Effect of Pre-Formed Microstructure on Mechanical Properties of Bainitic Steel

Abstract

1. Introduction

2. Experimental Procedures

3. Research Advance

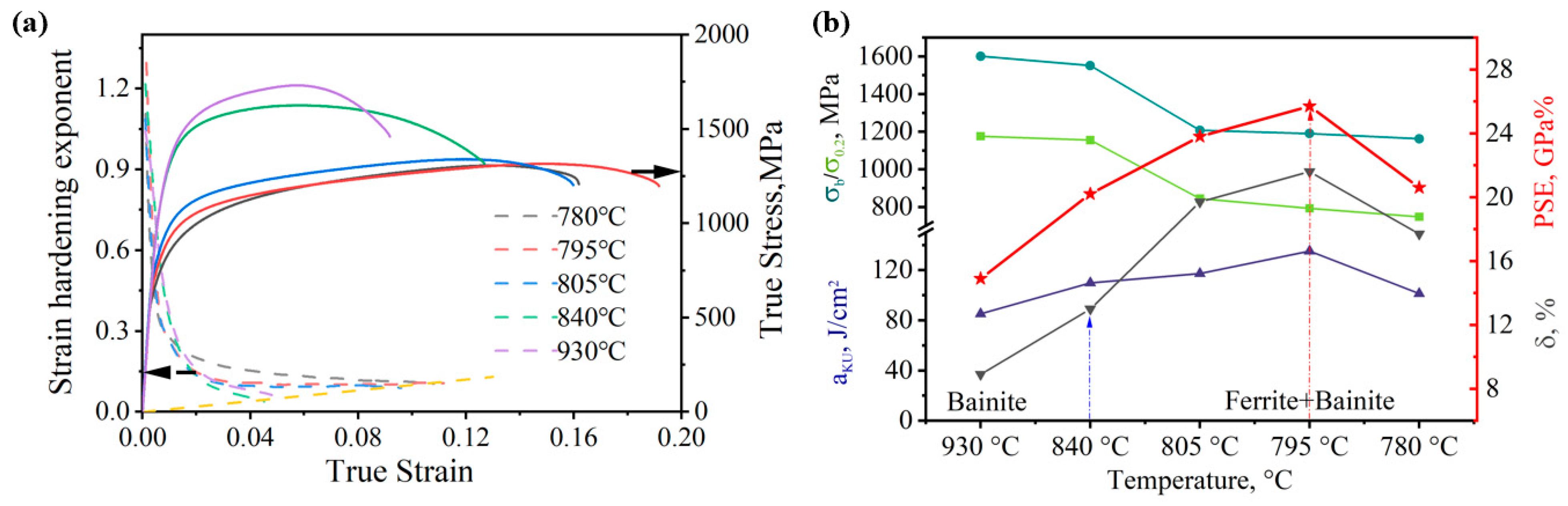

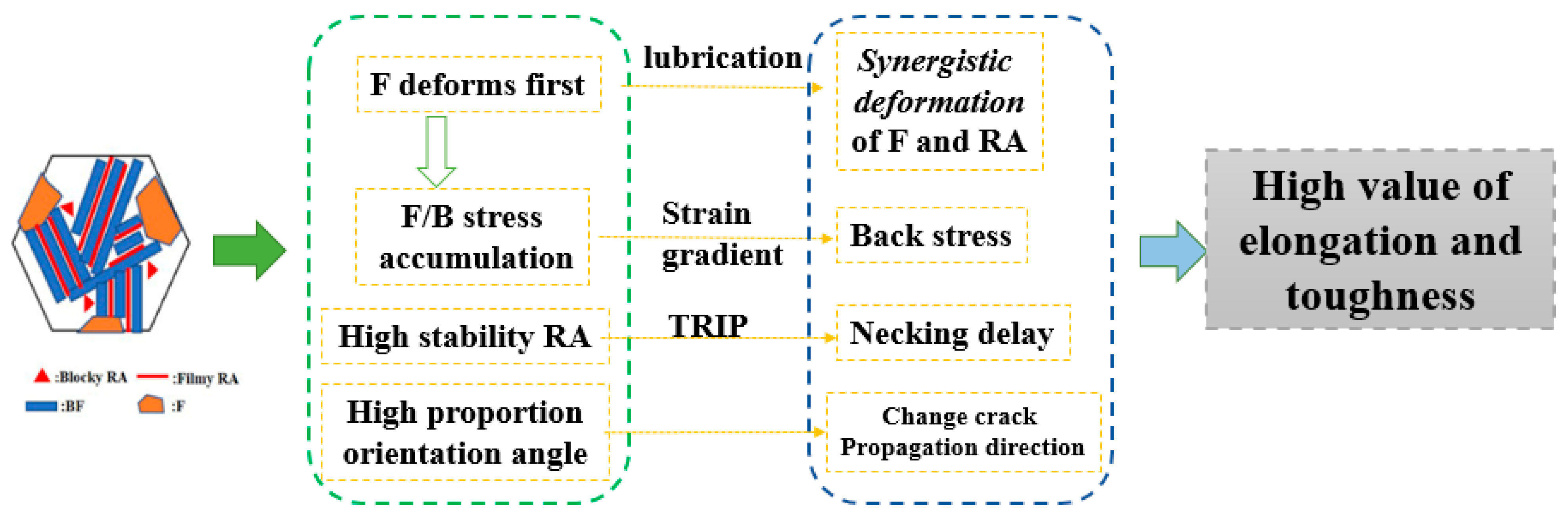

3.1. Pre-Formed Ferrite

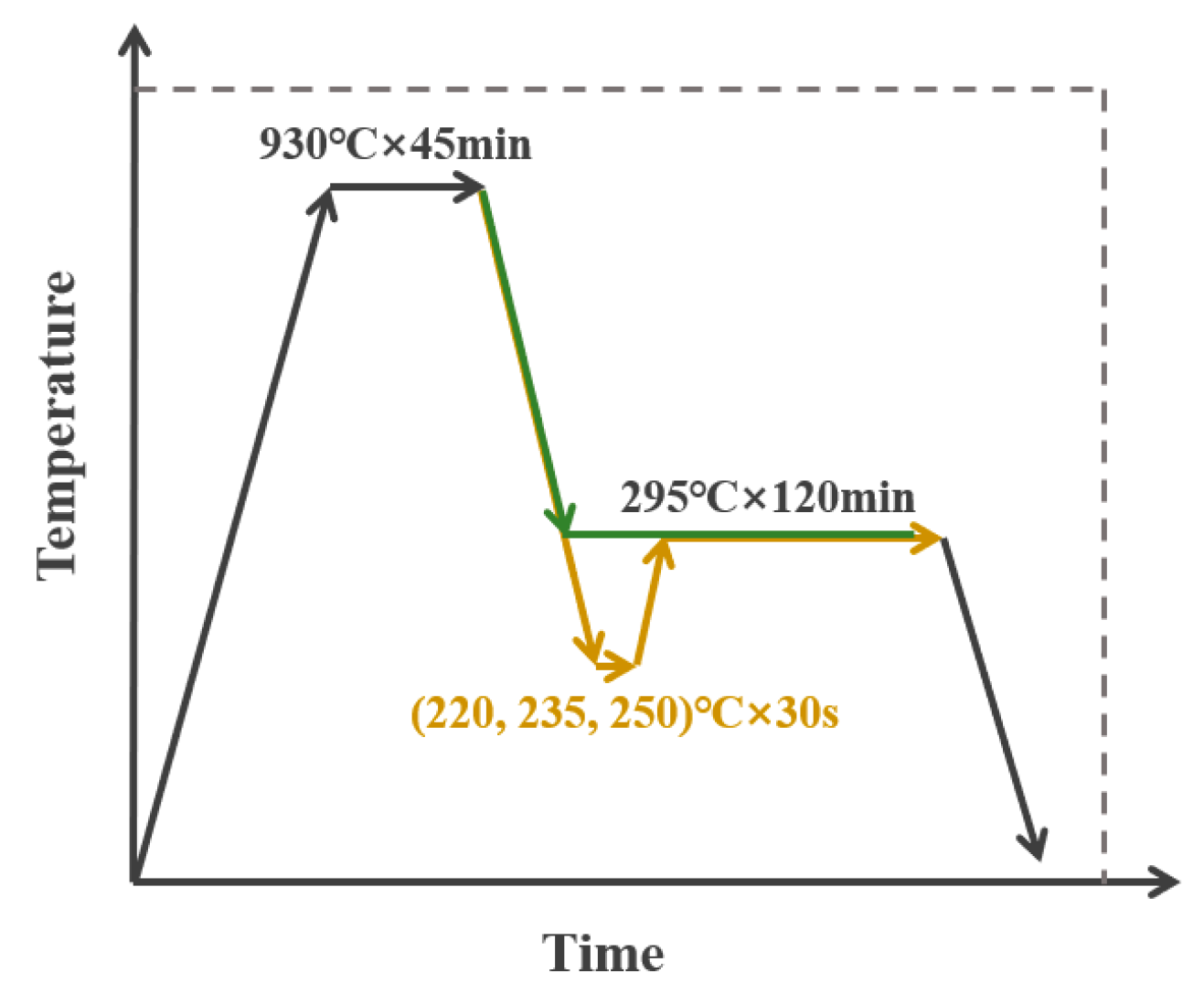

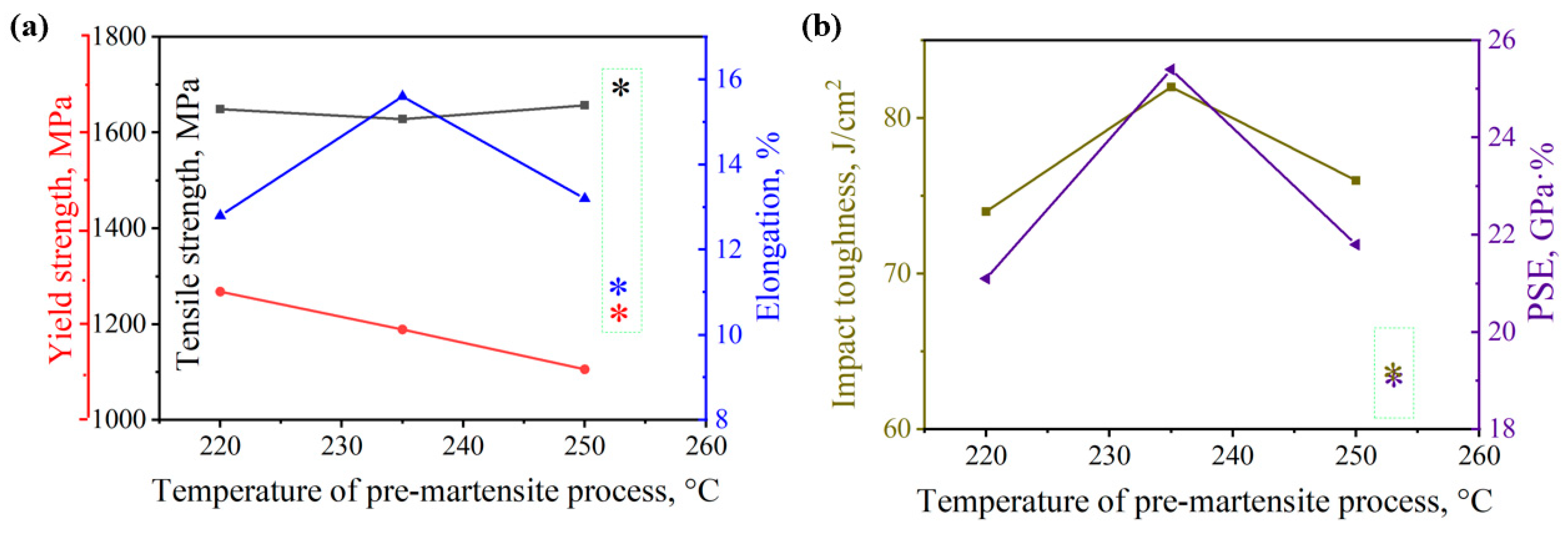

3.2. Pre-Formed Martensite

3.3. Precipitated Particles

3.4. Other Factors

4. Conclusions and Expectation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, S.H.; He, B.B.; Zhu, K.Y.; Huan, M.X. On the correlation among dislocation density, lath thickness and yield stress of bainite. Acta Mater. 2017, 135, 382–389. [Google Scholar] [CrossRef]

