M.; Gallus, E.; Pugno, N.M. Finite Element Simulations and Statistical Analysis for the Tribological Design of Mutually Textured Surfaces and Related Experimental Validation. J. Tribol. 2024, 147, 3. [Google Scholar] [CrossRef]

- Narayanan, V.; Singh, R.; Marla, D. A 3D Computational Model of Nanosecond Pulsed Laser Texturing of Metals for Designing Engineered Surfaces. J. Manuf. Sci. Eng. 2024, 146, 5. [Google Scholar] [CrossRef]

- Chua Abdullah, M.I.H.; Abdollah, M.F.B.; Amiruddin, H.; Tamaldin, N.; Mat Nuri, N.R. Optimization of Tribological Performance of hBN/Al2O3 Nanoparticles as Engine Oil Additives. Procedia Eng. 2013, 68, 313–319. [Google Scholar] [CrossRef]

- Iruthaya Raj, J.M.; Manisekar, K.; Gupta, M. Central Composite Experimental Design Applied to the Dry Sliding Wear Behavior of Mg/Mica Composites. J. Tribol. 2018, 141, 011603. [Google Scholar] [CrossRef]

- Salahshoori, I.; Seyfaee, A.; Babapoor, A.; Neville, F.; Moreno-Atanasio, R. Evaluation of the Effect of Silica Nanoparticles, Temperature and Pressure on the Performance of PSF/PEG/SiO2 Mixed Matrix Membranes: A Molecular Dynamics Simulation (MD) and Design of Experiments (DOE) Study. J. Mol. Liq. 2021, 333, 115957. [Google Scholar] [CrossRef]

- Laki, G.; Boros, L.; Nagy, A.L. Topography Pre-Treatment of Laser-Textured Surfaces for Friction Simulation in AVL Excite. Eng. Proc. 2024, 79, 95. [Google Scholar] [CrossRef]

- Németh, P.; Hanula, B.; Nagy, A.L. Smart Hybrid Energy Management System in a Passenger Car. Chem. Eng. Trans. 2023, 107, 457–462. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Yin, B.; Xu, B.; Jia, H.; Hua, X.; Fu, Y. Experimental research on the frictional performance of real laser-textured cylinder liner under different lubrication conditions. Int. J. Engine Res. 2021, 23, 693–704. [Google Scholar] [CrossRef]

- Akbarzadeh, A.; Khonsari, M.M. Effect of untampered plasma coating and surface texturing on friction and running-in behavior of piston rings. Coatings 2018, 8, 110. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M.M. The effect of laser machined pockets on the lubrication of piston ring prototypes. Tribol. Int. 2016, 101, 273–283. [Google Scholar] [CrossRef]

| “A” (Depth) | “B” (Distance) | “C” (Diameter) | Simulated Friction Power Loss |

|---|---|---|---|

| 1.5 µm | 80 µm | 70 µm | 8.976 W |

| 1.5 µm | 80 µm | 60 µm | 9.001 W |

| “A” (Depth) | “B” (Distance) | “C” (Diameter) |

|---|---|---|

| 0.5 µm | 80 µm (not changed in this study) | 65 µm |

| 1 µm | 60 µm | |

| 1 µm | 70 µm | |

| 1.5 µm | 55 µm | |

| 1.5 µm | 65 µm | |

| 1.5 µm | 75 µm | |

| 2 µm | 60 µm | |

| 2 µm | 70 µm | |

| 2.5 µm | 65 µm |

| “A” (Depth) | “B” (Distance) | “C” (Diameter) |

|---|---|---|

| 2 µm | 80 µm (not changed in this study) | 50 µm |

| 2.5 µm | 45 µm | |

| 2.5 µm | 55 µm | |

| 3 µm | 50 µm | |

| 3 µm | 60 µm | |

| 3.5 µm | 55 µm |

| “A” (Depth) | “B” (Distance) | “C” (Diameter) | Model Prediction | Simulation Result | Deviation |

|---|---|---|---|---|---|

| 1.5 µm | 80 µm | 60 µm | 9.028 W | 9.001 W | −0.3% |

| 2 µm | 80 µm | 65 µm | 9.027 W | 9.022 W | −0.06% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laki, G.; Pintér, D.; Boros, L.; Nagy, A.L. Optimizing Parameter Sets for Laser-Textured Piston Rings Using Design of Experiments and Multibody Dynamics Calculations. Coatings 2025, 15, 528. https://doi.org/10.3390/coatings15050528

Laki G, Pintér D, Boros L, Nagy AL. Optimizing Parameter Sets for Laser-Textured Piston Rings Using Design of Experiments and Multibody Dynamics Calculations. Coatings. 2025; 15(5):528. https://doi.org/10.3390/coatings15050528

Chicago/Turabian StyleLaki, Gábor, Dominika Pintér, László Boros, and András Lajos Nagy. 2025. "Optimizing Parameter Sets for Laser-Textured Piston Rings Using Design of Experiments and Multibody Dynamics Calculations" Coatings 15, no. 5: 528. https://doi.org/10.3390/coatings15050528

APA StyleLaki, G., Pintér, D., Boros, L., & Nagy, A. L. (2025). Optimizing Parameter Sets for Laser-Textured Piston Rings Using Design of Experiments and Multibody Dynamics Calculations. Coatings, 15(5), 528. https://doi.org/10.3390/coatings15050528