- Ungar, T.; Harjo, S.; Kawasaki, T.; Tomota, Y.; Ribárik, G.; Shi, Z. Composite behavior of lath martensite steels induced by plastic strain, a new paradigm for the elastic-plastic response of martensitic steels. Metall. Mater. Trans. A 2017, 48, 159–167. [Google Scholar] [CrossRef]

- Kinsman, K.; Aaronson, H. Transformation and Hardenability in Steels; Climax Molybdenum Co.: Leadville, CO, USA, 1967; p. 109. [Google Scholar]

- Aaronson, H.I.; Furuhara, T.; Hall, M.G.; Hirth, J.P.; Nie, J.F.; Purdy, G.R.; Reynolds, W.T., Jr. On the mechanism of formation of diffusional plate-shaped transformation products. Acta Mater. 2006, 54, 1227–1232. [Google Scholar] [CrossRef]

- Ravi, A.M.; Kumar, A.; Herbig, M.; Sietsma, J.; Santofimia, M.J. Impact of austenite grain boundaries and ferrite nucleation on bainite formation in steels. Acta Mater. 2020, 188, 424–434. [Google Scholar] [CrossRef]

- Hüper, T.; Endo, S.; Ishikawa, N.; Osawa, K. Effect of Volume Fraction of Constituent Phases on the Stress-Strain Relationship of Dual Phase Steels. ISIJ Int. 1999, 39, 288–294. [Google Scholar] [CrossRef]

- Nie, W.; Shang, C.; Guan, H.; Zhang, X.; Chen, S. Control of microstructure of ferrite /bainite(F/B) dual-phase steels and analysis of their resistance to deformation behavior. Acta Metall. Sin. 2012, 48, 298–306. [Google Scholar] [CrossRef]

- Qian, L.; Li, K.; Huang, F.; Li, D.; Wang, T.; Meng, J.; Zhang, F. Enhancing both strength and ductility of low-alloy transformation-induced plasticity steel via hierarchical lamellar structure. Scr. Mater. 2020, 183, 96–101. [Google Scholar] [CrossRef]

- Varshney, A.; Sangal, S.; Kundu, S.; Mondal, K. Super strong and highly ductile low alloy multiphase steels consisting of bainite, ferrite and retained austenite. Mater. Des. 2016, 95, 75–88. [Google Scholar] [CrossRef]

- Ishikawa, N.; Sueyoshi, H.; Endo, S.; Shikanai, N. Effect of Microstructure on Deformation Behavior of Ferrite-Bainite Steels. Tetsu-to-Hagane 2005, 91, 809–815. [Google Scholar] [CrossRef]

- Zhao, F.; Chen, P.; Xu, B.; Yu, Q.; Misra, R.D.K.; Wang, G.; Yi, H. Martensite transformation of retained austenite with diverse stability and strain partitioning during tensile deformation of a carbide-free Bainitic steel. Mater. Charact. 2021, 179, 111327. [Google Scholar] [CrossRef]

- Avishan, B.; Khoshkebari, S.M.; Yazdani, S. Effect of pre-existing martensite within the microstructure of nano bainitic steel on its mechanical properties. Mater. Chem. Phys. 2021, 260, 124160. [Google Scholar] [CrossRef]

- Qian, L.; Li, Z.; Wang, T.; Li, D.; Zhang, F.; Meng, J. Roles of pre-formed martensite in below-Ms bainite formation, microstructure, strain partitioning and impact absorption energies of low-carbon bainitic steel. J. Mater. Sci. Technol. 2022, 96, 69–84. [Google Scholar] [CrossRef]

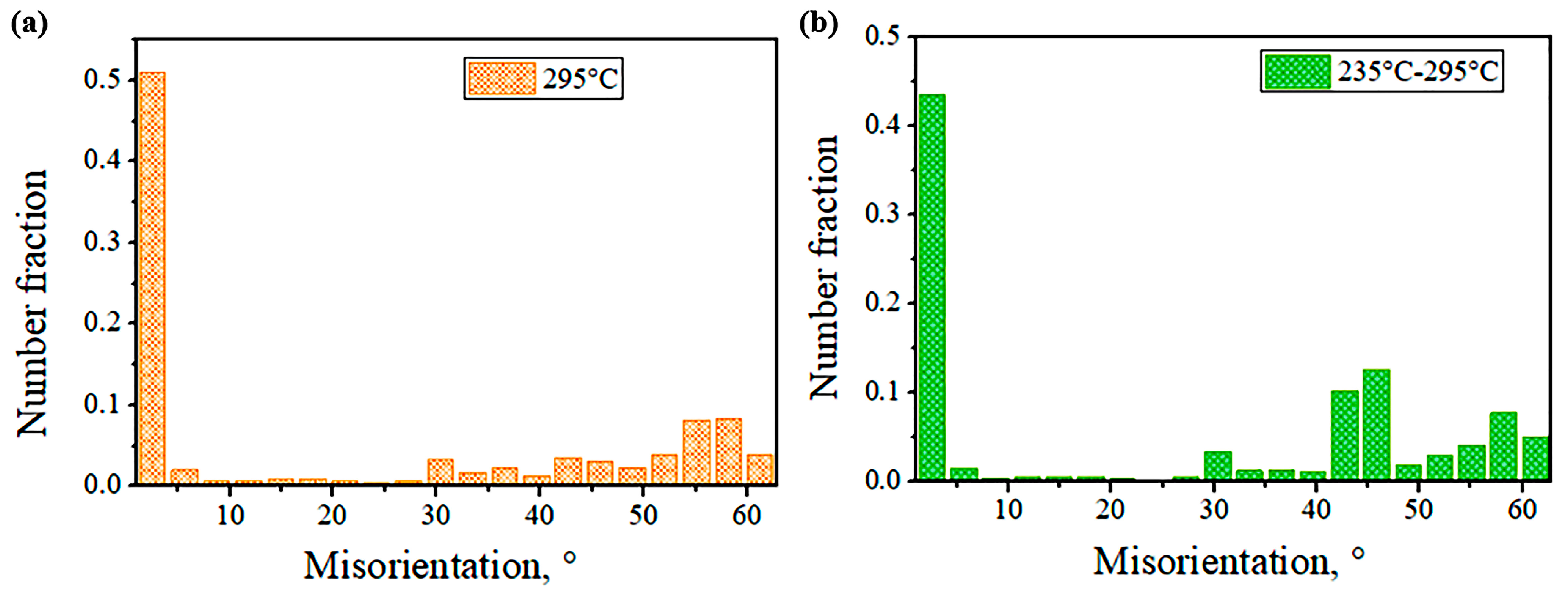

- Long, X.; Sun, D.; Wang, K.; Zhang, F.; Yang, Z.; Li, Y.; Zheng, C. Effect of carbon distribution range in mixed bainite/martensite /retained austenite microstructure on mechanical properties. J. Mater. Res. Technol. 2022, 17, 898–912. [Google Scholar] [CrossRef]

- Zhong, J.; Huang, L.; Su, X.; Guo, J.; Sun, Z.; Zhang, C.; Li, J.; Wang, J.; Lv, D.; Zheng, Y.; et al. Tempering properties of a new ultrahigh strength martensitic steel. J. Mater. Res. Technol. 2025, 35, 5884–5893. [Google Scholar] [CrossRef]

- Mazánová, V.; Heczko, M.; Polák, J. On the mechanism of fatigue crack initiation in high-angle grain boundaries. Int. J. Fatigue 2022, 158, 106721. [Google Scholar] [CrossRef]

- Long, X.; Zhang, Y.; Liu, W.; Feng, X.; Zhang, F.; Yang, Z.; Li, Y. Effect of cooling rate in the mid-temperature region on fatigue crack propagation rate of bainitic steel. J. Mater. Res. Technol. 2024, 32, 227–238. [Google Scholar] [CrossRef]

- Sun, X.W.; Sun, D.Y.; Wang, Y.; Zhang, F.C.; Sheng, G.; He, Y.; Wang, T.S. Microstructure analysis and quantitative strengthening evaluation of medium carbon bainitic multiphase steel. J. Mater. 2022, 57, 17462–17480. [Google Scholar] [CrossRef]

- Liu, H.; Gao, H.; Chen, J.; Liu, R.; Zhang, Y.; Yin, Y.; Liu, H.; Fan, S.; Liu, H. Study of corrosion and failure mechanism of the galvanized steel pipes of meteorological tower serviced in the south China sea. Eng. Fail. Anal. 2025, 167, 108933. [Google Scholar] [CrossRef]

- Long, X.; Liu, W.; Zhu, R.; Zhang, Y.; Zhang, F.; Yang, Z.; Li, Y. Effect of the cooling rate in the medium temperature zone on the phase transformation and microstructure of carbide-free bainitic steel. J. Mater. Res. Technol. 2024, 29, 50–66. [Google Scholar] [CrossRef]

- Díaz-Fuentes, M.; Iza-Mendia, A.; Gutiérrez, I. Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction. Study of their toughness behavior. Metall. Mater. Trans. A 2003, 34, 2505–2516. [Google Scholar] [CrossRef]

- Hu, H.; Xu, G.; Li, W.; Xue, Z.; Zhang, Y.; Liu, G. The effects of Nb and Mo addition on transformation and properties in low carbon bainitic steels. Mater. Des. 2015, 84, 95–99. [Google Scholar] [CrossRef]

- Wang, T.Y.; Gu, S.J.; Wang, J.; Wei, F.L.; Zeng, Z.Y.; Jiang, Y.F.; Shi, H.F.; Li, C.R.; Li, Z.Y. Study on the Effect of Long Holding Time on Improving the Microstructure and Mechanical Properties of Nb Microalloyed Steels. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

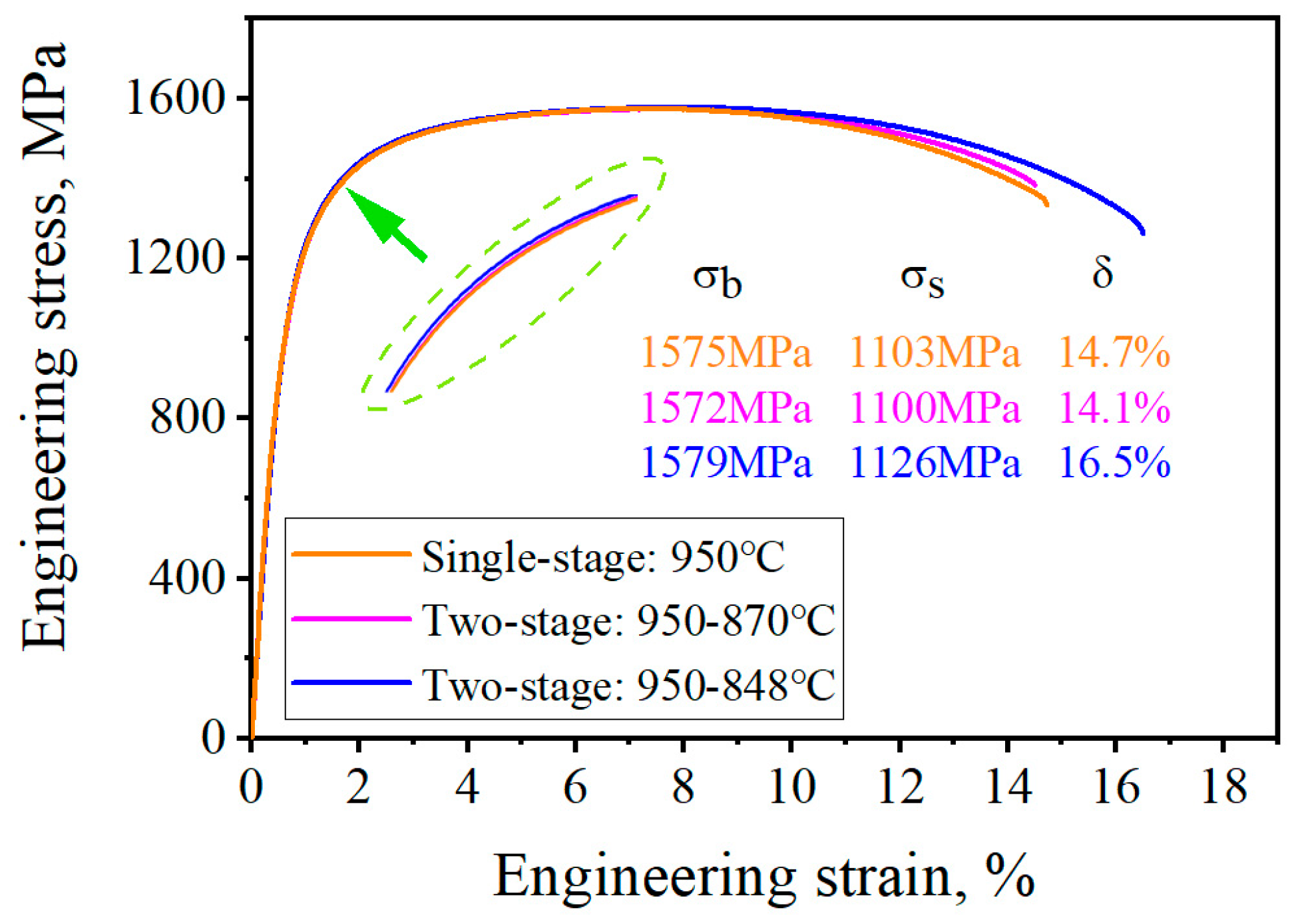

- Kong, X.; Lan, L.; Hu, Z.; Li, B.; Sui, T. Optimization of mechanical properties of high strength bainitic steel using thermo-mechanical control and accelerated cooling process. J. Mater. Process. Technol. 2015, 217, 202–210. [Google Scholar] [CrossRef]

- Ko, T.; Cottrell, S.A. The formation of bainite. J. Iron Steel Inst. 1952, 172, 307–313. [Google Scholar]

- Lv, B.; Yin, D.X.; Sun, D.Y.; Yang, Z.N.; Long, X.Y.; Liu, Z.L. Effect of Two-Step High Temperature Treatment on Phase Transformation and Microstructure of V-Bearing Bainitic Steel. Metals 2022, 12, 983. [Google Scholar] [CrossRef]

- Singh, N.; Casillas, G.; Wexler, D.; Killmore, C.; Pereloma, E. Application of advanced experimental techniques to elucidate the strengthening mechanisms operating in microalloyed ferritic steels with interphase precipitation. Acta Mater. 2020, 201, 386–402. [Google Scholar] [CrossRef]

- Inoue, K.; Nakamura, S. Influence of alloying elements on mechanical properties and fatigue strength in notched specimens of bainitic microalloyed steels. Steel Mak. 1998, 69, 27–34. [Google Scholar] [CrossRef]

- Siwecki, T.; Eliasson, J.; Lagneborg, R.; Hutchinson, B. Vanadium microalloyed bainitic hot strip steels. ISIJ Int. 2010, 50, 760–767. [Google Scholar] [CrossRef]

- Nafisi, S.; Arafin, M.; Glodowski, R.; Collins, L.; Szpunar, J. Impact of vanadium addition on API X100 steel. ISIJ Int. 2014, 10, 2404–2410. [Google Scholar] [CrossRef]

- Nafisi, S.; Amirkhiz, B.S.; Fazeli, F.; Arafin, M.; Glodowski, R.; Collins, L. Effect of vanadium addition on the strength of API X100 linepipe steel. ISIJ Int. 2016, 56, 154–160. [Google Scholar] [CrossRef]

- Singh, S.; Bhadeshia, H. Estimation of bainite plate-thickness in low-alloy steels. Mater. Sci. Eng. A 1998, 245, 72–79. [Google Scholar] [CrossRef]

- Cornide, J.; Garcia-Mateo, C.; Capdevila, C.; Caballero, F. An assessment of the contributing factors to the nanoscale structural refinement of advanced bainitic steels. J. Alloys Compd. 2013, 577, S43–S47. [Google Scholar] [CrossRef]

- Chiang, J.; Lawrence, B.; Boyd, J.; Pilkey, A. Effect of microstructure on retained austenite stability and work hardening of TRIP steels. Mater. Sci. Eng. A 2011, 528, 4516–4521. [Google Scholar] [CrossRef]

- He, S.; He, B.; Zhu, K.; Ding, R.; Chen, H.; Huang, M. Revealing the role of dislocations on the stability of retained austenite in a tempered bainite. Scripta Mater. 2019, 168, 23–27. [Google Scholar] [CrossRef]

- Guo, H.; Fan, Y.; Feng, X.; Li, Q. Ultrafine bainitic steel produced through ausforming-quenching process. J. Mater. Res. Technol. 2020, 9, 3659–3663. [Google Scholar] [CrossRef]

| Parameter | 295 °C | 220–295 °C | 235–295 °C | 250–295 °C |

|---|---|---|---|---|

| VRA, % | 15.5 ± 1.8 | 20.8 ± 2.2 | 18.5 ± 2.1 | 17.4 ± 2.5 |

| CRA, wt.% | 1.20 ± 0.14 | 1.30 ± 0.16 | 1.51 ± 0.19 | 1.33 ± 0.17 |

| VM, % | 0 | 51.1 | 42.3 | 31.9 |

| VBF, % | 84.5 ± 1.8 | 28.1 ± 2.2 | 39.2 ± 2.1 | 50.7 ± 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Long, X.; Li, Y.; Feng, X.; Liu, Z. Effect of Pre-Formed Microstructure on Mechanical Properties of Bainitic Steel. Coatings 2025, 15, 529. https://doi.org/10.3390/coatings15050529

Zhang Y, Long X, Li Y, Feng X, Liu Z. Effect of Pre-Formed Microstructure on Mechanical Properties of Bainitic Steel. Coatings. 2025; 15(5):529. https://doi.org/10.3390/coatings15050529

Chicago/Turabian StyleZhang, Yu, Xiaoyan Long, Yanguo Li, Xiaoyong Feng, and Zeliang Liu. 2025. "Effect of Pre-Formed Microstructure on Mechanical Properties of Bainitic Steel" Coatings 15, no. 5: 529. https://doi.org/10.3390/coatings15050529

APA StyleZhang, Y., Long, X., Li, Y., Feng, X., & Liu, Z. (2025). Effect of Pre-Formed Microstructure on Mechanical Properties of Bainitic Steel. Coatings, 15(5), 529. https://doi.org/10.3390/coatings15050529